Abstract

Inspired by pH variation in corrosion microenvironment and the emerging solid-liquid composite strategies, this study presents an innovative self-healing coating based on pH-responsive confined solid-liquid transition behavior, with anti-corrosion functionality as a proof of concept. The coating integrates poly (vinyl alcohol) (PVA) crosslinked with boronic acid (BA) through an in-situ solvent exchange process, forming borate ester-based, pH-responsive PVA-BA (AB) hydrogel microdomains within a poly (3-(trimethoxysilyl) propyl methacrylate) (PTPM) network. The AB/PTPM coating achieves healing within 30 min, based on gel-sol transitions of the AB hydrogel microdomains triggered by different pH conditions (pH = 7 and 11). The hydrophobic PTPM network prevents AB hydrogel microdomains from water intrusion. This design balances the fluidity and stability, providing a solution to enhance the durability of protective coatings. The AB/PTPM coating was applied as a topcoat over an epoxy (EP) primer, and the formed bilayer AB/PTPM@EP coating exhibits excellent anti-corrosion restoration properties after self-healing.

Similar content being viewed by others

Introduction

Coatings, as protective physical barriers, are widely used across various industries, including corrosion protection of metals, construction waterproofing, and biomedical applications1,2,3. In the field of corrosion protection, coatings are the most cost-effective solution, accounting for 66.15% of protective measures4. However, when exposed to harsh environments like marine, coatings often suffer from localized damage due to exposure to H₂O, O₂, Cl⁻, UV radiation, and mechanical loads5,6. Under these conditions, cathodic delamination initiates in the damaged area and progressively spreads, ultimately leading to complete coating failure7,8,9. Self-healing technology provides a promising solution to address coating damage by repairing microcracks with the minimal external intervention, significantly extending the service life of coatings10,11,12.

Self-healing technology was pioneered in 2001 when White et al. introduced the “extrinsic” strategy, embedding microcapsules containing healing agents into the material matrix13. These microcapsules rupture upon damage, releasing agents to fill cracks or inhibit corrosion reactions. This approach exhibits the desirable healing autonomy, with healing agent release triggered by material damage or microenvironmental factors such as pH, H2O14, and Cl⁻15. However, in many cases, due to the limited dosage of microcontainers, the extrinsic self-healing strategy can only complete a limited number of healing cycles16. The “Intrinsic” self-healing strategy, utilizing reversible chemistries such as Diels-Alder reactions17, disulfide bonds18,19, coordination bonds20,21, supramolecular chemistry22, hydrogen bonding23,24, π-π interactions25, and transesterification reactions26, can achieve repeatable self-healing. However, most intrinsic self-healing mechanisms rely on external energy-input triggers like light27, heat28, or magnetic induction29 for bond breakage and reformation. Ideal self-healing materials are expected to possess mild or autonomous triggering conditions along with intrinsic self-healing capabilities.

Additionally, the construction of intrinsic self-healing coatings faces a key challenge: the adhesion of coatings to substrates can impede contact between damaged interfaces without external assistance. Effective interface contact is crucial for intrinsic self-healing, enabling reversible groups or chain segments to undergo molecular diffusion, entanglement, or chemical bond reconstruction30. The solid-liquid composite design strategy provides an inspiration by integrating the dynamic, diffusive, self-healing, and adaptive properties of liquid-like materials within a solid matrix31,32. Although extensively studied in liquid-infused porous surfaces33, liquid-gated membranes34, and soft material electronics35, this approach remains underexplored for self-healing coatings. Incorporating liquid-like materials into coatings can enhance flowability, facilitating interface contact at damaged regions36,37. The key mechanism of it lies in achieving a balance between “fluidity” and “stability”. Our previous research developed photothermal-induced self-healing coatings via introducing stable polymer networks that encapsulate solid-liquid phase transition materials38,39,40. This establishes a self-healing strategy based on confined solid-liquid transition, where the transition promotes effective contact of damaged interfaces while the polymer network maintains stability. However, the healing process requires energy-intensive light or heat triggers. To address this, herein we try to combine the confined solid-liquid transition self-healing technology with environmental triggers, for developing a novel low-energy intrinsic self-healing coating.

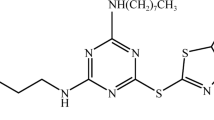

The corrosion microenvironment undergoes continuous pH fluctuations, driven by specific redox reactions: the anode experiences a pH drop due to metal oxidation, while the cathode undergoes a pH increase from H⁺ reduction41. This dynamic pH variations within the corrosion microenvironment provide a critical insight: utilizing this process to establish self-healing functionality. Most current pH-responsive self-healing systems employ an extrinsic strategy, where microcontainers respond to pH changes to release healing agents42,43,44. For intrinsic strategies, boronic/borate ester bonds45,46,47, catechol-derived bonds48,49,50, and imine bonds51,52 are typical pH-responsive dynamic reversible chemical units. Catechol-derived bonds are limited to alkaline environments53, while imine bonds are effective only in neutral conditions54. In contrast, borate ester bonds exhibit a broader pH response range, make them more suitable for the design of pH-responsive materials in slightly alkaline (pH=8 ~ 8.5) marine environments. Additionally, the dynamic dissociation-association of borate ester bonds generally enables a gel-sol transition55, providing great potential for integrating liquid-like characteristics into self-healing coatings.

This study introduces a pH-responsive self-healing technique that utilizes the gel-sol (solid-liquid) transition behavior of hydrogels, which facilitates contact at damaged coating interfaces through liquid-like characteristics while providing a mild triggering mechanism to achieve intrinsic self-healing in coatings. The innovative approach incorporates pH-responsive borate ester-based hydrogel microdomains into a photopolymerized hydrophobic polysilicon coating matrix through an in-situ solvent exchange process. Briefly, a composite of poly (vinyl alcohol)/poly (3-(trimethoxysilyl) propyl methacrylate) (PVA/PTPM) was prepared via photopolymerization, and subsequently treated with a boric acid (BA) solution to facilitate solvent exchange, enabling in-situ crosslinking of PVA with BA. This process resulted in the uniform formation of borate ester-based PVA-BA (AB) hydrogel microdomains within the PTPM network, producing a novel structured coating (AB/PTPM). The AB hydrogel microdomains exhibit confined solid-liquid transitions in response to pH fluctuations (pH = 9–7 and pH = 9–11), while the hydrophobic PTPM matrix effectively prevents the loss of AB components. This design achieves a balance between confined solid-liquid transition-based self-healing and structural stability. The AB/PTPM coating was applied as a topcoat over an epoxy primer, forming an integrated self-healing anti-corrosion system capable of efficient crack healing and corrosion protection restoration. Furthermore, the hydrophobic siloxane segments in the PTPM network enhance underwater adhesion (shear strength of 0.33 MPa) by establishing hydrogen and covalent bonds with substrate.

