Abstract

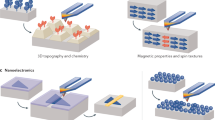

Scanning probe microscopy (SPM) is a powerful technique for mapping nanoscale surface properties through tip–sample interactions. Thermal scanning-probe lithography (tSPL) is an advanced SPM variant that uses a silicon tip on a heated cantilever to sculpt and measure the topography of polymer films with nanometer precision. The surfaces produced by tSPL—smooth topographic landscapes—allow mathematically defined contours to be fabricated on the nanoscale, enabling sophisticated functionalities for photonic, electronic, chemical and biological technologies. Evaluating the physical effects of a landscape requires fitting arbitrary mathematical functions to SPM datasets; however, this capability does not exist in standard analysis programs. Here, we provide an open-source software package (FunFit) to fit analytical functions to SPM data and develop a fabrication and characterization protocol based on this analysis. We demonstrate the benefit of this approach by patterning periodic and quasi-periodic landscapes in a polymer resist with tSPL, which we transfer to hexagonal boron nitride (hBN) flakes with high fidelity via reactive ion etching. The topographic landscapes in polymers and hBN are measured with tSPL and atomic force microscopy, respectively. Within the FunFit program, the datasets are corrected for artifacts, fit with analytical functions and compared, providing critical feedback on the fabrication procedure. This approach can improve analysis, reproducibility and process development for a broad range of SPM experiments. The protocol can be performed within a working day by a trained graduate student or researcher, where fabrication and characterization take a few hours, and software analysis takes a few minutes.

Key points

-

Thermal scanning-probe lithography (tSPL) is a fabrication technique with the ability to pattern mathematically defined landscapes with nanoscale dimensions.

-

This protocol describes how to structure nanomaterials with tSPL and provides a software package to analyze topographic data and optimize the fabrication process.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data for the figures in this protocol are available in DTU Data with the following identifier: https://doi.org/10.11583/DTU.29094524.

Code availability

The software package FunFit is freely available on GitHub at https://github.com/Snunder/FunFit. It can also be found on DTU data with the identifier https://doi.org/10.6084/m9.figshare.29108132.

References

Binnig, G., Rohrer, H., Gerber, C. & Weibel, E. 7 × 7 reconstruction on Si(111) resolved in real space. Phys. Rev. Lett. 50, 120–123 (1983).

Garcia, R., Knoll, A. W. & Riedo, E. Advanced scanning probe lithography. Nat. Nanotechnol. 9, 577–587 (2014).

Ryu, Y. K. & Rodrigo, J. M. Scanning Probe Lithography: Fundamentals, Materials, and Applications 1st edn (CRC Press, 2023).

Mamin, H. J. & Rugar, D. Thermomechanical writing with an atomic force microscope tip. Appl. Phys. Lett. 61, 1003–1005 (1992).

Drechsler, U. et al. Cantilevers with nano-heaters for thermomechanical storage application. Microelectron. Eng. 67–68, 397–404 (2003).

Pires, D. et al. Nanoscale three-dimensional patterning of molecular resists by scanning probes. Science 328, 732–735 (2010).

Howell, S. T., Grushina, A., Holzner, F. & Brugger, J. Thermal scanning probe lithography—a review. Microsyst. Nanoeng. 6, 21 (2020).

Ryu Cho, Y. K. et al. Sub-10 nm feature size in silicon using thermal scanning probe lithography. ACS Nano 11, 11890–11897 (2017).

Rawlings, C. D. et al. Control of the interaction strength of photonic molecules by nanometer precise 3D fabrication. Sci. Rep. 7, 16502 (2017).

Lassaline, N. et al. Freeform electronic and photonic landscapes in hexagonal boron nitride. Nano Lett. 21, 8175–8181 (2021).

Zheng, X. et al. Patterning metal contacts on monolayer MoS2 with vanishing Schottky barriers using thermal nanolithography. Nat. Electron. 2, 17–25 (2019).

Lassaline, N. et al. Optical Fourier surfaces. Nature 582, 506–510 (2020).

Liu, X. et al. Deterministic grayscale nanotopography to engineer mobilities in strained MoS2 FETs. Nat. Commun. 15, 6934 (2024).

