Abstract

In this study, we synthesized ten g-C3N4-based covalent organic frameworks (COFs) and identified CN-306 as the most effective catalyst for visible-light-driven hydrogen peroxide (H2O2) production. Systematic optimization revealed that increasing ethanol proportions in the reaction medium significantly enhanced H2O2 yield, achieving a remarkable production rate of 5352 μmol g−1h−1 with a surface quantum efficiency of 7.27% at λ = 420 nm. Intriguingly, mechanistic investigations uncovered that excessive generation of singlet oxygen (1O2) acts as a critical inhibitory factor, impeding H2O2 accumulation. Multimodal characterization techniques combined with density functional theory (DFT) calculations were employed to unravel the origin of CN-306’s superior performance. Theoretical analyses demonstrated that CN-306 exhibits enhanced electron-hole separation efficiency, attributed to its reduced energy gap between the highest occupied molecular orbital (HOMO) and lowest unoccupied molecular orbital (LUMO), which facilitates photocarrier migration and suppresses detrimental recombination. Furthermore, this work elucidates the structure-function relationships governing site-specific functional group modifications in COFs and their profound influence on photocatalytic activity. These findings provide molecular-level insights into rational catalyst design for optimizing surface structures and advancing solar-driven H2O2 synthesis applications.

Similar content being viewed by others

Introduction

Hydrogen peroxide (H2O2) is a widely used oxidizing agent and disinfectant, finding applications across industries such as textiles, pharmaceuticals, papermaking, and environmental protection1. Various methods can be used to prepare hydrogen peroxide, with the most common being the Baeyer-Villiger oxidation2.This method involves dissolving hydrogen peroxide gas in water and converting it to hydrogen peroxide with a catalyst. Another prevalent technique is the electrolysis of aqueous solutions, where the passage of current through the solution leads to electrolytic reactions generating oxygen and hydrogen gases along with hydrogen peroxide3. The different methods available for preparing hydrogen peroxide ensure the efficient acquisition of the desired solution4. The anthraquinone process is a well-known industrial technique for producing hydrogen peroxide, involving a large production line, high energy consumption, and the production of organic byproducts and wastewater5. Nevertheless, a potential pathway for sustainable development involves using photocatalysts and solar energy to facilitate the two-electron oxygen reduction reaction (ORR) under mild temperature and pressure conditions6,7.

Although photocatalytic technology has opened new pathways for green synthesis, the development of alternative catalytic systems still requires overcoming the application bottlenecks of key materials. Recently years, the exceptional electronic structures and catalytic properties of rare metal materials like platinum, rhodium, and palladium, platinum, rhodium, and palladium make them essential in the in production of hydrogen peroxide8. These materials are crucial in the chemical industry as they significantly boost reaction rates and decrease energy consumption. However, their their limited availability and expensive prices present major obstacles for widespread production and real-world use9. The extraction and refining of rare metal resources come with high costs and environmental impacts. Consequently, the cost-effectiveness of rare metal catalysts is not ideal, limiting their industrial applications. Furthermore, concerns arise over the stability of the supply of these metals, given their uneven global distribution and export restrictions imposed by some countries, leading to further uncertainties in market supply10. Scientists are currently exploring non-precious metal catalysts and metal-free materials as alternatives, as they are more costs-effective and environmentally friendly, These research could help alleviate the scarcity of rare metal catalysts. Nevertheless, many non-precious metal catalysts encounter obstacles like deactivation in the dark and degradation when exposed to light, resulting in decreased catalytic performance and limited photochemical stability11. To overcome these limitations, Scientists are improving catalyst design and preparation techniques to improve photochemical stability. The incorporation of innovative metal-free materials such as carbon nanotubes and grapheneshows potential in addressing the deactivation and photodegradation issues linked to non-precious metal catalysts12.

While these advances highlight progress in metal-free catalyst design, recent research has shifted focus toward precise structural engineering of semiconductor photocatalysts like graphitic carbon nitride. The modification of graphitic carbon nitride (g-C3N4) through organic compounds has garnered significant attention in recent years, with studies focusing on enhancing its photocatalytic performance via structural and electronic tailoring13. Previous reports have demonstrated that covalent functionalization with organic moieties, such as aromatic rings, heteroatom-containing groups, and conjugated polymers, can modulate the electronic structure of g-C3N4 to improve charge separation and light absorption14. For instance, doping with electron-rich or electron-deficient organic units has been shown to alter the bandgap and electron cloud density distribution, thereby influencing photocatalytic activity15. Similarly, the integration of π-conjugated systems, such as benzene derivatives or triazine-based frameworks, has been explored to extend charge carrier lifetimes by enhancing π-π interactions. Despite these advancements, existing strategies often face limitations in achieving balanced electron-hole separation efficiency and long-term stability under operational conditions. Many modifications rely on non-specific physical adsorption or complex synthetic routes, which compromise scalability or fail to address the inherent recombination losses in g-C3N416.

