Abstract

The traditional approaches for improving corrosion resistance of alloys typically lead to the sacrifice of mechanical properties because the microstructures needed for improving corrosion resistance often contradict those for high strength. Here we demonstrate that selected laser melting (SLM), a net-shape additive manufacture technique, can maintain good mechanical properties while double the corrosion-resistance of a N-doped CoCrFeNi HEA. The SLM processed sample possesses a heterogeneous microstructure with 3D dislocation cells inside each grain. The SLM-induced 3D dislocation cell structure can provide effective diffusion paths to significantly promote Cr outward segregation, forming a thick protective Cr oxide layer, which renders excellent corrosion resistance. Furthermore, Cr segregation along cell boundaries provides numerous sites for nucleation of oxides, and stabilizes the cell structure for good mechanical properties. The strategy discovered here may also be applied to other HEAs with multiple strengthening mechanisms.

Similar content being viewed by others

Introduction

Marine machinery and engine components reply deeply on steels or Ni-based materials with high strength and excellent corrosion resistance due to their humid and electrolytic service environment. However, the designing strategies to improve both strength and corrosion resistance are very challenging. It is well known that high alloy strength and good corrosion resistance often cannot be obtained at the same time. Single-phase alloys usually have low strength. Engineering second phase(s) and/or precipitates has been proven an effective approach to increase strength significantly. However, galvanic corrosion would occur between the matrix and other phases due to their electrode potential difference. It is well known that secondary thermomechanical treatments could increase the strengths appreciably. However, the accumulated grain boundaries with long-range distribution intrinsically could cause intergranular corrosion.

The conventional microstructure engineering via ingot casting and thermomechanical processing could hardly overcome this dilemma. Recently, hierarchically heterogeneous microstructures induced in the selective laser melted (SLM) austenitic steels present a new pathway to improve strength, work hardening, and ductility. The resulting microstructure in SLM-processed alloys, mostly composed of submicron dislocation walls, may have the potential to improve corrosion resistance. Moreover, high entropy alloys (HEAs) were proposed from a metallurgical design concept, in which the multi-principal-element system may maintain single-phase state by its high entropy. At the same time, the enrichment of anti-corrosion elements (such as Cr) may provide good corrosion resistance. Previous studies have reported the corrosion behavior of FeCoCrNi-based HEAs fabricated by melting, rolling, laser cladding, selective laser melting, and directed energy deposition1,2,3,4. The better corrosion resistance the SLM-processed CoCrFeMnNi HEA in a 3.5 wt% NaCl solution was attributed to the homogeneity of its components and grain refinement3.

In this work, we demonstrate SLM processing can produce a single-phased HEA samples with not only exceptional strength-ductility combinations, but also excellent corrosion resistance in acidic environments. Particularly, the SLM-produced sample is more than twice corrosion resistant than the sample made by hot isostatic pressing (HIP) with the same composition, as measured by their corrosion current density.

Results

Microstructures and tensile properties of the CoCrFeNiN0.07 HEA

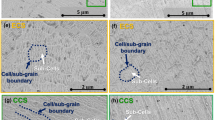

We fabricated the N-doped equiatomic CoCrFeNiN0.07 HEA with typical cell microstructures by SLM to study its corrosion behavior. The chemical composition of the SLMed HEA is shown in Supplementary Table 1. For comparison, N-doped equiatomic CoCrFeNiN0.07 HEAs with different types of microstructures were also fabricated by HIP and HIP + CR. Figure 1 shows these three kinds of typical microstructures and elemental distribution in the CoCrFeNiN0.07 samples. The HIP-processed sample has a random crystallographic texture with an average grain size of around 32 μm with extensive annealing-twins, as shown in Fig. 1c. Figure 1f shows the cold rolled microstructure with a (101) crystal preferred orientation. The microstructure of SLM-processed sample is significantly different. From the cross-section vertical to the build direction, a heterogeneous layer structure with alternative fine-grains and coarse-grains exist. The widths of fine-grained and coarse-grained layers are about 30 μm and 70 μm, respectively (shown in Fig. 1i). The average grain size of fine-grain layers is about 18 μm, and that of coarse-grain layer is about 52 μm. Most of grains in fine-grain layers are equiaxed, but those in coarse-grain layers are columnar. Taking along the build direction, it can be seen that grains grow epitaxially. Figure 1l displays solidification cell structures that are commonly observed in the 3D printed samples. As shown, high density of dislocations are entangled together to form the cell structure. The microscopic compressive stress caused by the periodic heating and cooling with high rates is one of the origins of dislocation generation and movement5,6,7. The X-ray diffraction (XRD) and the inserted selected area diffraction (SAD) patterns inserted in Fig. 1 confirm a single FCC phase structure in all of three samples. Atomic probe tomography, as displayed in Fig. 1m, shows the nanoscale uniform elemental distributions, with no apparent local chemical ordering, indicating the sample is in a FCC solid solution state.

