Abstract

Urine leakage volume is an important indicator reflecting the severity of incontinence in patients. Currently, there are limited smart diapers capable of continuous dynamic monitoring of urine volume. This study developed two types of urine volume sensors, resistive and capacitive, which were integrated with traditional diapers to assess urine leakage levels: mild leakage (0–5 mL), moderate leakage (6–12 mL), and severe leakage (above 12 mL). Three patterns of resistive urine volume sensors were designed, and the results showed that the A pattern could accurately determine urine volume and frequency levels. Additionally, three electrode spacing designs were tested for the capacitive urine volume sensors. The results indicated that the sensor with a 1 cm electrode spacing could determine the urine volume range, with each 1 mL increase in urine causing a capacitance rise of approximately 1.5–1.8 pF, with an error of about ± 0.5 mL per increment. Both resistive and capacitive methods showed high accuracy in monitoring urine volume and frequency. This study validated the feasibility of smart flexible fabric sensors in detecting urine volume and frequency, providing a potential solution for better assessing and managing the condition of incontinence patients.

Similar content being viewed by others

Introduction

Urinary incontinence refers to a condition where an individual is unable to control the release of urine, leading to accidental leakage1,2. Population-based studies have shown that urinary incontinence is more common in women than in men, with approximately 10% of adult women experiencing this condition3,4. Urinary incontinence can result in social isolation, depression, anxiety, and other psychological issues for patients, severely affecting their daily lives and work. As age increases, the elasticity of the body’s muscles declines, particularly the pelvic floor muscles, reducing the ability to control urine. This is especially true for individuals over the age of 55, where the prevalence of urinary incontinence significantly rises. In the current medical context, the study of urinary incontinence is of great importance5,6,7. A deeper understanding of the mechanisms and influencing factors of urinary incontinence helps in formulating more precise treatment and rehabilitation strategies, thereby improving the quality of life for patients8,9,10,11. The volume and frequency of leakage are critical indicators reflecting the severity of urinary incontinence; the greater the leakage volume and frequency, the more severe the condition.

With the continuous advancement of medical technology, smart textiles are gradually transforming our approach to healthcare. These smart textiles are more comfortable and easier to wear, effectively enhancing user applicability and comfort. Smart textiles provide new solutions for care, primarily including smart diapers12, smart pads13, incontinence pads14, underwear15, and mattresses16. These textiles are equipped with various sensors, such as humidity sensors that can monitor urine moisture in real-time. Through wireless data transmission, these smart textiles can provide instant urine monitoring data, making them widely applicable in the care of infants, incontinence patients, and long-term bedridden patients. In this revolutionary era, smart diapers, as an effective assistant for urinary incontinence patients and caregivers, are bringing convenience and comfort to daily life with their unique smart technology and user-friendly design12.

In recent years most of the researchers have investigated different preparation process moisture sensing and continuously proved out the feasibility of moisture sensing for urine output monitoring. Meltem Tekcin et al.17 used office inkjet printers to fabricate moisture sensors by printing conductive PEDOT: PSS polymer inks on polyamide-based taffeta label fabrics, and dropping adult diapers with 0.1–100 mL of saline to simulate incontinence detection. The results showed that the resistance of the sensor varied with the amount of water. Ngo et al.18 designed a wireless incontinence sensor system using flexible screen-printed Interdigital Electrodes (IDE) sensors and biocompatible electrically conductive PEDOT: PSS material, combined with a battery, a sensor signal-reading device, and a wireless module. The capacitive method is more reliable in detecting urine volume than the conventional resistive sensors for urinary incontinence. However, it is known from ink printing analysis that prolonged exposure to urine will lead to dissolution of some of the ink, which may be harmful to the human body. Parkova et al.19,20 prepared two types of fabrics, single electrode sensors and dual electrode sensors, using a computerized embroidery machine to improve the comfort of the urine loss alarm system using a cotton fabric as the base and a polyamide silver-plated yarn as the embroidery yarn. Liang et al.21 proposed that self-stretching BC/CNT (BCT) helical fibers with excellent mechanical properties were prepared by solution spinning and winding processes using bacterial cellulose (BC) as a water-sensitive matrix and carbon nanotubes (CNT) as the sensing material. Due to the design with helical structure, smart diapers with fast response were prepared by combining the fibers with diapers and weighing scales (weighing wires). However, for the existing conductive yarn prepared sensing, did not complete the continuous urine frequency monitoring, can only remind the leakage of urine, the main use scenario is used to remind infants and young children to change diapers, and did not form the incontinence patients leakage frequency and leakage of urine monitoring function.