Results

Fabrication of AB/PTPM coating with AB hydrogel microdomains

To investigate the incorporation of AB hydrogel microdomains into the AB/PTPM coating, the pure AB hydrogel was synthesized for comparison (Fig. 1a), which appears as a malleable, transparent gel (Fig. 2a). The fabrication of AB/PTPM coating involves a two-step procedure (Fig. 1b): (1) photopolymerization of the PVA/TPM precursor into PVA/PTPM composite, and (2) solvent exchange with a BA solution. First, PVA was combined with the photosensitive monomer 3-(Trimethoxysilyl) propyl methacrylate (TPM) and dissolved in dimethyl sulfoxide (DMSO) to form the PVA/TPM precursor. In the presence of photoinitiator (2,2- dimethoxy-2-phenylacetophenone, DMPA), TPM monomer was UV-cured under 365 nm light irradiation to yield the PVA/PTPM composite. As compared in the FTIR spectra (Supplementary Fig. 1) of TPM and PVA/TPM with PTPM and PVA/PTPM, the absorption peak for the C = C bond (1638 cm-1) disappears post-photopolymerization, and the wavenumber of the C = O ester group shifts from 1710 to 1730 cm-1, indicating successful polymerization56. Afterwards, the PVA/PTPM composite was immersed in a BA solution for solvent exchange, allowing BA molecules to infiltrate the PVA/PTPM network and react with the hydroxyl groups of PVA. At the same time, the siloxane segments in PTPM hydrolyze and then condense to form a hydrophobic Si-O-Si network. Notably, both the PTPM and PVA/PTPM coatings are transparent, whereas the AB/PTPM coating exhibits slightly diminished clarity (Fig. 2b). This observation is supported by the UV-vis spectra in.

Supplementary Fig. 2, where the absorbance in the visible region for the AB/PTPM coating increases significantly. The UV absorption change of AB/PTPM-wet, immediately after solvent exchange, is more pronounced and primarily attributed to water absorption (Supplementary Fig. 2). The FTIR spectra of the residual solution post solvent exchange exhibits a characteristic S = O peak of DMSO at 1025 cm-1 (Supplementary Fig. 3), confirming the occurrence of solvent exchange. According to the FTIR spectra in Fig. 2c, compared to PVA/PTPM, the AB hydrogel and AB/PTPM exhibit a characteristic peak at 1408 cm⁻¹, corresponding to the stretching vibration of B-O, and a characteristic peak at 680 cm⁻¹ attributed to the bending vibration of B-O-C, confirming the successful synthesis of AB hydrogel and AB/PTPM through the formation of borate ester bonds57. Thus, the reduced transparency of the AB/PTPM coating can be attributed to the formation of borate ester-based hydrogel microdomains within the coating, which increase light scattering. Moreover, XPS analysis in Fig. 2d indicates that only AB/PTPM displays B-O bond-related peak at 192.5 eV (Fig. 2e and Supplementary Fig. 4)58. These findings suggest that BA molecules successfully infiltrated into the PVA/PTPM network through solvent exchange and reacted with the hydroxyl groups of PVA, forming AB/PTPM coatings with borate ester linkages.

To further confirm the linkage of borate ester, and the AB hydrogel microdomains within the AB/PTPM coating, as well as their interactions with the PTPM network, TOF-SIMS in negative ion mode was used to scan the cross-section of coating. This technique allows for the scanning and visualization of ultralight elements such as boron (B). Negative ions BO3− (m/z = 58) and SiO2− (m/z = 59) were selected to represent borate ester bonds and siloxane chain segments, respectively. As shown in Fig. 3a, b, these ions are found evenly distributed throughout the cross-section, indicating the uniform distribution of borate ester bonds and siloxane segments in the AB/PTPM coating. Meanwhile, several strong peaks are observed in the negative spectra (Supplementary Fig. 5a), associated with borate ester bonds at m/z = 27 (BO−) and siloxane chains at m/z = 119 (Si2O4−). The negative ion scans in Supplementary Fig. 5b, c further confirm that BO− and Si2O4− are uniformly distributed in the AB/PTPM coating, reinforcing the even distribution of borate ester bonds and siloxane chains. Notably, additional strong peaks are observed in the negative spectra (Supplementary Fig. 5a) at m/z = 86 (SiBO3−), m/z = 102 (SiBO4−), m/z = 118 (SiBO5−), and m/z = 134 (SiBO6−), suggesting interactions between borate ester bonds and siloxane chains. The corresponding chemical mapping scans in Fig. 3c, d and Supplementary Fig. 5d, e also confirm these findings. 3D depth analysis mode of TOF-SIMS was utilized for further investigation. BO2− was selected to represent the borate ester bonds. The analysis also reveals a uniform distribution of borate ester bonds (Fig. 3e, i) and siloxane chains (Fig. 3f, j), as well as their interactions (Fig. 3g, k, h and l). The depth analysis curve indicates no significant change in the ion strength of BO−, BO2−, and SiO2−, SiO3B−, and SiO4B− with increasing depth (Supplementary Fig. 6).

Morphological analysis of AB/PTPM coating

Figure 4 presents SEM images of the surface and cross-sections of AB hydrogel, PVA/PTPM, and AB/PTPM coatings. The surface of AB hydrogel appears wrinkled (Fig. 4a), a common feature in hydrogel materials post freeze-drying, induced by rapid solvent evaporation, freezing-induced stress, and partial collapse of the porous structure. In contrast, the surfaces of PVA/PTPM and AB/PTPM are smoother and flatter (Fig. 4b, c), suggesting that the hydrophobic polymer network PTPM acts as a supporting skeleton for the AB hydrogel. Additionally, atomic force microscopy (AFM) characterization (Supplementary Fig. 7) reveals the decreasing surface roughness (Rq = 3.52 nm) of AB/PTPM coating compared to PVA/PTPM coating (Rq = 3.75 nm), indicating a smoother surface due to the presence of the AB hydrogel microdomains. The cross-section of the AB hydrogel shows pores of varying sizes (Fig. 4d), attributed to the formation and sublimation of solvent ice crystals during freeze-drying. In contrast, the cross-sections of PVA/PTPM (Fig. 4e) and AB/PTPM (Fig. 4f) are compact, with the latter appearing smoother, and having a thickness of approximately 196 μm (Fig. 4g). To further understand the morphological differences between PVA/PTPM and AB/PTPM, XRD analysis was conducted. The XRD patterns (Supplementary Fig. 8) reveal that pure PVA has a distinct peak at 2θ = 19.5°, indicating significant crystallinity. The XRD pattern of AB shows a broad, flat peak, characteristic of amorphous materials, suggesting reduced crystallinity due to crosslinking with BA. Besides, PTPM incorporation similarly reduces the crystallinity of PVA. The AB/PTPM sample exhibits an even flatter peak, indicating further decreased crystallinity. These results suggest that AB and PTPM interaction results in the increased amorphous phase composition in the material, forming a more disordered structure and promoting the higher degree of molecular chain entanglement59. EDS analysis of the cross-sections of PVA/PTPM and AB/PTPM coatings reveals a large and uniform distribution of Si (Fig. 4h, i), C, and O elements (Supplementary Fig. 9), confirming the homogeneity of composite coating.