Notably, while efforts have been made to functionalize g-C3N4 with organic small molecules, systematic investigations into the relationship between substituent electronic properties and spatial charge separation remain sparse17. Earlier studies predominantly focused on bulk modifications, such as heteroatom doping or composite formation, rather than targeted molecular-level engineering of the conjugated framework. This gap underscores the need for rational design strategies that precisely control electron cloud redistribution to minimize carrier recombination18,19. Furthermore, the photochemical stability of organically modified g-C3N4 under prolonged visible-light irradiation has not been thoroughly addressed, with many systems exhibiting degradation or deactivation over time20.

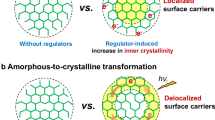

To address these gaps, our work systematically investigates substituent electronic effects through molecular-level engineering while simultaneously evaluating photochemical stability under sustained irradiation. In this study, we propose a method to enhance the separation of photo-generated charge carriers by modifying the electronic cloud density distribution of the organic conjugated framework through amino modification21. We achieved this by introducing organic small molecules containing benzaldehyde to g-C3N4, resulting in an imide structure with an expanded shift in electron cloud density. Through theoretical analysis and a review of existing literature, we examined the impact of substituents on the electron cloud density above the benzene ring. It was found that introducing a strong electron-withdrawing group onto the benzene ring can improve the effective separation of electrons and holes22. Using Density Functional Theory (DFT), we calculated the distribution patterns of electron-hole pairs in the first excited state (S1) for six unique functional groups, as well as the distribution of electron-hole pairs from the first excited state to the fifth excited state (S1 ~ S5) of CN550 and CN-306 (Fig. 1)23.

Materials with high catalytic activity under visible light were rapidly assessed for their ability to degrade Rhodamine B. Our analysis emphasizes the superior efficacy of CN-306 in facilitating the separation of electron-hole pairs. This method not only enhances π-π bond conjugation and extends the distance between electron-hole pairs but also increases the number of active sites per unit volume, significantly boosting photocatalytic activity.

Results

Catalysts preparation

To synthesize CN-300 compounds, urea was heated 580 °C in air, then the resulting product A in was stirred in pure water at room temperature for 24 hours and dried. Next, product A was then reacted with terephthalaldehyde in ethanol with acetic acid as a catalyst at 80 °C for 12 hours to yield product B24. Product C was prepared under identical conditions by reacting B with para-aminobenzaldehyde to obtain D. CN-301 to CN-310 were synthesized by condensing D with various benzaldehyde compounds in ethanol using acetic acid as a catalyst. During the preparation process, the yield of the parent compound A was approximately 10%, whereas the subsequent steps (B, C, D) and final products all achieved yields exceeding 90%. (Fig. 2a). The scalability of this synthesis method is supported by its high reproducibility, mild reaction conditions (ambient to moderate temperatures, atmospheric pressure), and reliance on inexpensive, commercially available catalysts (e.g., acetic acid). While the parent compound A exhibited a modest initial yield (~10%), the subsequent steps (B, C, D) and final products consistently achieved >90% yields, minimizing resource waste and simplifying purification-critical factors for industrial adoption. Further scale-up feasibility would require evaluating solvent recovery systems, continuous flow reactor compatibility, and the availability of benzaldehyde derivatives in bulk quantities, which are common considerations for transitioning lab-scale photocatalytic materials to industrial H2O2 production.

Catalysts characterization and analysis

Following the successful synthesis of these derivatives, structural and morphological analyses were conducted to correlate molecular modifications with crystallographic changes. To analyze the crystal structures of bulk g-C3N4(CN550) and CN-306, we examined their X-ray powder diffraction (XRD) patterns (Fig. 2b). These patterns revealed two distinct diffraction peaks: one at 13.1° representing the (100) in-plane long-range atomic order, and another at 27.3° representing the (002) interlayer-stacking motif25. Importantly, the enhancement of crystallinity in the material was significantly observed with the addition of electron-donating groups at the amino position (CN-306).

The Fourier Transform Infrared Spectroscopy (FTIR) of CN550 and CN-301 ~ CN-310 is depicted in Figs. 2c and S1. The presence of a heptazine structure in CN-306 is confirmed by the characteristic peak at around 803 cm−1. Peaks between 900 and 1700 cm−1 correspond to the melamine framework of the N-C = N ring. A peak at 1311 cm−1 indicates an increase in C-F/C-N bonds in CN-306. The broad peak in the 3000–3500 cm−1 region is due to the stretching vibration of amino and hydroxyl groups26. The SEM images in Figs. 2d-e and S2 reveal that CN550 and CN-306 exhibit a 2D plate structure attributed to strong π–π stacking. Furthermore, HRTEM images of CN-306 in Fig. 2 depict a transparent sheet-like morphology. However, the selected area electron diffraction (SAED) pattern (Fig. 2f, inset) lacks lattice fringes, indicating that CN-306 is amorphous27.

