Abstract

Textiles, integral to human life for centuries, have recently garnered significant interest for electronic applications. However, traditional fabrication methods for electronic textiles (E-textiles) are typically complex. This research introduces an innovative approach utilizing Direct Ink Writing (DIW) 3D printing to develop multifunctional wearable electronic textiles. Specifically, the study addresses the creation of a strain sensor and an interconnect electrode directly printed onto textile substrates. The DIW-printed strain sensor exhibited excellent sensitivity, achieving a gauge factor of 11.07, significant linearity (R2 ~ 0.99), and consistent performance under repeated mechanical stress. Additionally, the interconnect electrode was engineered to selectively bridge textile layers through controlled impregnation, resulting in stable resistance values (0.2–0.4Ω) under strain and pressure. These components were effectively incorporated into smart garments, facial masks, and multilayered gloves, enabling precise real-time monitoring of body movements, respiration, and tactile recognition, thus significantly advancing functionality and versatility in wearable electronics.

Similar content being viewed by others

Introduction

The development of stretchable and wearable electronic devices has gained significant attention in recent years due to their potential applications in physiological monitoring1,2,3,4,5,6,7, intelligent robots8,9,10,11, human‒machine interfaces12,13,14, and other fields15,16,17,18,19,20,21,22,23. This growing interest is largely driven by the need for devices that can conform to the human body and accurately monitor physiological parameters while maintaining functionality under various strains and deformations24. Over years of extensive research, various substrates have been explored for fabricating wearable devices, but fabric and textile substrates remained the most widely utilized25,26,27,28,29,30. This is because textiles are the most familiar material that humans regularly wear.

Textile-based wearable electronic devices have been the subject of ongoing research, employing several strategies to enhance performance. Various materials, including conductive polymers31,32,33,34,35, and nanocarbon materials36,37,38,39,40,41, have been used to improve the sensing and wearable performance of these sensors. Until now, yarn coating42,43,44,45,46,47,48 and textile coating technologies49,50,51,52 have been the primary methods for fabricating textile-based wearable electronic devices. Yarn coating technology involves applying a conductive material to yarn, which is then woven into the textile. Research has been conducted with a focus on enhancing the sensitivity and durability of the coated yarns. However, as higher-performance yarns have been developed, production methods have become increasingly complex, resulting in longer production times. Textile coating, which involves applying polymers and conductive materials directly to textiles, is a simpler process compared to yarn coating. Screen printing is a widely utilized technique for fabricating patterned textile coatings. This method requires the creation of stencils that selectively allow ink to pass through, necessitating a unique stencil for each distinct design. In E-textile applications, where adaptability to human interaction is essential, variations in individual body shapes significantly increase the number of required stencils to accommodate diverse users. To address these issues, solution-based direct ink writing (DIW) printing technology was utilized. This technology allows for high-speed printing of solutions in desired shapes, overcoming the limitations of yarn and textile coating methods. Previous studies on DIW-printed textiles have primarily focused on enhancing printing resolution through advanced techniques, improving the performance of printed sensors and electrodes, increasing the stability of ink–textile interfaces, and investigating the interfacial behavior between the ink and textile substrate53,54,55,56,57,58,59,60,61,62,63,64,65 (Supplementary Table 1). However, these studies have been limited in their ability to utilize both sides of the textile or fabricate multilayered structures, and they have lacked a fully integrated platform. In contrast, the present study introduces an interconnected E-textile that enables bidirectional functionality and the creation of multilayered textile architectures. Additionally, we have optimized the printing process to enable the simultaneous fabrication of five distinct functional inks, including sensors and electrodes, within a single DIW printing system. For the development of E-textiles utilizing DIW printing technology, three types of inks were developed: strain sensors, interconnect electrodes, and temperature sensors. The DIW 3D-printed strain sensor features a gauge factor (GF = (ΔR/R0)/ε) of 11.07 and high linearity (R2 ~ 0.99). It also demonstrates a wide strain range of 102% and stable performance even after 10,000 cycles at 30% strain. The Ag-based electrodes were engineered to exploit varying impregnation levels (i.e. penetration depth of the ink) within the textile substrate. This allows the formation of via holes selectively connecting the two sides of the textile.

To demonstrate the potential of these devices, garments incorporating strain sensors and electrodes were fabricated for the detection of biomechanical activities such as running, jumping jacks, and push-ups. Additionally, strain sensors were printed onto a facial mask for monitoring of respiration during exercise. Furthermore, tactile object recognition systems were demonstrated using gloves integrated with an array of the electronics, applying machine learning for object recognition tasks. Finally, leveraging the developed via-connection technology in textiles, we demonstrated a multilayer E-glove that enables simultaneous detection of strain and pressure at a single point, enhancing multifunctional sensing capabilities.

