Abstract

Fermentation techniques produce distinct microbes and qualities of various fermented chili peppers. However, comparative studies on chili peppers fermented using different techniques are limited. This study investigated the characteristic microbes and qualities of pickled and salted chili peppers through targeted and non-targeted analysis. The results revealed that Lactiplantibacillus and Weissella were the dominant microbes in pickled and salted chili peppers respectively. Additionally, pickled chilli peppers contained 6 key unique volatiles, with geraniol and β-myrcene showing significant positive correlation with Lactiplantibacillus. In contrast, salted chilli peppers contained 3 key unique volatiles, with no significant correlation with Weissella. Naringenin, trans-ferulic acid, and DL-p-hydroxyphenyllactic acid in pickled chili peppers exhibited significant positive correlation with Lactiplantibacillus. The weak correlation between Weissella and qualities in salted chili peppers may result from the inhibition of high-salt environment. This study provides insights for inoculated fermentation strategies to preserve microbial diversity and distinct flavors in different fermented chili peppers.

Similar content being viewed by others

Introduction

Chili pepper is an important part of the agricultural industry in Guizhou, and the largest chili pepper planting area is in Guizhou (>3070 km2)1. Chili pepper is celebrated not only for their regional flavors but also for their nutritional benefits, making it a staple in the dietary habits of the population in Guizhou, where the per capita chili pepper consumption reaches 98.5 kg2,3,4. Natural fermentation is the predominant method for preserving and enhancing the sensory characteristics of chili peppers, which mainly includes two fermentation methods: pickling and salting2,5,6. Natural fermentation is influenced by the processing method with different fermentation conditions, which foster diverse microbial communities that play a crucial role in flavor and nutrition development, attributed to the biochemical transformations facilitated by microbes during the fermentation process7,8. Therefore, two kinds of fermented chili peppers have different qualities, with pickled chili peppers being predominantly sour and mainly used as a seasoning in Chinese Sichuan cuisine (e.g., pickled chili pepper beef), and salted chili peppers being predominantly salty and mainly used as a seasoning in Chinese Hunan cuisine (e.g., salted chili pepper fish head). Further, it is necessary to explore the main microbes and characteristic qualities of fermented chili peppers with different processing methods and to further differentiate between the two common types of fermented chili peppers (pickled and salted chili peppers), which can be better targeted at different fermented chili products for the creation of inoculated fermentation processing technology.

Recent advancements in multi-omics analysis have provided valuable insights into the complex interactions between microbial communities and the physicochemical properties of fermented foods, including microbiomes and metabolomes9. By employing next generation sequencing techniques, researchers can now elucidate the microbial diversity present during fermentation6. Furthermore, metabolomes enable the identification and quantification of volatile and non-volatile substances, providing a comprehensive understanding of the sensory attributes of fermented chili peppers10. Correlation analysis, inoculated fermentation experiments can further explore the role of dominant microbial metabolism in key flavor formation processes. Researches have studied that Lactiplantibacillus, Weissella and Pediococcus were the most abundant at the genus level in the fermented chili peppers from Guizhou provinces3,6. The key volatile and aroma-active substances of fermented chili peppers were identified as esters (e.g., methyl salicylate), alcohol (e.g., linalool, and phenylethyl alcohol), sour (e.g., n-Hexadecanoic acid) and so forth6,11,12,13. The non-volatile and nutritional substances of fermented chili peppers often contained elevated levels of bioactive substances, including antioxidants and vitamins, which contributed to health benefits such as improving digestion and enhancing immune response14,15. Additionally, flavonoids, crucial plant constituents exhibiting antioxidant activity, also could reduce the oxidative browning of chili pepper in low oxygen and acid fermentation environment, and make the fermented chili pepper maintain good color16.

Due to different varieties of chili peppers and different fermentation environments caused by processing techniques, the dominant microbes in fermented chili peppers are different, thus forming a variety of fermented chili products with various flavors, such as pickled chili peppers, salted chili peppers, fermented chili sauce, zao chili peppers, kaili red sour soup and zha chili peppers. However, the existing studies only choose the fermented chili pepper processed by one technique as the experimental sample to explore its microbes and fermentation qualities, and there is a lack of research on the impact of different processing techniques on the formation of characteristic microbes and flavor profiles of the same chili pepper variety, which is not conducive to exploring the influence of environmental factors on microbial communities and fermentation quality. Therefore, this paper focused on two major types of fermented chili peppers - pickled and salted chili peppers. In addition, the time for fermented maturation of fermented chili peppers is not uniform in Guizhou, usually fermenting and maturing in 30 or 45 days. Therefore, in this paper, pickled and salted chili peppers with two-time endpoints of 30 and 45 days were selected as experimental samples, and the fermented chili peppers with better fermentation degree were further selected for investigation. Next generation sequencing was employed to analyze the dominant microbes. Additionally, ion chromatography (IC), high performance liquid chromatography (HPLC), and other techniques were used to determine targeted indicators, including total acid content (TA), pH, salt content, monosaccharides, organic acids, nitrites, and biogenic amines. High-resolution chromatography mass spectrometry was applied for non-targeted screening of volatile and non-volatile substances to identify novel and characteristic volatiles and non-volatiles. Ultimately, this study provides a comprehensive summary of the dominant microbes and characteristic qualities of pickled and salted chili peppers, providing valuable insights for future studies on the inoculated fermentation of these two common fermented chili peppers.

Results and discussion

Microbial analysis of dominant microbes

Figure 1a, b showed the microbial composition of pickled and salted chili peppers at genus level on days 30 and 45. Four non-fermentative microbes—Raoultella, Serratia, Pseudomonas, and Pectobacterium, constituted a significant portion of the microbial community in these products, originating from the planting environment of the chili pepper raw materials2,17,18. No significant differences were observed in these microbes between days 30 and 45, regardless of the fermentation process. However, Pseudomonas decreased in abundance in pickled chili peppers on day 45, likely due to its intolerance to high acidity12.

Lactic acid bacteria (LAB) were common fermented microbe. In pickled chili peppers, Lactiplantibacillus exhibited the highest relative abundance, comprising 28.00% on day 30 and 42.99% on day 45. Other LAB, including Weissella, Lactococcus, and Pediococcus, accounted for 4.37% and 1.58%, 7.98% and 0.37%, 2.05% and 4.96% on day 30 and 45, respectively. A similar composition was observed in zha-chili, a regionally fermented chili pepper from Guizhou19. Additionally, the percentages of Weissella and Lactococcus in pickled chili peppers decreased over fermentation time, likely due to their intolerance to low pH, as noted in studies of fermented chili sauce from Northeast China20,21. Weissella was the dominant microbe in salted chili peppers, with relative abundances of 4.11% and 7.22% on days 30 and 45, while Lactococcus accounted for 1.42% and 2.78%, respectively, aligning with previous research22. However, the abundance of LAB in salted chili peppers was lower than pickled ones, which may be attributed to the high salt content used during the salted process, which was not conducive to the growth of LAB22,23.

