Abstract

Tin halide perovskites (THPs) have emerged as promising lead-free candidates for eco-friendly perovskite solar cells, but their photovoltaic performance still lags behind that of lead-based counterparts due to poor thin-film quality. Constructing two-dimensional/three-dimensional (2D/3D) heterostructures can effectively regulate crystallization and suppress defect formation for developing high-quality THP thin films. However, the high aggregation barrier prevents large 2D perovskite colloids from forming stable clusters, making 2D THPs nucleate more slowly than their 3D analogues. Such distinct nucleation kinetics cause undesirable 2D/3D phase segregation that compromises both photovoltaic performance and device durability. Here we introduce small inorganic caesium cations to partially replace bulky organic cations in the electrical double layers of 2D THP colloids, reducing the colloid size to lower their aggregation barrier. The reduced electrostatic repulsion promotes the coagulation of 2D and 3D THP colloids in the precursor solution, synchronizing their nucleation kinetics for the growth of 2D/3D heterostructured THP thin films with a homogeneous microstructure and markedly reduced trap states. Consequently, the caesium-incorporated THP solar cells deliver an excellent power conversion efficiency of 17.13% (certified 16.65%) and exhibit stable operation under continuous one-sun illumination for over 1,500 h in nitrogen without encapsulation. This study offers new insights into the colloidal chemistry and crystallization engineering of mixed-dimensional heterostructures, paving the way for high-performance lead-free perovskite photovoltaics.

Similar content being viewed by others

Main

Metal halide perovskites have garnered enormous interest from both academia and industry for next-generation low-cost thin-film photovoltaic (PV) technologies, yet the inclusion of toxic lead continues to impede their commercialization1,2,3. To mitigate the environmental and health concerns, tin halide perovskites (THPs) have been recognized as promising lead-free alternatives due to their desirable optoelectronic properties, which include ideal bandgaps (1.3–1.4 eV), high charge-carrier mobilities and low exciton binding energies4,5. Compared with the inert 6s electron pair of Pb2+, Sn2+ bears two active 5s electrons for a much higher Lewis acidity, leading to relatively fast crystallization rates and the easy oxidation of THP films with poor morphology control and abundant defects6,7. To address this issue, constructing two-dimensional/three-dimensional (2D/3D) heterostructures by incorporating bulky alkylammonium cations in the precursor solution has been widely adopted to regulate the crystallization process for fabricating high-quality THP films8,9,10. Such an approach has triggered a steady improvement in the power conversion efficiency (PCE) of tin halide perovskite solar cells (THPSCs), with 15% recently being surpassed11,12. Typically, the introduction of phenethylammonium cations (PEA+) in the precursor solution induces the formation of 2D perovskite frameworks that template the oriented growth of 3D FASnI3 crystals (FA = formamidinium) with substantially reduced morphological and crystal defects13,14,15,16,17.

According to the hard–soft acid–base principle, the small FA+ cation (~253 pm) can act as a hard Lewis acid to form strong hydrogen bonds with iodostannate complexes of [SnX6]nm− (X is I, Br or dimethyl sulfoxide), constituting aggregated FA-based colloidal clusters as primary nucleation sites in the precursor solution18,19,20,21. Conversely, the soft and bulky PEA+ cations (~552 pm) loosely coordinate with iodostannate complexes22, resulting in more dispersed PEA-based colloidal particles that must undergo further condensation and agglomeration periods to reach the critical nucleation radius defined by classical nucleation theory (Supplementary Note 1)23. Such a discrepancy of the colloidal coagulation dynamics leads to distinct nucleation kinetics between 3D and 2D THPs. As a result, these 2D THPs tend to sediment in the bottom region during the top-down crystallization processes of perovskite films, leading to a vertically graded distribution of 2D perovskite segments across the bulk 2D/3D THP films8,9. Although the gradient 2D/3D heterostructure can provide an additional built-in potential to facilitate charge-carrier separation, the bottom-enriched 2D THP segments may impede efficient hole transfer at the buried interface. More importantly, the delayed maturation of 2D phases during crystallization leads to the uncontrolled growth of 3D THP grains with abundant trap states and pronounced pinholes in the upper region, greatly deteriorating the optoelectronic properties of these 2D/3D phase-segregated heterostructures17,24. By contrast, the synchronized nucleation of 2D and 3D THPs enables the development of homogeneous 2D/3D heterostructures, where uniformly embedded 2D fragments can not only template the growth of a high-quality 3D THP matrix with substantially reduced defects but also facilitate the isotropic charge transport of 2D phases for achieving high-efficiency THPSCs25,26. Motivated by early experimental attempts using alkali metal cations to homogenize the phase distribution of their 2D Pb-based analogues27,28, introducing small and ionically bound caesium cations (Cs+) (~188 pm) into the precursor solution is expected to strengthen the adduct coordination within these PEA-rich colloids. This can facilitate their coagulation with the primary FA-based clusters for promoted nucleation, therefore providing a promising opportunity to narrow the nucleation kinetic gap between 2D and 3D THPs to achieve homogeneous 2D/3D heterostructures.

Here we introduce a Cs-incorporated colloidal chemistry engineering strategy to regulate the nucleation kinetics of mixed-dimensional perovskites, enabling THPSCs with a homogeneous 2D/3D bulk heterostructure and thus improved PCE values that exceed 17%. On ionic diffusion, small inorganic Cs+ can partially substitute bulky organic PEA+ cations in the electrical double layers (EDLs) of PEA-rich colloids, reducing their aggregation barrier with FA colloids for enlarged 2D/3D THP clusters in the precursor solutions. This approach successfully facilitates evenly distributed 2D/3D perovskite nuclei across the bulk film matrix, where 2D THPs template the growth of 3D THPs with improved crystallinity and preferential out-of-plane orientation. Benefiting from decreased morphological and crystallographic defects in the bulk film, the resultant homogeneous 2D/3D heterostructured THPSC with an optimal Cs+ molar ratio of 5% demonstrated an excellent PCE of 17.13% (certified 16.65%) and exceptional shelf and operational stability, retaining 93.3% and 92.0% of their initial peak PCEs after 6,000 h dark storage and 1,500 h under continuous one-sun illumination in nitrogen without encapsulation, respectively.