To further investigate the structural attributes and surface chemical characteristics of CN-306, we performed comprehensive X-ray photoelectron spectroscopy (XPS) analyses. As shown in Fig. S2a-f, the C 1 s and N 1 s spectra exhibit characteristic peaks of C and N heterocycle frameworks. Specifically, the N═C─N, N─(C)2, and N─(C)3 peaks are observed at 288.1, 398.5, and 400.7 eV, respectively28. The higher binding energies of the C 1 s and N 1 s observed in CN-306 are associated with the structural change modified by p-nitrobenzaldehyde. Notably, the integrated peak area ratio of N-(C)2 in N 1 s significantly increases from 31.6% in CN550 to 36.8% in CN-306, indicating the effectiveness of the modification in altering the material’s surface chemical properties29.

To study the alterations in surface chemical characteristics of CN-306 after being exposed to air and under illumination, we conducted XPS comparisons under different illumination periods and in the absence of light in a gas mixture (80% N2 and 20% O2). As shown in Figs. S3g and S4, the surface elemental bands of CN-306 show significant changes under dark and light conditions. The C-C peak at 284 eV in the C 1 s spectrum decreases from 18.63% to 13.18%, while the N-C = C content increases from 30.98% to 34.47%. In the N 1 s spectrum, the N-(C)2 peak increases from 37.07% to 41.98%, and N-(C)3 increases from near 11.17% to 7.87%. Additionally, the valence band decreases from 1.26 eV under dark conditions to 1.09 eV. These results indicate significant surface modifications and potential enhancements in the photocatalytic performance of CN-30630.

The amino modification plays a crucial role in determining the optical properties and light absorption capabilities of CN-306, while the differences in calcination temperature also impact these characteristics significantly. UV-vis DRS analysis shows that CN-306 exhibits stronger and red-shifted absorption compared to CN550 (Fig. S5a). The calculated Kubelka-Munk function reveals a gradually narrowed, direct bandgap, decreasing from 2.63 eV in CN550 to 2.45 eV in CN-306 (Fig. S5b)31. The conduction band (CB) edge potentials are directly estimated from the measured Mott-Schottky plots (Fig. 3a-b), while the valence band (VB) edge potentials of CN550 and CN-306 are estimated as 1.76 and 1.65 eV, respectively. This establishes the band structure alignments shown in Fig. 3c. Charge transfer and separation in CN-306 are further elucidated through steady-state and time-dependent photoluminescence (PL) measurements. These confirm a red-shift in CN-306, indicating a reduced bandgap (Fig. 3d)32.

a, b Mott-Schottky plots of CN550 and CN-306 (The potential values in these figures can be converted to potential relative to the standard hydrogen electrode (NHE) using the formula: E (NHE) = E (Ag/AgCl) + 0.197 V); c Band structure alignments; d Steady-state PL spectra of CN550 and CN-306; e Time-resolved photoluminescence spectra of CN550 and CN-306; f ON/OFF photocurrent response; g Nyquist plots periodic of CN550 and CN-306 from Electrochemical impedance spectroscopy; h N2 adsorption isotherms of CN550 and CN-306; i The BJH pore size distributions.

After fitting a double exponential equation, it was found that CN550 had relatively short electron/hole recombination lifetimes. Nevertheless, following amino site modification, there was a significant improvement in the recombination lifetimes33. Considering the longer photoluminescence (PL) lifetime, CN-306 emerged as the optimal choice (Fig. 3e). The photocatalytic performances of CN550 and CN-306 were assessed using photocurrent response (Fig. 3f). A comparison between CN-306 and CN550 revealed that CN-306 exhibited lower resistance, indicating improved electron mobility within CN-306. Furthermore, changes in amino modification and calcination temperature altered the electron transfer pathways, influencing the intensity of the photoresponse signal. As depicted in Fig. 3g, both CN550 and CN-306 exhibited type IV isotherms due to abundant mesopores. However, CN-306 catalysts demonstrated significantly higher specific surface areas and porosities than CN550, rising from 52.07 m2g−1 and 0.073 cm3g−1 to 83.56 m2g−1 and 0.192 cm3g−1, respectively. This facilitates mass diffusion kinetics during catalysis as shown in Fig. 3h. Unlike CN550, where pore volumes were distributed incrementally, CN-306 displayed concentrated pore sizes at 3-6 nm, leading to higher adsorption capacity as seen in Fig. 3i34.

From Data S1, analysis of the ID/IG ratio from Raman spectroscopy shows that most samples in the CN-300 series have ID/IG values between 0.67 and 0.88, which is consistent with the common range (0.7–1.2) reported in the literature for g-C3N4. This indicates that most samples exhibit a moderate defect density. The positive correlation between ID and IG—where ID and IG intensities increase or decrease synchronously in most samples—suggests that the intensities of the defect peak and graphitic peak are influenced by common factors. The high-defect sample CN-306 exhibits superior performance in photocatalysis (Fig. S6)35.