In summary, the proportion of LAB on day 45 was significantly higher than that on day 30, suggesting that a fermentation period of 45 days is optimal for the production of fermented chili peppers. Besides, as shown in Fig. 1c, d, the dominant LAB identified was Lactiplantibacillus, which exhibited acid tolerance in pickled chili peppers, and Weissella, which showed salt tolerance in salted chili peppers.

Salt, water activity, pH, TA

The salt content, water activity (aw), pH and TA content reflected the fermentation environment. As Fig. 2a shown, the salt content did not change significantly between days 30 and 45 for both pickled and salted chili peppers, as salt was not utilized by microbes during fermentation24. Notably, the salt content in salted chili peppers (20.45 g/100 g) was nearly 4 times than that of pickled chili peppers (5.28 g/100 g) on days 45. Because salted chili peppers were preserved primarily through salt, while pickled ones relied on both salt and acid, necessitating a higher addition of salt in salted processing. Further, the aw of salted chili peppers was lower than that of pickled chili peppers due to the higher salt content, measured at 0.785 ± 0.01 on days 456. And as shown in Fig. 2b, the pH on days 45 of pickled and salted chili peppers was 3.71 and 4.49, respectively. As shown in Fig. 2e, the observed decrease in pH over time in pickled chili peppers could be attributed to the acid production by Lactiplantibacillus during fermentation, consistent with findings in Chinese pickled radishes25. The TA in pickled chili peppers was nearly six times higher than that in salted chili peppers, mainly due to the addition of acid during the pickling process and Lactiplantibacillus fermentation.

Physicochemical properties through targeted analysis of pickled and salted chili peppers (a–d); correlation analysis with microbes (e). (P_30 d, P_45 d: pickled chili peppers at 30 days and 45 days; S_30 d, S_45 d: salted chili peppers at 30 days and 45 days). (*, ** and *** indicate p < 0.05, p < 0.01 and p < 0.001, respectively).

Overall, the salt content, aw, and TA content were stable between days 30 and 45, indicating a stable fermented environment over this period. However, the pH of pickled chili peppers fermented for 45 days was lower than those fermented for 30 days, reflecting the effects of Lactiplantibacillus fermentation. Pickled chili peppers had higher acid content and more pronounced sourness, while salted chili peppers had higher salt content and more salty taste.

Monosaccharides and organic acids

As shown in Fig. 2c, the galactose, glucose and fructose contents of both pickled and salted chili peppers at day 45 were lower than those at day 30 because of their provision of energy for microbial fermentation and continued utilization by Lactiplantibacillus and Weissella26.

Eleven common organic acids were analyzed, including acetic acid, chlorogenic acid, D-(-)-quinic acid, citric acid, caffeic acid, ascorbic acid, aconitic acid, malic acid, L-lactic acid, vanillic acid and succinic acid. Among these organic acids, the content of acetic acid, D-(-)-quinic acid, citric acid, ascorbic acid, malic acid, L-lactic acid and succinic acid were higher than the other four organic acid, which were derived from materials or prduced byfermentation. Furthermore, the levels of four organic acids, acetic acid, citric acid, L-lactic acid and succinic acid, were significantly higher in pickled chili peppers, contributing to their enhanced sourness27, of which L-lactic acid and acetic acid were only detected in pickled chili peppers. Thus, as shown in Fig. 2e, the higher contents of four organic acids in pickled chili peppers were attributed to the exogenous addition of citric and acetic acids, as well as acid production by Lactiplantibacillus through both homo- and hetero-fermentation processes28.

In summary, glucose and fructose were the main sources of energy required for microbial fermentation. Besides, glucose and fructose were the main sources of sweetness in fermented chili peppers. Pickled chili peppers had a greater variety and content of organic acids, with L-lactic, acetic, citric and succinic acids being the main characteristic acidic substances.

Nitrite and biogenic amines

Figure 2d presented indicators related to safety during fermentation, including nitrite and nine biogenic amines. The nitrite content in pickled and salted chili peppers was ranged from 0.22-0.28 mg/kg, well below the limit of 20 mg/kg set by the Chinese national standard29. Tryptamine, phenylethylamine, and histamine were not detected. In pickled chili peppers, the content of putrescine, cadaverine, octopamine, tyramine, spermidine and spermine was approximately 6–15 mg/kg on day 30, decreasing to 0.7–2.6 mg/kg by day 45. In salted chili peppers, the content of putrescine, cadaverine, tyramine, spermidine, and spermine was around 0.2–4 mg/kg on day 30 and remained at about 0.5–4 mg/kg on day 45. Overall, the content of biogenic amines was significantly lower than the 750 mg/kg threshold30, indicating that both pickled and salted chili peppers met the safety standards for food consumption.

Furthermore, as shown in Fig. 2e, the content of biogenic amines in pickled chili peppers was higher than that in salted ones due to the higher percentage of LAB (Lactiplantibacillus) among microbial communities. Because studies reported that Lactiplantibacillus and Pediococcus were the main LAB which possessed the amino acid decarboxylase gene that was responsible for producing biogenic amines20,31. Some strains of Lactiplantibacillus and Pediococcus have been shown to degrade biogenic amines through the action of amine oxidase enzymes, as observed in wine and soy sauce32. Therefore, a 45-day fermentation was preferable, as it had lower content of biogenic amines compared to 30 days.

The composition of total volatile substances

As shown in Fig. 3a, b, the volatile substances of pickled and salted chili peppers fermented for 30 and 45 days were different. Further, the volatile substances of chili peppers fermented for 30 and 45 days were analyzed comparatively using the screening criteria of FC > 2 and p < 0.05, and it was found that chili peppers fermented for 45 days contained more volatile substances (as shown in the yellow highlighted part in the volcano diagram), especially the salted peppers. Therefore, in this paper, we chose the chili peppers fermented for 45 days as samples to further study their volatile substances. As Fig. 3c presented, there were eight types of volatile substances identified in pickled and salted chili peppers: ester, alkane, olefin, alcohol, phenol, ketone, aldehyde, and acid. In addition, as shown in Fig. 3d, esters and alcohols presented the highest content of all volatile substances. Previous studies have also reported that esters were the predominant volatile substances in fermented chili peppers6,33.