pH-Responsive viscoelastic properties of AB/PTPM coating

Based on the material design concept, the pH-responsive solid-liquid transition of AB hydrogel microdomains within the PTPM network is crucial for the self-healing of the AB/PTPM coating. In this study, pH = 9, pH = 7, and pH = 11 were selected as representative conditions to simulate the marine environment and the pH shifts in the microenvironment that occur during corrosion. Figure 5a illustrates the pH-responsive behavior of the AB hydrogel when treated with pH = 7 or pH = 11 buffer solutions after being in a pH = 9 buffer solution. After 1 h of treatment, the AB hydrogel collapses from a cube to a flat round shape, indicating a preliminary gel-sol (solid-liquid) transition process. To further verify this pH-responsive behavior and examine its integration into the PTPM network, the rheological properties of both the AB hydrogel and AB/PTPM coating at room temperature under pH = 7 and pH = 11 conditions were investigated (Fig. 5b, c). Under pH = 9 condition, the AB hydrogel behaves as an elastic solid (G’ > G”), whereas at pH = 7 and pH = 11, it transitions to a viscoelastic liquid (G” > G’). Crucially, AB/PTPM retains its elastic solid state (G’ > G”) regardless of the pH conditions (Fig. 5c), although its viscosity under pH = 7 and pH = 11 conditions is lower than its original state (Fig. 5d). The lower viscosity suggests the AB hydrogel microdomains undergo a pH-responsive solid-liquid transition, increasing molecular mobility within the network. However, the solid-liquid transition process has a minimal impact the stability of AB/PTPM composite, because the PTPM network can provide robust structural support and maintain its elastic properties during the transition. The PTPM network effectively confines the AB hydrogel transition, preventing complete flow and material loss. These findings illustrate that the PTPM network stabilizes the AB hydrogel, enabling confined solid-liquid transition of AB hydrogel microdomains under varying pH levels.

Swelling stability and confinement by PTPM network

To further investigate the confinement of PTPM network, the swelling behavior of AB hydrogel and AB/PTPM was tested in a 3.5 wt% NaCl solution over 14 days60. As shown in Fig. 6a, the AB hydrogel completely dissolved after 4 days. This is because the borate ester crosslinks in the AB hydrogel are reversible and can dissociate in the presence of water, leading to the breakdown of the gel network and loss of structural integrity. In contrast, AB/PTPM exhibits a relatively low swelling ratio (SR) and retained its shape even after 14 days of immersion in 3.5 wt% NaCl solution (Fig. 6b). Figure 6c shows that although AB/PTPM reached the highest SR of 47.16% on the third day, the SR gradually decreased over the next 11 days and kept stable after the 11th day. The enhanced stability can be attributed to the introduction of the PTPM network, which consists of hydrophobic siloxane segments. These segments provide a robust structural backbone that supports and confines the AB hydrogel, preventing complete dissolution by water. This ensures that the composite coating retains its integrity and mechanical properties even in challenging aqueous environments. Previous studies on PVA-based hydrogels have reported similar findings61, suggesting that the hydrophobic siloxane segments in PTPM contribute to the overall stability of the composite.

Underwater interfacial adhesion of AB/PTPM coating

In addition to stability, underwater interfacial adhesion is crucial for anti-corrosion coatings, especially for marine applications where underwater adhesion strength is paramount. Given the dissociation risk of pure AB hydrogel in water, it is essential to evaluate the interfacial adhesion strength of AB/PTPM in both air and underwater conditions. Figure 7 shows the lap shear test apparatus designed to measure the interfacial adhesion strength of the AB/PTPM coating. Unlike conventional tests, this apparatus features a customized PMMA substrate with drilled holes to facilitate solvent exchange during the preparation of AB/PTPM (Fig. 7a). To confirm successful solvent exchange through the drilled holes, FTIR testing was performed on the non-porous areas of the apparatus. The results revealed a characteristic peak at 1408 cm⁻¹, corresponding to the stretching vibration of B-O (Supplementary Fig. 10). For comparison, test apparatuses for PTPM and PVA/PTPM were also prepared. After curing, PTPM, PVA/PTPM, and AB/PTPM test apparatuses were immersed underwater for 24 h, and their maximum shear forces were tested using a universal tensile testing machine (Fig. 7b). Three parallel experiments were conducted. The results demonstrate that PVA/PTPM exhibited the strongest adhesion, with a shear strength of 0.37 MPa. This is due to the siloxane segments of the PTPM network forming hydrogen and covalent bonds with the hydroxyl groups of substrates. However, AB/PTPM shows a slightly reduced shear strength of 0.33 MPa (Fig. 7c, d). The maximum weight that PVA/PTPM and AB/PTPM-based apparatuses could withstand underwater was tested. The PVA/PTPM apparatus could lift at least 12 kg (Supplementary Fig. 11), while the AB/PTPM apparatus could lift 10 kg (Fig. 7e). This slight reduction can be attributed to the inherent properties of the AB hydrogel microdomains. While the AB component offer excellent self-healing and flexibility, its integration with PTPM may introduce minor structural compromises and heterogeneity at the molecular level. Additionally, the solvent exchange required for AB/PTPM preparation could lead to variations in cross-linking density, further contributing to the decrease in underwater adhesion.

Surface mechanical properties of AB/PTPM coating

The surface Young’s modulus reflects critical mechanical properties such as intermolecular cohesion strength and surface stiffness of polymer coatings. Generally, a higher degree of internal crosslinking corresponds to a greater surface Young’s modulus. AFM was used to measure the surface Young’s modulus of PVA/PTPM and AB/PTPM coatings (Fig. 8). The Young’s modulus of the PVA/PTPM coating ranged from 1000 to 4100 MPa (Fig. 8a, b), while the AB/PTPM coating ranged from 930.9 to 3700 MPa (Fig. 8c, d). Statistical analysis of the Young’s modulus for the two coatings is presented in Fig. 8e. The surface Young’s modulus of the AB/PTPM coating surface was lower than that of the PVA/PTPM coating due to the presence of AB hydrogel microdomains. However, it should be noted that the PTPM coating without AB hydrogel.

microdomains becomes brittle, cracks, and delaminates after 2 days at room temperature (Fig. 8f). Therefore, although AB hydrogel microdomains reduce the mechanical properties of the AB/PTPM coating, their flexibility offsets the brittleness of the PTPM segments, resulting in enhanced ductility and durability for the AB/PTPM coating.