Colloidal stability and nucleation kinetics

According to classical nucleation theory, manipulating cluster sizes in the colloidal precursor solution is a direct route for regulating the nucleation kinetics of THPs by tailoring the Gibbs free energy (Supplementary Note 1)29,30. Given the dispersive nature of colloidal THP precursor solutions, the dissociated A-type cations (for example, FA+, PEA+, Cs+) are electrostatically attracted by the negatively charged iodostannate complexes of [SnX6]nm−, forming EDL configurations of FA-based or PEA-rich colloids (Fig. 1a and Supplementary Fig. 1a). On the basis of DLVO (Derjaguin–Landau–Verwey–Overbeek) theory31,32, the colloidal stability is mainly determined by the total repulsive potential (Wtotal) in the dispersing medium by integrating the van der Waals attraction (Wa) and the EDL repulsion (Wr) between two colloidal particles (Supplementary Fig. 1b). Thus, the aggregation barrier (ΔW*) is primarily dependent on the radius of the colloidal particle (R), where larger colloids possess a high aggregation barrier that makes them difficult to form stable nucleation clusters (Supplementary Note 2)31. As the inherently large size of the PEA+ cation expands the stern and diffuse layers in the EDL (RFA < RPEA), the bulky PEA-rich colloids possess a higher aggregation barrier than FA colloids (ΔW*FA < ΔW*PEA), leading to more electrostatically repulsive PEA-rich colloidal dispersions (Supplementary Fig. 2). In the 2D/3D THP precursor solutions, the small FA-based colloids easily undergo coagulation to form large clusters as primary nuclei, whereas the large PEA-rich colloids are expelled from the FA-dominant clusters due to their relatively high aggregation barrier (ΔW*FA–FA < ΔW*PEA–FA). Such segregation results in the delayed nucleation of 2D THPs and the early precipitation of 3D THPs for gradient 2D/3D heterostructures (Supplementary Note 3). Incorporating smaller Cs+ that form stronger ionic bonds with the inner iodostannate adducts can substitute PEA+ and FA+ cations in the EDLs, causing the volume to shrink for both colloids (RCs-PEA < RPEA, RCs-FA < RFA). This leads to a markedly reduced repulsion potential between the Cs-PEA and Cs-FA colloids (ΔW*Cs-PEA–Cs-FA < ΔW*PEA–FA), facilitating their coagulation to form mixed-phase PEA–FA clusters (Supplementary Figs. 3 and 4) and thus synchronizing the nucleation kinetics of 2D and 3D THPs.

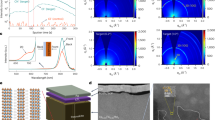

a, Schematic illustration of the primary colloidal stabilization of PEA-rich colloids and FA-based colloids, cluster formation and nucleation kinetics, and the growth processes of 2D/3D THPs with and without Cs+ incorporation. b, Colloidal cluster size distributions of THP precursor solutions (Cs0–Cs20) with different Cs+ ratios of 0–20 mol% characterized via DLS. The dashed line refers to the evolution of the average colloidal cluster size with different Cs+ ratios. c, In situ observation of the XRD patterns of Cs0 and Cs5 wet films (at 0 min following spin-coating) upon post-annealing treatment from 20 to 80 °C (at a ramp rate of 1 °C min−1) and being held at 80 °C for 10 min. The intensities of the 2D peaks are amplified 100-fold. (110)3D denotes the diffraction of the (110) plane of the 3D perovskite; (002)n=1, (002)n=2, (004)n=2 and (006)n=2 indicate the diffraction of the specific 2D perovskite plane with n = 1 or 2. d, XRD patterns (3–15°) of Cs0 and Cs5 wet films before annealing (# denotes residual SnI2). e, XRD patterns of polycrystalline Cs0 (top) and Cs5 (bottom) films after post-annealing treatment. The insets show the amplified diffraction peaks of the 2D perovskites for the 3–13° range. (110)3D and (220)3D are, respectively, the main diffraction peaks of the (110) and (220) planes of the 3D perovskites.

To verify the colloidal dynamics with different cations, we prepared mono-cation precursor solutions of PEA2SnI4, FASnI3, and CsSnI3 for dynamic light scattering (DLS) measurements, where their average cluster size variance agrees with the expected trend of CsSnI3 > FASnI3 > PEA2SnI4 (Supplementary Fig. 5). Incorporating 5 mol% Cs enlarges the average cluster size of PEA2SnI4 by 75%, whereas the FASnI3 clusters are expanded by only ~40%. The impact of Cs+ in the 2D/3D system was examined by preparing triple-cation (Cs–FA–PEA) precursor solutions with different Cs+ ratios for DLS analysis, where the Csx notation refers to the varying precursor compositions of (CsI)x/100(PEA0.15FA0.85SnI2.85Br0.15)1–x/100. As summarized in Fig. 1b, the average cluster size of the 2D/3D THP precursor solutions showed vigorous growth from 369 nm to 934 nm as x is increased from Cs0 to Cs5, whereas the less notable rates of increase from Cs7 to Cs20 can be attributed to the saturated Cs+ in the EDL structure. Thus, the Cs0 and Cs5 precursor solutions were selected for comparing the crystallization dynamics with and without Cs+. As monitored using in situ optical microscopy (Supplementary Fig. 6), the Cs5 precursor solution with large clusters displayed fewer nucleation sites at the primary nucleation stage, fostering more controlled growth of homogeneous perovskite grains upon gradient monomer diffusion.