a Morphology of HEA raw powder. b A schematic of three different kinds of processing routes. c, f Electron backscatter diffraction (EBSD) inverse-pole maps of HIP and CR. i, j EBSD inverse-pole maps of SLM from cross-section vertical and parallel to the build direction. d, g, l A bright-field transmission electron microscopy (TEM) image and the corresponding selected area electron diffraction (SAED) patterns of HIP, CR, and SLM samples. e, h, k X-ray diffraction patterns of HIP, CR, and SLM samples. m Three-dimensional (3D) reconstructions of a typical atom probe tomography (APT) tip showing atomic maps of Fe, Co, Cr, Ni, and N in the SLM sample.

The room temperature tensile properties of all three samples are presented in Supplementary Fig. 1. As a solid-state diffusion-assisted process, HIP mainly achieves densification of metallic powders by high isostatic pressures combined with high temperatures8. HIP processing at a high temperature of 1523 K for 2 h produced samples with chemical homogeneity and uniform grain structures, which demosntrates a low yeild strength and high tensile elongation. When the HIP-sample was deformed by cold rolling (CR), hereafter referred to as the CR sample, high lattice distortion, propagation of high-density dislocation and grain refinement occurred. The CR sample achieved a much higher yield strength but sacrifice tensile plasticity down to about 6%. Importantly, the hierarchically heterogeneous structures were observed in the SLM sample, leading to the good strength-ductility combination9.

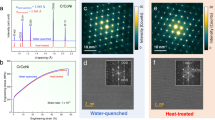

Corrosion behavior in dilute sulphuric acid

The corrosion resistance was comparatively evaluated for all three types of samples by potentiodynamic polarization (PDP) curves in 0.5 M H2SO4 solution. In Fig. 2a, the three HEAs all exhibit typical passive behavior with a wide passive region. While most of the relevant electrochemical parameters displayed in Supplementary Table 2 are nearly identical, it is worth mentioning that the SLM sample exhibited a much lower passive current density (ip, 6.1 A cm−2) than that of HIP (13.8 A cm−2) and CR (19.6 A cm−2). Due to the value of ip can approximately reflect the dissolution rate of passive film10,11,12, the lowest value of ip denotes the passive film formed on the SLM sample can inhibit the dissolution more effectively than the passive films formed on HIP and CR. If the inverse of the corrosion current (1/ip) is used as a measure of corrosion resistance, the SLM sample is more than two times corrosion resistant than the HIP sample, and more than three times corrosion resistant than the CR sample, demonstrating the advantage of the SLM process.

To further analyze the corrosion behavior of the CoCrFeNi-N HPEAs, EIS measurements were performed at OCP. As indicated by Nyquist plots, as shown in Fig. 2b, the SLM sample has the largest diameter of the capacitive semicircle. The lager the diameter of the semicircle indicates the less susceptible to corrosion of the passive films and better corrosion resistance13,14. In Fig. 2c, the Bode plots patterns of all the CoCrFeNiN0.07 samples display maximum and relatively constant phase angles (about −80°) over the intermediate range of frequencies. That means stable passive films can form on the surface of all three samples, which is strongly related to the chemical composition of samples15. While the polarization resistances of the alloys are distinguished. Generally, the decrease of the phase angle at lower frequency region (between 0.01 Hz and 1 Hz) reflects the dissolution behavior of the passive film16. SLM has the highest value of |Z| at 0.1 Hz representing the best polarization resistance. Figure 2d shows the equivalent electron circuit used for fitting the EIS results, and it contains two constant phase elements (CPE) to represent the non-ideal capacitance behavior of the system. In this circuit, Rs is the solution resistance, Qf is the CPE representing the passive film capacitance, Rf represents the resistance of passive film and Rct represents the charge transfer resistance between the HEA and passive film, Qdl is the CPE representing the double layer capacitance. The related fitting parameters are presented in Supplementary Table 3. The SLM sample showed relatively higher Rf and Rc values compared with those of HIP and CR samples, suggesting the protective ability of the passive film formed on the SLM sample is stronger.

