Abstract

Composite porous foam NiZn alloy electrodes with nano pore structure were prepared by the combination of eletrodeposition, heat treatment and HCl etching. The morphology of the electrodes was examined by scanning electron microscopy (SEM). And the component of the electrodes was analyzed by Energy Dispersive Spectrum (EDS). The specific surface area and pore size of the electrode were investigated by nitrogen adsorption. The phase constituents were analyzed by X ray diffraction (XRD), and the electrocatalytic characteristics for hydrogen evolution reaction of the electrodes in 30% (mass fraction) KOH solution were investigated by cathode polarization curve. The experimental results showed that the pores were formed on surface of the foam NiZn alloy electrodes after heat treatment at 600 °C, and with the etching by 10% HCl, nano layered structure was formed on the surface of the porous skeleton. Compared with the nickel foam, the surface area of the NiZn foam alloy electrode became larger, and the nano pore structure had good catalytic activity. At current density of 200 mA·dm−2, the hydrogen evolution overpotential of the NiZn foam alloy electrodes were reduced by 222 mV and 276 mV, respectively, through heat treatment of 600 °C and etching in 10% HCl solution, which indicated that the hydrogen evolution overpotential was effectively reduced because of the composite nano porous structure, while the activity of hydrogen evolution of the electrodes was obviously improved.

Similar content being viewed by others

Introduction

Hydrogen is a good clean fuel with a combustion value of up to 142.35 kJ·kg−1 and the combustion product is only the water without causing any environmental problems1,2. Electrolysis of water is an important way to obtain hydrogen on a large scale. The performance and price of the electrode material are the keys to achieve the industrialization for hydrogen production by electrolysis. The metal alloys are usually used as the electrode materials which have different characteristics of electronics and structures from the pure metals. In addition, increasing the exposed surface of the electrode materials can also improve the power efficiency3,4,5. Therefore, nickel, iron, platinum and other metals have been studied for the production of hydrogen evolution electrode6,7.

Foam nickel has lower mechanical and corrosion resistance with respect to bulk Ni. However, beacause of its large specific surface area, more and more persons studied it8,9,10. The catalyst carrier with foam nickel as the electrode of the electrolytic cell can effectively reduce the hydrogen evolution potential, and the energy conversion efficiency can be further improved by depositing nanomaterials on the foam nickel11,12,13,14,15. Ouyang et al.11 deposited a Ni3S2 nano-rod array on the surface of the foamed nickel by one-step hydrothermal method. Under 10 mA·cm−2 in 1 M KOH solution, the hydrogen evolution potential and oxygen evolution potential of the electrode surface were 200 mV and 217 mV, respectively. Tang et al.12 deposited a Ni3S2 nano-sheet array on a foamed nickel by hydrothermal method. In alkaline media, the overpotentials of the formed material at 10 mA·cm−2 and 100 mA·cm−2 were 123 mV and 260 mV, respectively. Although the results of the preparation and hydrogen evolution of foam nickel-based materials have been achieved16,17,18,19,20,21,22,23,24, it is still a challenge on how to reduce the over-potential of electrochemical hydrogen production on nickel electrodes.

Zn is a typical amphoteric metal that is chemically active in the alloy materials. So, the electrodeposition of Zn and Ni has generated a great amount of interest. The coatings of nickel electrodes with Zn prepared on some metal substrates were studied25,26,27,28,29,30,31,32. However, the NiZn foam alloy electrodes on the foam nickel substrates have not been studied extensively. In this paper, composite porous foam NiZn alloy electrode with nanoporous structures was prepared by the combination of electrodeposition, heat treatment and etching in HCl solution. The specific surface area of the electrode is increased. At the same time, the overpotential of hydrogen evolution of the prepared electrode is reduced.

Experimental

Preparation of electrodes

The scheme of the preparation of porous foam NiZn alloy electrode was shown in Fig. 1. The process was described as follows.

-

(1)

Pretreatment of foam nickel: Foam nickel with thickness of 2 mm was used as the substrate, cleaned by acetone, soaked and degreased in alkaline solution (60 g·L−1 NaOH, 15 g·L−1 NaPO4, 30 g·L−1 Na2CO3 and 5 g·L−1 Na2SiO3) and then soaked in 10% dilute hydrochloric acid to remove the surface oxide.

