Abstract

Construction and global infrastructure depend on cement production. It is one of the biggest carbon emitters, making it an aspect of environmental sustainability and climate change mitigation. Each stage of cement production releases CO2 and other greenhouse gasses. About 8% of worldwide CO2 emissions come from the cement sector, making it a major contributor. Different supplementary cementitious materials (SCMs) like fly ash (FA), silica fume (SF), and slag are used to partially replace traditional raw materials like limestone, reducing the environmental impact. This study investigated the use of supplementary cementitious materials, specifically FA and alccofine (AF), as partial replacements for cement in concrete to reduce environmental impact. The study first identified an optimal replacement percentage for FA (20%, 30%, and 40%) by weight of cement. Subsequently, using the optimal FA percentage, AF was added at varying percentages (5%, 10%, and 15%) by weight of cement. The study evaluated the mechanical properties of the concrete mixtures, including workability, compressive strength, split tensile strength, and flexural strength. Durability, measured by water sorptivity and rapid chloride penetrability tests, was also assessed. The microstructural properties of the concrete were analyzed to understand their influence on performance. As a result of the significant environmental implications of producing and using concrete for all activities, an in-depth life cycle assessment (LCA) was conducted. Additionally, artificial neural networks were employed to predict the compressive strength of the concrete. The study concluded that incorporating FA and AF in concrete mixtures is a promising approach to producing more environmentally friendly concrete.

Similar content being viewed by others

Introduction

The construction industry plays a significant role in environmental degradation, contributing to global warming and climate change1,2. The construction activity rate is steadily rising to accommodate the expanding population and improve living standards3,4,5. Consequently, there are inherent environmental expenses associated with this outcome. The construction industry is responsible for significant carbon emissions and holds the third position regarding contributors to carbon emissions. Cement is identified as the construction industry's primary source of carbon emissions. On an international scale, numerous researchers are currently striving to replace cement with alternative materials for the purpose of reducing CO2 emissions6,7,8. According to9,10, for the production of 1 tonne of ordinary Portland cement (OPC) about 1 tonne of CO2 is released into the atmosphere. This emission directly leads to global warming, degradation of the ozone layer, climate change, and other significant environmental issues. Recently, there has been a growing inclination toward utilizing industrial by-products as a partial substitute for cement, as examined11,12,13. Extensive studies have been conducted on the utilization of various forms of industrial waste, such as pozzolanic or binder materials, in the production of concrete. The evaluation considered factors such as strength and resistance to corrosion when exposed to seawater or acid rain, the ability to prevent the passage of substances via underground structures, and the ability to withstand heavy loads—among other factors14,15,16.

On the other hand, FA is a secondary product produced in power plants. FA exhibits pozzolanic properties and reacts chemically with water to form a cementitious material, and some researchers refer to it as a supplementary cementitious material. The use of FA material as a partial replacement for cement can increase the strength of concrete as well as reduce segregation17,18. It offers cost savings, eco-friendliness, and reduces carbon footprint19,20,21. When compared with OPC, the total embodied energy is lower. The usefulness of cement pastes is critical to the efficiency of the cementitious composites. Significant improvements can be achieved by controlling the formation of the hydration products. AF, on the other hand, is a relatively recent supplementary cementitious material that is created by finely grinding high-reactivity metakaolin. The presence of AF improves compressive strength, particularly in the early stages, as well as durability in challenging conditions. Additionally, in certain situations, it can also enhance the flexural strength. It is frequently employed in conjunction with other additives to achieve the desired characteristics of the concrete22,23,24. Additional research has demonstrated that the inclusion of FA and AF in concrete can provide several benefits, including enhanced compressive strength, reduced permeability, increased resistance to corrosion, and improved durability21,25,26.

Recently, there has been a notable increase in the use of alternative materials in construction. This is due to a growing global awareness of the importance of environmental sustainability and the need to reduce carbon footprints27,28,29. An area that has received significant scientific attention is the utilization of FA and AF as partial substitutes for cement in concrete. FA and AF are secondary products of industrial processes and mostly consist of pozzolanic materials that are well-suited for the manufacturing of concrete. FA is a finely ground substance that is generated by the combustion of coal in power plants. However, AF is a highly refined substance derived from the iron ore sector. There is an increasing interest in utilizing alternative materials such as FA and AF in the manufacturing of concrete. These attributes are attributed to their pozzolanic nature and their ability to enhance the fresh, mechanical, and durability characteristics of concrete30,31,32,33,34. Based on the literature, certain industrial by-products, including FA and AF, have demonstrated substantial enhancement when utilized entirely or partially as substitutes for cement in concrete construction. Researchers have noted that FA can effectively alter the different structures in concrete when utilized as a substance that partially replaces cement. AF, derived from the iron industry, has been discovered to possess pozzolanic properties and can be used as a whole or partial substitute for cement in concrete35,36. Multiple empirical investigations have been carried out to comprehend the impact of partial substitutions of FA and AF on concrete with regard to its new characteristics, mechanical strength, and durability. Martina, et al.37 examined the enhancement of concrete strength by substituting conventional fine aggregates with foundry slag and cement with AF. The study demonstrated that including AF as a partial substitute for cement improved the compressive strength and durability characteristics of the concrete. A separate study examined the use of FA as a substitute for a portion of the cement in concrete. The study demonstrated that the addition of FA enhanced the ease of working with the concrete and decreased the heat generated during hydration38,39. Furthermore, the study indicated that including FA as a substitute for a portion of the cement in concrete led to enhanced compressive strength and heightened resistance to sulphate attack. In addition, raising the proportion of AF substitution beyond 10% enhanced the workability of concrete.