pH-Responsive self-healing performance and mechanisms of AB/PTPM coating

The self-healing process and performance of PTPM, PVA/PTPM, AB/PTPM coatings were observed using optical microscopy. As shown in Fig. 9a, the crack sites on AB/PTPM coating closed within 30 min under both pH = 7 and pH = 11 conditions. However, no crack closure was observed for the AB/PTPM coating under pH = 9 condition (Supplementary Fig. 12). The cracks on the PTPM and PVA/PTPM coatings also show negligible shrinkage under the same conditions (Fig. 9b, c). Intriguingly, crack on AB/PTPM coating heals more rapidly at pH = 7 compared to pH = 11. As reported in the literature55, at pH = 7, ~60% of boric acid exists in its neutral form (H₃BO₃), while the remainder primarily consists of triborate anions (B₃O₄(OH)₃⁻) and other anionic species. These species promote increased dynamic reversibility of the borate ester bonds, resulting in a network that becomes more fluid-like under stress. At alkaline pH 11, the neutral form of boric acid disappears, leaving only B(OH)₄⁻ ( > 90%). These anionic species enable the formation of a crosslinked hydrogel; however, the association strength of B(OH)₄⁻ to diols in PVA is relatively weak so that the system still exhibits liquid-like behavior, with a viscosity slightly higher than that of the sol state at pH = 7. Thus, self-healing can be achieved both at pH = 7 and pH = 11 conditions.

Based on the observed self-healing behavior and structural characteristics of AB/PTPM coatings under different pH levels, a microstructural self-healing mechanism is proposed. As illustrated in Fig. 10, when the coating sustains local damage, the borate ester bonds in the AB hydrogel microdomains within the AB/PTPM coating dissociate in response to pH changes, causing the hydrogel to transition from an elastic solid gel to a viscoelastic liquid state. This dissociation, an entropy-increasing process, significantly enhances the mobility of molecular chain segments, allowing them to move, adjust, and realign more rapidly at the crack site before equilibrium is restored. Meanwhile, the PTPM supporting network confines the liquid-state microdomains, preventing uncontrolled flow and ensuring effective self-healing. Consequently, the liquid-state AB hydrogel microdomains migrates to the damaged area, filling the cracks and achieving self-healing. Furthermore, multiple scratch-healing cycle tests show that self-healing can be achieved repeatedly at the same location (Supplementary Fig. 13).

Anti-corrosion performance of AB/PTPM coating

To evaluate the self-healing capabilities of the AB/PTPM coating in anticorrosive applications and ensure coating durability, the classical “primer + topcoat” scheme was adopted. An epoxy resin coating (EP) was used as the anticorrosive primer, with the AB/PTPM coating applied as the self-healing topcoat, forming a dual-layer system (AB/PTPM@EP). The anti-corrosion performance of AB/PTPM@EP coating on a bare carbon steel substrate (CS) before and after self-healing was evaluated using electrochemical impedance spectroscopy (EIS). Typically, the |Z | 0.01 Hz value in the Bode plot represents the coating’s ability to impede ion movement between the cathode and anode regions in a corrosive primary cell. A higher |Z | 0.01 Hz value indicates greater corrosion resistance62,63. As shown in Fig. 11a, the |Z | 0.01 Hz of the AB/PTPM@EP coating is 4.4 × 109 Ω·cm2, significantly higher than the 3.5 × 106 Ω·cm2 of pure EP coating, indicating that the overall anti-corrosion performance was enhanced by AB/PTPM as the topcoat by three orders of magnitude. After the AB/PTPM topcoat was cracked (Top Cracked, TC), the |Z | 0.01 Hz of AB/PTPM@EP-TC decreased to 1.3 × 107 Ω·cm2. However, after the topcoat was repaired (Top Repaired, TR), the corrosion resistance of AB/PTPM@EP-TR reached levels comparable to the undamaged sample. In general, the negative phase angle at high frequencies indicates the coating’s integrity64. Both the AB/PTPM@EP-TR coatings repaired at pH = 7 and pH = 11 exhibited phase angles comparable to the original AB/PTPM@EP coating at high frequency (Fig. 11b). In addition, the diameter of the Nyquist capacitor arc is positively correlated with the corrosion resistance of the coating65,66. The Nyquist plot in Fig. 11f shows that the capacitance arc diameter of the AB/PTPM@EP-TC coating is 107 orders of magnitude. However, the AB/PTPM@EP-TR repaired at pH = 7 (Fig. 11g) and pH = 11 (Fig. 11h) showed capacitance arc diameters comparable to the undamaged coatings (Fig. 11e), around 109 orders of magnitude. Furthermore, when both layers of the coating were cracked (AB/PTPM@EP-BC) and the top layer was repaired only (TRO), the capacitance arc diameter of the AB/PTPM@EP-TRO coating were 107 orders of magnitude under both pH = 7 and pH = 11 repairing conditions (Supplementary Fig. 14, Supplementary Fig. 15, and Supplementary Table 1), which still outperformed the pure EP coating in terms of corrosion resistance. In conclusion, the AB/PTPM topcoat exhibits enhanced corrosion resistance and excellent pH-responsive self-healing capability when combined with a primer.

To further investigate the corrosion resistance of AB/PTPM@EP coating, ZSimpWin software was utilized to fit the EIS data, maintaining the chi-square value within 10-4 during fitting. Equivalent circuits, R(QR), were introduced to simulate the service process of coatings, with the simulated results presented in Table 1. Rs and Rct correspond to the solution resistance and charge transfer resistance, respectively. CPEdl represents the capacitive behavior related to the barrier properties of the coating. In general, Rct is positively correlated with corrosion resistance67,68. As shown in Table 1, coating the bare sample with AB/PTPM@EP increased the Rct value significantly from 3010 Ω·cm2 to 4.4 × 109 Ω·cm2. After the top coat cracked (AB/PTPM@EP-TC), Rct decreased to 1.3 × 107 Ω·cm2, but was restored to the 109 Ω·cm2 level after healed at pH = 7 and pH = 11 (AB/PTPM@EP-TR), comparable to that of the undamaged sample.

Additionally, Rct can be used to evaluate the corrosion protection efficiency (η)69:

where Rct1 and Rct2 represent the charge transfer resistance of bare steel and AB/PTPM@EP coating, respectively. It is calculated that the corrosion inhibition efficiency (η) of AB/PTPM@EP coating can be as high as 99%.

