Abstract

High-power amplifiers are critical components in optical systems spanning from long-range optical sensing and optical communication systems to micromachining and medical surgery. Today, integrated photonics with its promise of large reductions in size, weight and cost cannot be used in these applications, owing to the lack of on-chip high-power amplifiers. Integrated devices severely lack in output power owing to their small size, which limits their energy storage capacity. For the past two decades, large mode area (LMA) technology has played a disruptive role in fibre amplifiers, enabling a dramatic increase of output power and energy by orders of magnitude. Owing to the ability of LMA fibres to support significantly larger optical modes, the energy storage and power handling capabilities of LMA fibres have significantly increased. Therefore, an LMA device on an integrated platform can play a similar role in power and energy scaling of integrated devices. In this work, we demonstrate LMA waveguide-based watt-class high-power amplifiers in silicon photonics with an on-chip output power exceeding ~1 W within a footprint of only ~4.4 mm2. The power achieved is comparable and even surpasses that of many fibre-based amplifiers. We believe that this work has the potential to radically change the integrated photonics application landscape, allowing power levels previously unimaginable from an integrated device to replace much of today’s benchtop systems. Moreover, mass producibility, reduced size, weight and cost will enable yet unforeseen applications of laser technology.

Similar content being viewed by others

Main

High-power amplifiers are usually associated with solid-state and fibre-based benchtop systems. This is due to the large energy storage capacity of such systems, owing to the large optical mode cross section, gain area and long optical path length. High-power amplifiers have a variety of applications such as in amplifying low-noise mode-locked laser pulses, continuous wave laser signals, high-power optical frequency comb generation, spectroscopy, laser detection and ranging, telecommunication (preamp, in-line and booster amplifiers), material processing and medical applications1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16. Benchtop high-power amplifiers are necessary for many photonic systems, but as we move towards systems level miniaturization11,12,13, especially for applications in hostile environments, such as deep space, their size and weight become a major roadblock as they are hard to scale down and mass-produce11,12,13,14,15,16,17,18,19,20,21.

Fibre amplifiers and semiconductor amplifiers, which can be electrically pumped, have been quite successful in the telecommunications industry and other applications. High-power semiconductor amplifiers, particularly slab-coupled optical waveguide amplifiers, have shown watt-level amplification in the telecom window22; however, so far, their photonic integration has met with challenges23,24. There are semiconductor amplifiers that can be heterogeneously integrated to silicon photonics. Such devices, despite being currently limited to a few tens of mW of amplified power (partly owing to high thermal instability and nonlinear loss), are going through a notable progress, especially in the fabrication yield and integration with silicon photonics, owing to the involvement of various industrial players23,24,25,26,27.

Rare-earth gain ions, owing to the shielding of the 4f shell, are relatively unaffected by their host environment and exhibit rich optical spectra while being barely affected by thermal instabilities and nonlinear losses. Hence, it is not surprising that most high-power solid-state and fibre amplifiers and lasers are based on rare-earth-doped gain media. In fact, owing to these excellent qualities, rare-earth-doped semiconductor devices were investigated even before the erbium-doped fibre amplifier (EDFA) was invented28,29,30. Over the past two decades, rare-earth gain media have been satisfactorily demonstrated at the chip scale31,32,33,34,35,36,37,38,39,40,41,42,43,44. However, the output power from these devices has remained low. Very recently, amplification up to 140 mW in the C-band with very long low-loss erbium-doped silicon nitride (SiN) waveguides was demonstrated44. However, this is at the expense of a complex fabrication process, and there are concerns about instabilities from nonlinear effects at high power (such as in fibres with long lengths and tight mode confinement) and multimodedness, which can lead to loss of energy to unwanted modes5. For high-power applications, it is desirable to have a shorter device that supports a large optical mode and gain region45,46,47,48, which increases the gain saturation power and helps to reduce nonlinear effects while simultaneously increasing the energy storage capacity. In integrated photonics, however, the very property of tight mode confinement, which enables a small form factor, becomes an impediment to high-power and energy applications, limiting the power to a few tens of mW (refs. 23,24,25), and only a few mWs in the mid-infrared window49. We have recently explored a CMOS-compatible large mode area (LMA) waveguide for integrated photonics50,51. Such an LMA waveguide helps to increase the energy storage capacity and gain saturation power while incurring negligible nonlinear instabilities within a compact footprint. In this work, we leverage such LMA technology and demonstrate for the first time a CMOS-compatible watt-class high-power amplifier with signal amplification reaching up to ~1 W in a compact footprint of 4.4 mm2 (0.2 × 21 mm). The signal power reaches and even surpasses the level enjoyed by many commercial benchtop fibre amplifiers (www.advaluephotonics.com; www.thorlabs.com). The LMA device supports a mode area in the range of tens of µm2, increasing the gain saturation power comparable to that of high-power fibre amplifiers. Moreover, unlike an LMA fibre amplifier, the on-chip LMA device supports only fundamental mode propagation, tight bends, seamless interfacing with different silicon photonic photonics components51, and high pump and signal mode overlap even when they are spectrally far apart.