Volatile substances of pickled and salted chili peppers at 30 and 45 days: analysis of differences by volcano plots (FC > 2, p < 0.05) (a, in pickled ones; b, in salted ones); composition and classification of volatile substances (c, d); correlation analysis with microbes (e, in pickled ones; f, in salted ones). (*, ** and *** indicate p < 0.05, p < 0.01 and p < 0.001, respectively).

The shared volatile substances in pickled and salted chili peppers

Among 64 volatile substances, a total of 29 volatile substances were detected in both pickled and salted chili peppers (as listed in Table S1). Among them, 7 volatile substances significantly contributed to the flavor of fermented chili peppers, as indicated by their OAV > 1. These included methyl salicylate, methyl palmitate, linalool, phenethyl alcohol, benzyl alcohol, β-ionone, and (Z)-β-ocimene, which have been frequently identified as key volatile substances in both fermented and fresh chili peppers11,34. Furthermore, as shown in Figs. 3e and 3f, among 7 volatile substances, none was found to be significantly correlated with Lactiplantibacillus and Weissella, so these volatile substances may be related to raw materials of fresh chili peppers. These substances imparted a range of flavors, including peppermint, citrus, honey, woody, and floral notes11,34,35,36.

The unique volatile substances in pickled and salted chili peppers

As Table 1 shown, there were 20 volatile substances only detected in pickled chili peppers, which could regard as the unique volatile substances of pickled chili peppers. And there were 6 volatile substances with OAV > 1 that could be used as key unique volatile substances in pickled chili peppers, and they were ethyl 2-hydroxybenzoate (OAV = 59.95), dihydro-β-ionone (OAV = 77), guaiacol (OAV = 245.83), 2-methoxy-4-methylphenol (OAV = 14.67), β-myrcene (OAV = 79.17) and geraniol (OAV = 303.64), providing sweet and fruity37, violet and citrus38, smoky and woody39, strong lilac40, and spicy aroma11. Among them, two of the terpenoids, geraniol and β-myrcene, were significantly and positively correlated with Lactiplantibacillus, because Lactiplantibacillus produced acids such as L-lactic acid during fermentation, which could damage plant cells and lead to the release of terpenoids. Lactiplantibacillus possessed terpene synthases, involved in terpene biosynthesis and biochemical reactions41.

As Table 2 shown, 25 volatile substances were exclusively found only in salted chili peppers, which could be regarded as the unique volatile substances of salted chili peppers. Among them, a total of 3 volatile substances of OAV > 1, 4-ethylphenol, 4-ethyl-2-methoxyphenol, and 2-methoxy-4-vinylphenol, were found to provide strong phenolic, sweet vanilla and lightly fruity aroma42,43,44. However, as Fig. 3f shown, no substance in salted chili peppers was found to be significantly and positively correlated with Weissella. This suggested that the changes in volatile substances in salted chili peppers were mainly related to salting and weakly related to LAB fermentation. After chopping and salting, a large amount of phenolic acids, tyrosine, and other substances in chili peppers were released, which may be metabolized and converted into 4-ethylphenol, 4-ethyl-2-methoxyphenol, and 2-methoxy-4-vinylphenol through enzymatic reaction45. In addition, due to the strong salt tolerance of yeast, the above three substances may also be obtained through fermentation with salt tolerant yeast46.

The composition of total non-volatile substances

As shown in Fig. 4a, b, the non-volatile substances of chili peppers fermented for 30 and 45 days were analyzed comparatively using the screening criteria of FC > 2 and p < 0.05, and it was found that there was no difference in non-volatile substances between 30 and 45 days fermented chili peppers. In keeping with the study of volatile substances, we selected 45-day fermentation samples for analysis of non-volatile substances.

Non-volatile substances of pickled and salted chili peppers at 30 and 45 days: analysis of differences by volcano plots (FC > 2, p < 0.05) (a, in pickled ones; b, in salted ones); composition and classification of non-volatile substances (c); correlation analysis with microbes (d, in pickled ones; e, in salted ones). (*, ** and *** indicate p < 0.05, p < 0.01 and p < 0.001, respectively).

As Fig. 4c presented, there were nine types of non-volatile substances identified in pickled and salted chili peppers: phenylpropanoids and polyketides, organic acids and their derivatives, organoheterocyclic substances, organic nitrogen substances, nucleosides, nucleotides and their analogues, organic oxygen substances, benzenoids, lipids and lipid-like molecules and homogeneous. Phenylpropanoids and polyketides were the most non-volatile substances, which contributed to the properties of antioxidant activity47. The organic acids and derivatives in chili peppers mainly consisted with amino acids, peptides and their analogues, which were responsible for the umami flavor and nutrition34. As for the other kinds of substances with less abundance in chili peppers, they were closely related to life activities.

The novel non-volatile substances in fermented chili peppers

As shown in Fig. 5, 11 non-volatile substances were detected for the first time in fermented chili peppers. Among them, 6 substances belonged to phenylpropanoids and polyketides, including 4-O-β-D-glucosyl-4-coumaric acid, apigenin 6,8-digalactoside, isorhamnetin 3-galactoside, 3-phenyllactic acid, DL-p-hydroxyphenyllactic acid and 6”-malonylgenistin, which were generally proven to have antioxidant and anti-inflammatory properties.

Besides, 4 substances belonged to peptides, including Ne, Ne, Ne trimethyllysine, 1-methyl-L-α-aspartyl-L-phenylalanate, Gly-Leu and isoleucylisoleucine, which may enhance the nutritional value, and had a positive impact on the flavor and taste of fermented chili peppers34. For example, Ne, Ne, Ne trimethyllysine is a derivative of lysine that mainly participates in regulating neurotransmitters, lipid metabolism, and immune function48,49,50. 1-Methyl-L-α-aspartyl-L-phenylalanate is a methyl ester of the dipeptide of the amino acid aspartic acid and phenylalanine51, that may improve cognitive function52. Gly-Leu is a dipeptide of glycine and leucine, which have antioxidant and anti-inflammatory properties to improve the freshness and antioxidant capacity of chili peppers53. Isoleucylisoleucine is a dipeptide composed of isoleucine, which is used to promote the production of glucose to provide immediate energy for the body, so it may have anti fatigue and enhanced exercise endurance effects54.

One of the remaining substances, acetylcholine, belonged to organonitrogen, which is a neurotransmitter that prevents Alzheimer’s disease55.

