Abstract

Slurry retention in fractures decreases after grouting is completed and the pressure supply is stopped, which affects the grouting sealing effect and prevents or restrains the occurrence of such adverse conditions. Based on the time-varying yield stress of grout, a theoretical analysis model of grouting diffusion decay is established, the decay height variation function and the minimum pressure stabilisation time calculation formula are derived, and the sealing mechanism of a jointed rock mass with multiple joints is studied. Moreover, a 3D visualisation laboratory test device for grouting diffusion decay of a jointed rock mass with layers was developed to analyse the diffusion and decay process of grout with different water-cement (W/C) ratios visually, and the correctness of the theoretical model was verified. The results show that: (1) the W/C ratio of grout should not be greater than 2, otherwise it is difficult for grout to remain in the cracks; (2) a large fissure opening easily spreads grout but is not conducive to the retention of grout; and (3) the time of stable pressure determines the retention rate of the slurry in the crack. When the horizontal crack opening width is 3 mm and the W/C ratio of the slurry is 1, the minimum stable pressure time to achieve a better sealing effect is 810 s. The research results can be used to reasonably plan the grouting time and improve the grouting efficiency to ensure the grouting effect, which is crucial for improving the theoretical system of grouting technology.

Similar content being viewed by others

1. Introduction

Geological disasters such as mud outbursts and water inrush often occur during the construction of karst tunnels, endangering construction safety and leading to environmental problems such as ground collapse, groundwater loss and surface water depletion (Teng et al2.; Zhang et al12.; Yi et al7). Given groundwater seepage with water-bearing carboniferous shale in the rock surrounding a tunnel, open horizontal bedding and connected vertical joints become the main channels for groundwater migration (Cao et al1.; Tan et al., 2022). Using curtain grouting technology to fill the primary fissure of the water-filled surrounding rock of a tunnel and the secondary fissure caused by excavation disturbance can achieve the effects of water plugging and reinforcement (Zhe et al13.; Yuan et al4.; Liu et al.9). Therefore, it is necessary to study how slurries seal water-conducting fissures and play a role in water control.

To date, many scholars have studied the diffusion law and sealing mechanism of grouting in fractured rock masses. The diffusion law mainly includes the study of morphology and distance.On the basis of the theory of viscous fluid mechanics, Li et al6. derived analytical expressions for the diffusion radius, radial velocity and pressure distribution between crack walls over time. Zhai et al3. used Bingham mud with time-varying characteristics as the study object to study the diffusion mechanism of mud in horizontal fractures of fractured aquifers. Zhang et al20. used COMSOL simulation software and reported that the grouting time increases exponentially with increasing of flow distance in a single crack and that the higher the ambient temperature is, the longer the grouting time. Zhang et al20. studied a type of fast condensing grouting that can effectively control the diffusion range of grouting, and established a two-dimensional cylindrical permeability grouting diffusion model. In terms of the sealing mechanism, the main research topics include grouting materials, admixtures and slurry viscosity. Sui et al15. studied the sealing effect of chemical grouting on fractured rock masses under dynamic water conditions. Wang et al1. performed rheological tests of a glass fiber cement slurry to analyse its blocking mechanism and applied this mechanism to prevent and control water inrush. Zhan et al.26 discussed the correlation between seepage pressure and the water-plugging effect in the process of crack grouting, and concluded that seepage pressure is the key factor affecting the permeability and diffusion of grouting materials and the final water plugging effect. Su et al15. studied the blocking rule of cement slurry under a high hydraulic gradient and obtained the best blocking flow rate.

In summary, current studies on the grouting diffusion law and plugging mechanism are limited to the grouting advancement process (Cheng et al2.; Kang et al1.; Wu et al19.). The diffusion and migration of grout in the fracture network of a rock mass after grouting is often ignored, and the diffusion sealing mechanism during this period is still in the exploratory stage. When the grouting pressure supply ends, the slurry in the vertical crack will move contrary to the grouting process under the influence of volume force, which is called grouting diffusion decay in this paper. The pressure regulation time in the grouting end standard is crucial for developing this process. The stable pressure time of grouting refers to the time at which the grouting pressure remains stable after reaching the predetermined value in the grouting project. This condition ensures that the slurry can fully fill the cracks and form a uniform slurry volume in the construction area, thus achieving the desired reinforcement effect. According to a summary of onsite construction experience, previous workers have proposed in relevant specifications and processes that pressure supply should continue for a period of time before the end of grouting (Zhang et al8.; Sharma13). Rafi and Stille12 proposed a method for determining the grouting pressure to ensure that grouting cracks eject and control deformation. Zhao et al33. proposed constant-pressure grouting technology for inorganic noncondensable materials by analysing the seepage capacity of slurries under different grouting pressures. However, the meaning and reasons for stable pressure have not been explained, and no relevant scholars have comprehensively researched this grouting process. The duration of the stable pressure time has always been within a relatively vague empirical interval.

