Abstract

Shape memory alloy (SMA) fibers demonstrate exceptional contraction strains and substantial load capacities, positioning them as highly promising actuators for advanced robotic hands and microrobotic systems. However, the practical deployment of SMAs has been critically hindered by their inherently slow thermal responsiveness and reliance on wired electrical connections. Here, we introduce a dual-responsive SMA technology that addresses these limitations by leveraging a novel surface modification comprising polydopamine integrated with silver nanowires. The modified SMA fibers exhibited an approximately 3.2 times faster actuation speed than unmodified fibers under near-infrared laser irradiation, with a 35% improvement in electrothermal responsiveness. These wireless, fast-responding actuators have been effectively integrated into microrobotic crawlers, demonstrating great potential for lightweight autonomous lunar rover applications. Fabricated via straightforward in-situ polymerisation methods, our dual-responsive SMA approach offers a compelling pathway toward the development of energy-efficient aerospace systems capable of operating reliably under extreme environmental conditions.

Similar content being viewed by others

Introduction

Shape memory alloys (SMAs) are indispensable in modern actuation systems ranging from anthropomorphic robotic hands to locomotion mechanisms in lunar rovers due to their unique ability to recover predefined shapes in response to thermal stimuli. Among these, nitinol (NiTi) alloys are particularly notable for their robust shape memory performance across wide temperature ranges, enabling reliable function under extreme environmental conditions1. Such capabilities make SMAs especially attractive for aerospace applications, where mechanical adaptability and resilience are critical. Recent advancements have brought anthropomorphic robotic hands2,3,4 and microrobots5,6,7 to the forefront as powerful tools for precision manipulation and autonomous exploration in aerospace environments. Bionic robotic hands, capable of mimicking the dexterity of human fingers, can dynamically modulate gripping force and form to accommodate diverse object geometries and thermal variations. Concurrently, microbots provide essential functions such as agile navigation through confined spaces, real-time environment awareness, and data transmission to support situational awareness and decision-making in extraterrestrial missions. To meet the adaptability and reliability demands of the above-mentioned modern actuation systems, extensive research has explored emerging smart materials for actuation. These include hydrogels8,9, low-dimensional carbon-based materials such as graphene and carbon nanotubes10,11,12, dielectric elastomers13, liquid crystal elastomers14,15,16,17, and SMAs18,19,20. Among these, SMA fibers stand out due to their lightweight nature, high power density, mechanical robustness, biocompatibility, and low-noise operation. As a result, they have found widespread application in fields ranging from wearable technologies to medical devices21 and soft robotics. Nevertheless, bare SMA coils (SMAcs) suffer from inherently slow thermal cycling rates and dependence on wired electrical connections. These limitations critically undermine real-time actuation performance and long-term reliability22,23,24. In demanding scenarios, such as the rapid deployment of components during lunar exploration or adaptive locomotion over unstable terrain, delayed thermal responses may jeopardize mission success. Moreover, the reliance on wired systems introduces complexity and increases the risk of failure in harsh, dusty, or vacuum environments.

To address these limitations, researchers have increasingly turned to near-infrared (NIR) light as a wireless actuation strategy, replacing conventional Joule heating due to its deep penetration capabilities and minimal electromagnetic interference. SMAs are known to absorb light in the 420–1000 nm range25, with NIR light enabling efficient internal heating by penetrating surfaces. However, the photothermal conversion (PTC) process remains sluggish, limiting actuation frequency. Efforts to enhance PTC efficiency26 have focused on incorporating photothermal materials such as carbon nanotubes27, neodymium iron boron microparticles28, graphene oxide29, and polydopamine30 (PDA). Among these, PDA is easy to prepare, exhibits an excellent PTC effect31,32, adheres strongly to various substrates, and can be directly applied for surface modification33,34. However, the current practice of using PDA alone as an in-situ photothermal coating is limited by its poor thermal conductivity, leading to heat accumulation at the coating surface rather than uniform transfer into the SMAc substrate. This limitation causes localized overheating and delayed actuation responses.

In this study, we propose an in-situ coating modification strategy that simultaneously incorporates PDA and silver nanowires (AgNWs) to meet the stringent demands for rapid response and high reliability in aerospace actuation systems. AgNWs significantly improve photothermal conversion efficiency due to their strong absorption in the near-infrared region, facilitated by localized surface plasmon resonance, thus synergistically complementing the absorption characteristics of PDA. Moreover, the high thermal conductivity of AgNWs (≈429 W/m·K) is considerably superior to that of PDA, enabling rapid and uniform heat dispersion throughout the SMAc, effectively preventing localized overheating and ensuring consistent actuation. By leveraging the synergistic properties of PDA, known for its high photothermal conversion efficiency and AgNWs35,36 offering excellent thermal conductivity along with a multiscale surface topology, we significantly enhance both the heating (33.3% enhanced) and cooling (38.5% enhanced) dynamics of SMAcs. Experimental validation under both NIR and electrothermal stimuli demonstrates that PDA/AgNWs-coated SMAcs exhibit markedly faster actuation responses (3.2 times) and allow for programmable control, paving the way for high-performance, wireless, miniaturized actuation in future aerospace and robotic systems.