In situ X-ray diffraction (XRD) was used to explain the nucleation and crystal growth kinetics of Cs0 and Cs5 THP wet films upon post-annealing treatment (Fig. 1c). Whereas the Cs0 wet film exhibited only sharp (110) and (220) peaks assigned to 3D FASnI3 (Supplementary Fig. 7a), the Cs5 wet film displayed both 3D perovskite peaks and the premature formation of 2D perovskite (n = 2), where n refers to the layer number of corner-sharing octahedra, indicating the presence of 2D perovskite nuclei in the shallow surface region immediately after spin-coating (Fig. 1d). In the Cs0 wet film, 2D perovskites (n = 1 and 2) appeared progressively upon thermal annealing after 10 min. The uneven 2D phase distribution with different n values can be attributed to the delayed nucleation of 2D perovskites during the top-down crystallization with solvent evaporation, along with the gradient depletion of FA+ cations and supersaturated PEA+ cations. By contrast, the steadily increasing XRD peak intensities at 4.2, 8.2 and 12.4° (corresponding to the 002, 004 and 006 planes, respectively) indicate the homogeneous growth of 2D perovskite (n = 2) domains across the Cs5 film. Benefiting from the crystal template effect of 2D perovskites33,34,35,36,37, the Cs5 film showed improved crystallinity with suppressed structural defects, as indicated by the 3D perovskite peaks with enhanced intensities and reduced full-width at half-maximum (FWHM) values (Fig. 1e and Supplementary Fig. 7b,c). Notably, there is no peak splitting at ~14°, suggesting the absence of the CsSnI3 phase impurity during crystallization. The dominant XRD peaks of both the 2D and 3D perovskites are rightshifted to higher angles with increased Cs ratios, indicating reduced lattice spacing from the cation substitution of FA+ for Cs+ in both 2D (n = 2) and 3D perovskite crystal phases (Supplementary Fig. 7d,e). However, the excessive incorporation of Cs+ induces a higher order of lattice mismatch for disoriented growth of the perovskite crystals, causing the reduced crystallinity of the Cs10 film.

Phase distribution and crystal orientation

Grazing-incidence wide-angle X-ray scattering (GIWAXS) is used to resolve the final microstructure of the perovskite films. Varying the incident angle adjusts X-ray penetration and scattering depths (Supplementary Fig. 8), enabling semi-quantitative depth profiles of the Cs0 and Cs5 films to be developed. In the control Cs0 sample, the absence of 2D perovskite diffraction spots at small grazing angles (that is, within 3–35 nm of the top surface) and their gradual appearance with increased penetration depth (~90–330 nm) confirms that 2D perovskite scattering domains tend to reside preferentially deep within the bulk film towards the buried interface (Fig. 2a and Supplementary Fig. 9). By stark contrast, pronounced 2D perovskite Bragg spots are observed throughout the Cs5 film sample at all grazing angles, emerging from the top surface to deep within the bulk film, revealing the formation of a well-distributed 2D/3D perovskite heterostructure. An azimuthal analysis of the (110) scattering plane at different X-ray scattering depths indicates that the presence of 2D perovskite segments at the shallow surface induces an improved out-of-plane orientation of the 3D perovskite crystals, as shown by the narrower azimuthal FWHM values across the Cs5 film (Fig. 2b,c). Consistent with the previous XRD result, the excessive incorporation of Cs+ induces a lattice-mismatch effect for increased disorientation of the 3D perovskite grains, as reflected via the Debye–Scherrer rings in the 2D GIWAXS patterns of Cs10 film with much higher azimuthal FWHM values (Supplementary Fig. 10). Benefiting from enhanced crystallinity and orientation, the Cs5 film shows a compact and dense surface morphology with negligible pinholes (Supplementary Fig. 11).

a, 2D GIWAXS patterns of Cs0 and Cs5 THP films with selected incident angle (α) values of 0.05, 0.16, 0.20 and 0.50°, where the missing out-of-plane wedges were omitted for clarity. The bright and dark colours indicate high and low diffraction intensities, respectively. b, Azimuthal distribution of the (110)3D plane of Cs0 and Cs5 THP films, with various X-ray scattering depths defined by incident angles and estimated X-ray scattering depths. c, Azimuthal FWHM variation of the (110)3D plane of Cs0 and Cs5 THP films with different incident angles. d,e, TOF-SIMS depth profiles of Cs0 (d) and Cs5 (e) THP films, where the pink region denotes the bulk perovskite film and the light-blue region indicates the glass substrate. The red, blue, cyan and yellow curves show the signals of the PEA, FA, Sn and Si species, respectively. c.p.s., counts per second.

The uniform distribution of 2D THP segments and Cs+ across the bulk film is further confirmed using time-of-flight secondary-ion mass spectrometry (TOF-SIMS) and in-depth X-ray photoelectron spectroscopy (XPS), respectively. As indicated by the TOF-SIMS results (Fig. 2d,e), the PEA+ signals are found to peak near the substrate in the Cs0 film (aggregated 2D perovskites at the buried interface), whereas the Cs5 sample shows a more even distribution of PEA+ throughout the film. Besides, the uniform distribution of Cs+ across the bulk film is verified by the depth XPS profile of the Cs5 film (Supplementary Fig. 12), which agrees with Cs+ substitution in both 2D and 3D THP domains corroborated by the XRD peak shift.