Based on the time-varying yield stress and viscosity characteristics of grout, this paper builds a theoretical analysis model of grout diffusion decay after the end of grouting pressure supply, explains that insufficient stable pressure time causes the phenomenon of grouting diffusion decay, and then studies the mechanism of grouting sealing for a layered rock mass with layered joints to ensure the sealing effect of grouting and improve the efficiency of grouting.

2. Research methods and materials

The routes and methods studied in this paper are shown in Fig. 1. First, the concept of the diffusion decay of grouting is proposed, and a model is established to explain it. On this basis, considering the time-varying yield stress and viscosity identification characteristics of grout, a theoretical model is developed for grout diffusion decay after the cessation of grouting, and the governing equation of grout diffusion is derived and analysed. A laboratory model is subsequently developed to perform grouting tests to verify the correctness of the theoretical derivation. Finally, the sealing mechanism of jointed rock masses with multiple joints is summarised.

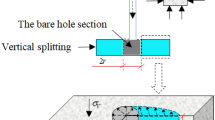

3. The concept of grouting diffusion decay

Horizontal bedding frequently extends well and has a wide opening in stratified jointed rock masses (Huang et al4.; Guo et al3.). Drilling holes can readily reveal and immediately connect horizontal bedding, as evidenced by the spatial relative position relationship between the axial direction of the holes and the formation of cracks, as opposed to vertical cracks. Slurry diffusion during grouting has the following features: Following grouting drilling, the slurry diffuses in horizontal cracks before entering each associated vertical fracture. During grouting, the horizontal diffusion distance is typically greater than that of the ideal model, assuming spherical grout diffusion (Song et al14.) (see Fig. 2). Grouting diffusion decay is an inevitable phenomenon that mostly manifests itself when the grouting pressure supply is cut off. The model is displayed in Fig. 2. Slurry migration has the following features: The slurry that initially fills the vertical crack starts to sink into the horizontal crack, and eventually, the actual diffusion height of the vertical crack is lower than that of the ideal model.

Grout migrates only when the pressure exceeds the grout yield stress (Zhang et al20.). Thus, the dead weight and yield stress in the grout characteristics are the primary components that considerably impact the process and degree of grouting diffusion decay. Numerous researchers have examined how time-varying viscosity affects the grouting process (Liang et al8.; Ma et al10.); additionally, time-varying grout yield stress has been observed (Xu et al20.; Nan et al11.); however, notably, the slurry is always in a flow state during the grouting process. The grout can be in a static state under a continuous pressure supply at steady pressure after grouting. Therefore, the time variation in the yield stress is evident.

The grout will have a sinking tendency when its volume force is greater than the yield stress in the vertical crack after grouting. The yield stress of the slurry is too low if the steady pressure time cannot satisfy the demand, which negatively impacts the retention rate of the slurry in the crack and has a poor water-plugging effect. Consequently, after the stable pressure time, the grout yield stress determines the maximum height of the diffusion decay caused by grouting.

4. Theoretical model of grouting diffusion decay

4.1. Basic assumptions of model construction

According to Yi et al12. and Zhu et al27., the grout constitutive equation satisfies Eq. (1), and the grout type in this study is considered a viscous modified Bingham fluid:

where \(\tau\) is the shear stress, \({\tau _0}\) is the yield stress, and \(\eta (t)\gamma\) is the slurry viscosity.

The following derivation should satisfy the following assumptions: (1) The grout movement satisfies the continuity equation; (2) the slurry bulk density does not change during the flow process, is isotropic and incompressible, and the flow rate is steady; (3) the grout flows laminarly except for turbulence near the grout hole, where the gaps between the fractures are fairly narrow; (4) the wall surface does not slip as the slurry moves through the breach; (5) the hydrostatic pressure acts on the slurry peak surface without causing it to dilute; (6) no energy is lost at the junction of vertical and horizontal fissures; and (7) at every location in the vertical crack, the slurry travels down the longitudinal axis without slipping to either side. It spreads linearly along a single cross-section as it descends from the vertical fracture to the horizontal crack.

