Abstract

In order to ensure the filling integrity of complex counter-gravity casting and improve metallurgical quality, it is necessary to shorten the filling time while avoiding air entrainments. To address this contradiction, a novel nonlinear pressurization method was proposed in this study. Through systematically analyzing the relationship between critical gating velocity and stable filling height, a criterion for iterative calculation of nonlinear pressurization curve was established, and an empirical expression between nonlinear pressurizing speed and the filling height was obtained. Based on the empirical expression, a nonlinear pressurization curve can be designed according to the casting structures and initial pressurizing speeds. The above nonlinear pressure curve design method was validated through water filling experiments. It was proved that the nonlinear pressure curve can shorten the filling time while avoiding air entrainments. It provides important processing control method for improving the low-pressure casting performance of complex castings.

Similar content being viewed by others

Introduction

Counter-gravity casting (CGC) has been widely applied in the production of high-precision light-weight alloy castings with the advantages in smooth filling process and excellent feeding capacity. And the advantages are attributed to the characteristics of bottom-up filling of liquid metal. The diagram of CGC equipment structure is shown in Fig. 1a. Numerous studies have shown that a primary cause of failure in lightweight alloy castings is the formation of double oxide films. This phenomenon occurs due to turbulence at the surface of the liquid metal when the gating velocity exceeds a critical value. Fox et al.1 used reduced pressure test for revealing the presence of double oxide film defects, and predicting the potential for the formation of hydrogen porosity in aluminum alloy castings. Oxide film defects were also found in tilt pouring of TiAl casting and the entrained oxide films act as heterogeneous nucleation sites, contributing to the formation of shrinkage2. In order to prevent the formation of the oxide defects, Afsharpour et al.3 used water modelling to study the influents of gating systems on oxide defects. It has been proved that the mechanical properties of aluminum and magnesium alloy castings can be improved by controlling the gating velocity through low-pressure casting4,5. Campbell et al.6 proposed that the critical gating velocity for aluminum alloys is ~ 0.5 m/s based on theoretical analysis. Bahreinian7 demonstrated that the critical gating velocity of aluminum alloys is 0.5 m/s, through experimental observation of the filling processes of an open space controlled by bottom gating system. Therefore, the gating velocity should be strictly controlled.

As the filling processes of CGC can be controlled by gas pressurization parameters, CGC has been regarded as the most promising method to eliminate double oxide film defects6. However, poor mechanical properties castings are occasionally obtained in practice when applying CGC process to some complex structure components. Liu et al. has conducted studies on the filling behaviors of expansion structures in CGC8,9. It has been demonstrated that the gating velocity of CGC is influenced not only by pressurization parameters but also by changes in the cross-sectional areas of the castings. During the spreading stage of filling a sudden expansion structure, the gating velocity increases rapidly with varying accelerations as the melt flows across the sudden expansion section. This occurs even at relatively low pressurization speeds, due to the growing pressure difference between the gas pressure in the crucible and the hydraulic head of the melt in the mold. The entrainment of oxide film occurs during the filling processes of CGC when the increased gating velocity exceeds the critical value, particularly if the pressurization speed is not properly controlled.

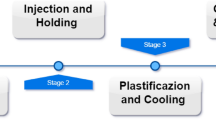

Filling process plays a crucial role in defects control. The casting parameters such as pouring temperature10 and melt treatments11,12 can influent the filling behaviors of melt. The filling processes of CGC are controlled by the pressurization curves. Typically, the pressurization curve of CGC includes stages such as rising liquid, filling, pressure boosting, and pressure holding. During each stage, the pressurization speed is maintained as a constant value, as shown in Fig. 1b. It is called the linear pressurization method. However, this kind of pressurization method cannot avoid filling turbulence at the cross-sectional area mutation of castings. It can be attributed to that the critical gating velocity is often treated as a constant previously, and the effect of mold cavity structure mutation on gating velocity is less considered. The critical gating velocity may also increase as the liquid metal level in the mold rises, due to the increased static pressure head on the inlet flow. Hence, the pressurization speed should be increased following the passage of the liquid metal front through the cross-sectional mutation area, resulting in a nonlinear pressurization curve rather than a traditional linear one. Moreover, it is helpful to minimize filling time, ensuring the filling integrity of large thin-walled castings.

