Abstract

Calcium-nitrate-based transparent completion fluids are widely used in the oil and gas industry for well completion and stimulation operations in carbonate reservoirs. These fluids have many advantages, such as medium density, low corrosion, good temperature stability, low clay swelling, and high wettability. However, the density of calcium nitrate brine is limited by its solubility, which can be increased by the addition of alcohols. This study investigated the effects of adding different types of alcohols (G1, G2, and G3) to calcium nitrate brine on the properties and performance of the completion fluid for carbonate reservoirs. The fluid properties and performance were evaluated through a series of laboratory tests, including density measurement, corrosion test, viscosity measurement, rheology test, temperature stability test, clay swelling test, wettability test, and compatibility test. The results showed that the addition of alcohols to brine can improve or reduce the fluid density, viscosity, corrosion, temperature stability, clay swelling, wettability, and compatibility, depending on the type and amount of alcohols. The optimum fluids have been selected based on their highest density, lowest viscosity, lowest corrosion, highest temperature stability, lowest clay swelling, highest wettability change, and highest compatibility with formation fluids. The densities of the fluids CN4, CNG14, CNG24, and CNG34 were respectively 96, 101, 101.5, and 100 pounds per cubic foot (pcf). Their rates of corrosion on L80 steel were respectively 0.829, 0.589, 0.720, and 0.599 mils per year (mpy). Their apparent viscosities at 62.4 °F were respectively around 15, 120, 100, and 60 centipoise (cp). Their apparent viscosities at 176 °F were all around 10 to 25 mpy. The fluids remained clear with no evidence of suspended solid particles at 20 °F, indicating their resilience to low-temperature conditions and suitability for use in cold weather operations. The fluid CNG24 becomes cloudy at 285 °F, and the fluid CNG34 becomes cloudy from 212 °F onward, but the CN4 fluid remains clear and transparent at all temperatures. In the tested high temperatures, the effect on their pH was around the same. The fluids CN4, CNG24, and CNG34 had a lower swelling index than 5 ml per 2 g of bentonite clay. The contact angles of oil and carbonate-type thin sections after their wettabilities were affected by the fluids were also 99.5, 36.54, and 46.03°, respectively. Finally, they’re all relatively compatible with formation fluids. The best completion fluid for carbonate reservoirs was CNG24, which contained calcium nitrate and G2 alcohol. This fluid had the best overall performance and safety of the fluids tested.

Similar content being viewed by others

Introduction

The oil and gas industry is a vital source of energy for the world, but it also faces many challenges in exploring and developing hydrocarbon reservoirs with extreme conditions. These reservoirs have high temperature and pressure and low permeability, which require special techniques and equipment for well completion and production. One of the essential aspects of well completion is the selection of completion fluid, which is a liquid that replaces the drilling mud and creates a balance in the well1,2. The American Petroleum Institute defines completion fluid as a particle-free liquid used in the final stages of oil and gas well development3. After completing the drilling operation, the completion fluid replaces the drilling mud using a series of fluids known as spacer fluid to minimize pollution, and it creates hydrostatic pressure to balance or overbalance the well and facilitate the operation for equipment installation in-well and well completion4. Packer fluid remains in the annular space during the well production time, reduces the pressure difference between the packer, casing, and tubing, and prevents collapse in the well5. Completion fluids are used for different treatments, such as wellbore cleaning, well stimulation, well control (including establishing pressure balance in the annular space of the well), installing gravel pack, drilling-in, and perforation. The initial cost of preparing completion fluid is relatively high, but the obtained functions by completion fluids are very important and can be compensated by the overall cost6,7. Two categories of well completion fluids exist: traditional completion fluids and clear completion fluids without solid particles. Traditional completion fluids resemble drilling mud and use several additives such as barite, hematite, calcium carbonate, sodium chloride, magnesium tetraoxide, etc. to increase fluid density7. These solid particles, such as barite and hematite, will result in settling-assisted-gravity (SAG) and cause the pipes to get stuck, change the density of the completion fluid, disturb the balance in the well control, and result in formation damage when they increase the weight of the completion fluids under high temperature and pressure conditions8,9. Another problem that sag causes is that during production, the settled solid materials may be produced along with oil and gas and damage the well equipment by erosion. The completion fluids without solid and transparent particles are salt-based and do not damage the formation due to suspended solid particles10,11,12.

The first use of clear completion fluids dates back to 1950. At that time, clear completion fluids that could meet the necessary expectations in high temperature and pressure conditions were scarce. A fluid that could provide all the conditions mentioned was very costly and had a limited availability in the market13,14. The salts used to make clear completion fluid include: bromides, chlorides, nitrates, phosphates, formates. The most common formate salts are cesium formate and potassium formate. Cesium formate weighs 2.42 g per cubic centimeter and potassium formate weighs 1.59 g per cubic centimeter. They first appeared in 1990 in the Gulfaks field in Norway. Potassium formate is highly corrosive and cesium is a radioactive element and poses a threat to the environment. Cesium formate is reused after each well application due to its high price15,16. The most common salts based on bromides are magnesium bromide with a weight of 1.61 g per cubic centimeter, calcium bromide with a weight of 1.7 g per cubic centimeter, and zinc bromide with a weight of 2.3 g per cubic centimeter. These fluids have a limited use due to their high corrosion and high cost. However, calcium bromide salt is combined with other brines to lower the corrosion potential5,11,17,18. The main salts based on nitrates are sodium nitrate, potassium nitrate and calcium nitrate. Among these fluids, calcium nitrate has the highest solubility in water at a temperature of 77 °F19. Calcium nitrate salt also serves as anti-corrosion in calcium chloride and calcium bromide fluids20. Nitrate brine was introduced in 2016 and demonstrated that nitrate-based brines enhance the porosity and permeability of the formation13.

