Abstract

A large portion of foodborne outbreaks are associated with leafy greens, including by the pathogen Listeria monocytogenes. Small and medium-sized leafy green growers commonly retrofit washing machines to dry triple-washed leaves, utilizing their spin cycle. The potential for this practice to cause microbial contamination has not been explored. This work investigated the risk of cross-contamination of Listeria associated with this practice. Listeria innocua was inoculated and dried onto spinach prior to washing, after which leaves were dried in a retrofitted washing machine. After drying, three contact surface layers of the machine were sampled. Nearly complete recovery of 98% and 99% from some contact points were observed, with the highest level of recovery observed in the bottom water-collecting contact points of the machine. Further, L. innocua from contaminated loading baskets were transferred to uninoculated spinach during the spin-drying process with a microbial recovery of 101–102 CFU/g, suggesting a risk of cross-contamination.

Similar content being viewed by others

Introduction

The CDC has reported that 16% of identified foodborne outbreaks are associated with produce, and amongst those, vegetable row crops such as leafy greens comprise 46% of the illnesses1. In part, the prevalence of produce-associated outbreaks is due to the fact that produce is often consumed raw, and is often not processed with a thermal inactivation step that can remove microbial contamination; therefore, it is imperative that Good Agricultural Practices (GAP) are used on-farm to reduce the produce safety risk. Microbial contamination of fresh produce can occur at multiple stages throughout the farm-to-fork chain2; during the cultivation of fresh produce, at harvest, during preparation/washing, within distribution chains and transport to shops, and during preparation3.

Listeria monocytogenes is a leading cause of foodborne death, often causing illness in neonates, pregnant women, and immunocompromised adults (CDC), and has also been associated with produce outbreaks4,5,6. The environment where produce is manipulated, such as food contact surfaces or equipment used in processing, can also play a role in L. monocytogenes contamination7. For example, reusable crates have been shown to be a potential source of cross-contamination among different batches of leafy greens8.

Recognizing the impact and effects of foodborne illness, the Food Safety Modernization Act was passed to improve and supervise food safety standards in the United States9. The implication of this act prioritized preventative measures to avoid the recurrence of foodborne outbreaks10. The management and the implementation of the regulations include worker training, recordkeeping, traceability practices, hazard analysis, monitoring procedures, and sanitary equipment design and maintenance11. The efficiency of the implementation of FSMA depends on the size and scope of the operation. Small-scale producers and farmers account for 91% of farms but only 23% of agricultural production12. The implementation of the changes to fulfill the requirements of the regulations will require substantially costly changes to every aspect of their practices. Hence, FSMA has specific qualifications for small farms to obtain differential treatment, however, the eligibility to obtain this exemption has been made stricter than originally intended11. This implementation requires the farmers to have standardized sanitation and equipment handling SOP’s for all food handling equipment’s. This includes commonly used food handling equipment’s as well as the use of cost-efficient retrofitted machines. However, the use of retrofitted machines involves an adapted process that does not include the standard safety protocols, handling documentation, or resources typically available. One such practice of concern is the use of do-it-yourself (DIY) washing machines to dry washed leafy greens, a practice increasingly being used by some of the nearly 1000 small scale and medium scale farmers13. Postharvest handling of leafy greens in large-scale facilities includes a series of steps whereby the produce is initially triple-washed to remove field heat and debris, followed by drying in a controlled environment where the air temperature, air speed and humidity levels are constantly monitored. With larger commercial operations, the drying is conducted in constantly moving belts or in commercial machines that utilize centrifugal forced spin cycle rotational force to dry the leafy greens. However, the cost of acquiring and using the necessary equipment is often too high for small and medium-scale producers. Alternatively, these producers have increasingly begun retrofitting washing machines by disassembling them and replacing the barrel of the machine with crates to turn the machine into a large salad spinner using its spin cycle (Fig. 1). Retrofitted washing machines also have the additional benefit of a brake system which helps with having controlled spinning movements at regular intervals while drying the leafy greens. Utilizing retrofitted washing machines is cost-efficient and has an effective production speed for drying leafy greens. However, the potential for the use of these retrofitted washing machines to contribute to contamination and/or cross-contamination of leafy greens has not been investigated. Although the recently implemented Food Safety Modernization Act (FSMA) Produce Safety Rule (PSR) does not prohibit the use of these retrofitted machines for drying leaves, there is a need to conduct a science-based risk hazard identification that helps in development of specific best practices to inform guidance for small and medium-sized producers to stay in compliance with the new rule3. The purpose of this study was to investigate the potential of retrofitted washing machines to result in contamination and cross-contamination of leafy greens with Listeria, as well as characterize the nature of such contamination if it occurs.