In order to achieve the design strategy of the nonlinear pressurization curve mentioned above, the filling behaviors of different ratios of cross-section area under different gating velocities should be analyzed. Recently, a large number of researches have been conducted to optimize CGC processes based on simulation and coupled experiments. Luo et al.13 summarized the advances in casting simulation and the concept of Integrated Computational Materials Engineering (ICME) for CGC casting applications. Fu et al.14 and Zhang et al.15 studied the effects of low-pressure casting process parameters on the mechanical properties, microstructure and residual stress of castings with simulation and experiments. Kuo et al.16 developed an interactive computer simulation system to aid the determination of the pressure–time relationship during the filling of a low-pressure casting to eliminate filling-related defects while maintaining its productivity. Liu et al.17 studied the effects of hollow sand mold on the microstructure and mechanical properties of a low-pressure casting through experiments. Dong et al.18 optimized the pressure holding time and cooling processes of low-pressure die casting process of wheel hub with simulation and experimental coupling methods. Moreover, machine learning-based design strategy has been proposed for the gating system design of CGC19. However, the effects of castings structures on the filling processes have been less studied.

This study introduced a critical gating velocity model that is associated with the height of liquid metal level. It presented an empirical equation for designing nonlinear pressurization curves, and thoroughly discussed the relationship between the parameters of these curves and the cross-sectional area ratios. An iterative algorithm based on critical gating velocity was employed to obtain a non-linear pressurization curve.

Simulation and experimental methods

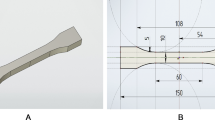

Simulation of the filling processes by FLUENT

The flow field of filling processes of different structures were analyzed by FLUENT software using the Volume of Fluid (VOF) model. The VOF model in Fluent software is a surface tracking technique applied to fixed Eulerian grids. The VOF model is used for two or more immiscible fluids, with the interface position between the fluids being of interest. In the VOF model, the fluids share a set of momentum equations and track the volume fraction of each fluid in each computational cell throughout the domain. The VOF model can be applied to: stratified flow, free surface flow, filling, sloshing, motion of large air bubbles in liquid, movement of liquids after dam breaches, prediction of jet breakup, and steady or transient tracking of any liquid–gas interface. The typical cross-sectional mutation structure of the casting is extracted as shown in Fig. 2. Table 1 provides a description of the specific size parameters and simulation parameters.

The numerical model of filling processes

A numerical model of filling processes was established for obtaining the filling data at each time step, such as gating velocity, liquid metal height, pressurizing speed, and getting the typic nonlinear pressurization curve through the iteration of pressurizing speed. The cross-sectional mutation structure used for numerical calculation was same as FLUENT simulation.

When the cross-sectional variation of the casting is not considered, the filling process of CGC shows dynamic attenuation oscillation. According to the Bernoulli equation20, this motion state can be expressed as

where Vf represents the average speed at which the metal liquid level in the riser rises, VF represents the average speed at which the metal liquid level in the crucible decreases, y represents the height at which the metal liquid rises in the riser, and H0 represents the depth below which the riser is inserted into the crucible, t represents the filling time, Af represents the cross-sectional area of the riser, AF represents the cross-sectional area of the crucible, ξ represents the coefficient of local head loss, g represents gravitational acceleration, P(t) represents the pressure as a function of filling time.

The filling process of CGC with sudden expansion section can be divided into spreading stage and filling stage distinguished by the gating velocity as dramatically increasing and keep constant, respectively10. The spreading stage can be described as

where λ represents the coefficient of head loss along the way, d represents the diameter of the riser, L represents the total length of the riser, θ indicates the contact angle of melt and riser.

The filling stage can be expressed as

where hf represents local resistance loss, h represents the highest height that the metal liquid can maintain under surface tension, Ac represents the cross-sectional area of the mold cavity.

The CGC filling experiments

Water filling experiments were conducted using the model shown in Fig. 3a to verify the design of nonlinear pressurization process. The experimental setup can be seen in Fig. 3b. The computer was responsible for setting up the initial pressure process. The flow state during the filling process was captured using a high-speed camera at a recording rate of 10 frames per second. By modifying the pressurization process using an adjustable flowmeter, it is feasible to regulate the flow characteristics of the gating velocity.