In 1989, Krilov et al. performed a pioneering research in the Argillos gas reservoirs in the Adriatic Sea, introducing ammonium nitrate fluid combined with methanol as a promising alternative to chloride salt-based fluids. This innovative approach provided stability to clay formations, a critical factor in reservoir management. By conducting a series of fluidization tests and SEM (Scanning Electron Microscope) imaging, they compared the performance of ammonium nitrate and methanol-based fluids to chloride-based counterparts such as sodium chloride, calcium chloride, and potassium chloride. Their findings showed that nitrate fluids caused significantly less formation damage than chloride fluids. Moreover, they established a noteworthy correlation between pH levels and the extent of permeability alterations due to flooding, revealing that higher pH values were associated with increased permeability damage21. In 2016, Sangka et al. conducted a noteworthy study on nitrate fluids, unveiling their multifaceted utility. Their research highlighted the cognitive effects of nitrate fluids, demonstrating their capacity to stimulate the core and enhance permeability. Furthermore, nitrate fluids emerged as potent anti-corrosion agents when confronted with chloride-based saltwater environments. Notably, these versatile nitrate fluids found practical application as completion fluids in regions such as South Sumatra and Riau, yielding significant boosts in oil and gas production, sometimes up to 20-fold13. In 2017, Belova et al. performed a comprehensive study investigating the phase equilibrium diagram of calcium nitrate and zinc nitrate. Their research explored the intricate interplay between these two substances, culminating in the establishment of a detailed phase diagram. Furthermore, Belova et al. meticulously examined the density and pH characteristics of these fluids across a temperature spectrum spanning − 4 °F, − 23 °F, and 50 °F22. In 2018, Dong et al. performed a comprehensive investigation into the corrosive effects of calcium chloride and calcium bromide fluids. Their study yielded a noteworthy breakthrough as they introduced a solution consisting of 10% by weight of calcium nitrate as a highly effective anti-corrosion additive for these fluids20. In 2020, Tariq et al. conducted a series of experiments on polyoxyethylene quaternary ammonium gemini surfactants in completion fluids as clay swelling additives to mitigate the formation damage in unconventional tight sandstone reservoirs enriched with high clay content. In their coreflood experiment it was revealed that the surfactant solution caused nearly no permeability reduction9.

The purpose of this article is to provide a comprehensive review of calcium nitrate-based transparent completion fluids in the oil and gas sector. The primary focus includes an analysis of three different alcohols used to increase the density of calcium nitrate. This is followed by a detailed examination of the effects and influences of these alcohols on fluid properties. This article attempts to advance completion fluid technology by presenting a novel formulation based on calcium nitrate and alcohols. This innovative blend aims to achieve optimum properties and exceptional density, all achieved through the artful fusion of alcohols and calcium nitrate, thereby advancing the field of fluid technology in the oil and gas industry. The experiments performed on completion fluids in this study include density while adhering to the ISO standard23, corrosion while adhering to the API RP13 standard24, temperature stability, clay swelling25, Wettability alteration and fluid compatibility.

Materials

Brine

In this study, four distinct brines were prepared in this study: a pure calcium nitrate brine (CN) and three mixed brines incorporating calcium nitrate with alcohols G1, G2, and G3. The method entailed creating a supersaturated solution of calcium nitrate at high temperatures, followed by the addition of alcohols in varying percentages as detailed in Table 1. The determination of alcohol concentrations was guided by an experimental design to achieve fluids with optimal stability and density, aligning with the objectives of the investigation. The rationale for employing various concentrations in density measurements stems from the distinct physicochemical properties of the alcohols when combined with calcium nitrate. The molecular structure of each alcohol influences its interaction with calcium nitrate, thereby affecting the density of the resulting brine. Through experimental design focused on the concentration of alcohol and calcium nitrate salt, optimal ratios were determined that produced a fluid with enhanced stability and high density, suitable for the intended applications.

Alcohols

In this research, three alcohols G1, G2, and G3 were utilized. G1 alcohol is clear, colorless, odorless, and soluble in water at any ratio. G2 alcohol is a viscous liquid, colorless, odorless, sweet, and has low toxicity. G3 alcohol is a sugar alcohol typically encountered as a white crystalline powder. Table 2 presents various chemical properties of the alcohols.

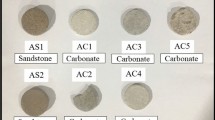

Thin sections

To assess the wettability changes induced by the completion fluids, carbonate and sandstone thin sections of 0.08 inch thickness were prepared, as shown in Fig. 1.

Corrosion coupons

Samples of steel made from L80 alloys have been used for the assessment of corrosion.