Skaug, M. J., Schwemmer, C., Fringes, S., Rawlings, C. D. & Knoll, A. W. Nanofluidic rocking Brownian motors. Science 359, 1505–1508 (2018).

Tang, S. W. et al. Replication of a tissue microenvironment by thermal scanning probe lithography. ACS Appl. Mater. Interfaces 11, 18988–18994 (2019).

Glauser, Y. M. et al. Diffraction of light from optical Fourier surfaces. ACS Photonics 12, 2664–2675 (2025).

Erbas, B. et al. Combining thermal scanning probe lithography and dry etching for grayscale nanopattern amplification. Microsyst. Nanoeng. 10, 28 (2024).

Liu, X. et al. Thermomechanical nanostraining of two-dimensional materials. Nano Lett. 20, 8250–8257 (2020).

Danielsen, D. R. et al. Fourier-tailored light–matter coupling in van der Waals heterostructures. ACS Nano 19, 20645–20654 (2025).

Lassaline, N. Generating smooth potential landscapes with thermal scanning-probe lithography. J. Phys. Mater. 7, 015008 (2024).

Dean, C. R. et al. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotechnol. 5, 722–726 (2010).

Danielsen, D. R. et al. Super-resolution nanolithography of two-dimensional materials by anisotropic etching. ACS Appl. Mater. Interfaces 13, 41886–41894 (2021).

Lisunova, Y., Spieser, M., Juttin, R. D. D., Holzner, F. & Brugger, J. High-aspect ratio nanopatterning via combined thermal scanning probe lithography and dry etching. Microelectron. Eng. 180, 20–24 (2017).

Cheong, L. L. et al. Thermal probe maskless lithography for 27.5 nm half-pitch Si technology. Nano Lett. 13, 4485–4491 (2013).

Rekola, H., Berdin, A., Fedele, C., Virkki, M. & Priimagi, A. Digital holographic microscopy for real-time observation of surface-relief grating formation on azobenzene-containing films. Sci. Rep. 10, 19642 (2020).

Oscurato, S. L. et al. Large-scale multiplexed azopolymer gratings with engineered diffraction behaviour. Adv. Mater. Interfaces 8, 2101375 (2021).

Brechbühler, R. et al. Compact plasmonic distributed-feedback lasers as dark sources of surface plasmon polaritons. ACS Nano 15, 9935–9944 (2021).

Sørensen, C. H. Smooth Greyscale Dielectric Nanopatterning of Graphene. MSc thesis, DTU Physics (2023).

Pálinkás, A. et al. The composition and structure of the ubiquitous hydrocarbon contamination on van der Waals materials. Nat. Commun. 13, 6770 (2022).

Holzner, F. et al. Selected placement of gold nanorods using a removable template for guided assembly. Nano Lett. 11, 3957–3962 (2011).

Bøggild, P. et al. Closing the reproducibility gap: 2D materials research. Preprint at https://arxiv.org/abs/2409.18994 (2024).

Rawlings, C. et al. Accurate location and manipulation of nanoscaled objects buried under spin-coated films. ACS Nano 9, 6188–6195 (2015).

Acknowledgements

N.L. acknowledges funding from the Swiss National Science Foundation (Postdoc Mobility P500PT_211105) and the Villum Foundation (Villum Experiment 50355). T.J.B. and P.B. acknowledge support from the Novo Nordisk Foundation (BIOMAG NNF21OC0066526).

Author information

Authors and Affiliations

Contributions

N.L. conceived the project and designed the protocol. M.V.N. and S.J.L. wrote the code with input from N.L., C.H.S. and R.J. C.H.S., D.H.N. and M.V.N. exfoliated hBN. N.L., C.E.I. and C.H.S. patterned polymer resist with tSPL. N.L., C.H.S. and M.V.N. etched hBN. C.H.S., M.V.N. and N.L. characterized hBN with AFM. C.H.S., M.V.N. and S.J.L. analyzed the data with input from N.L. C.H.S., M.VN., S.J.L. and N.L. produced the figures. C.H.S. and N.L. wrote the manuscript with input from all authors. N.L., S.R., P.B. and T.J.B. supervised the project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Protocols thanks Oleg Kolosov and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Key references