Results

Integrated textile electronics

In this study, we fabricated the strain sensor, electrode, and temperature sensor on a textile substrate using a commercial DIW 3D printer (Fig. 1a, Supplementary Table 1). The printer is capable of printing multiple inks simultaneously (Supplementary Figs. 1, 2) allowing ease of integration of a strain sensor, an electrode, and a temperature sensor. The DIW printing process is compatible with various textile substrates (Fig. 1b). The scanning electron microscopy (SEM) images of the strain sensor and electrodes in Fig. 1c reveal uniformly coated ink materials on the textile.

a Schematic of DIW printed tactile sensors on textile for integrated wearable devices, including CNT-SBS strain sensor and Ag flake-PS interconnect electrode. b A photograph picture of 3D printed strain sensor and electrode on various textiles. c Scanning electron microscope (SEM) images of the strain sensor and electrode.

DIW printed textile strain sensor

The strain sensor achieves stretchability through SBS and creates an electrical pathway via MWCNT. SEM imaging confirmed that SBS and MWCNT are stably distributed within the textile substrate (Supplementary Fig. 3). Additionally, the sensor was designed with the appropriate viscosity for printing, enabling customization into various shapes (Supplementary Fig. 4). The print quality of DIW printing is primarily governed by nozzle speed, extrusion pressure, nozzle diameter, and the gap between the nozzle and the substrate. Extrusion pressure demonstrated a positive correlation with resolution, but excessive pressure led to ink merging, while insufficient pressure caused discontinuous printing. Conversely, nozzle speed and the gap-to-nozzle diameter ratio exhibited an inverse relationship with resolution (Supplementary Fig. 5). Furthermore, experimental results on the effect of textile surface roughness on print quality suggest that, unlike textile material and fiber density, surface roughness has a minimal impact on print quality (Supplementary Fig. 6). The printed strain sensor exhibits a line resolution of approximately 440 µm. Initial resistance and gauge factor are the key parameters, which were controlled by MWCNT wt. %. The 2 wt. % MWCNT sample exhibited a Gauge factor (GF) of 11.07, and an R2 of 0.99, indicating high linearity (Fig. 2a). The sensor exhibited strong reproducibility, as confirmed through reproducibility validation experiments (Supplementary Fig. 7). A lower MWCNT content results in a weaker electrical pathway, leading to a small resistance change rate (ΔR/R0). Conversely, an excessive MWCNT content reduces the change in the electrical pathway under strain, making the resistance change rate (ΔR/R0) less sensitive.

a Sensitivity analysis of the strain sensor depending on CNT ratio. b Maximum strain rate and linearity analysis of the strain sensor depending on SBS ratio. c Hysteresis test of strain sensor with repeated strains of 30% under 10 cycles. d Relative change in resistance under repeated application and release of 10%, 20%, and 30% strain. e Sensing stability at a fixed strain of 30% over 10,000 loading-unloading cycles.

SBS polymer is a stretchable polymer composed of polystyrene and butadiene, thus imparting stretchability to the CNT-based strain sensing ink. The sample with 20% SBS content exhibited the best strain limit of 102% (Fig. 2b). SBS content exceeding 20% led to aggregations in the ink, making printing unfeasible. The sensor exhibited low hysteresis with the degree of hysteresis value of 14.0% (Fig. 2c). This can be attributed to the exceptional stretchability of both the textile substrate and the SBS block copolymer used in the strain sensor. Within the SBS block copolymer, polystyrene functions as a physical crosslinking point, facilitating shape recovery after deformation, while polybutadiene provides flexibility and enables high stretchability. As a result, even after 10,000 cycles under 30% strain, the sensor maintained a low hysteresis value of 15.2% (Supplementary Fig. 8). This can be attributed to the strong binding of the ink to the textile substrate. Moreover, the sensor demonstrated high reliability in distinguishing various strains (Fig. 2d), and long-term reliability (Fig. 2e). The strain sensor maintained the resistance change (ΔR/R0) even after 10,000 cycles of stimulation at 30% strain. Additionally, the strain sensor showed minimal response to stimuli other than strain. Under 100 kPa pressure, the resistance change rate (ΔR/R0) remained below 0.1, distinctively lower than the response at 20% strain (Supplementary Figs. 9, 10). The strain sensor printed on the textile exhibited no material transfer and maintained its stable performance even after 100 cycles of lateral friction under a vertically applied force of 9 N (Supplementary Fig. 11). Finally, the strain sensor demonstrated washability and maintained repeatable performance even after 10 cycles under 30% strain (Supplementary Figs. 12, 13). This can be attributed to the strong physical bonds formed between the hydrophobic polymers SBS and PS and the textile66,67.

Impregnation Mechanism for DIW Interconnect Electrode

The interconnecting conductive ink as depicted in Fig. 3a was made by mixing Ag with polystyrene (PS) in toluene. Figure 3b, Supplementary Fig. 14 shows that depending on the ratio of toluene to polystyrene, the viscosity can be controlled. Figure 3c demonstrates that depending on the ink used, the impregnation varies from 10% to 100%. Therefore, by using different inks, interconnects and via-holes can be printed. Figure 3a right show a “T” shaped cross-sectional SEM/EDS image, where the middle region was printed using low viscosity ink for full penetration through the textile while two ends were printed with high viscosity inks. The impregnation ratio exhibited a strong linear correlation with viscosity (R² ~0.99) (Supplementary Fig. 15).