DFT calculations

To understand the electronic origins of these defect-mediated photocatalytic improvements, we employed density functional theory (DFT) calculations to probe charge carrier dynamics at the quantum mechanical level. To investigate how amino functionalization affects the distribution of electron-hole pairs, we carried out DFT calculations based on first-principles. This method enabled us to analyze the electronic structure at a quantum mechanical level. Following structure optimizing and single-point energy calculations, we examined the energy of the first excited state. By comparing the distribution of electrons and holes in the first excited state with the experimental rates of RhB photocatalytic degradation (Fig. S7a) and photoluminescence (PL) (Fig. S7b), we observed that higher proportions of electrons and holes on the modified fragments were associated with higher catalytic rates. Additionally, our analysis showed that the electronically excited holes in the modified catalysts CN-301 ~ CN310 were effectively separated (Fig. S7c). Figure 4 show that the energy difference (ΔE) between the highest occupied molecular orbital (HOMO) and the lowest unoccupied molecular orbital (LUMO) of the modified CN-300 series decreased by approximately 0.5 ~ 1.0 eV. Judging from the heat map of the electron-hole distribution in Fig. 5 and Data S2, the remarkable feature of CN-306 is that, compared to CN550, after being modified, it effectively separates electrons and holes, thereby decreasing the rate of electron-hole recombination within itself and consequently enhancing the photocatalytic efficiency. This indicates that the modification effectively reduces the energy required to reach the first excited state36. Additionally, the significant red shift observed in PL of CN-306 helps to explain why it exhibits the highest photocatalytic efficiency among the CN-300 series.

We performed fragment-based density of states (DOS) analyses for the parent and modified structures. As clearly shown in the TDOS and PDOS plots in the Data S3-4, the modified CN-300 series exhibits increased position, height, and width of the TDOS peaks. This indicates a higher number of quantum states within this energy range, which is associated with the new electronic structures introduced by the modification37.

From the electron transfer quantities calculated for the fragments, the significantly increased net electron transfer in the modified CN-300 series implies more efficient separation of photogenerated charge carriers, reducing their recombination probability. This allows more carriers to participate in redox reactions, thereby enhancing photocatalytic activity. The altered direction and magnitude of electron transfer in the modified catalysts lead to an electronic structure that facilitates directional transport of photogenerated electrons and holes, providing a more favorable pathway for photocatalytic reactions and boosting overall photocatalytic efficiency. The work function of the modified catalyst adjusts the electronic binding properties of the material and optimizes its electronic structure, providing more favorable charge transfer pathways and active sites for photocatalytic reactions. This demonstrates potential advantages over the parent CN550 in photocatalytic applications (Data S5-8)38.

Photocatalytic preparation of hydrogen peroxide and degradation tests

Building on these electronic structure enhancements, the modified catalysts’ improved charge separation efficiency was experimentally validated through hydrogen peroxide production and degradation tests under optimized solvent conditions. In the investigation of hydrogen peroxide production using water as a substrate, ethanol as a sacrificial agent, and the CN-300 series as a catalyst, we conducted experiments with different water/ethanol ratios as reaction solvents. We observed that as the proportion of ethanol increased, the rate of hydrogen peroxide production also increased. Specifically, when the ratio of water to ethanol was 3:997, the rate of hydrogen peroxide production reacheed 5022 μmolg−1h−1 (Fig. 6a–d). Under otherwise identical conditions, we conducted additional experiments for H2O2 synthesis under illumination at wavelengths of 510, 420, 395, and 365 nm, achieving production rates of 1581, 5352, 2708, and 425μmolg−1h−1, respectively (Fig. S8).

a The efficiency of CN550 and CN-300 series in preparing H2O2 under H2O/EtOH = 9/1 conditions; b The efficiency of CN550 and CN-300 series in preparing H2O2 under H2O/EtOH = 3/997 conditions; c The absorbance of hydrogen peroxide production from CN-306 in H2O/EtOH mixtures at 404 nm over time; d The efficiency of hydrogen peroxide production from CN-306 in differen H2O : EtOH mixtures; e Degradation of RhB by CN-306-PMS; f Degradation of FDN by CN-306-PMS.