This study proposes two types of wearable flexible fabric urine volume sensors based on different measurement principles to address the issues of light urine leakage volume and urination frequency monitoring in patients with various types of incontinence. Compared to previous research, it has been found that most studies are limited to laboratory tests without real-life on-body experiments or tests conducted by medical personnel specializing in pelvic diseases. These studies often lack accuracy in urination frequency detection and do not provide techniques for evaluating urine leakage volume. The current smart diapers available on the market primarily function to alert for diaper saturation or bowel movements and do not cater to incontinence patients with pelvic diseases. Many adult women suffer from incontinence, and when medical personnel inquire about their urination frequency and volume, most patients find it challenging to provide accurate information due to a lack of understanding or embarrassment about their condition. This significantly complicates the medical staff’s ability to assess and diagnose the severity of the incontinence. Through this study, we designed a highly sensitive interdigital flexible sensing circuit that demonstrated high accuracy in monitoring urine leakage volume and urination frequency using resistive humidity sensors. These sensors can accurately determine the range of urine leakage volume and frequency and have undergone corresponding on-body tests. The flexible capacitive sensors showed better accuracy in urine volume monitoring compared to the resistive sensors. However, because the capacitive sensors are significantly affected by external pressure, ongoing research is focused on mitigating these effects during on-body experiments. The planar studies on flexible capacitive sensors provide a foundation for subsequent on-body monitoring research. This technology for monitoring urine volume and frequency is characterized by ease of use and high accuracy, offering a more convenient and discreet treatment option for incontinence patients. It also provides clinicians with more precise and comprehensive data for disease assessment and treatment planning. Additionally, this technology has broad applications in medical research, sports training, and other fields, supporting the advancement of related domains.

Experimental materials and equipment

Experimental materials

The conductive materials chosen for the functional electrodes are silver-plated yarn with a fineness of 31.8 tex and a resistivity of 1.68 × 10−5 Ω m, and graphene yarn with a resistivity of 2.5 × 10−3 Ω m. The silver-plated conductive yarn consists of 18% silver and 82% nylon (manufacturers: Shenzhen Guolongfei Trading Co., Ltd.; Zhejiang Riffon Nano Biotechnology Co., Ltd.), with the basic mechanical properties shown in Table 1. The electrode substrate materials are non-woven fabric I (polypropylene (PP) spunlace non-woven fabric; 25 g/m2; Zhengzhou Yuli New Material Technology Co., Ltd.) and non-woven fabric II (polypropylene (PP) meltblown non-woven fabric; 20 g/m2; Zhengzhou Yuli New Material Technology Co., Ltd.). The capacitive electrodes use silver-plated conductive fabric (composition: silver fiber; density: 100 g/m2; manufacturer: Jinan Yumo Technology Co., Ltd.), and the base material is woven fabric made of raw cotton (composition: ultra-high molecular weight polyethylene fiber; manufacturer: Dongguan Sovet Special Thread Co., Ltd.). The adhesive spray used is from 3 M China Co., Ltd.

The conductive liquid used in the experiments was artificial urine with a pH of 6.5 (manufactured by Dongguan Chuang feng Automation Technology Co, Ltd). The liquid carrier was selected as Jie hu jia adult diapers (Beijing Bei shute Maternal and Child Supplies Co, Ltd), specifically designed for urinary incontinence patients, featuring an inner core with larger capacity and faster absorption rate.

Experimental equipment

Brother Automatic Embroidery and Sewing Machine NV180 (Brother (China) Commercial Co, Ltd): This machine allows the independent design of patterns on design software and automatic embroidery. The electrode pattern design software used was PE-DESIGN 10.

Data Acquisition Module with nRF52832 Chip (Nordic Company): This module serves as the main control chip for data collection.

LCR Meter (Model: IM3533-01, Manufacturer: HIOKI Corporation, Japan): Used for collecting capacitance data.

Multimeter (Model: VC89A, Manufacturer: Victor (Sheng li) Corporation): Utilized for checking if the freshly embroidered sensors are short-circuited.

Sensor design and fabrication

Sensor structure design

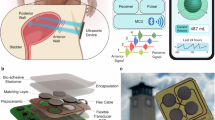

For the design of the resistive sensor, a serpentine electrode array was formed on hydrophilic non-woven fabric using silver-plated conductive yarn through sewing techniques. The sensor layer was tightly adhered to the surface of the diaper using adhesive spray, encapsulating it to integrate leakage detection and diaper functionality into a smart diaper. Diapers generally consist of four parts: the surface layer, flow guide layer, absorbent core layer, and bottom layer22,23,24,25. In this study, the urine volume sensor was embedded between the surface layer and the flow guide layer of the diaper. This configuration is shown in Fig. 1.

To measure urine leakage and frequency using the capacitive method, the sensor needs to be combined with the diaper selected for this study for performance testing. The design for measuring urine volume and leakage frequency using the capacitive method involves placing the sensor layer at the bottom layer of the diaper to receive capacitive data. The functions and materials of each layer are similar to those of the resistive smart diaper. As shown in Fig. 1.

Electrode pattern design and fabrication

Design and fabrication of resistive sensor

In this study, silver-plated yarn was chosen as the conductive material, and hydrophilic non-woven fabric and hydrophobic non-woven fabric were used as the substrate and insulating materials, respectively, to fabricate the sensor. Considering the standard dimensions of diapers commonly used by patients and comfort requirements, specific size limitations were applied in the research, with the diaper size set at 7 cm × 24 cm. Therefore, the overall dimensions of the electrode pattern were limited within the range of 5 cm × 20 cm.