Supplementary Fig 16 are top-view pictures of printed conductive ink on textile, showing that it can be printed with high consistency. The resolution of the conductive lines can reach approximately 430 µm when printed. The resolution of the electrode ink followed a trend similar to that of the strain sensor ink, displaying a positive correlation with extrusion pressure and a negative correlation with nozzle speed and the gap-to-nozzle diameter ratio (Supplementary Fig. 17). The resistance of the conductive ink must remain stable under various mechanical stimulations for stable signal acquisition under user movement and daily activity. Hence, the conductive ink incorporating the rigid polymer PS is designed to remain physically unchanged while the textile substrate stretches under strain. As depicted in Fig. 4a–c, the more the conductive ink impregnated the textile (higher I/H value), the higher the resistivity, as impregnation reduces the number of secured electrical pathways. However, even at full impregnation, the resistance of our interconnection was 0.4 Ω (with a resistivity of 5.16 ×10−8 Ω⋅m), which is sufficiently low to avoid affecting strain sensors. The printed electrodes at all impregnations showed no change even under 30% strain and 50 kPa pressure over 1000 cycles (Fig. 4a, b), showing high degree of stability. The maximum strain rate of the printed electrode varied according to the degree of impregnation. Figure 4c is the stretchability limit of the conductive inks at different impregnation levels. The higher the impregnation, more stretchable the conductors became (up to 115%), which can be ascribed to stronger bonding between the textile and the ink due to larger interfacial area. Two conductive lines with 10% impregnation were printed perpendicular to each other, where each line was printed on different sides of the textile sheet, as depicted in Fig. 4d top. Since the two lines only penetrate 10% into the textile, no conduct path is made. Then, at the region where the two lines crossed, conductive ink with 100% impregnation was printed, resulting in electrical connection of the top and bottom lines (Fig. 4d bottom). Thus, by simply printing layers with different conductive inks, via holes can be selectively patterned using interconnect electrodes, enabling complex circuit fabrication utilizing both sides of the textile sheets.

a–c Performance of electrode. a Cyclic test at strain 30% under 1000 cycles. b Cycle test at pressure 50 kPa under 1000 cycles. c Strain – resistance change curve for maximum strain rate. d Illustration and photographs showing the absence of electrical pathways in the 10% impregnated electrode printed horizontally on the top surface and vertically on the back surface, and the formation of electrical pathways due to the 100% impregnated electrode.

DIW printed visible temperature sensor

Temperature sensors are essential for recognizing environmental changes. Although temperature is not directly categorized as a tactile sense, temperature detection is crucial for understanding the surrounding environment or objects. Most temperature sensors require additional substrates and power for processing temperature values through electrical signals68,69,70. However, the temperature sensor we developed allows temperature estimation through color change without needing an electrode or signal processing system. Leuco dye, used in the sensor, consists of an electron donor and acceptor, with the electron acceptor separating and changing color according to temperature. This material changes color as electrons are oxidized or reduced by heat71,72. Unlike other tactile sensors, this temperature sensor is not checked through electrical signals but visually by the user, with color changing according to temperature range. Additionally, it can be printed into user-desired shapes (Supplementary Fig. 18) The variations in the temperature sensor were characterized using a thermal imaging camera. (Supplementary Fig. 19) Although it does not provide precise temperature measurements, it can estimate a temperature range, which may be sufficient depending on the application. The color hue changes within five seconds when the temperature shifts from 0 to 90 degrees Celsius (Supplementary Table 2).

Real-time monitoring of human physiological movement using textile tactile sensors

Human motion detection is widely used to demonstrate effectiveness of tactile sensors. Our strain sensor not only measures lateral strain but also bending (Fig. 5a, b). Our strain sensors were placed on the shoulder, inner elbow, and knee—large moving joints—and conductive lines were placed on the inner side of the clothing as interconnects. (Fig. 5c). The relative resistance change (ΔR/R0) of the strain sensor was measured during running, jumping jacks, and push-ups. Depending on the exercise, the ΔR/R0 values of the sensors placed at different joints varied, thus allowing identification of the type of exercise being done by the user. Furthermore, the sensors can quantify the number of exercise movements, and monitor user’s posture during exercise (since higher resistance change indicated greater bending). The developed wearable smart textile platform must ensure stability and reliability in direct skin-contact environments. In particular, it is crucial to validate its performance under sweat exposure conditions. Since sweat absorption on the MWCNT composite surface alters contact resistance, the initial resistance of the sensor decreased by 3.65% in the presence of sweat and by 2.22% after drying. Although a slight reduction in initial resistance was observed, no significant performance degradation was detected in the strain sensor’s primary sensing mechanism, which relies on relative resistance change (ΔR/R0) (Supplementary Fig. 20). Such human motion detection and monitoring can be utilized in various industrial fields, including robotics, healthcare, military, and sports.

a Relative change in resistance vs bending strain plots of strain sensors for bending estimation. b Resistance changes measured by the strain sensor during 16 push-ups. c Resistance changes of sensors printed on the knee, shoulder, and elbow for real-time monitoring of body movements during running, jumping jacks, and push-ups. d Resistance changes of sensors printed on the mask for real-time monitoring of respiration patterns during 30 jumping jacks.