Results

Determination of the degree of contamination from inoculated produce to contact points

The purpose of this study was to evaluate the potential of retrofitted washing machines to result in contamination of leafy greens with Listeria. There are a series of steps followed during postharvest handling of spinach, and the wash step is very important as it is imperative for the removal of debris and dirt from the soil. Hence, it was also important to include a wash step during microbiological analysis to evaluate the degree of microbial contamination in the washing machine. From the results, it was seen that there was a loss of 3.19 ± 0.38 log CFU/ml of Listeria innocua in the wash water prior to loading into the retrofitted machines, irrespective of the initial microbial load.

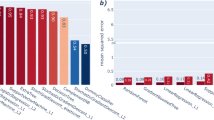

Initial preliminary studies were conducted varying the amount of spinach used in the machine, ranging from 100–500 grams. The specific contact point B2 was chosen to present the data for evaluating the microbial recovery based on varying volume of spinach as shown in Supplementary Table S1. The higher volume of spinach (500 g) added to the machine for spin drying resulted in reduced microbial recovery (Supplementary Table 1). Hence, a consistent volume of 250 g of spinach was chosen for conducting subsequent experimental trials. Initial inoculation studies were conducted using a lower concentration of L. innocua, which closely mimics real contamination conditions. This can be seen in Fig. 1A, when lower microbial concentration of 102 initial inoculation load was used the microbial recovery was lower than limit of detection (<25 CFU/10 cm2) and this was not sufficient to exhibit the extent of spread of immediate microbial contamination throughout the different parts of the machine for experimental purposes. The initial microbial load inoculated on the spinach surface was also lost in the wash water during the washing step prior to spin drying in the retrofitted machine. Hence, this concentration was not chosen for further studies. There are three different layers of the retrofitted machine and three specific sampling points assigned to each layer for swabbing. as depicted in Fig. 1B. The highest level of contamination when using inoculated spinach leaves was observed on the three bottom most contact points of the machine, such as B1, B2, B3 as well as from the immediate contact points L1 and R1 (Fig. 1A). The degree of microbial recovery was on a higher level irrespective of the logarithmic load of the initial L. innocua microbial culture inoculated onto the spinach surface. There was also a consistent microbial loss of around 3 log CFU/ml of Listeria after the single wash step and prior to adding the inoculated spinach leaves in the retrofitted machine for spin drying and there was a nearly complete recovery of 98% and 99% from 103 and 106 of initial L. innocua on washed leaves loaded into the machine, respectively.

Nearly complete recovery of L. innocua was observed for both 103 and 106 CFU/cm2 initial inoculum loads, respectively (Fig. 2A, B). From all the different contact points, it can be inferred that the highest level of contamination was observed in the B1, B2, and B3 contact points.

A Microbial recovery from the various contact points after inoculation of 103 CFU/cm2 post wash step; B Microbial recovery from the various contact points after inoculation of 106 CFU/cm2 post wash step. Ns not significant difference in the means of the individual groups. *-statistically similar individual means of the groups; LOD- The limit of detection is <25 CFU/10 cm2.

Determination of the degree of contamination from a contaminated washing machine to uninoculated produce

In addition to introducing contaminated spinach into the washing machine, the potential for L. innocua from an environmentally contaminated washing machine to contaminate uninoculated fresh spinach and its degree of spread to other parts of the machine from the initial inoculated contact point was also evaluated. In order to conduct this analysis, the contact points pertaining to the three different layers of the machine were inoculated separately in each experimental analysis. The results from this have shown there was no microbial spread from the contact points that were initially inoculated (B2, L2, R2) to the other non-inoculated contact points of the machine as seen in Fig. 3A Further, no cross-contamination of the uninoculated spinach was observed from the non-direct contact points such as B2, L2, R2 and B3, L3, R3. However, 1 log CFU/g of transfer to the spinach was observed when the orange load basket was contaminated with 3.77 ± 0.29 log CFU of L. innocua as seen in Fig. 3B. This suggests that there are lower possibilities for contamination of greens from the lower layers of the machine, but the potential for cross-contamination from direct contact points of the machine does exist.

