Abstract

Screen printing of cotton fabric using newly synthesized azo reactive dyes was carried out in the present study. Functional group chemistry and its effect on the printing properties of cotton fabric by varying the nature, number and position of reactive groups of synthesized azo reactive dyes (D1–D6) was studied. Different printing parameters (Temperature, alkali and urea) and their effect was explored on the physicochemical printing properties e.g., fixation, color yield, and penetration of the dyed cotton fabric. Data revealed that dyes with more reactive groups and having linear and planar structures (D-6) showed enhanced printing properties. Spectraflash spectrophotometer was used to evaluate the colorimetric properties of screen-printed cotton fabric and results showed superb color buildup. Printed cotton samples displayed excellent to very good ultraviolet protection factor (UPF). Presence of sulphonate groups and excellent fastness properties may entitle these reactive dyes as commercially viable for urea free printing of cotton fabric.

Similar content being viewed by others

Introduction

Printing is the coloration process of creating spectacular motifs and smashing color effects on cellulosic fabric having widespread applications in garment industry, home textile and composite materials1,2,3. Reactive dyes for their wide variety of stunning shades, outstanding fastness properties, simplicity of application methods and forming permanent covalent bonding are more popular for cellulosic fabric printing4,5,6. There is an important role of functional group chemistry and dye structure in the proper dye fiber linkage. The nature, number, and position of the reactive functional groups in the dye molecule have a distinctive impact on printing properties3,7,8. Coplanar, linear, sterically less hindered structures having more functional groups are key factors in attaining good quality printing with excellent color yield9,10,11. Fiber reactive dyes comprising of heterofunctional reactive groups have better color yield and greater fixation as compared to reactive dyes containing monofunctional reactive groups12 and are more suitable for printing because they exhibit high solubility, high diffusion, low affinity and high printing paste ability13,14,15. Moreover, for practical application of dye on cellulosic fabric there are some technical problems including diffusion and solubility of dyes in the printing paste7,16. Meantime, the high substantivity of dyes on the cotton fabric is responsible for patchy printing and the difficult washout process of unfixed dye on printed fabric17,18,19. So, fiber reactive dyes particularly with better and enhanced printing properties are still in demand. Reactive dyes having high solubility in the printing paste with sufficient affinity and substantivity are requisites for the printing of cellulosic fabric at the same time20,21,22. Moreover, dyes should have suitable tinctorial yield, great reactivity, and less dye effluent with the highest degree of fixation. In the current study, six hetero-functional reactive dyes that were designed and synthesized in our previous studies by varying the nature, position and number of functional groups were selected for screen printing of cellulosic fabric to explore the effect of reactive group chemistry on the printing properties. Different process parameters (temperature, urea, alkali) were also optimized to enhance color yield, fastness properties and to maximally reduce the dye discharge in the wastewater, to ensure the sustainable environmental development. Reactive dyes containing both monohlorotriazine (MCT) and sulphatoethylsulphone (SES) reactive moieties with sulphonate groups were used for achieving printed samples with proficient printing and aesthetic properties than dyes containing only one type of reactive group by increasing their solubility in printing paste.

Experimental

Materials

A bleached, mercerized 100% cotton fabric (having 124 and 84 ends per inch (epi) and picks per inch (ppi) respectively) with plain weave and areal density of 97.8 g/m2 was used in the present research work for the application of reactive dyes through the screen-printing technique. Solid raw materials used for dye synthesis including 2,4,6 trichloro-1,3,5 triazine, 2[(4-Aminophenyl) sulfonyl] ethyl hydrogen sulfate and 1-amino-8-hydroxynaphthalene-3,6-disulphonic acid were taken from Sandal Dyes and Chemical, (Pvt.) Ltd. Faisalabad, Pakistan. Analytical grade printing auxiliaries including urea, sodium alginate, NaHCO3, perlavin PAM detergent were obtained from BASF Germany.

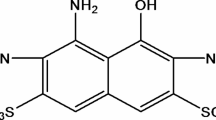

Synthesis of heterofunctional reactive dyes

Condensation, diazotization of sulphatoethylsulphone and H-acid coupling reactions were carried out for the synthesis of heterofunctional reactive dyes (D-1 to D-6) as described in the previous study3. The structures of the synthesized dyes are given in Scheme 1. New dye structures were characterized and confirmed through ultraviolet–visible, Fourier transform infrared and electrospray ionized mass spectrometry analytical techniques as discussed in previous study13. Characterization results are also given in supplementary data.