Real-time monitoring of human breathing detection using textile tactile sensors

Our strain sensor and electrode were also integrated into a tightly fitting cotton face mask for breathing monitoring. As illustrated in Fig. 5d, before exercise, steady breathing was observed. However, during 30 jumping jacks, the intensity and frequency of breathing gradually increased. After exercise, a gradual decrease in the intensity and frequency was observed. To evaluate the practical applicability of the facial mask in daily use, its performance was assessed under simulated ambient airflow conditions. The ΔR/R0 values remained as low as ~ 0.05 under wind speeds ranging from typical daily airflow (0.5–1.5 m/s) to strong winds (5–15 m/s). In contrast, normal breathing resulted in a ΔR/R0 value of approximately 0.25. This difference arises because the semi-enclosed space between the face and the mask leads to relatively higher localized pressure, enhancing the sensor’s response to breathing (Supplementary Fig. 21). This demonstrates that our strain sensors can also be used to monitor breathing, which can be used with the joint bending sensing to increase accuracy in human health and motion monitoring.

Object recognition application using a smart glove

The mechanical movements of the hand can be translated into electrical signals using strain sensors. For this purpose, a textile glove was equipped with strain sensors at the finger joints and pressure sensors at the fingertips (Supplementary Figs. 22, 23) A total of 10 sensors were connected via electrodes. During the experiment, the user trained the glove by grasping six different objects (basketball, Styrofoam ball, doll, glass cup, paper cup, pen) 30 times each (Fig. 6a). When subsequently tested with an unknown object, the glove achieved an identification accuracy of 98.32% using a Random forest and 96.64% with a Gradient Boosting classifier. These results underscore the sensor’s reliability and functional efficacy (Fig. 6b), opening up the possibility of utilizing our sensor platform for robotic, VR/AR, and wearable electronics.

Tactile sensing using an interconnect multilayer glove

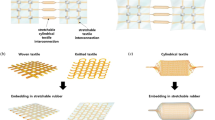

To demonstrate the feasibility of E-textiles with interconnect electrodes, a multilayered glove was fabricated, integrating multiple sensing functionalities. The top layer consisted of a cotton textile with unidirectional stretchability, onto which the strain sensor was printed. The middle layer contained an unconnected electrode, facilitating signal transmission between the top and bottom layers, while the bottom layer housed the pressure sensor. As illustrated in Fig. 7a, interconnect electrodes were strategically printed to establish electrical connections, with a strain sensor-to-unconnected electrode interconnect (marked in blue) and a pressure sensor-to-unconnected electrode interconnect (marked in green). This multilayered structure enabled simultaneous acquisition of strain and pressure signals through the middle layer during various functional tasks, including hand clenching and releasing, finger pressing and releasing, and umbrella grasping (Fig. 7b).

a Fabrication scheme of the interconnect multi-layered E-textile. Layered structure: top layer – strain sensor, middle layer – electrode, bottom layer – pressure sensor. The top and middle layers were textile substrates stretchable only along the x-axis, while the bottom layer, on which the pressure sensor was printed, was a non-elastic textile substrate. b Motion recognition using the interconnect multi-layered E-textile platform: hand clenching and releasing, finger pressing and releasing, and object grasping.

These results validate the practical viability of leveraging multilayer textile architectures and dual-sided utilization for E-textiles. By incorporating via connections, the integration density of electronic components is significantly enhanced, allowing for optimized substrate utilization while preserving textile flexibility. This study underscores the potential of via-connected E-textiles in enabling highly integrated, multifunctional wearable electronics, paving the way for their adoption in advanced applications.

Discussion

This study successfully integrated tactile sensors into textile substrates via a direct printing approach, overcoming previous limitations in user customization and the complexities associated with textile-tactile sensor research. By optimizing the viscosity of the printing solution, we enabled higher-density integration on both sides of the textile, a significant advancement over previous studies where dual-sided utilization was restricted. Traditional approaches to electrode development aimed to produce soft electrodes with minimal resistance changes; however, resistance variations due to physical changes in material behavior were unavoidable. The textile-electrode fabricated in this study limited the physical changes of the electrode itself by employing rigid PS, while the textile substrate ensured the overall device’s stretchability. This approach also yielded a strain sensor with excellent linearity (R2 ~ 0.99) and consistent performance across 10,000 strain cycles. The wearable tactile sensor developed here demonstrated the capability to monitor dynamic human movements and sensitive breathing patterns, proving its potential applicability in military or sporting uniforms. The potential of multilayer E-textiles was particularly demonstrated, highlighting their promising applicability across various fields. The ultimate goal of tactile sensor research is to accurately record human sensory data, requiring the sensors to be comfortably wearable without interfering with daily activities. Given the variability in body size, curvature, and individual preferences, it is crucial to produce tactile sensor arrays tailored specifically to each user. While this study makes significant research contributions, several challenges remain to be addressed. A key limitation of DIW printing technology is its difficulty in achieving high-resolution patterns, primarily due to the inherent gap between the substrate and the nozzle. Moreover, printing conditions must be fine-tuned based on textile type, introducing variability in process optimization. Overcoming these limitations, in conjunction with the novel wearable interconnect E-textile platform proposed in this study, could drive substantial advancements in both E-textile research and industrial applications.

