Abstract

The present work demonstrates the impact of thermal annealing on the structural, linear, and non-linear optical characteristics of thermally evaporated BixIn35-xSe65 (x = 0, 5, 10, 15 at%) thin films. The prominent crystalline phases have been developed for all annealed films at 450 °C whereas the films remain amorphous at 350 °C annealing. The XRD and Raman analysis showed the phase transformation of Bi-doped films and new Bi2Se3 phases developed upon annealing at 450 °C. The phase transformation induced change increased the linear and nonlinear properties with great extent as seen from the UV–visible optical studies. The direct and indirect optical bandgaps decreased with annealing temperature and also with Bi % content due to the formation of surface dangling bonds near the crystallite sites. The static linear refractive index and high-frequency dielectric constants were increased with annealing. The third-order non-linear susceptibility and non-linear refractive index were found to be greatly influenced by annealing temperature and increased with bismuth content. The FESEM micrographs also showed the phase transformation and EDX analysis showed the composition. The results obtained from the materials showed the potentiality to be useful for photovoltaic and optoelectronic applications.

Similar content being viewed by others

Introduction

The amorphous chalcogenide materials have been intensively investigated because of their promising optoelectronic properties and hence possible applications in optical fibers, memory devices1, solar cells2, optical telecommunication3, and sensors4. The high non-linear refractive index of these materials makes them to play a significant role in applications such as supercontinuum, all-optical switching, and wavelength conversion5,6. With the increasing concerns and demands nowadays, improvements are needed to achieve the most resonant characteristics for device applications. So many studies have concentrated on the effect of external energy input such as doping of foreign elements7, thermal annealing8, laser irradiation9, ion irradiation10, etc. on the properties of the films. Among these processes, thermal annealing method is well known for the reduction in the structural defects and increment in the crystallite size that is responsible for the change in their structural and optical characteristics11. The influence of heating treatment on different properties has been studied by various researchers. Thermal annealing induces crystallization accompanied by the change in band gap and activation energy of Ga15Se77In8 thin film was studied by Al-Agel et al.12. The crystallized GeSe2 and Bi2Se3 phases with monoclinic and hexagonal crystal structures have been observed upon annealing Bi5Ge40Se55 thin films at different temperatures which results in the decrease in bandgap and changes in dielectric properties13. The annealing induced large non-linear optical changes in Ge20Se65S15 thin films suggests for use in low-power devices like optical computers, ultrafast switches, and pulsed lasers14.

In this regard, the In–Se (III-VI) system is considered as an archetypical semiconducting chalcogenide that takes an important place in applications such as electrical switching, nonlinear optics, diodes, photodetectors15,16. Several studies based on the additives in In–Se chalcogenide systems have grabbed much attention due to changes in their optoelectrical properties which may be seen as new optimistic applications of multicomponent chalcogenide systems17,18,19. Among them, bismuth as a dopant showed significant influence on the host InSe material by several modifications such as phase transformation, carrier type reversal, and change in optoelectrical properties which supports the understanding of the fundamental mechanisms inside the system20.

Previously, we have studied the doping effect of bismuth into BixIn35-xSe65 thin films prepared by thermal evaporation technique which showed the presence of crystallinity behavior in 7% and 15% Bi-doped films with significant modification in linear and non-linear optical characteristics21. However, in the present report, we have focused on the analysis of the optical and structural properties of thermally annealed BixIn35-xSe65 chalcogenide thin films. The glass transition temperature (Tg) plays an important role in the characterization of glassy materials that represents the temperature above which an amorphous matrix attains various structural configurations. The Tg influenced different parameters such as average coordination number, enthalpy of atomization, mean bond energy, and bandgap22. Therefore, the annealing temperatures in glassy materials were taken by considering Tg value. In this regard, we have annealed the film with above Tg (at 350 °C and 450 °C) as our case study to investigate the influence of annealing temperature on different properties. The Tg for the Bi–In–Se system with low In% content were found to be 324 K (51 °C)23. The annealing effect on the Se85In15-xSbx films at temperatures above Tg showed improved linear optical properties of the host matrix which is due to the structural rearrangement that occurred from amorphous to crystalline transformation18. Furthermore, the appearance of binary Bi2Se3 and BiSe2 phases with the reduction in the optical bandgap and activation energy were observed due to annealing below Tg (~ 429 K) in Sn10Sb20-xBixSe70 (0 ≤ x ≤ 8) films that improved the device performance24. The increase in annealing temperature not only increases the crystallinity growth but also showed an increase in the absorption capability which causes blue shift of the optical bandgap25. Similarly, annealing of BixIn25-xSe75 films at 440 K (167 °C) showed an appearance of crystallized Bi2Se3, Se, In2Se3 phases at x = 7 at % that induces an increase in optical bandgap which is explained by the thermal relaxation of the vapor quenched state and density of defect states20. However, the annealing-induced studies on the Bi–In–Se system were restricted up to 7% Bi doping. The annealing induced changes in higher Bi% and the changes in nonlinear parameters such as non-linear refractive index and third-order non-linear susceptibility with annealing is the prime aim of the present work.

The objective of the present study is to investigate the annealing induced effects on the linear and nonlinear optical parameters such as absorption coefficient, extinction coefficient, optical band gap, static refractive index, third-order optical susceptibility, nonlinear refractive index of thermally evaporated BixIn35-xSe65 (x = 0, 5, 10, 15 at %) thin films at 350 °C and 450 °C annealing temperatures. The elemental composition and morphological identifications were done through Energy dispersive X-ray analysis (EDX) attached with the Field emission scanning electron microscope (FESEM). The annealing-induced structural modifications and phase transformation were investigated by X-ray diffraction method (XRD) and Raman spectra analysis. The optical constants have been estimated from the transmittance data obtained by UV–Vis spectrophotometer over the range 600–1100 nm wavelength.

