Abstract

The development of deep high-temperature oil and gas reservoirs gives rise to a rise in reservoir temperature along with the depth of the oil reservoir, thereby imposing higher requirements on the heat resistance of fracturing fluid. Guar gum fracturing fluid has difficulty tolerating temperatures exceeding 160 °C, thereby demanding the development of corresponding cross-linking agents, temperature stabilizers, and other additives to enhance the thermal stability of the fracturing system. Considering the distinctive characteristics of deep and ultra-deep reservoirs, such as extreme burial depth (exceeding 6000 m), ultra-high temperature (higher than 160 °C), and high fracturing pressure, an experimental modification of a guar gum fracturing fluid system was carried out, specifically tailored for ultra-high temperatures. The experiment identified and selected individual agents for ultra-high temperature fracturing fluids, including crosslinking agents, thermal stabilizers, flowback aids, and clay inhibitors. Through rigorous experimentation, these key agents for an ultra-high temperature fracturing fluid system have been successfully developed, including the optimal thickener GBA1-2, crosslinking agent BA1-1, anti-swelling agent FB-1, and gel breaker TS-1. The evaluation of diverse additive dosages has facilitated the development of an optimal guar fracturing fluid system, which exhibits outstanding high-temperature resistance while minimizing damage and friction. The outcomes of our experiments indicate that even after subjecting our ultra-high temperature fracturing fluid to 2 h of shearing at 170 s−1 at 180 °C, its viscosity remained above 200 mPa s—a distinct proof of its superior performance in withstanding high temperatures. This achievement represents a substantial progress in providing a suitable fracturing fluid system for the transformation and stimulation of ultra-deep and ultra-high temperature reservoirs, and also lays a solid foundation for further exploration and application in related fields in the future.

Similar content being viewed by others

Introduction

Currently, the research on stimulation measures for oil and gas fields centers on enhancing the performance of fracturing fluid as the primary research objective, as it directly affects the efficiency of fracturing operations. During the fracturing process, the fracturing fluid mainly functions to transfer hydraulic pressure, convey proppants into the formation to create fractures, and clean the formation after construction1,2,3. Hence, there are numerous factors influencing the performance of fracturing fluid, including viscosity, low permeability, rheology, thermal stability, shear resistance, and breaking performance; each factor must meet the general technical requirements and exhibit superior performance4. With the continuous progress of oil and gas exploration and development towards deeper reservoirs, most of which are low-permeability tight reservoirs, the post-completion production is frequently very restricted or even non-existent. Thus, it is essential to carry out reservoir fracturing operations to effectively exploit deep oil and gas resources5. As the burial depth of oil and gas resources increases, the reservoir temperature also rises significantly. The temperatures in these high-temperature deep wells have reached 150 °C, and some even exceed 200 °C. Conventional fracturing fluids degrade rapidly at such high temperatures and are unable to provide sufficient viscosity for the sand-carrying capacity needed for fracturing operations6. Therefore, there is an urgent demand for the development of high-temperature resistant fracturing fluids.

The thickifier is a key component that significantly impacts the performance of water-based fracturing fluid. It can be categorized into three types based on different chemical structures: natural galactose, synthetic polymer, and cellulose7,8,9. Guar gum and its derivatives are natural galactose thickeners commonly used in regular fracturing fluids, derived from the endosperm of the guar bean plant10,11,12,13. Improved water solubility and reduced insoluble content necessitate modification of guar gum’s molecular structure to meet high temperature fracturing fluid requirements14,15,16. The plentiful hydroxyl groups on guar gum’s molecular chain can be modified through etherification, esterification, or oxidation under specific conditions to produce ether and ester derivatives, allowing for molecular chain modification. Hydroxypropyl guar gum, obtained through the reaction between guar gum and propylene oxide in an alkaline medium, is considered a superior derivative of guar gum17,17. Studies have indicated that the thermal stability of glycosidic bonds is 177 °C, and above this temperature, the molecular chains of plant-based gum will degrade rapidly. However, in practice, degradation of the plant-based gum molecular chains begins well below this temperature; therefore, the actual operational temperature is significantly lower than 177 °C18,19.

Guar gum’s heat resistance and final fracturing fluid heat resistance depend on the number of crosslinkable groups participating in crosslinking20,21. To meet requirements, development of corresponding crosslinking agents, temperature stabilizers and other additives is necessary to enhance system’s temperature resistance22,23,24. Boron and transition metal crosslinking agents, mainly zirconium, aluminum, and titanium, are widely used. The main challenges of organoboron crosslinking agents include poor temperature resistance, short crosslinking time, and low stability. Meanwhile, the main drawbacks of organotriazole crosslinking agents are inadequate shear resistance, limited recovery after high-speed shear, high residue content and degradation difficulty, as well as high raw material cost and complex synthesis process25. Additionally, controlling delayed crosslinking is also a challenge. Therefore, there is an urgent need to develop a new crosslinking agent that not only possesses the strong shear resistance and low residue content of organoboron crosslinking agents but also exhibits delayed crosslinking performance and high temperature resistance similar to that of organotriazole crosslinking agents.

Clay stabilizers are added to the fracturing fluid to prevent swelling caused by clay mineral hydration. Studies suggest that clay stabilizers can disrupt the ion exchange capacity of clay surfaces and influence repulsive forces between ion double layers, achieving effective clay stabilization26,27. Clay mineral composition affects response to fracturing fluids in oil and gas reservoirs, leading to different levels of water-induced swelling and particle mobilization28. Incorporating effective clay inhibitors into these fluids represents a crucial strategy for stabilizing clays while mitigating particle migration within water-sensitive formations subjected to hydraulic fracturing operations29. Nevertheless, conventional inorganic cation-based inhibitors exhibit limited durability, while organic cationic surfactants have potential drawbacks such as inducing oleophilicity within reservoir rocks30. Furthermore, studies have demonstrated that employing heteroatom-substituted polysaccharides as crosslinking agents for fracture gels can serve to stabilize clays without promoting oleophilic behavior within reservoirs31.

Surfactants are commonly used in water-based fracturing fluids for post-fracturing flowback assistance, anti-emulsification demulsification, defoaming during fluid preparation, and as emulsifiers in emulsified fracturing fluids or foaming agents in foam fracturing fluids. It is crucial to consider that the ionic nature of surfactants used in fracturing fluids can impact the wetting properties of the formation32. Surfactants are commonly utilized in aqueous fracturing fluids to aid in post-fracturing flowback, prevent emulsification, facilitate demulsification, control foam formation during fluid preparation, and serve as emulsifiers or foaming agents in emulsified or foam-based fracturing fluids33. One common mechanism involves the presence of oxygen, which accelerates the degradation rate of the fracturing fluid. Therefore, anti-high-temperature stabilizers typically involve oxygen removal and commonly used substances such as methanol, sodium thiosulfate, and triethanolamine8.