Design and experiments

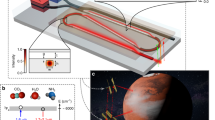

The gain waveguide cross section is shown in Fig. 1a, where an active layer is on top of a passive layer. Devices based on an active layer on top of a passive layer have been explored before for signal gain and modulation52,53,54,55. Semiconductor gain52,53,54 and rare-earth gain media31,42,56 have been implemented in this manner; however, owing mainly to the small mode area, the power has remained low. Here we introduce an LMA gain layer while maintaining a compact footprint. The gain waveguide consists mainly of a bottom SiN layer buried in silica and a top gain layer. The SiN thickness can vary depending on the wavelength of interest and the foundry of fabrication, allowing flexible fabrication at different CMOS foundries. For the proof-of-principle demonstration, we chose a thulium-doped aluminium oxide gain medium (Tm3+:Al2O3) owing to its ease of availability and various mid-infrared medical and defence applications57,58,59,60,61. The thickness of the gain layer is >1.35 µm on top of a silica cladding layer within which an 800 nm thick SiN layer is buried (such a thick SiN allows seamless integration to conventional nonlinear photonics components). The SiN layer was designed to have a width (w) of 280 nm, and the interlayer oxide thickness (g) was designed to be 310 nm. The simulated transverse magnetic (TM) mode profile of the signal is shown in Fig. 1b, with a pump and signal mode overlap of >98%. The mode area is ~30 µm2 around the signal (1.85 µm) and 31 µm2 around the pump (1.61 µm) wavelength. The signal and pump mode overlap with the gain layer are 92% and 94%, respectively. A schematic of the LMA amplifier is shown in Fig. 1c. The LMA gain sections are the straight sections within the gain deposition region (enclosed with the green box). To obtain a compact footprint, these gain sections are interconnected with each other with the help of tight bends in which the large modes from the LMA sections are transitioned into small modes (~1.5 µm2 mode area) through adiabatic tapers, shown as brown lines. The length of the gain section is ~6.2 cm. For pumping the gain medium, we chose an in-band pumping scheme. Such a scheme helps to reduce the quantum defect (difference in the pump and the signal photon energy), and thus helps to improve conversion efficiency62,63,64 and allows for a relaxed choice of pump wavelength, which can be within the range from 1.55 µm to 1.7 µm for thulium-doped aluminium oxide. A simplified energy diagram is shown in Fig. 1d, which shows the upper and lower energy-level manifolds. Signal generation can span from 1,750 nm to more than 2 µm (ref. 62), owing to the broadband gain bandwidth of thulium-doped glass. The device was fabricated in a silicon photonics foundry on a silicon-nitride-on-silicon platform. The thickness of the SiN layer is 800 nm (thinner layers that are commonly available in a CMOS facility can equally be applied with minor modification of the waveguide cross section). The photonic stack consists of a layer of silicon, bottom silicon, bottom silicon dioxide, SiN (800 nm thick), top silicon dioxide and the gain aluminium oxide layer. A gain layer (Tm3+:Al2O3) >1.35 µm thick was deposited with a radio-frequency (RF) sputtering tool at a rate of 5 nm min−1 at a substrate temperature of 400 °C (ref. 65) (Supplementary Information). The estimated concentration was between 5.5 × 1020 cm−3 and 6.5 × 1020 cm−3 and the passive film loss was ≤0.1 dB cm−1 at 1.61 µm. Subsequently, the device was characterized with a pump at 1.61 µm. The experimental set-up is shown in Fig. 2a. The pump laser was coupled through a lens into the pump channel of the fibre wavelength division multiplexer (WDM), which was fusion spliced to a lensed fibre with a 3 µm spot size. The signal was centred around 1.85 µm, filtered from a supercontinuum source (NKT Fianium) with a band-pass filter, which was launched into the signal channel of the WDM. The coupling loss for the signal and the pump was between 2.5–2.8 dB per facet and 3.5 dB per facet, respectively. In the experiment, we use a co-propagating pump and signal scheme owing to the ease of operation; however, the counterpropagating scheme can equally be implemented because not much difference between the two schemes in the experiment was observed (Supplementary Fig. 10). This is because the amplified spontaneous emission (ASE), which usually takes away the gain from a small signal, depending on the direction of pumping, is dominated by the strong seed signal used in this work66. The chip was mounted on a thermally conductive tape for stable operation at high power. The signal was collected at the output with a lensed fibre connected to a WDM, which was, down the line, connected through an attenuator to a calibrated optical spectrum analyser and a power meter. The on-chip amplified signal power at the output (Fig. 2b) and the net gain as a function of pump power are shown in Fig. 2c,d, respectively. In this report, the stated optical power is the on-chip power, unless otherwise stated. The output signal power reached close to 1 W amounting to an ~14.5 dB net gain for an input signal power of ~36 mW (the maximum signal limited by the source). A 16.5 dB net gain was seen for a signal of approximately 18 mW before parasitic lasing occurred, as shown later. The conversion efficiency at the maximum output ranges between 63% and 66% (taking into account uncertainty in the pump power coupling). The amplifier was also tested at a lower signal power as shown in Fig. 3. The signal ranged from <0.1 mW to ~36 mW, and the pump was varied from 140 mW to 1.48 W. The green shaded region depicts the parasitic lasing region from facet reflection, which caused gain clamping. This is mainly because the signal amplification overcomes the roundtrip loss leading to lasing; such a phenomenon is a well-known nuisance in amplifiers44,46,67.

a, The LMA waveguide cross section, where t is the thickness of the gain film (>1.35 µm), g is the thickness of the interlayer oxide (310 nm), and h and w are the height (800 nm) and width (280 nm) of the SiN layer. b, The signal mode profile at 1.85 µm, with an Aeff ~ 30 µm2. c, Amplifier schematic, in which the pump and the signal are launched from the input side and the amplified signal is collected at the output. The small modes around the bends indicate the tight confinement region where the mode is well confined within the SiN layer. The images of large mode indicate the LMA region where the pump excites the gain ions to the upper state to amplify the co-propagating signal. The brown sections indicate the adiabatic tapers used to transition the large modes back to the tight modes to allow for tighter bends. d, A simplified energy diagram of thulium-doped alumina with the pump at 1.61 µm and the signal ranging from 1.8 µm to 2 µm.

a, Experimental set-up. BP is a band-pass filter, PC is a polarization controller, WDM is a wavelength division multiplexer, D is a pump dump, A is a variable attenuator and DUT is the device under test. b, Spectra of the input signal and amplified output signal (with sharp absorption lines owing to atmospheric water vapour seen in the spectrum between 1,810 nm and 1,940 nm). c, On-chip output signal power as a function of pump power for on-chip signal power ranging from 18 mW to 36 mW. d, Net on-chip gain as a function of pump power. The error bars in c and d represent the uncertainty owing to input and output coupling loss around the mean value estimated from at least four different measurements.

