Abstract

Single-crystal MoO3 micrometer to millimeter even centimeter belts were prepared via a novel route of oxidizing a discarded molybdenum disilicide heating element at 1000 °C for 3 h. The morphology and structure features, and growth mechanism of the products were evidently investigated by X-ray diffraction, Fourier transform infrared spectroscopy, X-ray photoelectron spectroscopy, scanning electron microscopy, and transmission electron microscopy. The results indicated that the powdery and fibrous products were typical α-MoO3 belt-like structures which size could develop from micrometer to several millimeter even centimeter in length and up to 0.5 mm in width. It should be formed preferentially along the [001] direction via layer by layer growth to form 1-D single MoO3 belts by vapor-solid mechanism. Thermal and luminescence properties of the products were revealed by thermogravimetric analysis and differential thermal analysis and photoluminescence spectra that the resultant α-MoO3 belts had good thermal stability and characteristics of luminescence with a central peak at 481 nm. The MoO3 belts are of good potential being applied to luminescent and high temperature devices.

Similar content being viewed by others

Introduction

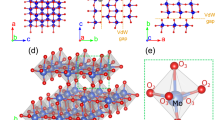

Molybdenum trioxide (MoO3) usually exhibits three polymorphic structures, orthorhombic (α-MoO3), monoclinic (β-MoO3), and hexagonal phase (h-MoO3), in which the former is the only thermodynamically stable phase1,2. α-MoO3 has attracted intense interest due to its distinctive layer structure, formed by bilayer sheets of MoO6 octahedra stacked together via van der Waals forces2,3,4. Because of its intrinsic structural anisotropy and the change ability in the oxidation state of molybdenum ion, α-MoO3 is considered to have many promising applications in lithium-ion batteries5,6,7, gas sensors8,9, catalysis10,11, field emission12, photochromic and electrochromic devices13,14.

α-MoO3 phase is known to develop into one-dimension (1D) structures (wires, tubes, belts)15. The past few years have witnessed significant advances in the synthesis of belt-like α-MoO3 using various methods, such as solution method16,17,18, hydrothermal method, thermal evaporation, flame synthesis using Mo wire mesh as the source as well as CH4, H2, and air as the supply fuels2. However, most of resultant products are nanometers or micrometers in size. The preparation of single-crystal belts on millimeter to centimeter-scale (or macroscopic) has been seldom reported19.

Here we present a novel route to prepare single-crystal α-MoO3 micrometer to millimeter even centimeter belts via oxidizing a discarded molybdenum disilicide heating element on the top of corundum crucible at 1000 °C for 3 h. The belt-like products are formed in the bottom of corundum crucible separated away from the raw materials, making it easy to collect. The resultant belts were fully characterized. Furthermore, their thermal and photoluminescence properties were tested. Based on the results, the relevant growth mechanisms of the belts were discussed, and the blue-indigo optical emissions of the α-MoO3 belts were revealed. In this way, we could recycle the malfunctioned MoSi2 heating elements for the production of MoO3 single crystal belts for the design and application of blue-indigo optoelectronic devices.

Results and Discussion

Phases, chemical compositions and states of the resultant products

A light green products with two parts of powdery and fibrous crystals were visually seen in the bottom of the corundum crucible after 3 h of reaction at 1000 °C in air (Fig. 1a), and the powders were covered by the fiber-like products. It is obviously that the fibrous products were several millimeters even up to centimeter long (Fig. 1c). Both powdery and fibrous products were collected respectively and subjected to the characterizations using XRD, FTIR, XPS, SEM and TEM.

The XRD results (Fig. 2I) indicated that the powdery and fibrous products only had the thermodynamically stable phase α-MoO3 (JCPDS card No. 05–0508) without impurity peaks, suggesting the high purity phase of the resultant α-MoO3. The obvious intensities of the (0k0) diffraction peaks with k = 2, 4 and 6 revealed anorientation along the [010] direction ascribed to its packed double layered crystal structure9. Furthermore, the intensities of other diffraction peaks of MoO3 in powdery product were much higher than those in fibrous one.