We conducted photocatalytic degradation tests using CN-306-PMS (Potassium peroxymonosulfate, PMS) on RhB and Fludioxonil (FDN), employing a catalyst concentration of 0.5 g/L. Through screening the degradation rate of RhB, we determined the optimal amount of PMS to be 20 g/L, with no significant enhancement observed beyond 200 μL. Subsequently, we tested RhB degradation rates in a 10 mL catalytic solution with 100-500 μL of PMS (20 g/L) added. Degradation rates began to decrease after adding more than 300 μL of PMS. Therefore, we opted for 300 μL of PMS in a 10 mL solution for the catalytic degradation reaction. Prior to PMS addition, the first-order rate constants (k) of CN-306 for RhB were 0.2125 min−1 (Text S2–3). After adding 300 μL of PMS, the degradation rates of RhB significantly increased, with k values of 0.0237 s−1. Initially, CN550 and CN-306 showed no photocatalytic degradation ability towards FDN. However, after adding PMS, the degradation rate constant was measured to be 0.0774 min−1 (Fig. 6e–f). To further analyze the degradation FLD, we plotted in situ trace UV-visible absorption spectra (Fig. S9). In order to delve deeper into CN-306’s photocatalytic efficiency, we evaluated its apparent quantum yield (AQY) for hydrogen peroxide production. At a wavelength of λ = 450 nm, CN-306 exhibited a quantum yield of 6.82% (Text S4).

In addition to thermodynamic activity trends and photo-induced charge dynamics, water is widely believed to play a crucial role in ORR, acting as a transporter, electron donor, and proton source. As shown in Fig. S10, the liquid (H2O:EtOH = 1:1) contact angle of CN-306 is approximately 50°, which is visibly smaller than that of CN550 (65°)39. The result suggests that the photogenerated electrons generated from CN-306 facilitate electron transfer to active sites, consequently accelerating ORR progress.

Durability is a key factor in evaluating the potential application of photocatalysts. Under identical conditions, photocatalytic experiments were conducted with CN-306 for 5 cycles. As shown in Fig. S11, after 5 cycles, the photocatalytic activity of CN-306 only decreased by a maximum of 5%. There were no significant changes in morphology, crystal structure, and compounds after 5 reactions (Figs. S12 and S13). CN-306 boasts superior light absorption capabilities, capturing solar energy across a broader spectrum for enhanced photocatalytic efficiency, outperforming its peers in photocatalytic performance. Its exceptional electron transfer properties facilitate the separation and migration of photogenerated carriers, minimizing electron-hole pair recombination, thereby significantly boosting the activity and stability of photocatalytic reactions. During the photocatalytic process, CN-306 exhibits outstanding chemical stability and cyclic performance, maintaining high catalytic activity even after prolonged use, extending service life, reducing costs, and ensuring reliable practical application. We conducted a comparative study with similar catalysts and found that the photocatalytic performance of CN-306 is at the cutting edge level (Table S1–2, Supporting Information).

Preparation mechanism of H2O2 and degradation mechanism with PMS

The proposed reaction mechanism shown in Fig. 7a is based on previous studies. When the pH is neutral (pH 7), visible light is absorbed by the CN-306 surface, which generates electrons and holes and results in charge separation. Nearby electrons activate oxygen molecules, leading to the production of ·O2− anion radicals through one-electron reduction of oxygen40,41. This process is possible because the conduction band (CB) edge potential of CN-306 is more negative than the redox potential42. The separation of electrons and holes, facilitated by amino site modification is crucial for the generation of reactive species (Text S1 Equations (1-3), Supporting Information)43

Photochemical oxidation involves various reactive species such as h+, ·O2−, ·OH, and 1O2.

We compared the electron spin resonance signals of CN550 and CN-306 in in both dark and illuminated conditions. Fig. S14a shows that the hole signal exhibits a triplet peak group. Under the same light exposure, the hole signal of CN-306 decreases more than that of CN550, indicating that CN-306 produces more electrons under illumination. This phenomenon fully demonstrates that CN-306 is more effective in generating H2O2 through ORR. No peaks were observed for ·O2−, ·OH, and 1O2 in the absence of light (Figs. 7b-c and S14b). However, after 5 minutes of illumination, spin trapping experiments using DMPO confirmed the formation of DMPO-·O2− complex (quartet, 1:1:1:1), DMPO-·OH complex (quartet, 1:2:2:1), and TEMP-1O2 (quartet, 1:1:1:1 and doublet, 1:1)40.

The study investigated the effect of adding varying amounts of PMS to the CN-306 visible light photocatalytic process for the degradation of RhB. The results revealed that without PMS, the degradation efficiency of RhB reached 76% (0.2125 min−1) within 6 minutes. However, with the addition of 100 μL of PMS (20 g/L) was introduced, the degradation efficiency increased to 100% (0.0109 s−1). Increasing the PMS concentration to 200 and 300 μL further enhanced the degradation rates to 0.0188 s−1 and 0.0237 s−1, respectively. This improvement was due to the increased generation of hydroxyl (·OH) and sulfate (·SO4−) radicals through PMS activation. Conversely, when the PMS dosage reached 400 μL, the degradation rate decreased to 0.0182 s−1. Excessive PMS can act as a scavenger for the primary radicals, weakening the radical species and inhibiting the degradation process. Additionally, an overdose of PMS may saturate the catalyst’s active sites of the catalyst, leading to a reduction in reaction rates. For more information, refer to Text S2 Equations (4-10) in the Supporting Information for further details.