Discussion

Cross-contamination has been estimated to be responsible for about 26% of all food safety loss incidents14, and processing operations of produce have been demonstrated to contain multiple points in which cross-contamination can occur11. Foodborne illness outbreaks caused by Listeria monocytogenes have occurred via food sources such as raw fruits and vegetables, raw milk, soft cheeses, deli meat and mushrooms15. The cause for a significant number of these have occurred due to transfer from contaminated food contact surfaces9,16,17. Additionally, Smolinski et al. (2018) and Buchholz et al. (2012) have reported microbial transfer and redistribution during pilot-scale processing of baby spinach, cilantro, and romaine lettuce. The results from the research findings have shown the highest level of inoculum transfer to the wash water, and the second highest product inoculum was lost during centrifugal drying18,19. The increasing use of retrofitted washing machines to dry leafy greens, primarily by small and medium-sized processors, may introduce another point of potential risk in produce processing; however, the degree and potential of this practice to result in contamination had hitherto not been explored. The results of the work reported here do suggest there is potential for both cross-contamination of equipment and greens to occur, using L. innocua as a surrogate.

About a 98–99% of microbial recovery was observed after initial inoculation of 106 and 109 log CFU/cm2 respectively. It should also be noted that there was a consistent loss of 3 log of Listeria innocua post the wash step, irrespective of the level of initial inoculation load. The wash step conducted in this work does not likely mimic that commonly used in industry (i.e., use of only water for only one wash), however the purpose of this work was to focus on the potential of contaminated produce after the wash step to result in transfer of pathogen to the machine and/or other produce. The results of this work suggest that if produce still containing residual load of Listeria is loaded into these machines, the risk of contamination of the machine as well as other produce exists. The goal of this work was to evaluate the potential for cross-contamination to occur in the instance that residual contamination on washed leaves exists when they are loaded into the machines. Because we avoided potential confounding factors like differential formation of biofilms that could influence the amount of bacteria removed during the upstream washing step, a notable amount of bacterial cells were lost in the wash step. Therefore, we required higher initial contamination loads of the leaves than often occur in the initial inoculation step. Further, the data reported here suggest that microbial spread throughout the different parts of the machine was more evenly distributed with a lower initial inoculation load (103 log CFU/cm2); although higher contamination was observed on direct contact points (B1, L1, R1) of the machine was observed when the inoculum was higher (106 log CFU/cm2). It should be noted that Listeria spp. is often found in quantities of <10 CFU/g in contaminated leafy greens, though it may not always be detected if the contamination is low-level or sporadic. In cases of contamination by pathogenic species, such as Listeria monocytogenes, even low counts such as 10–100 CFU/g can be hazardous, especially for at-risk groups like immune- compromised adults, neonates, and pregnant women20,21. More specifically, L. monocytogenes is considered a zero-tolerance organism in food safety testing, meaning that its detection in ready-to-eat foods (like leafy greens) typically results in recalls or other corrective actions, even if concentrations are low22. Thus, the degree to which these direct contact points pose a higher risk relative to other parts of the machine requires further investigation. Regardless of initial inoculum load, the potential for pathogen contamination of the washing machines if Listeria is present on washed leaves being loaded into the machine exists. This is of particular importance for Listeria, as it has been well known to be able to environmentally persist in food processing plants and equipment, often in the form of difficult-to-remove biofilms. The limit of detection of our assay in this work was 25 CFU/10 cm2, and it is likely that cell transfer in other conditions below this LOD was occurring but not in a quantifiable manner.

In addition, a study was also conducted to evaluate the potential for Listeria transfer from an environmentally contaminated washing machine to uninoculated fresh produce. The results presented here suggest that although cross-contamination was not observed at high levels or from the indirect contact points of the machine, some transfer of about 1 log CFU/g was observed from the direct contact points of the machine to spinach, which is a potential concern for Listeria as it has potential to grow in the refrigeration conditions in which the leafy greens are commonly stored. However, a detectable signal was only observed when the direct food contact surfaces of the machine were contaminated, and not from lower levels of the machine. The results here underscore the need to maintain strict sanitation and testing regimes for food contact surfaces in produce processing.

Although the purpose of this study was exploratory, there were a number of limitations. Food contact surfaces are considered high risk even in conditions where the concentration of microorganisms is on the lower side, as the risk is evaluated based on the presence or absence of contamination and not based on the concentration. Hence, natural contamination conditions result in much lower concentrations of microbial enumeration when compared to the concentration used for conducting experimental trials.