Their FT-IR spectra are shown in the Fig. 2II, which were obtained the range of wave numbers from 400 to 1800 cm−1. The characteristic peaks at 478, 650, 895 and 992 cm−1 were arisen from the fundamental vibrational modes of Mo=O20. The peak at 843 cm−1 was due to the characteristic vibration of Mo-O-Mo bridging bonds. The peak at approximately 1358 cm−1 was assigned to the vibration mode of the Mo–OH bond whereas the peak at 1631 cm−1 was associated with the δ (O-H) vibration of adsorbed water17. As for the absorption peaks between 478 and 650 cm−1 were because of the stretching vibration of the O atom link to three Mo atoms17,18,21.

Photoelectron spectroscopy (XPS) was further employed to determine the chemical compositions and chemical states of products. Figure 3a,d show the survey scan X-ray photoelectron spectrum of the two parts products respectively, revealing the peaks assigned to molybdenum (Mo), oxygen (O), a trace amount of carbon (C) and O-KLL Auger peaks. The peak at around 284.8 eV was corresponded to C-1s fine structure singlet of carbon, which was used as a charge correction reference in this XPS test. The high resolution narrow scan XPS spectra of Mo-3d and O–1 s core levels were further recorded in order to identify the chemical states of elements. The narrow scan XPS spectrum of Mo-3d core level (Fig. 3b) in powdery products showed the existence of two well resolved spectral lines. This was ascribed to the spin-orbit split of Mo-3d levels with the binding energy at 232.81 eV and 235.95 eV relate to Mo-3d5/2 and Mo-3d3/2, respectively. The energy gap between Mo-3d5/2 and Mo-3d3/2 is 3.14 eV, and their corresponding integral area ratio was about 3:2, supporting the presence of single + 6 oxidation state in molybdenum22. The peak at 530.72 eV (Fig. 3c) was assigned to the O2- ions in the MoO3. Thus, these binding energy peak positions and energy gap were in highly consistent with the past reports for MoO316,22,23. Meanwhile, the fibrous products exhibited nearly the same results to the powdery one. So it is believed that the powdery and fibrous products were MoO3.

Morphology and microstructure of the resultant products

The morphologies of the two parts products can be observed clearly under SEM. Figure 4 shows the different magnifications SEM micrographs of powdery MoO3 having different shape, length and width. Figure 4a displays a great number of lamelliform MoO3 crystals, which had clear outline and smooth surface, length was range from 10 μm to 50 μm. Figure 4b displays that the product was composed of gathered lamelliform MoO3 microbelts with various sizes, which should be caused by the inhomogeneous nucleation of single crystalline MoO3 particles17. Figure 4c,d show interspersed growth of MoO3 to form flower-like and cross-shaped structures with the size of 15~40 μm long, and 5~12 μm wide. The surface of the MoO3 microbelts was smooth.

The SEM images of fibrous MoO3 products are shown in the Fig. 5, indicating their belt-like structures. Figure 5a–c shows that the large size MoO3 belts were 0.2 mm wide, and up to several centimeters long. This should be the largest size MoO3 belts reported. The MoO3 belt was highly curved (Fig. 5b), indicating good flexibility. The MoO3 belts decreased gradually in size and had a needle-like tip at its terminal (Fig. 5a,b). After further enlarging the image, the MoO3 belts had a smooth surface and a neat edge with the thickness of about 2 μm (Fig. 5d). Sometimes, the belts with a zigzag edge composed of triangles having tip angles were found (Fig. 5e), and their surfaces had a layered structure in both horizontal and vertical directions (Fig. 5e–h). Further enlargement of Fig. 5e, it shows that the MoO3 belt grew layer by layer and started horizontally in the middle of the belt. The thickness of each layer was approximately tens of nanometers, and the horizontal spacing of each layer was approximately 10–15 μm. Observed from Fig. 5g, the surface of the MoO3 belt had a distinct step shape. Enlarging the image (Fig. 5h), it could be observed that the surface of the MoO3 belt had two row layered growth structures with several vertical layers on each row.