Photovoltaic performance and device stability

Encouraged by the promising crystallographic features and film microstructure, we fabricated solar cells with a p–i–n (p-type–intrinsic–n-type) architecture of ITO/PEDOT:PSS/THP/ICBA/BCP/Ag (see Methods for component materials) and an optimal absorber thickness of ~300 nm (Fig. 3a). By measuring the current density–voltage (J–V) curves under simulated one-sun AM1.5 illumination, the champion Cs5 device delivered a high PCE of 17.13% with an open-circuit voltage (Voc) of 0.99 V, a short-circuit current density (Jsc) of 23.07 mA cm−2 and a fill factor (FF) of 74.83%, whereas the best Cs0 device achieved only a modest PCE of 13.49% (Fig. 3b). Consistently, the Cs5 device exhibited a stabilized PCE of 17.04% under steady-state maximum power output tracking, which is higher than that (13.31%) of the Cs0 device. As shown in the external quantum efficiency (EQE) plots (Fig. 3c), the Cs5 device possessed an improved photocurrent response across the visible and near-infrared region, yielding an integrated Jsc of 22.34 mA cm−2 that is comparable to the value extracted from the J–V curves. In the statistical PV performance distribution from devices with different Cs ratios, the Cs5 devices achieved the highest average PCE of 16.57 ± 0.34% (Fig. 3d, Supplementary Fig. 13 and Supplementary Tables 1–3), further confirming the optimal Cs molar ratio of 5% and good device reproducibility. We also demonstrated a certified PCE of 16.65% from Shanghai Institute of Microsystem and Information Technology, an accredited independent PV calibration laboratory (Supplementary Figs. 14 and 15). The best PCE achieved in the laboratory (17.13%) and the certified PCE (16.65%) are among the highest reported efficiency values for THPSCs (Fig. 3e and Supplementary Table 4)11,12,29,38. Minor hysteresis with an average hysteresis index of 2.95% was observed in the target devices (Supplementary Fig. 16), which is probably due to the electric field-induced iodide migration accelerated by the Sn4+ species at the top surface39.

a, Schematic of the device structure and cross-sectional scanning electron microscope image of THPSCs. b, J–V curves (dotted line, forward scan; solid line, reverse scan) and stabilized power outputs (inset) of the champion Cs0 and Cs5 devices in the laboratory. The maximum power output of the Cs0 and Cs5 devices was tracked at 0.73 and 0.85 V, respectively. c, EQE plots (solid lines and symbols) and integrated photocurrent responses (dashed lines) of the Cs0 and Cs5 devices. d, Statistical PCE distributions of THPSCs with different Cs molar ratios. Statistics were derived from 20 devices for each condition from different batches (whiskers: maxima and minima; bounds of box: 25th and 75th percentile; centre: mean). e, Comparison between certified PCE values from previously reported THPSCs (Supplementary Table 4) and this work. The red star indicates the certified PCE of this work. f, Shelf stability of unencapsulated THPSCs under dark conditions in N2 at 35 ± 5 °C for 6,000 h (initial PCEs: 12.73% for Cs0 and 16.39% for Cs5). g, Operational stability of unencapsulated THPSCs under continuous one-sun illumination at open-circuit status in N2 at 60 ± 5 °C for 1,500 h (initial PCEs: 12.55% for Cs0 and 17.09% for Cs5).

Subsequently, the long-term stability of the Cs0 and Cs5 devices was examined under dark conditions and continuous light illumination. The unencapsulated Cs5 device showed excellent shelf stability, retaining 93.3% of the initial PCE after being stored in N2 under dark conditions for 6,000 h, whereas the Cs0 device showed a rapid decay in performance after 2,000 h (Fig. 3f). Such improved shelf stability in the Cs5 devices can be attributed to the presence of 2D perovskite segments across the bulk THP film that provide steric hindrance for oxygen and moisture permeation from the atmosphere. We then compared the operational stability of unencapsulated Cs0 and Cs5 devices under continuous illumination with a light-emitting diode (100 mW cm−2 equivalent to one-sun intensity) at 60 ± 5 °C. The target Cs5 device maintained 92.0% of the original PCE after 1,500 h (Fig. 3g), surpassing operational stabilities reported for other THPSCs (Supplementary Table 4).

Optoelectronic properties and charge-carrier dynamics

Owing to the reduced crystal lattice spacing by cationic substitution, incorporating 5% Cs+ results in an upshifted valence band and thus a narrowed energy bandgap of the THPs from 1.435 to 1.415 eV (Supplementary Fig. 17)40. This aligns with the redshifted emission peak in the steady-state photoluminescence (PL) spectrum of the Cs5 sample, and the increased PL intensity of the Cs5 sample can be attributed to the suppressed trap-assisted non-radiative recombination from the improved microstructure (Fig. 4a). As shown in the time-resolved PL decay profile (Fig. 4b), the Cs5 film exhibits a twofold-enhanced charge-carrier lifetime of 15.13 ns compared with that (6.15 ns) of the Cs0 film (Supplementary Table 5). The electron and hole diffusion lengths of the Cs0 and Cs5 films were then quantified by measuring their charge-carrier lifetimes with quenching layers41 (Fig. 4c, Supplementary Fig. 18 and Supplementary Table 6). Compared with those of the Cs0 film (240 nm for electrons and 225 nm for holes), the Cs5 film shows remarkably prolonged diffusion lengths of 488 nm and 454 nm for electrons and holes, respectively. The ultraviolet photoelectron spectroscopy (UPS) results of the pristine 2D and 3D THP films suggest a type-I energy-band alignment within the 2D/3D THP heterostructures (Supplementary Fig. 19), where the generated excitons of high-bandgap 2D phases can be energy funnelled to the surrounding low-bandgap 3D phase scaffold that dominates the dissociation and transport of free charge carriers42,43. Thus, the limited charge diffusion lengths in the Cs0 film are primarily due to the rich trap states of low-quality 3D THP crystals, induced by the inadequate 2D phase templating during the upper-region crystallization (Supplementary Fig. 20). Either a thicker Cs0 film or an additional 2D perovskite interlayer results in pronounced photocurrent losses, highlighting the impaired hole extraction from the bottom-enriched 2D phases at the buried interface (Supplementary Fig. 21 and Supplementary Table 7). By contrast, the longer diffusion lengths in the Cs5 film enable thicker perovskite layers (>300 nm) for enhanced light harvesting, as its homogeneous 2D/3D heterostructure can effectively regulate the growth of high-quality 3D THPs across the bulk film. Consistently, the Cs5 film possesses a lower Urbach energy (EU) of 34.32 meV compared with that of the Cs0 film (45.47 meV; Fig. 4d), suggesting the reduced energetic disorder in the homogeneous 2D/3D heterostructures44. The electron and hole trap densities of the perovskite films are estimated through space-charge-limited current measurements of devices that contain only electron transport layers (ETLs) or hole transport layers (HTLs) based on the Cs0 and Cs5 films (Supplementary Fig. 22). The lower electron and hole trap densities of the Cs5 samples are derived from the improved crystal quality of the 3D THPs assisted by the uniformly dispersed 2D nucleation templates (Supplementary Table 8). These characteristic features collectively underscore the reduced trap states from the improved microstructure of the Cs5 film, leading to suppressed non-radiative recombination and thus a much higher Jsc. The impedance spectra on different voltage biases further corroborate the increased recombination resistances in the target device (Supplementary Fig. 23)45, which agrees well with the higher built-in potential of 0.82 V as estimated in the Mott–Schottky plot of the Cs5 device (Fig. 4e), contributing to the improved Voc of the target device.