The washing of fresh produce is an important step for removing soil and debris and some studies have reported a 1–6 log CFU/ml microbial load reduction on the surface of produce23. However, the use of untreated wash water can increase the risk of spreading contamination as it can be inferred from research conducted by Buchholz et al. and Jensen et al. where the result showed a 90% transfer of inoculum to the wash water and a transfer of 90–99% of the bacteria to the wash water irrespective of the wash time respectively19,23. Similarly, in this work, we conducted a single wash step prior to spin drying the inoculated spinach leaves in the machine and observed a loss of about 3.19 + 0.38 log CFU/ml of Listeria after the wash for all the initial concentrations evaluated. In our research, treated wash water with an antibacterial component already present was not used. Hence, changing the frequency of water, use of treated water, cleaning and the use of food contact surface approved sanitizers are the best practices to reduce the risk of contamination24. However, given the numerous outbreaks of triple-washed leafy greens in the past, the potential for contaminated leaves to be loaded into these machines still exists25,26. Further, the levels of Listeria used may not mimic some instances of contamination of lettuce. Higher levels were evaluated in this study based on the limit of detection of the plating technique we used. It is possible that transfer with initial inoculum levels below those used here may not result in the same degree of contamination of the machine. However, Listeria is notably capable of growing and persisting in the environment, often in the form of biofilms; thus, even low levels of contamination in a processing environment present a potential concern. Additionally, the inoculated spinach leaves were allowed to dry for about 2 h, as the focus of the research was on estimating the extent of microbial spread in the machine and not focused on the contamination of the spinach leaves. Incubating for longer times may have provided additional unnecessary variability, as the focus of the study was to evaluate the potential of leaves with residual Listeria after washing to contribute to contamination of the machine. As mentioned, Listeria has the tendency to form biofilms and microbial adhesion and subsequent biofilm formation could have influenced the degree to which contamination occurs. Future work investigating the potential of spinach to contaminate the machine after a longer inoculation time would be of value, given the results presented here. Additionally, future studies evaluating whether these same experimental conditions result in risk with a gram-negative bacterium like Salmonella enterica would also be of value.

The results from the experimental analysis suggest that the utilization of these machines poses a potential risk for cross-contamination with Listeria during leafy green processing with these machines. A logical next step of this research should focus on evaluating the efficiency of various risk reduction mitigation strategies commonly followed for food contact surfaces to reduce the contamination observed here. The results of this work will also help inform areas of concern for producers to stay in compliance with the recently implemented Food Safety Modernization Act (FSMA) Produce Safety Rule (PSR) that states specific sanitary regulatory conditions and there are specific regulations that discuss postharvest handling and sanitation.

Methods

Materials

The washing machine, Speed Queen TC5000, Classic Clean™ were purchased from US Appliances (Alliance Laundry Systems LLC, Ripon, WI). Listeria innocua (ATCC 33090) was obtained from ATCC and cultivated per manufacturer's instructions (American Type Culture Collection, Manassas, Virginia). 3M Quick microbial swabs were purchased from 3M (Maplewood, Minnesota, USA). Listeria selective media, Oxford agar and Oxford agar supplements were purchased from Fisher Scientific USA, Waltham, MA. In addition, nonselective media such as tryptic soy agar (TSA) was purchased from Fisher Scientific USA, Waltham, MA. Baby spinach was obtained from The University of Massachusetts Amherst Dining Services, Amherst, MA.

Sourcing, procurement and building of the DIY converted washing machines

The DIY retrofitted washing machine was built with the help of the University of Vermont’s Agricultural Engineering Extension team. A detailed conversion guide is available online 11. Based on the steps mentioned, the different parts of the washing machine, such as the panels, were taken apart and rewired to only keep the central water collecting drum and the brake system intact. Additionally, a stopwatch timer was attached to the machine to keep the time of each spin-drying cycle while drying the leafy greens, to ensure consistency. The series of steps involved in building the retrofitted machines are depicted in Fig. 4. Traditional perforated fishing baskets were inserted into the machine that were used for loading and unloading the spinach. The machine was placed at the pilot plant in Chenoweth Laboratory, University of Massachusetts Amherst, MA. A protective enclosure was built with polyethylene sheets and PVC pipes (Lowe’s, Mooresville, North Carolina) to ensure that there was no spread of the aerosolized microorganisms during spin drying experimental analysis to meet the Environmental Health and Safety Standards.