Experimental details

Bulk BixIn35-xSe65 (x = 0, 5, 10, 15) samples were prepared from the stoichiometric mixture of high purity (99.999% Sigma Aldrich) Bi, In, and Se by conventional melt quenching process. The detailed procedure for the preparation of bulk and thin film samples are reported in our earlier study21. The glass slides were used as substrate for film deposition and were cleaned by dipping into hydrogen peroxide (H2O2), subsequently treated in trichloro ethylene, acetone, and methanol in an ultrasonic bath. The prepared thin films were annealed at 350 °C and 450 °C both at above Tg for 2 h under pressure 10–3 Torr, and the temperature gradient during the annealing process was ~ 5 to 6 °C/h.

The amorphous state and crystalline structure were studied by using XRD (Brucker D8 Advanced) with Cu Kα line (λ = 1.54 Å). The scanning range was 20°–60° at a step size of 0.02°/s with grazing angle 1° and scan speed 1°/min. The verification of the concentration, surface morphology, and elemental analysis of the annealed films was examined by EDX technique linked with FESEM unit (Carl Zeiss Ultra 55). The system was operated with accelerating voltage of 20 kV with emission current 40 mA for 1 cm2 sample size at 3–4 positions under high vacuum conditions (2 × 10–7 Torr). The Raman spectra (LabRAM HR system) for the annealed films were recorded by employing argon laser (514.5 nm) source over the range 50–40 °C m−1 through backscattering mode of CCD detector. The optical transmission data of the annealed films were recorded by using UV–Vis spectrophotometer (Bruker Optics (IFS66v/S)) over 600–1100 nm range. The optical parameters such as absorption constants, optical density, skin depth, extinction coefficient, direct and indirect bandgap, Tauc parameters for the studied films were estimated and discussed by using suitable empirical relations and models. The linear static refractive index (n0), high-frequency dielectric constant (ε∞), and non-linear parameters such as third-order non-linear susceptibility (χ(3)), non-linear refractive index (n2) were calculated from Miller’s rule and Dimirov-Sakka empirical relation.

Results and discussions

Structural analysis

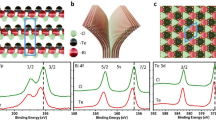

X-ray diffraction study

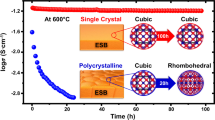

The XRD spectrum of the annealed BixIn35-xSe65 thin films is shown in Fig. 1a which confirms the amorphous nature for 350 °C annealed 5%, 10%, and 15% Bi-doped films. However, the 450 °C annealed films showed polycrystalline nature. The hexagonal phase of γ-In2Se3 has been represented by diffraction peaks such as 25.00° (1 1 0), 27.77° (0 0 6), 30.95° (2 0 2), 43.92° (3 0 0), (ICSD card: 00-023-0294) and 45.98° (1 2 5), 32.35° (2 0 3), 50.10° (1 1 9) (ICSD card: 01–071-0250) respectively. The observed diffraction peaks support the result obtained various workers26,27,28,29,30. The other peaks at 26.06° (1 0 1), 26.65° (0 1 2) corresponds to rhombohedral phase of InSe (ICSD card: 00–029-0676) have been indexed in the figure. The subsequent annealing after the introduction of bismuth in In–Se alloys resulted in an additional diffraction peak at 29.29° which represents the rhombohedral Bi2Se3 (0 1 5) (ICSD card: 00-033-0214) respectively. The different phases obtained in this study are matching with the reported data31. The XRD analysis of these annealed Bi-doped (5%,10%, and 15% Bi) samples enables us to ensure the phase transformation from amorphous to crystalline phase while annealing from 350 to 450 °C that supports several studies32,33. The amorphous nature of 350 °C Bi-doped annealed films signifies no structural transformation inside the films annealed at 350 °C. This behavior may be due to the incorporation of high-density bismuth atoms that increases the disorder and density inside the system34. The appearance of polycrystallinity in all the 450 °C annealed films induces crystallization in semiconductor chalcogenide films. In the case of In35Se65 films, the increase in annealing temperature from 350 to 450 °C decreased the intensity and, sharpness of the crystalline peaks indicating to decrease in crystallinity35.

Several structural parameters were estimated by using the well-known Scherrer and the Williamson-Hall equations of the sample. Based on the Scherrer equation, the crystallite size D (in nm) is inversely dependent on peak width β (full-width half maxima) as follows36,

where λ is the wavelength of Cu Kα-line (1.54 Å), β is the full-width half maxima (FWHM) in radians and θ is the Bragg’s angle. The values of average crystallite size at different temperatures for different Bi concentrations are tabulated in Table 1. The crystallite size increased with the annealing temperature which is due to the increase in the grain size as a result of an increase in the mobility and migration of atoms. During the thermal annealing process, the atoms receive enough energy that helps them migrate to relative equilibrium positions. This causes an enhancement of the grain growth and decreases of lattice dislocation in the films36 as a result of which there is increased formation of lattice grains and lattice imperfections.

The other microstructural parameters such as lattice strain (ε), dislocation density (δ), the number of crystallites per unit surface area (Nc) of the films were calculated using the following relations37,

The obtained values for dislocation density and Nc from average crystallite size were tabulated in Table 1. It is seen that bismuth incorporated annealed films showed higher dislocation, strain, and lower crystallite size with respect to In35Se65 film, which is due to an increase in the densification with doping that leads to the formation of smaller grains. Overall, decreasing behavior in the dislocation density inside the crystal is due to the refinement of crystallite size and annihilation of dislocation inside the films which indicates an increase in the crystallinity of the material38. The Nc decreased with annealing temperature may be due to the change in structure or formation of smaller crystallites39.