D-1

Physical state: powder, Colour: Red, Yield: 85%, Molecular formula: C25H17N7O14S4ClNa3, UV/Vis spectra in water: 459 nm, IR (KBr cm−1): 1543.57 (N=N Stretching), 1049.17–1201.76 (–S=O Stretching), 3417.87 (–NH Stretching), 1489.21 (–C–N Stretching), 740–799 (–C–Cl Stretching), ESI–MS: m/z = 413.42 [M-2Na] were detected.

D-2

Physical state: Powder, Color: Red, Yield: 82%, Molecular formula: C25H17N7O14S4ClNa3, UV/Vis spectra in water: 462 nm, IR (KBr cm−1): 1573.91 (N=N Stretching), 1193–1050 (–S=O Stretching), 3395.83 (–NH-Stretching), 1379.83 (–C–N Stretching), 740–799 (–C–Cl Stretching), ESI–MS: m/z at 268.75 [M-3Na] were detected.

D-3

Physical state: Powder, Color: Red, Yield: 78%, Molecular formula: C29H22ClN7Na4O19S6, UV/Vis spectra in water: 477 nm, IR (KBr cm−1): 1573.92 (N=N Stretching), 1050.51 (–S=O Stretching), 1195 (–SO3 Stretching), 1409.15 (–C–N Stretching), 742–801 (–C–Cl Stretching), ESI–MS: m/z = 522.50 [M-2Na] were detected.

D-4

Physical state: powder, Color: Red, Yield: 79%, Molecular formula: C29H22ClN7Na4O19S6, UV/Vis spectra in water: 475 nm, IR (KBr cm−1): 1574.19 (N=N Stretching), 1049.59 (–S=O Stretching), 1201–1135 (–SO3 Stretching), 1410.19 (–C–N Stretching), 738–801 (–C–Cl Stretching), ESI–MS: m/z = 522.50 [M-2Na] were detected.

D-5

Physical state: Powder, Color: Red, Yield: 75%, Molecular formula: C29H22ClN7Na4O19S6, UV/Vis spectra in water: 475 nm, IR (KBr cm−1): 1573.80 (N=N Stretching), 1050.21 (–S=O Stretching), 1201–1134 (–SO3 Stretching), 2956.34 (–C–H Stretching), 737.50–995.58 (–C–Cl Stretching), ESI–MS: m/z = 249.83 [M-4Na] were detected.

D-6

Physical state: Powder, Color: Red, Yield: 80%, Molecular formula: C29H22ClN7Na4O19S6, UV/Vis spectra in water: 480 nm, IR (KBr cm−1): 1573.92 (N=N Stretching), 1051.34 (–S=O Stretching), 1139.08 (–SO3 Stretching), 1433.07 (C=C Stretching), 996.17 (–C–Cl Stretching), ESI–MS: m/z = 249.83 [M-4Na] were detected.

Screen printing

Printing paste preparation

Printing paste was prepared using auxiliaries including 8% urea and 6% NaHCO3 (alkali) and 4% sodium alginate as thickening agent for the application of each dye on the cotton fabric. Each dye Stock solution (3% w/w) was employed in the printing paste preparations23.

Printing technique

Screen printing technique using Flat Bed Screen Printing Machine Tsujii Printing Machine Mfg. Co. Ltd. Osaka/Japan (SP-300AR) was carried out for the application of printing paste on cotton fabric at the viscosity of 2300 cps using a laboratory-scale printing machine. Steaming of printed samples using Mathis laboratory steamer CH-8155 (Wenner Mathis Co., Switzerland) was carried out for 15 min at 105 °C. After printing unfixed dye and thickener were detached from the printed cotton sample by rinsing through cold then hot water until the bleeding stopped; perlavin PAM (2 g/L) was used 15 min for soaping at the boil and finally dry in the open air. Fastness properties were determined employing different fastness testing and spectraflash spectrophotometer Color Eye, Gretagmacbeth (7000 A) was used to evaluate the colorimetric data of the printed fabric24.