Moreover, the corrosion resistance of the composite coatings was further examined using the potentiodynamic polarization test. Higher corrosion potentials (Ecorr) and lower corrosion current densities (icorr) indicate better corrosion protection. As shown in Fig. 12a, the corrosion potentials of the AB/PTPM@EP-TR coatings repaired at pH = 7 and pH = 11 significantly shift into the positive direction compared to the cracked coating AB/PTPM@EP-TC. The fitting result are shown in Table 2, the corrosion rate Pi can be calculated as follows70:

Table 2 shows that for AB/PTPM@EP-TR coatings repaired at pH = 7 and pH = 11, the corrosion potential increases, while both the corrosion current density and rate are decreased by three orders of magnitude. These results are consistent with the EIS findings, further suggesting the excellent corrosion resistance and self-healing ability of AB/PTPM@EP coating.

The corrosion protection mechanism is illustrated in Fig. 12b. The corrosion process of AB/PTPM@EP coatings is governed by the barrier properties of the AB/PTPM layer. During the initial immersion, the electrolyte gradually infiltrates the AB/PTPM surface layer through a swelling-driven process. Throughout the tested period, the EIS spectra of all samples could be fitted by a single-time-constant equivalent circuit (R(QR)), in which the AB/PTPM self-healing layer contributes both resistive and capacitive (constant phase) behaviors. No additional time constant was observed, indicating that the barrier function of the AB/PTPM layer remained effective and prevented significant interfacial degradation.

Discussion

In summary, this study presents an innovative approach to construct intrinsic self-healing coatings by incorporating pH-responsive hydrogel microdomains into a hydrophobic polymer network. This novel structure exhibits confined pH-responsive solid-liquid transition behavior, effectively mitigating the inherent brittleness of PTPM network through the flexibility of AB hydrogel microdomains while maintain the stability of coatings. The confinement of the PTPM network on these microdomains ensures stability across varying pH levels. Upon damage, the pH-induced dissociation of borate ester linkages transforms the AB hydrogel microdomains from an elastic solid into a viscoelastic liquid, facilitating their controlled migration within the PTPM network to the damaged areas and enabling the AB/PTPM coating efficient and repeatable self-healing. Under pH = 7 and 11 conditions, the AB/PTPM coating achieves rapid crack healing within 30 min. When used as a top coat with an epoxy primer, the |Z | 0.01 Hz of repaired AB/PTPM@EP-TR reaching 109 Ω⋅cm2, comparable to the undamaged sample. At the same time, both the corrosion current density and rate decrease by three orders of magnitude after healing. In addition to epoxy, the AB/PTPM coating can also be applied as a topcoat on other polar resins (e.g., acrylic- and polyurethane-based primers) to form integrated self-healing anti-corrosion coating systems. This work provides innovative insights into self-healing coating design, with the in-situ solvent exchange approach opening new possibilities for integrating functional hydrogel materials into advanced coatings, potentially revolutionizing other functional composite technologies.

Methods

Materials

Poly (vinyl alcohol) (PVA, Mw 13000–23000 g/mol, 87–89% hydrolyzed), 3-(Trimethoxysilyl) propyl methacrylate (TPM, 97%, containing 100 ppm BHT stabilizer), 2,2-Dimethoxy-2-phenylacetophenone (DMPA, >99%), dimethyl sulfoxide (DMSO, >99%), and boric acid (BA, ≥99.5%) were all procured from Aladdin. All chemicals were employed as received without further purification. Epoxy resin (E51) and curing agent were purchased from Ailik New Materials Ltd, China. Q235 carbon steel specimens (2.0 × 3.0 × 0.6 mm) were purchased from Xindazhou Metal Material Co., Ltd., China.

Synthesis of AB hydrogel

3.6 g of PVA was dissolved in 15 mL of deionized (DI) water and stirred at 80 °C for 2 h until fully dissolved. Subsequently, 2 g of BA was added to the solution and stirred vigorously until a gel-like consistency was achieved. Finally, the obtained hydrogel was placed in 2 mL of pH = 9 buffer solution for 30 min, resulting in the formation of AB hydrogel in an elastic state.

Fabrication of AB/PTPM and AB/PTPM@EP coating

3.6 g of PVA was dissolved in 15 mL of DMSO and stirred at 80 °C for 2 h until fully dissolved. Then, 15 mg of DMPA and 0.5 mL of TPM were added and stirred in the dark for 20 min. After defoaming, 0.5 mL of the solution was deposited onto a substrate (glass slide or carbon steel) and irradiated with a UV lamp (λ = 365 nm) for 2 h until solidified. All Q235 carbon steel substrates were sanded with 400-grit sandpaper, ultrasonically cleaned in ethanol and water, and air-dried before use. Finally, the cured coating was immersed in a 1.5 wt% BA solution for 30 min for solvent exchange, followed by drying at room temperature to obtain the AB/PTPM coating. For the AB/PTPM@EP coating, the epoxy primer was prepared by mixing the resin and curing agent at a 1:1 ratio. The mixture was then applied onto polished steel substrates and cured at 60 °C. Subsequently, the PVA/TPM casting solution was coated onto the epoxy primer and UV-cured for 2 h. Finally, the sample was immersed in 1.5 wt% BA solution for 30 min for solvent exchange, and then cured at room temperature to obtain the AB/PTPM@EP coating.

Characterization

Fourier transform infrared (FTIR) spectra were obtained using an Thermo Scientific Nicolet iS20 infrared spectrometer equipped with an attenuated total reflection detector. The spectra were recorded over the range of 4000 ~ 500 cm-1 with a resolution of 2 cm-1. Surface composition of materials was analyzed by X-ray photoelectron spectroscopy using a Thermo Scientific K-Alpha spectrometer. Monochromatic Al Kα X-rays (hν = 1486.6 eV) were used as the excitation source, operating at 12 kV. The neutral C1s peak (C–C(H), set to 284.80 eV) was employed for charge correction. The distribution of borate ester bonds and siloxane chain segments within the AB hydrogel and AB/PTPM coating, as well as their potential interactions, were investigated using time-of-flight secondary ion mass spectrometry (TOF-SIMS) with ION-TOF GmbH TOF.SIMS 5 spectrometer. 3D imaging was performed on the cross-sectional surface and at a depth of 1 μm below the cross-section of the AB/PTPM sample. The samples were bombarded with Bi3+ primary ions accelerated at 30 keV with an average pulsed current of 0.43 pA. The raster area was 400 × 400 μm, and the acquisition time for each spectrum was 40 s, corresponding to an ion dose of < 4 × 1011 ions/cm2. Three positive and three negative spectra were recorded at different positions for each sample. The absorbance of the coating in the UV, visible, and near-infrared regions was measured in absorbance mode using a Shimadzu UV-3600 UV-Vis-NIR spectrophotometer. The crystalline characteristics of the samples were characterized using X-ray diffraction with a Rigaku SmartLab SE spectrometer over a 2θ range of 10–80°. The surface roughness and surface modulus of PVA/PTPM and AB/PTPM coating were characterized using NanoTest Vantage atomic force microscopy. The morphological structure and elemental distribution of samples were examined using a ZEISS GeminiSEM 300 scanning electron microscope equipped with an energy-dispersive X-ray spectrometer (EDS). Prior to observation, all samples were freeze-dried using a Ningbo Xinzhi SCIENTZ-10N vacuum freeze dryer and prepared for cross-sectional observation by liquid nitrogen freeze-fracturing.