A Retrofitting a washing machine and B adding loading baskets to reduce contact exposure to C adding leafy greens to the three layered retrofitted machine D operating as a dry triple-washed produce27.

Bacterial inoculum preparation

Listeria innocua SLCC 3379 (ATCC 33090), a surrogate for Listeria monocytogenes, was inoculated onto spinach and food contact points with initial inoculation loads (106 and 109 log10 CFU/cm2) to evaluate microbial transfer. L. innocua was cultured in tryptic soy broth (TSB) at 37 °C for 18 h with continuous shaking at 130 rpm to obtain an inoculum level of 9 log10 CFU/ml, and that was further diluted with TSB to obtain inoculation load of range 103–109 CFU/ml. The growth curve of the microbe was determined by measuring the Optical Density (OD600) at regular intervals in the Spectrophotometer machine, followed by plating, and OD600 was used to normalize the inoculum level. Ten individual spinach leaves were premarked using black permanent markers, placed in empty petri plates, and 10 ml of prepared Listeria innocua culture was equally distributed on the spinach surface by inoculating with micropipettes. The inoculated leaves were placed in a biohazard cabinet and allowed to dry for 1 h.

Spin drying of produce

The initial spin-drying assay was conducted by analyzing a range of volumes of spinach between 100 and 500 g, added in each spin-drying cycle, as well as with a low microbial load and a high microbial load (106 and 109 log10 CFU/cm2). The spinach volume of 250 g was chosen for conducting further spin-drying experimental analysis. The inoculated spinach leaves, which were premarked using permanent black markers to allow recovery of inoculated leaves, were mixed with non-inoculated spinach totaling up to volume of 250 g, per spin drying cycle. A washing step was then conducted, where the batch of spinach was dipped in non-contaminated distilled water, after which the water was discarded accordingly. The washed spinach was added to the external perforated orange load basket, placed inside the retrofitted washing machine, and spun six times at 1400 rpm for 10 s each to conduct spin cycle drying to remove the water from the spinach. Premarked inoculated spinach leaves sample of 25 g were removed from the retrofitted washing machine post-spin drying and added into stomacher bags with 250 ml of 0.1% peptone water. The bags were stomached for 10 min, serially diluted, and enumerated by plating on Oxford agar plates after incubation at 37 °C for 48 h. All assays were repeated on separate days as biological triplicates.

Determination of the degree of contamination from inoculated produce to contact points

Three different layers in the retrofitted machine and three contact points were assigned to each layer as seen in Fig. 5. 3M Quick microbial swabs (Minnesota, USA) were used to swab the contact points in a defined 10 cm2 area of swabbing and recovered Listeria was enumerated by serial dilution and plating on Oxford agar plates and TSB plates at 37 °C for 48 h. The microbial recovery experiments were conducted in biological triplicate along with positive and negative controls, such as swabbing the machine prior to spin drying with inoculated spinach, followed by plating in duplicate (technical replicates) as well as plating directly Listeria innocua culture.

Determination of the degree of contamination from a contaminated washing machine to uninoculated produce