The shared non-volatile substances in pickled and salted chili peppers

Among the 62 non-volatile substances, a total of 59 shared nonvolatile substances were detected in pickled and salted chili peppers (as listed in Table S2), i.e., the non-volatile substances in pickled and salted chili peppers were almost identical, and it was possible that the non-volatile substances were less affected by the fermentation process, and were mainly related to the varieties of the raw materials of fermented chili peppers. Furthermore, as shown in Fig. 4d, there were two non-volatile substances with significantly positive correlation with Lactiplantibacillus, namely naringenin and trans-ferulic acid, which could be regarded as characteristic non-volatile substances of pickled chili peppers fermented with Lactiplantibacillus. It has been shown that Lactiplantibacillus could produce glycosidic bond cleavage enzymes that broke down naringenin-7-O-rutinoside into naringenin, which had higher bioavailability56. Similarly, Lactiplantibacillus was able to convert polyphenols into active phenolic metabolites such as trans-ferulic acid57.

The unique non-volatile substances in pickled chili peppers

As Table S2 shown, there were three non-volatile substances only detected in pickled chili peppers, namely 3-phenyllactic acid, DL-p-hydroxyphenyllactic acid and acetycholine. 3-Phenyllactic acid and DL-p-hydroxyphenyllactic acid are aromatic and phenolic acids that result from the catabolism of phenylalanine by Lactiplantibacillus58,59,60. Research indicated that Lactiplantibacillus can produce acetylcholine through esterification, enhancing its biological activity61. What’s more, DL-p-hydroxyphenyllactic acid had significantly positive correlation with Lactiplantibacillus, which could be regarded as characteristic non-volatile substance of pickled chili peppers fermented with Lactiplantibacillus. However, as Fig. 4e shown, there was no non-volatile substance with positive correlation with Weissella.

Antioxidant activities of pickled and salted chili peppers

The DPPH values of pickled chili peppers fermented for 30 and 45 days were 2.16 ± 0.09 mmol/kg and 2.00 ± 0.03 mmol/kg, respectively, while those of salted chili peppers were 2.07 ± 0.22 mmol/kg and 1.93 ± 0.05 mmol/kg, respectively. Therefore, it was found that there was no significant difference in DPPH values between pickled and salted chili peppers (p > 0.05). In addition, the FRAP values of pickled chili peppers fermented for 30 and 45 days were 14.65 ± 0.58 mmol/kg and 12.96 ± 2.10 mmol/kg, respectively, and the FRAP values of salted chili peppers were 7.91 ± 0.45 mmol/kg and 6.44 ± 0.37 mmol/kg, respectively. Therefore, it was found that the FRAP values of pickled chili peppers were significantly higher than those of salted chili peppers (p < 0.001).

Rumpf et al. 62 found that DPPH values indicated the antioxidant activity of hydrophobic substances, and the FRAP values indicated the antioxidant activity of hydrophilic substances. Therefore, fermented chili peppers had a high content of hydrophilic antioxidant substances, such as phenylpropanoids and polyketides. What’s more, it indicated that the content of hydrophilic antioxidant substances in pickled chili peppers was higher than that in salted chili peppers. The results in 2.3 and 2.11 found that the substances with high content in pickled chili included citric acid, acetic acid, succinic acid, L-lactic acid, 3-phenyllactic acid, DL-p-hydroxyphenyllactic acid and acetycholine, which all had certain antioxidant activity as hydrophilic substances. This may be the reason why pickled chili peppers had better antioxidant activity related to FRAP.

Methods

Samples collection

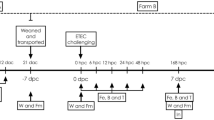

As shown in Fig. 6, approximately 13 tons of chili peppers were fermented in a brine solution. The 38-ton fermentation system, comprising both chili peppers and brine, included 85 kg of salt, 0.5 kg of sodium metabisulfite, 6 kg of citric acid, 4 kg of acetic acid, and 3 kg of calcium chloride per ton to maintain adequate salinity and acidity. The fermentation pool was then sealed with a plastic sheet and sticks for either 30 or 45 days. During the initial 7 days, the brine was circulated using a machine to ensure thorough mixing of the additives with the water. Additionally, salted chili peppers were prepared by mixing chopped chili peppers with salt (8:2, w/w) and fermenting them in a three-layer nylon bag for either 30 or 45 days. This bag consisted of an innermost plastic layer for food contact, a black plastic layer in the middle for UV blocking, and a coarse woven layer on the outside for dust protection, oxygen-proofing, and insulation.

In this study, we collected pickled chili pepper samples (P_30 d/45 d) and salted chili pepper samples (S_30 d/45 d) after 30 and 45 days of fermentation. And we selected three pools of pickled chili peppers and three bags of salted chili peppers as biological replicates. The samples were collected using sterile sampling bags, with a portion of the samples immediately used for water activity, salt content, pH, and TA determination after collection, and a portion of the samples stored in a refrigerator at −80 °C for the determination of remaining indicators.

Aw and salt content

The determination of aw was conducted using a fast aw meter (HD-4, Huake Instrument Co., Wuxi, China). The method for determining salt content adhered to research of Peng et al. 6, with revisions made to the sample pre-treatment procedure. Specifically, 5 g of crushed samples (accurate to 0.01 g) were placed in a 100 mL stoppered cuvette, followed by the addition of 50 mL of hot water at 70 °C. The mixture was sonicated for 20 minutes, allowed to cool to room temperature (20–25 °C), then diluted with water to a final volume of 100 mL and shaken thoroughly. Subsequently, 5 mL of the test solution was pipetted into a 250 ml triangular flask, to which 50 ml of water and 1 mL of 10% potassium chromate solution were added. While shaking, drops of silver nitrate standard titration solution (0.1 mol/L) were added until the color changed from yellow to orange, maintaining the color for 1 min without fading. The volume of silver nitrate standard titration solution consumed was recorded. Each sample underwent three biological replicates and two extraction replicates.

pH and TA

The pH was determined following the method of Wen et al. 63. The juice from the crushed sample was extracted using three layers of gauze, and the pH electrode (PHS-3E, Shanghai Yidian Scientific Instrument Co., Shanghai, China) was immersed in the specimen for measurement.

TA was determined using the acid-base indicator titration method. A 10 g sample (accurate to 0.01 g) was weighed into a 250 mL volumetric flask, followed by the addition of 50 mL of water at 80 °C. The mixture was thoroughly mixed and then placed in a boiling water bath for 20 minutes, with shaking 2–3 times to ensure complete dissolution of all organic acids in the solution. After cooling to room temperature (20–25 °C), the solution was diluted to 250 mL with water and shaken well. Subsequently, 10 mL of the test solution was pipetted into a 250 mL triangular flask, to which 50 mL of de-carbonated purified water was added, along with 3 drops (10 g/L) of phenolphthalein indicator. The solution was titrated with 0.1 mol/L sodium hydroxide standard titrimetric solution until a slight red color persisted for 30 s without fading, and the volume of the 0.1 mol/L sodium hydroxide titrimetric solution consumed was recorded. Each sample was analyzed with three biological replicates and two extraction replicates.