On-chip output signal power as a function of on-chip input signal power at different pump power levels. The green shadowed region depicts the region of parasitic lasing. The dotted lines connecting the data points are guides for the eye. The error bars indicate the uncertainty in the coupling loss to the chip around the mean value estimated from four different measurements.

The maximum net gain achieved was approximately 16.5 dB before parasitic lasing sets in, which can be avoided with angled inverse tapers (in a stand-alone device), or high-power index matching glue (http://www.luvantixadm.com), or it can be avoided altogether in a photonic circuitry where the amplifier will be seamlessly connected to other photonics components without strong Fresnel reflection. The gain is the highest when the pump and signal are in the same polarization (which ensures that the pump and signal modes are of similar size), which is obtained with the help of waveplates and a polarization controller. The input and amplified output signal polarizations were measured to be the same with an extinction ratio of 35 dB at the input and output. For an on-chip pump power higher than 0.6 W, the gain saturation power can be estimated to be between 50 mW and 90 mW (the signal power for which gain drops to half of its small-signal value), which corresponds to an approximate saturation energy of 35–63 µJ for an upper-state lifetime of 700 µs.

To study the luminescence properties of the active ions in the gain film, we performed photoluminescence (PL) measurements. To avoid effects such as reabsorption, ASE and wavelength-dependent loss of the waveguide, we coupled the pump into the waveguide with end-fire coupling and collected the PL with an out-of-plane collection set-up (see Methods and Supplementary Fig. 4 for details). The measured upper-state lifetime for the TM mode at low power was 1 ms, which decreased to 720 µs for high pump power (>300 mW) owing to energy transfer up-conversion processes62,68,69,70. Similar measurements were performed for the signal and pump in transverse electric (TE) mode with a larger mode area (<60 µm2). A slightly shorter lifetime was measured for the larger TE mode, ~660 µs at higher pump power. We also compared the PL strength of the two modes (Fig. 4a), and we observed that the larger mode gave stronger PL, which is mainly due to exciting a large number of ions, suggesting a higher gain for the larger mode (we note that the peak of the PL is approximately 1,830 nm unlike the gain (at 1,850 nm), which is due to lower absorption loss at 1,850 nm). The shapes of the PL spectra for the TE and TM modes remained the same, except for the variation in strength for the measured pump power. The simulated mode profiles of the TE and TM modes are shown in Fig. 4b. The mode overlap between the pump and the signal is more than 98% for both of the polarizations. The group indices are 1.75 and 1.77 for the TE and TM modes, respectively. The gain was measured for the TE mode, and the difference in gain between the TE and TM modes at different pump powers is shown in Fig. 4b (for an on-chip signal power of ~18 mW). The TE mode gain gradually increases with the pump power and surpasses the TM gain at approximately 0.4 W of pump power. At higher pump power, the TE mode experienced parasitic lasing, which is mainly due to high gain for the TE mode, which is related to strong PL for the TE mode and the fact that a larger optical mode leads to a higher gain saturation power; however, the effect of stronger interaction with the inhomogeneities in the film cannot be ruled out (causing localized index variation and lifetime variations between the TE and TM modes)71,72, which can enhance backscattering and induce early onset of parasitic lasing73. This behaviour can be avoided by improving the film quality, which is sensitive to the initial deposition conditions71. Nevertheless, this demonstrates that even a larger mode reaching the level of a single mode fibre is achievable without incurring high losses. Thus, a smaller amplifier with high energy storage is foreseeable and will be the subject of future device optimization.

a, PL power spectral density (PSD) curves of the TE and TM modes taken at 950 mW pump power, along with the integrated PL power with respect to the pump power (inset). b, The mode profiles of the TM mode and the TE mode and the difference between the measured net gain between the two (the straight dashed line is the linear fit to the data). c, RIN of the output signal at different pump powers. The dotted curve is the RIN of the reference signal. d, The RIN of the signal for different input signal powers at a fixed pump power of 1.1 W. e, NF measurement at different seed powers. f, The ASE spectra with different on-chip pump powers. The water absorption lines are less visible (unlike in Fig. 2b) owing to taking spectra with low spectral resolution.