The study conducted by Jain et al.40 supports the assertion that using FA and AF as substitutes for cement in concrete can enhance the efficiency and sustainability of concrete constructions. It is crucial to note that the appropriate replacement amounts of FA and AF depend on several parameters, including the application and desired qualities of the concrete. Furthermore, researchers must take into account the potential ramifications of utilizing FA and AF on the ecosystem. The examination uncovered that utilizing FA and AF as partial substitutes for cement in concrete enhances the short-term compressive strength, durability, and environmental sustainability of the concrete. Nevertheless, it is important to carry out tests and research in order to ascertain the most favourable FA and AF ratio for various concrete applications. For instance41,42 discovered that substituting 15% of cement with AF enhanced the strength of M30-grade concrete by contributing to its overall strength. By contrast, Siddharth et al. discovered that the inclusion of FA and AF in a self-compacting reinforced concrete beam led to an enhancement in both bearing capacity and strength. Furthermore, it is important to take into account the potential effects of FA and AF on the environment, as highlighted by Naqash and Reddy43. Additional research is required to examine the lasting effects of FA and AF when they are partially substituted, rather than trying to establish the specific degrees of substitution that could result in the indicated ideal ratio44,45,46,47,48.

The utilization of FA and AF as partial substitutes for cement in concrete has been observed to yield a beneficial effect on the strength and longevity of concrete buildings. According to the study conducted by49, the utilization of FA and AF (alkali-activated FA) as partial substitutes for cement results in enhancements in compressive strength, splitting tensile strength, and toughness. Naqash and Reddy43 observed enhanced compressive, splitting tensile, and flexural strengths when using FA and AF as partial substitutes in cement. As an illustration49 observed that when 40% of the material was replaced, the compressive, splitting tensile, and flexural strength were measured at 42.3 MPa, 7.9 MPa, and 8.3 MPa, respectively. Siddharth further stated that using high-performance concrete for the placement of PF and FA improved the load-bearing capacity and strength of the reinforced self-compacting concrete beam with a grade of M60. The results indicate that FA and AF are ideal for partially replacing cement in concrete due to their favourable mechanical qualities and performance.

In addition to proposing an improved mixture, LCA is frequently used as the basis for the criteria used to assess sustainability. LCA is a widely used tool in environmental management that assesses the environmental consequences and burdens of commodities and services. It accomplishes this by scrutinizing the energy and material usage, as well as the release of waste into the ecosystem, across the whole lifespan of a product. Although the primary emphasis of this strategy is on the environment, it may not comprehensively tackle the social and economic issues. However, its life cycle methodology and approach can be adaptably utilized in different domains50,51,52. The LCA methodology is used to evaluate the global warming potential (GWP) of a combination. The LCA analysis in this study was conducted using the framework outlined in the ISO 1404053,54,55 and ISO 1404453,54,56 standards. The guidelines provided by50,54 delineate the four primary elements of the iterative framework used to carry out an LCA study. The components encompass objective and scope formulation, life cycle inventory (LCI) analysis, life cycle impact assessment computation, and outcome interpretation. Introducing FA and AF into concrete mixtures can greatly enhance the strength and longevity of concrete structures. These additional cementitious materials provide sustainable and pragmatic answers to contemporary construction difficulties while minimizing the environmental impact.

Simultaneously with the proposal to deploy an enhanced blend, LCA is commonly utilized as the basis for evaluating sustainability criteria. LCA is a widely used environmental management tool that assesses the impacts and burdens associated with products and services. This is accomplished by checking product energy and material usage and the waste discharged into the environment over a product’s whole life cycle. Although the primary focus of this scheme is on the environment, it may be incomplete without fully covering social and economic aspects. The life cycle procedure and approach, on the other hand, may be used in a variety of domains since its methodology offers policy flexibility. LCA determines the global warming potential (GWP) of a blend. The LCA examines the mixture according to the methodology described by the ISO 14040 and ISO 14044 standard frameworks. The main elements of the iterative framework of an LCA study are reported in50,56,57,58. The first item on the list is the goal and scope definition, and then the life cycle inventory is analyzed, and a life cycle impact is calculated, followed by the obtained result being interpreted. Both the strength and longevity of concrete construction may be significantly improved by incorporating FA and AF. Similarly, efficient, sustainable, and cost-effective techniques to address contemporary building concerns with contributions are established to decrease the carbon impact.

This study distinguishes itself from previous research by systematically investigating the synergistic effects of fly ash and alccofine as supplementary cementitious materials in concrete. While prior studies may have explored these materials in isolation or limited combinations, this research focuses on determining the optimal percentage of FA replacement, followed by incorporating AF at various percentages. This approach enables the identification of a specific combination that maximizes both mechanical and durability performance. Furthermore, this study extends beyond conventional assessments of mechanical and durability properties by delving into the microstructural characteristics of the modified concrete. This analysis provides valuable insights into the underlying mechanisms responsible for the observed improvements, contributing to a deeper understanding of FA and AF's influence on concrete behavior.

Recognizing the limitations of traditional experimental testing, this research employs artificial neural networks to predict the compressive strength of concrete containing FA and AF. This approach offers a promising avenue for optimizing mix designs while reducing reliance on time-consuming and costly experimental procedures. Moreover, while previous studies may have acknowledged the environmental benefits of supplementary cementitious materials, this study explicitly emphasizes the sustainability aspect of utilizing FA and AF to mitigate the carbon footprint associated with cement production. By integrating these elements, this study presents a comprehensive analysis of FA and AF incorporation in concrete, offering valuable insights for developing sustainable, high-performance concrete solutions.

Materials

Cement

Grade 53 ordinary Portland cement used in this study conforms to the IS: 12269-2013 specifications. It came from only one source (Ultra-tech, Gudivada) as shown in Fig. 1. The specific gravity of the cement was 3.12, and it had a specific surface area of 225 m2/g. The initial and final setting times were 40 and 480 min, respectively. The chemical composition of cement was tabulated in Table 1.