-

(2)

The nickel plate was used as the anode, and the foam nickel substrate was used as the cathode. The electrodeposition was carried out with the process parameters listed in Table 1 to obtain the foam NiZn alloy electrodes.

Table 1 Process parameters of foam NiZn alloy electrodes. -

(3)

The foam NiZn alloy electrode was heat treated in a hydrogen atmosphere at a constant temperature of 500 °C, 600 °C and 700 °C, respectively, for 2 hours to obtain a higher mechanical strength and a better antioxidant performance.

-

(4)

The foam NiZn alloy electrode was etched in 10% HCl for 2 hours to remove part of the Zn.

Test Methods

The surface morphology and energy spectrum of the electrode were observed by scanning electron microscopy (SEM, Nova Nano SEM 430). The specific surface area and pore size of the electrode were measured with Kubo-X 1000 multi-station microporous surface area analyser. The composition of the alloy was analyzed by X Pert - MRD diffractometer. The steady-state cathodic polarization curve of the electrode in a 30 wt% KOH solution at a temperature of 30 °C was obtained on a CHI660D electrochemical workstation with a scanning speed of 1 mV·s−1. The work station used a three-electrode system. A Pt electrode of large area was used as the auxiliary electrode. Saturated calomel electrode was used as the reference electrode. Three kinds of electrodes, i.e., a foam Ni electrode with a size of 10 mm × 10 mm, a foam NiZn alloy electrode after heat treatment and a foam NiZn alloy electrode treated with HCl, were tested as the working electrodes.

Results and Discussion

Morphology and energy spectrum analysis

Figure 2 shows the SEM morphology of the foam nickel substrate. The pore sizes of the mesh structure are in the range of 100–800 μm.

Figure 3 shows effect of temperature after the heat treatment. The surface of the foam NiZn alloy electrode after electrodeposition is uniform, as shown in Fig. 3a. However, after heat treatment at 500 °C, the electrode surface has pores, as shown in Fig. 3b. This is mainly due to the fact that the Zn layer is diffused into the pure Ni layer of the foam nickel substrate to form NiZn alloy, while the Ni layer remains solid in the alloy coating, and does not enter the foam nickel substrate layer with Zn, resulting in the occurrence of pores. With the heat treatment at 600 °C, the melting rate of Zn is increased and thus its diffusion to the Ni layer is accelerated. The pore structure is more obvious and the pore depth is increased, as shown in Fig. 3c. Figure 3d shows that the fracture phenomenon of the NiZn alloy coating occurs, when the temperature reaches 700 °C.

The EDS energy datas of foam NiZn alloy electrodes treated at different temperatures are shown in Table 2. Without heat treatment, the Zn content on the alloy surface is 71%. After heat treatment, the surface of the alloy layer is mainly rich in Ni, and the Zn content decreases with the increase of the heat treatment temperature. It is proved that Zn in the alloy layer melts and diffuses into the pure Ni layer, and the diffusion degree increases with the increase of the temperature.

Figure 4 shows the surface variation of the foam NiZn alloy electrode when it was etched in 10% HCl for 2 h. Most of the zinc in the foam NiZn alloy electrode was etched away, and a composite porous foam alloy electrode with nanoporous structure was formed on the surface of the coating. The nano-lamellar structure can further increase the specific surface area of the foam NiZn alloy electrode.

The data of EDS energy spectrum of the foam NiZn alloy treated in HCl with different time period are shown in Table 3. At the beginning of the treatment, the Zn content in the alloy coating is higher and the etching rate of Zn is faster. As the amount of Zn decreases, the etching rate slows down. After 60 min, the Zn content in the alloy layer is reduced to 12%. After 90 min, the Zn content in the alloy coating is almost constant. After 120 min, the Zn content in the NiZn electrode is 8% and the Ni content is 92%.

Specific surface area and pore size

Table 4 shows the specific surface area and pore size of the foam nickel substrate and the foam NiZn alloy electrode after different treatments. The average pore size of the foam NiZn alloy electrode after heat treatment at 600 °C is 67 nm, and the specific surface area of that is significantly increased and nearly 29 times higher than that of the foam nickel substrate. After the treatment in HCl solution, the nano-porous structure is formed on the surface of the coating, which further reduces the average pore size of the electrode. And the surface area of the electrode is nearly 25 times higher than that of the foam NiZn alloy electrode after heat treatment.