Formation fluid

In this study, formation water, crude oil, and condensate from an oil and gas field in southern Iran were collected and prepared for experiments. The formation water, crude oil, and condensate samples were collected from different wells in the field and transferred to the laboratory under controlled conditions. The samples were then filtered, stabilized, and stored in appropriate containers until further analysis. The ionic constituents of the formation, water, crude oil, and condensate, were determined using standard methods and instruments such as ion chromatography, gas chromatography, and mass spectrometry. The results are presented in Tables 3, 4, and 5, respectively.

Methods

Density

To control the oil and gas flow after drilling a well, completion fluids are used. These fluids create hydrostatic pressure with their density value and control the well’s production. The hydrostatic pressure also enables the installation of the equipment and the completion of the well. The completion fluid density is influenced by various factors, such as the salt concentration, the salt type, the pressure, and the temperature1. The density varies inversely with the temperature but directly with the pressure. The fluid density increases with the pressure in the well but decreases with the temperature in the well26. The temperature has a larger impact on the density than the pressure. The completion fluid density declines when it faces high temperature conditions at the well. The required density of completion fluid for each well can be determined by Eq. (1)6.

ρ: Brine Density on surface (lb/gal), Pr: Reservoir Pressure (psi), ∆P: Over Balance Pressure (psi), TVD: True Vertical Depth (ft).

The average well temperature affects the completion fluid density and needs a correction. Equation (2) expresses this correction6.

\({\uprho }_{\text{t}}\): Adjusted Brine Density, \({\uprho }_{70}\): Brine Density at the API Reference Temperature of 70 °F (degree Farenheit), \(\overline{{\text{T}}}\): Average Wellbore Temperature (°F), α: Expansion Coefficient in (vol/vol/°F).

An International Organization for Standardization (ISO) standard pycnometer with a volume of 25 cc was used to measure the completion fluid density27. The pycnometer was weighed before and after it was filled with the completion fluid. The weight difference was divided by the pycnometer volume to obtain the fluid density1. The density of completion fluids at different temperatures was also measured to examine the temperature effect on the fluid density.

Corrosion

Corrosion The downhole equipment can be corroded by high temperatures, and the presence of CO2 and H2S gas. The packer fluid should also protect the pipes in the well from corrosion28. Brine has cations such as calcium, zinc, and sometimes magnesium that can cause corrosion due to dissolved oxygen, entrained air, or acidity from metal ion hydrolysis29. Calcium nitrate is usually added as an anti-corrosion agent to these salts20. The acceptable corrosion rate of workover fluid is less than 0.5 mil per year and that of packer fluid is less than 1 mil per year, while the maximum corrosion rate of workover fluid is 1 mil per year and that of packer fluid is 5 mil per year. The corrosion rate tends to increase with temperature. Corrosion can damage the downhole equipment and the formation if corrosive fluids enter the formation and produce insoluble corrosion products30. The completion fluids should not be corrosive to the equipment and should be compatible with it. In this section, a corrosion test was performed for three completion fluids at 300 °F according to the API RP13 standard. The reason this experiment was performed at this temperature aside from it being mentioned in the standard is to investigate the corrosion caused by the completion fluid in high temperature wells. According to the definition of a high temperature well, these tests were performed at this temperature31.The test used the weight loss of L80 steel to measure the corrosion rate of fluids after 72 h using Eq. (3)24.

W = Weight Loss (gr), D = Copoun Density (gr/cm3), A = Sample Area (in2), T = Test Time (days).

Viscosity

The completion fluid viscosity affects the frictional pressure drop due to the fluid flow inside the well and pipes. The pressure drop in the production pipe and wall pipe increases with the fluid viscosity. This requires the pump to pump the fluid into the well with a high pressure, which can damage the pump. The fluid viscosity decreases with increasing temperature, as the intermolecular forces decrease with increasing temperature. However, the fluid viscosity increases slightly with increasing pressure. The pressure effect on the fluid viscosity is weaker than the temperature effect32. In this study, the Brookfield DV-II + Pro device was used to measure the viscosity and rheological properties of fluids. The shear stress versus shear rate, and viscosity versus spindle rotation speed graphs were obtained at two distinct temperatures: 77 °F, representing ambient conditions, and 176 °F, to simulate the elevated temperatures typically encountered within well environments. This range was specifically chosen to investigate the changes in fluid viscosity that occur from standard ambient conditions to the higher temperatures found in geothermal gradients, providing a comprehensive analysis of fluid behavior under varying thermal conditions.

Temperature stability

The solubility of salts in water usually varies with temperature. As the temperature increases, the salts dissolve more, and as the temperature decreases, the salts precipitate more. The true crystallization temperature (TCT) is the temperature at which the brine solution becomes fully saturated with the least soluble salt in it. The brine crystallization condition is very important in the deep water environment, as it can cause severe damage to the well by increasing the pressure and decreasing the temperature. When the fluid is used in the well, its density parameters and pH value cannot be controlled at the surface. These parameters for the completion fluid must be stable under high temperature conditions (300 °F) and low temperature conditions (20 °F). Otherwise, it can lead to uncontrolled reservoir pressure, formation damage, and even a well blowout. The reason for performing the test at 300 °F is to analyze the fluid’s behaviour in high temperature wells. According to the definition of a high temperature well, these tests were performed at this temperature31. When using the completion fluid in different environments, the fluid with a TCT lower than the environmental temperature is chosen. In field conditions, brine with a TCT between 15 and 20 °F is usually used. In this experiment, according to the API RP 13J standard, the fluid TCT was measured inside an ice bath24. Then, for high temperature stability, 100-cc samples of fluids were separately exposed to temperatures of 105, 140, 175, 212, 250, and 285 °F for 24 h. The fluid density and pH were recorded at each stage of the experiment.