The detailed crystalline structure and growth direction of MoO3 belt-like products were further detected by TEM and high resolution TEM (HRTEM). Figure 6a,b showed the product with a typical belt-like geometry as well as a uniform width along its length. EDS was also recorded to determine the chemical composition of α-MoO3 belts (Fig. 6c). Except the C and Cu peaks from TEM grid, just the elements of Mo and O were detected in the belts. Thus, both XRD and EDS analyses revealed that the pure α-MoO3 product had been successfully synthesized. The HRTEM lattice images (Fig. 6d) revealed the microbelts possessed a well-defined crystal structure, and the spacing between the two sets of parallel fringes was 0.373 nm and 0.387 nm, corresponding to the two vertical planes (001) and (100) of α-MoO314,24,25,26. Therefore, the HRTEM image and SAED pattern (Fig. 6d), recorded with the incident electron beam perpendicular to the nanobelt face, confirmed that the microbelts were composed of crystalline orthorhombic α-MoO3 with top/bottom surfaces of (010) and a growth direction of [001], similar to previously reported2,9,26.

Growth mechanism

Based on the above observations and analysis, the formation mechanism and growth process of α-MoO3 belts prepared via the route of oxidizing a discarded molybdenum disilicide heating element at 1000 °C can be schematically illustrated in Fig. 7 and described as follows. At 1000 °C, molybdenum disilicide heating element should be oxidized to form MoO3 and SiO2, according to eqn (1). It is known that the melting point and boiling point of MoO3 are 795 °C and 1155 °C, lower than those of SiO2, 1650 °C and 2230 °C, respectively. Therefore, in this work, MoO3 must be volatilized, condensed and deposited in the bottle of corundum crucible whereas SiO2 should be formed on the surface of heating element.

Firstly, at the test temperature, significant MoO3 vapor would be generated in a mass, and after a cooling process the MoO3 vapor would be condensed and the MoO3 seed nuclei generated with the octahedral structure (Fig. 7Ia-c), followed by the formation of a proto-belt of MoO3 with the vapor-solid mechanism. To form these proto-belts, the initial growth in the width direction should be quicker than along the thickness direction. Because the MoO3 crystal have an orthorhombic system with the lattice parameter: a = 3.96 Å, b = 13.86 Å and c = 3.70 Å, its growth along c direction would be favored because of a lowest surface energy of the (001) plane and the formed belt-like structure should be resulted from large differences in the close-packing rate among the (100) and (010) planes. The α-MoO3 has an intrinsic tendency to grow an anisotropic structure because the planar growth rate along axis of the crystal has the following sequence {001} > {100} > {010}27,28. Therefore, after the formation of the proto-belt of MoO3, it should be grown preferentially along the [001] direction to form 1-D single MoO3 belts (Fig. 7Id-e). As the reaction progresses, the MoO3 microbelts were formed by layer by layer growth, eventually forming ribbon-shaped, cross-shaped, and flower-like MoO3 structures (Fig. 7If). The macroscopic growth mechanism of single MoO3 crystals in this study were as shown in Fig. 7-II(a-c). In the VS mechanism, the size of MoO3 crystal was proportional to growth time and growth rate which depended on evaporation rate and system pressure29. So the molybdenum disilicide rod was oxidized and sublimated to form MoO3 gas phase molecules at high temperature, which were then deposited on the bottom of the crucible and grown to form MoO3 crystals. The initially formed seed crystals had enough time and rapid growth rate to develop MoO3 belts up to millimetres or even centimeters, while the seed crystals generated at the later period at cooling down with short time and slow growth rate just were grown forming small microbelts.