Results

PDA-AgNWs in situ coated on SMAc

Compared to fibrous forms, coiled SMA (SMAc) structures exhibit greater actuation stroke. The process of preparing SMA fibers into SMAcs (mold dimension is shown in Supplementary Fig. 1) is illustrated in Supplementary Fig. 2. To address the issue of slow heating and cooling in traditional SMAcs, for the first time, we used an in-situ coating of PDA-AgNWs on SMAcs, which enhances the PTC effect and accelerates cooling. The method employed is simple, produces uniform coatings, and ensures strong adhesion. To eliminate the constraints of wired connections, NIR light wireless actuation was used, and fast heating and accelerated cooling were implemented to improve actuation speed. In the complex environment of the lunar, SMAc can be used for both photoactuated microrobot and electroactuated anthropomorphic robotic prosthetic hand (Fig. 1a). Figure 1b shows the PDA-AgNWs in situ coated SMAc artificial muscle. Before the in-situ coating of PDA-AgNWs, the SMAcs underwent plasma treatment to enhance the long-term stability and reliability of the PDA-AgNWs coating. Dopamine was prepared using dopamine hydrochloride (DA-HCl), sodium periodate (NaIO4), and sodium acetate buffer. The AgNWs were then mixed with the dopamine solution and continuously stirred with a magnetic stirrer. This mixture was in situ coated onto the surface of SMAcs at room temperature, forming a PDA-AgNWs coating. The coated SMAcs exhibit excellent thermal conductivity while maintaining a superior photothermal conversion effect. The uniform PDA-AgNWs coating on the SMAc surface enhances the PTC effect, accelerating the heating process. Simultaneously, the coating increases the surface area-to-volume ratio, promoting thermal convection and thereby accelerating heat dissipation for fast cooling.

a The application of mining lunar soil by PDA-AgNWs@SMAc actuated lunar rover and robotic hand. b Schematic illustration of the synergistic effect and in situ coating for the PDA-AgNWs@SMAc. c Heating and cooling time under electrothermal. d PDA-AgNWs@SMAc under dual energy actuation. e Heating and cooling time under photothermal.

Furthermore, the photothermal heating and natural cooling time of PDA-AgNWs@SMAc is significantly reduced due to the synergistic effect of PDA and AgNWs. When heated, PDA can efficiently absorb light energy and convert it into heat under near-infrared (NIR) irradiation. AgNWs also exhibit significant surface plasmon resonance effects in the NIR region, enhancing light absorption. When combined, the synergistic effect of PDA and AgNWs can significantly enhance the photothermal conversion efficiency. The presence of AgNWs enhances the light absorption of PDA and effectively transfers heat to SMAc through localized thermal conduction, thereby increasing the intensity of the photothermal effect. When cooled, due to their excellent thermal conductivity, AgNWs can rapidly transfer heat to the surrounding environment after heating. The surface structure of the PDA can enhance heat transfer to the external environment, thereby increasing the rate of heat dissipation. Additionally, the hydrophilicity of PDA aids in accelerating heat dissipation through the evaporative cooling effect, further enhancing the cooling efficiency. As shown in Fig. 1c, the electrothermal cooling time is shortened. And the phase transformation of SMAc can be made either electrothermal or photothermal (Fig. 1d). As shown in Fig. 1e, photothermal heating and photothermal cooling time are both shortened.

Characterization of the B-SMAc and the PDA-AgNWs@SMAc

The schematic diagram of polydopamine synthesis is shown in Fig. 2a, b illustrates the synthetic procedure for coating PDA-AgNWs on the surface of the SMAc. The scanning electron microscope (SEM) image of the B-SMAc surface (Fig. 2c, d) displays its relatively smooth oxidized surface layer, together with the energy dispersive spectrometer (EDS) results of Ni and Ti elements (Fig. 2e). The element weight ratio of Ni is 56.8% and Ti is 43.2% (Supplementary Fig. 3a).

a Schematic diagram of polydopamine synthesis. b Schematic diagram of the surface coating process of B-SMAc with PDA-AgNWs. Surface SEM images of: c B-SMAc; d Locally magnified area SEM images of B-SMAc; e EDS result of B-SMAc. Surface SEM images of: f PDA-AgNWs@SMAc; g locally magnified area SEM images of PDA-AgNWs@SMAc; h EDS result of PDA-AgNWs@SMAc.