Passive film analysis

To reveal the mechanisms behind the significant improved corrosion resistance of the SLM sample compared to other samples, comprehensive research on passive films was conducted. Figure 3a shows the cross-section at passive films areas of CoCrFeNiN0.07 HEAs and the middle layer displays the passive films. It is worthy to note that the thickness of passive films in SLM (9.37 nm) is near two times as large as that of the HIP sample (5.65 nm) and CR (5.24 nm). Figure 3b shows the Mott-Schottky plots of the passive films formed on the HEAs. The Mott-Schottky plots exhibit p-n heterojunction: one with a positive slope, indicating n-type semiconductor behavior and the other with a negative slope, reflecting p-type semiconductor behavior. The similar phenomena were also observed in Fe-Cr alloys, Ni-based alloys, and CoCrFeMnNi HEA13,17,18. Figure 3d shows the values of ND and NA obtained from the M-S plots of samples. Notably, the donor and acceptor densities for the passive film on the SLM sample are about one-half of the densities for the passive film on the CR sample. As such, the rather low number of point defects indicates that the oxide film formed on the SLM sample is more compact and less defective which can retard the corrosion rate by inhibit the electron transfer during electrochemical reactions. Yoon et al.19 suggested that the corrosion resistance of the passive film decreased with the increasing of point defect densities.

We carried out a series of XPS experiments to characterize the chemical composition of the passive films which may have great impacts on the corrosion behavior and semiconducting properties20. The high-resolution XPS spectra of the Cr 2p3/2, Fe 2p3/2, Co 2p3/2, Ni 2p3/2, O1s, and N1s recorded from the outmost surface of the three HEAs are shown in Supplementary Figs. 2–4. For the fitted spectra of N1s, NH3 (398.8 eV), and NH4+ (400.3 eV) were detected in three samples but Cr2N (397.6 eV) only appeared in the CR. It is generally accepted that the N element can promote the formation of passivation film with low defect concentration by entering the passivation film and changing the zero-charge pH of the passivation film. Also, the formation of NH3 and NH4+ could consume protons and prevent local acidification, thus improve the corrosion resistance. However, the existence of Cr2N can induce Cr-depleted regions in the matrix, which is detrimental to corrosion resistance21,22. The relative fraction (Cx) of each species in a passive film can be calculated and are shown in Fig. 3c. Evidently, all the passive films are rich in Cr, and the content of Cr in the passive films (~60 at.%) are significantly higher than that in the HEAs matrixes (~25 at.%). Therefore, it indicates that Cr is the key component in the passive films and has a decisive effect on the corrosion resistance23. Since Cr2O3 is more stable and compact than Cr(OH)324, it is desirable for a passive film to contain more Cr2O3 to enhance its corrosion resistance. The fractions of Cr2O3 in the passive film of the SLM sample is about 40%, which is obviously higher than that of the HIP (30%) and CR (25%) samples, contributing to the better corrosion resistance of the SLM sample.