Next, we measured the relative intensity noise (RIN) introduced by the amplifier with a signal source analyser (which was locked at the repetition rate of the signal, 78 MHz; see Methods for details). The noise spectrum at an offset frequency ~0.8 kHz and beyond the carrier is shown in Fig. 4c. We launched the signal with power >30 mW and varied the pump power from 180 mW to 1.1 W. The input signal noise is already high as we use the filtered long wavelength edge of the supercontinuum, which is known to have high amplitude noise owing to amplified input shot noise through nonlinear processes and spontaneous Raman scattering in the photonic crystal fibre74. From a few kHz to several hundred kHz, the RIN drops below the input noise, which is due to the high-pass filtering effect of the gain with respect to the signal noise75,76,77. This is because the gain is unable to react to the amplitude modulation in the signal (owing to noise) below the cut-off frequency (which increases linearly with the output signal power up to the point where the residual pump power starts to increase). In Fig. 4c, we see that the curve shifts to higher cut-off frequencies with the increasing input pump power up to the point where the residual pump power at the output starts to increase, which is approximately >0.85 W of pump power. This is because as the residual pump power increases, the low-frequency component of noise from the pump starts to dominate because the gain (population inversion) acts as a low-pass filter for the pump fluctuation75,76. For the same reason, in the sub-kHz range, the noise is dominated by the pump amplitude noise. We also measured the RIN at different signal powers (above the parasitic lasing threshold) at a fixed pump power, as shown in Fig. 4d. The noise increased from high-power to low-power input signal by <0.4 dB, which is due to the gradual increase in the ASE power as the signal power decreased. The noise performance is better than that of a clad pumped LMA fibre high-power amplifier for a similar gain system, most likely because our device operates with single fundamental mode, avoiding excitation of ASE in the higher-order modes as is the case with LMA fibre amplifiers46,78. In addition, we have tested the noise figure (NF) with a continuous wave laser79. The NF is defined as NF = PASE/(hυΔυG) + 1/G, where PASE is the amplified spontaneous emission power measured over 0.5 nm bandwidth (Δυ) with the OSA, Yokogawa AQ6376 (measured 4 nm away from the amplified signal), hυ is the signal photon energy and G is the linear gain (ratio of amplified signal output to input seed power). We measured the NF for two different signal seed powers, 36 mW and 82 mW. We observe that as the net gain increases (with the increasing pump power), the NF starts to decrease, which is expected since the NF is inversely proportional to the gain. In addition, at lower gain (owing to lower pump power), the ASE noise is higher, which is directly proportional to the spontaneous emission factor, nsp. The spontaneous emission factor reduces as the gain increases, because nsp = N2/(N2 − σaN1/σe), where N2 is the concentration of excited ions and N1 is the concentration of ground state ions, and σa and σe are the absorption and emission cross sections, respectively66. As we increase the pump power, the N2 increases (causing an increase in the gain), which, in turn, reduces the nsp and therefore the NF. At low seed power, the NF is higher compared with high seed power (for a fixed gain) owing mainly to the high PASE; however, as the gain for low seed power increases, the overall NF drops owing to the inverse relationship between the gain and NF, which is much more dominant than the increase in PASE associated with higher gain (owing to stronger pumping). A small bump in NF of ~0.7 dB seen around 6 dB net gain can be attributed to pump/signal fluctuation. In addition, we plot the ASE spectra as a function of pump power from the 6 cm device (we limit the pump power here, as too high of a pump power leads to lasing without any seed signal). Here we see that the ASE peak shifts towards 1,830 nm with the pump power, which is due to an increase in excitation of ions with the pump, which is expected because the PL measurement shows a peak signal around 1,830 nm.

In conclusion, we have demonstrated the first high-power amplifier on a silicon photonics platform with a watt-level output power within a footprint of only ~4 mm2. The LMA waveguide demonstrated here is a broadband device and as mentioned above is not limited to any specific foundry and therefore can easily be adapted to different spectral windows limited only by the material absorption (for example, a thin SiN layer for short-wavelength applications can be utilized). Moreover, the mode area exploited here was approximately 30 µm2 and even larger modes (60 µm2) were demonstrated with low loss, suggesting that even higher power with even larger mode area and more compact amplifier can be achieved. Larger mode area can be achieved by having a modified design in which the thickness of the gain film, interlayer oxide and the width of the SiN layer are judiciously varied, to allow a mode size similar to an LMA fibre where the mode area is usually larger than 100 μm2 (in case the interlayer oxide thickness and SiN width cannot be varied much, then a larger mode can be achieved by simply increasing the thickness of the gain film). Such high-power devices will be useful not only for applications requiring high-power signals but also for applications that demand high beam quality. The beam quality at the output of the chip is high owing to the fact that the output waveguide is a single mode waveguide supporting only fundamental mode, which has a beam quality in the far field close to that of a Gaussian beam. Polarization-independent gain can be achieved with appropriately designed amplifiers or with a polarization diversity scheme seamlessly integrated with the amplifier80,81. Moreover, pulses can be amplified to very high energy, especially in combination with chirped pulse amplification using apodized chirped gratings already demonstrated82. Such LMA-based high-power amplifiers and lasers in the 2 µm window will prove quite beneficial for commercial and scientific applications. For example, small satellites for earth and planetary sciences, especially the small size and weight CubeSat lidars, can be used for greenhouse gas monitoring, such as CO2 and H2O detection and mapping, which are also essential for detecting signs of life on other planets21,83. Owing to strong water absorption, lasers operating at approximately 1.9 µm are being used for medical surgeries, where miniaturization of these systems is highly desirable for wider accessibility57,84,85. Moreover, it is estimated that next-generation gravitational wave detectors will have a fivefold greater detection range when silica-based mirrors are replaced with silicon mirrors, which suffer less from thermal noise86. The high transparency of silicon at 2 µm makes the thulium-based lasers appropriate for such upgrades, especially the future space-based gravitational observatories, which will benefit from millimetre-scale high-power lasers. Similarly, an optical frequency synthesizer with all silicon components will require long-wavelength lasers for second harmonic generation in silicon where multiphoton absorption is weak13,87, enabling self-referencing for stable comb generation with all CMOS circuitry for applications in optical atomic clocks, coherent telecommunication and microwave photonics. Application requiring high-power delivery to a single mode optical fibre will benefit from improved spot-size converters, for example, with SiN, one can achieve coupling to a fibre with very low loss, ranging between 0.2 dB and 1 dB (refs. 88,89). In addition, by reducing the facet reflection with index matching glue or anti-reflection coating, one can achieve high net gain (J. Lorenzen et al., manuscript in preparation). Scaling to other important wavelength windows is also straightforward, for example, 1 µm for high-power applications with ytterbium ions, 1,300 nm for data centre applications with neodymium ions and 1,550 nm for telecom applications with erbium ions. Together with the integration of pump diodes90, discussed further in Supplementary Information, the silicon photonics-based LMA waveguide technology is poised to broaden the integrated photonics application landscape substantially beyond today’s imagination.