Leveraging the good adhesion properties of PDA, the cleaned and pre-treated B-SMAcs were immersed in the uniformly mixed DA-AgNWs solution. The SEM images of the PDA-AgNWs@SMAc surface after in-situ coating (Fig. 2f, g) reveal that the SMAc surface transitioned from relatively smooth to having a significantly increased surface area. This greatly enhances the surface area of the SMAcs. Although the PDA on the surface of PDA-AgNWs@SMAc significantly enhances the PTC effect and increases the surface area-to-volume ratio, thereby promoting fast photothermal heating and convection, the heat generated by photothermal conversion needs to be quickly transferred to the SMAc to achieve fast heating and cooling. Since silver is renowned for its superior thermal conductivity, far exceeding that of other metals, AgNWs are the ideal medium for enhancing heat dissipation from the SMAc. The nanostructured AgNWs provide an optimal medium for the efficient outward transfer of heat from the SMAc. PDA not only enhances the PTC effect but also acts as an adhesive, tightly bonding SMAc with AgNWs. As shown in Fig. 2h, the EDS results indicate that AgNWs are coated on the surface of SMAc in a PDA-AgNWs mixture. The element weight ratio of Ni is 50.66%, Ti is 40.46% and Ag is 8.88% (Supplementary Fig. 3b). We used the tape test to assess the adhesion of the PDA-AgNWs, as shown in Supplementary Fig. 4, the PDA-AgNWs remained intact on SMA substrates, after the adhesive tape was removed. Supplementary Fig. 5 shows the differential scanning calorimetry (DSC) results for SMAc, revealing that the martensitic start temperature (Ms) is 30 °C, the martensitic finish temperature (Mf) is 14 °C, the austenitic start temperature (As) is 33 °C, and the austenitic finish temperature (Af) is 52 °C. The principle of NIR photothermal actuation for B-SMAc and PDA-AgNWs@SMAc is illustrated in Supplementary Fig. 6. Following long-term durability testing under real-world conditions, the PDA-AgNWs@SMAc maintained excellent actuation performance (Supplementary Fig. 7).

PDA-AgNWs@SMAc artificial muscles for versatile prosthetic hand and soft hand

In the exploration of the moon, robotic hands are essential. To enhance the dexterity of robots, scientists have begun to emulate human hand operations. The human hand is one of the most dexterous tools in nature. SMAc, as artificial muscles, share the same mechanism as skeletal muscles, enabling them to effectively mimic the functions of human muscles.

The schematic diagram of the prosthetic hand and the soft hand is shown in Fig. 3a. The design principle of the prosthetic hand actuation by using PDA-AgNWs@SMAc artificial muscle is shown in Fig. 3b, this work designed a prosthetic hand with independently movable fingers capable of performing various actions (dimensions detailed in Supplementary Fig. 8), using fast-acting PDA-AgNWs@SMAc bundles as artificial muscles and nylon strings as artificial tendons. Each segment of the fingers is connected with Thermoplastic Urethane (TPU), and the 3D-printed hand is assembled with a 3D-printed exoskeletal forearm. One end of the PDA-AgNWs@SMAc bundle is attached to the forearm, while each finger is connected to the other end of the artificial muscle via nylon tendon strings. The structural components of the prosthetic hand are shown in Supplementary Fig. 9. Thus, each finger’s bending angle and frequency can be controlled by adjusting the current magnitude and duty cycle (the experimental control setup is depicted in Supplementary Fig. 10), with the force of the SMAc artificial muscles transmitted through the nylon tendon strings. Similar to the actuation properties previously studied, the contraction and expansion speed of the finger is highly dependent on the actuation speed of the PDA-AgNWs@SMAc artificial muscle. Figure 3c shows the actuation frequency of each finger at full stroke, measured while using either B-SMAc or PDA-AgNWs@SMAc as artificial muscles. As a result, fingers using the cool-accelerated PDA-AgNWs@SMAc had an activation frequency 1.6 times higher than that obtained when B-SMAc was used as a muscle.

a Blueprint of the prosthetic hand and the soft hand. b The design principle of the prosthetic hand and soft hand actuation by using PDA-AgNWs@SMAc artificial muscle. c The actuation frequency at full stroke measured with the prosthetic hand using the B-SMAc and PDA-AgNWs@SMAc with heating and natural cooling. d Images of the prosthetic hand with PDA-AgNWs@SMAc artificial muscles accurately grasping and placing an object. e The soft hand combined with robotic arms accurately grasps the glowing sphere and smooth cylinder.

When mounted on a robotic arm, the prosthetic hand can dexterously grasp a “soft panda” object (Fig. 3d), similar to the capabilities of a human hand. The robotic arm can rotate as flexibly as a human arm, and by controlling the input power of the PDA-AgNWs@SMAc, the prosthetic hand can precisely grasp the “soft panda” object. Each finger applies varying forces, allowing the “soft panda” object to be lifted with precision and without damage and then placed into a basket (details shown in Supplementary Video 1). Moreover, several challenging tasks were developed to test the capabilities of the prosthetic hand, as illustrated in Supplementary Fig. 11. These tasks included human-robot interactions such as single-finger contact with a human hand, as well as the ability to dexterously grasp complex objects of varying sizes, including scissors, bananas, and ping-pong paddles. In addition, we measured the gripping force of the prosthetic hand actuator to be 4.6 N. The gripping force of the system is primarily determined by the SMAc, and the force output of SMAc is influenced by factors such as input current, strain, and outer diameter. We have provided supplementary data on the force generated by a single SMAc under varying currents, strains, and outer diameter, which are included in Supplementary Fig. 12.

To improve the flexibility, this work also designed a soft robotic hand, the detailed schematic illustration of fixtures provided in Supplementary Fig. 13, and the soft finger size shown in Supplementary Fig. 14. The custom-designed control system enables independent actuation of one or multiple soft fingers (Supplementary Fig. 15).