Design requirements: The sewn part on the surface of the sensor should be smooth and uniform; there should be no distortion in the overall conduction spacing; no short circuits should occur in the conductive areas, and good contact needs to be ensured.

Design of conduction spacing and patterns: Preliminary experiments revealed that the liquid absorption and spreading of each drop of artificial urine on the substrate material ranged approximately from 0.5 to 0.7 cm. Therefore, in this study, the designed conduction spacing for the urine volume sensor’s serpentine electrode array was set at 0.5 cm. To investigate the influence of different patterns on urine volume sensing performance, three different patterns, labeled A, B, and C, were designed with varying numbers of modules and different arrangements. Pattern A: This pattern comprises 2 conductive lines and 1 module, occupying the entire urine volume sensor area. Pattern B: This pattern includes 4 conductive lines and 3 modules arranged in an “upper-middle-lower” configuration. Pattern C: This pattern features 5 conductive lines and 4 modules arranged in a “cross” configuration. To ensure the flexibility of the designed sensor and to avoid discomfort during wear, straight-line stitches were used in the sewing process, with a stitch distance of 1.0 mm. The design schematic is illustrated in Fig. 2.

The designed resistive urine volume sensing patterns are sewn using a Brother NV180 automatic embroidery and sewing machine. The specific preparation process is as follows: First, cut two pieces of hydrophilic non-woven fabric (Q1, Q2) measuring 10 cm × 25 cm each. Sew the conductive yarn onto Q1 according to the designed pattern, ensuring continuity and consistent spacing of each wire during the sewing process. Next, trim any burrs on the completed sensor and use a multimeter to check for any breaks in individual wires or short circuits between adjacent wires. If any wire is broken or adjacent wires are short-circuited, the urine volume sensor is considered faulty and needs to be re-prepared.

After confirming the functionality of the semi-finished urine volume sensor using a multimeter, proceed with the assembly process. Overlay Q2 onto the sensor, and apply conductive tape at the junctions of the conductive yarn. Utilize snap fasteners at the conductive tape locations to secure the layers. After fastening, cut a piece of hydrophobic non-woven fabric measuring 10 cm × 15 cm. Use this fabric to cover areas outside the urine volume sensor pattern. Its purpose is to prevent urine from dripping onto conductive yarn outside the sensor pattern during experiments, ensuring the accuracy of experimental data. Following these steps, the resistive urine volume sensor is fully assembled and prepared for use. Its physical appearance is depicted in Fig. 2.

Design and fabrication of capacitive urine volume sensor

Following the selection of the fabrication process used for the resistive urine volume sensor and considering practicality for optimal results, the fabrication process for the capacitive urine volume sensor also involves sewing. Initially, the conductive electrodes are connected to the surface of the base material using black polyester yarn. Subsequently, during the sewing process, the yarn is threaded through the base material using stitches, securing the electrode yarn on it. Wave patterns are incorporated to enhance both decorative aspects and comfort. Throughout the sewing process, it is ensured that the electrode yarn is tightly and securely connected to the base material, preventing any looseness or breakage to ensure reliable electrode contact.

For the fabrication of the capacitive urine volume sensor, silver-plated conductive fabric and cotton woven fabric are chosen as the conductive and base materials, respectively. Considering the specifications of diapers commonly used by patients as well as comfort, the dimensions of the entire urine volume sensor are set at 10 cm × 28 cm, within the constraints of the selected diaper size (7 cm × 24 cm).

Design requirements: The sewn surface of the sensor must be smooth and uniform. Ensuring a tight and secure connection between the electrode yarn and the base material is imperative. Avoiding situations of loosening or breakage is crucial to guarantee excellent electrode contact.

The size of the capacitor is directly related to the area facing the electrodes and the alignment of the electrodes. Considering that a larger electrode area can increase the capacitance value, enhancing sensitivity, it’s important to balance this with the potential difficulties and costs associated with excessively large electrode areas. Additionally, there are constraints posed by the size of the diaper. Thus, this study maintains a consistent electrode area, with individual electrodes measuring 3 cm × 28 cm, and only varies the distance between the electrodes.

The sensitivity of a capacitive sensor is inversely proportional to the distance between the electrodes; a smaller distance between electrodes can increase the sensitivity but might also lead to mutual interference between the electrodes. Generally, the electrode spacing should be moderate, ensuring sensitivity while minimizing mutual interference. The distance between electrodes is also influenced by the presence of urine; if the distance between electrodes is too small, urine might form a bridge between them, causing erroneous measurements. When designing the electrode spacing, the flow of urine needs to be considered to prevent such occurrences. Therefore, the design of the electrode distance for capacitive urine volume sensors needs to consider multiple factors, including sensitivity and the flow of urine.

Therefore, this design keeps the electrode area constant and only varies the distance between the two electrodes. Three different electrode spacings have been chosen: 1 cm, 2 cm, and 3 cm. The design diagram is illustrated in Fig. 3.