During the hydraulic fracturing process in deep high-temperature reservoirs, problems like gel degradation resulting from high-temperature shear conditions may occur, which can lead to insufficient sand-carrying viscosity of the fracturing fluid and potentially have an impact on the efficiency of the fracturing operation. A composite crosslinking agent suitable for high-temperature fracturing fluid was developed by utilizing borax, zirconium oxychloride, and other raw materials. Experimental evaluations were carried out on various additives such as thickeners, crosslinking agents, temperature stabilizers, displacement aids, anti-swelling agents, and breakers. After optimization efforts, a high-temperature (180 °C) fracturing fluid system was successfully formulated, which fulfills the requirements for stimulating super-deep and ultra-high-temperature oil and gas reservoirs.

Principles of single components in fracturing fluid system

The single-component performance of the fracturing fluid directly influences its behavior under high temperatures and is crucial for successful fracturing operations and enhanced production. When conducting fracturing in deep, high-temperature oil and gas reservoirs to boost production, it is indispensable to employ stable thickeners for suspending and transporting the proppant-laden fracturing fluid. Considering the depth of the well, the crosslinker must demonstrate a longer delayed crosslinking time to control filtration loss in the fracturing fluid. Furthermore, minimizing the viscosity of the fracturing fluid is of paramount importance for reducing the pumping pressure during operations. Additionally, the gel formed at elevated temperatures should have a strong carrying capacity after prolonged shear and excellent delayed breaking characteristics.

By the meticulous selection of key single agents of the fracturing fluid, such as the modification technology of the ultra-high temperature guar gum system and the ultra-high temperature crosslinking agent, the interrelationships between the fundamental formula of the ultra-high temperature fracturing fluid and its performance under various high-temperature levels and different additive dosages are investigated, the optimal formula system that complies with the low damage performance and low friction resistance performance is determined, and the fracturing fluid system that accommodates the stimulation and reformation requirements of ultra-deep and ultra-high temperature is established.

Experimental methods

Methods

Deep, high-temperature fracturing operations necessitate specific requirements for the thickening agents in the fracturing fluid. The stability of these agents at elevated temperatures is crucial to ensure the carrying capacity and gel-breaking performance of the fracturing fluid. Additionally, due to the well’s depth, the crosslinker must not only possess an extended delayed crosslinking time but also exhibit exceptional carrying capacity and effective delayed breaking gel performance following prolonged shear. To address these demands, it was conducted experimental studies on super-high-temperature thickeners, delayed crosslinkers, temperature stabilizers, anti-swelling agents, and breakers. Through comprehensive assessment and optimization efforts, a suite of ultra-high-temperature fracturing fluid systems suitable for enhancing deep-well fracturing was successfully developed (Fig. 1). This ultra-high-temperature fracturing fluid system demonstrates outstanding stability at elevated temperatures and effectively mitigates various challenges that may arise during deep, high-temperature reservoir fracturing operations. Throughout the experimental process, diverse additives were fine-tuned for varying depths, temperatures, and shear conditions—providing robust support for optimizing the performance of the fracturing fluid.

Thickening agent

The laboratory conducted experiments to investigate the key factors influencing the performance of modified high-temperature guanidine gum products, including alkali concentration, alcohol content, water quantity, ethylene oxide dosage, reaction temperature and time. The modification experiment of guanidine gum was carried out using a 500 mL four-hole round-bottom flask equipped with a stirrer, condenser, dropper and thermometer. Initially, an appropriate amount of industrial ethanol was added at room temperature and stirred thoroughly. Then, a suitable quantity of guanidine collagen powder was introduced into the mixture. Subsequently, NaOH solution was slowly added at room temperature to initiate the alkalization reaction. As soon as the alkalization reaction completed, the temperature started to rise gradually while ethylene oxide and cationic etherifying agent were slowly dripped into the flask simultaneously through a dropper. The reactant-containing flask was placed in a water bath to maintain consistent reaction conditions at a predetermined temperature for a specific duration. Upon completion of the reactions, the flask was cooled to room temperature and hydrochloric acid was gradually added during the cooling process until reaching a pH value of 7.0. The resulting product underwent centrifugation, drying at 100 °C, milling, and filtration through a screen mesh with an aperture size of 0.125 mm to yield ultra-high-temperature modified guanidine gum (GHPG) products. The evaluation experiment focused on investigating the impact of different alkali amounts, water amounts, reaction temperatures, reaction times, and ethylene oxide amounts on the water insoluble content of ultra-high temperature modified guar gum (GHPG).

Crosslinking agent

To meet the performance requirements of the crosslinking agent under high temperature and shear conditions, boron and zirconium were selected as the central ions, with the total mass of boric acid and zirconium oxychloride set at 16% of the mass of the crosslinking agent. Initially, zirconium oxychloride was combined with its corresponding ligand in a suitable solvent, followed by heating and stirring in a water bath until it dissolved into a colorless and transparent liquid. Subsequently, 6 parts of boric acid were dissolved in 2 parts of solvent, with an addition of a specific amount of NaOH for complete hydrolysis. After adding a certain amount of ligand, this mixture was also heated and stirred to form another colorless and transparent liquid. Finally, these two mixtures were combined and continuously heated while being stirred to yield a faint yellowish slightly viscous transparent liquid—the desired crosslinking agent.

The organic boron zirconium crosslinking agent exhibits delayed crosslinking functionality, and its mechanism of slow crosslinking is as follows: under alkaline conditions, there is a strong affinity between the organic coordination entity and the boron ion. Leveraging this affinity, the excess coordination entity encapsulates the colloidal particles of the organic boron zirconium crosslinking agent, with a stronger affinity observed at higher levels of alkalinity. The coordination entity functions as a protective film formed on the surface of the organic boron zirconium crosslinking agent, and the tightness of this film depends on adjusting alkalinity levels. By manipulating alkalinity, one can effectively control exposure levels of the organic boron zirconium crosslinking agent and regulate its potential reaction with hydroxyl groups in vegetable gums to achieve precise control over crosslinking time. The delayed crosslinking experiment results indicate that the viscosity of the organic boron-zirconia crosslinking agent reaches its first inflection point at approximately 6 min. At this stage, the system demonstrates a localized linear structure, showing strong flowability and low friction characteristics. Around 14 min, the second inflection point emerges, leading to the formation of a reticular structure in the system. This structure displays high viscoelasticity and is accompanied by an observed “picking tongue” characteristic (Table 1 and Fig. 2).