Methods

Materials

Polystyrene-block-polybutadiene-block-polystyrene (SBS, Avg Mw ~140,000), Polystyrene (PS, Avg Mw ~350,000) were purchased from Sigma-Aldrich. Multi-wall carbon nanotube (MWCNT, Diameter ~20 nm, Length ~10 μm) was purchased from Applied carbon nano technology. Poly(3-dodecylthiophene-2,5-diyl) (P3DDT) was purchased from Rieke metals. Toluene was purchased from Samchun pure chemical. And leuco dye (Color change from black to white) was purchased from Sion science. These materials were employed as received, without any additional treatment.

Preparation of DIW printed tactile sensor

Strain sensor; 0.08 g of MWCNT and 0.08 g of surfactants are added to 4 g of Toluene, and then tip sonicated for 1 h. Then, 0.8 g of SBS is added and heat at 80 °C for 6 h on a hot plate using magnetic stirring. Using a DIW 3D printer, print the desired shape onto the textile with a 25 G nozzle, 80 kPa pressure, and a speed of 10 mm/s. The characteristics of the manufactured electrode are measured using a force gauge (Mark-10) and an LCR meter (Table 1).

Interconnect electrode; Add 5 g of PS to 20 g toluene. Thereafter, magnetic stirring is used at 60 °C on a hot plate for 6 h. Then, 30 g of Ag flake is added and then mixed for 1 min using a mixing machine

Unconnected electrode; Add 15 g of PS to 20 g toluene. Then, magnetic stirring is used at 60 °C on a hot plate for 12 h. Thereafter, 30 g of Ag flake is added and then mixed for 1 min using a mixing machine. Using a DIW printer, print the desired shape onto the textile substrate with a 25 G nozzle, applying 150 kPa for the unconnected electrode and 100 kPa for the interconnect electrode, at a speed of 10 mm/s. The manufactured electrode measures resistance changes using a force gauge (Mark-10) and an LCR meter.

Temperature sensor; Add 5 g of leuco dye to 5 g dichloromethane. Using a DIW printer, print the desired shape onto the textile substrate with a 25 G nozzle, at 100 kPa pressure and a speed of 10 mm/s.

Washability test of printed textile sensors

The sensors printed textile was washed by a household washing machine (TR12BL, LG electronics, Republic of korea). The washing time was set to be 60 min, including washing and drying processes. The temperature of the water was ∼25 °C. A conventional laundry detergent (Persil deepclean powergel, Persil, Germany) was used for the washing stability.

Mechanical robustness test of the strain sensor printed on textile

The robustness of the tactile sensor printed on textile was evaluated using an AATCC crock meter (Dazhong Instrument Co., LTD.). Due to the weight of the device, a force of 9 N was applied, pressing the sensor against the textile surface. Under this condition, the textile surface underwent 100 reciprocating rubs. 100 cycles were completed in approximately 2 min, corresponding to 50 RPM.

Fabrication of the human body monitoring wearable textile

The strain sensor was printed onto a cotton cloth using the composite ink to track human body movements. The strain sensors were embedded in the shoulder, inner elbow, and knee area. Similar to measurement of the sensor, the cotton cloth for body motion tracking was measured using an LCR meter. To create a smart facial mask for measuring breathing intensity and frequency, the strain sensor and electrodes were printed on the outside of the cotton mask.

Performance evaluation of the strain sensor under perspiration exposure and post-drying conditions

To replicate the composition and electrical conductivity of sweat, 0.6% NaCl was dissolved in distilled water. This solution was sprayed onto the sensor printed on the textile using an atomizer. Initial resistance and resistance change as a function of strain were measured for both the sprayed and dried samples.

Performance testing of the sensor-printed facial mask in an ambient environment

Performance evaluation under airflow generated by an electric fan and air blower. To simulate everyday wind conditions (0.5–5 m/s), airflow was generated using a household fan and measured at a distance of 1 m in front of the fan. To simulate strong winds similar to those in typhoons (5–15 m/s), airflow was generated using an air blower and measured at a distance of 3 m in front of the blower. The air blower supply pressure was set to 3 bar, and considering the distance, the expected wind speed effect was approximately 10 m/s.

Fabrication of the smart sensing glove

A smart glove was fabricated to identify grasped objects using machine learning techniques. Strain sensors were positioned on the finger joints and pressure sensors on the fingertips of the glove. A total of 10 sensors were printed with electrodes connected to them. The pressure sensor was fabricated by incorporating polyurethane beads into the strain sensor ink. The resistance values obtained from the smart glove were collected using an LCR meter for subsequent machine learning analysis.