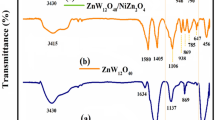

XRD analysis

Figure 5 shows the XRD pattern of the non-heat treated foam NiZn alloy electrodes and that after heat treatment at 600 °C. Before heat treatment. Ni and Zn peaks can be found in the XRD patterns of the electrode samples. After heat treatment, the three main peaks of Zn disappear, and the diffraction peaks of NiZn appear, which indicates that the NiZn alloy crystals are formed in the foam NiZn electrodes after heat treatment at 600 °C.

Electrocatalytic characteristics for hydrogen evolution reaction

Figure 6 shows the cathodic polarization curves of the foam NiZn alloy electrodes with the different treatments.

According to the Tafel equation

with

and

In the formula above, η is the hydrogen evolution potential, j is the reaction current, a is the value related to the electrode material properties, the electrode surface state, the solution composition, the temperature, etc, α is the transfer coefficient, j0 is the exchange current density, and b is the tafel slope. In the cathodic polarization curve, a Tafel region with a good linearity is obtained, and its straight line is extended to intersect with a straight line of η = 0. The current density at this point is the exchange current density j0, which is the tafel slope b. Using j0 to characterize the catalytic activity of the electrode material, the greater the j0, the higher the catalytic activity of the electrode.

It can be seen from the Fig. 6 that, at the same current density, the polarization potential of foam NiZn alloy electrode with 600 °C treatment is significantly reduced compared with that of the foam Ni substrate. This shows that the higher hydrogen evolution activity is mainly caused by the heat treatment. The pores with an average pore size of 67 nm formed in the alloy coating, increase the specific surface area of the electrode and reduce the hydrogen evolution potential.

It can be seen from Table 5 that, the hydrogen evolution potentials of the two foam NiZn alloy electrodes after 600 °C treatment and HCl treatment are reduced by 222 mV and 276 mV at 200 mA·dm−2, respectively, compared with the foam nickel electrode. It indicates that the composite porous foam alloy electrode with nano-pore structure can significantly reduce the hydrogen evolution potential and improve the hydrogen evolution activity of the electrode.

The second line in Table 5 shows the exchange current density j0 of the electrode based on the polarization curve. As can be seen from it, both of the 600 °C treatment and the HCl treatment can increase the exchange current density of the foam nickel electrode. The exchange current density of the foam NiZn alloy electrode is 2.3 × 10−2 A·cm−2, which is much larger than that of foam Ni. The NiZn alloy electrode has higher hydrogen evolution activity after the HCl treatment.

The charge transfer control process and the diffusion process are two control steps in the hydrogen evolution process of the nickel electrode, the former being, the rate control step. The foam NiZn alloy electrode treated in HCl is a composite porous foam with nanoporous structure. Its good electrocatalytic ability is derived from the faster charge transfer rate during the hydrogen evolution reaction process, and more electrochemically active sites provide more reactive centers to increase the charge transfer rate. With the increase of the electrode surface porosity, the specific surface area increases, and its electrocatalytic activity increases under alkaline condition. Increasing the specific surface area of the electrode not only reduces the true current density in the electrolysis, but also reduces the hydrogen evolution potential of the electrode during the electrolysis reaction, and provides more hydrogenation activity centers, thus improving the electrocatalytic efficiency of hydrogen evolution. In addition, nickel has been widely used in the water electrolysis industry because there are unpaired electronson the 3d track of the outer layer of nickel atom as the transition metal, which makes it easy to form Ni-H adsorption bonds with hydrogen atom with the 1 s orbital electrons. However, to obtain highly active hydrogen evolution electrode, the good desorption capacity is also needed, which requires the use of alloying way to change the state of outer electrons of nickel atoms. Therefore, Ni-Zn alloying can reduce the nickel atoms on the surface of the rich d electrons and the active hydrogen atoms between the bonding capacity, and improve the ability of active hydrogen desorption.

Conclusions

According to the analyses above, it is concluded that:

-

(1)

The NiZn alloy electrode with pore structure on the surface of the electrode was prepared by the method of electrodeposition and heat treatment. The optimum heat treatment temperature is 600 °C.

-

(2)

On the basis of heat treatment, the nanoporous structure is formed on the surface of alloy pore skeleton through etching in 10% HCl, resulting in a kind of composite porous foam alloy material, which further increases the specific surface area of the foam NiZn alloy electrode.