Monosaccharides

A sample weighing 2.50 g (accurate to 0.01 g) was placed into a 50 mL plastic centrifuge tube, to which 25 mL of ultrapure water was accurately added. The mixture was subjected to ultrasonic treatment for 30 min at 20 °C, followed by centrifugation at 12,000 × g for 15 minutes at 20 °C. The supernatant was diluted ten-fold and then filtered through the 0.22 µm aqueous PES membrane. Each sample included three biological replicates and two extraction replicates.

IC (ICS 3000 + , ThermoFisher Scientific, USA) method for monosaccharides determination was based on the research of Wang et al. 64.

Organic acids

Organic acids content was determined following the method of Wen et al. 65 with modifications. Ground samples were prepared using a freeze grinder (Ikea Co, Sweden) with liquid nitrogen. Approximately 1 g (accurate to 0.0001 g) of ground samples were transferred into a 5 mL centrifuge tube. Extraction was performed by adding 3 mL of 70% methanol solution (v/v) followed by ultrasonic treatment for 10 min. Subsequently, the samples were centrifuged at 10,000 × g and 4 °C for 10 minutes. The supernatant was collected and the residue was subjected to two additional extractions under the same conditions. All extracts were combined, diluted to 10 mL with 70% methanol (v/v), and filtered through a 0.22 µm nylon membrane prior to analysis. A blank test was conducted using the same procedure, and data processing was conducted according to reference.

Organic acids were analyzed using ultra-high performance liquid chromatography-tandem triple quadruple mass spectrometry (UPLC-QqQ-MS/MS) (Waters Xevo TQ-S, Waters Corporation, Massachusetts, USA) equipped with an HSS T3 column (1.8 µm, 2.1 × 150 mm, ACQUITY UPLC® HSS T3, Waters Corporation, Massachusetts, USA). The UPLC conditions included a column temperature of 30 °C, a flow rate of 0.2 mL/min, and an injection volume of 1 μL. Mobile phase A was 0.1% formic acid in water (v/v), and mobile phase B was methanol. The gradient elution conditions were as follows: 0–0.5 min, 2% B; 0.5–4 min, 2–35% B; 4–8 min, 35–50% B; 8–12 min, 50–2% B; 12–16 min 2% B. MS/MS analysis employed electrospray ionization (ESI) in negative ion mode and multiple reaction monitoring (MRM) mode. Optimal daughter ions, cone voltage, and collision energy were determined using standards via intellistart. The desolvation gas temperature was maintained at 550 °C with a gas flow of 1000 L/h, and capillary voltage set at 3.0 kV.

Nitrite and biogenic amine

Nitrite determination was conducted in accordance with the Chinese agriculture industry standards66. Each sample included three biological replicates and two extraction replicates.

For the determination of biogenic amines, the sample pre-treatment and Ultra-performance liquid chromatography (UPLC) (AcquityTM Ultra Performance LC, Waters Corporation, Massachusetts, USA) methods were revised according to Li et al. 67. Weigh 3.00 g (accurate to 0.01 g) of the chili peppers sample into a 50 mL stoppered plastic centrifuge tube, then accurately add 15.00 mL of 0.1 mol/L HCl solution. Sonicate the mixture for 15 min at 20 °C, followed by centrifugation at 12,000 × g and 4 °C for 15 min. Take 1 mL of the supernatant or 1 mL of the biogenic amine standard solution in a 15 mL centrifuge tube. Next, add 200 µl of 2 mol/L NaOH to alkalinize the solution. Subsequently, add 300 µL of saturated sodium bicarbonate solution for buffering, followed by the addition of 1 mL of 10 mg/mL dansulfonyl chloride solution (dissolved in acetone). Vortex the mixture for 1 minute in the dark and incubate in a 40 °C water bath for 45 min. After incubation, add 100 µL of concentrated ammonia and place the mixture in a dark environment for 30 minutes to interrupt the reaction and remove excess dansulfonyl chloride. The solution was then subjected to nitrogen blowing to reduce the volume to approximately 1–1.5 mL. Finally, add acetonitrile to reach a final volume of 2 mL and filter through a 0.22 µm organic filter membrane (PTFE) before proceeding to UPLC analysis. The UPLC conditions were as follows: the column was an EC-C18 (100 mm × 3.0 mm, 2.7 μm) from Agilent (California, USA), with a column temperature set at 30 °C and a detection wavelength of 254 nm. The sampling volume was 10 µL, and the flow rate was maintained at 0.4 mL/min. The mobile phases consisted of 5 mM ammonium acetate solution (solvent A) and acetonitrile (solvent B), with the elution gradient as follows: 0–5 min, 40% A; 5–12 min, 40–25% A; 12–20 min, 25–5% A; 20–22 min, 5% A; 22–22.1 min, 5–40% A; and 22.1–25 min, 40% A. The concentration of the standard solution, all solution configurations, and final calculations were referenced according to Li et al. 67. Each sample included three biological replicates and two extraction replicates.

Volatile substances analysis by GC-MS

The volatile substances were identified and quantified using gas chromatography mass spectrometry (GCMS) with reference to the method of Peng et al. 6, with pre-treatment protocols adapted from our research: 0.5 g (accurate to 0.0001 g) of the sample was weighed into a 20 mL glass vial, followed by the addition of 20 μL of 2-methyl-3-heptanone (104-fold dilution) as an internal standard. Each sample consisted of three biological replicates and two extraction replicates.

Non-volatile substances analysis by HPLC-qTOF-MS

Chili peppers were crushed using a Freeze Grinder (Ikea Co, Sweden) after being frozen with liquid nitrogen. A weight of 3 g (accurate to 0.0001 g) of chili pepper powder was measured and mixed with 15 mL of methanol-water solution (7:3, v/v), followed by vortexing. The mixture was allowed to stand in an ice bath for 12 h. Subsequently, the solution was centrifuged at 8000 rpm and 4 °C for 10 min, and the supernatant was filtered through a 0.22 µm nylon membrane into a liquid-phase vial, which was then stored at −80 °C for injection. Quality control (QC) samples were prepared by combining all the sample solutions to be tested in equal proportions. Each sample was subjected to three biological replicates and three extraction replicates to collect parent ion information.