The simultaneous effect on the lattice strain and crystallite size on the peak broadening, the Williamson-Hall relation was used which is given by40,41,

The first term on the right-hand side of the equation demonstrates the Scherrer equation, which signifies the effect of crystallite size. Whereas, the second part shows the change in microstrain associated with nanoparticles on the broadened peak which is known as the Stokes and Wilson expression. Generally, the width β in a diffraction peak gets influenced by the change in instrumental factors, change in strains, crystallite size, and presence of crystal defects. When the peak broadening shows independence over 1/D, an enhancement in 1/D values increased the strain broadening. In this case, the size and strain of the crystallites are evaluated simultaneously. Therefore, the W–H plots were presented in Fig. 1b and c by taking (β cosθ) in the Y-axis and (4sinθ) in the X-axis, where the crystallite size (D) = kλ/(y-intercept), and the slope gives the strain values in Fig. 1b tabulated in the Table 1. The estimated values were very different from the value obtained in the Scherrer equation. In general, the W–H plot shows both positive and negative slopes, where positive values correspond to tensile strain and negative values to compressive strain. The estimated strain values for 350 °C annealed films in Fig. 1c are 0.225 (15% Bi), 0.366 (10% Bi), and corresponding crystallite size are 1.554 (15% Bi), 0.723 (10% Bi) respectively. In our case, all the values were positive slopes which appear as tensile strain may be due to contact and coherency stress, grain boundary, stacking faults41. This results in the shifting of peak position was observed from Fig. 1a.

Raman analysis

Raman spectroscopic analysis is a useful chemical analysis technique that provides useful information on molecular interactions, crystallinity, crystal phase, and chemical structure. The significant information on the structural rearrangements and phase transitions of the samples due to annealing are obtained from spectral analysis of vibrational levels. The Raman spectra of the 350 °C and 450 °C annealed BixIn35-xSe65 thin films are shown in Fig. 1d that showed different peaks in between 50 and 40 °C m−1 range. The In35Se65 spectrum contains peaks at 96 cm−1, 156 cm−1, 238 cm−1, among which the former two peaks (96 cm−1, 156 cm−1) are related to the In–Se phase41,43. The weaker broad peak at 238 cm−1 is attributed to the homopolar Se–Se vibrational chain30 that disappeared after Bi doping except for 450 °C annealed 5% Bi-doped film. New additional peaks at 67 cm−1, 127 cm−1, 172 cm−1, and 253 cm−1 arise due to Bi doping and subsequent annealing of Bi–In–Se films. The peak at 67 cm−1 corresponds to the Eg1 mode of the Bi–Bi vibrational bond44. Two prominent peaks at 127 cm−1, 172 cm−1 are assigned to Eg2 and A1g2 mode of Bi2Se3 band45, and the broad sharp Raman vibrational peak at 253 cm−1 is due to the presence of Sen rings43,46. This broad peak shifts slightly towards higher wave number which shows the annealing induced structural modification due to the evolution of crystalline phases. Among all the annealed films, 5% Bi-doped annealed film peak showed the maximum intensity that indicates the greater structural modifications inside the matrix and decreases simultaneously for higher Bi-doped films. The overall increases in Raman intensity of all the peaks and the slight shifting to high wavenumbers with an increase in the annealing temperature indicate significant structural change in the glass structure and the formation of micro crystallites14. Further, on increasing Bi concentration from 5 to 15%, Raman intensity decreases and broadening increases due to an increase in lattice defect concentration which is confirmed from XRD analysis47.

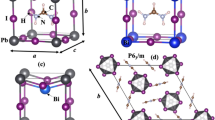

Morphological analysis

EDX analysis

The EDX pictures are shown in Figs. 2 and 3 that represent the presence of the constituent elements in the 350 °C and 450 °C annealed BixIn35-xSe65 thin films. The In35Se65 annealed film as shown in Fig. 2 showed the presence of only In and Se whereas the other annealed Bi5In30Se65 films showed the evidence of bismuth content through Bi-peaks along with In and Se peaks. Similarly, different peaks correspond to constituent elements present in the Bi10In25Se65 and Bi15In20Se65 thin films annealed at 350 °C and 450 °C can be seen in Fig. 3. The composition of the different annealed films is shown in Table 2 which shows nearly equal concentration as that of the calculated values. The error in composition with annealing is within 3%. The peak at 2.25 keV in the In35Se65 annealed films may be due to indium concentration which got unseen due to the presence of the Bi peak in Bi-doped films48. The suppression of selenium peak in the Bi 5% doped 450 °C annealed film occurred along with slight increase with Bi peak intensities. This kind of behaviour has also seen in reference49 which is due to an increase in the annealing temperature. This suppression behaviour has not observed in other films which may be due to the increase in the Bi concentration in the samples.

FESEM analysis

The FESEM images at 200 nm scale for 350 °C and 450 °C annealed BixIn35-xSe65 films are shown in Figs. 2 and 3 respectively. The images show the homogeneous and smooth nature of the annealed films. Annealing at 450 °C results in an increase in particle density which can be observed from both the figures as compared with the 350 °C annealed films. We have calculated the particle size for each sample by using ImageJ software (version -Java 1.8.0_172) and done the statistical analysis which is shown in Fig. 4. It can be observed that the particle size increased with increase in annealing temperature i.e., from 350 to 450 °C. The overall particle size decreased considerably with higher bismuth concentration which can be seen from the histogram distribution. The Bi 5% annealed film at both 350 °C and 450 °C shows the particles in the form of nanorod like structures. Similarly, the Bi 10% annealed film at both the temperatures shows particles with fragmentation form.