Results and discussion

The relationship between critical gating velocity and filling height

Figure 4 shows the simulation results of the filling processes of mutation structures with different cross-sectional area ratios. The filling processes of mutation structures can be divided into two stages, the spreading stage and the filling stage, as shown in Fig. 4a. Air entrainment was observed when the liquid metal just entered the large cross-sectional area. It can be attributed to the gating velocity exceeding the critical velocity of 0.5 m/s according to the theory proposed by Campbell et al.11. When the gating velocity was 0.5 m/s, no air entrainment appeared during the melt entering the large cross-sectional area as shown in Fig. 4b. Therefore, when the large cross-sectional area was empty, it is necessary to control the gating velocity below 0.5 m/s in order to achieve smooth filling during the spreading stage. However, if the gating velocity was too large, the air entrainment would continuously occur during the filling stage. Based on the simulation results, a stable filling height was observed for a specific ratio of cross-sectional area change and gating velocity. Beyond this threshold, the melt flow transitioned into a sustained filling state.

The filling processes of mutation structures with different cross-sectional area ratios. (a) The filling processes of mutation structure with cross-sectional area ratio 1:100 under the gating velocity of 1 m/s, (b) The filling processes of mutation structure with cross-sectional area ratio 1:100 under the gating velocity of 0.5 m/s, (c) The stable filling height of structures with different area ratios at gating velocity of 1 m/s.

The stable filling height was not only dependent on the gating velocity, but also on the cross-sectional area ratios, as suggested by Fig. 4c. At a gating velocity of 1 m/s, the stable filling height exhibited an increasing trend with the cross-sectional area ratio until reaching its maximum value, after which it remained constant. The underlying mechanism can be explained as shown in Fig. 5.

When the liquid metal entered an open cavity, the liquid front presented as the green lines in Fig. 5, and the open cavity can be divided into three sections. The sections I, II and III from Fig. 5 were determined based on the direction of the velocity vector in the simulation results. Sections I and II were melt, and section III was air. The velocity vector directions of sections I were mainly upward. The velocity vector directions of sections II were mainly downward. In section I, the liquid metal exhibited an upward velocity field. The metals in section II showed a spreading trend, and the cavity of section III would be filled in the following spreading and filling stages. As the shape of section I and II was determined by gating velocity, the diameter of large section would affect the stable filling height. As shown in Fig. 5, the large section walls of Area ratio 1 and Area ratio 2 both intersected with section I, and the stable filling heights of these ratios were determined by the intersection point of walls and section I. For these small area ratios, the filling processes only contained spreading stage, and the stable filling heights increased with the cross-sectional area ratio. The stable filling height would be affected by the diameters of the large section until the cross-sectional area exceeded section II, seen Area ratio 3 shown in Fig. 5. So, the stable filling height was related to the area of large section when the area ratio was small, and the filling processes of these structures can be treated as transition states of riser tube, which has no cross-sectional area changes. Then the stable filling height would become into a constant when the area ratio was larger than a critical value at which the cross-section area getting into the section III determined by the gating velocity.

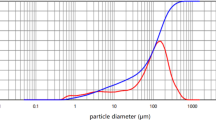

Due to the frequently substantial cross-section area ratio leading to the attainment of section III, the stable filling height would be determined solely by gating velocity. The stable filling height at different gating velocities were summarized in Fig. 6, according to simulation results. It is interesting that a continuous model could be introduced to well fit the data, as shown in Fig. 6. The model is

where A1 and A2 are constant, and x0 is a parameter with unite of speed.

The design of nonlinear pressurization curve

The iterative calculation of nonlinear pressurizing speed

In order to get the basic rules of designing nonlinear pressurization curve, the relationship between pressurizing speed and the filling height was analyzed based on the typic mutation structures (as shown in Fig. 2). The calculation processes were illustrated in Fig. 7. Table 2 listed the parameters used in the calculation. Equation (4) was used as the criterion of stable filling and the filling data was calculated through Eqs. (1–3). The results can be seen in Fig. 8.