-

(3)

At the current density of 200 mA·dm−2 the hydrogen evolution potential of the foam NiZn alloy electrode after HCl treatment is 276 mV, which is lower than that of the foam nickel electrode, and the exchange current density is 2.3 × 10−2 A·cm−2, It is shown that the composite porous foam alloy electrode with nano-pore structure can improve the hydrogen evolution activity of the electrode.

References

Momirlan, M. & Veziroglu, T. The properties of hydrogen as fuel tomorrow in sustainable energy system for a cleaner planet. Int. J. Hydrogen Energ. 30, 795–802 (2005).

Wang, J. W. et al. Optimization of electrocatalytic properties of NiMoCo foam electrode for water electrolysis by post-treatment processing. Rare Metals. 34, 802–807 (2015).

Jaksic, M. M. Advances in electrocatalysis for hydrogen evolution in the light of the Brewer-Engel valance-bond theory. J. Mol. Catal. A-Chem. 38, 161–202 (1986).

Zeng, K. & Zhang, D. K. Recent progress in alkaline water electrolysis for hydrogen production and applications. Prog. Energ. Combust. 36, 307–326 (2010).

Jaksic, M. M. Electrocatalysis of hydrogen evolution in the light of the brewer-engel theory for bonding in metals and intermetallic phases. Electrochim Acta. 29, 1539–1550 (1984).

Salvi, P. et al. Hydrogen evolution reaction in PTFE bonded Raney Ni electrodes. Int. J. Hydrogen Energ. 36, 7816–7821 (2011).

Zhang, J. H., Hui, Z. L. & Fang, Z. Q. Preparation and Properties of Nickel Foam. Rare Metals. 25, 230–234 (2001).

Paserin, V., Marcuson, S., Shu, J. & Wilkinson, D. S. CVD technique for Inco nickel foam production. Adv. Eng. Mater. 6, 454–459 (2004).

Kim, S. & Lee, C. W. A review on manufacturing and application of open-cell metal foam. Procedia Materials Science. 4, 305–309 (2014).

Tang, X. Y. Study of Preparation and Properties of Hydrogenevolution Electrodes. Ph. D. Thesis, The University of Hunan, Changsha. (2014).

Ouyang, C. B. et al. Hierarchically Porous Ni3S2 Nanorod Array Foam as Highly Efficient Electrocatalyst for Hydrogen Evolution Reaction and Oxygen Evolution Reaction. Electrochim Acta 174, 297–301 (2015).

Tang, C. et al. Ni3S2 nanosheets array supported on Ni foam: A novel efficient three-dimensional hydrogen-evolving electrocatalyst in both neutral and basic solutions. Int. J. Hydrogen Energ. 40, 4727–4732 (2015).

Tang, C., Cheng, Y. N., Pu, Z. H., Xing, W. & Sun, X. P. NiSe Nanowire Film Supported on Nickel Foam: An Efficient and Stable 3D Bifunctional Electrode for Full Water Splitting. Angew. Chem. Int. Edit. 54, 9351–9356 (2015).

Yan, X. D., Tian, L. H., He, M. & Chen, X. B. Three-Dimensional Crystalline/Amorphous Co/Co3O4 Core/Shell Nanosheets as Efficient Electrocatalysts for the Hydrogen Evolution Reaction. Nano Lett. 15, 6015–6021 (2015).

Luo, J. S. et al. Water photolysis at 12.3% efficiency via perovskite photovoltaics and Earth-abundant catalysts. Science. 345, 1593–1596 (2014).

Jafariana, M., Azizi, O. & Gobal, F. Kinetics and electrocatalytic behavior of nanocrystalline CoNiFe alloy in hydrogen evolution reaction. Int. J. Hydrogen Energ. 32, 1686–1693 (2007).

Gao, C. H. & Li, N. Hydrogen evolution reaction activity of electrodeposited amorphous/nanocrystalline Ni-Mo-La alloy electrode. The Chinese Journal of Nonferrous Metals. 21, 2819–2824 (2011).

Cao, Y. Synthesis of Highly Active Nichel Based Hydrogen Evolution Electrodes and Their Hydrogen Evolution Behavior in The Alkaline Medium. M. S. Thesis, Beijing Institute of Technology. 154 (2014).

Chen, X. Preparation and Catalytical Performance of Ni-Based Ni/RuO2 Composite Electrodes and Ni-P Alloy Electrodes for Hydrogen Evolution Reaction. Ph. D. Thesis, The University of Chongqing, Chongqing. 19 (2013).