Optical data analysis

Linear optical parameters

Transmittance (T) and absorption coefficient (α)

The UV–visible transmission study provides valuable information regarding the response of materials towards light. Electromagnetic waves with weak or moderate intensity interact with the material, leads to an induced polarization, and are affected linearly by the electric field. These linear responses can be explained through reflection, transmission, absorption, or scattering. So, these linear optical characteristics play an important role in the application perspective50. The transmission spectra of annealed BixIn35-xSe65 (x = 0, 5, 10, 15 at %) films for the wavelength interval of 600–1100 nm are presented in Fig. 5a. The transmission % decreased with an increase in both annealing temperature as well as dopant concentration as reported for other studies also51,52. The vertical arrow signifies the decrease in transmittance of the samples whereas the horizontal arrow signifies the shifting of absorption edge towards higher wavelength. It can be clearly observed that annealing at 350 °C films showed better transmittance than at 450 °C annealed films. The decreased transmittance with annealing temperature is accompanied by the structural transformation of the film as a result of the growth of crystallites in the material53.

The absorption edge shifted towards higher wavelength with increasing annealing temperature and Bi concentration. This red shift of absorption edge is due to an enhancement in grain boundary defects created by the crystallites formed due to annealing which decreases the optical bandgap. The appearance of transmission fringes nearly at 700 nm beyond the visible wavelength of light in some films (350 °C annealed films) provides good evidence on the interference phenomenon of light with the material medium that indicates the homogeneity and smoothness throughout the film thickness54.

The optical absorption coefficient (α) is considered as an important parameter for the evaluation of the optical band gap and Tauc parameter of the thin films. The parameter ‘α’ provides information on the absorption of light energy during the electronic transition. The ‘α’ value was calculated from the measured values of transmittance (T) by using the following equation55;

where ‘d’ represents the thickness of the film (~ 800 nm). The absorption coefficient spectra for the 350 °C and 450 °C annealed BixIn35−xSe65 thin films as a function of wavelength is shown in Fig. 5b. The obtained absorption coefficient is of the order of 104–105 cm−1 which showed good agreement with the results by various workers. It can be noticed that the absorption coefficient decreased with wavelength which satisfies the increase in the transmittance behavior at higher wavelength region. The absorption coefficient showed redshift on increase in the annealing temperature as well as with doping content. The 450 °C annealed 10% and 15% Bi-doped films showed different behavior than other films. This behavior can be explained by using the relationship between free carrier absorption in solids and the number of carriers. As the number of carriers increases during an increase in annealing which enhances the absorption capability significantly56. In-other way it can be explained through structural aspects of the modification through phase transition. The grain boundaries formed during phase transition indicate an increase in crystallinity and significantly affect the transmittance and absorbance behavior57. The high concentration of heavily dense bismuth increases the absorption significantly and correspondingly decreases the transmittance. Thus, in Fig. 5b, the 10% and 15% Bi-doped 450 °C annealed films showed a higher absorption value over the wavelength range. Such type of behavior has also been seen in the absorption coefficient (α) plot of N. M. Shah et al.58 work for high-temperature annealing.

Optical band gap (Eg) and Tauc parameter (B1/2)

The optical band gap (Eg) of the studied films from the high absorption region was calculated by using Tauc relation59;

where ‘B’ is known as the Tauc parameter which represents the degree of disorder in the materials and depends on the transition probability, ‘ν’ is the frequency of the incident beam, Eg is the optical band gap, p (exponent) is related to the nature of various electronic transitions. The value of ‘p’ has different values such as ½, 2, 3/2, and 3 depending on the different types of transition such as direct allowed, indirect allowed, direct forbidden, indirect forbidden respectively. According to Tauc, the amorphous materials showed indirect allowed bandgap whereas crystalline possesses direct allowed bandgap respectively. Since, here as a consequence of annealing induced phase transformation, both the amorphous (350 °C annealed 5%, 10%, and 15% Bi-doped films) as well as crystalline structure have been observed, thus we are concentrating on both direct and indirect allowed transition for the films. The optical band gap (Eg) and Tauc parameters of different annealed samples were obtained from the slope and intercept obtained by plotting the dependence of (αhv)1/p on photon energy(hv) and extrapolating the linear part of the curves to the energy axis for zero absorption coefficient. Figure 5c and d presents the variation of (αhv)2 with incident energy (hv) for directly allowed transitions and (αhv)1/2 with incident energy (hv) for indirect allowed transitions in annealed BixIn35-xSe65 films. The horizontal arrow in the Fig. 5d represents the decrease in the indirect optical band gap values for the studied films. The calculated values of Eg and Tauc parameters for both direct and indirect transitions are shown in Table 3. The observed indirect bandgap values decreased as found in Table 3. The obtained values agree with those obtained by other investigations20,25. The direct bandgap values also decreased with annealing like indirect bandgap for the studied films. From Fig. 5c and d, it is observed that the optical band gap values decreased upon an increase in the annealing temperature from 350 to 450 °C which is ascribed to the annealing induced phase transformation in the evaporated films. Generally, annealing above the glass transition temperature (Tg) causes crystallization inside the alloy along with the production of surface dangling bonds around the formed crystallites during the crystallization process. According to the ‘density of state model’ proposed by Mott and Davis60, an ideal amorphous solid shows phase transformation under heat treatment, and during the crystallization process, dangling bonds were produced around the crystallite surfaces. Further annealing causes the crystallite to break down into micro crystallites, thereby increasing the number of surface dangling bonds61. These bonds were responsible for the formation of defects in the polycrystalline solids. As the number of dangling bonds and defects increases, the concentration of localized states in the band structure gradually increases. Hence, an increase in the energy width of the localized state thereby reduces the bandgap61,62. Such type of behavior supports the results of various workers63,64. The subsequent increase in the bismuth content in the annealed films causes an increase in the density defect states by creating more localized states over the bandgap which consequently decreases the bandgap values65.

The Tauc parameter (B1/2) is inversely proportional with the degree of disorder and is dependent on the nature of bonding which measures the disorderness. Here, the B1/2 value for BixIn35-xSe65 films decreases upon annealing which is due to the increase in chemical disordering induced by the annealing process that increases the defect states and reduces bandgap. This decrease in optical band gap upon annealing showed the potentiality of these films to act as an absorber layer in various photovoltaic applications66,67.