Fine aggregate

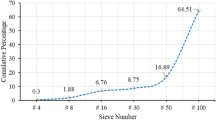

The fine aggregate used had a size range of 0.075–4.75 mm, and sourced from a nearby river, Gudivada as shown in Fig. 2. The physical properties of fine aggregate were tabulated in Table 2.

Coarse aggregate

The coarse granite aggregate was obtained crushed rock from Gudivada as shown in Fig. 3. It had a size distribution ranging from 12.5 to 20 mm, which was free of elongated and flaky particles and is confirmed to IS 383–2002. The physical properties of fine aggregate were tabulated in Table 3.

Fly ash

For this study, FA belonging to the F class category was obtained from VTPS located in Vijayawada as shown in Fig. 4 with a specific gravity of 2.34 and a fineness of 320 m2/kg. The chemical constituent of Class F FA was tabulated in Table 4.

Alcoffine

The AF material used in the investigation as shown in Fig. 5 exhibited a specific gravity of 2.86 and a bulk density of 682 kg/m3. The chemical constituent of AF was tabulated in Table 5.

Mix proportions

M30 grade concrete was designed as per IS 10262:2009. The proportion of the mixes is given in Table 6.

Experimental methodology

Mixing

Concrete mixing adhered to IS 179–1985 standards, utilizing a mechanical drum mixer (Fig. 6). The mixing sequence involved introducing dry materials first, followed by a portion of the required water. Subsequently, evaluated aggregates and cement were added, and finally, the remaining water was incorporated. This sequence ensured homogenous mixing, achieved by operating the drum mixer for a minimum of one minute.

Casting

Concrete placement was executed in a controlled manner, ensuring continuous pouring within each layer to prevent segregation. Careful attention was given to maintain a homogenous mixture, preventing cement slurry drainage and ensuring uniform aggregate distribution. Following placement, the concrete was promptly compacted using a tamping rod, employing gentle pressure to avoid air entrapment. Specimens were then cast in appropriately labeled moulds and allowed to harden undisturbed for 24 h (Fig. 7). Upon reaching sufficient strength, specimens were carefully demoulded and subjected to a designated curing regimen.

Curing

Curing plays a critical role in concrete strength development. To optimize hydration and enhance strength gain, specimens were submerged in a controlled curing tank, ensuring an environment free from deleterious substances such as salinity, debris, vegetation, and chemicals (Fig. 8). This study investigated concrete performance at designated curing durations of 7 and 28 days.

Workability

The workability of the mixtures was determined using the slump test shown in Fig. 9, which is a test that measures the consistency of fresh concrete. Slump tests were conducted in accordance with IS:1159-1959, as follows: a cone-shaped mould measuring 200 mm at the bottom diameter, 100 at the top diameter, and 300 mm in height was filled with fresh concrete in three layers, each tamped five times. The top of the concrete was smoothened, and the mould was then removed with the concrete settling down. The vertical displacement measures the slump and indicates the workability of the concrete. The difference in the level of the mould and the highest point of the concrete mass measures the slump value of the concrete.

Compressive strength

The IS 516–1959 recommends casting a cube of 150 × 150 × 150 mm for testing the compressive strength of concrete as shown in Fig. 10. Next, the cube should be placed in such a way that the load is transmitted directly from the area of application to the opposite face uniformly. Subsequently, without allowing any slack space or disturbing the specimen, an axial load is to be applied. Finally, the maximum load in which the cube fails is noted. It will be used to calculate its strength in compression.

Split tensile strength

According to ASTM C496, a test of applying the radial force on a cylindrical specimen of 150 mm diameter and 300 mm height, at which a vertical crack is formed along the diameter of the body as shown in Fig. 11. The split tensile strength measurement allows an indirect assessment of the tensile strength of concrete.

Flexural strength

The flexural strength of concrete was tested on prisms of dimensions 100 × 100 × 50 mm as shown in Fig. 12. These prisms were placed in the testing machine in a perfect manner while the load was placed on the topmost surface of the mould, focusing on two contact points of 133 mm distance. Finally, the maximum load the specimen could bear was measured in accordance with IS 516.

Water sorptivity

For the ASTM C1585 test on the water sorptivity of concrete through capillary action as shown in Fig. 13, the specimens are dried in a forced ventilation oven at 105 °C until a constant weight is obtained. The wax coating was applied to specimens of concrete on three sides, and one was kept open for absorption. The tray’s bottom had support rods to ensure the specimen’s level after the tray was full of water 1–3 mm above it. The sorptivity coefficient (S) calculation utilizes least-squares linear regression analysis based on cumulative water absorption per unit cross-sectional area (i) plotted against the square root of time √t.

Rate of chloride penetrability

The ASTM 1202 determines the chloride penetrability rate. The test requires 100-mm diameter, 50-mm thickness cylindrical specimens to be cast. Specimens are placed in cells and preserved for 6 h in 60 V; a single compartment has to be charged with 3 percent NaCl and the other one with 0.3 mol/L NaOH. The electrical current of the concrete cylinder is monitored so that the total charge passed is indicated in coulombs, proving the concrete to chloride ion penetration as shown in Fig. 14. This provides significant and comprehensive information on the durability of concrete concerning the chloride-ion response as it gets scoured for a period.

Results and discussion

Workability

Workability, a crucial aspect of concrete performance, is influenced by various factors, including mix proportions. This study investigated the workability of concrete mixes incorporating ordinary Portland cement, fly ash, and alccofine in varying proportions, utilizing slump tests as the primary evaluation method. As illustrated in Fig. 15, the addition of FA to OPC resulted in increased slump values, indicating enhanced workability. This observation aligns with previous research highlighting FA's pozzolanic properties, which contribute to improved particle lubrication and flowability59,60. Conversely, incorporating AF into FA and OPC mixes led to a decrease in slump values with increasing AF percentages. This trend suggests that higher AF proportions tend to reduce workability, potentially due to the fine particle size and increased reactivity of AF, necessitating higher water demand and consequently diminishing mix fluidity.