Cao, Y. L. et al. Electrochemical Preparation and Electrocatalytic Mechanisms of Ni-S Active Cathode for Hydrogen Evolution. Acta Phys-Chim. Sin. 25, 1979–1984 (2009).

Cao, Y. L. et al. Electrochemical Preparation of Ni-Sn Active Cathode and Its Electrocatalytic Hydrogen Evolution Reaction Mechanisms in Alkaline Solution. Acta Phys-Chim. Sin. 29, 1479–1486 (2013).

Li, Y. X., Li, H., Li, Y. F., Peng, S. Q. & Hu, Y. H. Fe-B alloy coupled with Fe clusters as an efficient cocatalyst for photocatalytic hydrogen evolution. Chem. Eng. J. 344, 506–513 (2018).

Zhang, W. Y., Li, Y. X. & Peng, S. Q. Template-free synthesis of hollow Ni/reduced graphene oxide composite for efficient H2 evolution. J. Mater. Chem. A. 5, 13072–13078 (2017).

Zhang, W. Y., Li, Y. X., Zeng, X. P. & Peng, S. Q. Synergetic effect of metal nickel and graphene as a cocatalyst for enhanced photocatalytic hydrogen evolution via dye sensitization. Sci. Rep-UK. 5, 10589 (2015).

Solmaz, R., Salcı, A., Yüksel, H., Doğrubaş, M. & Kardaş, G. Preparation and characterization of Pd-modified Raney-type NiZn coatings and their application for alkaline water electrolysis. Int. J. Hydrogen Energ. 42, 2464–2475 (2016).

Telli, E., Solmaz, R. & Kardaş, G. Electrocatalytic oxidation of methanol on Pt/NiZn electrode in alkaline medium. Russ. J. Electrochem. 47, 811–818 (2011).

Solmaz, R. Gold-supported activated NiZn coatings: hydrogen evolution and corrosion studies. Int. J. Energ Res. 41, 1452–1459 (2017).

Nady, H., Negem, M. & Phys, Z. Microstructure and Corrosion Behavior of Electrodeposited NiCo, NiZn and NiCu Nanocrystalline Coatings in Alkaline Solution. Zeitschrift Fã¼r Physikalische Chemie 231, 1159–1178 (2016).

Solmaz, R. Electrochemical Preparation, Characterization, and Application of a Novel Cathode Material, Mild Steel/Ni/NiZn-Pt, for Alkaline Water Electrolysis. Energ. Source Part A. 36, 1212–1218 (2014).

Solmaz, R. & Kardaş, G. Hydrogen evolution and corrosion performance of NiZn coatings. Energ Convers Manage. 48, 583–591 (2007).

Solmaz, R., Döner, A. & Şahin, İ. The stability of NiCoZn electrocatalyst for hydrogen evolution activity in alkaline solution during long-term electrolysis. Int. J. Hydrogen Energ 34, 7910–7918 (2009).

Solmaz, R., Döner, A. & Kardaş, G. Enhancement of electrochemical activity of Raney-type NiZn coatings by modifying with PtRu binary deposits: Application for alkaline water electrolysis. Int. J. Hydrogen Energ. 41, 1432–1440 (2016).

Acknowledgements

This study was financially supported by the Program of International S&T Cooperation of China (No. 2014DFR51130), the Science and Technology Planning Project of Beijing (No. Z161100001116080) and the Science and Technology Major Project of Beijing (No. Z171100002017014).

Author information

Authors and Affiliations

Contributions

Jingguo Zhang, Shaoming Zhang and Limin Wang designed experiments; Shuo Li and Fei Ma carried out experients; Jingguo Zhang and Ligen Wang analyzed experimental results; Jingguo Zhang, Youzhi Zhou and Qiang Hu wrote the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, J., Zhou, Y., Zhang, S. et al. Electrochemical Preparation and Post-treatment of Composite Porous Foam NiZn Alloy Electrodes with High Activity for Hydrogen Evolution. Sci Rep 8, 15071 (2018). https://doi.org/10.1038/s41598-018-33205-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-018-33205-4

Keywords

This article is cited by

-

Preparation and Electrochemical Performance of Ni-Mo-W/NF Electrodes for Alkaline Water Electrolysis

Catalysis Letters (2024)