As the pressurizing speed of each time step was obtained through iterative calculation, the pressure curve was essentially piecewise linear, as shown in Fig. 8a. The pressurizing speed should be reduced to ~ 500 Pa/s for eliminating the air entrainments during spreading stage10. In the filling stage, the pressurizing speed can be gradually increased. As shown in Fig. 8b, the calculated results of filling height as a function of time showed that the filling processes was smooth and no severe fluctuations appeared. The relationship between pressurizing speed and filling height of expansion section was fitted as shown in Fig. 8c. It indicated that the pressurizing speed can be represented as a function of filling height of the expansion section (seen Eq. 5), and this expression can be used as an empirical equation to design new nonlinear pressurization curves for castings, for avoiding the iterative calculation processes mentioned above, and simplifying the design of pressurization curves.

where dP/dt was the pressurizing speed, He was the filling height of the expansion section. There were three parameters in this expression, P0, a and b, which were determined by the structure of cavity and initial pressurizing speed. It has been proved that x0 has little effect on the shape of the pressurization curve, so b was defined as a constant 1.39.

The nonlinear pressurization curves suitable for different area ratios and initial pressurizing speeds have been deduced based on the empirical expression Eq. (5), and the corresponding nonlinear pressurizing speed parameters have been listed in Table 3. The nonlinear pressurization curves can be designed based on the area ratios and initial pressurizing speeds according to Table 3. Due to the discreteness of the data in Table 3, the nonlinear pressurization parameters for the cross-sectional area ratio and initial pressurization speed that are not explicitly provided in Table 3 can be estimated using an interpolation method.

The influence of castings height on the nonlinear parameters

The typic nonlinear pressurization curve can be seen in Fig. 9. As mentioned above, the line of theoretical stable filling height based on calculated gating velocity cannot perfectly match with that of the actual filling height, seen Fig. 9a. The line of theoretical stable filling height showed two peaks after finishing the spreading stage, seen Peak 1 and Peak 2 marked in the Fig. 9a. Such peaks of stable filling height line can be attributed to the fluctuation of gating velocity shown in Fig. 9b. The pressurization curve in Fig. 9b was suitable for the castings with a height less than 1.2 m, as Peak 2 exceeded the actual filling height. The air entrainments may appear in the filling process beyond 1.2 m, and the corresponding pressurizing speed should be further reduced. Therefore, the heights of castings should also be considered during the design of nonlinear pressurization curves.

The Water filling processes of linear and nonlinear pressurization methods

To verify the effectiveness of nonlinear pressurization, water filling experiments were conducted. According to the diameters of cavity used in water filling experiments, three pressurization curves were designed as shown in Fig. 10a. Curve 1 and Curve 2 presented the traditional linear pressurization curves. The pressurizing speeds of Curve 1 and Curve 2 were 10 kPa/s and 13 kPa/s, respectively. Curve 3 was a nonlinear pressurization curve, which was designed based on the strategy proposed above. The filling processes of these curves can be seen in Fig. 10b–d.

From the perspective of Fig. 10b, Curve 1 can avoid air entrainments due to its low pressurizing speed, and the gating velocity was controlled below the critical velocity. However, the liquid flow front was almost horizontal, indicating that a higher gating velocity can also induce stable filling. As shown in Fig. 10c, the pressurizing speed of 13 kPa/s caused the gating velocity exceeding the critical velocity, and air entrainments obviously appeared during the spreading stage and initial period of the filling stage. At the final period of the filling stage, air entrainments stopped and the flow front presented a swelling, indicating that a larger gating velocity may still cause air entrainments. The ridge appeared on the flow front at 4.6 s of pressurization curve 3, and increasing the pressurizing speed of pressurization curve 3 may make the ridge growing larger. Large ridge would cause air entrainments when the raised liquid flow front falling back. It can be inferred that the pressurization curve 3 may be the pressurization curve with the fastest pressurizing speed for smooth filling. Pressurization curves with faster pressurizing speed would cause air entrainments. When the filling process was controlled using the nonlinear pressurization curve, air entrainments was eliminated and the flow front kept swelling during the whole filling process, seen Fig. 10d. It proved that nonlinear pressurization curve was helpful to avoid air entrainments and minimize the filling time.