However, it is important to note that despite the observed slump reduction with increasing AF content, all FA and AF blends exhibited superior workability compared to the control mix containing solely OPC. This finding underscores the beneficial influence of FA and AF on workability, even at higher replacement levels.

Compressive strength

The compressive strength results of the concrete mixes tested in this research study demonstrate that the addition of FA and AF additives has a substantial impact on the mechanical properties of the concrete. Figure 16 shows the compressive strength data collected at 7 and 28 days for the various mixtures.

To begin, adding FA up to a particular proportion increases compressive strength when compared to OPC alone. Specifically, mixes containing 20% and 30% FA have better compressive strength than OPC. This discovery is consistent with the pozzolanic character of FA, which helps to increase cementitious qualities and strength development in concrete. However, when the FA concentration was increased to 40%, compressive strength decreased slightly. The decrease in the strength of the concrete may be attributed to factors such as the dilution impact of FA at higher concentrations. In addition, the inclusion of AF in the FA mixes led to a substantial enhancement in compressive strength when compared to both OPC and binary FA mixes. The highest value was seen in the mixture containing 30% FA and 15% AF.

The inclusion of AF results in an increase in compressive strength, which can be attributed to various factors. AF, an extremely reactive supplementary cementitious material, generates additional cementitious compounds and increases the density of the concrete matrix61,62. Moreover, AF can promote the pozzolanic response of FA, hence amplifying its advantageous impact on the development of strength.

Flexural strength

The flexural strength outcomes were clearly observed while using FA and AF additives, which have a substantial influence on the flexural performance of the concrete. The flexural strength values obtained at 7 and 28 days for the different mixtures are displayed in Fig. 17. Initially, in line with the findings regarding compressive strength, the addition of FA up to a specific proportion enhanced the flexural strength when compared to using only OPC. More precisely, the mixtures containing 20% and 30% FA demonstrated superior flexural strength compared to OPC, whereas the mixture with 40% FA exhibited a decrease in flexural strength. This trend aligns with the pozzolanic capabilities of FA, which enhance the cohesion and binding strength within the concrete matrix, leading to improved flexural performance. Moreover, the inclusion of AF in the FA blends resulted in a substantial enhancement in flexural strength, surpassing that of OPC and binary FA blends. The flexural strength increased in direct proportion to the amount of AF in the blends, reaching its greatest value in the combination consisting of 30% FA and 15% AF.

The observed enhancement in flexural strength resulting from the incorporation of AF can be ascribed to multiple factors. AF serves as an additive in cement, allowing for the creation of novel cement compounds and enhancing the compactness of the concrete microstructure. This leads to enhanced adhesion between the aggregates and the matrix, as well as enhanced resilience against bending forces, hence enhancing flexural performance63,64.

Split tensile strength

The split tensile strength results of the concrete mixes indicate that the inclusion of FA and AF additives significantly affects the tensile performance of the concrete. The split tensile strength data collected at 7 and 28 days for the different mixtures is presented in Fig. 18.

Based on the results of compressive and flexural strength tests, incorporating a specified proportion of FA improves the split tensile strength compared to using only OPC. More precisely, the concrete mixes containing 20% and 30% FA exhibited superior split tensile strength compared to OPC, however the mix with 40% FA had a slight decrease. The observed pattern aligns with the pozzolanic properties of FA, which enhance the cohesiveness and binding strength within the concrete matrix, therefore enhancing its tensile performance. In addition, the inclusion of AF in FA mixtures resulted in a substantial enhancement in split tensile strength compared to mixtures containing only OPC or binary FA blends. As the proportion of AF in the blends increased, the split tensile strength also increased, reaching its greatest value for the combination of 30% FA and 15% AF.

The observed augmentation in split tensile strength following the addition of AF can be ascribed to a multitude of factors. AF serves as an additional cementitious ingredient, facilitating the creation of novel cement compounds and enhancing the compactness of the concrete microstructure65,66. This enhances the cohesion between the aggregates and the matrix, as well as the ability to withstand pulling forces, leading to improved split tensile performance.

Water sorptivity

The water sorptivity data obtained from Fig. 19 demonstrate that the use of FA and AF additives significantly affects the water absorption characteristics of concrete. As the amount of FA in concrete mixtures increases, the water sorptivity decreases in contrast to OPC concrete. This pattern indicates that the inclusion of FA in the concrete matrix enhances its resistance to water infiltration. The pozzolanic properties of FA contribute to the compaction of the concrete microstructure, reducing the presence of small pores and enhancing its resistance to the passage of fluids. Consequently, when the FA fractions are increased, the water sorptivity decreases, which suggests that there is improved durability and resistance to moisture infiltration.

When the AF concentration reaches its optimal FA levels, the water sorptivity decreases in comparison to both OPC and binary FA combinations. This data suggests that the addition of AF enhances the water resistance properties of concrete, even when used in conjunction with FA. AF, an extremely reactive supplementary cementitious material, promotes the creation of a more compact microstructure in concrete by reducing pore connectivity and capillary activity. Consequently, the concrete exhibits reduced water sorptivity, which signifies enhanced durability and resilience against moisture infiltration67,68,69.

Ultimately, mixtures including both FA and AF have a reduced sorptivity coefficient, which measures the rate at which concrete absorbs water, compared to mixtures containing either OPC or a combination of OPC and FA. The decrease in the sorptivity coefficient indicates that the addition of supplementary cementitious materials like FA and AF enhances the water resistance properties of the concrete. Lower sorptivity coefficients suggest reduced water absorption rates and increased resistance to moisture-induced deterioration, implying that concrete structures have the potential to be more long-lasting and durable.