Formation damage

Formation damage can happen at any stage of drilling, completion, or stimulation of oil and gas wells. The fluids used for these operations may enter the formation and damage it33,34,35. Therefore, it is important to evaluate the formation damage mechanisms caused by completion fluids to prevent or reduce the formation damage12. The pH of the completion fluid should be between 7 and 9, as higher values can damage the sandstone reservoir’s structure8. In this section, the clay swelling mechanisms due to brines, the fluid effect on formation wettability, and the brine compatibility with formation fluids were investigated.

Clay swelling

The clay minerals in the reservoir structure can become unstable due to contact with the high-pH completion fluid. The high-pH completion fluid reacts quickly with clay particles and destabilizes clay minerals. These interactions depend on pH, fluid design, clay type, temperature, and rock acidity. The completion fluid should have a pH between 7 and 936,37,38. When the high-pH completion fluid and formation water mix, they can cause the precipitation of particles such as calcium carbonate and sodium chloride, which can block the reservoir pores and reduce permeability. The clay swelling test was performed according to the ASTM D5890 standard. In this test, 25 cc of each of the three fluids (CN4, CNG24, and CNG34) were poured into a graduated cylinder. 2 g of bentonite were added to each fluid at a rate of 0.1 g per 10 min. After 24 h, the volume changes caused by bentonite were measured25. According to the National Iranian Drilling Company (NIDC) standard, the bentonite volume changes due to the contact with the completion fluid should be less than 5 ml/2 g, as higher values can cause clogging of the reservoir and affect hydrocarbon production1.

Wettability alteration

Wettability is the tendency of a fluid to adhere to and spread on a solid surface. Generally, if the reservoir rock is oil-wet, it impedes the oil flow in the porous medium, and if the reservoir rock or the porous medium is water-wet, the oil flows easily in the porous medium and the residual oil is reduced1,39,40. In this experiment, thin-sections of carbonate and sandstone were first put in a solution of 0.01 M n-heptane and stearic acid at 150 °F for 72 h. After that, their contact angle and ability to stick to other things were measured. Then they were exposed to selected brines for 72 h at 150 °F, their contact angle was measured again, and the effect of brines on the wettability of thin-sections was evaluated. The reason for performing this test at the temperature of 150 °F instead of 300 °F is that performing these tests at a higher temperature gives a more favorable answer; And investigating the effect of completion fluid on formation damage in relatively lower temperature wells is also desired.

Fluid compatibility

The compatibility of the completion fluids with the formation fluids is a major issue in the field of formation damage due to the completion fluid. When the completion fluid penetrates the formation and mixes with the formation fluids, it can cause sedimentation and permeability reduction in the wellbore and formation damage if it is not compatible41,42. In this section, the three selected completion fluids were mixed with formation water, crude oil, and condensate in three ratios of 25:75, 50:50, and 75:25. The mixtures were placed in an oven at 150 °F for 72 h. The pH of the fluids before and after the oven exposure and the appearance properties of the fluids were evaluated in terms of suspended, settled sediments, water, and hydrocarbon emulsion formation. The reason for performing this test at the temperature of 150 °F instead of 300 °F is that performing these tests at a higher temperature gives a more favorable answer; And investigating the effect of completion fluid on formation damage in relatively lower temperature wells is also desired.

Results and discussion

Density

In this section, four types of fluids with varying densities were prepared: CN, CNG1, CNG2, and CNG3, as shown in Table 1.

The optimal fluids were chosen based on their highest density and stability. CN, CNG2, and CNG3 fluids satisfied this criterion. However, CNG1 fluid was more unstable than other alcohols. Therefore, this alcohol was not used for further tests. Table 1 shows that three fluids, CN4, CNG24, and CNG34, were selected as optimal fluids. Other fluids in Table 1 had either higher or lower densities. The fluids with a lower density than the optimal fluids were not selected, as the fluids with the highest density were of interest. The fluids with a higher density than the optimal fluids were also not selected, as they were unstable (sedimentation and gelation after 24 h, etc.).

The density of brine is also affected by the temperature. As the well temperature increases, the fluid unit volume slightly expands, and the brine density decreases. This density reduction must be controlled and calculated, as it may not provide enough pressure to balance the reservoir pressure. The well temperature is usually much higher than the surface temperature1. Therefore, the density changes with respect to temperature were also examined in this section (Fig. 2). Additionally, Fig. 3 will include a graph depicting the solubility of calcium nitrate in water at various temperatures. This illustration is critical for understanding the temperature-dependent changes in solubility and the behavior of these fluids under different thermal conditions.

The expansion coefficient was calculated from these tests using Eq. (2). The expansion coefficient is the change in fluid volume per unit of temperature in Fahrenheit. The expansion coefficient values of brines were obtained from the fluid density values at different temperatures and reported in Table 6.

Figure 2 shows that the brine density decreases from 140 °F onward as the temperature increases. Therefore, the density behavior with respect to temperature increases is similar for all brines. The expansion coefficient results also show that adding alcohol increases the expansion coefficient values. This means that the brine density changes more with respect to temperature when alcohols are added.

