Abstract

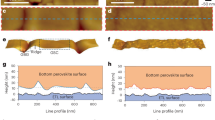

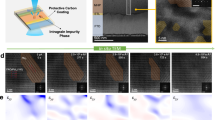

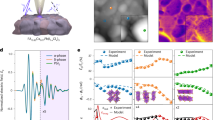

Multiscale cation inhomogeneity has been a major hurdle in state-of-the-art formamidinium–caesium (FA–Cs) mixed-cation perovskites for achieving perovskite solar cells with optimal power conversion efficiencies and durability. Although the field has attempted to homogenize the overall distributions of FA–Cs in perovskite films from both plan and cross-sectional views, our understanding of grain-to-grain cation inhomogeneity and ability to tailor it—that is, spatially resolving the FA–Cs compositional difference between individual grains down to the nanoscale—are lacking. Here we reveal that as fundamental building blocks of a perovskite film, individual grains exhibit cationic compositions deviating from the prescribed ideal composition, severely limiting the interfacial optoelectronic properties and perovskite layer durability. This performance-limiting nanoscopic factor is linked to thermodynamic-driven morphological grooving, leading to a segmented surface landscape. At the grain triple junctions, grooves form nanoscale groove traps that hinder the mixing of solid-state cations across grains and thus retard inter-grain FA–Cs mixing. By rationally modulating the heterointerfacial energies, we reduced the depth of these nanoscale groove traps by a factor of three, significantly improving cation homogeneity. Perovskite solar cells with shallower nanoscale groove traps demonstrate enhanced power conversion efficiencies (25.62%) and improved stability under various standardized international protocols. Our work highlights the significance of resolving surface nano-morphologies for homogeneous properties of perovskites.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data that support the main findings are available in the main text and the Supplementary Information. Source data are provided with this paper.

References

Kojima, A., Teshima, K., Shirai, Y. & Miyasaka, T. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc. 131, 6050–6051 (2009).

Jiang, Q. et al. Surface reaction for efficient and stable inverted perovskite solar cells. Nature 611, 278–283 (2022).

Zhao, Y. et al. Inactive (PbI2)2RbCl stabilizes perovskite films for efficient solar cells. Science 377, 531–534 (2022).

Zhou, Y. et al. Advances and challenges in understanding the microscopic structure–property–performance relationship in perovskite solar cells. Nat. Energy 7, 794–807 (2022).

Min, H. et al. Efficient, stable solar cells by using inherent bandgap of α-phase formamidinium lead iodide. Science 366, 749–753 (2019).

Koh, T. M. et al. Formamidinium-containing metal-halide: an alternative material for near-IR absorption perovskite solar cells. J. Phys. Chem. C 118, 16458–16462 (2014).

Pellet, N. et al. Mixed-organic-cation perovskite photovoltaics for enhanced solar-light harvesting. Angew. Chem. Int. Ed. 53, 3151–3157 (2014).

Zheng, X. et al. Improved phase stability of formamidinium lead triiodide perovskite by strain relaxation. ACS Energy Lett. 1, 1014–1020 (2016).

Wang, Y. et al. Unlocking the ambient temperature effect on FA-based perovskites crystallization by in situ optical method. Adv. Mater. 36, 2307635 (2023).

Li, Z. et al. Stabilizing perovskite structures by tuning tolerance factor: formation of formamidinium and cesium lead iodide solid-state alloys. Chem. Mater. 28, 284–292 (2016).

Yi, C. et al. Entropic stabilization of mixed A-cation ABX3 metal halide perovskites for high performance perovskite solar cells. Energy Environ. Sci. 9, 656–662 (2016).

Jacobsson, T. J. et al. Unreacted PbI2 as a double-edged sword for enhancing the performance of perovskite solar cells. J. Am. Chem. Soc. 138, 10331–10343 (2016).

Hao, M. et al. Ligand-assisted cation-exchange engineering for high-efficiency colloidal Cs1−xFAxPbI3 quantum dot solar cells with reduced phase segregation. Nat. Energy 5, 79–88 (2020).

Liang, Z. et al. Homogenizing out-of-plane cation composition in perovskite solar cells. Nature 624, 557–563 (2023).

Bai, Y. et al. Initializing film homogeneity to retard phase segregation for stable perovskite solar cells. Science 378, 747–754 (2022).