Clay stabilizing agent

The binder utilized is a low-concentration organic cationic polymer with multiple adsorption sites, exhibiting resistance to acids and saltwater. Through dissociation, the organic cationic polymer generates positively charged cations that effectively neutralize the negative charge on the clay surface (Fig. 3), thereby demonstrating excellent prevention of clay swelling.

The starch-cadmium iodide approach was utilized to investigate the saturated adsorption capacity and adsorption attributes of the clay stabilizer. At first, the working curve of the cationic polymer was ascertained by means of a spectrophotometer to establish a quantitative correlation between optical density and concentration. Then, the optical density of the supernatant from the developed color in the adsorption system was gauged, and the adsorption capacity of the system was computed using the established working curve. The experiment contrasted polymers with different degrees of cationization and evaluated how cationization influenced their saturated adsorption capacity (Table 2, Fig. 4). As the degree of cationization rises, the saturated adsorption quantity of the polymer on the clay surface and the positive charge adsorption unit within its molecule also escalate, thereby strengthening the stability of the clay.

Temperature stabilizers

In this experiment, TS-1 was chosen as the temperature stabilizer. It is a colorless or light-yellow liquid with a density range of 1.05–1.18 g/cm3 and pH value ranging from 9.0 to 11.0. Gel samples were loaded into sample cups of a high-temperature and high-pressure coaxial cylinder rotary viscometer for controlled-rate heating experiments at 3 ± 0.2 °C per minute while rotating at a shear rate of 170 s−1. The fracturing fluid sample underwent continuous shearing during heating until its apparent viscosity decreased to reach a value of 50 mPa·s in order to assess its temperature resistance. The enhancement in the sample’s temperature resistance was evaluated by comparing differences before and after adding cross-linked gel.

where ΔT represents the amount of temperature increase, °C. T1 represents the measurement temperature without adding the temperature stabilizer, °C. T2 represents the measurement temperature after adding the temperature stabilizer, °C.

Experimental instruments and materials

The main instruments and reagents used in the experiments are shown in Tables 3 and 4 below. These experimental reagent products are all industrial-grade items of qualified quality, provided by chemical enterprises located in Sichuan Province in western China, and some of the products are synthesized within the laboratory.

Principle of single agent performance

Thickener

-

(1)

Guan gum thickeners

Plant gum serves as the primary thickener for water-based fracturing fluid, constituting over 90% of usage. Among various thickeners such as guar powder or modified guar powder, soybean gum, hydroxy methyl cellulose (CMC), guar gum or its modified derivatives, modified guar gum is recognized as the most effective thickener due to its strong affinity for water and ability to swell upon contact with water, leading to water coagulation34. This is attributed to its abundance of hydroxyl groups that form hydrogen bonds with water, allowing the polymer chains formed by these groups to disperse in water. The resulting dispersed solution resembles swollen long fiber bundles suspended in water, which intertwine and obstruct solution flow, thereby increasing viscosity35. While guan gum and its derivatives can meet the basic requirements of conventional fracturing operations, their thermal performance is limited to temperatures below 180 °C. To address this limitation and meet operational needs, corresponding crosslinking agents, temperature stabilizers and other additives must be developed to enhance the thermal performance of the fracturing system36.

The resistance of guar gum-based thickeners to high temperatures (180 °C) in fracturing fluid systems is still relatively uncommon, primarily due to the hydrolysis of sugar glycosidic bonds in the molecular main chain under high temperature and alkaline conditions, resulting in a rapid decrease in system viscosity and failure to meet sand-carrying requirements.

-

(2)

Complex Thickener

A composite thickener involves the combination of two thickeners, such as guar gum and polyacrylamide. These high-molecular-weight compounds can form a hydrogen bond structure resembling a ladder, which allows the chains to protect each other and enhance their thermal stability37. The presence of this ladder structure ensures that the breakage of one chain does not disrupt the overall network structure, provided it occurs in different sections of the ladder grid. Therefore, incorporating an additional compatible thickener alongside guar gum can significantly enhance the thermal and shear resistance properties of the fracturing fluid system38.

-

(3)

Synthetic Polymer Thickeners

Conventional synthetic polymer fracturing fluids suffer from poor temperature and shear stability. The primary approach to improving the shear resistance of polymer fracturing fluid is currently by increasing the rigidity of the main chain molecules of the polymer thickener. In comparison with plant-based natural high molecular weight materials, synthetic polymer thickeners offer advantages such as strong thickening ability, easy flow restoration after breakage, and low residue content. Particularly for polymers, they exhibit excellent thermal stability. Due to the large bond energy in C–C single bonds that constitute the high molecular chains of synthetic polymers, they are less prone to breaking at elevated temperatures. Therefore, when designing the molecular chains of synthetic thickeners, functional requirements should be considered and side chains with functional groups such as hydroxyl groups and cross-linking groups should be selected for incorporation into the high molecular chains. Additionally, heat resistance of these side chains must also be taken into account. The crushing, drying, and dispersing processes during solution synthesis of synthetic polymer thickeners significantly impact their heat resistance performance in process configuration. Thus, fracturing fluid prepared using a powder preparation method exhibits markedly lower heat resistance performance compared to that prepared using a gel preparation method.

Comparing the three types of thickeners, guar gum-based thickeners offer the advantages of consistent performance, easy product accessibility, cost-effectiveness, and minimal reservoir damage. Furthermore, their heat resistance can be enhanced through modification.

Crosslinking agents

To meet the performance requirements of the crosslinking agent under high temperature and shear conditions, boron and zirconium were selected as the central ions. The mass ratio of boric acid to zirconium oxychloride was set at 16% of the total mass of the crosslinking agent. Initially, zirconium oxychloride was combined with its corresponding ligand, followed by addition of an appropriate amount of solvent. The mixture was heated and stirred in a water bath until it dissolved into a colorless and transparent liquid. Subsequently, 6 parts of solvent were added to 2 parts of boric acid and stirred until dissolution occurred. A certain quantity of NaOH was then introduced to facilitate complete hydrolysis of boric acid, along with a specific amount of ligand. The resulting mixture was heated and stirred in a water bath to yield a colorless and transparent liquid. Finally, the two liquids were blended together and continuously heated and stirred to produce a faint yellow, slightly viscous transparent liquid—the crosslinking agent.