Corrosion

The completion fluid should have a pH between 7 and 9 to control corrosion and prevent clay swelling. The corrosion of fluids was evaluated by four tests with all four fluids at 300 °F. Table 7 shows the results of these tests.

The results indicate that CN4 fluid has a higher corrosion rate than CNG14, CNG24, and CNG34 fluids. This implies that adding alcohols reduces the corrosion in the CN4 completion fluid slightly. In addition, alcohols act as a disinfectant and antibacterial agent and can reduce the growth and proliferation of bacteria and fungi on different surfaces. This action can lead to the reduction of corrosion and corruption of surfaces and equipment. Therefore, the use of alcohols may be an effective method to reduce the corrosion rate in some industries and applied spaces. Figure 4 shows that the L80 steel parts did not change much in appearance after the test.

Viscosity

In this study, the viscosity and rheological properties of fluids were measured at two temperatures of 62.4 and 176 °F. Figure 5 shows the viscosity vs. spindle rotation speed graphs, which indicate that adding alcohols increases the fluid viscosity. CNG14 fluid had the highest viscosity and was rejected as a completion fluid as it had a high apparent viscosity (about 120 cp) at 62.4 °F. Figure 6 shows the shear stress vs. shear rate graphs of fluids at 62.4 °F. These graphs show that all fluids had a Newtonian behavior similar to water at this temperature, despite the increased viscosity due to alcohols.

The viscosity and rheological properties of fluids were also evaluated at 176 °F. Figure 7 shows the viscosity vs spindle rotation speed graphs at this temperature. The graphs show that the brine viscosity decreased as the temperature increased from 62.4 to 176 °F, but CNG24 and CNG34 fluids still had higher viscosities than CN4 at 176 °F.

Figure 8 presents the shear stress versus shear rate graphs for fluids at 176 °F. The R-squared values for each graph exceed 80%, indicating a high level of accuracy. This data corroborates the conclusion that three of the fluids demonstrate Newtonian behavior. The consistent slope of the CN4 fluid curve, relative to the other two fluids, aligns with expectations due to the lack of alcohol in its composition. The inclusion of alcohol in the remaining fluids explains the variance in their rheological behavior. Generally, the addition of alcohols to brine increases both density and viscosity, which in turn elevates the pressure drop resulting from fluid friction.

Temperature stability

The temperature stability of the completion fluid is important for its performance in different environments. The fluid’s density and pH changes at high and low temperatures can serve as indicators of its temperature stability. Figure 2 shows the density changes of the fluids with respect to temperature. As explained in the density section, the density of the fluids decreases with increasing temperature due to the expansion of the fluid volume. Figure 9 shows the pH changes of the fluids with respect to temperature, and Fig. 10 shows the images of the fluids after exposure to different temperatures. Figure 9 shows that CN4 fluid has a higher rate of pH reduction with increasing temperature than CNG24 and CNG34 fluids. This means that CN4 fluid becomes more acidic at high temperatures. Figure 10 shows that CNG24 fluid becomes cloudy at 285 °F and CNG34 fluid becomes cloudy from 212 °F onward. This indicates that adding alcohols to CN4 fluid reduces its transparency at high temperatures. However, the CN4 fluid remains clear and transparent at all temperatures.

The low-temperature stability tests for the fluids were conducted with consideration of the well temperatures typically encountered in cold climate regions. These regions often experience temperatures that can induce crystallization in completion fluids, adversely affecting their properties, such as density. To simulate these conditions, the fluids were subjected to a controlled environment at temperatures below 20 °F. This temperature threshold was selected based on the potential for crystal formation, which could significantly reduce fluid density and compromise the fluid’s performance. The results, as detailed in Table 8, demonstrate that the fluids maintained stability, did not crystallize, and preserved their fluidity when placed in an ice bath at 20 °F. Post-testing, the fluids remained clear with no evidence of suspended solid particles, indicating their resilience to low-temperature conditions and suitability for use in cold weather operations.

Formation damage

Clay swelling

The clay swelling caused by the selected fluids was evaluated to measure the formation damage due to the completion fluid. The results show that adding alcohols to calcium nitrate fluid reduces clay swelling due to the fluid contact. Figure 11 shows that CNG24 and CNG34 fluids, which contain G2 and G3 alcohols, have lower clay swelling than CN4 fluid. The clay swelling of all three fluids is below the National Iranian Drilling Company (NIDC) standard, which means that they do not cause significant formation damage.

Wettability alteration

In this section, the wettability of carbonate and sandstone thin sections was evaluated after exposure to selected fluids. The thin sections were first made oil-wet by using a drop of kerosene and then exposed to brine. Figure 12 shows the images of thin sections after becoming oil-wet (before exposure to brine). Figure 12 shows that the three selected thin sections for CN4, CNG24, and CNG34 fluids had contact angles of 149.7, 145.2, and 147.6° with the thin section surface, respectively. This indicates that the kerosene drop was attached to the thin section surface, and the thin section was oil-wet.

After becoming oil-wet, the thin sections were exposed to fluids at 150 °F for 72 h. Figure 13 shows the images of thin sections after becoming water-wet by CN4, CNG24, and CNG34 fluids. Figure 13 shows that CN4, CNG24, and CNG34 fluids had contact angles of 99.5, 36.54, and 46.03° with the thin section surface, respectively. This indicates that the kerosene drop was detached from the thin section surface compared to the previous state, and the thin section was water-wet. Figure 13 also shows that fluids containing alcohol (CNG24 and CNG34) caused more wettability changes from oil-wet to water-wet than CN4 fluid. Therefore, these fluids are a suitable option for use in carbonate and sandstone reservoirs in terms of wettability.