Rheological test

Dynamic rheological tests were conducted on AB hydrogel, PVA/TPM, PVA/PTPM, and AB/PTPM samples at room temperature using a Haake Mars60 strain-controlled rheometer equipped with a 20 mm diameter parallel plate. Initially, a strain sweep test was performed on the hydrogel samples at a constant frequency of ω = 10 Hz to determine the linear viscoelastic region, where the storage modulus (Gʹ) and loss modulus (G") are independent of the strain amplitude. Subsequently, a frequency sweep test was conducted at a constant strain (γ = 0.5%) to investigate the viscoelastic behavior of the samples over a wide range of angular frequencies (0.1 ~ 100 Hz).

Underwater swelling test

AB hydrogel and AB/PTPM samples were prepared in a 2 cm square polytetrafluoroethylene (PTFE) molds. The samples were weighed using an analytical balance until the weight difference over three days was less than 0.01 g to ensure complete weight stabilization. The average weight was recorded as the dry weight (Wd). Afterwards, the dry samples of AB hydrogel and AB/PTPM were immersed in a 3.5 wt% NaCl solution at ambient temperature for 14 days. During immersion, the samples were removed and weighted once every 24 h, and their surface water was gently blotted with absorbent paper. The samples were then immediately weighed using the analytical balance. This process was repeated for the entire 14-day period. The average of three measurements taken at each weighing was recorded as the swollen weight (Ws). The swelling ratio (SR) was calculated using the following formula:

Underwater adhesion test

To investigate the underwater adhesion strength of AB/PTPM coating materials, an interfacial adhesion strength test apparatus was designed. The apparatus consists of two stacked PMMA substrates, A and B, each measuring 2.5 × 8 cm, with the AB/PTPM composite sandwiched between them. Since the preparation of AB/PTPM involves solvent exchange between PVA/PTPM and BA solution, PMMA substrate A was customized by drilling holes in half of its area to facilitate subsequent solvent exchange. Each hole has a diameter of 0.5 cm, and there are 15 holes in total, resulting in a combined area of ~2.94 cm2. The specific preparation method for the test samples is as follows: First, the PVA/PTPM precursor solution was applied onto the surface of PMMA substrate B. Before the solution dried completely, half of the PMMA substrate A with the perforated side was overlapped with PMMA substrate B, starting from the midpoint of the slide. The overlapped samples were then cured under a UV lamp. After curing, the samples were immersed in a BA solution to complete the solvent exchange process. To ensure that the BA solution successfully penetrated through the holes to perform a uniform solvent exchange reaction within the system, FTIR testing was conducted on the non-perforated regions of the samples after the exchange and drying process. Once the exchange was complete and the samples were dried, the assembled AB/PTPM samples were subjected to weights of 5 and 10 kg of water to roughly observe their interfacial adhesion strength. Finally, the interfacial shear strength of the sample was measured using a Labthink C610M universal tensile testing machine. By subtracting the total area of the holes from the total overlapping area, the actual overlapping area was determined to be approximately 7.06 cm2.Thus, the lap joint strength per unit area can be determined. For comparison, lap joint samples of pure PTPM and PVA/PTPM were also prepared with similar procedure and tested under the same conditions.

Self-healing performance

Coating cracks were produced using a scalpel, with the scratch length controlled at approximately 1 cm and the width at about 100 μm. The cracks were treated with approximately 0.05 mL of buffer solution at pH = 7, pH = 9 or pH = 11 to facilitate the healing process. The self-healing behavior of the coating cracks under different pH conditions was observed using an Olympus BX53-P optical microscope.

Anti-corrosion performance

The corrosion resistance of coatings was assessed using electrochemical impedance spectroscopy (EIS). The coating samples were prepared as follows: AB/PTPM@EP-TC was scratched on the topcoat, leaving the primer layer intact; AB/PTPM@EP-TR was prepared by treating the scratched sites of AB/PTPM@EP-TC with 0.05 mL of buffer solution at pH = 7 or 11; AB/PTPM@EP-BC was scratched through both the topcoat and primer layer, exposing the steel substrate; and AB/PTPM@EP-TRO was prepared by treating the scratched sites of AB/PTPM@EP-BC with 0.05 mL of buffer solution at pH = 7 or 11. EIS measurements were performed on a Gamry Reference 3000 electrochemical workstation, applying a 10 mV AC voltage over a frequency range from 105 to 10-2 Hz. A three-electrode setup was utilized for all electrochemical experiments, including an Ag/AgCl (3.5 M KCl solution) reference electrode, a platinum sheet as the counter electrode, and a Q235 carbon steel working electrode covered with the coating under investigation. To mimic a standard corrosive environment, a 3.5 wt% NaCl solution served as the electrolyte. The obtained EIS data were analyzed using ZSimpWin software.

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Fotovvati, B., Namdari, N. & Dehghanghadikolaei, A. On coating techniques for surface protection: a review. J. Manuf. Mater. Process. 3, 28 (2019).

Jin, H., Tian, L., Bing, W., Zhao, J. & Ren, L. Bioinspired marine antifouling coatings: Status, prospects, and future. Prog. Mater. Sci. 124, 100889 (2022).

Abdeen, D. H., El Hachach, M., Koc, M. & Atieh, M. A. A review on the corrosion behaviour of nanocoatings on metallic substrates. Materials 12, 210 (2019).

Hou, B. et al. The cost of corrosion in China. npj Mater. Degrad. 1, 4 (2017).

Sørensen, P. A., Kiil, S., Dam-Johansen, K. & Weinell, C. E. Anticorrosive coatings: a review. J. Coat. Technol. Res. 6, 135–176 (2009).

Ma, L. et al. Self-reporting coatings for autonomous detection of coating damage and metal corrosion: a review. Chem. Eng. J. 421, 127854 (2021).

Leng, A., Streckel, H. & Stratmann, M. The delamination of polymeric coatings from steel. Part 1: calibration of the Kelvinprobe and basic delamination mechanism. Corros. Sci. 41, 547–578 (1998).

Leng, A., Streckel, H. & Stratmann, M. The delamination of polymeric coatings from steel. Part 2: first stage of delamination, effect of type and concentration of cations on delamination, chemical analysis of the interface. Corros. Sci. 41, 579–597 (1998).

Khayatan, N. et al. On the rate determining step of cathodic delamination of delamination-resistant organic coatings. Corros. Sci. 239, 112396 (2024).