As shown in Supplementary Fig. 16, the designed soft hand can flexibly grasp the “soft panda” object and place it into a basket (Supplementary Video 2 for detailed procedures). Similar to the prosthetic hand mentioned above, the soft hand is combined with a robotic arm. As shown in Fig. 3e, the soft hand can adaptively grasp according to the shape of the object.

PDA-AgNWs@SMAc with photothermal fast actuating response

As shown in Fig. 4a, the SMAc artificial muscle was suspended on a test rig with a 50 g weight hanging below it. The muscle was then irradiated with NIR light as a heat source at the same power density (13.75 mW/mm²). All tests were conducted under natural conditions, ensuring that each sample was tested in the same environment.

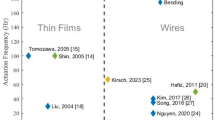

a Schematic diagram of the actuation test rig of SMAc. b The actuation strain at the frequency of 1 Hz. c Average actuation speed of the uncoated and the coated measured under natural cooling. d Variation of axial force over for uncoated and coated at different stretching lengths. e At the power density of 13.75 mW/mm2, the temperature transition of different coated samples from 30 °C heating to 60 °C, and then from 60 °C cooling to 30 °C. f Ashby plot of the ave. Actuation speed versus contractile stroke of the SMA-based actuators25,40,41,42,43.

The experiment tested the actuation strain at four frequencies: 0.1 Hz, 0.2 Hz, 0.5 Hz, and 1 Hz. As shown in Fig. 4b, c and Supplementary Fig. 17, the average actuation speed of the B-SMAc and the PDA-AgNWs@SMAc measured under different frequencies, the maximum average actuation speed of PDA-AgNWs@SMAc is 3.2 times that of the uncoated sample. The coating thickness and cooling performance of SMA with different coating durations (1 h, 2 h, 3 h, and 4 h) are shown in Supplementary Fig. 18a, b. At each frequency, the actuation strain of PDA-AgNWs@SMAc was significantly greater than that of B-SMAc. As shown in Supplementary Video 3, under the same power density (13.75 mW/mm²) of NIR light irradiation, the actuation speed of PDA-AgNWs@SMAc was much faster than that of SMAc.

Supplementary Fig. 19 explores the actuation profiles under different loads and tests the strain cycle at different frequencies under the same load, photograph of the experimental setup for investigating the actuation performances of SMAc as shown in Supplementary Fig. 20. The axial output force generated by SMAc under the same strain but with different power densities of NIR light was explored, and the testing setup is shown in Supplementary Fig. 21. In preliminary experiments, it was found that when the strain of SMAc was below 40%, the axial output force was very small and unstable. Thus, our study started testing SMAc from a strain of 40% and tested the tensile force of SMAc at strains of 40%, 100%, 200%, and 300%, providing an experimental basis for the design of the axial output force of SMAc under a strain of 300%. Figure 4d and Supplementary Fig. 22 illustrate the changes in the tension of SMAc at different strains under the same NIR light power density. However, when the strain of SMAc reaches 300%, the maximum tension decreases instead of increasing, approaching the tension at 200% strain. To verify the reliability of the actuation performance of SMAc, Supplementary Fig. 23 shows that after 100 cycles at frequencies of 0.1 Hz, 0.2 Hz, 0.5 Hz, and 1 Hz of NIR light, the light-driven performance of SMAc remains unchanged. Under a NIR light power density of 13.75 mW/mm2, the tension of PDA-AgNWs@SMAc is 0.77 N at a strain of 40% and increases to 1.72 N at a strain of 200%.

From Fig. 4d and Supplementary Fig. 22, under the NIR optical power density of 13.75 mW/mm², the maximum tensile force is 1.14 and 1.78 times greater than those at 7.13 mW/mm² and 3.64 mW/mm², respectively. Similarly, the actuation response at 13.75 mW/mm² is 1.26 and 1.44 times faster than those at 7.13 mW/mm² and 3.64 mW/mm², respectively. Furthermore, at the same NIR light power density and strain, the maximum tension of PDA-AgNWs@SMAc is greater than that of B-SMAc. Therefore, it can be concluded that the performance changes of PDA-AgNWs@SMAc and B-SMAc in terms of actuation tension, response speed, heating and cooling rates, and strain speed are consistent. Thus, PDA-AgNWs@SMAc can achieve much larger strokes and tensions than B-SMAc at high actuation speeds. When utilizing SMAc as an artificial muscle to drive the movement of a humanoid arm (dimensions detailed in Supplementary Fig. 24), the actuation speed of SMAc coated with PDA-AgNWs was significantly faster than that of B-SMAc (data comparison shown in Supplementary Fig. 25, demonstration video available in Supplementary Video 4).