Methods

Fabrication

The passive section was fabricated in LIGENTEC. The photonic layer stack, as mentioned above, consists of a layer of silicon, bottom silicon dioxide, SiN, top silicon dioxide and aluminium oxide. The sidewall angle of the etched SiN waveguide measured by LIGENTEC was 89°, and the standard variation in SiN thickness and refractive index were ±5% and ±0.25%, respectively. The silicon substrate thickness was 230 µm, the bottom oxide thickness was 4 µm, and the top oxide thickness was 3.3 µm. Following the patterning of the SiN layer, a silica layer was deposited, which was subsequently etched away (to create the gain deposition window; Fig. 1c) up to the point where the silica layer was 310 nm thick on top of the SiN layer—the interlayer oxide. SiN fill patterns were fabricated to maintain sufficiently high enough density of SiN (>20%) across the die to avoid fabrication complications. The gain layer was deposited at the University of Twente with an RF sputtering tool (details in Supplementary Information). The chip was mounted in a holder, loaded into an AJA ATC 15000 RF reactive co-sputtering system through a load-lock and placed on a rotating holder in the main reaction chamber. A two-inch aluminium target (99.9995% purity) and a thulium target are powered through their own RF sources. A power of 200 W is used for the aluminium target and 21 W is used for the thulium target, which determines the ion concentration in the film. The expected deposition temperature was ~400 °C and the rate of deposition was approximately 4–5 nm min−1, which varied by ±1 nm from run to run. After deposition, the film quality of the sample was characterized with a prism coupling tool (Metricon 2010/M).

Spectroscopic measurements

For the upper-state lifetime measurements (see Supplementary Information for details), the device was optically pumped by an amplified low-noise continuous wave laser (Alnair Labs, TLG 220). We used a high-power polarization maintaining L-band amplifier (IPG EAR-10-1610-LP-SF). The same pump was used for amplifier testing. The pump laser went through a free space set-up (consisting of two collimating lenses with 20 cm of free space between them and a chopper was placed between them). The pump was edge coupled to the waveguide and a multimode fibre (Thorlabs M43LO2) was used to couple the light out with an out-of-plane set-up. Subsequently, the signal went through a free space set-up with a lens collimator and a band-pass filter (Thorlabs FB 1900-200, to remove the residual pump), and a focusing lens was used to direct light on to a fixed gain amplified InGaAs detector (Thorlabs PDA-10D2), which was connected to an oscilloscope (RS Pro RSDS 1304 CFL) through a 20 kHz low-noise low-pass filter (Thorlabs EF-120). To measure the PL light, the pump was launched into the gain layer and the out-of-plane multimode fibre collected the PL light, which was connected to an OSA. We note that the PL spectrum was also measured with a 790 nm pump, and the spectrum was similar to that obtained with 1.61 µm pumping.

RIN measurement

The signal and the pump were coupled into the chip as shown in Fig. 1. At the output, the signal port of the WDM goes through a free space set-up (two collimating lenses coupled to single mode fibres with a 20 cm long free space in between the lenses) in which a band-pass filter to remove pump light was placed. The signal was further attenuated with a variable attenuator to avoid detector saturation (Thorlabs VOA-50FC/APC). The light was detected with an InGaAs 12 GHz detector (EOT ET 5000F/APC), which passes through a band-pass filter (41–120 MHz), to detect the signal at approximately 78 MHz (repetition rate of the NKT signal source), which passes through a low-noise amplifier ZX60-33LN-S+ (Mini-Circuits) and then into a signal source analyser to measure the AM noise (SSA-E5052B).

Refractive index

The optical constants of the Al2O3 film were measured with a VASE ellipsometer (J.A. Woollam) covering the wavelength range from 240 nm to more than 11 µm (see Supplementary Information for details). To isolate the influence of the silicon and silica substrates, samples with only oxidized silicon and bare silicon were also measured. The refractive index at 1.9 µm of the film was measured to be ~1.7.

Data availability

All the relevant data supporting this study are available from the corresponding author on reasonable request.

Code availability

All the relevant computer codes supporting this study are available from the corresponding author upon reasonable request.

References

Willner, A. E. et al. Optics and photonics: key enabling technologies. Proc. IEEE 100, 1604–1643 (2012).

Shi, W., Fang, Q., Zhu, X., Norwood, R. A. & Peyghambarian, N. Fiber lasers and their applications. Appl. Opt. 53, 6554–6568 (2014).

Richardson, D. J., Nilsson, J. & Clarkson, W. A. High power fiber lasers: current status and future perspectives. J. Opt. Soc. Am. B. 27, B63–B92 (2010).

Zervas, M. N. & Codermard, C. A. High power fiber lasers: a review. IEEE J. Sel. Top. Quantum Electron. 20, 219–241 (2014).

Jauregui, C., Limpert, J. & Tunnermann, A. High-power fibre lasers. Nat. Photon. 7, 861–867 (2013).