Evaluation of fixation, penetration and colorimetric data of printed samples

K/S values of the printed cotton samples were determined before and after washing treatments which reflects the fixation percentage of dye covalently attached to the fabric. Spectraflash spectrometer was used for the determination of the color strength of printed samples at their particular λmax. Calculations of fixation ratio were carried out using Eq. (1) 25.

where (K/S)1 and (K/S)2 denotes the color strengths of the printed cotton samples before and after washing, respectively.

The penetration percent (P %) was calculated according to Eq. (2).

where (K/S)b and (K/S)f represent the non-printed back face and printed front face values of K/S of fabric, respectively. If penetration percentage higher than it shows the greater penetration of the dye into the fabric26.

Printed samples were subjected to LCH and CIELAB system for the evaluation of colorimetric data L*, a*, b*, C* and h* representing lightness/darkness, redder/greener, redder/greener, chroma, and hue, respectively for one color determination27. Spectraflash spectrophotometer 7000 A (Color Eye, Gretagmacbeth) was used for the determination of color parameters in National Textile University Faisalabad. The colorimetric data of the printed fabric is given in Table 1.

UPF and fastness properties of the printed fabric

Ultraviolet protection factor (UPF) and fastness properties of the printed samples were evaluated using AATCC TM 183 and different ISO test methods respectively. ISO-105 CO3 test method was used for assessing the washing fastness, ISO 105-X12 test method for Crock fastness, ISO 105-B02 for light fastness, ISO-E04 for perspiration fastness, and ISO 105-E03 test method for evaluating the fastness to chlorinated water of printed samples.

Results and discussion

Effect of temperature on printing properties of reactive dyes

Reactive dyes first adsorbed on the fabric surface through an ionic bond. Once assembled, the ionic bond was then converted to a covalent bond at required optimum temperatures28,29. The optimum temperature for steaming of printed cotton samples was 105 °C at which maximum penetration, fixation, and color yield was obtained30 as shown in Fig. 1. Rate of dye fixation decreased at high temperature because activation energy for dye-fiber interaction is 9.2–15.8 kcal while for dye-water interaction is 16.4–26.2 kcal28. So, at higher temperature than optimum the dye-water reaction rate increased which is responsible for dye hydrolysis and in turn poor washing fastness. Dye hydrolysis also increases the loss of dye in the effluent which caused potential pollution problems. At low temperature dye molecules mobility could be low which required more printing time. Klančnik32 also studied the effect of temperature on the dyeing behaviour of the reactive dyes31,32.

Urea influence on the fixation and color yield of reactive dyes

The key function of the urea in the printing paste is to facilitate the dye-fiber interaction by reducing the dye aggregation and increasing its solubility in the reaction medium32. It also retards the evaporation of water during drying and swelling of cellulosic fabric in the printing process33,34. All heterofunctional reactive dyes used during the printing technique were water-soluble, vinylsulphone based, and have sulfonate groups which increased their solubility in printing paste29,35. So, color yield and fixation % of the printing samples were not affected greatly by the urea concentration. The effect of urea on the K/S and fixation values of dyes (D-1 to D-6) is shown in Fig. 2. These results demonstrated that urea free dyeing is possible for vinylsulphone based dyes having sulfonate groups in their structures26,36,37. Urea poses many environmental and ecological issues due to high nitrogen contents in the printing effluent.

Alkali influence on the fixation and color yield of reactive dyes

Alkali was very important for screen printing of dyes because sulphatoethylsulphone reactive groups were converted into their active vinylsulphone form through addition reaction which was possible in the presence of alkali and at appropriate pH. Alkali was also necessary for the activation of the cotton material so that fabric pores are in exact orientation in the printing medium for covalent bonding with the dye molecules38,39. The effect of alkali on the color yield and % fixation of the printed cotton samples is shown in Fig. 3. It was clear from data that printing properties (K/S and fixation, penetration) were increased with the alkali concentration up to a specific limit. Beyond this limit, printing properties started decreasing because the rate of dye hydrolysis might be increased in the printing medium40,41.