Rate of chloride penetrability

The research findings from Fig. 20 show that as the concentration of FA in the concrete mixes increases, the rate of chloride penetration decreases significantly when compared to OPC concrete. This trend recommends using FA as an additional cementitious ingredient to increase concrete resistance to chloride ion invasion. FA's pozzolanic capabilities promote densification of the concrete microstructure, reducing matrix permeability and limiting chloride ion migration. As a result, concrete mixes containing larger percentages of FA had better durability performance against chloride penetration, showing the favourable effects of FA in reducing the danger of chloride-induced deterioration in concrete structures.

The study also reveals that as AF content increases, particularly at optimum FA levels, there is a considerable reduction in the rate of chloride penetrability. The mixes containing both FA and AF, especially those with 30% FA and 10% or 15% AF, exhibit notably low rates of chloride penetrability compared to OPC and binary FA mixes. This observation underscores the synergistic effect of AF and FA in enhancing the durability of concrete against chloride ingress. AF, as a highly reactive supplementary cementitious material, complements the pozzolanic action of FA, leading to further refinement of the concrete microstructure and increased resistance to chloride ion penetration70,71. The resulting denser and more impermeable matrix effectively shields the embedded reinforcement from corrosive chloride ions, thereby prolonging the service life of concrete structures exposed to chloride-rich environments.

Microstructural investigation

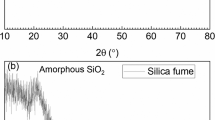

Usually, SEM is the most effective method for examining the microstructure of SCMs because it produces detailed images of electrically conductive specimens. Figures 21 and 22 depict the SEM micrographs of OPC and FA30AF10 mixes. Mix FA30AF10, with the maximum compressive strength, has a compact matrix morphology that corroborates its superior strength development pattern compared to OPC concrete. There is more silicate re-organization in the cement matrix, ultimately leading to a more significant formation of the C-S-H gel and a dense skeletal framework in the FA30AF10 mix. The presence of pozzolanic activity leads to an increase in the hydration reaction and refinement of the concrete microstructure, improving the concrete’s overall qualities. This is a result of the pozzolanic reaction between SCMs (FA and AF), which resulted in the consumption of calcium hydroxide (CH) and the generation of supplementary hydration products through the consumption of CH. The increase in strength of the FA30AF10mix was attributed to the development of extra C-S-H, which effectively filled the existing pores, resulting in a reduction in pore size.

Life cycle assessment

Figures 23 and 24 show the analysis of environmental load and normalized environmental scores reveal significant variations across different concrete mixes, particularly concerning parameters such as global warming potential, ozone formation potential, human health impacts, fine particulate matter formation, and terrestrial acidification and ecosystem impacts. Significantly, blends including 30% FA and 30% FA with 10% AF exhibit superior environmental efficacy compared to OPC concrete. These mixtures exhibit reduced environmental impacts and consistent environmental ratings across several categories of influence, indicating decreased environmental burdens across the manufacturing and utilization processes72.

The research findings emphasize the ecological advantages of including FA and AF additives in concrete mix compositions. The combination of 30% FA and 10% AF exhibits superior environmental performance compared to the mixes using OPC and 30% FA. This is seen in the reduced environmental burdens and normalized environmental scores. This implies that the collaborative integration of FA and AF aids in alleviating environmental issues linked to the production and utilization of concrete, specifically by reducing energy consumption, greenhouse gas emissions, and adverse impacts on human health and ecosystems.

The observed improvements in environmental performance highlight the necessity of incorporating additional cementitious components such as FA and AF in the production of concrete. By substituting a fraction of the cement with these materials, the ecological footprint of concrete can be significantly reduced while simultaneously enhancing several engineering characteristics and performance aspects. Utilizing FA and AF in the construction industry promotes resource conservation and waste reduction and enhances sustainability. This coincides with global efforts to encourage ecologically responsible practices and alleviate the repercussions of climate change.

ANN by MATLAB

Artificial neural networks (ANNs) consist of numerous interconnected processing elements known as neurons, which operate simultaneously to address challenges. ANN possesses the capability to identify non-linear functions based on the input. They can accurately approximate nonlinear systems to the highest degree. The system primarily comprises neurons that represent input and output variables, with hidden layers that are related through weights. The efficacy of an Artificial Neural Network (ANN) is contingent upon the algorithm employed, the quantity of neurons in the hidden layer, the rate at which it learns, and the nature of the implicit member function. ANNs offer a robust framework for the training and assessment of data, and MATLAB's Neural Network Toolbox is a valuable set of tools for this objective. This toolbox comprises a diverse array of functions and tools that streamline the process of constructing, training, and evaluating ANNs.

The success of the network relies on meticulously curated training and testing datasets. This involves the process of scaling or normalizing the input and output variables. Within the MATLAB software, data is partitioned into three distinct and separate datasets: training, validation, and test sets. The division of the data is done randomly. The tool function enables the partitioning of data into random subsets, with the flexibility to adjust the ratios for training, validation, and testing73,74,75.

In our study, 70% of the data was used for training, while the remaining 30% was divided equally between the validation and testing sets. Afterwards, the number of neurons in the hidden layer of fitting networks (Fig. 25) was determined using a prescribed method.

The network was then trained to establish correlations between inputs and corresponding outputs (targets). Evaluation metrics such as mean square error and R2 values were calculated for the training, validation, and testing datasets, with an optimal R2 range of 0.75 ≤ R2 < 1 for engineering problems.

Regression lines depicted in Fig. 26 showcased R2 values exceeding 0.90 across various subsets, indicating high precision in projected values and substantial associations between training and testing samples. Error histograms (Fig. 27) and validation performance (Fig. 28) further underscored the effectiveness of the ANN model in accurately forecasting concrete compressive strength.

ANN by response surface methodology

In this study, we employed Response Surface Methodology (RSM) to assess the effects of several factors on the compressive strength of concrete, such as cement, FA, AF, fine aggregate, and coarse aggregate as shown in Fig. 29. The correlation between the anticipated and real compressive strength values (Fig. 30) indicates a high level of agreement, suggesting that the model accurately depicts the relationship between the input parameters and the response.