Testing process

Resistive measurement process

Using the resistive method to measure urine volume primarily involves evaluating urine volume and frequency based on the analog resistance values. A urine volume detection platform was designed and constructed, with a data acquisition front-end module sampling frequency of 50 Hz. The Analog-to-Digital Converter (ADC) converts analog signals into digital values, representing the relative magnitude of input signals within a specified range. Therefore, all sampled values of the data acquisition device in this study are analog resistance values, and the waveform changes on the upper computer represent amplitude changes, not actual resistance or voltage values.

To begin, open the serial port debugging assistant on the computer to receive analog resistance data. Use a disposable sterile syringe to draw a quantified amount of artificial urine and drop it at regular intervals onto the same location of the diaper to activate the embedded urine volume sensor. The data acquisition device transmits the collected resistance values in real-time to the computer via the serial port debugging assistant. After completing an experiment, save the raw data in Excel and use Origin to plot charts to observe changes in analog resistance. Through these steps, the entire process of measuring urine volume using the resistive method is completed. Refer to Fig. 4 for details.

The sampling amplitude range (K) of the data acquisition device in this study is from 0 to 950, with around 925 considered as “returning to the initial state”. As artificial urine drops, the analog resistance begins to decrease, and as the urine permeates, the analog resistance gradually rises. The specific experimental steps are as follows: Start by opening the serial port debugging assistant on the computer to receive data. The initial values of the development board are around 925. Secure the resistive urine volume sensor and the diaper with a clip, flatten them on a surface, connect the front-end module to the urine volume sensor using DuPont wires, connect the front-end module to the computer, and then start the experiment. On the smart diapers designed with three different urine volume sensors (A, B, and C), drop 1 mL, 2 mL, and 3 mL of artificial urine respectively. Drip once every 2 min, and drop 5 times for each milliliter. Then, based on the sampling amplitude values collected by the front-end module, plot trend curves to observe and evaluate the urine volume sensors. It is essential to simulate real urinary incontinence scenarios as closely as possible, by dropping artificial urine at the same position of the urine volume sensor and avoiding the edges of the diaper. After completing the 5 drops of urine experiment, continue observing the analog resistance changes for about 1 min. Develop urine volume grades based on the sensor’s performance and qualitatively assess urine volume and frequency.

Capacitance measurement process

The data acquisition device in this study had a sampling capacitance range of 0–60 pF. The “initial state recovery” capacitance values differed for smart diapers with different electrode spacings. As artificial urine drops, the capacitance value gradually increases, and with the infiltration of urine, the rising trend of capacitance becomes smoother. The specific experimental steps are as follows: Turn on the LCR meter, set the mode to LCR mode, adjust the instrument parameters as follows: measurement frequency at 1 kHz, measurement level signal at CV 1.5 V, voltage/current limit off, DC bias off, trigger set to INT, range set to HOLD 10 MΩ, measurement speed set to MED, averaging off, trigger delay at 0.2 s, and trigger synchronization output function off. Adjust the spacing between the electrodes, fix the capacitive urine volume sensor and the diaper, spread them flat on a plane, and use the LCR meter’s clamp to hold them on the protruding electrode fabric. Then start the experiment. Use a disposable sterile medical syringe to draw a specific volume of artificial urine. Drop 1 mL, 2 mL, and 3 mL of artificial urine on smart diapers with three different electrode spacings, respectively. Drip once every 1 min, 10 times for each milliliter. Then, collect the capacitance data using the LCR meter, plot the trend curve, observe, and evaluate the manufactured urine volume sensor. As shown in Fig. 5.

Experimental results analysis

For the evaluation of the leakage range using the resistance method, assessment is primarily based on the sampling amplitude changes, with evaluation references including the response difference value (KX), response final value (RFV), response minimum value (RMV), response rate (KL), and response final value (RFv).

In the case of the capacitive method for evaluating urinary incontinence range, the assessment was primarily based on the variation in values obtained from the LCR tester.

\(\varepsilon\) is the dielectric constant of the material between the electrodes, S is the effective area of the opposing metal electrodes, d is the distance between the opposing metal electrodes.

Standard deviation of capacitance increase:

x is the mean of the capacitance increase, xn is the individual capacitance increase values, S is the standard deviation of the capacitance increase.

Determination of the optimal urinary volume resistive sensor

Experiment results and analysis for pattern A

The module structure of pattern A is shown in the figure. At the central position of pattern A, 1 mL, 2 mL, and 3 mL of artificial urine were dropped every 2 min, with 5 drops per milliliter each time. The sampling amplitude change curves of module 1 are shown in Fig. 6.

The analysis of sampling amplitude changes for module 1 in the above figure is summarized in Table 2. The response difference is denoted by KX, and the response rate is denoted by KL (%).

Based on the analysis of Fig. 6; Table 2, it is found that the resistance sensing in Pattern A cannot accurately determine the specific urine volume. Therefore, this design will define three levels of urinary incontinence: mild, moderate, and severe. The range for mild incontinence is 0–5 mL, moderate incontinence is 6–12 mL, and severe incontinence is above 12 mL.