Discussion

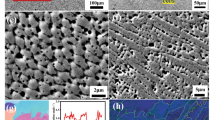

The high corrosion resistance of the SLM sample can be summarized as two aspects, the ability of rapid passivation and the apparently low passive current. Both of them can be attributed to the high nucleation and growth rate of the passive film. Considering the view of crystallographic defects, the passive film would preferentially nucleate and grow at active sites including dislocations, grain boundaries, or triple points25,26. Cell structures as a kind of distinctive microstructure are commonly observed in 3D printed alloys. The cell structures in SLM are shown in the edge-on and end-on orientation in Fig. 4a, and the dislocation cell structures are elongated and parallel with an average size of about 500 nm. There is entanglement of high-density of dislocations around the cell structure boundaries, which provide numerous sites for nucleation of oxides. On the other hand, Fig. 4b presents the elemental distribution vertical to dislocation cell structure from edge-on orientation. The EDS line scan result reveals the nanoscale segregation of Cr along the dislocation cell boundary and there are ~3 at.% greater Cr contents at the dislocation cell boundaries than the cell interiors. The STEM image in Fig. 4c and the associated EDS elemental mapping from end-on orientation also show the enrichment of Cr contents at the cell boundaries. Conventionally, the chemical segregation in the macro-scale will hurt the corrosion resistance for the occurrence of galvanic corrosion. But the localized segregation of Cr in nanoscale can lead to the micro-galvanic coupling effect between dislocation cell boundaries and cell interiors, thus accelerating the rapid formation of the passive film inside the cells27,28.

Different from the nucleation period, growth of passive film mainly depends on both clustering and diffusion of the anti-corrosion elements, such as Cr29,30. The formation of passive film on the CoCrFeMnNi HEA has been reported to be governed by defects for effective ion transport31. It was shown that the growth of oxides is dominated by the outward cation diffusion through the passive film, while the slower inward anion diffusion may also contribute to the minor growth of oxides in the inner layer of the passive film. The cell structures, as a type of 3D microscale defects built by arrays of high-density dislocations, would always prompt an effective diffusion of mass32.

The high-density of dislocations could enhance ion diffusion from the surface into the bulk. As illustrated by the curves shown in Fig. 2a, the current density of SLM sample dropped very quickly to a low value during the active to passive transition, and this feature indicates that the passive film grew rapidly. The cell boundaries in the SLM sample can act as 3D fast diffusion networks and enhance the diffusion rate of cations substantially33,34, as compared to HIP and CR sample without such microstructures. Obvious evidence can also be found in XPS results, showing that the passive film in SLM possesses a higher Cr2O3/Cr(OH)3 ratio by facilitating the oxidation of Cr into Cr2O3 rather than Cr(OH)3. It is the cations with faster outward diffusion, especially the segregated Cr at the dislocation cell boundaries, which would reinforce the spontaneous passivation and promote the formation of a protective sound passive film. Different corroded surfaces after PDP tests for the SLM, HIP, and CR samples are shown in Supplementary Figs. 5 and 6. Both the HIP and CR samples show seriously corroded grain boundaries, indicating they underwent severe intergranular corrosion. On the surface of the SLM sample, there are corroded cell structure boundaries on different orientations with no obvious corroded grain boundaries, in sharp contrast to those found in the HIP and CR sample. It is also suggested that, in an environment encouraging passivity like 0.5 M H2SO4 solution, the widespread formation of cell structures can act as grain boundaries for rapid diffusion path, while preventing from intergranular corrosion because of the submicron structure size and small chemical potential difference between interiors and boundaries. As a result, the improvement of corrosion resistance is achieved.

In summary, the 3D printing by selected laser melting (SLM) produced a HEA that can avoid the trade-off between the strength and corrosion resistance, which has been a long-lasting dilemma. This superior combination of two mutually exclusive properties is attributed to the fine dislocation cell structure that was uniquely produced by the SLM 3D printing. This strategy may also be applicable to single-phase HEAs containing anti-corrosion elements to resist acid attack and satisfy mechanical strengthening.