The residual plot of the model, as shown in Fig. 31, had no discernible patterns, suggesting that the conditions for homoscedasticity and normality were satisfied. This confirms the efficacy of our model in accurately forecasting compressive strength across a diverse set of input variables. Moreover, the response plots provided useful insights into the precise impacts of each element on compressive strength.

Analysis of the response plots (Figs. 32, 33, 34, 35, 36) demonstrated the diverse levels of impact that cement, FA, AF, fine aggregate, and coarse aggregate exerted on the compressive strength of concrete. Significantly, augmenting the number of certain materials, such as FA and AF, led to a non-linear enhancement in compressive strength. This suggests the potential to enhance concrete mixtures by adjusting the composition of its components within specific limitations.

The precision of the model is crucial in the concrete industry, where the goal is to optimize combinations to achieve specific performance characteristics. Through the utilization of RSM, engineers, and practitioners can optimize the design of concrete formulations to fulfill desired strength criteria while simultaneously reducing material consumption and expenses. Furthermore, our findings contribute to the ongoing efforts to enhance the sustainability of concrete production by promoting supplementary materials like FA and AF.

Conclusions

This research provides compelling evidence for the beneficial influence of fly ash and alccofine additives on key properties of concrete.

-

FA enhanced workability as measured by slump, AF exhibited a reducing effect. However, all FA-AF blends demonstrated superior workability compared to concrete containing solely ordinary Portland cement, highlighting the complex interplay of factors influencing this property.

-

The incorporation of FA and AF significantly enhanced compressive, flexural, and split tensile strengths. FA additions up to a certain percentage increased strength, with further improvements observed upon incorporating AF. This synergistic effect underscores their combined contribution to enhanced cementitious reactions, matrix densification, and bond strength.

-

Furthermore, FA and AF additions significantly reduced water sorptivity and chloride ion penetration, indicating improved durability and resistance to deleterious environmental interactions. These findings highlight the potential of these supplementary cementitious materials to extend the service life of concrete structures, particularly in chloride-rich environments.

-

Importantly, the study demonstrated the environmental benefits of utilizing FA and AF in concrete mixes. The mix containing 30% FA and 10% AF exhibited a reduced environmental footprint compared to OPC concrete, emphasizing the importance of these materials in promoting sustainable construction practices.

-

Finally, this research showcased the efficacy of advanced modeling techniques in predicting and optimizing concrete properties. The successful application of MATLAB's Neural Network Toolbox for compressive strength prediction and Response Surface Methodology for mix optimization underscores the value of these tools in advancing concrete technology and design.

Data availability

The data that supports the findings of the study are represented article itself. No Separate data sets are used.

References

Zamora-Castro, S. A. et al. Sustainable development of concrete through aggregates and innovative materials: A review. Appl. Sci. 11(2), 629 (2021).

Meyer, C. The greening of the concrete industry. Cement Concrete Compos. 31(8), 601–605 (2009).

Soleymani, A. & Esfahani, M. R. Effect of concrete strength and thickness of flat slab on preventing of progressive collapse caused by elimination of an internal column. J. Struct. Constr. Eng. 6(1), 24–40 (2019).

Jahangir, H. & Eidgahee, D. R. A new and robust hybrid artificial bee colony algorithm–ANN model for FRP-concrete bond strength evaluation. Compos. Struct. 257, 113160 (2021).

Naik, T. R. Sustainability of concrete construction. Pract. Periodical Struct. Des. Constr. 13(2), 98–103 (2008).

Salesa, Á. et al. Physico-mechanical properties of multi-recycled self-compacting concrete prepared with precast concrete rejects. Constr. Build. Mater. 153, 364–373 (2017).

Lippiatt, N., Ling, T. C. & Pan, S. Y. Towards carbon-neutral construction materials: Carbonation of cement-based materials and the future perspective. J. Build. Eng. 28, 101062 (2020).

Shah, I. H. et al. Cement substitution with secondary materials can reduce annual global CO2 emissions by up to 1.3 gigatons. Nat. Commun. 13(1), 5758 (2022).

Durastanti, C. & Moretti, L. Environmental impacts of cement production: A statistical analysis. Appl. Sci. 10(22), 8212 (2020).

Gartner, E. & Hirao, H. A review of alternative approaches to the reduction of CO2 emissions associated with the manufacture of the binder phase in concrete. Cement Concrete Res. 78, 126–142 (2015).

Liew, K. M., Sojobi, A. O. & Zhang, L. W. Green concrete: Prospects and challenges. Constr. Build. Mater. 156, 1063–1095 (2017).

Ting, M. Z. Y. et al. Prediction model for hardened state properties of silica fume and fly ash based seawater concrete incorporating silicomanganese slag. J. Build. Eng. 41, 102356 (2021).

Baidya, R. & Ghosh, S. K. Co-processing of industrial trade rejects in cement plant. Waste Manag. Res. 38(12), 1314–1320 (2020).

Alyousef, R. et al. An integrated approach to using sheep wool as a fibrous material for enhancing strength and transport properties of concrete composites. Materials 15(5), 1638 (2022).

Wang, L. E. I. et al. Pore structural and fractal analysis of the influence of fly ash and silica fume on the mechanical property and abrasion resistance of concrete. Fractals 29(02), 2140003 (2021).

Min, J. et al. The numerical analysis of replenishment of hydrogel void space concrete using hydrogels containing nano-silica particles through ELM-ANFIS. Gels 8(5), 299 (2022).

Che Amat, R. et al. Effects of metakoalin on municipal solid waste incineration (MSWI) bottom ash-cement composite. In Materials Science Forum, Vol. 1010 (Trans Tech Publications Ltd, 2020).