Colorimetric data

Colorimetric properties of the printed cotton fabric with heterofunctional reactive dyes were obtained through spectraflash spectrophotometer and results are presented in Table 1. Different patterns of screen printing were employed on cotton fabric by six heterofunctional azo reactive dyes which are represented by Fig. 4. The h° (hue angle) values from the colorimetric data illustrated purple-red shades for all dyes and K/S values suggested high color strength on printed cotton fabric. All printed samples have brighter (higher C* values) and darker shades (low L* values) demonstrating that the printing technique was suitable for the synthesized heterofunctional reactive dyes. Trifunctional reactive dyes (D-3 to D-6) have low L* values and higher a* values representing darker shades and redder tones on printed fabric. Conversely, bifunctional reactive dyes (D-1 and D-2) have lighter (high L* value) shades and gave a bluer tone on the cotton fabric (higher − b* values). Colorimetric values from a* and b* represented the much redder and less yellowish tones of the printed samples. Data from K/S values revealed that the color yield of trifunctional reactive dyes was higher as compared to bifunctional reactive dyes.

UPF and color fastness of the printed cotton samples

UPF factor of the control (non-printed) fabric was 3.5. Results from Table 2 showed that the UPF factor of the printed fabrics was excellent to very good at 3% dye shade. UPF value increased as dye fixation and penetration increased on the cotton fabric and results showed that D-6 has highest UPF value having highest color yield35,42. This is related to its more planar and sterically less hindered trifunctional structure responsible for highest penetration and fixation of dye on the cotton fabric as reactive groups are present at the para positions in D-6. D-2 has lowest UPF value which may be attributed to its bifunctionality and meta position of the reactive groups.

Data outcomes from Table 2 showed good (4) washing fastness of printed cotton samples which may be credited to dye molecules fixation through covalent bond formation with the cotton samples43. Crock fastness was also good of the printed cotton samples. Bifunctional reactive dyes have moderate rubbing as compared to trifunctional reactive dyes. Hydrolyzed dye on the fiber surface was responsible for staining during rubbing fastness and results from Table 2 showed that contents of hydrolyzed dye was minimum because maximum dye molecules fixed on printed samples dye to strong covalent bonding. Good to excellent (4–5) light fastness was observed from results which may be attributed to the fact that H-acid azo dyes chromophores can undergo to azo-hydrazone tautomerism making H-acid azo dyes stable to photoreduction44. Presence of heterofunctional reactive groups (triazine and vinylsulphone) in newly synthesized azo dyes makes them stable to both alkaline and acidic conditions showing good perspiration fastness36. Fastness to chlorinated water showed moderate (3) results for bifunctional dyes while moderate to good (3–4) results were obtained for the trifunctional reactive dyes.

Reactive group chemistry and printing properties

There is an important role of functional group chemistry and dye structure in the proper dye fiber linkage. The heterofunctional reactive groups are responsible for greater affinity of dye molecule towards cellulosic fiber. Coplanar, linear, sterically less hindered structures having more functional groups are key factors in attaining good quality printing with excellent color yield. In this context, in present study printing properties were investigated by changing the number and positions of reactive groups during screen printing of cellulosic fabric45. Reactive dyes attached and fixed on the cotton fabric by forming a permanent covalent bond between the fiber hydroxyl and dye reactive groups46,47,48. As the reactive group's number increased, the extent of bonding increased which ultimately increased fixation and color yield. The increasing order of printing properties D6 ˃ D-5 ˃ D-4 ˃ D-3 ˃ D-2 ˃ D-1 showed that trifunctional reactive dyes revealed enhanced printing properties (penetration, fixation, UPF value and color yield) as compared to bifunctional reactive dyes (Table 3). Dye structures should be more planar and sterically less hindered so that effective dye fiber interaction takes place, which consequently increased the dye penetration and fixation in the cellulosic fabric pores3,46,49. As penetration and fixation increased, the color yield of printed fabric automatically increased50,51. D-6 having more planar and sterically less hindered structure (reactive groups present at para positions) had increased color yield, higher fixation, penetration and UPF value as compared to D-1, D-2, D-3, D-4, and D-5. The penetration and fixation of dyes increased into the cotton fabric by increasing the number of reactive groups because more reactive sites were available to fiber substrate for binding which leads to high color yield52,53,54. Therefore, trifunctional reactive dyes have high UPF value than bifunctional reactive dyes as UPF value depends on color strength27,43. Synthesized dyes were vinylsulphone based having sulfonate groups in their structures so they have a higher solubility in water and consequently in the printing paste which makes them more suitable for urea free printing26. Different patterns of screen-printed cotton fabrics by heterofunctional reactive dyes are shown in Fig. 4.