Thermal and photoluminescence properties

The powdery and fibrous products were confirmed to be α-MoO3 microbelts and millimeter-belts. In order to understand their thermal stability and relative weight loss, thermogravimetric and differential thermal analysis (TG-DTA) were performed in air atmosphere. Figure 8a shows the TG-DTA curves of powdery α-MoO3 microbelts, initial weight was around 3.293 mg, and its weight had hardly significant change before 700 °C as well as the TG curve without ant stage decomposition, and only a loss of weight was about 4.03% due to the evaporation of water molecules in the product, so that powdery α-MoO3 microbelts had good thermal stability before 700 °C. Whereas, there was an intense endothermic peak at about 795 °C in the DTA curve which was corresponding to the temperature of melting point of α-MoO3. At this temperature, there was a dramatic weight loss of about 57.27% in the TG curve, resulted from the sublimation of MoO321,28. Similarly, fibrous products with α-MoO3 millimeter-belts had similar results (Fig. 8b), but it has two inapparent endothermic peak at about 237 °C and 383 °C in the DTA curve, and a loss of weight about 5.17% should be due to the evaporation of water molecules in the product, and a loss of weight about 66.3% due to sublimation of MoO3 at 795 °C. It is verified that the two kinds of belts had favourable flame retardancy and thermal stability before 700 °C.

Figure 9 shows the representative photoluminescence (PL) spectra of the two kinds of α-MoO3 belts in the wavelength range from 250 to 700 nm under the excitation of 240 nm at room temperature. Both of the powdery microbelts and millimeter-belts exhibited a strong emission from around 465 nm to 495 nm with a central peak at 481 nm (~2.578 eV) located in the blue-indigo spectral range, corresponding to the recombination between electron and hole of the α-MoO3 belts. But the fibrous α-MoO3 millimeter-belts had stronger peaks than the MoO3 powder, which should be due to the difference between the crystal size and the degree of edge distortion. It could be valuable for the future potential applications in optoelectronic devices29.

In conclusion, α-MoO3 belt-like structures were obtained by oxidizing a waste molybdenum disilicide heating element at 1000 °C. The oxidized products were consisted of two parts, powdery and fibrous crystals, in which the sizes of the former were 15~40 μm long, some of them could grow into flower-like and cross-shaped structures, and the later could develop to millimeter even centimeter long. A series of characterizations revealed that the α-MoO3 belt-like structures had good crystallinity, high purity and good thermal stability as well as luminescence property of 2.578 eV. It may be used in high-temperature devices and has good potential in light-emitting devices, which realized the recycling of discarded molybdenum disilicide heating element.

Methods

A discarded silicon molybdenum rod was used as the raw material in this experiment, the surface of which was polished to remove the formed oxide before using. Then the silicon molybdenum rod with fresh surface was put on top of a corundum crucible. The set was then placed in a high temperature furnace and heated at 1000 °C in air for 3 h. After furnace-cooling to room temperature, the product deposited in the bottom of the corundum crucible was subjected to detailed characterization using the techniques described below.

The phases of the resultant products were identified by X-ray diffraction (XRD; XD–3, Purkinje General Instrument Co., Ltd) with Cu Kα1 radiation (λ = 1.5406 Å). The qualitative information was obtained by X-ray photoelectron spectrometer (XPS, Axis Ultra DLD) and Fourier transformation infrared spectroscopy (FTIR, Thermo Nicolet 5700). Their morphologies and microstructures were observed with both a scanning electron microscope (SEM; JEM–6460 LV microscope, Japan), and a transmission electron microscope (TEM, JEOL JEM-2010, Japan) equipment with an energy dispersive spectroscope (EDS, INCA, Oxford Instrument, UK) and selected area electron diffraction (SAED). The thermogravimetric and differential thermal analysis (TG-DTA, 404F3/200F3) of the products were carried out in air atmosphere on the pan of Al2O3 at 10 °C min−1. The room-temperature photoluminescence (PL) spectra of the as-prepared products were examined by a fluorescence spectrophotometer (Hitachi Model F-7000 FL Spectrophotometer).