Each of the 10 QC samples was fragmented at varying ion fragmentation energies to obtain daughter ion information. The samples were then analyzed using an Agilent 1290 HPLC system (Agilent, Santa Clara, CA, USA) coupled with a Triple TOF G6560B system (Agilent, Santa Clara, CA, USA) featuring an electrospray ionization (ESI) source in both positive and negative modes. In ESI+ and ESI- modes, mobile phases A and B consisted of 0.1% formic acid in water and acetonitrile, respectively. The injection volume was 2 µL. Chromatographic separation was achieved with a BEH C18 column (2.1 × 100 mm, 2.7 µm; Waters Pacific Pte. Ltd., Singapore) at a flow rate of 0.3 mL/min, using the following gradient: 0-2 min, 98% A; 2–2.50 min, 98–82% A; 2.50–6 min, 82–70% A; 6–9.50 min, 70–46% A; 9.50–14.00 min, 46–18% A; 14.00–15.00 min, 18–1% A; 15–15.10 min, 1–98% A; and 15.10–18.00 min, 98% A. The acquired mass range was set to 100–3000 Da for both TOF and product ion scans. The accumulation time was 0.5 s for TOF scans and 0.25 s for product ion scans. The ion fragmentation energies for MS/MS were set at 10, 20, 40, and 60 eV, respectively. The capillary voltage was maintained at 3000 V, the nozzle voltage at 1500 V, and the fragmentor voltage at 380 V. The gas parameters were as follows: gas temperature at 325 °C, nebulizer pressure at 35 psi, gas flow at 7 L/min, sheath gas flow at 11 L/min, and sheath gas temperature at 350 °C. The injection sequence included blanks (ultrapure water), background controls (methanol:water = 7:3, v/v), and three injections of QC samples at the beginning of the sequence to ensure system stability and repeatability. Subsequently, samples were injected randomly into the system to minimize signal drift effects, with a QC sample placed after every six samples. To ensure mass accuracy, automated mass calibration using the Agilent reference solution was performed in real time.

Microbial diversity by next generation sequencing

The study of microbial diversity was referred from Peng et al. 6, and the pretreatment of samples was revised. In a sterile environment, chili pepper samples were cut and mixed. Approximately 1.0 g of chili peppers was weighed into sterile tubes and subsequently stored in a −80 °C refrigerator. Each sample included three biological replicates. The samples were then transported to Majorbio Bio-pharm Technology Co., Ltd (Shanghai, China) on dry ice.

Determination of antioxidant activity

The 2,2-Diphenyl-1-picrylhydrazyl (DPPH) radical scavenging ability and Ferric ion reducing antioxidant power (FRAP) of fermented chili peppers samples were evaluated using DPPH kit (A153-1-1, Nanjing Jiancheng Bioengineering Institute, Nanjing, China) and FRAP kit (S0116, Beyotime Biotechnology, Shanghai, China), and the pretreatment of samples was revised. A weight of 0.1 g (accurate to 0.0001 g) of chili pepper samples was measured and mixed with 1.5 mL of methanol-water solution (8:2, v/v). The results were expressed as trolox equivalents mmol/kg.

Data processing, statistical analysis, and visualization

For the analysis of volatile substances using GC-MS, raw data collection and identification were deconvoluted with Agilent MassHunter Unknown software. Substance screening was conducted with the NIST14 mass spectrum database, applying a quality match score threshold of > 60%. The mean concentration of each volatile substance was semi-quantitatively determined based on the peak area relative to that of the internal standard. For non-volatile substances analyzed by HPLC-qTOF-MS, peak extraction, alignment, and correction were executed using MS-DIAL version 4.36 software. The parameters were configured as follows: MS1 and MS2 tolerances were set at 0.01 Da and 0.05 Da, respectively, for identification settings. Retention time tolerance and MS1 tolerance for peak alignment were established at 0.05 min and 0.015 Da; a peak was considered valid if it had a detection rate exceeding 50% in at least one group, and the signal-to-noise (S/N) ratio (maximum in the sample/mean in the blank sample) was set to 5. The exported MS1 peak list was further analyzed using Microsoft Office Excel 2020 (Microsoft Corporation, USA) to exclude MS1 features with a relative standard deviation (RSD) greater than 30% in the quality control (QC) group68. substance identification was facilitated by MS-FINDER version 3.50, MassHunter PCDL version B.07.00, and LibraryViewTM version 1.1. For 16S rRNA sequencing, data were analyzed using online tools from Majorbio. Data analysis was performed using MetaboAnalyst version 4.0 and SIMCA 14.1. Mean values with relative standard deviation (RSD) were calculated, and statistical analyses were conducted with Microsoft Office Excel 2020 (Microsoft Corporation, USA). The significance of differences was assessed using SPSS® 20.0 software (Chicago, Illinois, USA).

Data availability

No datasets were generated or analysed during the current study.

References

Zou, Z. & Zou, X. Geographical and ecological differences in pepper cultivation and consumption in China. Front. Nutr. 8, 718517 (2021).

Chen, Z. et al. Relationship between microbial community and flavor profile during the fermentation of chopped red chili (Capsicum annuum L.). Food Biosci. 50, 102071 (2022).

Liu, M. et al. Characterisation of flavour profiles and microbial communities of fermented peppers with different fermentation years by combining flavouromics and metagenomics. Food Chem. 443, 138550 (2024).

Wang, X. R. Spicy red in Shrimp Town: Smart farming and settler colonialism in Guizhou province. N. Media Soc. 25, 1888–1912 (2023).

Li, D. et al. Physiochemical, microbiological and flavor characteristics of traditional Chinese fermented food Kaili Red Sour Soup. LWT 142, 110933 (2021).

Peng, S. et al. Microbial community and volatile metabolites related to the fermentation degree of salted fermented chili peppers. Lwt 181, 114752 (2023).

Voidarou, C. et al. Fermentative Foods: Microbiology, biochemistry, potential human health benefits and public health issues. Foods 10, 69 (2020).

Zhang, K. et al. The regulation of key flavor of traditional fermented food by microbial metabolism: A review. Food Chem. X 19, 100871 (2023).

Kwoji, I. D., Aiyegoro, O. A., Okpeku, M. & Adeleke, M. A. Multi-omics’ data integration: applications in probiotics studies. npj Sci. Food 7, 25 (2023).

Gao, Y. et al. Metabolomics approaches for the comprehensive evaluation of fermented foods: A review. Foods 10, 2294 (2021).

Xiao, Y. et al. Characterization of key aroma-active compounds in fermented chili pepper (Capsicum frutescens L.) using instrumental and sensory techniques. Food Chem.: X 23, 101581 (2024).