a, Steady-state PL spectra of the Cs0 and Cs5 THP films with the emission peak wavelengths labelled. b, Time-resolved PL decay profiles of the Cs0 and Cs5 THP films. τavg, average charge-carrier lifetime. c, Estimated electron (\({L}_{{\mathrm{D}}}^{{\mathrm{e}}}\)) and hole (\({L}_{{\mathrm{D}}}^{{\mathrm{h}}}\)) diffusion lengths of the Cs0 and Cs5 THP films.τQ and τ0 refer to the estimated average charge carrier lifetimes of perovskite films with and without a quenching layer. d, Urbach energy (EU) plots of the Cs0 and Cs5 THP films. hν, photon energy; α, absorption coefficient. e, Mott–Schottky plots of the Cs0 and Cs5 THPSCs. C, capacitance; Vbi, estimated built-in potential. f, Variation of the Sn4+ molar ratio across the Cs0 and Cs5 THP bulk films derived from depth XPS profiles with different etching time intervals, where the yellow, pink and light-blue regions denote the top surface, bulk film and bottom interface, respectively.

Owing to fast crystallization rates, the shallow trap states (for example, undercoordinated Sn2+) tend to gather on the surface and at grain boundaries within the THP films, before evolving into Sn4+ as deep-level defects by a trace amount of oxygen or oxidizing vapour inside the glovebox46,47. In-depth XPS is used to quantify the distribution of Sn4+ states at the surface and across the bulk film. With various Cs ratios of 0–10 mol%, the Cs5 film showed the lowest Sn4+ ratio of 5.14% at the top surface (Supplementary Fig. 24). At different argon-etching time intervals, the Cs5 film demonstrated much lower Sn4+ ratios across the bulk film (average 2.18%) compared with the Cs0 film, which had an average Sn4+ ratio of 5.18% (Fig. 4f and Supplementary Figs. 25 and 26). The reduced crystalline defects on the surface and at the grain boundaries of the Cs5 film can effectively inhibit the undesired ion migration activated by thermal or light stress, therefore contributing to the improved operational stability of the target device.

Conclusions

We have developed a facile colloidal regulation strategy to synchronize the nucleation kinetics of 2D and 3D THPs, enabling the fabrication of homogeneous 2D/3D heterostructures for high-quality THP thin films. Whereas the improved microstructure effectively suppresses defect formation within the bulk film, residual trap states at the top surface and the buried interface could be further eliminated through interfacial engineering, such as bilayer 2D/3D heterostructures and surface ligand decoration48,49. Beyond PVs, this approach could also be applicable for other THP devices that require high-quality perovskite thin films, including light-emitting diodes, photodetectors, lasers and transistors, facilitating high-performance lead-free perovskite optoelectronics in the future.

Methods

Materials

Indene-C60 bisadduct (ICBA) and poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) (Clevios P VP AI 4083) were purchased from 1-Material and Xi’an Yuri Solar Co., respectively. Tin powder (<45 μm particle size, 99.8%), iodine (99.8%), tin fluoride (SnF2) (99.999%), ammonium thiocyanate (NH4SCN), bathocuproine (BCP, 99%), N,N-dimethylformamide (DMF), dimethyl sulfoxide (DMSO), chlorobenzene, toluene and isopropyl alcohol (IPA) were purchased from Sigma-Aldrich. Formamidinium iodide (FAI) and phenethylammonium bromide (PEABr) were purchased from Greatcell Solar Materials.

Precursor solution preparation

Iodine (1.14 g) was first dissolved in DMSO (0.75 ml), then DMF (3 ml) was added to obtain a 1.2 M iodine solution. The concentration of the final precursor solutions was modified by adjusting the amount of iodine added for SnI2 synthesis (for example, 0.76 g for 0.8 M or 1.33 g for 1.4 M). An excess of Sn powder (>1 g) was added to the solution, which was then stirred overnight in a nitrogen-filled glovebox to prepare a SnI2 solution in DMF:DMSO (4:1 v/v). Then, FAI, PEABr, SnF2 and NH4SCN with a stoichiometric molar ratio of 0.85:0.15:0.08:0.05 were dissolved in the prepared SnI2 solution to form perovskite precursor solutions of 0.8, 1.2 and 1.4 M. To prepare the Cs-incorporated precursor solutions, a caesium iodide (CsI) stock solution (1.5 M in DMSO) was blended with the prepared 2D/3D THP precursor solutions to reach the target Cs+ ratios (1–20 mol%) before deposition. Specifically, the CsI stock solution (39.75 µl) was added to 1.2 M FA–PEA perovskite precursor solutions (1 ml) to achieve 5 mol% Cs. The perovskite precursor solutions were aged inside a nitrogen-filled glovebox for 48 h to ensure uniform colloidal cluster formation, whereas an excess of Sn powder (10 mg ml−1) was added to the perovskite precursor to prevent oxidation and was filtered directly before use. To prepare the pristine 2D and 3D perovskite films, the stoichiometric molar ratios of the precursor solutions are adjusted to FAI:SnI2 (1:1) for FASnI3, CsI:FAI:SnI2 (0.05:0.95:1) for Cs0.05FA0.95SnI3, PEAI:SnI2 (2:1) for PEA2SnI4, PEA:FAI:SnI2 (2:1:2) for PEA2FASn2I7 and PEA:CsI:FAI:SnI2 (2:0.95:0.05:2) for PEA2(Cs0.05FA0.95)Sn2I7, respectively. To prevent oxidation, 8 mol% of SnF2, 5 mol% of NH4SCN and an excess of Sn powder (10 mg ml−1) were added to these precursor solutions.