To further investigate the contribution of free radicals in the ORR process for hydrogen peroxide production using CN-306, we conducted experiments to capture singlet oxygen with DMSO, peroxide radicals with EDTA, and without any capture agent. From Fig. S15, it’s clear that the addition of DMSO to capture singlet oxygen increases the production of hydrogen peroxide, indicating the inhibitory role of singlet oxygen in hydrogen peroxide generation. In the EDTA capture test for peroxide radicals, the the curve of hydrogen peroxide generation shows a ‘S’ shape pattern throughout the test duration, suggesting that the overall production of hydrogen peroxide remains relatively low44. From the free radical capture experiments, it can be concluded that 1O2 inhibits H2O2 production in the catalytic reaction. Moreover, we found that ·O2- are the primary source of ·OOH during hydrogen peroxide production. When ·O2- interact with photogenerated h+ first, they produce 1O2, which not only consumes ·O2- but also generates more 1O2, ultimately hindering the production of H2O2.

Discussion

In light of these findings, we designed and synthesized ten g-C3N4-based COFs, among which CN-306 emerged as the most effective photocatalyst for RhB degradation. We examined different ratios of water and ethanol as reaction solvents, observing an increase in hydrogen peroxide yield with higher ethanol proportions. At a water to ethanol ratio of 3:997, the hydrogen peroxide yield reached 5352 μmolg−1h−1. Surface quantum efficiency of CN-306 at λ = 420 nm was determined to be 7.27%. When combined with PMS, CN-306 exhibited a degradation rate for RhB 32 times faster than CN550 (k = 0.0446 min−1 vs. k = 0.0237 s−1). Neither CN550 nor CN-306 showed degradation effects on FDN, yet the addition of PMS significantly enhanced FDN degradation (k = 0.0774 min−1). DFT calculations revealed that modified CN-306 exhibited superior electron-hole separation in the excited state, with a reduced energy gap between modified HOMO and LUMO, facilitating the generation of photocarriers. We further elucidated the structure-function relationship of different functional groups’ modifications at the same site and their impact on photocatalysis. This research provides valuable insights into the relationship between surface structure and photocatalytic applications.

Methods

Materials and reagents

Urea, absolute ethyl alcohol, glacial acetic acid, DMSO, DMPO, TEMP, RhB, and FDN were purchased from Macklin. 3,4-dimethoxyaniline (CN-301), 2-fluoro-4-methylaniline (CN-302), 3,4-difluoroaniline (CN-303), 3,5-difluoroaniline (CN-304), 2-chloro-6-methylaniline (CN-305), 4-(trifluoromethyl)aniline (CN-306), 3,4-dimethylaniline (CN-307), 2,4,5-trifluoroaniline (CN-308), 4-chloro-2-methylaniline (CN-309), 3-methoxy-5-(trifluoromethyl)aniline (CN-310), terephthalaldehyde, and 4-aminobenzaldehyde were purchased from Aladdin.

Synthesis of pristine g-C3N4(CN550) and CN-301 ~ CN310

The CN550 were fabricated by a typical synthesis route. In brief, urea (10.0 g) in a silica boat was heated at 550 °C for 3 h using a heating rate of 10 °C min−1 in a muffle furnace in an air atmosphere. The resulting yellow product was pulverized using an agate mortar for further utilization. The synthesis of A is similar to CN550, with the only difference being its calcination temperature at 580 °C. Place 0.5 g of A into a 100 mL round bottom flask and add 50 mL of anhydrous ethanol. Stir the mixture evenly and then add 0.1 g of terephthalaldehyde. Reflux the solution at 80 °C for 12 hours. Once the reaction is complete, pour the mixture into 200 mL of ice water and stir for 10 minutes. Then, filter it, rinse it three times with distilled water, followed by three rinses with anhydrous ethanol. Dry the product in an 80 °C oven for 2 hours and grind it into powder(B) using an agate mortar. The synthesis conditions and post-treatment for intermediate C are identical to those for synthesis B, using 4-aminobenzaldehyde as the reagent. CN-301 ~ 310 were prepared using the same method as for C, with different amine substances used for modification.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Campos-Martin, J. M., Blanco-Brieva, G. & Fierro, J. L. G. Hydrogen peroxide synthesis: an outlook beyond the anthraquinone process. Angew. Chem. Int. Ed. 45, 6962–6984 (2006).

Peeters, E. et al. Highly Dispersed Sn-beta zeolites as active catalysts for Baeyer–Villiger oxidation: the role of mobile, in situ Sn(II)O species in solid-state stannation. ACS Catal. 11, 5984–5998 (2021).

Scott, K. Process intensification: An electrochemical perspective. Renew. Sustain. Energy Rev. 81, 1406–1426 (2018).

Wang, S. et al. Efficient photocatalytic production of hydrogen peroxide using dispersible and photoactive porous polymers. Nat. Commun. 14, 6891 (2023).