Wang, Y. et al. Photothermally activated self-healing coatings for corrosion protection: a review. Prog. Org. Coat. 185, 107886 (2023).

Fu, X. et al. Stimuli-responsive self-healing anticorrosion coatings: from single triggering behavior to synergetic multiple protections. Mater. Today Chem. 22, 100575 (2021).

An, S., Lee, M. W., Yarin, A. L. & Yoon, S. S. A review on corrosion-protective extrinsic self-healing: comparison of microcapsule-based systems and those based on core-shell vascular networks. Chem. Eng. J. 344, 206–220 (2018).

White, S. R. et al. Autonomic healing of polymer composites. Nature 409, 794–797 (2001).

Davydovich, D. & Urban, M. W. Water accelerated self-healing of hydrophobic copolymers. Nat. Commun. 11, 5743 (2020).

Zhou, L. et al. Chloride ion-responsive active protection epoxy composite coatings realized by 2-Mercaptobenzimidazole and 2-Mercaptobenzothiazole intercalated Mg-Al layered double hydroxides. Corros. Sci. 234, 112144 (2024).

Vimalanandan, A. et al. Redox-responsive self-healing for corrosion protection. Adv. Mater. 25, 6980–6984 (2013).

Chen, X. et al. A thermally re-mendable cross-linked polymeric material. Science 295, 1698–1702 (2002).

Wu, J. et al. Rapid self-healing and high-mechanical-strength epoxy resin coatings incorporating dynamic disulfide bonds. ACS Appl. Polym. Mater. 6, 4778–4788 (2024).

Chen, T. et al. Self-healing polymer coatings of polyurea-urethane/epoxy blends with reversible and dynamic bonds. Prog. Org. Coat. 147, 105876 (2020).

Auepattana-Aumrung, K. & Crespy, D. Self-healing and anticorrosion coatings based on responsive polymers with metal coordination bonds. Chem. Eng. J. 452, 139055 (2023).

Li, Y. et al. Mechanically robust and fast room-temperature self-healing waterborne polyurethane constructed by coordination bond and hydrogen bond with antibacterial and photoluminescence functions. Prog. Org. Coat. 174, 107256 (2023).

Cordier, P., Tournilhac, F., Soulié-Ziakovic, C. & Leibler, L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature 451, 977–980 (2008).

Nardeli, J. V., Fugivara, C. S., Taryba, M., Montemor, M. F. & Benedetti, A. V. Self-healing ability based on hydrogen bonds in organic coatings for corrosion protection of AA1200. Corros. Sci. 177, 108984 (2020).

Zhang, T., Deng, J. & Zhang, L. Z. A photothermal self-healing superhydrophobic coating with anti-frosting and anti-corrosion properties. Prog. Org. Coat. 180, 107569 (2023).

Burattini, S., Colquhoun, H. M., Greenland, B. W. & Hayes, W. A novel self-healing supramolecular polymer system. Faraday Discuss. 143, 251–264 (2009).

Montarnal, D., Capelot, M., Tournilhac, F. & Leibler, L. Silica-like malleable materials from permanent organic networks. Science 334, 965–968 (2011).

Li, Y. M., Zhang, Z. P., Rong, M. Z. & Zhang, M. Q. Sunlight stimulated photochemical self-healing polymers capable of re-bonding damages up to a centimeter below the surface even out of the reach of the illumination. Adv. Mater. 35, 2211009 (2023).

Zhang, X., Zhang, H., Zhou, G., Su, Z. & Wang, X. Flexible, thermal processable, self-healing, and fully bio-based starch plastics by constructing dynamic imine network. Green. Energy Environ. 9, 1610–1618 (2024).

Diodati, L. E., Liu, S., Rinaldi-Ramos, C. M. & Sumerlin, B. S. Magnetic nanoparticles improve flow rate and enable self-healing in covalent adaptable networks. ACS Appl. Mater. Interfaces 15, 32957–32966 (2023).

Yang, Y. & Urban, M. W. Self-healing polymeric materials. Chem. Soc. Rev. 42, 7446–7467 (2013).

Sheng, Z. et al. Solid–liquid host–guest composites: the marriage of porous solids and functional liquids. Adv. Mater. 33, 2104851 (2021).

Zhang, Y. & Hou, X. Liquid-based materials. Natl Sci. Open 1, 20220035 (2022).

Deng, R. et al. Slippery liquid-infused porous surfaces (SLIPSs): a perfect solution to both marine fouling and corrosion? J. Mater. Chem. A 8, 7536–7547 (2020).

Sheng, Z. et al. Liquid-based porous membranes. Chem. Soc. Rev. 49, 7907–7928 (2020).

Style, R. W., Tutika, R., Kim, J. Y. & Bartlett, M. D. Solid–liquid composites for soft multifunctional materials. Adv. Funct. Mater. 31, 2005804 (2021).

Lim, A. T. O., Cui, C., Jang, H. D. & Huang, J. Self-healing microcapsule-thickened oil barrier coatings. Research 2019, 1–14 (2019).

Yu, Z., Lim, A. T. O., Kollasch, S. L., Jang, H. D. & Huang, J. Oil-based self-healing barrier coatings: to flow and not to flow. Adv. Funct. Mater. 30, 1906273 (2020).

Wei, J. et al. Colorable photothermal-induced self-repairing anti-corrosion coating based on confined solid-liquid transition. J. Mater. Sci. Technol. 197, 227–237 (2024).

Shen, T., Liang, Z.-H., Yang, H.-C. & Li, W. Anti-corrosion coating within a polymer network: Enabling photothermal repairing underwater. Chem. Eng. J. 412, 128640 (2021).

Shen, T. et al. Recyclable and self-repairable epoxy anticorrosion coatings with curing-controlled thermoplasticity. ACS Appl. Polym. Mater. 4, 1035–1046 (2022).

Yimyai, T., Crespy, D. & Rohwerder, M. Corrosion-responsive self-healing coatings. Adv. Mater. 35, 2300101 (2023).

Ghahremani, P., Sarabi, A. A. & Roshan, S. Cerium containing pH-responsive microcapsule for smart coating application: characterization and corrosion study. Surf. Coat. Technol. 427, 127820 (2021).

Ren, S. et al. A self-healing epoxy composite coating based on pH-responsive PCN-222 smart containers for long-term anticorrosion of aluminum alloy. Corros. Sci. 221, 111318 (2023).

Li, D., Gong, B., Liu, Y. & Dang, Z. Self-healing coatings based on PropS-SH and pH-responsive HNT-BTA nanoparticles for inhibition of pyrite oxidation to control acid mine drainage. Chem. Eng. J. 415, 128993 (2021).

Wang, Y. et al. Ultrafast self-healing, reusable, and conductive polysaccharide-based hydrogels for sensitive ionic sensors. ACS Sustain. Chem. Eng. 8, 18506–18518 (2020).