Pattern A for urine volume sensing consists of only one module covering the entire urine volume sensing area. Therefore, this analysis does not involve the position and quantity of urine volume sensing modules. From the figure and table, a common trend is observed: as artificial urine continues to drip, the difference in response values of urine volume sensing gradually decreases, and the recovery rate of sampling amplitude also decreases. There is no significant relationship between urine volume and the lowest value of sampling amplitude during dripping.

In the experiment where 1 mL of artificial urine was dropped each time, totaling 5 mL of artificial urine, the resistance-based urine volume sensing still shows a significant difference in response values, indicating that there is still some distance from saturation of the diaper, hence defined as mild urinary incontinence.

In the experiment where 2 mL of artificial urine was dropped each time, after the first two drops, which is 4 mL of artificial urine, the resistance-based urine volume sensing also shows a significant difference in response values, consistent with the analysis above. However, after the third drop of artificial urine, the KX value of the urine volume sensing remains around 75, and KL also remains around 12%. At this point, the diaper has absorbed a considerable amount of urine, thus defined as moderate urinary incontinence.

In the experiment where 3 mL of artificial urine was dropped each time, the sampling amplitude variation of urine volume sensing in the first 4 drops is generally consistent with the analysis above. However, when the last drop of artificial urine is added, KL can still reach over 10%, but KX is only 28. At this point, the smart diaper is approaching saturation, thus defined as severe urinary incontinence above 12 mL.

For pattern A, when the KX value can consistently remain above 100, it is defined as mild urinary incontinence. When the resistance KX is less than 100 but greater than 50, and KL remains above 10%, it is defined as moderate urinary incontinence. When KX is less than 50 or KL is less than 10%, it is defined as severe urinary incontinence. The frequency of urinary leakage is determined to be 5 times based on the KX change interval values, consistent with the actual titration frequency.

Experiment results and analysis for pattern B

The structure of module B is shown in the diagram below. At the central position of pattern B, 1 mL, 2 mL, and 3 mL of artificial urine are dropped every 2 min. As this sensor is designed with module two at the center, modules 1 and 3 serve mainly as reference modules for observing urine permeation. Each milliliter is dropped 5 times, and the sampling amplitude variation curves for modules 1, 2, and 3 are shown in Fig. 7.

The analysis of the amplitude variation in sampling for Module 2, as depicted in the above figure, is summarized in Table 3.

Through the analysis of Fig. 7; Table 3, it is still evident that there is a common pattern in the change of sampling amplitudes. Specifically, this design cannot accurately determine the specific urine volume. As artificial urine continues to drip, the KX and KL of urine volume sensors gradually decrease, and the relationship between urine volume and the lowest sampling amplitude during dripping is not significant.

The three modules in Pattern B are distributed in an “upper-middle-lower” pattern. Artificial urine always drips into the central part of the sensor. As a result, when there is sufficient urine, it starts to spread upwards and downwards, causing changes in resistance in the upper and lower modules. As observed from the figure, when the urine volume is between 2 and 5 mL, the sampling amplitudes of the upper and lower modules start to change, and they still follow the common pattern mentioned earlier.

Therefore, Pattern B did not achieve the expected results, and there is not much difference in KX and KL between the 1mL dripping experiment and the 3 mL dripping experiment. Pattern B can only detect mild urinary incontinence as defined earlier. This also indicates that with a larger measurement range, i.e., measuring larger volumes (4 mL, 5 mL, 6 mL) of urine, the device can still differentiate, but more urine is required to reach saturation. Additionally, based on the KX change interval, it can be determined that the leakage frequency of 5 times matches the actual dripping times in Module 2. However, there are sometimes deviations in leakage positions, leading to increased difficulty in analyzing leakage frequency in other modules.

Experimental results and analysis for pattern C

The structure of Module C is shown in the figure below. Every 2 min, 1 mL, 2 mL, and 3 mL of artificial urine are dripped in the center of module C, with a total of 5 drips. The sampling amplitude change curves for module 1, module 2, module 3, and module 4 are shown in Fig. 8.

The modules in Pattern C are distributed in a “field” shape. When artificial urine is dropped in the center of the smart diaper, the sampling amplitudes of all four modules will change. However, the general rule of sampling amplitude change can still be observed from the graph, where a larger urine volume leads to a lower sampling amplitude recovery rate and a smaller sampling amplitude recovery difference. However, there are significant differences between Pattern C and Patterns A and B. From the graph, it can be observed that when artificial urine is dropped in volumes ranging from 0 to 5 mL, the sampling amplitudes of all modules generally recover to above 450. After dropping urine volumes of 6–12 mL, the differences in sampling amplitude changes between the modules become significant, making it difficult to determine moderate urinary leakage. When urine volumes exceed 12 mL, the sampling amplitudes of Module 1 and Module 2 begin to recover more slowly, but it cannot be solely determined as severe urinary leakage based on the small difference in sampling amplitude recovery between Module 1 and Module 2.