Fabrication of the interconnect multi-layered E-textile glove

To demonstrate the interconnect multi-layered E-textile, a strain sensor was printed on the top layer, an unconnected electrode on the middle layer, and a pressure sensor on the bottom layer. To connect the sensors on the top and bottom layers to the unconnected electrode in the middle layer, interconnect electrodes were printed at two designated points on each layer. Fabric glue (Nippon Paint Co.) was applied to the edges of the fabricated interconnect multi-layered E-textile to attach it to a cotton glove. Sensor signals were then recorded while performing various hand movements, including hand clenching, finger pressing, and object grasping.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Wicaksono, I. et al. A tailored, electronic textile conformable suit for large-scale spatiotemporal physiological sensing in vivo. npj Flex. Electron. 4, 1–13 (2020).

Fan, W. et al. Machine-knitted washable sensor array textile for precise epidermal physiological signal monitoring. Sci. Adv. 6, eaay2840 (2020).

Chow, L. et al. Army Ant Nest Inspired Adaptive Textile for Smart Thermal Regulation and Healthcare Monitoring. Adv. Mater. 37, 2406798 (2024).

Hui, Z. et al. Solution-processed sensing textiles with adjustable sensitivity and linear detection range enabled by twisting structure. ACS Appl. Mater. interfaces 12, 12155–12164 (2020).

Li, J., Yin, J., Wee, M. G. V., Chinnappan, A. & Ramakrishna, S. A self-powered piezoelectric nanofibrous membrane as wearable tactile sensor for human body motion monitoring and recognition. Adv. Fiber Mater. 5, 1417–1430 (2023).

Zhao, H. et al. Ultrastretchable and washable conductive microtextiles by coassembly of silver nanowires and elastomeric microfibers for epidermal human–machine interfaces. ACS Mater. Lett. 3, 912–920 (2021).

Guo, Y. et al. Conductive chromotropic fiber filament sensors with ultrahigh stretchability for wearable sensing textiles toward 3D optical motion capture. J. Mater. Chem. A 11, 9597–9607 (2023).

Sundaram, S. et al. Learning the signatures of the human grasp using a scalable tactile glove. Nature 569, 698–702 (2019).

Lu, H. et al. Intelligent perceptual textiles based on ionic-conductive and strong silk fibers. Nat. Commun. 15, 3289 (2024).

Buckner, T. L., Bilodeau, R. A., Kim, S. Y. & Kramer-Bottiglio, R. Roboticizing fabric by integrating functional fibers. Proc. Natl Acad. Sci. 117, 25360–25369 (2020).

Granberry, R., Barry, J., Holschuh, B. & Abel, J. Kinetically tunable, active auxetic, and variable recruitment active textiles from hierarchical assemblies. Adv. Mater. Technol. 6, 2000825 (2021).

Xiong, J., Chen, J. & Lee, P. S. Functional fibers and fabrics for soft robotics, wearables, and human–robot interface. Adv. Mater. 33, 2002640 (2021).

Ma, S. et al. Optical micro/nano fibers enabled smart textiles for human–machine interface. Adv. Fiber Mater. 4, 1108–1117 (2022).

Wang, H. et al. Smart textiles for human–machine interface fabricated via a facile on-site vapor-phase polymerization. J. Mater. Chem. C. 10, 13930–13938 (2022).

He, J. et al. Scalable production of high-performing woven lithium-ion fibre batteries. Nature 597, 57–63 (2021).

Shirzaei Sani, E. et al. A stretchable wireless wearable bioelectronic system for multiplexed monitoring and combination treatment of infected chronic wounds. Sci. Adv. 9, eadf7388 (2023).

Wang, T. et al. Reconfigurable neuromorphic memristor network for ultralow-power smart textile electronics. Nat. Commun. 13, 7432 (2022).

Mo, F. et al. An overview of fiber‐shaped batteries with a focus on multifunctionality, scalability, and technical difficulties. Adv. Mater. 32, 1902151 (2020).

Xue, E., Liu, L., Wu, W. & Wang, B. Soft Fiber/Textile Actuators: From Design Strategies to Diverse Applications. ACS Nano 18, 89–118 (2023).

Nikbakhtnasrabadi, F., El Matbouly, H., Ntagios, M. & Dahiya, R. Textile-based stretchable microstrip antenna with intrinsic strain sensing. ACS Appl. Electron. Mater. 3, 2233–2246 (2021).

Yong, S. et al. Ti3C2 MXene as Additive for Low‐Cost Textile Supercapacitors with Enhanced Electrical Performance. Adv. Mater. Technol. 9, 2301266 (2024).

Lin, Y. et al. Thermally laminated lighting textile for wearable displays with high durability. ACS Appl. Mater. Interfaces 15, 5931–5941 (2023).

Meena, J. S., Choi, S. B., Jung, S.-B. & Kim, J.-W. Electronic textiles: New age of wearable technology for healthcare and fitness solutions. Mater. Today Bio 19, 100565 (2023).

Wei, R. et al. Revolutionizing wearable technology: advanced fabrication techniques for body-conformable electronics. npj Flex. Electron. 8, 1–20 (2024).

Libanori, A., Chen, G., Zhao, X., Zhou, Y. & Chen, J. Smart textiles for personalized healthcare. Nat. Electron. 5, 142–156 (2022).