The conventional crosslinking agents used at high temperatures pose two main challenges. Firstly, the rapid crosslinking rate leads to increased flow resistance of fracturing fluid in the pipeline. Secondly, the continuous shearing of fracturing fluid in deep wells makes it difficult to maintain its performance. Therefore, there is a need for a delayed crosslinking agent that can prevent or partially delay the crosslinking of fracturing fluid in the surface pipe string and gradually achieve the desired viscosity before entering the wellbore and reaching the target layer. This not only facilitates construction pumping but also ensures optimal fracturing fluid performance, thus introducing delayed crosslinking technology. Currently, delayed crosslinking technology primarily focuses on four aspects: incorporating delaying agents to extend the crosslinking time; utilizing formation heat; controlling dissolution rate; adjusting pH change and polymer hydration reaction. Organic zirconium-based crosslinking agents are suitable for high-temperature (200 °C) formations as they do not hydrolyze and can maintain viscosity for an extended period at elevated temperatures. Additionally, their residue after breaking down can serve as a clay stabilizer. Commonly used organic zirconium compounds include triethanolamine zirconium, acetylacetone zirconium, sodium zirconium citrate, and sodium zirconium tartrate chelates. Combining boron with zirconium not only combines boron’s shear stability advantages with zirconium’s heat stability but also reduces expensive usage of zirconium while remaining effective at high/ultra-high temperatures.

An exceptional organic boron-zirconium crosslinker has been developed, which exhibits superior temperature resistance and delayed crosslinking compared to inorganic boron crosslinkers. Furthermore, it mitigates fracturing fluid-induced damage to formation permeability when compared to organic titanium or chromium crosslinkers. The organic boron-zirconium crosslinker is synthesized under strictly controlled reaction conditions for the incorporation of organic zirconium complexes into organic boron. The resulting larger colloidal ions are attributed to stronger complex bonds formed between the zirconium ions and the organic boron colloidal particles, thereby further enhancing the gel’s crosslinking density and strength while improving its temperature and shear resistance properties. This principle is illustrated in Fig. 5.

Anti swelling agent

The presence of clay in the formation presents two challenges: firstly, expansible clay minerals (mainly montmorillonite) undergo expansion upon exposure to water, leading to a reduction in reservoir permeability; secondly, non-expansible clay minerals (such as kaolinite, illite, chlorite) migrate when fluid flow rate exceeds a certain threshold, resulting in pore structure blockage and further reduction of reservoir permeability. Therefore, addressing clay stability requires measures to prevent the expansion of expansible clay minerals and inhibit the migration of non-expansible clay minerals.

Clay stabilizers are chemical agents that inhibit the swelling of clay or migration of clay particles. Various chemical methods and techniques have been employed to mitigate or prevent reservoir damage caused by clays and particles. Essentially, montmorillonite, kaolinite, illite, and their mixed forms are the most prevalent clays found in natural accumulations within reservoirs, characterized by a significant presence of negatively charged clay surfaces. These negative charges exhibit high sensitivity towards liquids, forming the basis for the development of most clay stabilizing additives. Similar to pore lining or filling minerals, clay minerals exist naturally in accumulations or occasionally occur as flakes within pores. They are surrounded by saline primary formation water primarily composed of Na+ and Ca2+, which form salt ions that adsorb onto the clay surface through electrostatic interactions acting as neutralizing agents for negative ions, thereby maintaining stability under normal conditions. However, infiltration of external fluids such as low-salt well treatment fluids or non-productive water dilutes the primary water and reduces its salt concentration. Consequently, diffusion of cations covering the clay surface occurs leading to expansion in montmorillonite and certain mixed clays while causing fractures in kaolinite, illite shale, and mixed rocks.

The main chemicals that possess both swelling and migration inhibitory properties are organic cationic polymers. Organic cationic polymer stabilizers offer several advantages, including a wide temperature range (24–260 °C), resistance to acid treatment, oil and water resistance, low dosage requirement with quick effect, long shelf life, and ease of use. Moreover, they exhibit good compatibility with working fluids and reservoirs while preventing issues such as oil-wet inversion on the hydrophilic surface of treated formations.

Demulsifying agent

Upon entering the oil and gas layer, fracturing fluid creates capillary pressure. The oil–water interface tension typically ranges from 25–35 mN/m but is affected by temperature, pressure, and oil composition. Gas–water interface surface tension can range from 74 to 40 mN/m, depending on temperature and pressure conditions. Most of the outlets for oil within rock layers have diameters greater than 1 μm. When contact angle equals 0° with σ = 30 mN/m, capillary pressure on the oil–water contact surface is approximately 0.12 MPa. Conversely, it is higher on gas–water contact surfaces. Water existing in bead form leads to increased capillary pressures due to Jamin effect at low permeability (0.1 × 10–3 μm2) and a saturation level of 60%, where even reaching up to 1.4 MPa may pose challenges during flowback processes when reservoir inflow rates are low or discharge times are prolonged.

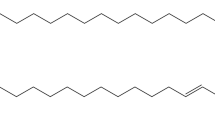

The displacement aid is a chemical substance utilized to decrease the surface tension of fracturing fluid or oil–water interface tension, enhance the contact angle with rock, augment energy, diminish capillary resistance during fracturing fluid return, facilitate complete return, and mitigate formation pollution. The critical micelle concentration (CMC) value of Gemini surfactants is typically 10–100 times lower than that of traditional surfactants. In comparison to conventional surfactants, Gemini surfactants exhibit superior efficacy in reducing water surface tension. For instance, Gemini-type surfactants possessing exceedingly high surface activity, excellent water solubility, and hydrophilic bonding groups demonstrate remarkably low kraff points. Ionic Gemini surfactants possess two polar groups and twice the charge which enables them to exert stronger attraction towards other electroneutral or oppositely charged surfactants. The synthetic pathway for the selected Gemini surfactant (Fig. 6) involves refluxing secondary amine and 3-chloroepoxypropane to generate bridging quaternary ammonium salt followed by reacting the quaternary ammonium salt with hydrogen peroxide to obtain oxidized quaternary ammonium salt. Finally purifying the product through recrystallization.

Gel breaker

In high-temperature layers, layer degradation typically occurs automatically with increased residence time. However, to expedite this process, a breaker is incorporated into the fracturing fluid. When natural polymers are employed as gelling agents, biological enzymes are often utilized as breakers, which do not affect the layers themselves. Suitable biological enzymes include α-amylase, β-amylase, maltose, cellulase, and hemicellulosic acid. Nevertheless, due to their limited thermal stability, biological enzymes can only be used for treatment when the temperature of the layers remains below 60 °C. Additionally, for fracturing fluids prepared from synthetic polymers, biological enzymes generally have negligible impact on layer degradation. Another category of oxidants can serve as film-breaking agents including potassium dichromate (K2Cr2O7), potassium permanganate (KMnO4), hydrogen peroxide (H2O2), persulfate (S2O82−), perethylenedibenzo-p-dioxin (PEDD), and peroxyt-butyl (–C(CH3)3). The former several types of inorganic oxidants are suitable for higher temperature layers while the latter two organic types are applicable to lower temperature layers. Oxidizing materials achieve film breaking effects by generating free radicals. When there exists a substance capable of providing reducing metallic ions (FeSO4), the formation of free radicals can be further accelerated to enhance film breaking rate. Oxidizing materials exhibit film breaking effects on both natural and synthetic polymers. However, it is generally believed that crosslinked natural polymers can also undergo self-decomposition at temperatures exceeding 70 °C.