4.2. Theoretical model of diffusion decay

The slurry recharge in a vertical fracture is derived primarily from the horizontal fracture connected to it during the continuous grouting pressure supply stage for a jointed rock mass with multiple joints. Figure 3 illustrates the slurry migration mechanism.

As illustrated in Fig. 4, grouting diffusion decay occurs when the grout weight in the vertical crack is greater than the yield stress. This condition causes the grout in the vertical crack to be reversely recharged into the horizontal crack.

Let the width of the horizontal crack be b, and the width of the vertical crack be a, where \(b>a\), the height of the vertical crack be h, the decay height be h, the hydrostatic pressure be \({p_w}\), the resistance of the slurry sinking in the vertical crack caused by the diffusion of the horizontal crack slurry be \({p_z}\), and the distributions of slurry pressure in the horizontal crack and vertical crack are \({p_l}\) and \({p_v}\), respectively .

Gravity’s influence in a horizontal crack can be disregarded since the grout in the crack flows less in the vertical direction and does not diffuse because of gravity once grouting is complete. In contrast, the vertical motion trace in vertical cracks is lengthy, and gravity dramatically affects the distribution of this motion. Furthermore, gravity in vertical fissures cannot be disregarded since it results in fresh grout migration following grouting. Based on the abovementioned hypotheses, a model for the grouting diffusion decay of a jointed rock mass with multiple layers is built. As shown in Fig. 4, a microelement is chosen to perform a grout migration force analysis of a vertical crack and a horizontal crack.

4.3. Control equation of slurry flow after grouting

4.3.1. Slurry diffusion in horizontal cracks

Once the grouting is complete, there is no longer any grouting pressure or slurry pouring into the grouting hole. The initial injection of slurry in the vertical fissure replenishes the slurry in the horizontal fissure, and the pressure created by the slurry’s gravity in the vertical fissure powers the slurry’s diffusion in the horizontal fissure. As shown in Fig. 4, force analysis was performed on the slurry microbody in the horizontal crack, and the microbody’s force balance equation was determined:

where\({p_l}\) is the slurry pressure of the slurry in the horizontal crack, Pa.

By omitting its higher-order small quantity of Eq. (2), it can be simplified as:

Because \(z=0\) and \(\tau {\text{=}}0\), the integral along the z direction can be obtained:

By substituting the Bingham fluid flow Eq. (1), the following result its obtained:

where \({u_l}\) is the velocity of the slurry in the horizontal crack, m/s, \({t_0}\) is the stable pressure time of grouting, s; and \({t_s}\) is the diffusion fading time of grout under the influence of dead weight without grouting pressure after grouting, s.

Because \(u{}_{l}{\text{=}}0\) when \(z{\text{=}}\frac{b}{2}\), the integral of Eq. (5) can be obtained:

By integrating Eq. (6) in the z direction, the average velocity of the radially diffused grout front can be obtained:

4.3.2. Diffusion decay in vertical cracks

The initially filled slurry in the vertical crack migrates downhill if, upon grouting, the volume force of the slurry in the vertical crack is greater than the total yield stress and the resistance of the slurry in the horizontal crack. As shown in Fig. 4, force analysis was performed on the slurry microbody in the vertical fracture, and the microbody’s force balance equation was determined:

where \({p_v}\) is the slurry pressure in the vertical crack, Pa.

By omitting its higher-order small quantity of Eq. (8), it can be simplified as:

Because \(y=0\) and \(\tau {\text{=}}0\), the integral along the y direction can be obtained:

Substituting the Bingham fluid flow into Eq. (1) obtains following results:

where \({u_v}\) is the velocity of the slurry in the vertical crack, m/s.

Because \(u{}_{v}{\text{=}}0\) when \(y{\text{=}}\frac{b}{2}\), the integral of Eq. (11) can be obtained:

By integrating Eq. (12) in the y direction, the average velocity of the radially diffused grout front can be obtained:

In the process of grout decay in vertical cracks, except for the volume force and shear force, the grout pressure on microunits does not change with the decay length, so \(\frac{{d{p_v}}}{{dz}}{\text{=}}0\). Equation (13) can be written as:

In the horizontal crack, the slurry flow q per unit time along the diffusion direction of the profile is as follows:

Equation (15) can be converted to:

By integrating Eq. (16) in the x direction and using \({\left. {{p_l}} \right|_{x=0}}=\rho gh\), we obtain:

When the slurry in the vertical crack drops to the maximum height \({h_z}\) (\(0 \leqslant {h_z} \leqslant h\)), the slurry in the horizontal crack also spreads to the farthest distance \({x_{\hbox{max} }}=\frac{a}{b}{h_z}\), at which time the slurry velocity is 0, and the slurry pressure is equal to the sum of the hydrostatic pressure and yield stress, that is \({p_l}={p_w}+{\tau _0}({t_0}+{t_s})\). The whole process of grouting diffusion decay is obviously less time-consuming than stable pressure grouting is, and the yield stress of the grout has little change in a short time; thus, \({t_s}\) can be ignored. The grout flow per unit length of the profile along the diffusion direction in the horizontal fracture is equal to the grout flow per unit length of the profile along the descending direction in the vertical fracture, that is, \(q={\bar {u}_v}a\). By substituting the above components into Eq. (17), the maximum height of grouting diffusion decay in a stratified jointed physical rock mass after grouting is completed can be obtained:

Equation (18) shows that the maximum height of the grouting diffusion decay of the stratified jointed rock mass is unrelated to the grout viscosity, and the initial yield stress and time variation of the yield stress of the grout play a decisive role in determining the height of decay. By converting Eq. (18), the yield stress calculation formula for preventing excessive decay of grouting diffusion is derived:

Yang et al. (1987) used rotary and capillary viscometers to test ordinary silicate cement slurry in the laboratory, and obtained the dynamic shear curve of the slurry within 6 h after mixing, which could be synthesised into the following formula:

where w is the water-cement ratio and where T is the hydration time, s.

Water blocking rate classification is an important index for evaluating the effect of curtain grouting, which is usually used to measure the effect of blocking groundwater or seepage after grouting construction. Zhan et al. (2023) also studied the correlation of factors affecting the water plugging rate. Although classification methods may differ among engineering projects or standards, in general, the classification of the water plugging rate for curtain grouting usually includes 5 grades, as shown in Table 1.

As shown in Table 1, the water plugging effect is not good when the water plugging rate is lower than 70%. Therefore, before the end of grouting, grouting pressure must be stabilised to prevent the height of grouting diffusion from fading more than 30%. At the end of grouting, pressure and grouting should be continuously supplied so that the grout can reach a certain yield stress with increasing time, prevent the excessive decay of grouting diffusion, and fill the grout in the horizontal and vertical cracks as much as possible to meet the sealing effect.

Based on this idea, letting \({h_z}=\frac{3}{{10}}h\), the minimum stable pressure time \({T_{\hbox{min} }}\) required for grouting and sealing of jointed rock masses with multiple layers can be obtained as:

5. Model analysis of grouting diffusion decay

5.1. Analysis of the strong influence of grout diffusion decay

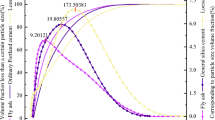

The formula for determining the maximum height of grouting diffusion decay of a jointed rock mass with multiple joints is obtained via Eq. (18). The slurry water‒cement ratio, steady pressure time, fracture width, vertical crack height, and hydrostatic pressure are the main influencing factors. When the slurry water‒cement ratio is 0.8, 1, 2, or 3, neglecting the hydrostatic pressure, Fig. 5 shows the change in the grouting diffusion decay height after various steady pressures are reached. Neglecting the hydrostatic pressure, Fig. 6 shows the variations in the height of grouting diffusion decay after various stable pressures are reached at a W/C ratio of 2. The horizontal crack width is 5 mm, and the vertical crack widths are 4.5 mm, 4 mm, 3.5 mm, and 3 mm. Neglecting the hydrostatic pressure, Fig. 7 shows the variations in the height of grouting diffusion decay after various stable pressures are reached when the W/C ratio is 2. The horizontal crack widths are 1.5 mm, 2 mm, 2.5 mm, and 3 mm, and the vertical crack width is 1 mm. Figure 8 illustrates the variations in the height of grouting diffusion decay following varying stable pressure periods. In this scenario, the hydrostatic pressures are 5 Pa, 10 Pa, 15 Pa, and 20 Pa, the horizontal crack width is 3 mm, the vertical crack width is 2 mm, and the water‒cement ratio is 2.