The NIR light heating and natural cooling performance after in situ coating is shown in Fig. 4e. Meanwhile, the cooling performance at different ambient temperatures (17 °C, 21 °C, 25 °C, and 29 °C) is shown in the Supplementary Fig. 26. The higher the power of near-infrared light, the shorter the heating time. The heat transfer is poor when only PDA is coated, resulting in slower heat transfer to SMAc. After the PDA-AgNWs coating, the synergistic effect of both reduces the heating and cooling times by 33.3% and 38.5%, respectively, compared to B-SMAc. To summarize, the performance metrics of the PDA-AgNWs@SMAc artificial muscle were compared with those in other previous reports, as shown in Fig. 4f. Notably, the PDA-AgNWs@SMAc provided the largest contractile stroke and ave. Actuation speed.

Geometric analysis and FEA of microrobot

Compared to traditional electrically driven robots, NIR light-induced actuation based on SMAc artificial muscles for microrobots37 not only eliminates the constraints of wires but also utilizes NIR light, which is a commonly used light source in medicine that can penetrate human skin and is relatively friendly to the human body. We propose a four-legged micro-crawling robot based on SMAc artificial muscle actuation, with a body length of about 15 mm and a weight of about 1 g. To enable the microrobot to crawl continuously, one SMAc artificial muscle is connected in parallel with two stainless steel springs to form an antagonistic structure.

The crawling process of the microrobot is illustrated in Fig. 5a. The body of the microrobot consists of two parallel steel springs, and the length of the steel springs remains constant throughout the crawling process, denoted as Ls. The two stainless steel springs are positioned at the same horizontal height and above the SMAc artificial muscle, with a height difference of h. The initial and crawling geometric models of the microrobot are shown in Fig. 5b. For ease of calculation, the geometric model of the microrobot in the crawling state is simplified by assuming that the SMAc and steel springs bend and contract into two concentric arcs. The radius and angle of the SMAc arc are denoted as R and δ, respectively. Let D be the displacement of one period of the robot’s forward movement and l be the horizontal distance between the front and rear legs of the microrobot after bending. D was calculated by Eq. (1), and l was calculated by Eq. (2)

a Schematic showing the crawling mode where the front foot and back foot of the microrobot move forward in coordination. b Model definition of the situations when initial, heating, and cooling microrobot. c Three-dimensional of the microrobot. d FEA of the initial state of the microrobot e FEA maximum stride state of the microrobot. f, g Horizontal crawling and climbing process of the microrobot. (Scale bar: 5 mm).

After the SMAc and steel springs bend and contract into two concentric arcs, due to the small length of the SMAc of the microrobot, the length of its arc can be approximated as l. δ was calculated by Eq. (3)

where le is the effective displacement of the SMAc. From Eq. (3), we can obtain:

From Eq. (3) and Eq. (4), we obtain:

Substituting Eq. (2) and Eq. (5) into Eq. (1), we obtain:

Ansys Workbench simulation software was employed in this study to analyze the crawling displacement of the microrobot under the action of force. This was done to study the crawling displacement of the microrobot (Fig. 5c) under the tension of the SMAc artificial muscle. As shown in Fig. 5d, the displacement of the microrobot is 0 mm when no force is applied. When the SMAc artificial muscle contracts due to heating, generating tension, the displacement of the microrobot is determined by the length of its backward steps. As shown in Fig. 5e, when the tension in the SMAc artificial muscle is 1.6 N, the step length of the rear leg is approximately 9.4 mm. The material of the spring in the finite element simulation is steel, while the material of the front and rear legs is resin. The mesh division is shown in Supplementary Fig. 27.

The front and rear legs of the microrobot are fabricated using 3D printing technology, with detailed dimensions shown in Supplementary Fig. 28. As depicted in Fig. 5f, with the NIR light source fixed, the initial relative distance between the NIR light and the microrobot is 10 cm. Furthermore, despite the decreasing power density of the NIR light, the crawling speed of the microrobot actuated by PDA-AgNWs@SMAc artificial muscles remains almost constant, whereas the speed of the microrobot actuated by B-SMAc artificial muscles noticeably slows down. This process can be found in Supplementary Video 5 and Supplementary Video 6. Additionally, the microrobot can crawl continuously on an inclined surface, as shown in Supplementary Video 7.

SMA fibers have a wide temperature range and are suitable for a variety of complex aerospace scenarios. We confirmed that the SMA can still actuate reliably under extreme conditions, including sub-zero temperatures below −30 °C (Supplementary Fig. 29a) and in a vacuum environment (Supplementary Fig. 29b). Additionally, we demonstrated that the microrobot is capable of crawling over rough terrain surfaces, as shown in Supplementary Fig. 29c. We hope that SMAc-based bionic artificial hands and micro-robots can be used in combination. For example, it can be used as a lunar exploration device to help people detect the moon and grasp the target lunar soil.