Methods

Materials processing

The pre-alloyed CoCrFeNiN0.07 powders were produced by gas atomization under a nitrogen atmosphere, during which nitrogen doping was achieved. The powders were spherical and had a size ranging from 2 to 100 μm with a mean powders size of 18 μm. The N-doped equiatomic CoCrFeNi HEAs were produced by selective laser melting (SLM), hot isostatic pressing (HIP), and HIP followed by cold rolling (CR). For the SLM process, an FS271M SLM machine (Farsoon, China) was applied. The laser powder was 400 W and the scanning speed was 1200 mm s−1. The beam size is about 120 μm, the scanning distance is about 100 μm and the layer thickness is around 30 μm. To prevent oxidation and stabilize the chemical composition, nitrogen atmosphere was used during the whole SLM process. To release concentration of stress, the laser was rotated 67° when a layer had been printed and the resulting printed sample was annealed at 673 K for 3 h followed by water quenching. For the hot isostatic pressing process, the alloyed powders were filled into a stainless steel can, which had a dimension of Φ 75 mm × 200 mm. The steel can filled with powders was degassed at 673 K for 10 h followed by isostatic pressing to be consolidated at 1523 K, 140 MPa for 2 h. Then the compacted billet was treated by furnace cooling. For the cold rolling (CR) process, sheet samples were first cut from the HIPed billet. The thickness of sheet samples was reduced from 10 mm to 2 mm (80% CR) by cold deformation with multiple passes. The densities of three samples were measured using Archimedes Drainage Method. Those of SLM, HIP, and CR are 8.098 ± 0.031, 8.113 ± 0.087, and 8.116 ± 0.040 g cm−3, respectively. The highest difference above the three densities is about 0.018 g cm−3, which can be ignored.

Microstructure characterization

The phase structures of SLM, HIP, and CR samples were identified by X-ray diffractometer (XRD, Rigaku Smartlab) with a Cu Kα radiation at the 2θ range of 20–100°. The surface corrosion morphologies were characterized by field-emission scanning electron microscope (SEM, FEI Quanta TM 450 FEG). The microstructures with more details, such as the fraction of different types of grain boundaries, were characterized by using SEM equipped with an electron backscatter diffraction (EBSD) analyzer. Cross-sectional specimens of the passivation films growing on the HEA surface were prepared using a dual beam focused ion beam (FIB, FEI Scios instrument). Needle-shaped specimens required for APT were also prepared by lift-outs and annular milled in a FEI Scios FIB. The APT was characterized in a local electrode atom probe (CAMEACA LEAP 5000 XR). The specimens were analyzed at 70 K in voltage mode and an evaporation detection rate of 0.2% atom per pulse. The microstructures were deeply characterized by bright-field image, dark-field image, and selected area electron diffraction (SAED) pattern using a transmission electron microscopy (TEM, JEOL 2100F, and FEI Talos F200X, operated at 200 kV). For Compositional analysis of passive films, the HEA specimens were passivated for 3 h in 0.5 M H2SO4 solution at a potential of 0.7 V (within the passive region). The chemical compositions of passive films were investigated by X-ray photoelectron spectroscopy (XPS, PHI Model 5802) with a monochromatized Al Kα radiation energy of 1486.6 eV. All XPS peaks were calibrated with the reference of standard carbon C 1s binding energy (284.8 eV), and the background was subtracted using the non-linear, iterative Shirley method.

Electrochemical testing

The electrochemical tests were carried out in 0.5 M H2SO4 at room temperature on an electrochemical workstation (CHI 670E). The HEA specimens were mounted in epoxy with an exposure area of 1.0 cm2 as a working electrode, then ground with SiC papers up to 2000 grit, and finally polished with a diamond powder. A typical three-electrode cell was used, consisting of the HEA specimens as the working electrode, a platinum plate as a counter electrode, and an Ag/AgCl electrode as a reference electrode. The open circuit potential (OCP) was recorded for 2 h to attain a steady value by immersing the working electrode in 0.5 M H2SO4 solution. Subsequently, the electrochemical impedance spectroscopy (EIS) measurements were performed at the OCP in the frequency range from 100 kHz to 10 mHz, with an alternating current amplitude of 10 mV. The potentiodynamic polarization (PDP) tests were performed from an initial potential of −0.4 V till the final potential of 1.5 V at a scan rate of 0.5 mV s−1. To investigate the semiconductive property of the passive film, Mott-Schottky (M-S) tests were conducted over the potential range from −0.3 to 0.9 V (vs. Ag/AgCl electrode) at a frequency of 1 kHz with an AC voltage signal of 5 mV, and the scan rate was 10 mV step. All the electrochemical tests were performed at least three times to ensure data reliability.

Data availability

The authors declare that the main data supporting the findings of this study are available within the article and its Supplementary Information files. Extra data are available from the corresponding author upon reasonable request.