Huang, J., Xu, P., Liu, J. & You, X.-Z. Sequential introduction of cations deriving large-grain CsxFA1−xPbI3 thin film for planar hybrid solar cells: insight into phase-segregation and thermal-healing behavior. Small 13, 1603225 (2017).

Li, N. et al. Microscopic degradation in formamidinium-cesium lead iodide perovskite solar cells under operational stressors. Joule 4, 1743–1758 (2020).

Liu, L. et al. A-site phase segregation in mixed cation perovskite. Mater. Rep. Energy 1, 100064 (2021).

Mullins, W. W. Theory of thermal grooving. J. Appl. Phys. 28, 333–339 (2004).

Zhao, B., Shvindlerman, L. & Gottstein, G. Line tension of grain boundary triple junctions in the copper tricrystals. In TMS 2014: 143rd Annual Meeting & Exhibition 1063–1068 (Springer, 2016).

Hao, M. et al. Flattening grain-boundary grooves for perovskite solar cells with high optomechanical reliability. Adv. Mater. 35, 2211155 (2023).

Yan, N., Fang, Z., Dai, Z., Feng, J. & Liu, S. Buried interface—the key issues for high performance inverted perovskite solar cells. Adv. Funct. Mater. 34, 2314039 (2024).

Dong, Q. et al. Interpenetrating interfaces for efficient perovskite solar cells with high operational stability and mechanical robustness. Nat. Commun. 12, 973 (2021).

Zhao, L. et al. Enabling full-scale grain boundary mitigation in polycrystalline perovskite solids. Sci. Adv. 8, eabo3733 (2022).

Hackl, K., Fischer, F. D. & Svoboda, J. A variational approach to the modelling of grooving in a three-dimensional setting. Acta Mater. 129, 331–342 (2017).

Mullins, W. W. The effect of thermal grooving on grain boundary motion. Acta Metall. 6, 414–427 (1958).

Saylor, D. M. & Rohrer, G. S. Measuring the influence of grain‐boundary misorientation on thermal groove geometry in ceramic polycrystals. J. Am. Ceram. Soc. 82, 1529–1536 (1999).

Correa-Baena, J.-P. et al. Homogenized halides and alkali cation segregation in alloyed organic-inorganic perovskites. Science 363, 627–631 (2019).

Macpherson, S. et al. Local nanoscale phase impurities are degradation sites in halide perovskites. Nature 607, 294–300 (2022).

Guthrey, H. & Moseley, J. A review and perspective on cathodoluminescence analysis of halide perovskites. Adv. Energy Mater. 10, 1903840 (2020).

Taylor, E. J. et al. Hyperspectral mapping of nanoscale photophysics and degradation processes in hybrid perovskite at the single grain level. Nanoscale Adv. 5, 4687–4695 (2023).

Yang, J. et al. Understanding the role of cesium on chemical complexity in methylammonium-free metal halide perovskites. Adv. Energy Mater. 13, 2202880 (2023).

Chen, J. et al. Efficient and bright white light-emitting diodes based on single-layer heterophase halide perovskites. Nat. Photon. 15, 238–244 (2021).

Ma, F. et al. Stable α/δ phase junction of formamidinium lead iodide perovskites for enhanced near-infrared emission. Chem. Sci. 8, 800–805 (2017).

Lai, M. et al. Structural, optical, and electrical properties of phase-controlled cesium lead iodide nanowires. Nano Res. 10, 1107–1114 (2017).

Wang, P. et al. Seed-assisted growth of methylammonium-free perovskite for efficient inverted perovskite solar cells. Small Methods 6, 2200048 (2022).

Chen, Y. et al. Strain engineering and epitaxial stabilization of halide perovskites. Nature 577, 209–215 (2020).

Saidaminov, M. I. et al. Multi-cation perovskites prevent carrier reflection from grain surfaces. Nat. Mater. 19, 412–418 (2020).

Tao, S. et al. Absolute energy level positions in tin- and lead-based halide perovskites. Nat. Commun. 10, 2560 (2019).

Narra, S. et al. Femtosecond transient absorption spectra and dynamics of carrier relaxation of tin perovskites in the absence and presence of additives. J. Phys. Chem. Lett. 11, 5699–5704 (2020).

Yang, L. et al. Record-efficiency flexible perovskite solar cells enabled by multifunctional organic ions interface passivation. Adv. Mater. 34, 2201681 (2022).

Duan, T. et al. Chiral-structured heterointerfaces enable durable perovskite solar cells. Science 384, 878–884 (2024).