Kumar, M., Sinha, A. K. & Kujur, J. Mechanical and durability studies on high-volume fly-ash concrete. Struct. Concrete 22, E1036–E1049 (2021).

Sandanayake, M. et al. Sustainable criterion selection framework for green building materials—An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 25, e00178 (2020).

Ibrahim, O. M. O. & Tayeh, B. A. Combined effect of lightweight fine aggregate and micro rubber ash on the properties of cement mortar. Adv. Concrete Constr. 10(6), 537–546 (2020).

Majhi, R. K., Nayak, A. N. & Mukharjee, B. B. An overview of the properties of sustainable concrete using fly ash as replacement for cement. Int. J. Sustain. Mater. Struct. Syst. 4(1), 47–90 (2020).

Siddique, R. & Khan, M. I. Supplementary Cementing Materials (Springer Science & Business Media, 2011).

Luo, M. F. Study on effects of concrete admixtures on performance of concrete. Appl. Mech. Mater. 94, 856–859 (2011).

Erofeeva, I. V. et al. Strength and deformability of cement composites of various types. In IOP Conference Series: Materials Science and Engineering. Vol. 1079. No. 5 (IOP Publishing, 2021).

Sujjavanich, S. et al. Synergistic effect of metakaolin and fly ash on properties of concrete. Constr. Build. Mater. 155, 830–837 (2017).

McCarthy, M. J. & Dhir, R. K. Development of high volume fly ash cements for use in concrete construction. Fuel 84(11), 1423–1432 (2005).

Narasimha Reddy, P. & Ahmed Naqash, J. Experimental study on TGA, XRD and SEM analysis of concrete with ultra-fine slag. Int. J. Eng. 32(5), 679–684 (2019).

Bamigboye, G. O. et al. Innovation in construction materials—A review. In IOP Conference Series: Materials Science and Engineering. Vol. 640. No. 1. (IOP Publishing, 2019).

Ondova, M., Stevulova, N. & Estokova, A. The study of the properties of fly ash based concrete composites with various chemical admixtures. Procedia Eng. 42, 1863–1872 (2012).

Papadakis, V. G. & Tsimas, S. Supplementary cementing materials in concrete: Part I: efficiency and design. Cement Concrete Res. 32(10), 1525–1532 (2002).

Kumar, M. G., Balasubramanian, M. & Kumar, A. A. J. Application of FGC blocks for sustainable infrastructure development. In IOP Conference Series: Materials Science and Engineering. Vol. 912. No. 6. (IOP Publishing, 2020).

Giergiczny, Z. Fly ash and slag. Cement Concrete Res. 124, 105826 (2019).

Saha, A. K., Khan, M. N. & Sarker, P. K. Value added utilization of by-product electric furnace ferronickel slag as construction materials: A review. Resour. Conserv. Recycl. 134, 10–24 (2018).

Záleská, M. et al. Physical and chemical characterization of technogenic pozzolans for the application in blended cements. Constr. Build. Mater. 160, 106–116 (2018).

Rajesh, K. S., Samanta, A. K. & Singha Roy, D. K. An experimental study on the compressive strength of alccofine with silica fume based concrete. Appl. Mech. Mater. 857, 36–40 (2017).

Ashraf, M. et al. Physico-chemical, morphological and thermal analysis for the combined pozzolanic activities of minerals additives. Constr. Build. Mater. 23(6), 2207–2213 (2009).

Sachdeva, A. Replacement of portland cement with alccofine: a review.

Barbhuiya, S. A. et al. Properties of fly ash concrete modified with hydrated lime and silica fume. Constr. Build. Mater. 23(10), 3233–3239 (2009).

Assi, L. N. et al. Observations of supplementary cementitious materials effects on the performance of concrete foundation. In IOP Conference Series: Earth and Environmental Science. Vol. 856. No. 1. (IOP Publishing, 2021).

Jain, K. L. et al. Impact of waste iron slag on mechanical and durability properties of concrete. Jordan J. Civil Eng. 17(1), 45–57 (2023).

Li, G. et al. Fly ash application as supplementary cementitious material: A review. Materials 15(7), 2664 (2022).

Singh, R. P., Rajasekhar, K. & Adiseshu, S. Experimental study on performance of M30 grade concrete by partial replacement with fly ash and granite powder. In Sustainable Construction and Building Materials: Select Proceedings of ICSCBM 2018 (Springer Singapore, 2019).

Naqash, J. A. & Reddy, N. Effect of alccofine on mechanical and durability index properties of green concrete. IJE Trans. 813–819 (2019).

Mahajan, L., Mahadik, S. & Bhagat, S. R. Investigation of fly ash concrete by slump cone and compaction factor test. In IOP Conference Series: Materials Science and Engineering. Vol. 970. No. 1. (IOP Publishing, 2020).

Jatoi, M. A. et al. Effect of Lakhra fly ash as partial replacement of cement in traditional concrete. Mehran Univ. Res. J. Eng. Technol. 38(4), 1045–1056 (2019).

Tai, B. et al. Recent progress of the effect of environmental factors on Aspergillus flavus growth and aflatoxins production on foods. Food Qual. Saf. 4(1), 21–28 (2020).

Oliva-Teles, A., Enes, P. & Peres, H. Replacing fishmeal and fish oil in industrial aquafeeds for carnivorous fish. In Feed Feeding Practices in Aquaculture 203–233 ((2015)).

Nair, P. K. R. Agroforestry systems and environmental quality: Introduction. J. Environ. Qual. 40(3), 784–790 (2011).

Srinath, B. S., Patnaikuni, C. K. & Raviteja, N. Comparative Studies of Cement and Alccofine and Their Suitability for Concrete (2022).

Xing, W. et al. Life cycle assessment of recycled aggregate concrete on its environmental impacts: A critical review. Constr. Build. Mater. 317, 125950 (2022).