The third type of gel breaker consists of inorganic or organic acids, which disrupt the gel structure by reducing the pH of the fracturing fluid. Commonly used acids include sulfuric acid, hydrochloric acid, acetic acid, and p-toluenesulfonic acid. Organic esters undergo hydrolysis at elevated temperatures, enabling their dispersion or dissolution in the fracturing fluid to automatically break down the gel within the formation. Examples of esters include ethyl formate, ethyl chloroacetate, titanium dibutyl ether, maleic dibutyl ether, and adipic dibutyl ether. It is widely acknowledged that dicarboxycyclopentadienyl dialkyl ethers exhibit enhanced effectiveness due to their slow hydrolysis upon injection into the formation; subsequently accelerating and disrupting the gel when temperatures reach 65 °C or higher.

The requirements for breaking the gel and flowback of fracturing fluid are opposite to those for sand fracturing. During the addition of sand, the fracturing fluid must have high viscosity and stability to effectively transport the sand, minimize filtration losses, and enhance liquid utilization efficiency. Conversely, during flowback, it is crucial for the viscosity of the fracturing fluid to rapidly decrease in order to reduce flow resistance, increase discharge speed, shorten discharge time, and ultimately maximize discharge efficiency. The stability of fracturing fluids is primarily influenced by two factors: high-speed shear degradation and high-temperature oxidation degradation. High-speed shear degradation mainly occurs during pumping between the wellbore and burst point; whereas high-temperature oxidation mainly occurs when the fracturing fluid comes into contact with formation rock resulting in heat exchange. Even with sufficient heat stabilizers at high temperatures, there may still be small amounts of dissolved oxygen due to chemical reaction equilibrium. These residual traces can cause partial degradation of fracturing fluids and require appropriate dosing of degumming agents for rehydration.

The ammonium sulfate functions as a breaker by decomposing free radicals (Fig. 7) within the formation via persulfate, which subsequently attacks the polymer chain of guanidine gum. This results in a complete reduction in viscosity of the fracturing fluid through the cascade reaction of free radicals.

The concentration of polymer in the fracturing fluid will increase by 5–7 times during the pumping and fracture closure process, due to filtration phenomenon. This presents challenges for breaking the fracturing fluid. When ordinary breaker is dissolved in the liquid, it flows into the reservoir with filtration phenomenon. However, due to the concentration of polymer on the filter cake, the dissolved breaker cannot effectively penetrate it and may cause permanent damage to the formation. At the same time, a high enough concentration of breaker must be added during construction to fully achieve polymer breaking effects. However, increasing breaker concentration prematurely reduces viscosity of fracturing fluid and may lead to increased sand removal and blockage problems. Ensuring viscosity of fracturing fluid during construction while achieving complete breaking after construction creates a mutually restrictive relationship. The new type of coated capsule breaker effectively solves this problem by delaying release time through a thin film coating instead of using ordinary particles form. This maintains required viscosity during construction while gradually releasing effective components under closure stress for section cleaning.

Results and discussion

Optimization of thickener performance

Factors affecting modification

-

(1)

Addition of base

To maintain an alkaline milieu throughout the reaction procedure, it is requisite to incorporate an alkaline solution into the reactants. The introduction of alkali has a twofold function: firstly, it regulates the pH level of guanidine gum molecules. Secondly, it acts as a catalyst. Insufficient alkali will fail to effectively diminish water-insoluble substances in the modified guanidine gum, while excessive amounts can undermine its molecular structure and reduce the viscosity of the final product. Elevated levels of alkali lead to a more substantial reduction of water-insoluble substances and exert a significant influence on viscosity (Fig. 8). For lower levels of water-insoluble substances and higher viscosity, it is recommended to keep the alkali levels beneath 8%.

-

(2)

Amount of alcohol

The experiment utilized industrial ethanol as the solvent, with the possibility of using other alcohols such as isopropanol. These alcohols do not actively participate in the chemical reaction but serve solely to dissolve the reactants. An appropriate quantity of solvent alcohol needs to be added to ensure thorough mixing within the stirrer. There are no strict requirements regarding the amount of alcohol to be added. For this particular experiment, a determined volume of 200 mL industrial ethanol was employed.

-

(3)

Amount of water

A moderate amount of water is essential for achieving slight expansion of the modified gum guanidine, while excessive water will lead to excessive expansion and decreased viscosity. Therefore, it is crucial to control the alcohol-to-water ratio within a range of 3:1–4:1, considering the amount of water generated by acid–base reaction. Experimental results show that adding 20 mL (volume content 9%) water significantly reduces the insoluble matter content in the modified product to 12.27%, which is notably lower than that in the original gum guanidine powder (24.16%) due to poor quality. Furthermore, adding 70 mL (volume content 25%) water minimizes the insoluble matter content to its lowest level (Fig. 9). As a result, a final solution containing 70 mL (volume content 25%) water has been determined.

-

(4)

Etherification agent

Increasing the dosage of the etherifying agent can effectively reduce the content of water-insoluble matter; however, once a certain threshold is reached, the reduction effect on water-insoluble matter becomes less pronounced (Fig. 10). Simultaneously, with an increase in the dosage of the etherifying agent, there is a decrease in product viscosity. Laboratory experiments indicate that an optimal addition amount of 12 mL (5% by volume) for the etherifying agent is most suitable.

-

(5)

Reaction time

The reaction rate is rapid, thereby reducing the degradation of alkali on the product. As the reaction temperature increases, the rate of reaction accelerates and the required time decreases. Under indoor conditions, at a temperature of 60 °C, the measured reaction times were respectively 2, 3, 4, and 5 h. The impact of these varying reaction times on the content of water-insoluble substances was observed to determine an optimal duration of 4 h (Fig. 11).

-

(6)

Reaction temperature

The temperature is a critical factor that affects the performance of modified guanidine gum products. The impact of temperature on the water insoluble content was investigated, and experimental results indicated that temperatures above 70 °C yielded better results (Fig. 12). It is advisable to utilize water bath heating instead of high-temperature steam heating during the heating process.