Fluid compatibility

This section examines the compatibility of the selected brines with formation water, crude oil, and condensate. The compatibility tests are carried out by mixing the brines with the formation fluids in different proportions and observing the changes in pH and appearance after 72 h. The brines used in this study are CN4, CNG24, and CNG34, based on calcium nitrate and various alcohols. The results of the compatibility tests are shown in Figs. 14, 15, and 16 and Table 9.

Figure 14 shows the compatibility of CN4 fluid with formation water before and after the test. It can be seen that there is no significant change in the appearance of the fluids after mixing. The pH values of the fluids are also similar before and after the test, except for the AUT-CFF-N95-3 mixture, which shows a decrease of 1.4 units in pH. This indicates that the CN4 fluid is compatible with the formation water and does not cause precipitation or corrosion.

Figure 15 shows the compatibility of CNG24 fluid with formation water before and after the test. It can be seen that there is a noticeable change in the appearance of the fluids after mixing. The fluids become more transparent and less turbid after 72 h. This is because CNG24 fluid contains G2 alcohol, which is a good solvent for dissolving and removing the sediments present in the formation water. The pH of the fluids also decreases after mixing, which can facilitate the dissolution of sediments.

Figure 16 shows the compatibility of CNG34 fluid with formation water before and after the test. It can be seen that there is no noticeable change in the appearance or pH of the fluids after mixing. This indicates that CNG34 fluid is compatible with formation water and does not cause precipitation or corrosion.

The results of this section demonstrate that calcium nitrate-based brines are compatible with formation water and can be used as clear completion fluids without causing damage to the formation. The effects of these brines on crude oil and condensate are discussed in the next section.

The compatibility of nitrate-based fluids with formation fluids (crude oil and condensate) was evaluated by mixing them in various proportions and observing their appearance and stability. Figures 17 and 18 show photographs of the mixed fluids after heating in an oven at 150 °F for 72 h. Table 10 summarizes the results of the compatibility tests.

According to Figs. 17 and 18, CN4 and CNG24 fluids were completely transparent and compatible after mixing with gas condensate and oil, and no emulsion was observed. The appearance of the fluids did not change after being placed in the oven, indicating that they were thermally stable. However, the CNG34 fluid changed color after mixing with gas condensate and oil, and the final fluid became slightly cloudy. The cloudiness of the fluid indicates that the CNG34 fluid is not highly compatible with gas condensate or oil and may form precipitates or emulsions under reservoir conditions. In general, CNG34 fluid showed poor compatibility with hydrocarbon fluids, whereas CN4 and CNG24 fluids showed excellent compatibility with hydrocarbon fluids.

The compatibility of nitrate-based fluids with formation fluids is an important factor in their successful use in well stimulation. Incompatible fluids can damage the formation or reduce the effectiveness of the treatment by blocking flow paths or reducing permeability. It is therefore recommended that CN4 or CNG24 fluids be used for stimulation of gas condensate or oil wells, as they have been shown to be compatible and stable with these types of formation fluids. On the other hand, CNG34 fluid should be avoided or used with caution as it can have a negative effect on reservoir performance.

Conclusion

-

1.

This study investigated the effects of adding different types of alcohols to calcium nitrate brine on the properties and performance of the completion fluid for carbonate and sandstone reservoirs.

-

2.

The results showed that adding alcohols to the brine can improve or reduce fluid density, viscosity, corrosion, temperature stability, clay swelling, wettability and compatibility, depending on the type and amount of alcohol added.

-

3.

The optimum fluids were selected based on the highest density, lowest viscosity, lowest corrosion, highest temperature stability, lowest clay swelling, highest change in wettability and highest compatibility with formation fluids.

-

4.

The optimum fluids were CN4, CNG24 and CNG34 for density; CNG24 and CNG34 for viscosity; CNG14, CNG24 and CNG34 for corrosion; CNG24 and CNG34 for temperature stability; CNG24 and CNG34 for clay swelling; CNG24 and CNG34 for wettability; and CN4 and CNG24 for compatibility. Therefore, the best completion fluid for reservoirs was CNG24 containing calcium nitrate and G2 alcohol.

-

5.

The densities of the fluids CN4, CNG14, CNG24, and CNG34 are respectively 96, 101, 101.5, and 100 pounds per cubic foot (pcf).

-

6.

Their rates of corrosion on L80 steel are respectively 0.829, 0.589, 0.720, and 0.599 mils per year (mpy).

-

7.

Their apparent viscosities at 62.4 °F are respectively around 15, 120, 100, and 60 centipoise (cp). Their apparent viscosities at 176 °F are all around 10 to 25 mpy.

-

8.

The fluids remained clear with no evidence of suspended solid particles at 20 °F, indicating their resilience to low-temperature conditions and suitability for use in cold weather operations. The fluid CNG24 becomes cloudy at 285 °F, and the fluid CNG34 becomes cloudy from 212 °F onward, but the CN4 fluid remains clear and transparent at all temperatures. In the tested high temperatures, the effect on their pH was around the same.

-

9.