References

Lou, X. W. & Zeng, H. C. Complex α-MoO3 nanostructures with external bonding capacity for self-assembly. J. Am. Chem. Soc. 125, 2697–2704 (2003).

Cai, L. L., Rao, P. M. & Zheng, Xl Morphology-controlled flame synthesis of single, branched, and flower-like α-MoO3 nanobelt arrays. Nano Lett. 11, 872–877 (2011).

Alejandro, M. et al. High rate and durable, binder free anode based on silicon loaded MoO3 nanoplatelets. Sci. Rep. 5, 10530 (2015).

Badica, P. Preparation through the vapor transport and growth mechanism of the first-order hierarchical structures of MoO3 belts on sillimanite fibers. Cryst. Growth Des. 7(4), 794–801 (2007).

Mai, L. Q. et al. lithiated MoO3 nanobelts with greatly improved performance for lithium batteries. Adv. Mater. 19, 3712–3716 (2007).

Sen, U. K. & Mitra, S. Electrochemical activity of α-MoO3 nano-belts as lithium-ion battery cathode. RSC Adv. 2, 11123–11131 (2012).

Hashem, A. M., Groult, H., Mauger, A., Zaghib, K. & Julien, C. M. Electrochemical properties of nanofibers α-MoO3 as cathode materials for Li batteries. J. Power Sources. 219, 126–132 (2012).

Comini, E., Yubao, L., Brando, Y. & Sberveglieri, G. Gas sensing properties of MoO3 nanorods to CO and CH3OH. Chem. Phys. Lett. 407, 368–371 (2005).

Rahmani, M. B. et al. Gas sensing properties of thermally evaporated lamellar MoO3. Sens. Actuators, B 145, 13–19 (2010).

Labanowska., M. EPR Monitoring of Redox Processes in Transition Metal Oxide Catalysts. ChemPhysChem 2, 712–731 (2001).

Fu, G., Xu, X., Lu, X. & Wan, H. Mechanisms of methane activation and transformation on molybdenum oxide based catalysts. J. Am. Chem. Soc. 127, 3989–3996 (2005).

Khademi, A., Azimirad, R., Zavarian, A. A. & Moshfegh, A. Z. Growth and field emission study of molybdenum oxide nanostars. J. Phys. Chem. C 113, 19298–19304 (2009).

Li, T., Zeng, W., Zhang, Y. Y. & Hussain, S. Nanobelt-assembled nest-like MoO3 hierarchical structure: Hydrothermal synthesis and gas-sensing properties. Mater. Lett. 160, 476–479 (2015).

Zhang, L., Liu, Z. L., Jin, L. & Zhang, B. B. Self-assembly gridding α-MoO3, nanobelts for highly toxic H2S gas sensors. Sens. Actuators, B 237, 350–357 (2016).

Chithambararaj, A., Sanjini, N. S., Chandra Bose, A. & Velmathi, S. Flower-like hierarchical h-MoO3: new findings of efficient visible light driven nano photocatalyst for methylene blue degradation. Catal. Sci. Technol. 3(5), 1405–1414 (2013).

Wang, L., Zhang, X., Ma, Y., Yang, M. & Qi, Y. X. Rapid microwave-assisted hydrothermal synthesis of one-dimensional MoO3, nanobelts. Mater. Lett. 164, 623–626 (2016).

Zhao, G., Zhang, N. & Sun, Q. K. Porous MoO3 films with ultra-short relaxation time used for supercapacitors. Mater. Res. Bull. 48(3), 1328–1332 (2013).

Alizadeh, S. & Hassanzadeh-Tabrizi, S. A. MoO3, fibers and belts: Molten salt synthesis, characterization and optical properties. Ceram. Int. 41(9), 10839–10843 (2015).

Liao, W. P. et al. Macroscopic single-crystal tubes assembled with porous supramolecular architecture of water-soluble calixarene and phenanthroline. Chem. Commun. 14(14), 1861–1863 (2009).