The potential for the retrofitted washing machine, environmentally seeded with L. innocua, to contaminate uninoculated spinach was evaluated. First, 3.77 ± 0.29 log CFU of L. innocua was inoculated onto direct contact points (Layer 1) as well as the indirect contact points (Layer 2 and 3) of the washing machine, followed by a spin-drying run of the fresh spinach as described above, except without inoculation of the leaves of spinach. After each dry run, 25 g of spinach were stomached in 250 ml of 0.1% peptone water for 10 min. The stomached media was then serially diluted and enumerated on Oxford agar and TSA plates as described above. The retrofitted washing machines were cleaned and sanitized post-spin drying analysis of the experimental conditions. Cleaning detergent such as Dawn® Heavyduty Degreaser (Procter & Gamble, Cincinnati, Ohio, USA) in the concentration of 7% Sodium cumenosulfonate surfactant was sprayed using a light nozzle spray for a contact time of 15 min in a volume of 300 ml along with water to physically remove soil and residue from the retrofitted washing machine. Scotch-Brite™ Non-Scratch Scrub Sponges Individually-Sealed (3 M, St. Paul, MN, USA) was used to scrub the surface of the different layers of the washing machine. Surfaces were scrubbed and rinsed to remove visible soil and debris. This was followed by scrubbing using a clean scrub brush (Holikme, Amazon, USA) and finally rinsed with clean water to remove all residue and suds. It was important to ensure all the residual detergent suds are completely removed to guarantee complete efficiency of the following application of the sanitizers. Machines were allowed to air dry prior to the application of the next step. The cleaning step was followed by application and investigation of two commonly used food contact surface approved sanitizers, SaniDate 15 (which is a 15% peroxyacetic acid-based sanitizer) (Biosafe Systems, Hartford, Connecticut, USA) and Clorox germicidal bleach (7.03% sodium hypochlorite chlorine-based sanitizer) (The Clorox Company, Oakland, California) in the volume of 300 ml and in the food contact surface approved concentrations such as 100 ppm free peroxyacetic acid and 200 ppm free chlorine respectively. The efficacy of the cleaning and sanitation steps were confirmed by swabbing the different contact points on defined 10 cm2 areas of the machine and enumerating them on both Oxford and TSA plates prior to the next experimental replicate. Additionally, Hygiena Ultrasnap ATP swabs and Hygiena ATP Lumitester machine (Hygiena, Camarillo, California, USA) were used to ensure the machine was cleaned thoroughly after each spin-drying cycle.

Statistical analysis

The experimental results from triplicate measurements were expressed as mean values and standard deviation (mean ± SD). GraphPad Prism was used to conduct the Turkey test and one-way ANOVA, and a multiple comparison Turkey test was performed using GraphPad Prism version 9.3.1 (350) for Mac OS X, GraphPad Software LLC, San Diego, California, USA (www.graphpad.com). A P value less than 0.05 was considered significant.

Data availability

The authors declare that all data supporting the findings of this study are available in the paper.

References

Self, J. L. et al. Multistate outbreak of listeriosis associated with packaged leafy green salads, United States and Canada, 2015–2016. Emerg. Infect Dis. 25, 1461 (2019).

Matthews, J. E. et al. The epidemiology of published norovirus outbreaks: a review of risk factors associated with attack rate and genogroup. Epidemiol. Infect. 140, 1161–1172 (2012).

Machado-Moreira, B., Richards, K., Brennan, F., Abram, F. & Burgess, C. M. Microbial contamination of fresh produce: what, where, and how?. Compr. Rev. Food Sci. Food Saf. 18, 1727–1750 (2019).

Lane, K., McLandsborough, L. A., Autio, W. R. & Kinchla, A. J. Efficacy of ATP monitoring for measuring organic matter on postharvest food contact surfaces. J. Food Prot. 83, 1829–1837 (2020).

CDC. Dole packaged salads. (2022).

CDC. Fresh express packaged salads. (2022).

Maurel, B. et al. Branched and fenestrated options to treat aortic arch aneurysms. J. Cardiovasc. Surg. 57, 686–697 (2016).

Murray, K., Wu, F., Shi, J., Jun Xue, S. & Warriner, K. Challenges in the microbiological food safety of fresh produce: limitations of post-harvest washing and the need for alternative interventions. Food Qual. Saf. 1, 289–301 (2017).

FDA. FSMA- Produce safety rule; https://www.regulations.gov/document/FDA-2011-N-0921-18558.

U.S. Department of Health & Human Services/U.S. Food & Drug Administration. FSMA factsheet. https://www.Fda.Gov/Media/81051/Download (2011).

U.S. Department of Health and Human Services Food and Drug Administration Center for Food Safety and Applied Nutrition. Hazard Analysis, and Risk-Based Preventive Controls for Human Food. https://www.Ecfr.Gov/Current/Title-21/Chapter-I/Subchapter-B/Part-117 (2024).

Vilsack, T. & Hamer, H. United States Summary and State Data Volume 1. Geographic Area Series. Part 51 (United States Department of Agriculture, 2009).

Reference M., Queen S. Washing machine/Greens spinner conversion SOP. 5, 1–5. https://blog.uvm.edu/cwcallah/2022/02/24/washing-machine-greens-spinner-conversion-guide/.

Costa, P. D., Andrade, N. J., Brandão, S. C. C., Passos, F. J. V. & Soares, N. D. F. F. ATP-bioluminescence assay as an alternative for hygiene-monitoring procedures of stainless steel milk contact surfaces. Braz. J. Microbiol. 37, 345–349 (2006).