-

(7)

Amount of guanidine collagen powder

Various samples were utilized for conducting modification experiments on the quality of guanidine collagen powder. The findings indicated that a lower water-insoluble matter content in guanidine collagen powder resulted in a decreased water-insoluble matter content in the modified products. Therefore, the selection of high-quality guanidine collagen powder can enhance the performance of modified products. Experimental analysis revealed that numerous factors influence the water-insoluble matter content of modified guanidine collagen. In addition to requiring fully qualified chemicals, it is essential to control various reaction conditions in order to synthesize modified guanidine collagen products meeting standard requirements.

Evaluation of conventional thickener performance

By increasing the molecular weight of thickeners and introducing groups with stronger hydration properties, the performance of fracturing fluids can be effectively improved (Tables 5 and 6).

The high-temperature evaluation outcomes at 180 °C and 170 s⁻1 reveal (Fig. 13) that the viscosity of this ultra-high temperature fracturing fluid remains above 400 mPa s within 40 min, and remains approximately at 350 mPa s after 60 min of shearing; when continuously sheared for 120 min, its viscosity is still higher than 250 mPa s. In the second half of the entire curve, its viscosity remains relatively stable on the whole, demonstrating excellent shear resistance. The temperature resistance capacity of conventional fracturing fluids is restricted to 140–160 °C. Experiments have affirmed that this fracturing fluid system is completely capable of fulfilling the requirements of formation fracturing operations at temperatures ranging from 160–180 °C and above.

Evaluation of crosslinking agent performance

The organic boron-zirconium composite crosslinking agent GBA1-2 is synthesized by introducing organic zirconium complexes into organic boron under strictly controlled reaction conditions. Compared with the complex bonds between boron and hydroxyl groups, the complex bonds formed between zirconium ions and organic boron colloidal particles are stronger, leading to a higher crosslinking density and strength, as well as improved temperature resistance and shear resistance of the gel. In GBA1-2, the ratio of boron to zirconium is greater than 40:1, mainly occurring in the crosslinking between polysaccharide molecules and boron ions. When subjected to strong shear actions, rupture will first occur in the complex bonds formed between colloidal particles, boron ions, and polysaccharide molecule hydroxyl groups. However, after the shear action weakens or disappears, the complex bonds formed at the rupture site can be re-connected.

Heat and shear resistance of different crosslinking agents

In the comparative assessment of crosslinking agent performance, various types and concentrations of crosslinking agents were utilized alongside consistent types and concentrations of thickeners and other additives, with the fracturing fluid being prepared based on a uniform crosslinking ratio (100:0.5). The concentrations of thickeners, different crosslinking agents, and other additives are detailed in Table 7.

The 0.5% GHPG fracturing fluid, consisting of 0.4% GBA1-2, 0.5% B-10, and 0.4% SL-10 crosslinkers, was injected into an RV20 rotary viscometer and subsequently heated to a constant temperature of 145 °C. The apparent viscosity curve over time was then measured for a duration of 120 min at a continuous shear rate of 170 s−1, as illustrated in Fig. 14.

The organoboron zirconium crosslinking agent GBA1-2 shows significantly improved heat and shear resistance compared to both the organoboron crosslinking agent B-10 and the organozirconium crosslinking agent SL-10. While the initial viscosity of GHPG fracturing fluid crosslinked by SL-10 (yellow curve) is high, it rapidly decreases after a period of shear, dropping below 100 mPa s within two hours. In contrast, GHPG fracturing fluid crosslinked by GBA1-2 (blue curve) exhibits exceptional temperature tolerance surpassing that of both B-10 and SL-10, with its viscosity remaining above 150 mPa s within 2 h.

Performance of breaking gel hydration

Incorporate 0.02% of ammonium persulfate ((NH4)2S2O8), a binder breaker, into GHPG fracturing fluid crosslinked with various binders. Transfer the mixture to an autoclave and stir at a speed of 20 r/min for 2 h under sealed conditions. Allow it to stand undisturbed for 24 h. After cooling, extract the broken fluid and determine its viscosity at 30 °C using a counterflow capillary viscometer, as presented in Table 8. The measured viscosity of the fractured binder liquid was found to be 1.87 mPa s, indicating complete and thorough breakdown of GHPG fracturing fluid crosslinked with GBA1-2.

After a comprehensive comparison and evaluation, it has been determined that the organic boron-zirconium composite cross-linker GBA1-2 exhibits superior temperature and shear resistance properties compared to individual organic boron and organic zirconium compounds. Furthermore, GBA1-2 demonstrates a high level of efficiency in cross-linking vegetable chitosan molecules while requiring a lower dosage, thereby reducing the cost of raw materials necessary for fracturing fluid preparation.

Evaluation of anti-swelling agent performance

A laboratory comparison of the effectiveness of four clay stabilizers was conducted: 2% KCl aqueous solution, SN-1, BFC-1, and BA1-1 (Fig. 15). These stabilizers are commonly used in clay stabilization and include options based on inorganic salts, cationic compounds, and organic polymers for their anti-swelling effects. Based on the aforementioned experimental data, it is evident that 1% BA1-1 exhibits significant resistance to initial swelling, while the initial swelling resistance of 2% KCl and the other two polymers is relatively low. After 24 h, KCl’s swelling resistance decreases to only 50%, whereas that of 1% BA1-1 remains high at 86%. Consequently, BA1-1 has been chosen as the clay stabilizer for this project with the objective of mitigating clay swelling migration and minimizing formation damage during fracturing operations.

Performance evaluation of flow-back Improver

When choosing a flow-back improver, it is important to consider the following factors: (1) Reservoir characteristics indicate that the sandstone surface carries a negative charge, requiring the use of anionic or nonionic surfactants to minimize their adsorption on the sandstone surface. (2) The displacement aid should aim to reduce interfacial tension and surface tension between liquids in order to mitigate resistance during fracturing fluid backflow. Extensive indoor comparative experiments were conducted on GH-1, GH-2, NC-1, BJ-1, and FB-1 (Fig. 16). Ultimately, FB -1 was identified as a highly effective displacement aid compatible with new high-temperature fracturing fluid while exhibiting exceptional performance. The recommended concentration for FB -1 was set at 1.0%. Experimental results demonstrated that this displacement aid could effectively lower the surface tension of broken gel liquid below 30 mN/m and significantly enhance fracturing array backflow rate, thereby achieving excellent backflow efficiency.