Optical density (OD) and skin depth (δ)

The optical density (OD) or absorbance is related to the film thickness (d) and the concentration of absorbing material. The optical density of the presented annealed BixIn35-xSe65 films can be estimated as68 OD = α × d. Figure 6a illustrates the variation of optical density (OD) with wavelength (λ) which shows the same variation as the absorption coefficient. The increasing trend of the OD values with respect to annealing temperature and with Bi doping concentration is due to high absorption coefficient values. This behavior clearly gives an indication of the increase in the absorption ability of the materials when exposed to incident radiation.

Skin depth (δ) represents the distance at which optical photon density becomes 1/e of the value at the surface after traveling the film thickness. The skin depth or penetration depth (δ) is related to the absorption coefficient (α) by the relation given by32, δ = 1/α. The dependency of skin depth on the incident photon energy (hv) is shown in Fig. 6b. It is clearly observed that the skin depth reduced to zero value for all films as the energy increases. The increase in annealing temperature in the studied films decreases the skin depth sequentially indicating loss in the transparency of the thin films.

Extinction coefficient (k), linear static refractive index (n0) and high frequency dielectric constant (ε∞)

The study of extinction coefficient (k) is extremely important to decide the usefulness of the prepared materials for application in photocatalytic, photochemical, photosensors, phase change materials, memory devices, etc. The extinction coefficient relates the extent of fraction of light losses due to scattering and absorption per unit distance of the medium that has been calculated by using absorption coefficient (α) and wavelength by following relation53,

The variation of ‘k’ with the energy of incident radiation is shown in Fig. 6c that showed an incremental behavior with annealing temperature. This behavior is due to the thermal annealing process that creates several structural disorders and surface defects by producing localized states thereby increasing the absorption of light. The change in extinction coefficient immensely affects the non-linearity of the materials.

The linear static refractive index (no) and high-frequency dielectric constant, ε∞ = n02 of the annealed BixIn35-xSe65 films were estimated by using the Dimirov and Sakka relation69;

where Eg corresponds to optical band gap estimated by using Tauc relation. The obtained values of static refractive index and high-frequency dielectric constant were tabulated in Table 3. From the obtained values, it is clearly observed that the refractive index increases with annealing temperature and also with Bi doping content. This increment is due to the amorphous-crystalline transition and lattice relaxation as a consequence of annealing70. This behavior also satisfied Moss’s rule i.e., Egn4 ~ constant71, which showed the optical band gap variation showed the opposite trend with respect to refractive index (no). The dielectric constant also increased with an increase in annealing temperature.

Nonlinear optical parameter

Nonlinear susceptibility (χ(3))

The nonlinearity of glassy materials depends on the electric field strength that is responsible for nonlinear effects in the system. Interaction in the nucleus due to the electronic polarization and also their impact on bond lengths is responsible for optical nonlinearities in the chalcogenide glasses72. Thus, the total electron polarizability(P) created due to such interaction can be presented as73;

where χ(1) is the linear optical susceptibility, χ(2) and χ(3) are the second-order and third-order nonlinear susceptibility respectively. For centrosymmetric optically isolated glasses the second-order non-linear susceptibility is 0. Thus, the third-order nonlinear susceptibility is the dominant nonlinearity in all glassy materials that produced by excitation in the transparent frequency region below the bandgap Eg. Therefore, according to Miller’s rule the χ(1) and χ(3) of annealed BixIn35-xSe65 thin films can be obtained by following relation74,

where n0 is the static refractive index for hv → 0 and A is a constant having value ~ 1.7 × 10–10 e.s.u. The obtained linear and non-linear susceptibility values for direct and indirect electronic transitions are tabulated in Table 3. It is observed that the third-order susceptibility χ(3) value for both transitions increased with annealing temperature and Bi doping concentration. The monotonical increase of susceptibility for both transitions with decreasing bandgap is clearly shown in Fig. 7a and b. The increase in the susceptibility upon annealing is due to the change in the material structure as a result of phase transformation. In other words, the thermal annealing process allows an enhancement of homogenization and polymerization due to increased chemical interactions between the fragments that enhances the susceptibility of the system. The increased non-linear susceptibility of the materials permits to be used in compact, small, and low power devices for the telecommunication purpose75.

Non-linear refractive index (n2)

The refractive index, ‘n’ can be expressed as n = n0 + n2 < E2 > , where static refractive index n0 and non-linear refractive index ‘n2’ do not depend on the intensity of light and n0 > > n2 and < E2 > is the mean square of the applied electric field76. According to Ticha and Tichy and Miller’s rule, the non-linear refractive index is related to χ(3) by using the following relation77,

The value of the non-linear refractive index obtained is listed in Table 3. The non-linear refractive index increases with annealing temperature, which is due to the production of defect states by annealing that enhances local polarizabilities78. The high values on ‘n2’ of the annealed BixIn35-xSe65 films indicate to be potential candidates for non-linear optical applications.

Conclusion

The analysis from the above study shows the amorphous-crystalline phase transformation at higher annealing temperatures. The new Bi2Se3 phases were formed as found from XRD and corresponding vibrational mode change as noticed from Raman study. It showed more structural alteration in the case of 450 °C annealed films than 350 °C films. The transmittance decreased whereas the absorption coefficient increased with annealing and doping content. The annealing induced reduction in direct and indirect optical band gap in all films is attributed to the production of surface dangling bonds around the crystallites during phase transformation. This behavior enables these materials to be useful for the absorber layer for photovoltaic applications. The increase in optical density, extinction coefficient, and decrease in skin depth behavior has been observed with an increase in annealing and Bi concentration. The static linear refractive index and high-frequency dielectric constants increased with temperature and doping content. The nonlinear third-order susceptibility and refractive index were increased consequently with annealing temperature. The large non-linear susceptibility of the materials enables them to be used for optical switching, and telecommunication purposes.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Change history

26 April 2024

A Correction to this paper has been published: https://doi.org/10.1038/s41598-024-60479-8

References

Ahluwalia, G. K. Applications of Chalcogenides: S, Se, and Te (Springer, 2017).