Segun, L., Figlaz, M., Cavagnat, R. & Lassegues, J. C. Infrared and Raman spectra of MoO3 molybdenum trioxides and MoO3. xH2O molybdenum trioxide hydrates. Spectrochim. Acta, Part A. 51, 1323 (1995).

Krishna, A. G. et al. Investigation and comparison of optical and raman bands of mechanically synthesised MoO3 nano powders. Mater. Today: Proceedings 3(1), 54–63 (2016).

Bica de Moraes, M. A., Trasferetti, B. C., Rouxinol, F. P. & Landers, R. Molybdenumoxide thin films obtained by the hot filament metal oxide deposition technique. Chem. Mater. 16, 513–520 (2004).

Wolden, C. A. et al. Synthesis of β-Mo2C thin films. Appl. Mater. Interfaces. 3, 517–521 (2011).

Pan, H. et al. A facile in-situ growth of large area flexible α-MoO3, microsheets aligned arrays for temperature sensor. J. Alloys Compd. 695, 2965–2968 (2017).

Arita, M., Kaji, H., Fujii, T. & Takahashi, Y. Resistance switching properties of molybdenum oxide films. Thin Solid Films. 520(14), 4762–4767 (2012).

Chen, C. Z., Li, Y. & Tang, X. D. Evidence of oxygen vacancy and possible intermediate gap state in layered α-MoO3 single-crystal nanobelts. Physica B. 481, 192–196 (2016).

Wang, Z., Madhavi, S. & Lou, X. W. Ultralong α-MoO3 nanobelts: synthesis and effect of binder choice on their lithium storage properties. J. Phys. Chem. C. 116, 12508–12513 (2012).

Dewangan, K. et al. Synthesis and characterization of single-crystalline α-MoO3 nanofibers for enhanced Li-ion intercalation applications. CrystEngComm. 13, 927–933 (2011).

Phadungdhitidhada, S., Mangkorntong, P., Choopun, S., Mangkorntong, N. & Wongratanaphisan, D. Synthesis of MoO3 nanobelts by medium energy nitrogen ion implantation. Mater. Lett. 65(3), 568–571 (2011).

Acknowledgements

This work was financially supported by the Natural Science Foundation of China (Grant No. 51772140 and 51862024), Aeronautical Science Foundation of China (Grant No. 2016ZF56019), Natural Science Foundation of Jiangxi Province (Grant No. 20171ACB21033) and Graduate Innovation Special Fund of Nanchang Hangkong University (YC2017003).

Author information

Authors and Affiliations

Contributions

J.H. and X.L. contributed to the conception and design of this experiment. X.H., M.L. and did the preparation experiments and performed XRD, SEM, TG-DTA and XPS characterization. Z.H. and M.Z. carried out TEM, FT-IR and PL tests. J.H., Z.F. and J.L. analysed the data. J.H., X.H. and M.L. wrote the paper. All authors discussed the results and reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hou, X., Huang, J., Liu, M. et al. Single-Crystal MoO3 Micrometer and Millimeter Belts Prepared from Discarded Molybdenum Disilicide Heating Elements. Sci Rep 8, 16771 (2018). https://doi.org/10.1038/s41598-018-34849-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-018-34849-y

Keywords

This article is cited by

-

Laser induced crystal formation of layered molybdenum trioxide

Advanced Composites and Hybrid Materials (2026)

-

Controllable growth of MoO3 dielectrics with sub-1 nm equivalent oxide thickness for 2D electronics

Nature Communications (2025)

-

Effects of synthesis temperature and polymer addition on the phase and morphology of molybdenum oxide by ultrasonic spray pyrolysis

Journal of Materials Science (2022)

-

3D CoMoO4 nanoflake arrays decorated disposable pencil graphite electrode for selective and sensitive enzyme-less electrochemical glucose sensors

Microchimica Acta (2022)

-

Mid infrared polarization engineering via sub-wavelength biaxial hyperbolic van der Waals crystals

Scientific Reports (2021)