Goyal, R., Singh, O., Agrawal, A., Samanta, C. & Sarkar, B. Advantages and limitations of catalytic oxidation with hydrogen peroxide: from bulk chemicals to lab scale process. Catal. Rev. 64, 229–285 (2020).

Lu, H. et al. Noble-metal-free multicomponent nanointegration for sustainable energy conversion. Chem. Rev. 121, 10271–10366 (2021).

Hu, C., Paul, R., Dai, Q. & Dai, L. Carbon-based metal-free electrocatalysts: from oxygen reduction to multifunctional electrocatalysis. Chem. Soc. Rev. 50, 11785–11843 (2021).

Melchionna, M., Fornasiero, P. & Prato, M. The rise of hydrogen peroxide as the main product by metal-free catalysis in oxygen reductions. Adv. Mater. 31, 1802920 (2018).

Su, P. et al. Efficient photocatalytic production of hydrogen peroxide by Z-scheme resorcinol-formaldehyde resin/g-C3N4 heterostructure under visible light. Chem. Eng. J. 454, 140504 (2023).

Zeng, K. et al. Recent advances in non-noble bifunctional oxygen electrocatalysts toward large-scale production. Adv. Funct. Mater. 30, 2000503 (2020).

Su, F. et al. Visible light-driven photocatalytic transformation of thiols to disulfides in water catalyzed by Bi2S3. Adv. Energy Sustainability Res. 4, 2300071 (2023).

Nasser, M. I. et al. Recent advances in photocatalytic hydrogen evolution with high-performance catalysts without precious metals. Renew. Sustain. Energy Rev. 132, 110813 (2020).

Wang, L., Chen, D., Jiang, K. & Shen, G. New insights and perspectives into biological materials for flexible electronics. Chem. Soc. Rev. 46, 6764–6815 (2017).

Dong, F., Li, Y., Wang, Z. & Ho, W.-K. Enhanced visible light photocatalytic activity and oxidation ability of porous graphene-like g-C3N4 nanosheets via thermal exfoliation. Appl. Surf. Sci. 358, 393–403 (2015).

Song, Y. et al. Photodegradation of sulfonamides by g-C 3 N 4 under visible light irradiation: Effectiveness, mechanism and pathways. Appl. Catal. B: Environ. 210, 88–96 (2017).

Wang, N., Cheng, L., Liao, Y. & Xiang, Q. Effect of functional group modifications on the photocatalytic performance of g-C3N4. Small 19, 2303255 (2023).

Arden, S. et al. A unit process log reduction database for water reuse practitioners. Water Res. X 23, 100226 (2024).

Tu H., et al. Unveiling the impact of microstructure alterations on photocatalytic hydrogen peroxide preparation via DFT prediction and analysis. Energy Environ Mater. e70016 (2025). https://doi.org/10.1002/eem2.70016

Yi F., et al. Dual S-Scheme g-C3N4/Ag3PO4/g-C3N5 photocatalysts for removal of tetracycline pollutants through enhanced molecular oxygen activation. Chinese Chem Lett. 110544 (2024) https://doi.org/10.1016/j.cclet.2024.110544

Tu, H. et al. Research on the influence of g-C3N4 microstructure changes on the efficiency of visible light photocatalytic degradation. Water Res. X 28, 100315 (2025).

Yang, Q., Luo, M., Liu, K., Cao, H. & Yan, H. Covalent organic frameworks for photocatalytic applications. Appl. Catal. B: Environ. 276, 119174 (2020).

Gu, Y. et al. Rational construction of edge-grafted g-C3N4 via cross-linking aromatic compounds with C F bonds for efficient photocatalytic H2 evolution. Chem. Eng. J. 476, 146555 (2023).

Lu, T. & Chen, F. Multiwfn: A multifunctional wavefunction analyzer. J. Comput. Chem. 33, 580–592 (2011).

Tu, H. et al. Synthesis and antibacterial activity of novel 1H-indol-2-ol Derivatives. J. Heterocycl. Chem. 55, 269–275 (2017).

Ge, L. & Han, C. Synthesis of MWNTs/g-C3N4 composite photocatalysts with efficient visible light photocatalytic hydrogen evolution activity. Appl. Catal. B: Environ. 117-118, 268–274 (2012).

Wang, H., He, W., Dong, X. A., Wang, H. & Dong, F. In situ FT-IR investigation on the reaction mechanism of visible light photocatalytic NO oxidation with defective g-C3N4. Sci. Bull. 63, 117–125 (2018).

Zeng, Y. et al. Sea-urchin-structure g-C3N4 with narrow bandgap (˜2.0 eV) for efficient overall water splitting under visible light irradiation. Appl. Catal. B: Environ. 249, 275–281 (2019).

Huang, Z. A. et al. Effect of contact interface between TiO2 and g-C3N4 on the photoreactivity of g-C3N4/TiO2 photocatalyst: (0 0 1) vs (1 0 1) facets of TiO2. Appl. Catal. B: Environ. 164, 420–427 (2015).