Device fabrication

Patterned indium tin oxide (ITO) glass substrates were sequentially cleaned with IPA, acetone and IPA for 15 min each, followed by ultraviolet-ozone treatment for 20 min before use. The PEDOT:PSS solution was filtered through a 0.45 µm polytetrafluoroethylene syringe filter and spin-coated onto the patterned ITO substrates at 6,000 revolutions per min (r.p.m.) for 40 s with an acceleration of 2,000 r.p.m. s−1. The substrates were then annealed at 140 °C for 20 min under ambient conditions, before immediately being transferred into a nitrogen-filled glovebox for deposition of the perovskite layer. Constant purging of the glovebox was carried out during the whole fabrication processes to maintain an oxygen level below 0.1 ppm. To deposit the perovskite film, the perovskite precursor (60 µl) was spun onto the PEDOT:PSS layer at 5,000 r.p.m. for 30 s at an acceleration of 2,000 r.p.m. s−1. After 10 s of spinning, toluene (500 µl) was quickly added dropwise onto the spinning substrate within 1–2 s (at a distance of ~1 cm between the pipette tip and the substrate), followed by annealing at 80 °C for 10 min. The ICBA solution (20 mg ml−1 in chlorobenzene) was spin-coated onto the perovskite layer at 1,000 r.p.m. for 30 s with an acceleration of 800 r.p.m. s−1, followed by annealing at 80 °C for 10 min. Subsequently, a 6-nm-thick layer of BCP and an 80-nm-thick layer of silver (Ag) were sequentially deposited via thermal evaporation at rates of 0.1 and 0.5 Å s−1, respectively. The active area of the solar cells was defined using a metal shadow mask of 0.0576 cm2 are for performance evaluation.

Material characterization

The colloidal cluster size distributions of the perovskite precursor solutions were characterized via DLS measurements using a Malvern Zetasizer Nano Analyzer. The in situ XRD patterns of premature perovskite films upon post-annealing after spin-coating were measured using a Rigaku MiniFlex diffraction meter equipped with a heating stage (a ramp rate of 1 °C min−1 from 20 to 80 °C and then kept at 80 °C for 10 min) under continuous nitrogen purging. The XRD patterns of the polycrystalline perovskite films were obtained using a Bruker Advanced X-ray diffractometer (40 kV, 30 mA, Cu Kα radiation). Perovskite films deposited on ITO substrates were used for GIWAXS measurements at the SAXS/WAXS beamline (Australian Synchrotron) using a 12.95 keV X-ray incident beam and an in-vacuum Pilatus 2M detector positioned 72 cm from the sample. TOF-SIMS was used for depth profiling of the perovskite films. A pulsed beam of primary ions was focused onto the sample surface to induce sputtering, generating secondary ions. The TOF-SIMS measurements were carried out using an IONTOF TOF-SIMS 5 system in positive polarity (MCs+ mode). A Cs-ion beam (500 eV) was used for erosion, and a Bi3+ pulsed primary ion beam (30 keV) was used for analysis. The surface morphology of the perovskite films and the cross-section microstructure of the full devices were recorded using a JEOL 7001 field-emission scanning electron microscope. The cryogenic transmission electron microscopy (cryo-TEM) images of colloidal particles were recorded using a JEM-Z300FSC cryo-electron microscope (CRYO ARM 300) equipped with a cold field-emission gun and an in-column Omega energy filter. The cryo-TEM samples were prepared by dropping aged precursor solutions (3–5 μl) onto continuous carbon-supported copper grids, followed by blotting inside a nitrogen-filled glovebox using filter papers and subsequently immediate freezing with liquid nitrogen. The TEM images of colloidal particles were recorded using a Hitachi HT7700 transmission electron microscope, where fresh TEM samples were prepared using the blotting protocol mentioned above inside a nitrogen-filled glovebox. The in situ optical images during perovskite crystallization were recorded using a Leica SP8 confocal microscope equipped with an incubation chamber at 50 °C, where the aged perovskite precursor solution (3–5 μl) was added dropwise onto a cover-glass slip (thickness 130–160 μm). The ultraviolet-visible light absorption of perovskite films was recorded using a Jasco V-650 spectrophotometer. Steady-state PL spectra were measured with a Horiba Fluoromax spectrofluorometer and FluorEssence software (version 3.9)50, using a monochromatized xenon lamp as the excitation source at 530 nm. Time-resolved PL decay profiles were measured using a fluorescence spectrophotometer (FLSP-900, Edinburgh Instruments) with a 532 nm pulsed diode laser as the excitation source. XPS and UPS spectra were acquired using a Kratos Axis Supra Plus XPS (Al Kα radiation source), calibrated using C1s (284.8 eV) as the reference.