Cingöz, A. et al. Direct frequency comb spectroscopy in the extreme ultraviolet. Nature 482, 68–71 (2012).

Schibli, T. R. et al. Optical frequency comb with submillihertz linewidth and more than 10 W average power. Nat. Photon. 2, 355–359 (2008).

Sugioka, K. & Cheng, Y. Ultrafast laser—reliable tools for advanced materials processing. Light Sci. Appl. 3, e149 (2014).

Zhang, X., Kwon, K., Henriksson, J., Luo, J. & Wu, M. C. A large-scale microelectromechanical-systems-based silicon photonics LiDAR. Nature 603, 253–258 (2022).

Li, Z. et al. Thulium-doped fiber amplifier for optical communications at 2 µm. Opt. Express 21, 9289–9297 (2013).

Del’Haye, P. et al. Phase-coherent microwave-to-optical link with a self-referenced microcomb. Nat. Photon. 10, 516–520 (2016).

Spencer, D. T. et al. An optical-frequency synthesizer using integrated photonics. Nature 557, 81–85 (2018).

Singh, N. et al. Silicon photonics optical frequency synthesizer. Laser Photonics Rev. 14, 1900449 (2020).

Hatcher, M. LASER 2022: SemiNex unveils high-gain optical amplifiers for lidar. optics.org https://optics.org/news/13/4/40 (2022).

Aboujja, S. & Chu, D. High-performance semiconductor optical amplifier and array for FMCW LiDAR in high-speed autonomous vehicles. In Proc. SPIE 12403, High-Power Diode Laser Technology XXI 1240305 (SPIE, 2023).

Canoglu, E. et. al. Semiconductor lasers and optical amplifiers for LiDAR photonic integrated circuits. In 2021 27th International Semiconductor Laser Conference 1–2 (IEEE, 2021).

Dailey, J. M. et. al. High output power laser transmitter for high-efficiency deep-space optical communications. In Proc. SPIE 10910, Free-Space Laser Communications XXXI 109100M (SPIE, 2019).

Cornwell, D. M. NASA’s optical communications program for 2017 and beyond. In 2017 IEEE International Conference on Space Optical Systems and Applications (ICSOS) 10–14 (IEEE, 2017).

Hemmati, H., Biswas, A. & Djordevic, I. B. Deep-space optical communications: future perspectives and applications. Proc. IEEE 99, 2020–2039 (2011).

Kaushal, H. & Kaddoum, G. Optical communication in space: challenges and mitigation techniques. IEEE Commun. Surv. Tutor. 19, 57–96 (2017).

Graydon, O. Conquering the final frontier. Nat. Photon. 12, 647–648 (2018).

Juodawlkis, P. W. et al. High-power, low-noise 1.5-µm slab-coupled optical waveguide (SCOW) emitters: physics, devices, and applications. IEEE J. Sel. Top. Quantum Electron. 17, 1698–1714 (2011).

Zhao, H. et al. High-power indium phosphide photonic integrated circuits. IEEE J. Sel. Top. Quantum Electron. 25, 4500410 (2019).

Gasse, K. V., Wang, R. & Roelkens, G. 27 dB gain III–V-on-silicon semiconductor optical amplifier with > 17 dBm output power. Opt. Express 27, 293–302 (2019).

Davenport, M. L. et al. Heterogeneous silicon/III–V semiconductor optical amplifiers. IEEE J. Sel. Top. Quantum Electron. 22, 3100111 (2016).

Zhou, Z., Yin, B. & Michel, J. On-chip light sources for silicon photonics. Light Sci. Appl. 4, e358 (2015).

Doylend, J. K. & Gupta, S. An overview of silicon photonics for LIDAR. In Proc. SPIE 11285, Silicon Photonics XV 112850J (SPIE, 2020).

Kenyon, A. J. Erbium in silicon. Semicond. Sci. Technol. 20, R65 (2005).

Ennen, H., Schneider, J., Pomrenke, G. & Axmann, A. 1.54-µm luminescence of erbium-implanted III–V semiconductors and silicon. Appl. Phys. Lett. 43, 943–945 (1983).

Tsang, W. T. & Logan, R. A. Observation of enhanced single longitudinal mode operation in 1.5-µm GaInAsP erbium-doped semiconductor injection lasers. Appl. Phys. Lett. 49, 1686–1688 (1986).

Purnawirman et al. C- and L-band erbium-doped waveguide lasers with wafer-scale silicon nitride cavities. Opt. Lett. 38, 1760–1762 (2013).

Agazzi, L. et al. Monolithic integration of erbium-doped amplifiers with silicon-on-insulator waveguides. Opt. Express 18, 27703–27711 (2010).

Belt, M. & Blumenthal, D. J. High temperature operation of an integrated erbium-doped DBR laser on an ultra-low-loss Si3N4 platform. In Optical Fiber Communication Conference (Optica Publishing Group, 2015).

Magden, E. S. et al. Monolithically-integrated distributed feedback laser compatible with CMOS processing. Opt. Express 25, 18058–18065 (2017).

Li, N. et al. Monolithically integrated erbium-doped tunable laser on a CMOS-compatible silicon photonics platform. Opt. Express 26, 16200–16211 (2018).

Rönn, J. et al. Ultra-high on-chip optical gain in erbium-based hybrid slot waveguides. Nat. Commun. 10, 432 (2019).

Sun, H. et al. Giant optical gain in a single-crystal erbium chloride silicate nanowire. Nat. Photon. 11, 589–593 (2017).

Choudhary, A. et al. A diode-pumped 1.5 µm waveguide laser mode-locked at 6.8 GHz by a quantum dot SESAM. Laser Phys. Lett. 10, 105803 (2013).