Dong, K., Peng, X. & Wang, Z. L. Fiber/fabric‐based piezoelectric and triboelectric nanogenerators for flexible/stretchable and wearable electronics and artificial intelligence. Adv. Mater. 32, 1902549 (2020).

Pu, J. et al. Textile electronics for wearable applications. Int. J. Extreme Manuf. 5, 042007 (2023).

Ma, C. et al. Ultrasensitive, highly selective, integrated multidimensional sensor based on a rigid-flexible synergistic stretchable substrate. Adv. Fiber Mater. 5, 1392–1403 (2023).

Liu, X. et al. Recent progress on smart fiber and textile based wearable strain sensors: materials, fabrications and applications. Adv. Fiber Mater. 4, 361–389 (2022).

Lu, D. et al. Highly durable and fast response fabric strain sensor for movement monitoring under extreme conditions. Adv. Fiber Mater. 5, 223–234 (2023).

Wang, X.-X. et al. Conductive polymer ultrafine fibers via electrospinning: Preparation, physical properties and applications. Prog. Mater. Sci. 115, 100704 (2021).

Yi, P. et al. MXene-reinforced liquid metal/polymer fibers via interface engineering for wearable multifunctional textiles. ACS Nano 16, 14490–14502 (2022).

Sarabia‐Riquelme, R. et al. Highly Conductive n‐Type Polymer Fibers from the Wet‐Spinning of n‐Doped PBDF and Their Application in Thermoelectric Textiles. Adv. Funct. Mater. 34, 2311379 (2024).

Wen, N. et al. Highly conductive, ultra-flexible and continuously processable PEDOT: PSS fibers with high thermoelectric properties for wearable energy harvesting. Nano Energy 78, 105361 (2020).

Zhang, J. et al. Fast and scalable wet-spinning of highly conductive PEDOT: PSS fibers enables versatile applications. J. Mater. Chem. A 7, 6401–6410 (2019).

Liu, F. et al. Continuously processing waste lignin into high-value carbon nanotube fibers. Nat. Commun. 13, 5755 (2022).

Hossain, M. M., Li, B. M., Sennik, B., Jur, J. S. & Bradford, P. D. Adhesive free, conformable and washable carbon nanotube fabric electrodes for biosensing. npj Flex. Electron. 6, 97 (2022).

Wang, H.-Z. et al. Highly Conductive Double-Wall Carbon Nanotube Fibers Produced by Dry-Jet Wet Spinning. Adv. Funct. Mater. 34, 2404538 (2024).

Wang, F. et al. Advanced functional carbon nanotube fibers from preparation to application. Cell Rep. Phys. Sci. 3, 100989 (2022).

Liu, Y., Zhang, S., Li, L. & Li, N. High-Performance Cellulose Nanofibers/Carbon Nanotubes Composite for Constructing Multifunctional Sensors and Wearable Electronics. Adv. Fiber Mater. 6, 758–771 (2024).

Hossain, M. M., Lubna, M. M. & Bradford, P. D. Multifunctional and washable carbon nanotube-wrapped textile yarns for wearable E-textiles. ACS Appl. Mater. Interfaces 15, 3365–3376 (2023).

Sun, T. et al. Stretchable fabric generates electric power from woven thermoelectric fibers. Nat. Commun. 11, 572 (2020).

Li, Y. et al. Ultrastretchable and wearable conductive multifilament enabled by buckled polypyrrole structure in parallel. npj Flex. Electron. 6, 42 (2022).

He, N., Song, J., Liao, J., Zhao, F. & Gao, W. Separator threads in yarn-shaped supercapacitors to avoid short-circuiting upon length. npj Flex. Electron. 6, 19 (2022).

Lee, J., Llerena Zambrano, B., Woo, J., Yoon, K. & Lee, T. Recent advances in 1D stretchable electrodes and devices for textile and wearable electronics: materials, fabrications, and applications. Adv. Mater. 32, 1902532 (2020).

Kim, J. et al. Hierarchically Plied Mechano-Electrochemical Energy Harvesting Using a Scalable Kinematic Sensing Textile Woven from a Graphene-Coated Commercial Cotton Yarn. Nano Lett. 23, 7623–7632 (2023).

Hong, X. et al. Washable and Multifunctional Electronic Textiles Via In Situ Lamination for Personal Health Care. Adv. Fiber Mater. 6, 458–472 (2024).

Jang, J. et al. Knitted strain sensor with carbon fiber and aluminum-coated yarn, for wearable electronics. J. Mater. Chem. C. 9, 16440–16449 (2021).

Wang, X. et al. Biocompatible and breathable healthcare electronics with sensing performances and photothermal antibacterial effect for motion-detecting. npj Flex. Electron. 6, 95 (2022).

Sadanandan, K. S. et al. Fabric-based triboelectric nanogenerators with ultrasonic spray coated graphene electrodes. Nano Energy 116, 108797 (2023).

Li, X. et al. Stretchable luminescent perovskite-polymer hydrogels for visual-digital wearable strain sensor textiles. Adv. Fiber Mater. 5, 1671–1684 (2023).