Device characterization

The J–V curves of the solar cell devices were obtained using a Keithley 2420 source meter and an Enli-Tech SS-F7-3A solar simulator with a calibrated silicon reference cell (100 mW cm−2, AM1.5G). The J–V curves were measured in reverse (from 1.0 to −0.1 V) and forward (from −0.1 to 1.0 V) scans with a 50 ms delay. The incident photon-to-current efficiency was measured using a 300 W xenon light source (Newport 66902) with an Oriel Cornerstone monochromator and a multimeter operating in a direct-current mode. The shelf stability of the devices was measured by storing then in nitrogen under dark conditions at 35 ± 5 °C. The operational stability of the devices was measured under continuous white light illumination from a light-emitting diode (100 mW cm−2 equivalent to one-sun intensity, open-circuit status) in nitrogen at 60 ± 5 °C. The space-charge-limited current measurements were conducted by recording the J–V curves of ETL-only devices (ITO/SnO2/perovskite/ICBA/BCP/Ag) and HTL-only devices (ITO/PEDOT:PSS/perovskite/Spiro-OMeTAD/Ag, where Spiro-OMeTAD is a hole transport material) under dark conditions in nitrogen for estimating the respective electron and hole trap densities of the perovskite films. The impedance spectra of the full devices were measured using an Ivium-n-Stat multichannel electrochemical analyser. The Mott–Schottky analysis was conducted by measuring the capacitance-voltage (C–V) curves of the completed solar cell devices under dark conditions in nitrogen, where the built-in potential (Vbi) values of the devices based on different perovskite compositions were estimated by linear fitting.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

Li, J. et al. Biological impact of lead from halide perovskites reveals the risk of introducing a safe threshold. Nat. Commun. 11, 310 (2020).

Zhang, H. et al. Lead immobilization for environmentally sustainable perovskite solar cells. Nature 617, 687–695 (2023).

Chen, H. et al. Improved charge extraction in inverted perovskite solar cells with dual-site-binding ligands. Science 384, 189–193 (2024).

Jiang, X. et al. Tin halide perovskite solar cells: an emerging thin-film photovoltaic technology. Acc. Mater. Res. 2, 210–219 (2021).

Zhu, Z. et al. Smooth and compact FASnI3 films for lead-free perovskite solar cells with over 14% efficiency. ACS Energy Lett. 7, 2079–2083 (2022).

Wang, J. et al. Controlling the crystallization kinetics of lead-free tin halide perovskites for high performance green photovoltaics. Adv. Energy Mater. 11, 2102131 (2021).

Zhang, Z. et al. Mechanistic understanding of oxidation of tin-based perovskite solar cells and mitigation strategies. Angew. Chem. Int. Ed. 62, e202308093 (2023).

Yu, B.-B. et al. Heterogeneous 2D/3D tin-halides perovskite solar cells with certified conversion efficiency breaking 14%. Adv. Mater. 33, 2102055 (2021).

Li, H. et al. High-member low-dimensional Sn-based perovskite solar cells. Sci. China Chem. 66, 459–465 (2023).

Shao, S. et al. Highly reproducible Sn-based hybrid perovskite solar cells with 9% efficiency. Adv. Energy Mater. 8, 1702019 (2018).

Shi, Y., Zhu, Z., Miao, D., Ding, Y. & Mi, Q. Interfacial dipoles boost open-circuit voltage of tin halide perovskite solar cells. ACS Energy Lett. 9, 1895–1897 (2024).

Chen, J. et al. Efficient tin-based perovskite solar cells with trans-isomeric fulleropyrrolidine additives. Nat. Photon. 18, 464–470 (2024).

Li, H. et al. Low-dimensional inorganic tin perovskite solar cells prepared by templated growth. Angew. Chem. Int. Ed. 60, 16330–16336 (2021).

Meng, X. et al. Surface-controlled oriented growth of FASnI3 crystals for efficient lead-free perovskite solar cells. Joule 4, 902–912 (2020).

Liu, X. et al. Templated growth of FASnI3 crystals for efficient tin perovskite solar cells. Energy Environ. Sci. 13, 2896–2902 (2020).

Liao, Y. et al. Highly oriented low-dimensional tin halide perovskites with enhanced stability and photovoltaic performance. J. Am. Chem. Soc. 139, 6693–6699 (2017).

Dong, J. et al. Mechanism of crystal formation in Ruddlesden–Popper Sn-based perovskites. Adv. Funct. Mater. 30, 2001294 (2020).

Kieslich, G., Sun, S. & Cheetham, A. K. Solid-state principles applied to organic–inorganic perovskites: new tricks for an old dog. Chem. Sci. 5, 4712–4715 (2014).

Pearson, R. G. Hard and soft acids and bases. J. Am. Chem. Soc. 85, 3533–3539 (1963).

Jiang, X. et al. One-step synthesis of SnI2·(DMSO)x adducts for high-performance tin perovskite solar cells. J. Am. Chem. Soc. 143, 10970–10976 (2021).

Flatken, M. A. et al. Role of the alkali metal cation in the early stages of crystallization of halide perovskites. Chem. Mater. 34, 1121–1131 (2022).

Jena, A. K., Kulkarni, A. & Miyasaka, T. Halide perovskite photovoltaics: background, status, and future prospects. Chem. Rev. 119, 3036–3103 (2019).

Jung, M., Ji, S.-G., Kim, G. & Seok, S. I. Perovskite precursor solution chemistry: from fundamentals to photovoltaic applications. Chem. Soc. Rev. 48, 2011–2038 (2019).

Quintero-Bermudez, R. et al. Compositional and orientational control in metal halide perovskites of reduced dimensionality. Nat. Mater. 17, 900–907 (2018).

Zhang, J. et al. Uniform permutation of quasi-2D perovskites by vacuum poling for efficient, high-fill-factor solar cells. Joule 3, 3061–3071 (2019).

Peng, W. et al. Reducing nonradiative recombination in perovskite solar cells with a porous insulator contact. Science 379, 683–690 (2023).

Zhang, X. et al. Stable high efficiency two-dimensional perovskite solar cells via cesium doping. Energy Environ. Sci. 10, 2095–2102 (2017).

Guo, Z. et al. Promoting energy transfer via manipulation of crystallization kinetics of quasi-2D perovskites for efficient green light-emitting diodes. Adv. Mater. 33, 2102246 (2021).

Wang, J. et al. Colloidal zeta potential modulation as a handle to control the crystallization kinetics of tin halide perovskites for photovoltaic applications. Angew. Chem. Int. Ed. 63, e202317794 (2024).

Meng, X. et al. Crystallization kinetics modulation of FASnI3 films with pre-nucleation clusters for efficient lead-free perovskite solar cells. Angew. Chem. Int. Ed. 60, 3693–3698 (2021).