References

Tian, Y., Lu, C., Shen, Y. & Feng, X. Microstructure and corrosion property of CrMnFeCoNi high entropy alloy coating on Q235 substrate via mechanical alloying method. Surf. Interfaces 15, 135–140 (2019).

Ye, Q. et al. Microstructure and corrosion properties of CrMnFeCoNi high entropy alloy coating. Appl. Surf. Sci. 396, 1420–1426 (2017).

Xu, Z. et al. Corrosion resistance enhancement of CoCrFeMnNi high-entropy alloy fabricated by additive manufacturing. Corros. Sci. 177, 108954 (2020).

Melia, M. A. et al. Mechanical and corrosion properties of additively manufactured CoCrFeMnNi high entropy alloy. Addit. Manuf. 29, 100833 (2019).

Wang, G. et al. The origin of high-density dislocations in additively manufactured metals. Mater. Res. Lett. 8, 283–290 (2020).

Murr, L. E. et al. Microstructures and mechanical properties of electron beam-rapid manufactured Ti–6Al–4V biomedical prototypes compared to wrought Ti–6Al–4V. Mater. Charact. 60, 96–105 (2009).

Bertsch, K. M., Meric de Bellefon, G., Kuehl, B. & Thoma, D. J. Origin of dislocation structures in an additively manufactured austenitic stainless steel 316L. Acta Mater. 199, 19–33 (2020).

Atkinson, H. & Davies, S. Fundamental aspects of hot isostatic pressing: an overview. Metall. Mater. Trans. A. 31, 2981–3000 (2000).

Song, M. et al. Nitrogen induced heterogeneous structures overcome strength-ductility trade-off in an additively manufactured high-entropy alloy. Appl. Mater. Today 18, 100498 (2020).

Luo, H., Su, H., Ying, G., Dong, C. & Li, X. Effect of cold deformation on the electrochemical behaviour of 304L stainless steel in contaminated sulfuric acid environment. Appl. Surf. Sci. 425, 628–638 (2017).

Heine, B. & Kirchheim, R. Dissolution rates of iron and chromium and Fe-Cr alloys in the passive state. Corros. Sci. 31, 533–538 (1990).

Yue, X. et al. Revealing the superior corrosion protection of the passive film on selective laser melted 316L SS in a phosphate-buffered saline solution. Appl. Surf. Sci. 529, 147170 (2020).

Luo, H. et al. Influence of carbon on the corrosion behaviour of interstitial equiatomic CoCrFeMnNi high-entropy alloys in a chlorinated concrete solution. Corros. Sci. 163, 108287 (2020).

Cao, C.-N. On the impedance plane displays for irreversible electrode reactions based on the stability conditions of the steady-state—I. One state variable besides electrode potential. Electrochim. Acta 35, 831–836 (1990).

Wei, L., Liu, Y., Li, Q. & Cheng, Y. F. Effect of roughness on general corrosion and pitting of (FeCoCrNi)0.89(WC)0.11 high-entropy alloy composite in 3.5 wt.% NaCl solution. Corros. Sci. 146, 44–57 (2019).

Tao, H. et al. Anomalous evolution of corrosion behaviour of warm-rolled type 304 austenitic stainless steel. Corros. Sci. 154, 268–276 (2019).

Ningshen, S., Kamachi Mudali, U., Mittal, V. K. & Khatak, H. S. Semiconducting and passive film properties of nitrogen-containing type 316LN stainless steels. Corros. Sci. 49, 481–496 (2007).

Huang, J., Wu, X. & Han, E.-H. Influence of pH on electrochemical properties of passive films formed on Alloy 690 in high temperature aqueous environments. Corros. Sci. 51, 2976–2982 (2009).

Lee, J.-B. & Yoon, S.-I. Effect of nitrogen alloying on the semiconducting properties of passive films and metastable pitting susceptibility of 316L and 316LN stainless steels. Mater. Chem. Phys. 122, 194–199 (2010).

Luo, H., Gao, S., Dong, C. & Li, X. Characterization of electrochemical and passive behaviour of Alloy 59 in acid solution. Electrochim. Acta 135, 412–419 (2014).

Feng, H. et al. Effect of nitrogen on corrosion behaviour of a novel high nitrogen medium-entropy alloy CrCoNiN manufactured by pressurized metallurgy. J. Mater. Sci. Technol. 34, 1781–1790 (2018).