Ren, Y. et al. A spiro-OMeTAD based semiconductor composite with over 100 °C glass transition temperature for durable perovskite solar cells. Nano Energy 81, 105655 (2021).

Xiao, T. et al. Elimination of grain surface concavities for improved perovskite thin-film interfaces. Nat. Energy 9, 999–1010 (2024).

Jiang, Q. et al. Towards linking lab and field lifetimes of perovskite solar cells. Nature 623, 313–318 (2023).

Chen, Y. et al. Nuclei engineering for even halide distribution in stable perovskite/silicon tandem solar cells. Science 385, 554–560 (2024).

Zhao, B., Ziemons, A., Shvindlerman, L. S. & Gottstein, G. Surface topography and energy of grain boundary triple junctions in copper tricrystals. Acta Mater. 60, 811–818 (2012).

Acknowledgements

Y.Z. acknowledges the research grants from the National Natural Science Foundation of China (NSFC) Excellent Young Scientists Fund (number 52222318), the Hong Kong Research Grant Council (RGC) Early Career Scheme (number 22300221) and General Research Fund (number 12302822), the NSFC/RFC Collaborative Research Scheme (number CRS_HKUST203/23) and the start-up grant from Hong Kong University of Science and Technology (number R9901). Y.Z. also acknowledges the support from the China Merchants Group, particularly China Merchants Testing Certification International Co. Ltd. and China Merchants Research Institute of Advanced Technology Co., Ltd. for translating fundamental research to future technology innovation. J.Y. and M.A. acknowledge the funding from the US National Science Foundation (number 2043205). Y.X. acknowledges the RGC General Research Fund (number 16301720). M.H. and T.X. acknowledge the Hong Kong PhD Fellowship Scheme. T.D. acknowledges the RGC Postdoctoral Fellowship Scheme. X.Z. acknowledges the K. C. Wong Education Foundation. Cathodoluminescence microscopy was supported by the Center for Nanophase Materials Sciences (CNMS), which is a US Department of Energy, Office of Science User Facility at Oak Ridge National Laboratory. The work at Yale University was supported by the US National Science Foundation (number DMR-2313648). We also acknowledge the experiment assistance from C. Yang and Y. Zhang from ΣLab of The Hong Kong University of Science and Technology (HKUST), S. Guo from The Hong Kong Polytechnic University and M.-G.J. from Southeast University.

Author information

Authors and Affiliations

Contributions

Y.Z. directed the project and conceived the idea. Y.Z. and M.H. co-designed the experiments. Y.Z. and M.A. supervised the project. M.H. performed the materials synthesis, device fabrication and materials/device characterizations. J.Y. and B.J.L. assisted with the CL testing and data analyses. W.Y. assisted in the solar cell fabrication and testing. Pengfei Guo (HKUST) assisted with the device characterization. T.X. assisted with the device stability tests. T.D. performed the XRD measurement and assisted with the mechanical adhesion test. X.Z. performed the theoretical calculations. L.C. and Peijun Guo (Yale) performed the photoluminescence experiments. Y.X. assisted in illustrating the mechanism of cation diffusion between adjacent grains. Y.Z. and M.H. co-drafted the paper, and all co-authors reviewed the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Nanotechnology thanks Rui Wang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–43, Tables 1 and 2 and Notes 1–3.

Supplementary Data 1

Source data for Supplementary Figs. 5, 15–18, 20, 23–26, 35 and 39.

Source data

Source Data Fig. 1

Statistical source data of nano-GT depth in Fig. 1f.

Source Data Fig. 4

Statistical source data of VOC in Fig. 4b.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hao, M., Yang, J., Yu, W. et al. Nanoscopic cross-grain cation homogenization in perovskite solar cells. Nat. Nanotechnol. 20, 630–638 (2025). https://doi.org/10.1038/s41565-025-01854-y

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41565-025-01854-y

This article is cited by

-

Axially chiral molecular contacts with low isomerization barriers for perovskite solar cells

Nature Photonics (2026)

-

Performance-limiting metastable intragrain impurity nanoclusters in metal halide perovskites

Nature Communications (2025)

-

Enhancing hole-conductor-free, printable mesoscopic perovskite solar cells through post-fabrication treatment via electrophilic reaction

Nature Energy (2025)

-

Laser-assisted materials engineering at the atomic and nanoscales

Nature Synthesis (2025)

-

Resolving nano-morphologies: a pathway to cross-grain homogeneous cation distribution in perovskites

Science China Materials (2025)