Byun, H. et al. Integrated low-jitter 400-MHz femtosecond waveguide laser. IEEE Photonics Technol. Lett. 21, 763–765 (2009).

Bradley, J. D. B. et al. Monolithic erbium- and ytterbium-doped microring lasers on silicon chips. Opt. Express 22, 12226–12237 (2014).

Dalfsen, K., Aravazhi, S., Grivas, C., García-Blanco, S. M. & Pollnau, M. Thulium channel waveguide laser with 1.6 W of output power and ∼80% slope efficiency. Opt. Lett. 39, 4380–4383 (2014).

Shtyrkova, K. et al. Integrated CMOS-compatible Q-switched mode-locked lasers at 1900nm with an on-chip artificial saturable absorber. Opt. Express 27, 3542–3556 (2019).

Kärtner, F. X. & Singh, N. Integrated CMOS-compatible mode-locked lasers and their optoelectronic applications. In 2019 IEEE BiCMOS and Compound semiconductor Integrated Circuits and Technology Symposium (BCICTS) 1–8 (IEEE, 2019).

Liu, Y. et al. A photonic integrated circuit-based erbium-doped amplifier. Science 376, 1309–1313 (2022).

Taverner, D. et al. 158-µJ pulses from a single-transverse-mode, large-mode-area erbium-doped fiber amplifier. Opt. Lett. 22, 378–380 (1997).

Ranaud, C. C. et al. Characteristics of Q-switched cladding-pumped ytterbium-doped fiber lasers with different high-energy fiber designs. IEEE J. Quantum Electron 37, 199–206 (2001).

Limpert, J. et al. 100-W average-power, high-energy nanosecond fiber amplifier. Appl. Phys. B 75, 477–479 (2002).

Cheng, M. Y. et al. High-energy and high-peak-power nanosecond pulse generation with beam quality control in 200-µm core highly multimode Yb-doped fiber amplifiers. Opt. Lett. 30, 358–360 (2005).

Volet, N. et al. Semiconductor optical amplifiers at 2.0-µm wavelength on silicon. Laser Photonics Rev. 11, 1600165 (2017).

Singh, N., Ippen, E. & Kärtner, F. X. Towards CW modelocked laser on chip—a large mode area and NLI for stretched pulse mode locking. Opt. Express 28, 22562–22579 (2020).

Singh, N. et al. Silicon photonics-based high-energy passively Q-switched laser. Nat. Photon. 18, 485–491 (2024).

Choi, S. J., Djordjev, K., Choi, S. J. & Dapkus, P. D. Microdisk lasers vertically coupled to output waveguides. IEEE Photonics Technol. Lett. 15, 1330–1332 (2003).

Fang, A. W. et al. Electrically pumped hybrid AlGaInAs-silicon evanescent laser. Opt. Express 14, 9203–9210 (2006).

Campenhout, J. V. et al. Electrically pumped InP-based microdisk lasers integrated with a nanophotonic silicon-on-insulator waveguide circuit. Opt. Express 15, 6744–6749 (2007).

Chen, H. W., Kuo, Y. H. & Bowers, J. E. A hybrid silicon-AlGaInAs phase modulator. IEEE Photonics Technol. Lett. 20, 1920–2922 (2008).

Belt, M. et al. Arrayed narrow linewidth erbium-doped waveguide-distributed feedback lasers on an ultra-low-loss silicon-nitride platform. Opt. Lett. 38, 4825–4828 (2013).

Scholle, K., Lamrini, S., Koopmann, P. & Fuhrberg, P. in Frontiers in Guided Wave Optics and Optoelectronics (ed. Pal, B.) Ch. 22 (IntechOpen, 2010).

Yang, K., Yang, Y., He, J. & Zhao, S. in Nonlinear Optics - From Solitons to Similaritons (eds Bakırtaş, İ. & Antar, N.) Ch. 5 (IntechOpen, 2021).

Boone, C. Medical applications are a surgical fit for 2 µm lasers. Laser Focus World (2022).

Xie, X. et. al. A brief review of 2 µm laser scalpel. In 2020 IEEE 5th Optoelectronics Global Conference (OGC) 63–67 (IEEE, 2020).

Singh, U. N. Progress on high-energy 2-micron solid state laser for NASA space-based wind and carbon dioxide measurements. In 2011 IEEE Photonics Society Summer Topical Meeting Series 64–65 (IEEE, 2011).

Sincore, A., Bradford, J. D., Cook, J., Shah, L. & Richardson, M. C. High average power thulium-doped silica fiber lasers: review of systems and concepts. IEEE J. Sel. Top. Quantum Electron. 24, 0901808 (2018).

Lenski, M. et al. Inband-pumped, high-power thulium-doped fiber amplifiers for an ultrafast pulsed operation. Opt. Express 30, 44270–44282 (2022).

Goodno, G. D., Book, L. D. & Rothenberg, J. E. Low-phase-noise, single-frequency, single-mode 608 W thulium fiber amplifier. Opt. Lett. 34, 1204–1206 (2009).

Emmerik, C. I. et al. Relative oxidation state of the target as guideline for depositing optical quality RF reactive magnetron sputtered Al2O3 layers. Opt. Mater. Express 10, 1451–1462 (2020).

Becker, P. C., Olsson, N. A. & Simpson, J. R. Erbium-Doped Fiber Amplifiers (Academic, 1999).

Brown, D. C., Jacobs, S. D. & Nee, N. Parasitic oscillations, absorption, stored energy density and heat density in active-mirror and disk amplifiers. Appl. Opt. 17, 211–224 (1978).