Wang, Z., Wang, Y. & Wang, C. Grain size effect on the hot ductility of high-nitrogen austenitic stainless steel in the presence of precipitates. Materials 11, 1026 (2018).

Lloyd, A. C., Noël, J. J., McIntyre, S. & Shoesmith, D. W. Cr, Mo and W alloying additions in Ni and their effect on passivity. Electrochim. Acta 49, 3015–3027 (2004).

Hashimoto, K., Asami, K. & Teramoto, K. An X-ray photo-electron spectroscopic study on the role of molybdenum in increasing the corrosion resistance of ferritic stainless steels in HC1. Corros. Sci. 19, 3–14 (1979).

Gaberšček, M. & Pejovnik, S. Impedance spectroscopy as a technique for studying the spontaneous passivation of metals in electrolytes. Electrochim. Acta 41, 1137–1142 (1996).

Li, T., Liu, L., Zhang, B., Li, Y. & Wang, F. An investigation on the continuous and uniform thin membrane passive film formed on sputtered nanocrystalline stainless steel. Corros. Sci. 104, 71–83 (2016).

Kong, D. et al. The passivity of selective laser melted 316L stainless steel. Appl. Surf. Sci. 504, 144495 (2020).

Leblanc, P. P. & Frankel, G. S. Investigation of filiform corrosion of epoxy-coated 1045 carbon steel by scanning Kelvin probe force microscopy. J. Electrochem. Soc. 151, B105 (2004).

Xie, Y. et al. A percolation theory for designing corrosion-resistant alloys. Nat. Mater. 20, 789–793 (2021).

Chao, C. Y., Lin, L. F. & Macdonald, D. D. A point defect model for anodic passive films: I. Film growth kinetics. J. Electrochem. Soc. 128, 1187–1194 (1981).

Wang, L. et al. Insight on passivity of high entropy alloys: thermal stability and ion transport mechanisms in the passive oxide film on CoCrFeMnNi surfaces. Corros. Sci. 188, 109540 (2021).

Vieregge, K. & Herzig, C. Grain boundary diffusion in α-zirconium: Part I: Self-diffusion. J. Nucl. Mater. 173, 118–129 (1990).

Kong, D. et al. About metastable cellular structure in additively manufactured austenitic stainless steels. Addit. Manuf. 38, 101804 (2021).

Jia, Q. et al. Precipitation kinetics, microstructure evolution and mechanical behavior of a developed Al–Mn–Sc alloy fabricated by selective laser melting. Acta Mater. 193, 239–251 (2020).

Acknowledgements

This work is supported by the National Key R&D Program of China (2021YFA1200202), and the sponsorship from City University of Hong Kong under the grant no. 9380088, 9360157, 9231348, 9360161, and 7005078.

Author information

Authors and Affiliations

Contributions

R.Z. and W.Y.C. conceived the project of 3D printed high entropy alloy in corrosion science and designed the experiments. W.P.L. conducted the TEM observations. T.H.C. and Y.H.C. carried out the electrochemical experiments. Y.L. and X.P.L. provided the machine support on 3D printing platform. R.Z., W.Y.C., Y.T.Z., and J.C.H. analyzed the data, co-wrote the manuscript and revised that. All authors contributed to the discussions and manuscript preparation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhou, R., Chen, W., Li, W. et al. 3D printed N-doped CoCrFeNi high entropy alloy with more than doubled corrosion resistance in dilute sulphuric acid. npj Mater Degrad 7, 8 (2023). https://doi.org/10.1038/s41529-023-00320-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41529-023-00320-1

This article is cited by

-

Aqueous corrosion of additively manufactured multi principal element alloys: a critical review

npj Materials Degradation (2025)

-

Review on corrosion-related aspects of metallic alloys additive manufactured with laser powder bed-fusion (LPBF) technology

Progress in Additive Manufacturing (2025)

-

Research on Electrochemical Corrosion and Passive Behavior of CoCrFeNi High-Entropy Alloy Compared with 304 Stainless Steel in a NaCl Environment

Journal of Materials Engineering and Performance (2025)