The analysis diagram of the many influencing elements shows that the height of grouting diffusion decay increases as the water–cement ratio, crack width, and crack height increase and decreases as the hydrostatic pressure increases. According to Fig. 9, grout must be retained over a stable pressure grouting time of more than 1600 s when the W/C ratio is 3. Therefore, using a slurry with an excessively high W/C ratio for grouting is not advisable since this approach will result in labour-intensive, time-consuming, and ineffective grouting. A ratio of one to two for the water–cement mixture is better. Large fractures require longer consistent grouting pressures to ensure that the fissures are sealed properly, as shown in Figs. 6 and 7. The more comprehensive the crack is, the more readily the grout will diffuse and migrate, making sealing comparatively tricky. Grout retention is facilitated by hydrostatic pressure, as shown in Fig. 8. Although hydrostatic pressure hinders grout diffusion during the grouting process, it also contributes to the inhibition of diffusion decay following grouting.

A satisfactory sealing result for jointed rock masses with multiple joints requires a stable grouting pressure. The excessive subsidence of grout due to its weight can be resisted once the yield stress is time-varying, allowing the grout to stay in the vertical crack; otherwise, the height of the crack will be reached by grouting diffusion decay. The evidence for this assertion is apparent in Fig. 9. Regardless of how the vertical crack height changes, under the preset grouting settings, the slurry can only stay in the vertical crack until the stable pressure time reaches 1200 s. At this point, the height of the grouting diffusion decay starts to decrease.

5.2. Analysis of the minimum stable grouting pressure time

The stable pressure‒time curves with various crack heights and decay rates are displayed in Fig. 10. When the crack height increases, the stability time clearly remains constant. This finding demonstrates that if a specific sealing rate is needed during the grouting process, then the steady pressure time of grouting does not affect the extension height of vertical fissures. Consequently, Fig. 11 displays the results considering the effects of the W/C ratio and crack width on the minimum stable pressure time. The water–cement ratio and fracture width increase the minimum stable grouting pressure time.

6. Laboratory test of grouting diffusion decay

6.1. Research and development of test equipment

A 3D visualization physical simulation test system for a jointed physical rock mass grouted with grouting holes is designed to better depict the diffusion and degradation features of the grouting process. The four critical modules of the system are the data processing module, the grouting module, the crack module, and the crack module. In Fig. 12, the test principle is displayed. The grout diffuses in the crack after flowing into the grouting hole through the grouting barrel and grouting pipe in response to an external force. The sensor can track the grout distribution law along the diffusion channel.

The crack system of the grouting test device, which comprises an acrylic plate with a thickness of 1.5 cm, two horizontal cracks with widths of 3 mm and eight vertical cracks with widths of 2 mm in the middle, allows for the spatial inspection of slurry diffusion. The vertical crack is 0.5 m high, and the horizontal crack is 2 m long. The nitrogen cylinder forces the slurry from the storage tank into the grouting hole, providing the grouting pressure. The horizontal crack’s bottom hole is where the valve is inserted and closed while grouting is performed. This valve is opened at various intervals after the slurry fills the cracks to model and examine the phenomena and procedure of grouting diffusion decay following various stable pressure times after grouting. Figure 13 shows the test device’s precise configuration.

6.2. Test programme design

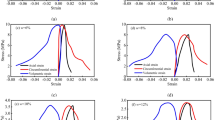

The grouting material is a pure cement slurry with P.O 42.5R ordinary Portland cement. A total of 10 groups of tests were performed, in which the slurry with a W/C ratio of 1 was tested by opening the bottom valve at 5 periods of 900 s, 1220 s, 1240 s, 1260 s and 1300 s after the slurry filled the crack. For the grout with a W/C ratio of 2, the bottom valve was opened 720 s, 750 s, 770 s, 800 s and 900 s after the grout filled the crack. Before the test, the six-speed rotating viscometer model ZNN-D6B in Fig. 14 was used to test the yield stress and viscosity of the slurry. For slurries with water‒cement ratios of 1 and 2, the yield stress distributions were 0.32 Pa and 0.19 Pa, and the viscosities were 0.0166 Pa·s and 0.008 Pa·s, respectively. During the test, the slurry flowing out after the bottom valve was opened was collected, the time-varying yield stress was tested, the theoretical calculation value was compared and analysed, and the diffusion and decay process of the slurry in the three-dimensional visualisation test device was recorded in real time by a camera.

6.3. Analysis of test results

6.3.1 process of grouting diffusion decay

Grout-water-to-cement ratios of 1 and 2 were chosen for the test. During the test, a camera was used to record the grout diffusion and decay process in the 3D visualisation test device. The test results for W/C ratios of 1 and 2 are displayed in Fig. 15 (a) and Fig. 15 (b), respectively.