Manivannan, R. & Victoria, S. N. Preparation of chalcogenide thin films using electrodeposition method for solar cell applications—A review. Sol. Energy 173, 1144–1157 (2018).

Meneghetti, M. et al. Purification of Ge-As-Se ternary glasses for the development of high quality microstructured optical fibers. J. Non-Cryst. Solids 503–504, 84–88 (2019).

Moreno, T. V. et al. Potentiometric sensors with chalcogenide glasses as sensitive membranes: A short review. J. Non-Cryst. Solids 495, 8–18 (2018).

Asoke, M. Nonlinear optical properties of chalcogenide glass fibers and their application to all optical switching. Opt. Fiber Technol. 3(2), 142–148 (1997).

Yu, Y. et al. Mid-infrared supercontinuum generation in chalcogenides. Opt. Mater. Exp. 3(8), 1075–1086 (2013).

Naik, R., Kumar, C., Ganesan, R. & Sangunni, K. S. Effect of Te addition on the optical properties of As2S3 thin film. Mater. Chem. Phys. 130, 750–754 (2011).

Abd-Elnaiem, A. M., Moustafa, S., Abdelraheem, A. M., Abdel-Rahim, M. A. & Mahmoud, A. Z. J. Non-Cryst. Solids 549, 120353 (2020).

Behera, M., Panda, R. & Naik, R. Laser induced Te diffusion in amorphous As50Se50 thin films probed by FTIR and XPS. Ind. J. Phys. 91(5), 555–562 (2017).

Aparimita, A., Naik, R., Sahoo, S., Sripan, C. & Ganesan, R. Influence of low energy Ag ion irradiation for formation of Bi2Se3 phase from Bi/GeSe2 heterostructure thin films. Appl. Phys. A 126, 203 (2020).

Chen, J. et al. Effect of thermal annealing on the optical stability of amorphous Ge–Se–Te films. Mater. Res. Express 7, 115201 (2020).

Al-Agel, F. A. Effects of annealing temperatures on optical and electrical properties of vacuum evaporated Ga15Se77In8 chalcogenide thin films. Vacuum 85, 892–897 (2011).

Abdel-Rahim, F. M., Hafiz, M. M. & Alsoroy, H. Thermal annealing effect on the structure and optical properties of Bi5Ge40Se55 thin films. J. Alloys Compd. 570, 76–80 (2013).

Dongol, M., Elhady, A. F., Ebied, M. S. & Abuelwafa, A. A. Effect of thermal annealing on the optical properties of Ge20Se65S15 thin films. Indian J. Phys. 95, 1245–1253 (2021).

Singh, H. et al. Composition dependent structural phase transition and optical band gap tuning in InSe thin films. Heliyon 5, e02933 (2019).

El-Kabnay, N., Shaaban, E. R., Afify, N. & Abou-sehly, A. M. Optical and physical properties of different composition of InxSe1−x thin films. Physica B 403, 31–36 (2008).

Srivastava, A., Tiwari, S. N., Alvi, M. A. & Khan, S. A. Phase change studies in Se85In15-xZnx chalcogenide thin films. J. Appl. Phys. 123, 125105 (2018).

Tripathi, R. P., Singh, K. & Khan, S. A. Crystallization kinetics and phase transformation studies on glassy Se85In15-xSbx system. Mater. Chem. Phys. 211, 97–106 (2018).

Panda, R., Naik, R. & Mishra, N. C. Thermal annealing induced evolution of AgIn5Se8 phase from Ag/In2Se3 bilayer film. J. Alloys Comp. 778, 819–826 (2019).

Sharma, S., Kumar, P. & Thangaraj, R. Effect of Bi additive on structure and optical properties of amorphous BixIn25−xSe75 chalcogenide films. Curr. Appl. Phys. 13, 731–735 (2013).

Priyadarshini, P. et al. Role of bismuth incorporation on the structural and optical properties in BixIn35-xSe65 thin films for photonic applications. J. Am. Ceram. Soc. https://doi.org/10.1111/jace.17960 (2021).

Lankhorst, M. H. R. Modelling glass transition temperatures of chalcogenide glasses. Applied to phase-change optical recording materials. J. Non-Cryst. Solids 297, 210–219 (2002).

Tripathi, R. P., Zulfequar, M. & Khan, S. A. Thickness dependent structural, optical and electrical properties of Se85In12Bi3 nanochalcogenide thin films. Mater. Res. Express 5, 046409 (2018).

Ahmad, M., Thangaraj, R. & Sathiaraj, T. S. Thermal annealing dependence of some physical properties of Bi-substituted Sn–Sb–Se glassy thin films. Eur. Phys. J.: Appl. Phys. 47, 30501 (2009).

Tripathi, R. P., Zulfequar, M. & Khan, S. A. Influence of thermal annealing on structural and optical properties of Se85In12Bi3 thin chalcogenide films. Mater Focus 6, 445–449 (2017).

Yang, M. D. et al. Structural and optical characteristics of γ-In2Se3 nanorods grown on Si substrates. J. Nanomaterials 976262, 1–5 (2011).

Ye, J., Soeda, S., Nakamura, Y. & Nittono, O. Crystal structures and phase transformation in In2Se3 compound semiconductor. Jpn. J. Appl. Phys. 37, 4264–4271 (1998).

Yan, Y. et al. Effects of pressure and deposition time on the characteristics of In2Se3 films grown by magnetron sputtering. Electron. Mater. Lett. 10, 1093–1101 (2014).

Lee, H. et al. Formation and characterization of CuInSe2 thin films from binary CuSe and In2Se3 nanocrystal-ink spray. Korean J. Chem. Eng. 33, 2486–2491 (2016).