Conclusion

The current study showed that reactive group chemistry significantly influences the printing properties of cotton fabric. The optimum temperature for steaming of printed cotton samples was 105 °C which prominently affects the printing properties of reactive dyes. Six heterofunctional reactive dyes were sensitive to alkali but urea concentration had no noticeable effect on the fixation and K/S values. All dyes showed excellent to good fastness properties onto the printed cellulosic fabric which may be attributed to the permanent covalent bonding of reactive dyes. Trifunctional reactive dyes (D-3 to D-6) have enhanced printing properties as compared to bifunctional reactive dyes (D-1 and D-2). The penetration and fixation of dyes increased into the cotton fabric as the number of reactive groups and planarity increased and steric hindrance decreased in the dye structures which consequently increased the K/S value. UPF of the printed samples was excellent to very good. Vinylsulphone reactive dyes having sulfonate groups in their structure have high solubility in printing paste. Therefore, it is suggested that these six reactive dyes could be commercially practicable for urea free printing of cellulosic fabric.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article including supplementary data.

References

Qiao, X. et al. High viscosity hydroxypropyl methyl cellulose to improve inkjet printing for cotton/polyamide fabrics. Ind. Crops Prod. 191, 115907 (2023).

Liu, K. et al. Hydroxyethyl methyl cellulose controls the diffusion behavior of pico-liter scale ink droplets on silk to improve inkjet printing performance. Int. J. Biol. Macromol. (2022).

Siddiqua, U. H., Ali, S., Iqbal, M. & Hussain, T. Relationship between structure and dyeing properties of reactive dyes for cotton dyeing. J. Mol. Liq. 241, 839–844 (2017).

Qiao, X. et al. Different influences of hydroxypropyl methyl cellulose pretreatment on surface properties of cotton and polyamide in inkjet printing. Prog. Org. Coat. 165, 106746 (2022).

Hamdy, D., Othman, H. & Hassabo, A. G. A recent uses of plasma in the textile printing. J. Text. Color. Polym. Sci. 19, 1–10 (2022).

Chouhan, S. & Butola, B. Functional Materials from Carbon, Inorganic, and Organic Sources 187–243 (Elsevier, 2023).

Firmanda, A. et al. 3D printed cellulose based product applications. Mater. Chem. Front. 6, 254–279 (2022).

Siddiqua, U. H. et al. Application of multifunctional reactive dyes on the cotton fabric and conditions optimization by response surface methodology. J. Nat. Fibers 19, 1094–1106 (2022).

Eko, I. J., Ademola, B. K., Obinna, N. P. & Kogo, A. Synthesis and structural-reactivity studies of bifunctional MCT/SES (monochlorotriazine/sulphatoethylsulphone) azo reactive disperse dyes applied to wool and polyester fabric. Chem. Sci. Int. J. 26, 1–10 (2019).

Hebeish, A., Ragheb, A., Nassar, S., Allam, E. & El Thalouth, J. A. Technological evaluation of reactive cyclodextrin in cotton printing with reactive and natural dyes. J. Appl. Polym. Sci. 102, 338–347 (2006).

Hunger, K. Industrial Dyes: Chemistry, Properties, Applications. (Wiley, 2007).

Khan, L., Kim, J. S., Huh, S.-H. & Koo, B. H. N-containing hybrid composites coatings for enhanced fire-retardant properties of cotton fabric using one-pot sol-gel process. Polymers 15, 258 (2023).

Siddiqua, U. H. et al. Hetero-functional azo reactive dyes applied on cellulosic fabric and dyeing conditions optimization to enhance the dyeing properties. J. Eng. Fibers Fabr. 16, 1558925021996710 (2021).

Siddiqua, U. H. et al. Computational and experimental study of heterofunctional azo reactive dyes synthesized for cellulosic fabric. J. Mol. Struct. 1221, 128753 (2020).

Siddiquaa, U. H. et al. Decolorization and mineralization efficiency of the hetero-functional reactive dyes using advanced oxidation processes. Desalin. Water Treat. 227, 350–359 (2021).