The grouting recession phenomena are more evident, as illustrated in Fig. 15. There is little grout retention in vertical fissures and a brief stable pressure time during grouting. Consequently, a crucial process in the actual construction process is continuous, stable pressure after grouting. The grouting effect is impacted by an inadequate stable pressure time. However, an excessively long stable pressure time is labour- and time-intensive and negatively impacts the construction process.

6.3.2 comparative analysis of experiments and theories

A comparison of the actual and theoretical findings for the grouting diffusion attenuation height under the same stable pressure conditions is presented in Fig. 16. The theoretical calculation and derivation of the grout decay height is carried out on the two-dimensional section. Just like the actual grouting process, when the grout decays from the vertical crack to the horizontal crack, the grout has its own movement trajectory, which is shown to spread around in space. However, in the laboratory test device test, due to the boundary constraints of the test device, the movement and diffusion of the slurry are concentrated at the bottom valve outlet, and the number of bottom valves is relatively small, which restricts the decay process of the slurry in the vertical crack to a certain extent. As a result, the test results as shown in Fig. 16 are all smaller than the theoretical calculated values. However, except for some data, the error between most test results and theoretical calculation values is less than 10%, and the difference is not statistically significant. Both results can function as reciprocal confirmations.

As shown in Fig. 17, the yield stress is measured by collecting the slurry that flows from the bottom and comparing it to the theoretically calculated value. The experimental value is similar but somewhat higher than the theoretical calculation value, indicating that the theoretical derivation has good dependability.

7. Grouting sealing mechanism of a jointed rock mass with multiple joints

Through the above theoretical model analysis and laboratory test study, to obtain a better water control effect, the horizontal cracks extending far in the plane direction should not only be blocked but also ensure that the slurry has a high retention rate in the vertical cracks that develop longitudinally. In vertical cracks, unlike horizontal cracks, gravity promotes the deposition of grout but is not conducive to the retention of grout, and the sealing of vertical cracks cannot be completed only by the deposition of cement particles. This situation emerges because gravity hinders grout diffusion when the grout enters a connected vertical fissure from a horizontal fissure in the process of grouting pressure supply. At this time, the grouting pressure is far greater than the grout weight, the cement particles continue to rise, and no deposition occurs. When the pressure supply is stopped or the grouting pressure is less than the dead weight of the grout, not only the cement particles but also the water in various states sinks under the action of gravity and returns to the horizontal crack; that is, the phenomenon of grouting diffusion decay occurs, which is proposed in this paper.

In summary, the grouting sealing of a jointed rock mass with multiple joints can be divided into three stages: (1) The continuous pressure supply and diffusion stage. The grouting pressure is far greater than the grout weight, and the grout enters the vertical crack after passing through the horizontal crack and climbs upwards continuously, as shown in Fig. 18(a). (2) The grouting diffusion decay stage. When the pressure supply is stopped or the grouting pressure is less than the body weight of the grout, the grout as a whole sinks back to the horizontal crack, as shown in Fig. 18(b). (3) The sedimentary water closure stage. When the grout sinks to a certain height, cannot be pushed back by its own weight to the horizontal crack, and continues to spread far away, the grout sinks to the lowest point, the cement particles are retained and deposited, and some vertical cracks are sealed, as shown in Fig. 18 (c). Therefore, reducing the degree of grouting diffusion decay as much as possible guarantees a better sealing effect of laying-out jointed physical rock mass grouting.

8. Conclusion

-

1.

The rationale and need for stable grouting pressure during the grouting process are discussed. The calculation formula for stable grouting pressure time under various water plugging rates is derived based on the fracture development of the grouting formation, and a reasonable value can considerably increase the grouting efficiency while guaranteeing the grouting effect.

-

2.

A grouting diffusion decay model was proposed, and the grouting sealing mechanism of jointed rock masses with multiple layers was examined on the basis of the grout’s time-varying yield stress. The grout yield stress, or the grout ultimate retention in vertical fissures, establishes the maximum height of the grout diffusion decay following stabilisation.

-

3.

The maximum height of slurry diffusion decay following pressure stabilisation, or the slurry stock in vertical fissures, is determined by the yield stress of the slurry. The development phase of grouting diffusion decay is independent of the slurry viscosity.

-

4.

The vertical crack extension height does not affect the grouting pressure stabilisation time when the sealing rate is constant, and the minimum grouting pressure stabilisation time increases as the W/C ratio and crack width increase. Although it prevents the slurry from diffusing, the hydrostatic pressure also partially prevents the diffusion from decaying after grouting.

-

5.