Conclusions

Nonlinear pressurization process and its design method for counter-gravity casting was proposed in this study, based on systematically analyses of the filling process of cross-sectional mutation structures. The main conclusions were summarized as follows.

-

(1)

It was proved by the FLUENT simulations that the critical gating velocity increased with the filling height due to the increasing of static pressure head, and the critical gating velocity for stable filling was influenced by the cross-sectional area ratio. The criterion function of stable filling height was deducted as \(H_{{{\text{stable}}}} { = 1}{\text{.78315}} - 1.88369/\left[ {1 + \left( {\frac{{V_{gate} }}{1.20782}} \right)^{6.42379} } \right]\) according to the simulation results.

-

(2)

The empirical expression between pressurizing speed and filling height was given as \(P = P_{0} + a\left( {H_{e} } \right)^{1.39}\) through iterative calculation based on the criterion function of stable filling height. According to this expression, new nonlinear pressurization curves for different structures and initial pressurizing speeds can be designed.

-

(3)

The method for nonlinear pressurization curves designing was proved through water filling experiments. Nonlinear pressurization can ensure smooth filling with the shortest possible filling time. It was meaningful to guarantee the filling integrity of complex thin-walled casting.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Abbreviations

- A c :

-

The cross-sectional area of the mold cavity

- A f :

-

The cross-sectional area of the riser

- A F :

-

The cross-sectional area of the crucible

- d :

-

The diameter of the riser

- dP/dt :

-

The pressurizing speed

- g :

-

Gravitational acceleration

- h f :

-

Local resistance loss

- h :

-

The highest height that the metal liquid can maintain under surface tension

- H 0 :

-

The depth below which the riser is inserted into the crucible

- H e :

-

The filling height of the expansion section

- L :

-

The total length of the riser

- P(t):

-

The pressure as a function of filling time

- t :

-

The filling time

- V f :

-

The average speed at which the metal liquid level in the riser rises

- V F :

-

The average speed at which the metal liquid level in the crucible decreases

- V gate :

-

The gating velocity

- y :

-

The height at which the metal liquid rises in the riser

- ξ :

-

The coefficient of local head loss

- λ :

-

The coefficient of head loss along the way

- θ :

-

The contact angle of melt and riser

References

Fox, S. & Campbell, J. Visualization of oxide film defects during solidification of aluminum alloys. Scr. Mater. 43, 881–886. https://doi.org/10.1016/S1359-6462(00)00506-6 (2000).

Mi, J., Harding, R. A., Wickins, M. & Campbell, J. Entrained oxide films in TiAl castings. Intermetallics 11, 377–385. https://doi.org/10.1016/S0966-9795(03)00006-2 (2003).

Afsharpour, M., Homayun, B. & Boutorabi, S. M. A. Water modelling of effects of pouring basin and sprue geometry on entrance of air bubbles into mould. Mater. Sci. Technol. 30, 152–159. https://doi.org/10.1179/1743284713Y.0000000335 (2014).

Cais, J., Weiss, V. & Svobodová, J. Microstructure and mechanical properties of products of alloy al+3%mg made by low-pressure casting. Metallurgist 60, 99–102. https://doi.org/10.1007/s11015-016-0258-y (2016).

Jiang, W., Fan, Z., Liao, D., Dong, X. & Zhao, Z. A new shell casting process based on expendable pattern with vacuum and low-pressure casting for aluminum and magnesium alloys. Int. J. Adv. Manuf. Technol. 51, 25–34. https://doi.org/10.1007/s00170-010-2596-4 (2010).

Campbell, J. Castings 2nd edn. (Elsevier, 2003).

Bahreinian, F., Boutorabi, S. M. A. & Campbell, J. Critical gate velocity for magnesium casting alloy (ZK51A). Int. J. Cast Metals Res. (Online) 19, 45–51. https://doi.org/10.1179/136404606225023264 (2006).

Liu, S. et al. Characteristics of mold filling and entrainment of oxide film in low pressure casting of A356 alloy. Mater. Sci. Eng.: A 626, 159–164. https://doi.org/10.1016/j.msea.2014.12.058 (2015).