Discussion

In this paper, we have developed coiled SMA artificial muscles with electrothermal and photothermal dual-responsive shape memory behavior using the interplay between the two coating components, PDA and AgNWs. The synergistic effects of photothermal conversion of PDA and the high heat conductivity of AgNWs significantly enhance the photothermal heating and passive cooling capabilities of SMAc without compromising its inherent advantages, greatly accelerating the actuation speed. As a result, PDA-AgNWs@SMAc showed a significantly improved actuation speed: maximum average actuation speed under NIR (808 nm) light was 3.2 times faster than that of B-SMAc, alongside a 35% enhancement in electrothermal response for a whole heating and cooling cycle. These improvements in the conventional heating process enable high-speed precise manipulation and adaptive shape compliance to irregular objects, critical for tasks such as lunar rock sampling or repairing equipment. Meanwhile, the photothermal wireless actuation method has been successfully integrated into miniature crawling robots, demonstrating its potential for lightweight, autonomous lunar rovers with energy-efficient operation and adaptive terrain capabilities. In addition to addressing the intrinsic limitations of SMAcs, this work bridges material innovation with practical engineering needs, adopting an easily scalable fabrication approach for dual-responsive systems through in-situ polymerization, which provides a foundational framework for intelligent, wirelessly controlled devices in space exploration and beyond.

Methods

Preparation of SMAc artificial muscles

The surface of the SMA fiber (MFWT00350CS11-01, PEIERTECH) is covered with black oxide. The diameter of SMA fiber is 350 μm, and to provide a larger stroke, SMA fiber was processed into a coil shape. The SMAcs were stretched by an antagonistic force; during heating, they contracted, and upon cooling, they returned to their stretched state, achieving continuous actuation through cyclic heating and cooling. Subsequently, the securely fixed samples are placed in a Muffle furnace at a temperature of 380 °C for 30 min. After heating, they are taken out and cooled in cold water to room temperature.

Coating of PDA-AgNWs on SMAc surfaces

To enhance the PTC effect and cooling speed of SMAcs, a DA reaction solution was mixed with AgNWs38 (length to diameter ratios 120), and the SMAcs were immersed in the solution to prepare PDA-AgNWs@SMAcs. Firstly, to clean impurities on the surface of SMAc, place it in a beaker containing anhydrous ethanol and deionized water, then put the beaker into an ultrasonic cleaner for ultrasonic cleaning. Next, dry the ultrasonically cleaned SMAc and place the dried SMAc into a plasma cleaner. Perform plasma treatment on SMAc to enhance hydrophilicity, enabling better contact with the surface for the DA-AgNWs aqueous solution, thereby improving the long-term stability and reliability of PDA-AgNWs coating on SMAc. DA-HCl, NaIO4, and sodium acetate buffer were used to prepare the dopamine reaction solution. Mix AgNWs with the DA reaction solution, and place SMAc in the uniformly mixed DA-AgNWs reaction solution. Continuously stir using a magnetic stirrer (rotation speed 300 rpm) to prepare PDA-AgNWs@SMAc. From the heating speed, cooling speed, and actuating speed, the improvement of photothermal conversion efficiency and the acceleration of the cooling speed of PDA-AgNWs can be directly judged.

Adhesive test

The tape test39 was used to assess the adhesion of the The PDA-AgNWs. The PDA-AgNWs@SMA films were cross-hatched with 1 × 1 mm squares over a 1 cm2 surface area with a razor blade. The 3 M 600 Scotch cellophane film tape was then firmly applied to the scribed surface and rapidly removed. Observed through the super-depth-of-field microscope (Leica DVM6), the adhesion was judged by the number of shedding after the adhesive tape was removed.

Fabrication of the humanoid arm model

The structure of the human arm was simplified, and 3D modeling was performed using Unigraphics NX. To ensure a perfect fit of the SMAc with the humanoid arm model, corresponding holes were reserved in the model. The humanoid arm model was then 3D printed (Formlabs Form3+) and assembled into the final arm model. The fibrous ends of the SMAc were placed in the reserved holes, and the holes were filled with resin. The resin was then cured under ultraviolet light, embedding the SMAc perfectly into the humanoid arm model.

Fabrication of the microrobot model

3D modeling was performed using Unigraphics NX. The microrobot features a quadrupedal structure, with bent legs designed for better ground grip and forward locomotion. Two cylindrical protrusions are placed above both the front and rear legs, with two stainless steel springs connecting through these protrusions. Additionally, holes were reserved in the legs to allow for the embedding of the SMAc within the leg structure. After the legs were 3D printed, the fibrous part of the SMAc was inserted into the reserved holes, and the holes were then filled with resin. Similarly, ultraviolet light was used to cure the resin, which solidified upon exposure, thus binding the SMAc with the 3D-printed legs. The stainless steel springs serve as the main body of the microrobot’s torso, and there is a height difference between the SMAc and the springs.

Mechanical testing method for SMAc

Supplementary Fig. 21 illustrates the constant-length heating mechanical testing setup for SMAc, with both ends of the SMAc fixed by the end fixture and the mechanical sensor fixture, respectively. In previous studies, we found that when the fixed length strain was set below 40%, the axial output force was minimal and unstable. Therefore, in the mechanical testing of SMAc, the fixed length should be set at 40% or higher. Consequently, the fixed lengths of SMAc were set starting from a strain of 40%, with subsequent settings at 40%, 100%, 200%, and 300%. Near-infrared light was used to irradiate and heat the SMAc; each test was repeated three times, and the test data were processed by a computer.