Niranjan, R. & Padha, N. Growth of γ- In2Se3 monolayer from multifaceted InxSey thin films via annealing and study of its physical properties. Mat. Chem. Phys. 257, 123823 (2021).

Chen, S., Hutabalian, Y., Gierlotka, W., Wang, C. & Lu, S. Phase diagram of Bi–In–Se ternary system. Calphad 68, 101744 (2020).

Sahoo, D. et al. Investigation of amorphous-crystalline transformation induced optical and electronic properties change in annealed As50Se50 thin films. Opt. Quant. Electron. 53, 197 (2021).

Aparimita, A., Naik, R., Sripan, C. & Ganesan, R. Annealing induced transformations in structural and optical properties of Ge30Se70−xBix thin films, Phase. Transit 92, 683–698 (2019).

Purohit, A., Chander, S., Nehra, S. P. & Dhaka, M. S. Effect of air annealing on structural, optical, morphological and electrical properties of thermally evaporated CdSe thin films. Physica E 69, 342–348 (2015).

Patterson, A. L. The Scherrer formula for X-ray particle size determination. Phys. Rev. 56, 978–982 (1939).

Moustaghfir, A. et al. Structural and optical studies of ZnO thin films deposited by RF magnetron sputtering: influence of annealing. Surf. Coatings Technol. 174–175, 193–196 (2003).

Naik, R., Aparimita, A. & Sripan, C. Structural, linear and non-linear optical properties of annealed and irradiated Ag/Se heterostructure films for optoelectronic applications. Optik 194, 162894 (2019).

Anuroop, R. & Pradeep, B. Structural, optical, ac conductivity and dielectric relaxation studies of reactively evaporated In6Se7 thin films. J. Alloy. Compd. 702, 432–441 (2017).

Abdel-Rahim, M. A., Hafiz, M. M. & Mahmoud, A. Z. Influence of thickness and annealing on optical constants of Se82.5Te15Sb2.5 chalcogenide thin films. Solid State Sci. 48, 125–132 (2015).

Mote, V. D., Purushotham, Y. & Dole, B. N. Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J. Theor. Appl. Phys. 6, 6 (2012).

Harbbi, K. H. & Jahil, S. S. Study the lattice distortion and particle size of one phase of MnO by using fourier analysis of X-ray diffraction lines. Adv. Phys. Theories Appl. 65, 6–22 (2017).

Panda, R., Naik, R. & Mishra, N. C. Low-temperature growth of γ phase in thermally deposited In2Se3 thin films. Phase Transit 91, 862–871 (2018).

Weszka, J., Daniel, Ph., Burian, A., Burian, A. M. & Nguyen, A. T. Raman scattering in In2Se3 and InSe2 amorphous films. J. Non-Cryst. Solids 265, 98–104 (2000).

Aparimita, A., Naik, R., Sripan, C. & Ganesan, R. Laser-induced optical photobleaching in Bi-doped Ge30Se70 amorphous thin films. Appl. Phys. A 126, 5 (2020).

Walsh, L. A. et al. Interface chemistry of contact metals and ferromagnets on the topological insulator Bi2Se3. J. Phys. Chem. C 121, 23551–23563 (2017).

Childres, I., Tian, J., Miotkowski, I. & Chen, Y. AFM and Raman studies of topological insulator materials subject to argon plasma etching. Philos. Mag. A 93(6), 681–689 (2013).

Chauhan, K., Deshpande, M. P., Patel, K. N., Chaki, S. H. & Pandya, S. Structural, morphological and vibrational properties of Bi substituted Sb2S3 nanoparticles. Mater. Res. Express 5, 105005 (2018).

Mathaswaran, P., Kumar, R. S. & Sathyamoorthy, R. Effect of annealing on the structural and optical properties of InSe bilayer thin films. Vacuum 85, 820–826 (2011).

Chuhadiya, S. et al. Thermal annealing induced physical properties of ZnSe thin films for buffer layer in solar cells. Phys. Low Dimens. Syst. Nanostruct. 117, 113845 (2020).

Shongalova, A. et al. On the identification of Sb2Se3 using Raman scattering. M. R. S. Commun. 8, 865–870 (2018).

Aparimita, A. et al. Effect of Bi addition on the optical properties of Ge30Se70-xBix thin films. J. Alloys Comp. 739, 997 (2018).

Hafiz, M. M., Othman, A. A., El-Nahass, M. M. & Al-Motasem, A. T. Composition and thermal-induced effects on the optical constants of Ge20Se80−xBix thin films. Physica B 390, 348–355 (2007).

Nyakotyo, H., Sathiaraj, T. S. & Muchuweni, E. Effect of annealing on the optical properties of amorphous Se79Te10Sb4Bi7 thin films. Opt. Laser Technol. 92, 182–188 (2017).

Naik, R., Jena, S., Ganesan, R. & Sahoo, N. K. Effect of laser irradiation on optical properties of Ge12Sb25Se63 amorphous chalcogenide thin films. Ind. J. Phys. 89(10), 1031–1040 (2015).

Behera, M., Mishra, N. C., Naik, R., Sripan, C. & Ganesan, R. Thermal annealing induced structural, optical and electrical properties change in As40Se60-xBix chalcogenide thin films. AIP Adv. 9, 095065 (2019).

Abd-Elnaiem, A. M. et al. Influence of annealing temperature on the structural and optical properties of As30Te70 thin films. Mat. Sci. Poland 35, 335–345 (2017).

Abd-Elrahman, M. I., Abdel-Latief, A. Y., Khafagy, R. M., Younis, N. & Hafiz, M. M. Thermal annealing effect on the optical properties of Ag10As30S60 thin film. Spectrochimica Acta A: Mol. Biomol. Spectrosc. 137, 29–32 (2015).

Shah, N. M. et al. Structural, optical, and electrical properties of flash-evaporated copper indium diselenide thin films. J. Mater. Sci. 44, 316–322 (2009).