Fang, X. et al. Ultralong-lived triplet excitons of room-temperature phosphorescent carbon dots located on g-C3N4 to boost photocatalysis. Sci. China Mater. 66, 664–671 (2022).

Chen, Z., Wang, T., Liu, Y., Liu, Y. & Yang, X. Hydrogen-titanate-protected SnO2@C coaxial nanocables as new nanocomposite anode materials for lithium-ion batteries. Chem. Eng. J. 483, 149381 (2024).

Ismael, M. Facile synthesis of NiO-loaded g-C3N4 heterojunction photocatalyst for efficient photocatalytic degradation of 4-nitrophenol under visible light irradiation. J. Photochem. Photobiol. A: Chem. 439, 114576 (2023).

Lahootifar, Z., Habibi-Yangjeh, A. & Khataee, A. One-pot decoration of CdS and CdMoO4 nanoparticles on g-C3N4 nanoplates: Boosted photocatalytic degradation of tetracycline. J. Alloy. Compd. 969, 172481 (2023).

Wang, J. et al. g-C3N4 in situ derived ionic-electronic dual-conducting interlayer with N-rich sites for long lifespan sodium metal anodes. Energy Storage Mater. 59, 102793 (2023).

Dhanaraman, E. et al. Bi2WO6 Incorporation of g-C3N4 to Enhance the Photocatalytic N2 reduction reaction and antibiotic pollutants removal. Sol. RRL 8, 2300981 (2024).

Wang, J. et al. Au@Ag/ultrathin g-C3N4/graphene composite surface-enhanced Raman scattering film with stable, flexible and self-cleaning capability. J. Alloy. Compd. 944, 169063 (2023).

Wang, G. et al. DFT Predirected molecular engineering design of donor-acceptor structured g-C3N4 for efficient photocatalytic tetracycline abatement. Small 20, 2311798 (2024).

Liu, Z., Wang, X., Lu, T., Yuan, A. & Yan, X. Potential optical molecular switch: Lithium@cyclo[18]carbon complex transforming between two stable configurations. Carbon 187, 78–85 (2022).

Zhang, J. & Lu, T. Efficient evaluation of electrostatic potential with computerized optimized code. Phys. Chem. Chem. Phys. 23, 20323–20328 (2021).

Li, Y., Pei, Z., Luan, D. & Lou, X. W. D. Triple-Phase Photocatalytic H2O2 Production on a Janus Fiber Membrane with Asymmetric Hydrophobicity. J. Am. Chem. Soc. 146, 3343–3351 (2024).

Deng, Y. et al. Reduction of superoxide radical intermediate by polydopamine for efficient hydrogen peroxide photosynthesis. Angew. Chem. Int. Ed. 63, e202319216 (2024).

Zhou, E., Wang, F., Zhang, X., Hui, Y. & Wang, Y. Cyanide-based covalent organic frameworks for enhanced overall photocatalytic hydrogen peroxide production. Angew. Chem. Int. Ed. 63, e202400999 (2024).

Sun, L. et al. A Minireview: The Mechanism of H2O2 Photoproduction by Graphitic Carbon Nitride. Adv. Energy Sustainability Res. 4, 2300090 (2023).

Li, P. et al. 1D covalent organic frameworks triggering highly efficient photosynthesis of H2O2 via controllable modular design. Angewandte Chemie International Edition 63, e202319885 (2024).

Gao, Y. et al. Redox property of coordinated iron ion enables activation of O2 via in-situ generated H2O2 and additionally added H2O2 in EDTA-chelated Fenton reaction. Water Res. 248, 120826 (2024).

Acknowledgements

This work was supported by National Ten Thousand Talents Plan and the high performance computing platform of Guizhou University. the Program of Introducing Talents to Chinese Universities (No. D20023), the Central Government Guides Local Science and Technology Development Fund Projects (Qiankehezhongyindi (2023) 001), the Frontiers Science Centre for Asymmetric Synthesis and Medicinal Molecules, Department of Education, Guizhou Province [Qianjiaohe KY (2020)004].

Author information

Authors and Affiliations

Contributions

Hong Tu designed and performed the experiments, collected and analyzed the data, and wrote the manuscript. Bihong Tian, and Shunshun Chen helped toperformed the experiments. Jingyi Xu, Jianrong Yang, Zhichao Zhao, and Shunhong Chen help to helped toperformed the experiments. Jian Wu conceived the project, analyzed the data, and improved the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Tu, H., Tian, B., Chen, S. et al. Enhancing photocatalytic efficiency through surface modification to manipulate internal electron-hole distribution. npj Clean Water 8, 48 (2025). https://doi.org/10.1038/s41545-025-00480-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41545-025-00480-4

This article is cited by

-

Magnetite/MXene Nanocomposites: Photocatalytic and Adsorption Applications in Water Treatment for Environmental Remediation

Journal of Inorganic and Organometallic Polymers and Materials (2025)