Samson-Bręk, I., Smerkowska, B. & Filip, A. Environmental aspects in the life cycle of liquid biofuels with biocomponents, taking into account the storage process. In Storage Stability of Fuels (2015).

Alsaadi, N. An Integrated Life Cycle Assessment and Optimization Approach for Automotive De-manufacturing Systems (University of Toledo, 2017).

ISO, I. Environmental Management–Life Cycle Assessment–Requirement and Guidelines. S. (2006b). ISO 14044 (2006).

Finkbeiner, M. et al. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 11, 80–85 (2006).

Guinée, J. B., Huppes, G. & Heijungs, R. Developing an LCA guide for decision support. Environ. Manag.Health 12(3), 301–311 (2001).

Finkbeiner, M. The international standards as the constitution of life cycle assessment: the ISO 14040 series and its offspring. In Background and Future Prospects in Life Cycle Assessment 85–106 (2014).

Dias, A. C. & Arroja, L. Comparison of methodologies for estimating the carbon footprint—Case study of office paper. J. Clean. Prod. 24, 30–35 (2012).

Blanco-Davis, E. & Zhou, P. LCA as a tool to aid in the selection of retrofitting alternatives. Ocean Eng. 77, 33–41 (2014).

Pitroda, J., Zala, L. B. & Umrigar, F. S. Experimental investigations on partial replacement of cement with fly ash in design mix concrete. Int. J. Adv. Eng. Technol. 3(4), 126–129 (2012).

Pratap, B., Mondal, S. & Rao, B. H. NaOH molarity influence on mechanical and durability properties of geopolymer concrete made with fly ash and phosphogypsum. Structures. 56, 105035 (2023).

Lee, J. et al. Assessment of optimum CaO content range for high volume FA based concrete considering durability properties. Appl. Sci. 10(19), 6944 (2020).

Pratap, B., Mondal, S. & Hanumantha, R. B. Synthesis of alkali-activated mortar using phosphogypsum-neutralised bauxite residue. Environ. Geotech. 40, 1–12 (2023).

Lin, W.-T. et al. Permeability of Ultra-Fine Reactive Fly Ash applied to Cement-Based Composites. (2020).

Pratap, B. & Kumar, P. Effect of the elevated temperature on the mechanical properties of geopolymer concrete using fly ash and ground granulated blast slag. J. Struct. Fire Eng. https://doi.org/10.1108/JSFE-06-2023-0028 (2023).

Mahajan, L., Mahadik, S. & Bhagat, S. R. Investigation of fly ash concrete by slump cone and compaction factor test. InIOP Conference Series: Materials Science and Engineering. Vol. 970. No. 1. (IOP Publishing, 2020).

Pratap, B., Mondal, S. & Hanumantha Rao, B. Mechanical and durability assessment of phosphogypsum-bauxite residue-fly ash-based alkali-activated concrete. Constr. Build. Mater. 411, 134670 (2024).

Nikoloutsopoulos, N. et al. Physical and mechanical properties of fly ash based geopolymer concrete compared to conventional concrete. Buildings 11(5), 178 (2021).

Pratap, B. et al. Mechanical and durability performance of fly ash on bauxite residue and ground granulated blast slag based geopolymer composite. Iran. J. Sci. Technol. Trans. Civil Eng. 1–17 (2024).

Pratap, B. et al. Synthesis of sustainable subgrade geocomposite material using phosphogypsum stabilized with red mud. Indian Geotech. J. 1–11 (2024).

Occhiuzzi, A. et al. Experimental results of a national technical assessment procedure on commercial FRP for structural strengthening: Wet-lay-up systems. Mater. Struct. 53, 1–14 (2020).

Sagar, B. & Sivakumar, M. V. N. An experimental and analytical study on alccofine based high strength concrete. Int. J. Eng. 33(4), 530–538 (2020).

Shahmansouri, A. A., Bengar, H. A. & AzariJafari, H. Life cycle assessment of eco-friendly concrete mixtures incorporating natural zeolite in sulfate-aggressive environment. Constr. Build. Mater. 268, 121136 (2021).

Shahmansouri, A. A., Akbarzadeh Bengar, H. & Jafari, A. Modeling the lateral behavior of concrete rocking walls using multi-objective neural network. J. Concrete Struct. Mater. 5(2), 110–128 (2020).

Ghanbari, S. et al. Compressive strength prediction of high-strength oil palm shell lightweight aggregate concrete using machine learning methods. Environ. Sci. Pollut. Res. 30(1), 1096–1115 (2023).

Jafari, A. et al. Quantitative fractography for brittle fracture via multilayer perceptron neural network. Eng. Fract. Mech. 291, 109545 (2023).

Acknowledgements

The authors are thankful for the support from all the faculty members and laboratory in charges of Civil Engineering Department, Gudlavalleru Engineering College and authors also thankful to Yogi Vemana University for giving permission use SEM laboratory.

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Siva Shanmukha Anjaneya Babu Padavala: conceptualization, investigation, methodology, visualization, validation, writing—original draft. Venkatesh Noolu: investigation, methodology, validation, visualization, writing—original draft. Yeswanth Paluri: conceptualization, investigation, writing—review and editing. Sudheer Kumar Reddy Bijivemula: review editing and visualization. Uday Akula: conceptualization, visualization, validation. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Padavala, S.S.A.B., Noolu, V., Paluri, Y. et al. A study on the synthesis and performance evaluation of fly ash and alccofine as sustainable cementitious materials. Sci Rep 14, 19115 (2024). https://doi.org/10.1038/s41598-024-67519-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-67519-3

Keywords

This article is cited by

-

Self-compacting concrete with fly ash and silica fume: experimental evaluation, microstructural analysis, and machine learning modeling

Scientific Reports (2025)

-

Microstructural and durability properties of concrete using alccofine as partial replacement of cement and M-Sand as fine aggregate

Multiscale and Multidisciplinary Modeling, Experiments and Design (2025)