Evaluation of temperature stabilizer

The presence of a temperature stabilizer is essential for the high-temperature fracturing fluid system due to the vulnerability of guanidine gum molecules containing acetal groups to oxidation and degradation in the presence of oxygen, leading to a significant decrease in system viscosity. The main purpose of the temperature stabilizer is to eliminate free oxygen within the system, thereby reducing its catalytic effect on thermal degradation and enhancing the thermal stability of thickener molecules. Additionally, by reacting with polymer free radicals, the temperature stabilizer can enhance affinity between cross-linked ions and polymer hydroxyl functional groups, thus improving the high-temperature stability of the fracturing fluid system and approaching or even surpassing that of vegetable glue. Figure 17 indicate that the temperature stabilizer TS-1 significantly improves the system’s resistance to high temperatures. As the concentration increases, there is a gradual improvement in the system’s ability to withstand elevated temperatures. Considering cost-effectiveness and practicality, it is recommended to maintain an optimal dosage of the temperature stabilizer.

Evaluation of damage to reservoir by fracturing fluid

The filtration loss performance of fracturing fluid

By simulating the forward and reverse flow of fracturing fluid within core samples, researchers can acquire highly valuable insights into the degree of formation damage and its subsequent influence. This comprehensive assessment enables a precise comprehension of how the fracturing fluid interacts with the oil layer within the formation. The experimental results presented in Table 9 indicate that the degree of damage to the oil layer following contamination by fracturing fluid ranges from 17.5 to 18.8%, all remaining below the threshold of 20%. These findings emphasize that although fracturing fluid contamination does exert an impact on the oil layer, it remains within acceptable bounds. Furthermore, this research offers critical guidance for industry practitioners involved in the selection and application of fracturing fluids during practical operations. Through understanding and quantifying these effects, engineers and decision-makers can make well-informed choices regarding which types of fracturing fluids are most appropriate for specific geological formations, thereby optimizing production efficiency while minimizing potential environmental impacts.

Solid residue rate test of fracturing fluid after gel breaking

The total volume of the gel breaker solution, which had a viscosity of 3 mPa s, amounted to 500 mL (where the concentration of guar gum was 0.55%). Four empty tubes (with a combined mass of 26.3286 g) were utilized to extract 40 mL and placed in a centrifuge. The centrifuge was run at a rotational speed of 3000 r/min for 30 min, and then taken out and placed in an oven with a temperature of 140 °C for heating and drying treatment. From the above experimental results (Fig. 18), it can be readily observed that the residue content of this ultra-high temperature fracturing fluid is lower than that of the conventional fracturing fluid and is fully capable of meeting the construction requirements.

Conclusions

The proposed approach encompasses the synthesis of an ultra-high temperature modified guanidine gum serving as a thickener. Initially, guanidine collagen powder is disseminated in an organic solvent under optimum dispersion circumstances, succeeded by an alkali-catalyzed reaction and the introduction of a cationic etherifying agent. Subsequently, a succession of post-treatment procedures are executed following sufficient reaction.

The organic boron-zirconium composite crosslinker GBA1-2 is fabricated by incorporating an organic zirconium complex into organic boron under stringently controlled reaction conditions, with its optimal application concentration being 0.4%. As a crosslinker, it conspicuously enhances the high temperature resistance and shear resistance of the fracturing fluid.

BA1-1 has been chosen as the clay stabilizer for this project to alleviate clay swelling and migration and minimize formation damage during fracturing operations, with its optimal concentration determined at 1.0%. The recommended concentration for FB-1 is also fixed at 1.0%. Experimental results have indicated that this displacement aid effectively lowers the surface tension of broken gel liquid to below 30 mN/m and significantly improves the backflow rate of the fracturing array, thereby attaining outstanding backflow efficiency.

With the escalation of the concentration of the temperature stabilizer TS-1, the temperature resistance of the fracturing fluid progressively enhances. Based on the experiment, the optimal concentration of the temperature stabilizer for the stable control of the temperature resistance of the fracturing fluid is 1%. The degree of damage to the oil layer subsequent to contamination by the fracturing fluid ranges from 17.5 to 18.8%, all being lower than 20%. Even after subjecting our ultra-high temperature fracturing fluid to shearing at a rate of 170 s−1 at 180 °C for 2 h, its viscosity remained above 200 mPa s.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Feng, X. Y. et al. High temperature deep wells fracturing technology in Qaidam basin. In Proceedings of the International Field Exploration and Development Conference 2020 1383–1393 (Springer, 2021).

Kang, W., Mushi, S. J., Yang, H., Wang, P. & Hou, X. Development of smart viscoelastic surfactants and its applications in fracturing fluid: A review. J. Petrol. Sci. Eng. 1(190), 107107 (2020).

Mao, Z. et al. Nanomaterials and technology applications for hydraulic fracturing of unconventional oil and gas reservoirs: A state-of-the-art review of recent advances and perspectives. ACS Omega 7(34), 29543–29570 (2022).

Wang, C., Ouyang, J. & Zhu, Z. Y. A novel fracturing fluid system with ultra-low concentration and high temperature resistant. Appl. Mech. Mater. 22(624), 651–656 (2014).

Xiao, B. & Ma, R. Experimental study on novel high density and high temperature tolerant fracturing fluid. Adv. Mater. Res. 22(1006), 152–155 (2014).

Ma, Z., Zhao, M., Yang, Z., Wang, X. & Dai, C. Development and gelation mechanism of ultra-high-temperature-resistant polymer Gel. Gels 9(9), 726 (2023).

Bajpai, P., Singh, J., Mandal, A. & Ojha, K. The synthesis and characterization of a clean hydrofracturing fluid. Pet. Sci. Technol. 28(17), 1750–1760. https://doi.org/10.1080/10916460903261723 (2010).

Barati, R. & Liang, J. T. A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J. Appl. Polym. Sci. https://doi.org/10.1002/app.40735 (2014).

Mao, J. et al. Viscosity reduction mechanism in high temperature of a Gemini viscoelastic surfactant (VES) fracturing fluid and effect of counter-ion salt (KCl) on its heat resistance. J. Pet. Sci. Eng. 164, 189–195. https://doi.org/10.1016/j.petrol.2018.01.052 (2018).

Elgaddafi, R., Ahmed, R. & Growcock, F. Settling behavior of particles in fiber-containing Herschel Bulkley fluid. Powder Technol. 301, 782–793. https://doi.org/10.1016/j.powtec.2016.07.006 (2016).

Wang, Z., Wang, S., Jing, Z. & Luo, X. Viscoelastic drag of particles settling in wormlike micellar solutions of varying surfactant concentration. J. Dispers. Sci. Technol. 37(3), 442–449. https://doi.org/10.1080/01932691.2015.1045597 (2016).

Yan, Z., Dai, C., Zhao, M., Sun, Y. & Zhao, G. Development, formation mechanism and performance evaluation of a reusable viscoelastic surfactant fracturing fluid. J. Ind. Eng. Chem. 37, 115–122. https://doi.org/10.1016/j.jiec.2016.03.012 (2016).