A laboratory test apparatus for determining the grouting diffusion decay of a jointed rock mass with multiple joints was designed via three-dimensional visualisation. The findings confirmed the validity of the theoretical derivation by demonstrating that the experimental values of the yield stress and decay height at the same pressure stabilising time were comparable to the predicted values.

.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper, its supplementary information files.

References

Cao, Z., Yang, X., Li, Z. & Du, F. Evolution mechanism of water-conducting fractures in overburden under the influence of water-rich fault in underground coal mining. J. Sci. Rep. 14(1), 5081–5081 (2024).

Cheng, X., Sheng, L., Xia, Z., Liu, Y. & Ma, X. Grouting theory and strategy of Simultaneous Control of the Horizontal and Vertical deformations of tunnels. J. Int. J. Geomech. 24(2). https://doi.org/10.1061/ijgnai.gmeng-8839 (2024).

Guo, Z., Fan, J., Wang, F., Zhou, H. & Li, W. Geomechanical model experiment study on deformation and failure mechanism of the Mountain tunnel in layered jointed Rock Mass. J. Adv. Civil Eng. https://doi.org/10.1155/2021/6645124 (2021).

Huang, X., Ruan, H., Shi, C. & Kong, Y. Numerical Simulation of stress arching effect in horizontally layered jointed Rock Mass. J. Symmetry. 13(7), 1138–1138 (2021).

Kang, H., Li, W., Gao, F. & Yang, J. Grouting theories and technologies for the reinforcement of fractured rocks surrounding deep roadways. J. Deep Undergr. Sci. Eng. 2(1), 2–19 (2022).

Li, X., Wang, L., Hao, M., Zhong, Y. & Zhang, B. An analytical solution for the radial flow of variable density grout in rock fractures. J. Constr. Building Mater. 206, 630–640 (2019).

Li, S., Bu, L., Shi, S., Li, L. & Zhou, Z. Prediction for Water Inrush Disaster source and CFD-Based Design of Evacuation routes in Karst Tunnel. J. Int. J. Geomech. 22(5). https://doi.org/10.1061/(ASCE)GM.1943-5622.0002305 (2022).

Liang, J. et al. Numerical and experimental study of diffusion law of foamed polymer grout in fracture considering viscosity variation of slurry. Tunn. Undergr. Space Technol.128. https://doi.org/10.1016/j.tust.2022.104674 (2022).

Liu, J. et al. Groundwater control and curtain grouting for tunnel construction in completely weathered granite. J. Bull. Eng. Geol. Environ. 77(2), 515–531 (2018).

Ma, J. et al. Pressure Model Study on Synchronous Grouting in Shield Tunnels Considering the Temporal Variation in Grout Viscosity. J. Applied Sciences. 13(18). (2023).

Nan, G. et al. Analytical solution of grouting fracturing height for the post-grouted bored piles using the Herschel–Bulkley model with time-varying viscosity. J. Arab. J. Geosci. 14(20). https://doi.org/10.1007/S12517-021-08456-7 (2021).

Rafi, J. & Stille, H. A Method for Determining Grouting Pressure and Stop Criteria to Control Grout Spread Distance and Fracture Dilation112 (J. Tunnelling and Underground Space Technology Incorporating Trenchless Technology Research, 2021).

Sharma, V. M. Grouting techniques. J. Water Energy Int. 69(10), 37–41 (2013).

Song, L. et al. Modified (spherical and cylindrical) permeation diffusion model considering deep Bed Filtration Effect. J. Build. 14(1). https://doi.org/10.3390/buildings14010124 (2024).

Su, P., Jia, Y., Liu, F. & Li, C. Cement Slurry Plugging Law and Optimal Plugging Flow Rate at a High Hydraulic Gradient. J. Advances in Civil Engineering. 2021. (2021).

Sui, W., Liu, J., Hu, W., Qi, J. & Zhan, K. Experimental investigation on sealing efficiency of chemical grouting in rock fracture with flowing water. J. Tunn. Undergr. Space Technol. Incorporating Trenchless Technol. Res. 50, 239–249 (2015).

Teng, Z. et al. Investigation of a new reverse drainage construction and the pressure-reducing effect of a tunnel in a water-rich karst location. J. Tunn. Undergr. Space Technol. Incorporating Trenchless Technol. Res. 145, 105580 (2024).

Wang, Q. et al. The rheological test and application research of glass fifiber cement slurry based on plugging mechanism of dynamic water grouting. J. Constr. Building Mater. 189, 119–130 (2018).