Biswas, T. T., Yu, J. & Nierstrasz, V. A. Piezoelectric inkjet printing of tyrosinase (polyphenol oxidase) enzyme on atmospheric plasma treated polyamide fabric. Sci. Rep. 12, 1–12 (2022).

Zhang, P. et al. Toward improved performance of reactive dyeing on cotton fabric using process sensitivity analysis. Int. J. Cloth. Sci. Technol. (2022).

Zhai, S. et al. Cationic cotton modified by 3-chloro-2-hydroxypropyl trimethyl ammonium chloride for salt-free dyeing with high levelling performance. Cellulose 29, 633–646 (2022).

Saad, F., Hassabo, A., Othman, H., Mosaad, M. M. & Mohamed, A. L. A valuable observation on thickeners for valuable utilisation in the printing of different textile fabrics. Egypt. J. Chem. 65, 1–2 (2022).

Diab, M. A. & El-Sakhawy, M. Three-dimensional (3D) printing based on cellulosic material: A review. Cell. Chem. Technol. 56, 147–158 (2022).

El-Sayed, E., Othman, H. & Hassabo, A. G. A short observation on the printing cotton fabric using some technique. J. Text. Color. Polym. Sci. 19, 17–24 (2022).

Kumar, A., Sharma, M. & Vaish, R. Screen printed calcium fluoride nanoparticles embedded antibacterial cotton fabric. Mater. Chem. Phys. 288, 126449 (2022).

Turk, S. Š & Schneider, R. Printing properties of a high substituted guar gum and its mixture with alginate. Dyes Pigm. 47, 269–275 (2000).

Kumbasar, E. P. A. & Bide, M. Reactive dye printing with mixed thickeners on viscose. Dyes Pigm. 47, 189–199 (2000).

Siddiqua, U. H., Ali, S., Hussain, T., Bhatti, H. N. & Asghar, M. The dyeing process and the environment: Enhanced dye fixation on cellulosic fabric using newly synthesized reactive dye. Pol. J. Environ. Stud. 26, 2215–2222 (2017).

Xie, K., Gao, A., Li, M. & Wang, X. Printing properties of the red reactive dyes with different number sulfonate groups on cotton fabric. Carbohyd. Polym. 101, 666–670 (2014).

Yang, Y. & Naarani, V. Improvement of the lightfastness of reactive inkjet printed cotton. Dyes Pigm. 74, 154–160 (2007).

Bristi, U. The effect of temperature variation on dyeing tie-dye cotton fabrics dyed with reactive dye. J. Text. Sci. Technol. 4, 117 (2018).

Abraham, L. A green nucleophilic aromatic substitution reaction. J. Chem. Educ. 97, 3810–3815 (2020).

Zhao, C. et al. Synthesis and properties of novel reactive dyes comprising acyl fluoride group on cotton fabrics. Molecules 27, 4147 (2022).

Bamfield, P. Chromic Phenomena: Technological Applications of Colour Chemistry. (Royal Society of Chemistry, 2010).

Klančnik, M. The influence of temperature on the kinetics of concurrent hydrolysis and methanolysis reactions of a monochlorotriazine reactive dye. Dyes Pigm. 46, 9–15 (2000).

Boroujeni, F. M. & Sharzehee, M. Synthetic oligomers with urea binding and their role as crosslinkers in improving the printing quality on cotton fabric. Fibers Polym. 1–13 (2023).

Akter, N., Akter, N., Pervin, M. & Repon, M. R. The influence of mixed thickeners on printing over lyocell knitted fabric. Heliyon (2023).

Patel, M. J., Tandel, R., Sonera, S. A. & Bairwa, S. K. Trends in the synthesis and application of some reactive dyes: A review. Braz. J. Sci. 2, 14–29 (2023).

Tang, Q., Chen, Q., Zhou, M. & Yang, D. Preparation of nano disperse dyes using sulfomethylated lignin: Effects of sulfonic group contents. Int. J. Biol. Macromol. 234, 123605 (2023).

Zhang, S., Fang, K., Liu, X., Qiao, X. & Wang, J. Simplified and efficient inkjet printing of cotton fabrics using cationic colored nanoparticles. Ind. Crops Prod. 193, 116217 (2023).