Polte, J. Fundamental growth principles of colloidal metal nanoparticles – a new perspective. CrystEngComm 17, 6809–6830 (2015).

Ohshima, H. Approximate analytic expression for the stability ratio of colloidal dispersions. Colloid Polym. Sci. 292, 2269–2274 (2014).

Wang, J. et al. Templated growth of oriented layered hybrid perovskites on 3D-like perovskites. Nat. Commun. 11, 582 (2020).

Lee, J.-W. et al. Solid-phase hetero epitaxial growth of α-phase formamidinium perovskite. Nat. Commun. 11, 5514 (2020).

Luo, C. et al. Facet orientation tailoring via 2D-seed-induced growth enables highly efficient and stable perovskite solar cells. Joule 6, 240–257 (2022).

Wang, J. et al. Oriented attachment of tin halide perovskites for photovoltaic applications. ACS Energy Lett. 8, 1590–1596 (2023).

Sidhik, S. et al. Two-dimensional perovskite templates for durable, efficient formamidinium perovskite solar cells. Science 384, 1227–1235 (2024).

Zhou, X. et al. Additive engineering with 2,8-dibromo-dibenzothiophene-S,S-dioxide enabled tin-based perovskite solar cells with 14.98% power conversion efficiency. Energy Environ. Sci. 17, 2837–2844 (2024).

Jokar, E. et al. Slow passivation and inverted hysteresis for hybrid tin perovskite solar cells attaining 13.5% via sequential deposition. J. Phys. Chem. Lett. 12, 10106–10111 (2021).

Gao, W. et al. Robust stability of efficient lead-free formamidinium tin iodide perovskite solar cells realized by structural regulation. J. Phys. Chem. Lett. 9, 6999–7006 (2018).

Zhu, P. et al. Aqueous synthesis of perovskite precursors for highly efficient perovskite solar cells. Science 383, 524–531 (2024).

Lin, Y. et al. Unveiling the operation mechanism of layered perovskite solar cells. Nat. Commun. 10, 1008 (2019).

Yuan, M. et al. Perovskite energy funnels for efficient light-emitting diodes. Nat. Nanotechnol. 11, 872–877 (2016).

Jiang, X. et al. Ultra-high open-circuit voltage of tin perovskite solar cells via an electron transporting layer design. Nat. Commun. 11, 1245 (2020).

Ghahremanirad, E., Bou, A., Olyaee, S. & Bisquert, J. Inductive loop in the impedance response of perovskite solar cells explained by surface polarization model. J. Phys. Chem. Lett. 8, 1402–1406 (2017).

Zhou, J. et al. Chemo-thermal surface dedoping for high-performance tin perovskite solar cells. Matter 5, 683–693 (2022).

Nasti, G. et al. Pyridine controlled tin perovskite crystallization. ACS Energy Lett. 7, 3197–3203 (2022).

Wang, T. et al. High open circuit voltage over 1 V achieved in tin-based perovskite solar cells with a 2D/3D vertical heterojunction. Adv. Sci. 9, 2200242 (2022).

Sun, C. et al. Well-defined fullerene bisadducts enable high-performance tin-based perovskite solar cells. Adv. Mater. 35, 2205603 (2023).

FluorEssence Version 3.9.1.16 (Horiba Scientific, 2012); https://www.horiba.com/int/scientific/products/detail/action/show/Product/fluoressence-1378

Acknowledgements

We acknowledge K. Wang, C.-H. Lin and M. Lyu for characterization discussions. This work was supported by the Australian Research Council via Laureate Fellowship (FL190100139 (L.W.)), Discovery Project (DP230100572 (P.C.)), Future Fellowship (FT230100251 (Z.W.)) and Discovery Early Career Researcher Awards (DE230101712 (P.C.), DE230100173 (J.A.S.) and DE230100163 (M.Z.)). Part of this research was undertaken on the GIWAXS/SAXS beamlines at the Australian Synchrotron. We acknowledge the Centre for Microscopy and Microanalysis and the Australian National Fabrication Facility, the University of Queensland Node and the Centre for Advanced Microscopy of the Australian National University.

Author information

Authors and Affiliations

Contributions

D.H., P.C. and L.W. conceived the idea and designed the experiments. D.H. fabricated the devices and performed the characterization experiments under the supervision of P.C. and L.W. The GIWAXS measurements and data interpretation were conducted by J.A.S. Data analysis was carried out by Z.W. and M.Z., who also assisted with device certification. Hongyi Xu and F.K. conducted the low-dose TEM and cryo-TEM measurements. C.Z., T.L., S.D., Hongzhe Xu and M.H. assisted with characterization of the materials. P.C., D.H. and L.W. draughted the manuscript. All of the authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Nanotechnology thanks Feng Yan, Antonio Abate and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–3, Figs. 1–26 and Tables 1–8.

Source data

Source Data Fig. 1

Source data of colloidal cluster size distributions, in situ XRD data and XRD data of wet films and crystalline films.

Source Data Fig. 2

Source data of azimuthal FWHM values with different incident angles and TOF-SIMS depth profiles.

Source Data Fig. 3

Source data of J–V curves, stabilized maximum power output, statistical distributions of photovoltaic parameters, shelf stability and operational stability monitoring.

Source Data Fig. 4

Source data of steady-state PL emission, time-resolved PL decay, Urbach energy and Sn4+ ratios with different etching time intervals.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

He, D., Chen, P., Steele, J.A. et al. Homogeneous 2D/3D heterostructured tin halide perovskite photovoltaics. Nat. Nanotechnol. 20, 779–786 (2025). https://doi.org/10.1038/s41565-025-01905-4

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s41565-025-01905-4

This article is cited by

-

Reproducible Fabrication of Perovskite Photovoltaics via Supramolecule Confinement Growth

Nano-Micro Letters (2026)

-

Colloidal chemistry in tin perovskite

Nature Nanotechnology (2025)