Tauc, J. Amorphous and liquid semiconductors 171 (Plenum Press, 1974).

Davis, E. A. & Mott, N. F. Conduction in non-crystalline systems V conductivity, optical absorption and photoconductivity in amorphous semiconductors. Philos. Mag. 22, 903–922 (1970).

Ibrahim, M. M. & Abdel-Rahim, M. A. Conduction behaviour of the system BixGe20Se80-x. Phys Scripta 38, 762–763 (1988).

Kotb, H. M., Dabban, M. A., Abdel-latif, A. Y. & Hafiz, M. M. Annealing temperature dependence of the optical and structural properties of selenium-rich CdSe thin films. J. Alloys Compd. 512, 115–120 (2012).

Aly, K. A., Osman, M. A., Abousehly, A. M. & Othman, A. A. Effect of heat treatment on the optical and electrical transport properties of Ge15Sb10Se75 and Ge25Sb10Se65 thin films. J. Phys. Chem. Solids 69, 2514–2519 (2008).

Sahoo, D. et al. Optimization of linear and nonlinear optical parameters in As40Se60 film by annealing at different temperature. Optik 219, 165286 (2020).

Suri, N., Bindra, K. S., Ahmad, M., Kumar, J. & Thangaraj, R. Optical and electrical studies of as-prepared and annealed Se–Te–Bi thin films. Appl. Phys. A 90, 149–151 (2008).

Sharma, R. et al. Influence of phase transformation on structure–property relationship in quaternary In10Sb10Ag10Se7°C halcogenide films. J. Mater. Sci. Mater. El. 31, 16398–16405 (2020).

Dwivedi, D. K., Pathak, H. P., Shukla, R. K. & Kumar, A. Effect of thermal annealing on the structural and optical properties of amorphous Se75−xTe25Sbx thin films by thermal evaporation method. Optik 126, 635–639 (2015).

Hassanien, A. S. & Akl, A. A. Effect of Se addition on optical and electrical properties of chalcogenide CdSSe thin films. Superlattice Microst. 89, 153–169 (2016).

Dimitrov, V. & Sakka, S. Linear and non-linear optical properties of simple oxides. J. Appl. Phys. 79, 1741–1745 (1996).

Atyia, H. E. & Hegab, N. A. Influence of thermal treatment on the optical aspects for Ge20In5Se75films. Optik 127, 3888–3894 (2016).

Moss, T. S. A relationship between the refractive index and the infra-red threshold of sensitivity for photoconductors. Proc. Phys. Soc. B 63, 167 (1950).

Mishra, S. et al. Investigation of glass forming ability, linear and non-linear optical properties of Ge–Se–Te–Sb thin films. Chem. Phys. 541, 111021 (2021).

Frumar, M., Jedelsky, J., Frumarova, B., Wagner, T. & Hrdlicka, M. Optically and thermally induced changes of structure, linear and non-linear optical properties of chalcogenides thin films. J. Non-Cryst. Solids 326–327, 399–404 (2003).

Wynne, J. J. Optical third-order mixing in GaAs, Ge, Si, and InAs. Phys. Rev. 178, 129 (1969).

Shaaban, E. R. et al. Structural, linear and non-linear optical properties of annealed As47.5Se47.5Ag5 thin films for optoelectronic applications. Opt. Mater. 86, 318–325 (2018).

Shkir, M., Ganesh, V., Alfaify, S., Yahia, I. S. & Zahran, H. Y. Tailoring the linear and nonlinear optical properties of NiO thin films through Cr3+ doping. J. Mater. Sci. Mater. El. 29, 6446–6457 (2018).

Ticha, H. & Tichy, L. Semiempirical relation between nonlinear susceptibility (refractive index), linear refractive index and optical gap and its application to amorphous chalcogenides. J. Optoelectron Adv. Mater. 4, 381–386 (2002).

Darwish, A. A. A. & Ali, H. A. M. On annealing induced effect in optical properties of amorphous GeSeSn chalcogenide films for optoelectronic applications. J. Alloys Compd. 710, 431–435 (2017).

Acknowledgements

The author Dr. Naik would like to thank the Department of Physics, Indian Institute of Science (IISc.) for Optical, Raman, and FESEM measurements. The usage of MNCF and NNCF facilities supported by Meity, DST and MOE are acknowledged.

Author information

Authors and Affiliations

Contributions

P.P.: writing, original draft, software, data curation, investigation, S.D.: data analysis, D.A.: sample preparation, investigation, R.G.: visualization, investigation, S.V.: data collection, investigation, R.N.: conceptualization, methodology, writing– review & editing, supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: The Acknowledgments section in the original version of this Article was incomplete. It now reads: “The author Dr. Naik would like to thank the Department of Physics, Indian Institute of Science (IISc.) for Optical, Raman, and FESEM measurements. The usage of MNCF and NNCF facilities supported by Meity, DST and MOE are acknowledged.”

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Priyadarshini, P., Das, S., Alagarasan, D. et al. Observation of high nonlinearity in Bi doped BixIn35-xSe65 thin films with annealing. Sci Rep 11, 21518 (2021). https://doi.org/10.1038/s41598-021-01134-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-021-01134-4

This article is cited by

-

Degradation of BiTeCl induced by thermal and laser treatment

Scientific Reports (2025)

-

Cubic silicon carbide anode material for low-temperature solid oxide fuel cell

Journal of Solid State Electrochemistry (2025)

-

Ameliorating the Features of TiN/SiO2 Promising Nanoceramic Doped Optical Polymer for Multifunctional Optoelectronics Applications

Silicon (2025)

-

Defect state enhanced third order thermo-optic nonlinearity in Bi3+ doped MnWO4 nanostructures

Applied Physics A (2025)

-

New materials with small optical band gap based on PMMA inserted with bitumen for laser cut-off

Emergent Materials (2025)