Wu, H. et al. SiO2 nanoparticle-assisted low-concentration viscoelastic cationic surfactant fracturing fluid. J. Mol. Liq. 266, 864–869. https://doi.org/10.1016/j.molliq.2018.06.107 (2018).

Dai, C. et al. The study of a novel nanoparticle-enhanced wormlike micellar system. Nanoscale Res. Lett. 12(1), 431–431. https://doi.org/10.1186/s11671-017-2198-2 (2017).

Zhao, M. et al. Can more vanoparticles induce larger viscosities of nanoparticle-enhanced wormlike micellar system (NEWMS)?. Materials 10(9), 1096. https://doi.org/10.3390/ma10091096 (2017).

Zhang, Y. et al. Rheological properties and formation dynamic filtration damage evaluation of a novel nanoparticle-enhanced VES fracturing system constructed with wormlike micelles. Colloids Surf. A Physicochem. Eng. Aspects https://doi.org/10.1016/j.colsurfa.2018.05.065 (2018).

Liu, S., Wang, X., Chen, L., Hou, L. & Zhou, T. Aggregation morphologies of a series of heterogemini surfactants with a hydroxyl head group in aqueous solution. Soft Matter 10(45), 9177–9186. https://doi.org/10.1039/C4SM01524J (2014).

Fogang, L. T., Sultan, A. S. & Kamal, M. S. Understanding viscosity reduction of a long-tail sulfobetaine viscoelastic surfactant by organic compounds. RSC Adv. 8(8), 4455–4463. https://doi.org/10.1039/C7RA12538K (2018).

Khan, M. Chemical and physical architecture of macromolecular gels for fracturing fluid applications in the oil and gas industry; Current status, challenges, and prospects. Gels 10(5), 338 (2024).

Yang, S., Zhan, Q., Pan, Y., Wang, X. & Narimane, B. Research progress on low-temperature rheology of high-performance ocean deepwater drilling fluids: An overview. J. Pet. Sci. Eng. 1(218), 110978 (2022).

Patil, P. & Kalgaonkar, R. Performance enhancements in metal-crosslinked fracturing fluid. In Paper SPE 152040 presented at the North Africa Technical Conference and Exhibition, Cairo, Egypt 20–22 (2012).

Jiang, Q. et al. A new high-temperature shear-tolerant supramolecular viscoelastic fracturing fluid. In IADC/SPE Asia Pacific Drilling Technology Conference. (Society of Petroleum Engineers, 2016) https://doi.org/10.2118/180595-MS.

Carman, P. & Gupta, D. S. Extreme simplicity: novel high-temperature fracturing fluid functions without a fuss. In SPE Hydraulic Fracturing Technology Conference (2011).

Prakash, C., Achalpurkar, M. P. & Uppuluri, R. Performance evaluation of high Temperature fracturing fluid. In Abu Dhabi International Petroleum Exhibition and Conference D041S071R005 (SPE, 2014).

Zhao, J. et al. High Performance clean fracturing fluid using a new Tri-Cationic surfactant. Polymers 10(5), 535–535. https://doi.org/10.3390/polym10050535 (2018).

Zhang, C. et al. Mechanism analysis of enhancing the temperature and shear resistance of hydroxypropyl guar gum fracturing fluid by boron-functionalized nanosilica colloidal crosslinker. Colloids Surf. A Physicochem. Eng. Aspects 676, 132154 (2023).

Chen, M. et al. Shale formation damage during fracturing fluid imbibition and flowback process considering adsorbed methane. Energies 15(23), 9176 (2022).

Chen, M. et al. Evaluation of aqueous phase trapping in shale gas reservoirs based on analytic hierarchy process. Energy Fuels 35(2), 1389–1397 (2021).

Zhang, J., Zhu, D. & Hill, A. D. Water-induced damage to propped-fracture conductivity in shale formations. SPE Prod. Oper. 31(02), 147–156 (2016).

Awejori, G. A. & Radonjic, M. Review of geochemical and geo-mechanical impact of clay-fluid interactions relevant to hydraulic fracturing. In Emerging Technologies in Hydraulic Fracturing and Gas Flow Modelling (IntechOpen, 2021).

Fu, L. et al. Preparation and inhibition mechanism of bis-quaternary ammonium salt as shale inhibitor used in shale hydrocarbon production. J. Mol. Liq. 309, 113244 (2020).

Gómez-Mascaraque, L. G., Méndez, J. A., Fernández-Gutiérrez, M., Vázquez, B. & San Román, J. Oxidized dextrins as alternative crosslinking agents for polysaccharides: application to hydrogels of agarose–chitosan. Acta Biomater. 10(2), 798–811 (2014).

Goddard, E. D. Polymer-surfactant interaction: Part I. Uncharged water-soluble polymers and charged surfactants. In Interactions of Surfactants with Polymers and Proteins 123–202 (CRC Press, 2018).

Al-Muntasheri, G. A. A critical review of hydraulic-fracturing fluids for moderate-to ultralow-permeability formations over the last decade. SPE Prod. Oper. 29(04), 243–260 (2014).

Xia, S. et al. Application of polysaccharide biopolymer in petroleum recovery. Polymers 12(9), 1860 (2020).

Chatterji, J. & Borchardt, J. K. Applications of water-soluble polymers in the oil field. J. Pet. Technol. 33(11), 2042–2056 (1981).

Liang, F. Hydraulic fracturing stimulation. In Fluid Chemistry Drilling and Completion 421–465 (Gulf Professional Publishing, 2022).

Madni, A. et al. Preparation and applications of guar gum composites in biomedical, pharmaceutical, food, and cosmetics industries. Curr. Nanosci. 17(3), 365–379 (2021).

Acknowledgements

Thanks to reviewers and editors for their careful review of this manuscript.

Funding

This research was funded by National Key Laboratory Open Fund for Mechanisms of Shale Oil and Gas Enrichment and Effective Exploitation—The collapse and instability mechanisms of shale oil reservoirs under drilling fluid circulation conditions (35800000-22-ZC0609-0018).

Author information

Authors and Affiliations

Contributions

Huimei Wu and Xiaopeng Zhai: writing—original draft, and writing—review and editing, conceptualization. Yinyan Li and Jian Li: project administration, resources. Zhonghui Li: visualization, methodology, investigation. Wentie Sun: formal analysis, data curation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wu, H., Zhai, X., Li, Y. et al. Modified guanidine gel fracturing fluid system and performance optimization for ultra-deep and ultra-high temperature oil and gas reservoirs. Sci Rep 14, 20764 (2024). https://doi.org/10.1038/s41598-024-70976-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-70976-5