Simpson, S. A. et al. Energy transfer up-conversion in Tm3+-doped silica fiber. J. Non-Cryst. Solids 352, 136–141 (2006).

Nykolak, G. et al. Concentration-dependent 4I13/2 lifetimes in Er3+ doped fibers and Er3+ doped planar waveguides. IEEE Photonics Technol. Lett 5, 1014–1016 (1993).

Kuroda, K., Nakandakari, M. & Yoshikuni, Y. Pump–probe measurement of metastable state lifetime reduced by cooperative upconversion in a high-concentration erbium-doped fiber. Appl. Opt. 57, 8819–8823 (2018).

Gardner, R. A., Peterson, P. J. & Kennedy, T. N. Stability of RF-sputtered aluminum oxide. J. Vac. Sci. Technol. 14, 1139–1145 (1977).

Hacker, E., Katenkamp, U. & Fischer, H. R.f.-sputtered SiO2 films for optical applications. Thin Solid Films 97, 145–152 (1982).

Hardy, A. A. & Oron, R. Amplified spontaneous emission and Rayleigh backscattering in strongly pumped fiber amplifiers. J. Light. Technol. 16, 1865–1873 (1998).

Corwin, K. L. et al. Fundamental noise limitations to supercontinuum generation in microstructure fiber. Phys. Rev. Lett. 90, 113904 (2003).

Novak, S. & Moesle, A. Analytic model for gain modulation in EDFAs. J. Light. Technol. 20, 975–985 (2002).

Tunnermann, H., Neumann, J., Kracht, D. & Peter, W. Gain dynamics and refractive index changes in fiber amplifiers: a frequency domain approach. Opt. Express 20, 13539–13550 (2012).

Zhao, J. et al. Gain dynamics of clad-pumped Yb-fiber amplifier and intensity noise control. Opt. Express 25, 357–366 (2017).

Guiraud, G. et al. High-power and low-intensity noise laser at 1064 nm. Opt. Lett. 41, 4040–4043 (2016).

Singh, N. et. al. High power 1.8 W tunable laser based on CMOS compatible power amplifier. In The 25th European Conference on Integrated Optics - Proceedings of ECIO 2024 (eds Witzens, J. et al.) 28–31 (Springer, 2024).

Barwicz, T. et al. Polarization-transparent microphotonic devices in the strong confinement limit. Nat. Photon. 1, 57–60 (2007).

Dai, D. & Bowers, J. E. Novel concept for ultracompact polarization splitter-rotator based on silicon nanowires. Opt. Express 19, 10940–10949 (2011).

Sinobad, M. et. al. Apodized chirped Bragg gratings in a silicon nitride-on-insulator platform at short-wave infrared wavelengths. In Conference on Lasers and Electro-Optics/Europe (CLEO/Europe 2023) and European Quantum Electronics Conference (EQEC 2023) (Optica Publishing Group, 2023).

Storm, M., Cao, H., Engin, D. & Albert, M. Cubesat lidar concepts for ranging, topology, sample capture, surface, and atmospheric science. In Proc. 31st Annual AiAA/USU 2017 Conference on Small Satellites (Utah State University, 2017).

Schliesser, A., Picque, N. & Hänsch, T. W. Mid-infrared frequency combs. Nat. Photon. 6, 440–449 (2012).

Fried, N. M. & Irby, P. B. Advances in laser technology and fibre-optic delivery systems in lithotripsy. Nat. Rev. Urol. 15, 563–573 (2018).

Kapasi, D. P. Tunable narrow-linewidth laser at 2 µm wavelength for gravitational wave detector research. Opt. Express 28, 3280–3288 (2020).

Singh, N. et al. Octave-spanning coherent supercontinuum generation in silicon on insulator from 1.06 μm to beyond 2.4 μm. Light Sci. Appl. 7, 17131 (2018).

Brunetti, G., Heuvink, R., Schreuder, E., Armenise, M. N. & Ciminelli, C. Silicon nitride spot size converter with very low-loss over the C-band. IEEE Photonics Technol. Lett. 35, 1215–1218 (2023).

Liang, Y. et al. Ultra-low loss SiN edge coupler interfacing with a single-mode fiber. Opt. Lett. 47, 4786–4789 (2022).

Theurer, M. et al. Flip-chip integration of InP to SiN photonic integrated circuits. J. Light. Technol. 38, 2630–2636 (2020).

Acknowledgements

This work is supported by DESY, a centre of the Helmholtz Association through the MML-Programme in POF IV and Maxwell Computing platform, the EU Horizon 2020 Framework Programme grant agreement no. 965124 (FEMTOCHIP), Deutsche Forschungsgemeinschaft (SP2111) contract no. 403188360, Helmholtz YIG VH-NG-1404 and EU Horizon 2020 ERC grant 853564.

Funding

Open access funding provided by Deutsches Elektronen-Synchrotron (DESY).

Author information

Authors and Affiliations

Contributions

N.S. originally conceived and conceptualized the LMA amplifier and subsequently designed and tested it. J.L. helped in the testing. K.W. and S.M.G.-B. deposited the gain film on the amplifier chip. H.F. and M.G. fabricated the chip. M.S., M.G. and T.H. supported the initial gain characterization. M.E. helped with the RIN measurements. F.X.K. initiated and supervised the project. All authors helped in writing the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Photonics thanks Andrea Melloni, Bojan Resan and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Sections 1–6, Figs. 1–11 and Table 1.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Singh, N., Lorenzen, J., Wang, K. et al. Watt-class silicon photonics-based optical high-power amplifier. Nat. Photon. 19, 307–314 (2025). https://doi.org/10.1038/s41566-024-01587-9

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s41566-024-01587-9