Pei, L. et al. Salt-free and alkali-free fixing method of wool fabric dyeing in non-aqueous media dyeing system. Fibers Polym. 1–11 (2023).

Nachiyar, C. V., Rakshi, A., Sandhya, S., Jebasta, N. B. D. & Nellore, J. Developments in treatment technologies of dye-containing effluent: A review. Case Stud. Chem. Environ. Eng. 100339 (2023).

Gorenšek, M. Dye–fibre bond stabilities of some reactive dyes on cotton. Dyes Pigm. 40, 225–233 (1999).

Hoveizavi, N. B. & Feiz, M. Synthesis of novel dyes containing a dichlorotriazine group and their applications on nylon 6 and wool. Dyes Pigm. 111086 (2023).

Sahar, A. & Ali, S. Treatment of cotton fiber with newly synthesized UV absorbers: Optimization and protection efficiency. Fibers Polym. 19, 2290–2297 (2018).

Christie, R. Colour Chemistry. (Royal society of chemistry, 2014).

Griffiths, J. II. Photochemistry of azobenzene and its derivatives. Chem. Soc. Rev. 1, 481–493 (1972).

Enawgaw, H. A compressive review on different surface finishing of cotton fabrics. Res. J. Text. Apparel (2023).

Klöckl, I. Handbook of Colorants Chemistry: In Painting, Art and Inks. (Walter de Gruyter GmbH & Co KG, 2023).

Islam, T., Repon, M. R., Islam, T., Sarwar, Z. & Rahman, M. M. Impact of textile dyes on health and ecosystem: A review of structure, causes, and potential solutions. Environ. Sci. Pollut. Res. 30, 9207–9242 (2023).

Gita, S., Hussan, A. & Choudhury, T. Impact of textile dyes waste on aquatic environments and its treatment. Environ. Ecol. 35, 2349–2353 (2017).

Zhao, W. et al. Sustainable green conversion of coal gangue waste into cost-effective porous multimetallic silicate adsorbent enables superefficient removal of Cd (II) and dye. Chemosphere. 138287 (2023).

Bae, S.-H., Motomura, H. & Morita, Z. Diffusion/adsorption behaviour of reactive dyes in cellulose. Dyes Pigm. 34, 321–340 (1997).

Yang, L. et al. Mono-/multiadsorption of chlorobenzene compounds on biochar: Influence of the properties of the chlorobenzene molecules and biochar. J. Soils Sediments. 1–16 (2023).

Hassaan, M. A., El Nemr, A. & Hassaan, A. Health and environmental impacts of dyes: Mini review. Am. J. Environ. Sci. Eng. 1, 64–67 (2017).

Zhai, X. et al. Investigation on dyeing mechanism of modified cotton fiber. RSC Adv. 12, 31596–31607 (2022).

Fang, J. et al. Eco-dyeing and functional finishing of cotton fabric by natural dye derived from lotus seedpod waste with chitosan-assistance. Fibers Polym. 1–11 (2023).

Acknowledgements

Authors acknowledge the Researchers Supporting Project number (RSP2023R393), King Saud University, Riyadh, Saudi Arabia for financial assistance of the current research work and University of Agricultural Faisalabad, Pakistan for providing Research facilities.

Author information

Authors and Affiliations

Contributions

U.H.S. carried out the whole research work and arranged the data. S.A. contributed in analysis of data. A.T. contributed in data analysis. M.K.G. contributed in data analysis. L.R. contributed in data analysis. M.W.Y. contributed in data analysis. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Siddiqua, U.H., Ali, S., Tufail, A. et al. Relationship between reactive group chemistry and printing properties of heterofunctional reactive dyes via screen printing. Sci Rep 13, 7259 (2023). https://doi.org/10.1038/s41598-023-33819-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-023-33819-3

This article is cited by

-

Constructing polyfunctional reactive dyes for printing of cotton fabrics with ultra-high fixation and ultra-low staining on the white ground

Cellulose (2025)

-

Regulation of symmetric polyfunctional reactive red dyes for ultra-high fixation on cellulose fibers in various dyeing and printing techniques

Cellulose (2025)

-

Effect of Silver Nanoparticles Finishing on Dyeing Properties of Newly Synthesized Reactive Dye Applied on Cellulosic Fabric

Fibers and Polymers (2024)