Therefore, Pattern C can determine mild urinary leakage. However, when the urine volume exceeds 5 mL, there are significant differences in sampling amplitudes between modules, along with some oscillation intervals, making it difficult to distinguish between moderate and severe urinary leakage. This also indicates that Pattern C is not suitable for estimating urine volume using the resistance method, highlighting the importance of careful design in urine volume measurement. Based on the KX variation range, urinary leakage frequency is estimated to be 5–7 times, which deviates from the actual urinary leakage count. Thus, Pattern C’s assessment of urinary frequency and volume is prone to errors and increases analytical complexity.

According to the cross-point circuit flexible sensing electrode for Patterns A, B, and C, the relationship between urine volume and resistance sensing is summarized in Table 4.

Based on the A, B, C crossed finger circuit flexible sensing electrodes, the correlation between urinary frequency and the resistance sensing method is determined. Each instance where KX exceeds 25 is recorded as one urinary leakage occurrence.

Optimal capacitance module spacing determination

Experiment and analysis of 1 cm electrode spacing

When the electrode spacing is 1 cm, the initial capacitance value of the LCR tester is approximately 8.20 pF. Artificial urine, 1 mL, 2 mL, and 3 mL, respectively, is dropped every minute at the central position of the capacitive sensor pad. The artificial urine is dropped ten times per milliliter. The capacitance change curve is shown in Fig. 9.

Based on the analysis from Fig. 9; Table 5, when the electrode spacing is 1 cm, the capacitance is quite sensitive. On average, the capacitance increases by approximately 1.5–1.8 pF per milliliter of artificial urine droplet. However, there is a considerable variance, indicating a high level of data dispersion. This preliminary judgment is likely due to the high sensitivity of the LCR tester, making it susceptible to significant environmental influences.

Therefore, a 1 cm electrode spacing can determine the range of urine volume, with an error of approximately ± 0.5 mL for each drop of artificial urine. The larger the urine volume, the greater the error, thus the accuracy of urine volume measurement with a 1 cm electrode distance in capacitive method is somewhat limited. However, it can roughly analyze the range of urine leakage values, and based on the DS variation, determine a leakage frequency of 10 times, consistent with the actual titration count.

Experiment results and analysis with 2 cm electrode spacing

When the electrode spacing is 2 cm, the initial capacitance value of the LCR tester is approximately 6.50 pF. Artificial urine droplets of 1 mL, 2 mL, and 3 mL are sequentially dropped onto the central position of the capacitance sensor in the urine volume sensor every minute, with 10 droplets for each milliliter of artificial urine. The capacitance change curves are illustrated in Fig. 10.

The comprehensive comparison of capacitance changes with a 2 cm electrode spacing, as analyzed from Fig. 10, is presented in Table 6.

From Fig. 10; Table 6, it can be observed that with a 2 cm electrode spacing, there is significant variation in capacitance. The average capacitance increase per milliliter differs significantly between the 1 mL artificial urine drop experiment and the 2 mL and 3 mL urine drop experiments. There is a notable difference in variance, indicating a high level of data dispersion.

Therefore, the 2 cm electrode distance urine volume sensing did not achieve the expected experimental results, as it cannot detect urine volume accurately. However, based on the DS variation, a leakage frequency of 10 times was determined, consistent with the actual titration count.

Experiment results and analysis with 3 cm electrode spacing

When the electrode spacing was 3 cm, the initial capacitance value measured by the LCR tester was approximately 5.30 pF. Artificial urine was dropped onto the central position of the capacitive sensor patch at intervals of 1 min, with 1 mL, 2 mL, and 3 mL of artificial urine being dropped each time. This process was repeated 10 times for each milliliter of artificial urine, and the capacitance change curve is shown in Fig. 11.

The comprehensive comparison of capacitance changes with a 3 cm electrode spacing, as analyzed from Fig. 11, is presented in Table 7.

From Fig. 11; Table 7, it can be observed that with a 3 cm electrode spacing, the capacitance change is relatively small, exhibiting unclear variations. There is a significant difference in the average capacitance increase per milliliter between the experiments with 1 mL artificial urine drops and those with 2 mL and 3 mL drops. The variance is high, indicating a considerable level of data dispersion.

Therefore, the 3 cm electrode distance urine volume sensing did not achieve the expected experimental results, as it cannot detect urine volume accurately. Additionally, based on the DS variation, monitoring the leakage frequency becomes challenging due to small DS variation values, leading to potential misjudgments and impacting the accuracy of leakage frequency monitoring.

Based on the tests with 1 cm, 2 cm, and 3 cm electrode distances, it was determined that a 1 cm electrode distance can more accurately analyze the range of urine leakage and ensure the accuracy of leakage frequency monitoring. A DS variation range of 1.5–1.8 pF corresponds to a urine leakage of 1 mL, and DS variation values greater than 0.4 pF are recorded as instances of leakage.

Experiment results and analysis of random urine volume with 1 cm electrode spacing

According to this study, a 1 cm electrode spacing can more accurately analyze the range of urinary incontinence volume. To validate the accuracy of monitoring urinary incontinence volume and frequency with a 1 cm electrode spacing, random titration tests were conducted using 1–10 mL of artificial urine, simulating random leaks 10 times. The resulting capacitance change curve is shown in Fig. 12.