Zhan, P. et al. A fibrous flexible strain sensor with Ag nanoparticles and carbon nanotubes for synergetic high sensitivity and large response range. Compos. Part A Appl. Sci. Manuf. 167, 107431 (2023).

Tenhunen, T.-M. et al. Surface tailoring and design-driven prototyping of fabrics with 3D-printing: An all-cellulose approach. Mater. Des. 140, 409–419 (2018).

Yu, J., Seipel, S. & Nierstrasz, V. A. Digital inkjet functionalization of water-repellent textile for smart textile application. J. Mater. Sci. 53, 13216–13229 (2018).

Zhu, H.-W. et al. Printable elastic silver nanowire-based conductor for washable electronic textiles. Nano Res. 13, 2879–2884 (2020).

Uzun, S. et al. Additive‐free aqueous MXene inks for thermal inkjet printing on textiles. Small 17, 2006376 (2021).

Wu, P., Fu, J., Xu, Y. & He, Y. Liquid metal microgels for three-dimensional printing of smart electronic clothes. ACS Appl. Mater. Interfaces 14, 13458–13467 (2022).

Pless, C. J. et al. Soft electronic block copolymer elastomer composites for multi‐material printing of stretchable physiological sensors on textiles. Adv. Electron. Mater. 9, 2201173 (2023).

Song, T., Jiang, S., Cai, N. & Chen, G. A strategy for human safety monitoring in high-temperature environments by 3D-printed heat-resistant TENG sensors. Chem. Eng. J. 475, 146292 (2023).

Wang, Y. et al. Multifunctional electronic textiles by direct 3D printing of stretchable conductive fibers. Adv. Electron. Mater. 9, 2201194 (2023).

Yang, L. et al. Direct ink writing-based cotton integration for enhanced mechanical and functional characteristics in 3D printed fabrics. Cellulose 31, 2685–2702 (2024).

Zhu, L. et al. Self-Adhesive Elastic Conductive Ink with High Permeability and Low Diffusivity for Direct Printing of Universal Textile Electronics. ACS Nano 18, 34750–34762 (2024).

Tu, R., Kim, H. C., Baabdullah, O. A. & Sodano, H. A. Alignment controlled aramid nanofiber‐assembled films. Adv. Funct. Mater. 34, 2315422 (2024).

Inman, A. et al. MXene-enabled textile-based energy grid utilizing wireless charging. Mater. Today 81, 59–69 (2024).

Wang, X., Kim, Y. I., Yarin, A. L. & Pan, Y. Electric field-assisted micro-scale direct ink writing for electronic textiles. Manuf. Lett. 41, 841–849 (2024).

Choi, B. et al. Highly conductive fiber with waterproof and self-cleaning properties for textile electronics. ACS Appl. Mater. interfaces 10, 36094–36101 (2018).

Jang, S. et al. Printable wet-resistive textile strain sensors using bead-blended composite ink for robustly integrative wearable electronics. Compos. Part B Eng. 210, 108674 (2021).

Dinh, T. et al. Environment-friendly carbon nanotube based flexible electronics for noninvasive and wearable healthcare. J. Mater. Chem. C. 4, 10061–10068 (2016).

Ryu, W. M., Lee, Y., Son, Y., Park, G. & Park, S. Thermally drawn multi-material fibers based on polymer nanocomposite for continuous temperature sensing. Adv. Fiber Mater. 5, 1712–1724 (2023).

Kuzubasoglu, B. A. & Bahadir, S. K. Flexible temperature sensors: A review. Sens. Actuators A Phys. 315, 112282 (2020).

Ko, I. J., Park, J. H., Kim, G. W., Lampande, R. & Kwon, J. H. An optically efficient full-color reflective display with an electrochromic device and color production units. J. Inf. Disp. 20, 155–160 (2019).

Shirasaki, Y. et al. Fused-fluoran leuco dyes with large color-change derived from two-step equilibrium: iso-aminobenzopyranoxanthenes. J. Org. Chem. 81, 12046–12051 (2016).

Acknowledgements

This work was supported by the Ministry of Trade, Industry & Energy (MOTIE, RS-2023-00258591), National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (RS-2019-NR040066) and National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. RS-2024-00407084).

Author information

Authors and Affiliations

Contributions

K. Pak and J. Kim designed the experiments; K. Pak prepared and conducted the experiments; K.Pak, T. Lee, D.H. Lee and S. Lee conducted experiments measuring body movements using garments and respiration using a facial mask. K. Pak, J. C. Yang and J. Y Sim conducted conducted a machine learning experiment utilizing a smart glove. D. H. Lee and B. Oh contributed to the illustration work. K. Pak, M. Kang and S. Park wrote the paper. J. Kim and S. Park supervised the project and all authors contributed to the general discussion.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Pak, K., Yang, J.C., Sim, J.Y. et al. Fabrication of multifunctional wearable interconnect E-textile platform using direct ink writing (DIW) 3D printing. npj Flex Electron 9, 48 (2025). https://doi.org/10.1038/s41528-025-00414-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-025-00414-7