Li, Y. et al. Quality improvement of fermented chili pepper by inoculation of Pediococcus ethanolidurans M1117: Insight into relevance of bacterial community succession and metabolic profile. Lwt 179, 114655 (2023).

Nor, S. M., Yusof, N. N. M. & Ding, P. Volatile organic compound modification by lactic acid bacteria in fermented chilli mash using GC-MS headspace extraction. IOP Conf. Ser.: Earth Environ. Sci. 765, 012043 (2021).

Leeuwendaal, N. K., Stanton, C., O’Toole, P. W. & Beresford, T. P. Fermented foods, health and the gut microbiome. Nutrients 14, 1527 (2022).

Nithya, A., Misra, S., Panigrahi, C., Dalbhagat, C. G. & Mishra, H. N. Probiotic potential of fermented foods and their role in non-communicable diseases management: An understanding through recent clinical evidences. Food Chem. Adv. 3, 100381 (2023).

Zhao, C. et al. Physicochemical, volatiles, non-volatiles, and microbial dynamics in dried versus traditional fresh red pepper paste fermentation: A comparative study. Food Biosci. 61, 104911 (2024).

Abu-Obeid, I. M. Soft rot disease in Jordan: A Review. Adv. Environ. Biol. 13, 1–6 (2019).

Parvin, S. M. R., Taghavi, S. M. & Osdaghi, E. Field surveys indicate taxonomically diverse Pectobacterium species inducing soft rot of vegetables and annual crops in Iran. Plant Pathol. https://doi.org/10.1111/ppa.13735 (2022).

Zhang, Z. et al. Bacterial diversity and its correlation with sensory quality of two types of zha-chili from Shennongjia region, China. Food Res. Int. 168, 112789 (2023).

Hao, Y. & Sun, B. Analysis of bacterial diversity and biogenic amines content during fermentation of farmhouse sauce from Northeast China. Food Control 108, 106861 (2020).

Wang, J. et al. Analysis of bacterial diversity during fermentation of Chinese traditional fermented chopped pepper. Lett. Appl. Microbiol. 69, 346–352 (2019).

Chen, M. et al. Illumina MiSeq sequencing reveals microbial community succession in salted peppers with different salinity during preservation. Food Res. Int. 143, 110234 (2021).

Joghataei, M., Shahidi, F., Pouladfar, G., Mortazavi, S. A. & Ghaderi, A. Probiotic potential comparison of Lactobacillus strains isolated from Iranian traditional food products and human feces with standard probiotic strains. J. Sci. Food Agriculture 99, 6680–6688 (2019).

Chun, B. H., Kim, K. H., Jeong, S. E. & Jeon, C. O. The effect of salt concentrations on the fermentation of doenjang, a traditional Korean fermented soybean paste. Food Microbiol. 86, 103329 (2020).

Tang, Y. et al. Effects of dry-salting and brine-pickling processes on the physicochemical properties, nonvolatile flavour profiles and bacterial community during the fermentation of Chinese salted radishes. Lwt 157, 113084 (2022).

Wang, Z., Ji, X., Wang, S., Wu, Q. & Xu, Y. Sugar profile regulates the microbial metabolic diversity in Chinese Baijiu fermentation. Int. J. Food Microbiol. 359, 109426 (2021).

Xiao, M. et al. Correlation between microbiota and flavours in fermentation of Chinese Sichuan Paocai. Food Res. Int. 114, 123–132 (2018).

Ye, Z. et al. Dynamic analysis of flavor properties and microbial communities in Chinese pickled chili pepper (Capsicum frutescens L.): A typical industrial-scale natural fermentation process. Food Res. Int. 153, 110952 (2022).

Luo, W. et al. Regulation of the nitrite, biogenic amine and flavor quality of Cantonese pickle by selected lactic acid bacteria. Food Biosci. 53, 102554 (2023).

Omer, A. K., Mohammed, R. R., Ameen, P. S. M., Abas, Z. A. & Ekici, K. Presence of biogenic amines in food and their public health implications: A review. J. Food Prot. 84, 1539–1548 (2021).

Bartkiene, E. et al. Changes of bioactive compounds in barley industry by‐products during submerged and solid state fermentation with antimicrobial Pediococcus acidilactici strain LUHS29. Food Sci. Nutr. 8, 340–350 (2020).

García-Ruiz, A., González-Rompinelli, E. M., Bartolomé, B. & Moreno-Arribas, M. V. Potential of wine-associated lactic acid bacteria to degrade biogenic amines. Int. J. Food Microbiol. 148, 115–120 (2011).

Xu, X. et al. Shifts in autochthonous microbial diversity and volatile metabolites during the fermentation of chili pepper (Capsicum frutescens L.). Food Chem. 335, 127512 (2021).

Liu, Z. et al. A systematic review on fermented chili pepper products: Sensorial quality, health benefits, fermentation microbiomes, and metabolic pathways. Trends Food Sci. Technol. 141, 104189 (2023).

Wang, Q. et al. Identification and characterization of the key volatile flavor compounds in black teas from distinct regions worldwide. J. Food Sci. 87, 3433–3446 (2022).

Yang, W. et al. Changes in nutritional composition, volatile organic compounds and antioxidant activity of peach pulp fermented by lactobacillus. Food Biosci. 49, 101894 (2022).

Yu, E. et al. Proteomic and metabolomic basis for improved textural quality in crisp grass carp (Ctenopharyngodon idellus C.et V) fed with a natural dietary pro-oxidant. Food Chem. 325, 126906 (2020).

Valverde, D., Behrends, B., Pérez-Esteve, É., Kuhnert, N. & Barat, J. M. Functional changes induced by extrusion during cocoa alkalization. Food Res. Int. 136, 109469 (2020).

Wang, H. & Chambers, E. Sensory characteristics of various concentrations of phenolic compounds potentially associated with smoked aroma in foods. Molecules 23, https://doi.org/10.3390/molecules23040780 (2018).

Pérez-Gálvez, A., Viera, I., Benito, I. & Roca, M. HPLC-hrTOF-MS study of copper chlorophylls: Composition of food colorants and biochemistry after ingestion. Food Chem. 321, 126721 (2020).

Mandha, J. et al. Effect of lactic acid fermentation on volatile compounds and sensory characteristics of mango (Mangifera indica) juices. Foods 11, 383 (2022).

Miossec, C., Mille, T., Lanceleur, L. & Monperrus, M. Simultaneous determination of 42 pharmaceuticals in seafood samples by solvent extraction coupled to liquid chromatography–tandem mass spectrometry. Food Chem. 322, 126765 (2020).

Lu, F. et al. Early-life polyphenol intake promotes Akkermansia growth and increase of host goblet cells in association with the potential synergistic effect of Lactobacillus. Food Res. Int. 149, 110648 (2021).