The capacitance values corresponding to the titration of random urinary volumes are analyzed from Fig. 12 and presented in Table 8.

Based on the analysis of Fig. 12; Table 8, random titration of artificial urine resulted in a capacitance increase of 85.43 pF. According to the sensor analysis with a 1 cm electrode spacing, the capacitance value changes by 1.5–1.8 pF per milliliter of artificial urine. Therefore, the estimated range of urinary incontinence is 47.45–56.93 mL. Integrating the data from the random simulation of artificial urine titration, a total of 56 mL was dripped, resulting in a monitoring difference of 0.93–8.55 mL compared to the actual urine leakage volume. Additionally, based on the DS change range, 10 instances of urine leakage were detected, consistent with the actual frequency of urine leakage. This analysis of urine leakage volume and frequency demonstrates that a 1 cm electrode spacing provides a basis for monitoring and analyzing urine leakage, aiding healthcare professionals in diagnosing the severity of urinary incontinence.

The actual results and analysis of pattern A

Volunteers in the laboratory walking test

To validate the feasibility of the study, the completed forked circuit flexible sensor was tested on volunteers by dripping 1 mL of artificial urine for the first three times, 2 mL for the fourth and fifth times, and 3 mL for the sixth and seventh times, totaling 13 mL of artificial urine. This is illustrated in Fig. 13.

Based on Fig. 13, the changes in KX and KL after each simulated urine leakage for A sensor pattern on the human body are shown in Table 9.

Based on the analysis of Fig. 13; Table 9, it is determined that the number of urinary leaks per drop of artificial urine is 7 times, which is consistent with the actual simulated urinary leak frequency. Judging from the KX value change interval and KL value for each drop of artificial urine in the table, it is determined that the urinary leakage volume is between 6 and 12 mL, with a small difference from the actual urinary leakage volume of 13 mL, which meets the error tolerance. This proves the feasibility of the A sensing pattern.

Medical volunteer upper body normal walking test

By contacting the local hospital, enlisting a basin disease health care workers as volunteers, the fork finger circuit flexible sensing upper body experiments, to complete the real urine leakage and leakage frequency monitoring, considering the volunteers’ own reasons, there is no photo of the volunteers, the volunteers agreed to keep the relevant data. As shown in Fig. 14.

The changes in KX and KL after each instance of real urine leakage in human volunteers with the A sensing pattern are analyzed from Fig. 14 and shown in Table 10.

Analysis from Fig. 14; Table 10 reveals that each drop of artificial urine resulted in a KX value indicating urinary leakage frequency of 7 times. The medical volunteer indicated consciously controlling 7 instances of urinary leakage, aligning with the monitoring results of A pattern for urinary leakage frequency. According to the KX value intervals for each drop of artificial urine in the table, the initial urinary leakage with a KX value of 68 and subsequent KX values consistently below 100, alongside the KL values, suggest a urinary leakage volume exceeding 24 mL. Weighing the used diaper after volunteer use confirmed a true urinary leakage volume of 33 mL, with a discrepancy of 9mL from the predicted urinary leakage volume. However, this validates the accuracy of A sensing pattern in monitoring urinary leakage frequency, providing an effective basis for estimating urinary leakage volume.

Conclusion

To address the monitoring challenges of urinary incontinence in patients, this study designed and fabricated both resistive and capacitive urine volume sensors, and analyzed their respective performance. By designing patterns for resistive urine volume sensing and determining electrode distances for capacitive urine volume sensing, these two types of sensors were prepared and integrated into the structure of regular diapers, resulting in smart diapers. This provided two effective preparation methods for feasible monitoring of urinary volume and frequency. Additionally, the relevant performance indicators of the sensors were outlined, providing a basis for further analysis and discussion. Furthermore, reliable urine volume sensors were selected. In the resistive urine volume sensing test, leakage levels were defined as follows: 0–5 mL for mild leakage, 6–12 mL for moderate leakage, and above 12 mL for severe leakage. The optimal A pattern could identify three levels of urinary leakage, whereas the B and C patterns could only detect mild leakage, making it difficult to distinguish between moderate and severe leakage. The A pattern largely met the desired objectives. In the capacitive urine volume sensing test, a 1 cm electrode spacing could determine the range of urine volume. Specifically, each 1 mL drop resulted in a capacitance increase of approximately 1.5–1.8 pF, with an error margin of about ± 0.5 mL per drop. This performance generally met the desired objectives. Through the 1 cm electrode spacing capacitance sensing random urine titration test, after analyzing the monitoring data to derive the relevant leakage interval and leakage frequency, the monitoring results will be compared with the real leakage volume and leakage frequency, to prove the feasibility of the 1 cm electrode spacing capacitance method of sensing. Through the upper-body test of A-pattern resistive sensing, we proved the accuracy of the resistive method in monitoring the frequency of urine leakage and the evaluation interval of urine leakage, and cooperated with the healthcare personnel related to pelvic diseases to conduct the upper-body leakage test to prove the feasibility of the A-pattern resistive method.