Wu, K. et al. Study on the mechanism of grouting under different tunnel depth of Cross passage. J. Geotech. Geol. Eng. 38(prepublish), 1–15 (2020).

Xu, Z., Miao, Y., Wu, H., Yuan, X. & Liu, C. Estimation of Viscosity and Yield Stress of Cement Grouts at True Ground Temperatures Based on the Flow Spread Test. J. Material. 13(13). (2020).

Yang, X. & Liu, J. Investigation of grouting of cement grouts. C. Scientific Research Institute of Hydraulic Research Papers Hydropower(27 Set). Beijing: China Water and Power. 184–192. (1987).

Yi, D. et al. Study on Penetration Grouting Mechanism Based on Newton Fluid of Time-Dependent Behavior of Rheological Parameters. J. Shock and Vibration. 2020. (2020).

Yi, T., Hao, C., Lv, W., Yan, W. & Guo, W. Calculation of the height of the Water-conducting fracture zone based on the analysis of critical fracturing of overlying Strata. J. Sustain. 14(9), 5221–5221 (2022).

Yuan, S., Sun, B., Han, G., Duan, W. & Wang, Z. Application and Prospect of Curtain Grouting Technology in Mine Water Safety Management in China: a review. J. Water. 14(24), 4093–4093 (2022).

Zhai, M., Ma, D. & Bai, H. Diffusion mechanism of slurry during grouting in a fractured aquifer: a Case Study in Chensilou Coal Mine, China. J. Math. 10(8), 1345 (2022).

Zhan, J., Sui, W. & Wang, W. Correlation analysis between seepage pressure and water plugging effect of fracture grouting. J. Geotech. Mech. 33, 2650–2655 (2012).

Zhan, K., Sui, W. & Wang, W. Correlation analysis of seepage pressure and water plugging effect during grouting into a fracture with flowing water. J. Rock. Soil. Mech. 33(9), 2650–2662 (2012b).

Zhang, D., Fang, Q. & Lou, H. Grouting techniques for the unfavorable geological conditions of Xiang’an subsea tunnel in China. J. J. Rock. Mech. Geotech. Eng. 6(5), 438–446 (2014).

Zhang, L. et al. Permeation Grouting Diffusion Mechanism of Quick Setting Grout. Tunn. Undergr. Space Technol.124. https://doi.org/10.1016/j.tust.2022.104449 (2022).

Zhang, Q., Zhang, C., Lin, Y., Li, Y. & He, L. Numerical Study on Seepage of Chemical Grout Flow in Rock Fracture under Temperature Field. J. Geofluids 1–15. https://doi.org/10.1155/2022/7123416 (2022).

Zhang, S. et al. Research on flow field characteristics in the karst tunnel face drilling hole (conduit) under the coupling between turbulence and seepage. Tunn. Undergr. Space Technol.143. https://doi.org/10.1016/j.tust.2023.105455 (2023).

Zhang, G., Zhang, J., Pei, X., He, Z. & Zheng, G. Study on numerical simulation method of viscosity time-varying slurry diffusion law. J. Frontiers in Earth Science. 2023b. (2023).

Zhao, P., Wang, Q., Wang, L., Wang, X. & Ma, H. Parameter Optimization of Constant Pressure Grouting Technology for Borehole Sealing with Inorganic Noncondensable Material in Tectonic Coalbed of South China. J. Geofluids. 2023 (2023). (2023).

Zhe, Y., Hou, K., Liang, W. & Sun, H. Research on Sustainable Mining and Water Prevention in large open-pit water deposits. J. Sustain. 15(13). https://doi.org/10.3390/su151310238 (2023).

Zhu, H. et al. The Split-Permeation Grouting mechanism of Loose and Broken Coal Rock Masses considering the temporal and spatial characteristics of Slurry Viscosity. J. KSCE J. Civil Eng. 25(5), 1–14 (2021).

Author information

Authors and Affiliations

Contributions

Y.Z. and K.H. wrote the main manuscript text. Z.W. and S.Y. performed the indoor grouting simulation test and data processing. Y.Y. studied the mechanism of grouting sealing in Chapter 2. All the authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yalei, Z., Kepeng, H., Zongyong, W. et al. The grouting plugging mechanism of layered jointed rock mass considering the time-varying yield stress of grout. Sci Rep 14, 23029 (2024). https://doi.org/10.1038/s41598-024-74583-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-74583-2

Keywords

This article is cited by

-

Novel nanomagnetic-based slurry for grouting fractured rocks

Discover Civil Engineering (2025)