FDA. Listeria (Listeriosis). https://www.fda.gov/food/foodborne-pathogens/listeria-listeriosis. (2024).

CDC, 2014 Outbreak of Listeria Infections Linked to Commercially Produced, Prepackaged Caramel Apples Made from Bidart Bros. Apples. https://archive.cdc.gov/www_cdc_gov/listeria/outbreaks/caramel-apples-12-14/index.html (2015).

CDC, 2011 Outbreak of Listeria Infections Linked to Whole Cantaloupes from Jensen Farms, Colorado. https://archive.cdc.gov/www_cdc_gov/listeria/outbreaks/cantaloupes-jensen-farms/index.html (2012).

Smolinski, H. S. et al. Transfer and redistribution of Salmonella typhimurium LT2 and Escherichia coli O157:H7 during pilot-scale processing of baby Spinach, Cilantro, and Romaine Lettuce. J. Food Prot. 81, 953–962 (2018).

Buchholz, A. L., Davidson, G. R., Marks, B. P., Todd, E. C. D. & Ryser, E. T. Quantitative transfer of Escherichia coli O157: H7 To equipment during small-scale production of fresh-cut leafy greens. J. Food Prot. 75, 1184–1197 (2012).

Buchanan, R. L., Gorris, L. G. M., Hayman, M. M., Jackson, T. C. & Whiting, R. C. A review of Listeria monocytogenes: an update on outbreaks, virulence, dose-response, ecology, and risk assessments. Food Control. 75, 1–13 (2017).

CDC. Surveillance for foodborne disease outbreaks. https://www.cdc.gov/mmwr/PDF/wk/mm5822.pdf (2009).

Gonzales-Barron U., Cadavez V., De Oliveira Mota J., Guillier L., Sanaa M. A critical review of risk assessment models for Listeria monocytogenes in produce. Foods 13, 1111 (2024).

Jensen, D. A., Friedrich, L. M., Harris, L. J., Danyluk, M. D. & Schaffner, D. W. Cross contamination of Escherichia coli O157:H7 between lettuce and wash water during home-scale washing. Food Microbiol. 46, 428–433 (2015).

Gombas, D. et al. Guidelines to validate control of cross-contamination during washing of fresh-cut leafy vegetables. J. Food Prot. 80, 312–330 (2017).

CDC. Dole packaged salads. www.cdc.gov/listeria/outbreaks/packaged-salad-mix-12-21/index.html. https://www.cdc.gov/listeria/outbreaks/packaged-salad-mix-12-21/index.html (2022).

CDC. Fresh express packaged salads. https://www.cdc.gov/listeria/outbreaks/packaged-salad-12-21-b/index.html. https://www.cdc.gov/listeria/outbreaks/packaged-salad-12-21-b/index.html (2022).

The University of Vermont Extension Agricultural Engineering, Green Spinners for Farm Use. https://blog.uvm.edu/cwcallah/2018/07/20/greens-spinners-for-farm-use/ (2018).

Acknowledgements

This work was supported by the Massachusetts Department of Agricultural Resources, MA and the Capital Area Food Protection Association, Washington, D.C. The author would like to thank the sponsors. This research was also done with help from the University of Vermont Agricultural Engineering Extension team. This publication was also supported by the Specialty Crop Block Grant Program at the US Department of Agriculture through grant SCBGP FY19, the National Institute of Food and Agriculture, US Department of Agriculture, the Center for Agriculture, Food and the Environment, and the Food Science department at University of Massachusetts Amherst, under project number MAS-00529. The contents are solely the responsibility of the authors and do not necessarily represent the official views of the USDA or NIFA.

Author information

Authors and Affiliations

Contributions

P.K. conducted primary bench research, study design, drafted the initial draft of the manuscript, and edited the manuscript. L.M. aided in study design and interpretation of results. M.D.M. aided conceptualization of the work, supervised bench research, aided study design, aided interpretation of results, and edited the manuscript. AK aided conceptualization of the work, supervised bench research, aided study design, aided interpretation of results, edited the manuscript, and acquired funding for this work.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kamarasu, P., McLandsborough, L., Moore, M.D. et al. Evaluating the potential for contamination of leafy greens with Listeria when using retrofitted washing machines. npj Sci Food 9, 126 (2025). https://doi.org/10.1038/s41538-025-00489-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41538-025-00489-6