Data availability

All data that support the finding of this study are included in this manuscript and its supplementary information files.

References

Kannan, P. & Bello, U. M. Efficacy of various forms of acupuncture for the treatment of urinary incontinence in women: a systematic review and meta-analysis. Explore. 19 (1), 26–35 (2023).

Torgbenu, E. et al. Prevalence and risk factors of urinary incontinence among women in Africa: a systematic review and meta-analysis. (2023).

Irwin, D. E., Kopp, Z. S., Agatep, B., Milsom, I. & Abrams, P. Worldwide prevalence estimates of lower urinary tract symptoms, overactive bladder, urinary incontinence and bladder outlet obstruction. BJU Int.108, 1132–1138 (2011).

Milsom, I. et al. Epidemiology of urinary incontinence (UI) and other lower urinary tract symptoms (LUTS), pelvic organ prolapse (POP) and anal (AI) incontinence. In Incontinence, 6th ed. 17–24 (Health Publications Ltd, 2016).

Neumann, P. B., Grimmer, K. A. & Deenadayalan, Y. Pelvic floor muscle training and adjunctive therapies for the treatment of stress urinary incontinence in women: a systematic review. BMC Women’s Health. 6 (1), 1–28 (2006).

McMillan, I. et al. Urinary incontinence in women 55 years and older: a scoping review to understand prevalence, incidence, and mortality of urinary incontinence during secondary care admission. Women’s Health. 19, 17455057231179061 (2023).

Milsom, I. & Gyhagen, M. The prevalence of urinary incontinence. Climacteric. 22 (3), 217–222 (2019).

Vaughan, C. P. & Markland, A. D. Urinary incontinence in women. Ann. Intern. Med.172 (3), ITC17–ITC32 (2020).

Saboia, D. M. et al. Impact of Urinary Incontinence Types on Women’s Quality of Life 51 (Revista da Escola de Enfermagem da USP, 2017).

Senra, C. & Pereira, M. G. Quality of life in women with urinary incontinence. Revista Da Associação Médica Brasileira. 61, 178–183 (2015).

Krhut, J. et al. Effect of severity of urinary incontinence on quality of life in women. Neurourol. Urodyn.37 (6), 1925–1930 (2018).

Cho, J. H. et al. A smart diaper system using bluetooth and smartphones to automatically detect urination and volume of voiding: prospective observational pilot study in an acute care hospital. J. Med. Internet. Res.23 (7), e29979 (2021).

Peng, Y. et al. A battery-free music-driven humidity sensor for intelligent wearable sensing system in smart diaper. Smart Mater. Struct.32 (2), 025016 (2023).

Fernandes, B. et al. Urinary incontinence: a vibration alert system for detecting pad overflow. Assist. Technol.23 (4), 218–224 (2011).

Long, A. et al. Clinical evaluation of a prototype underwear designed to detect urine leakage from continence pads. J. Wound Ostomy Cont. Nurs.42 (6), 632–639 (2015).

Marc, M. E., Ignacio, G. & Raúl, F. G. A smart textile system to detect urine leakage. IEEE Sens. J.21 (23), 26234–26242 (2021).

Tekcin, M. et al. Wearable and flexible humidity sensor integrated to disposable diapers for wetness monitoring and urinary incontinence. Electronics. 11 (7), 1025 (2022).

Ngo, H. D. et al. A novel low cost wireless incontinence sensor system (screen-printed flexible sensor system) for wireless urine detection in incontinence materials. Proceedings. MDPI. 2(13), 716. (2018).

Parkova, I. Woven textile moisture sensor for enuresis alarm treatment. Key Eng. Mater.604, 146–149 (2014).

Parkova, I. et al. Design of textile moisture sensor for enuresis alarm system. Mater. Sci. (1691–3132), 2012 (7).

Liang, Q. et al. Self-stretchable fiber liquid sensors made with bacterial cellulose/carbon nanotubes for smart diapers. ACS Appl. Mater. Interfaces. 14 (18), 21319–21329 (2022).

Lewis, A. Absorbency of Disposable Diapers (Unitas, 2020).

Li, G. B. Design of Composite Absorbing core Layer and its Application in Diapers (Fujian Normal University, 2015).

Wang, Y. Study on the Performance of Deflector Layer of Hot-air Diapers (Tianjin Polytechnic University, 2017).

Nagaswarna, R. Overview of disposable diaper parts and their purpose. (2019).

Funding

This study was supported by the Science and Technology Guidance Project of China National Textile and Apparel Council in 2021.

Author information

Authors and Affiliations

Contributions

F.X. and Y.L. participated in the design of the study, literature review, writing, and manuscript revision. C.X., Z.W., J.Z., H.Y., M.F., C.Y., J.Z., C.W., and C.G. were involved in the manuscript revision. All authors have read and approved the submitted version.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xiong, F., Li, Y., Xie, C. et al. Research on dynamic urine volume detection system based on smart flexible textile sensors. Sci Rep 14, 22459 (2024). https://doi.org/10.1038/s41598-024-73179-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-73179-0