Lassaline, N. et al. Nature 582, 506–510 (2020): https://doi.org/10.1038/s41586-020-2390-x

Lassaline, N. et al. Nano Lett. 21, 8175–8181 (2021): https://doi.org/10.1021/acs.nanolett.1c02625

Lassaline, N. J. Phys. Mater. 7, 015008 (2024): https://doi.org/10.1088/2515-7639/ad0f31

Extended data

Extended Data Fig. 1 Loading a cantilever for tSPL.

a–d, Loading the cantilever into the cantilever holder by pressing the holder down with one hand and using tweezers to insert the cantilever into the holder with the other hand. Both the hand and tweezers let go when complete. e–h, Attaching the cantilever holder to the NanoFrazor scan head and closing the housing. The user can now approach the tip to the sample below, where the tool is ready for configuration.

Extended Data Fig. 2 Configuration.

Screen capture of the NanoFrazor software displaying typical results of the configuration procedure. The configuration is run by pressing the green play button once the tip has been brought close (<100 µm) to the sample surface.

Extended Data Fig. 3 Import pattern geometry and set dimensions.

Screen capture of the NanoFrazor software displaying a typical setup of pattern geometry. Here, a bitmap is loaded, and the pixel size is set in the NanoFrazor software, for which 20 nm × 20 nm is a typical value. The user then sets the depth range for the pattern. Here, the range is set to 30–70 nm into the surface to provide 40 nm of modulation depth and 30 nm of buffer for etching. The pattern is then imported.

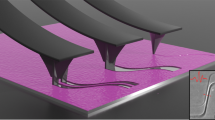

Extended Data Fig. 4 tSPL patterning.

Screen capture of the NanoFrazor software displaying the patterning process of a quasi-crystal structure into a PPA film. The top right image is an optical microscope looking down on the cantilever from the top, here showing the cantilever patterning a PPA film spin-coated on top of a hBN flake. The pattern is fabricated, and the topography is measured simultaneously, where the tSPL probe acts as a combined read–write lithography and imaging tool. The measured topography is shown in the middle, and a line-by-line comparison between the target surface and measured profile is shown below. Here, we use a temperature setpoint of 1,100 °C, a forward height of 225 nm and a user-defined force initialization of applied voltages in the range of 4.8–7.0 V (with Kalman Feedback and Bowing Correction on) to ensure that the write forces applied by the tool lie in the middle of their dynamic range (0–9.5 V). This is important to ensure that the tool can increase or decrease the write forces as necessary on the basis of the feedback from the controller.

Extended Data Fig. 5 Geometry to be etched.

Illustration of the cross-section for a patterned PPA layer spin-coated on an hBN flake. The etch time can be calculated by the following formula: \({\rm{Etch\; time}}={\rm{strike\; time}}+\frac{{\rm{cushion}}+2A+D}{{{\rm{rate}}}_{{\rm{PPA}}}}\) where the strike time is how long it takes for the plasma to be generated after the etching recipe is started (~7 s in our system), the cushion and pattern amplitude A are typically in units of nanometers, D is a user-defined offset (typically in nanometers) that can be positive or negative to engineer a ‘miss’ to one side of the under-etch–over-etch balance if it is critical for the process and ratePPA is the etch rate of PPA (typically in units of nanometers per second).

Extended Data Fig. 6 Determining the etch rate.

Schematic showing the approach to determine the unknown etch rate of a particular system. The etch rate is guessed to be ~1 nm s−1, and by measuring the film thickness before and after etching with AFM, this guess can be applied to etch a film approximately in half. The etch rate can be calculated from this experiment, providing an updated guess for the etch rate. Because of natural deviations in determining the etch rate, this process can be repeated until it converges on a representative etch rate of a particular system in a particular state. For our system, the etch rate of PPA was determined to be 1.35 nm s−1 by using 15 sccm of SF6 gas and a substrate bias of 40 V. The FunFit software package can be used to determine etch rates and pattern amplification/compression factors for when the patterns in PPA are transferred to other materials such as hBN.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sørensen, C.H., Nielsen, M.V., Linde, S.J. et al. Quantitative mapping of smooth topographic landscapes generated using thermal scanning-probe lithography. Nat Protoc (2025). https://doi.org/10.1038/s41596-025-01228-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41596-025-01228-7