The fluids CN4, CNG24, and CNG34 have a lower swelling index than 5 ml per 2 g of bentonite clay.

-

10.

The contact angles of oil and carbonate-type thin sections after their wettabilities were affected by the fluids were also 99.5, 36.54, and 46.03°, respectively.

-

11.

Last but not least, they’re all relatively compatible with formation fluids.

-

12.

CNG24 had the best overall performance and safety of the fluids tested. The results of this study can provide useful information and guidance for the selection and design of completion fluids for carbonate and sandstone reservoirs.

Data availability

All data generated or analysed during this study are included in this published article.

Abbreviations

- CN:

-

Water based completion fluid made using water and calcium nitrate salt

- CNG1:

-

Water based completion fluid made using water, calcium nitrate salt and g1 alcohol

- CNG2:

-

Water based completion fluid made using water, calcium nitrate salt and g2 alcohol

- CNG3:

-

Water based completion fluid made using water, calcium nitrate salt and g3 alcohol

- NIDC:

-

National Iranian drilling company

- °F:

-

Degree Farenheit

- mpy:

-

Mils per year

- W:

-

Weight loss (g)

- D:

-

Copoun density (g/cm3)

- A:

-

Sample area (in2)

- T:

-

Test time (days)

- TCT:

-

True crystallization temperature

- G1:

-

An alcohol which is clear, colorless, odorless, and soluble in water at any ratio

- G2:

-

A viscous liquid, colorless, odorless and sweet alcohol with low toxicity.

- G3:

-

A sugar alcohol typically encountered as a white crystalline powder.

- ρ:

-

Brine density on surface (lb/gal)

- Pr:

-

Reservoir pressure (psi)

- ∆P:

-

Over balance pressure (psi)

- TVD:

-

True vertical depth (ft)

- ρt :

-

Adjusted brine density

- ρ70 :

-

Brine density at the api reference temperature of 70°F

- T:

-

Average wellbore temperature (°F)

- α:

-

Expansion coefficient in (vol/vol/°F)

- ISO:

-

International organization for standardization

References

Kalatehno, J. M. & Khamehchi, E. A novel packer fluid for completing HP/HT oil and gas wells. J. Pet. Sci. Eng. 203, 108538 (2021).

Jia, H., Niu, C.-C. & Hu, Y.-X. The potential study of ultra-high density heteropolysate solid free brine as well completion fluid for deep reservoir development. J. Nat. Gas Sci. Eng. 84, 103638 (2020).

Singh, R., Sharma, R. & Rao, G. R. (eds.) A deep sea completion fluid technology-novel high density brine-based completion fluid for applications in high pressure and high temperature petroleum reservoirs. In OCEANS 2022-Chennai (IEEE, 2022).

Wang, Q. Fluid Chemistry, Drilling and Completion (Gulf Professional Publishing, 2021).

Singh, R., Sharma, R. & Rao, G. R. Magnesium bromide as novel high-density packer fluid in oilfield applications. J. Energy Resour. Technol. 145(3), 033501 (2023).

Bellarby, J. Well Completion Design (Elsevier, 2009).

Hassan, A. et al. Interactions of drilling and completion fluids during drilling and completion operations. Dev. Pet. Sci. 78, 41–74 (2023).

Khan, R. A. et al. Ionic liquids as completion fluids to mitigate formation damage. J. Pet. Sci. Eng. 214, 110564 (2022).

Tariq, Z. et al. Polyoxyethylene quaternary ammonium gemini surfactants as a completion fluid additive to mitigate formation damage. SPE Drill. Complet. 35(04), 696–706 (2020).

Jia, H., Hu, Y. X., Zhao, S. J. & Zhao, J. Z. The feasibility for potassium-based phosphate brines to serve as high-density solid-free well-completion fluids in high-temperature/high-pressure formations. SPE J. 24(05), 2033–2046 (2019).

Jia, H., Niu, C.-C. & Dai, C.-L. Solid-free flexible colloidal completion fluid with variable density for gas well completion in high-temperature and high-pressure reservoirs: Experimental study and pilot test. SPE J. 27(01), 186–203 (2022).

Zhao, X. et al. Formation damage mechanisms associated with drilling and completion fluids for deepwater reservoirs. J. Pet. Sci. Eng. 173, 112–121 (2019).

Sangka, N. B. & Budiman, H. (eds.) Application of nitrate based fluid as a completion fluid. In Abu Dhabi International Petroleum Exhibition and Conference (SPE, 2016).

Singh, R., Sharma, R. & Rao, G. R. Development of a novel high density completion fluid with CuO nanoparticle as promising additive to improve the rheological properties. Results Eng. 15, 100520 (2022).

Bungert, D. et al. (eds.) The evolution and application of formate brines in high-temperature/high-pressure operations. In SPE/IADC Drilling Conference and Exhibition (SPE, 2002).

Saasen, A. et al. (eds.) Drilling HT/HP wells using a cesium formate based drilling fluid. In SPE/IADC Drilling Conference and Exhibition (SPE, 2002).

Singh, R., Sharma, R. & Rao, G. R. Aging effects on the rheological properties of novel magnesium bromide hexahydrate-based completion fluids for oil and gas reservoirs. Arab. J. Sci. Eng. 47(9), 11929–11939 (2022).