Finite element analysis of the microrobot

The actuation crawl displacement of the microrobot was calculated using finite element analysis, with the calculations performed in ANSYS 2020 R2. The microrobot model was scaled at a 1:1 ratio, with a mesh size of 0.2 mm. The material for the stainless steel springs was set to 304 stainless steel, while the leg material was set to resin. The contact between the stainless steel springs and the legs was modeled with a bonded constraint. The bottom position of the front legs was fixed, and equivalent forces were applied to the microrobot based on the magnitude and position of the actual forces. The motion state and displacement of the microrobot were computed under the influence of SMAc forces.

Characterization methods

The surface and cross-sectional morphology of the SMAc were observed using a scanning electron microscope (ZEISS Gemini SEM 560), and EDS spectra of the SMAc were also captured. To obtain parameters such as Ms, Mf, As, and Af for the SMA fiber, DSC measurements were conducted using a TA Instruments Q2500, with a heating/cooling rate of 10 °C/min under nitrogen purging. To obtain better adhesion between SMAc and PDA-AgNWs, SMAc was treated with oxygen plasma (Harrick Plasma PDC-002) for 5 min at an oxygen pressure of 5 mbar and power of 30 W. The temperature changes of the SMAc under near-infrared stimulation were recorded using an infrared thermal camera (FLIR E96). Images and videos of the SMAc were captured using a digital camera (NIKON Z5).

Data availability

Data is provided within the manuscript or supplementary information files.

References

Ding, T. et al. A flexible self-perceiving/repairing parachute (FSPRP) system adapted to the Martian dust storm environment. Nano Energy 99, 107358 (2022).

Qiu, Y. et al. A tactile perception method with flexible grating structural color. Natl. Sci. Rev. 12, nwae413 (2024).

Sankar, S. et al. A natural biomimetic prosthetic hand with neuromorphic tactile sensing for precise and compliant grasping. Sci. Adv. 11, eadr9300 (2025).

Yang, H. et al. A lightweight prosthetic hand with 19-DOF dexterity and human-level functions. Nat. Commun. 16, 955 (2025).

Zhakypov, Z. et al. Designing minimal and scalable insect-inspired multi-locomotion millirobots. Nature 571, 381–386 (2019).

Kakei, Y. et al. Integration of body-mounted ultrasoft organic solar cell on cyborg insects with intact mobility. npj Flex. Electron. 6, 78 (2022).

Chen, Y. et al. Controlled flight of a microrobot powered by soft artificial muscles. Nature 575, 324–329 (2019).

Ikejiri, S., Takashima, Y., Osaki, M., Yamaguchi, H. & Harada, A. Solvent-free photoresponsive artificial muscles rapidly driven by molecular machines. J. Am. Chem. Soc. 140, 17308–17315 (2018).

Qin, H. et al. Anisotropic and self-healing hydrogels with multi-responsive actuating capability. Nat. Commun. 10, 2202 (2019).

He, J. et al. High-temperature-tolerant artificial muscles using poly (p-phenylene benzobisoxazole) composite yarns. Adv. Fiber Mater. 4, 1256–1266 (2022).

Kotal, M. et al. Metal-organic framework-derived graphitic nanoribbons anchored on graphene for electroionic artificial muscles. Adv. Funct. Mater. 30, 1910326 (2020).

Xu, L. et al. Artificial muscle with reversible and controllable deformation based on stiffness-variable carbon nanotube spring-like nanocomposite yarn. Nanoscale 11, 8124–8132 (2019).

Wang, D. et al. Dexterous electrical-driven soft robots with reconfigurable chiral-lattice foot design. Nat. Commun. 14, 5067 (2023).

He, Q. et al. Electrospun liquid crystal elastomer microfiber actuator. Sci. Robot. 6, eabi9704 (2021).

Kim, D. S. & Lee, Y. J. Autonomous, untethered gait-like synchronization of lobed loops made from liquid crystal elastomer fibers via spontaneous snap-through. Sci. Adv. 9, eadh5107 (2023).

Sun, J. et al. Additive manufacturing of liquid crystal elastomer actuators based on knitting technology. Adv. Mater. 35, 2302706 (2023).

Chen, W. et al. Knotted artificial muscles for bio-mimetic actuation under deepwater. Adv. Mater. 36, 2400763 (2024).

Gómez-Cortés, J. F. et al. Size effect and scaling power-law for superelasticity in shape-memory alloys at the nanoscale. Nat. Nanotechnol. 12, 790–796 (2017).

Huang, X. et al. Crystal structures and shape-memory behaviour of NiTi. Nat. Mater. 2, 307–311 (2003).

Arab Hassani, F. et al. Soft sensors for a sensing-actuation system with high bladder voiding efficiency. Sci. Adv. 6, eaba0412 (2020).

Sui, M. et al. A soft-packaged and portable rehabilitation glove capable of closed-loop fine motor skills. Nat. Mach. Intell. 5, 1149–1160 (2023).

Li, Y. et al. Multi-degree-of-freedom robots powered and controlled by microwaves. Adv. Sci. 9, 2203305 (2022).