Yuan, D. et al. Biomimetic water-responsive self-healing epoxy with tunable properties. ACS Appl. Mater. Interfaces 11, 17853–17862 (2019).

Ji, F. et al. Alkaline monomer for mechanical enhanced and self-healing hydrogels based on dynamic borate ester bonds. Polymer 184, 121882 (2019).

Peng, W. L., Zhang, Z. P., Rong, M. Z. & Zhang, M. Q. Reversibly interlocked macromolecule networks with enhanced mechanical properties and wide pH range of underwater self-healability. ACS Appl. Mater. Interfaces 12, 27614–27624 (2020).

Xia, N. N., Xiong, X. M., Wang, J., Rong, M. Z. & Zhang, M. Q. A seawater triggered dynamic coordinate bond and its application for underwater self-healing and reclaiming of lipophilic polymer. Chem. Sci. 7, 2736–2742 (2016).

Zheng, H., Chen, M., Sun, Y. & Zuo, B. Self-healing, wet-adhesion silk fibroin conductive hydrogel as a wearable strain sensor for underwater applications. Chem. Eng. J. 446, 136931 (2022).

He, C. L. et al. Super tough and spontaneous water-assisted autonomous self-healing elastomer for underwater wearable electronics. Adv. Sci. 8, 2102275 (2021).

Zhao, L. et al. Multifunctional ionic conductive double-network hydrogel as a long-term flexible strain sensor. ACS Appl. Polym. Mater. 3, 5494–5508 (2021).

Chen, J. & Zeng, H. Mussel-inspired reversible molecular adhesion for fabricating self-healing materials. Langmuir 38, 12999–13008 (2022).

Lei, Z. Q., Xie, P., Rong, M. Z. & Zhang, M. Q. Catalyst-free dynamic exchange of aromatic Schiff base bonds and its application to self-healing and remolding of crosslinked polymers. J. Mater. Chem. A 3, 19662–19668 (2015).

Chen, M., Murphy, B. B., Wang, Y., Vitale, F. & Yang, S. SMART silly putty: stretchable, malleable, adherable, reusable, and tear-resistible hydrogels. Small 19, 2205854 (2023).

Shi, J., Xu, L. & Qiu, D. Effective antifogging coating from hydrophilic/hydrophobic polymer heteronetwork. Adv. Sci. 9, 2200072 (2022).

Li, Q. et al. Strong, spontaneous, and self-healing poly(ionic liquid) elastomer underwater adhesive with borate ester dynamic crosslinking. Adv. Mater. 36, 2413901 (2024).

Xue, H. et al. A high-toughness, tailorable, wearable multifunctional sensor based on multisynergistic fabric-hydrogel constructed via dual-function boric acid bridge. Mater. Today Chem. 33, 101696 (2023).

Wang, Y., Wang, J., Ma, Z. & Yan, L. A highly conductive, self-recoverable, and strong eutectogel of a deep eutectic solvent with polymer crystalline domain regulation. ACS Appl. Mater. Interfaces 13, 54409–54416 (2021).

Zhang, J. et al. Durable hydrogel-based lubricated composite coating with remarkable underwater performances. J. Colloid Interface Sci. 654, 568–580 (2024).

Zhang, Z., Abidi, N. & Lucia, L. A. Dual crosslinked-network self-healing composite hydrogels exhibit enhanced water adaptivity and reinforcement. Ind. Eng. Chem. Res. 61, 17876–17884 (2022).

Pirhady Tavandashti, N. et al. Inhibitor-loaded conducting polymer capsules for active corrosion protection of coating defects. Corros. Sci. 112, 138–149 (2016).

Parichehr, R., Dehghanian, C. & Nikbakht, A. Preparation of PEO/silane composite coating on AZ31 magnesium alloy and investigation of its properties. J. Alloy. Compd. 876, 159995 (2021).

Eivani, A. R., Mehdizade, M., Chabok, S. & Zhou, J. Applying multi-pass friction stir processing to refine the microstructure and enhance the strength, ductility and corrosion resistance of WE43 magnesium alloy. J. Mater. Res. Technol. 12, 1946–1957 (2021).

Wu, S. W. et al. Environmentally friendly expanded graphite-doped ZnO superhydrophobic coating with good corrosion resistance in marine environment. Rare Met. 42, 3075–3087 (2023).

Huang, N. et al. Multifunctional coating on magnesium alloy: superhydrophobic, self-healing, anti-corrosion and wear-resistant. Surf. Coat. Technol. 463, 129539 (2023).

Sheng, X., Cai, W., Zhong, L., Xie, D. & Zhang, X. Synthesis of functionalized graphene/polyaniline nanocomposites with effective synergistic reinforcement on anticorrosion. Ind. Eng. Chem. Res. 55, 8576–8585 (2016).

Huang, H. et al. Modification of graphene oxide with acrylate phosphorus monomer via thiol-Michael addition click reaction to enhance the anti-corrosive performance of waterborne epoxy coatings. Prog. Org. Coat. 146, 105724 (2020).

Li, X., Deng, S. & Fu, H. Triazolyl blue tetrazolium bromide as a novel corrosion inhibitor for steel in HCl and H2SO4 solutions. Corros. Sci. 53, 302–309 (2011).

Bakhsheshi-Rad, H. R., Abdul-Kadir, M. R., Idris, M. H. & Farahany, S. Relationship between the corrosion behavior and the thermal characteristics and microstructure of Mg–0.5Ca–xZn alloys. Corros. Sci. 64, 184–197 (2012).

Acknowledgements

The authors gratefully acknowledge the financial support through the National Natural Science Foundation of China (52401408, 52271355), the Henan Provincial Science and Technology Research Joint Fund-Young Scientist Project (225200810108), the Basic Scientific Research Fund Project of Henan Academy of Sciences (230618023), the Research Startup Fund of Henan Academy of Sciences (231818027, 232018001), and the Henan Academy of Sciences High-level Achievement Award and Cultivation Project (242218021). The authors gratefully acknowledge the support of Henan Provincial Key Laboratory of Infrastructure Corrosion Prevention and Control.

Author information

Authors and Affiliations

Contributions

J.Y.: Conceptualization, Methodology, Writing – original draft. T.S.: Investigation, Methodology, Funding Acquisition, Writing – review & editing. J.W.: Investigation, Methodology. C.C.: Investigation, Methodology. W.C.: Investigation. W.L.: Conceptualization, Funding Acquisition, Supervision. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yang, J., Shen, T., Wei, J. et al. pH-responsive intrinsic self-healing coating via in-situ confined solid-liquid transition of hydrogel microdomains. npj Mater Degrad 9, 98 (2025). https://doi.org/10.1038/s41529-025-00656-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41529-025-00656-w