Liu, Y. et al. Corrosion mechanism of 13Cr stainless steel in completion fluid of high temperature and high concentration bromine salt. Appl. Surf. Sci. 314, 768–776 (2014).

Laue, W., Thiemann, M., Scheibler, E. & Wiegand, K. W. Nitrates and nitrites. In Ullmann’s Encyclopedia of Industrial Chemistry (2000).

Dong, S. et al. Steel corrosion inhibition by calcium nitrate in halide-enriched completion fluid environments. NPJ Mater. Degrad. 2(1), 32 (2018).

Krilov, Z. et al. (eds.) Low-pH ammonium nitrate-methanol completion fluid: A promising alternative for calcareous, Argillaceous sand formations. In SPE International Conference on Oilfield Chemistry? (SPE, 1989).

Belova, E. V., Brusinski, N. A., Mamontov, M. N. & Uspenskaya, I. A. A zinc nitrate–calcium nitrate–water system: The solubility of solids and the density of liquids in a wide range of temperatures. J. Chem. Eng. Data 62(4), 1544–1549 (2017).

ISO I. 13503-1. Petroleum and natural gas industries-completion fluids and materials-Part 1. In Measurement of Viscous Properties of Completion Fluids (2011).

API. Testing of Heavy Brines-Recommended Practice RP 13J (American Petroleum Institute, 2014).

ASTM D. Standard Test Method for Swell Index of Clay Mineral Component of Geosynthetic Clay Liners, 5890–06 (American Society for Testing and Materials, 2006).

Jinhua, H. et al. Preparation, characterization and application of environment-friendly high density and low damage solid free completion fluids for completing HTHP oil and gas wells. Geoenergy Sci. Eng. 221, 211351 (2023).

ISO. Petroleum and Natural Gas Industries-Completion Fluids and Materials-Part 3: Testing of Heavy Brines (2006).

Xu, P., Tao, Z. & Wang, Z. Corrosion-resistant systems of formate packer fluid for G3/N80/TP110SS pipes at high temperature, high pressure and high H2S/CO2 ratios. R. Soc. Open Sci. 5(7), 180405 (2018).

Brondel, D. et al. Corrosion in the oil industry. Oilfield Rev. 6, 2 (1994).

Manual, W. C. Drilling Department Petronas Carigali SDN BHD (1998).

Shadravan, A. & Amani, M. (eds.) HPHT 101-what every engineer or geoscientist should know about high pressure high temperature wells. In SPE Kuwait International Petroleum Conference and Exhibition (SPE, 2012).

Cengel, Y. & Cimbala, J. Ebook: Fluid Mechanics Fundamentals and Applications (SI Units) (McGraw Hill, 2013).

Civan, F. Reservoir Formation Damage (Gulf Professional Publishing, 2015).

Dargi, M., Khamehchi, E. & Mahdavi, K. J. Optimizing acidizing design and effectiveness assessment with machine learning for predicting post-acidizing permeability. Sci. Rep. 13(1), 11851 (2023).

Mahdavi Kalatehno, J., Khamehchi, E., Abbasi, A. & Khaleghi, M. R. A novel approach to determining appropriate additive concentrations for stimulation of gas carbonate reservoirs. Results Eng. 20, 101440 (2023).

Hamzaoui, B. & Moajil, A. M. (eds.) Scaling and completion fluid pH effect on sandstone formation damage. In SPE/IADC Middle East Drilling Technology Conference and Exhibition (SPE, 2018).

Hamzaoui, B. et al. (eds.) Causes and mitigation of completion fluids-induced formation damage in high temperature gas wells. In SPE International Conference and Exhibition on Formation Damage Control (OnePetro, 2018).

Hamzaoui, B. et al. (eds) Completion Fluids-Induced Formation Damage in High Temperature Gas Wells: Causes and Mitigation (Offshore Technology Conference, 2018).

Ahmed, T. Petroleum Engineering Handbook (Gulf Professional Publishing, 2006).

Yousefmarzi, F., Haratian, A., Mahdavi Kalatehno, J. & Keihani, K. M. Machine learning approaches for estimating interfacial tension between oil/gas and oil/water systems: A performance analysis. Sci. Rep. 14(1), 858 (2024).

Montgomery, D. C. Design and Analysis of Experiments (Wiley, 2017).

Keihani Kamal, M., Mahdavi Kalatehno, J., Daneshfar, P. & Yousefmarzi, F. A comprehensive analysis of carbonate matrix acidizing using viscoelastic diverting acid system in a gas field. Sci. Rep. 14(1), 1499 (2024).

Acknowledgements

This work has been supported by the Center for International Scientific Studies & Collaborations (CISSC), Ministry of Science Research and Technology of Iran.

Author information

Authors and Affiliations

Contributions

R.E., E.K., P.K.H. and J.M.K. contributed equally to writing the article. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ebadi, R., Khamehchi, E., Kazemihokmabad, P. et al. A novel formulation of an eco-friendly calcium nitrate-based heavy completion fluid. Sci Rep 14, 21256 (2024). https://doi.org/10.1038/s41598-024-72277-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-72277-3

Keywords

This article is cited by

-

Experimental study on property enhancement of potassium Brines with alcohol additives for well completion applications

Scientific Reports (2025)

-

A successful case study of using HCl and viscoelastic diverting acid systems for carbonate matrix acidizing in an oil well with optimized predictive model

Journal of Petroleum Exploration and Production Technology (2025)