Kim, M. et al. Shape memory alloy (SMA) actuators: The role of material, form, and scaling effects. Adv. Mater. 35, 2208517 (2023).

Qiu, J. et al. A Gecko-inspired robot with a flexible spine driven by shape memory alloy springs. Soft Robot. 10, 713–723 (2023).

Nam, S. et al. Active tissue adhesive activates mechanosensors and prevents muscle atrophy. Nat. Mater. 22, 249–259 (2023).

Craighero, M. et al. Poly (benzodifurandione) coated silk yarn for thermoelectric textiles. Adv. Sci. 11, 2406770 (2024).

Liang, X. et al. Stable and biocompatible carbon nanotube ink mediated by silk protein for printed electronics. Adv. Mater. 32, 2000165 (2020).

Cai, B. & Li, X. Multimode opto-magnetic dual-responsive actuating fibers and fabrics programmed via direct ink writing. Chem. Commun. 59, 14419–14422 (2023).

Mu, J. et al. Origami-inspired active graphene-based paper for programmable instant self-folding walking devices. Sci. Adv. 1, e1500533 (2015).

Zheng, R. et al. Polydopamine-coated magnetic composite particles with an enhanced photothermal effect. ACS Appl. Mater. Interfaces 7, 15876–15884 (2015).

Zhao, H. et al. A synergistic DNA-polydopamine-MnO2 nanocomplex for near-infrared-light-powered DNAzyme-mediated gene therapy. Nano Lett. 21, 5377–5385 (2021).

Aguilar-Ferrer, D. et al. Understanding the photothermal and photocatalytic mechanism of polydopamine coated gold nanorods. Adv. Funct. Mater. 33, 2304208 (2023).

Liu, L. et al. Stable and low-resistance polydopamine methacrylamide-polyacrylamide hydrogel for brain-computer interface. Sci. China Mater. 65, 2298–2308 (2022).

Hemmatpour, H. et al. New insights in polydopamine formation via surface adsorption. Nat. Commun. 14, 664 (2023).

Han, Y. et al. Multifunctional thermally conductive composite films based on fungal tree-like heterostructured silver nanowires@boron nitride nanosheets and aramid nanofibers. Angew. Chem. Int. Ed. 62, e202216093 (2023).

Zhao, Y. et al. Electrical and thermal transport through silver nanowires and their contacts: effects of elastic stiffening. Nano Lett. 20, 7389–7396 (2020).

Yang, X. et al. An 88-milligram insect-scale autonomous crawling robot driven by a catalytic artificial muscle. Sci. Robot. 5, eaba0015 (2020).

Yao, M. et al. Room temperature high-efficiency welding of an ultra-long silver nanowire network for flexible transparent electrodes. Chem. Commun. 60, 8884–8887 (2024).

Peng, Z. et al. All-organic superhydrophobic coatings with mechanochemical robustness and liquid impalement resistance. Nat. Mater. 17, 355–360 (2018).

Oh, S. et al. Cooling-accelerated nanowire-nitinol hybrid muscle for versatile prosthetic hand and biomimetic retractable claw. Adv. Funct. Mater. 32, 2111145 (2022).

Wu, G. et al. Electro-thermal responses polymer systems with continuous shape memory alloys: merging rapid shape memory and color transitions. Chem. Eng. J. 503, 158264 (2025).

Perez-Zúñiga, M. G. et al. Enhanced photomechanical response of a Ni-Ti shape memory alloy coated with polymer-based photothermal composites. Smart Mater. Struct. 26, 105012 (2017).

Ma, K. et al. Synergizing structural stiffness regulation with compliance contact stiffness: bioinspired soft stimuli-responsive materials design for soft machines. Adv. Eng. Mater. 26, 2400461 (2024).

Acknowledgements

This research was supported by the National Key R&D Program of China (2023YFC3603500, 2024YFF0508600), the Fundamental Research Funds for the Central Universities (2232025A-06, 2232024Y-01, 2232025D-06, DHU Distinguished Young Professor Program (LZB2025002)), the Key R&D Program of Shandong Province, China (2024CXGC010411), the Taishan Industrial Experts Programme Special Funding (NO.tscx202408117), the Pujiang Project of the Shanghai Magnolia Talent Program (No. 24PJD001), Young Elite Scientist Sponsorship Program by CAST (YESS) (NO. YESS20240225). Appreciation to npj Flexible Electronics for the invitation to contribute to the Fibers, Yarns, and Textile-based Electronics Collection.

Author information

Authors and Affiliations

Contributions

X.L. and B.C. are the co-first authors. X.L. and B.C conceived and designed the research. X.L., B.C, H.Z., R.J., and X.W. performed the experiment. X.L., R.X., Y.Z. Q.W. analyzed the data. X.L., M.Z., H.S., and G.W. wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, X., Cai, B., Zhao, H. et al. Scalable functionalized shape memory alloy fiber with synergistic effect for robotic hand and microrobot. npj Flex Electron 9, 88 (2025). https://doi.org/10.1038/s41528-025-00455-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-025-00455-y

This article is cited by

-

Selecting the state of shape memory alloys by optical filtering

Optical and Quantum Electronics (2025)