Senosy, I. A. et al. Magnetic solid-phase extraction based on nano-zeolite imidazolate framework-8-functionalized magnetic graphene oxide for the quantification of residual fungicides in water, honey and fruit juices. Food Chem. 325, 126944 (2020).

Zhang, Y. et al. Improving Soy Sauce Aroma Using High Hydrostatic Pressure and the Preliminary Mechanism. Foods 11, 2190 (2022).

Feng, L., Wang, S. & Chen, H. Research progress on volatile compounds and microbial metabolism of traditional fermented soybean products in China. Food Biosci. 61, 104558 (2024).

Cho, S.-Y. et al. Antioxidant and Anti-Inflammatory Activities in Relation to the Flavonoids Composition of Pepper (Capsicum annuum L.). Antioxidants 9, 986 (2020).

Günay, Ç. et al. Shared biological pathways and processes in patients with intellectual disability: a multicenter study. Neuropediatrics 54, 225–238 (2023).

Oktaviono, Y. H. et al. The roles of trimethylamine-N-oxide in atherosclerosis and its potential therapeutic aspect: A literature review. Biomol. Biomed. 23, 936–948 (2023).

Shi, W., Cheng, Y., Zhu, H. & Zhao, L. Metabolomics and lipidomics in non-small cell lung cancer. Clin. Chim. Acta 555, 117823 (2024).

Aborhyem, S. M., Khamise, N. A. & Tayel, D. I. Potential effect of high consumption of artificial sweeteners on glucose homeostasis and complete blood count in male albino rats. Int. J. Pharma. Sci. Res. https://doi.org/10.13040/IJPSR.0975-8232.13(9).3561-71 (2022).

Alamgir, A. N. M. Vitamins, Nutraceuticals, Food Additives, Enzymes, Anesthetic Aids, and Cosmetics, bookTitle= Therapeutic Use of Medicinal Plants and their Extracts: Volume 2: Phytochemistry and Bioactive Compounds. (Springer International Publishing, 2018).

Prakash, M. D. et al. Anti-Cancer Effects of Carnosine-A Dipeptide Molecule. Molecules 26, 1644 (2021).

Chen, H. et al. A multi-ingredient formula ameliorates exercise-induced fatigue by changing metabolic pathways and increasing antioxidant capacity in mice. Foods 10, 3120 (2021).

Goh, Y. Q., Cheam, G. & Wang, Y. Understanding choline bioavailability and utilization: first step toward personalizing choline nutrition. J. Agric. Food Chem. 69, 10774–10789 (2021).

Guo, X., Cao, X., Fang, X., Guo, A. & Li, E. Inhibitory effects of fermented Ougan (Citrus reticulata cv. Suavissima) juice on high-fat diet-induced obesity associated with white adipose tissue browning and gut microbiota modulation in mice. Food Funct. 12, 9300–9314 (2021).

Shi, H. et al. The potential of lactic acid bacteria in fermented herbs-derived food products. Food Biosci. 61, 104714 (2024).

Xu, J.-J., Sun, J.-Z., Si, K.-L. & Guo, C.-F. 3-Phenyllactic acid production by Lactobacillus crustorum strains isolated from naturally fermented vegetables. Lwt-Food Sci. Technol. 149, https://doi.org/10.1016/j.lwt.2021.111780 (2021).

Lipinska-Zubrycka, L. et al. Anticandidal activity of Lactobacillus spp. in the presence of galactosyl polyols. Microbiol. Res. 240, 126540 (2020).

Lee, S.-J., Jeon, H.-S., Yoo, J.-Y. & Kim, J.-H. Some Important Metabolites produced by lactic acid bacteria originated from Kimchi. Foods 10, 2148 (2021).

Casertano, M., Fogliano, V. & Ercolini, D. Psychobiotics, gut microbiota and fermented foods can help preserving mental health. Food Res. Int. 152, 110892 (2022).

Rumpf, J., Burger, R. & Schulze, M. Statistical evaluation of DPPH, ABTS, FRAP, and Folin-Ciocalteu assays to assess the antioxidant capacity of lignins. Int. J. Biol. Macromol. 233, 123470 (2023).

Zheng, Y. et al. The effect of dielectric barrier discharge plasma gas and plasma-activated water on the physicochemical changes in button mushrooms (Agaricus bisporus). Foods 11, 3504 (2022).

Wang, B. et al. Development and validation of an analytical method for the quantification of arabinose, galactose, glucose, sucrose, fructose, and maltose in fruits, vegetables, and their products. Food Anal. Methods 14, 1227–1238 (2021).

Mingchun, W. et al. Monitoring of pickled tea during processing: From LC-MS based metabolomics analysis to inhibitory activities on α-amylase and α-glycosidase. J. Food Composition Anal. 117, 105108 (2023).

GB 5009.33-2016, In Determination of nitrite and nitrate in national food safety standard, Standardization Administration of China, (2016).

Li, J. et al. Fermented minced pepper by high pressure processing, high pressure processing with mild temperature and thermal pasteurization. Innovative Food Sci. Emerg. Technol. 36, 34–41 (2016).

Wang, K., Zhao, Y., Xu, L., Liao, X. & Xu, Z. Health outcomes of 100% orange juice and orange flavored beverage: A comparative analysis of gut microbiota and metabolomics in rats. Curr. Res. Food Sci. 6, 100454 (2023).

Acknowledgements

This work was supported by Special National Key Research and Development Plan (2021YFD1600100), China Agriculture Research System of MOF and MARA, Professor Workstation of China Agricultural University and Guisanhong Food Company, and the 2115 Talent Development Program of China Agricultural University.

Author information

Authors and Affiliations

Contributions

Jiayue Xu: Conceptualization, Data Curation, Formal analysis, Investigation, Methodology, Validation, Writing-original draft. Zhiyuan Zeng: Writing-original draft, Validation. Xiaolei Zheng: Investigation, Validation. Zejun Chu: Investigation. Sijia Peng: Investigation, Methodology. Dong Yang: Investigation, Methodology. Siwei Wu: Funding acquisition, Project administration. Liang Zhao: Conceptualization, Funding acquisition, Project administration, Resources, Supervision, Writing-review and editing. Xiaojun Liao: Conceptualization, Funding acquisition, Project administration, Resources, Supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xu, J., Zeng, Z., Zheng, X. et al. Mining of characteristic microbes and qualities in pickled and salted chili peppers through integrated analysis. npj Sci Food 9, 77 (2025). https://doi.org/10.1038/s41538-025-00442-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41538-025-00442-7