Liu, S. et al. Effect of pressurizing speed on fi lling behavior of gradual expansion structure in low pressure casting of ZL205A alloy. China Foundry 15, 276–282. https://doi.org/10.1007/s41230-018-8044-z (2018).

Kim, B. H., Shin, J. S., Lee, S. M. & Moon, B. M. Improvement of tensile strength and corrosion resistance of high-silicon cast irons by optimizing casting process parameters. J. Mater. Sci. 42, 109–117. https://doi.org/10.1007/s10853-006-1081-9 (2007).

Wang, L. & Shivkumar, S. Strontium modification of aluminium alloy castings in the expendable pattern casting process. J. Mater. Sci. 30, 1584–1594. https://doi.org/10.1007/BF00375269 (1995).

Samuel, A. M. & Samuel, F. H. Various aspects involved in the production of low-hydrogen aluminium castings. J. Mater. Sci. 27, 6533–6563. https://doi.org/10.1007/BF01165936 (1992).

Luo, A. A., Sachdev, A. K. & Apelian, D. Alloy development and process innovations for light metals casting. J. Mater. Process Technol. 306, 117606. https://doi.org/10.1016/j.jmatprotec.2022.117606 (2022).

Fu, P. et al. Low-pressure die casting of magnesium alloy AM50: Response to process parameters. J. Mater. Process. Technol. 205, 224–234. https://doi.org/10.1016/j.jmatprotec.2007.11.111 (2008).

Zhang, Z. et al. Optimization of residual stress in low-pressure casting of ZL205A alloys. J. Manuf. Process. 99, 338–350. https://doi.org/10.1016/j.jmapro.2023.05.040 (2023).

Kuo, J., Hsu, F. & Hwang, W. Development of an interactive simulation system for the determination of the pressure time relationship during the filling in a low pressure casting process. Sci. Technol. Adv. Mater. 2, 131–145. https://doi.org/10.1016/S1468-6996(01)00039-0 (2001).

Liu, B., Kang, J., Yang, X., Zhang, B. & Bian, Y. Effects of hollow sand mold on the microstructure and mechanical properties of a low pressure aluminum alloy casting. J. Mater. Res. Technol. 28, 4488–4497. https://doi.org/10.1016/j.jmrt.2023.12.270 (2024).

Dong, G. et al. Process optimization of A356 aluminum alloy wheel hub fabricated by low-pressure die casting with simulation and experimental coupling methods. J. Mater. Res. Technol. 24, 3118–3132. https://doi.org/10.1016/j.jmrt.2023.03.214 (2023).

Duan, Z., Chen, W., Pei, X., Hou, H. & Zhao, Y. A multimodal data-driven design of low pressure die casting gating system for aluminum alloy cabin. J. Mater. Res. Technol. 27, 2723–2736. https://doi.org/10.1016/j.jmrt.2023.10.076 (2023).

Pas, C. T. et al. Understanding the dynamics of fluid–structure interaction with an Air Deflected Microfluidic Chip (ADMC). Sci. Rep. 12(1), 20399 (2022).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Granted No. 51827801, No. 52105349), National Key Lab Funding (Granted No. 6142909220102), Foundation of National Key Laboratory for Precision Hot Processing of Metals (Granted No. DCQQ2790100724).

Author information

Authors and Affiliations

Contributions

Z.A.Q. performed the simulations, analysed and interpreted the data, writed and revised the manuscript. C.J.Z. helped the data collection, writed and revised the manuscript. L.Y.Z. provided the physical simulation method. X.Y.Z. writed and revised the manuscript, provided valuable comments in the design of the study. FY.C. helped revised this manuscript. H.X.S. helped the data analysising. L.L. analysed and interpreted the data. ZS.J. helped the simulations. HQ.S. revised all the figures. J.F.S. suporvised the manuscript. All authors read and approved the fnal manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Qiu, Z., Zhang, C., Zhang, L. et al. A novel nonlinear pressurization method for counter-gravity casting of cross-sectional mutation structures. Sci Rep 14, 20470 (2024). https://doi.org/10.1038/s41598-024-71572-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-71572-3