Abstract

The ZnFe prussian blue analogue [ZnFe(PBA)] was infused with Ti3C2Tx (MXene) denoted as ZnFe(PBA)@Ti3C2Tx and was prepared by an in-situ sonication method to use as a non-enzymatic screen printed electrode sensor. The advantage of non-enzymatic sensors is their excellent sensitivity, rapid detection, low cost and simple design. The synthesized ZnFe(PBA)@Ti3C2Tx was characterized for its physical and chemical characterization by XRD, Raman, XPS, EDAX, and FESEM analysis. It possessed multiple functionalized layers and a cubic structure in the nanohybrid. Further, the sensor was investigated by using electroanalytical studies such as cyclic voltammetry and chronoamperometry analysis. The enhanced surface area with a cubic structure of ZnFe(PBA) and the excellent electrical response of Ti3C2 nanosheet support the advancement of a non-enzymatic electrochemical glucose sensor with improved sensitivity of 973.42 µA mM−1 cm−2 with the limit of detection (LOD) of 3.036 µM (S/N = 3) and linear detection range (LDR) from 0.01 to 1 mM.

Similar content being viewed by others

Introduction

Monitoring blood sugar levels is crucial for managing diabetes, a chronic condition that disrupts glucose regulation. Diabetes has become one of the world’s most serious health concerns, impacting over 220 million people, and the number of diabetic patients is expected to more than double in the next 20 years1. Clark and Updike found the first enzyme electrode and amperometry enzymatic biosensors in the 1960s2. Detection and quantitative measurement of glucose, a monosaccharide group, plays an important role in environmental protection, especially food glucose concentration, medical monitoring and biotechnology Industries3.

The amperometry electrochemical sensor is classified into non-enzymatic and enzymatic sensors based on glucose oxidation by the electrocatalyst activity. Enzymatic glucose sensors rely on the glucose oxidase (GOx) enzyme, which exhibits high sensitivity and targeted glucose selectivity rather than the other components in the sample. Despite its high manufacturing costs and poor long-term stability, the enzymatic sensor is still commercial. In contrast, the non-enzymatic sensor is becoming more attractive and desirable. The non-enzymatic glucose sensor-based electrochemical sensor based on nanostructure compounds exhibits high durability even though there are many metal oxides, nanoparticles, and bimetallic Prussian blue analogues have been employed as a non-enzymatic glucose sensor due to their high surface area; excellent chemical stability, high electrocatalytic activity, efficient electron transfer, ease of synthesis, and low precursor cost4,5,6. Due to this technology gap, chemical sensors have developed quickly. They can now non-invasively detect analytes in readily available biofluids, giving us a window into the body’s entire dynamic biomolecular state. There are several potential biofluids; however, most have drawbacks for wearable sensing. Implantable medical devices can continually monitor blood and interstitial fluid (IF), but non-invasive access through a wearable platform is challenging. Because saliva greatly influences recent meals, urine-based sensors cannot be incorporated into wearable devices, although they may be able to offer some physiological information. Tears can be unpleasant or unsafe to source, and discomfort might lead to reflex tears that cause problems in sensor readings. Sweat, on the other hand, has considerable potential for wearable sensing7,8. Glucose levels vary significantly between blood and sweat. Human blood glucose levels range from 3.9 to 5.5 mM when fasting and can rise up to 7.8 mM after eating. Meanwhile, human sweat glucose level is substantially lower, generally falling within the range of 0.06 to 0.22 mM9.

Owing to its unique structure, ferrocene (Fc) has high electrocatalytic and stable chemical properties. Two cyclopentadienyl groups are wedged between an excited state ferrous iron ion. As a result, ferrocene has recently been attracting a lot of interest in the disciplines of electrochemical and energy storage devices like supercapacitors, batteries, and electrochemical sensors. Under investigations, ferrocene has a strong capacity to oxidize or reduce the number of small biological molecules, namely glucose, urea, ascorbic acid, xanthine, and DNA10.

Prussian blue analogues (PBAs), intriguing crystalline metal-organic frameworks (MOFs) defined by the formula A₃(II)[-A’(III)(CN)⁶]₂ (where A and A’ are redox-active transition metals), possess remarkable properties like high surface area, porosity, and reversible redox behaviour11. While ZnFe-PBA, a prominent example, excels in electrochemical sensing, it’s rapid crystallization and subsequent self-agglomeration during synthesis hinder its broader material applications12.

MXenes can be prepared by targeted removal of layer A from the MAX phase. M denotes a transition metal, A denotes group A elements, and X denotes C or N4,5. MAX phase is a densely packed stacked layer structure comprising alternative layers of A and M connected by a dominant metal, covalent M-X link and a weak M-A connection. MAX phases, on the other hand, have impressive electrical and thermal conducting qualities, resistance to chemical assaults, and a low thermal expansion coefficient. MXenes are described by the generic formula Mn+1XnTx, where T denotes surface functional groups (-OH, =O, and -F) and n is an integer between 1 and 313,14. MXenes have received attention from the scientific community and industry because of their large surface area, layered structure, strong electrical conductivities, excellent hydrophilicity, good thermal stability, and environmentally favourable properties15.

Li et al. designed a flexible wearable non-enzymatic sensor based on Pt/MXene with a sensitivity of 3.43 µA mM−1 cm−2 and a limit of detection of 29.15 µM (S/N = 3)16. Zahed et al. used carbon at MXene for real-time monitoring of sweat glucose with epidermal patches with a sensitivity of 100.85 µA mM−1 cm−2 within physiological levels (0.003 − 1.5 mM). Subramania et al. used NiCo2O4 with Ti2NbC2 (double MXene) for the detection of glucose from human sweat by electrochemical correlation method with a sensitivity of 429.9 µA mM−1 cm−2 and with a rapid reaction time of 2 s. Neravathu et al. used a hybrid nanomaterial of ZnFe2O4/α-Fe2O3 implanted graphene with a sensitivity of 609 µA mM−1 cm−217.

This study marks the first explored ZnFe(PBA)@Ti3C2Tx nanohybrid for non-enzymatic biosensor applications. The metal-organic framework (MOF) derived ZnFe(PBA) was synthesized via co-precipitation, followed by the preparation of Ti3C2Tx using chemical etching and probe sonication. The resulting ZnFe(PBA)@Ti3C2Tx nanohybrid was thoroughly characterized using XRD, Raman spectroscopy, EDAX, XPS, and FESEM. The paper highlights this novel nanohybrid’s development and electrochemical performance for non-enzymatic glucose sensing. Various electrochemical techniques were employed to evaluate its sensing behaviour, demonstrating its effectiveness. Finally, the real-world applicability of the sensor was tested by analyzing glucose in sweat samples.

Experimental section

Chemical required

MAX phase powder (Ti3AlC2) was bought from Nanochemazone, Canada. Hydrofluoric acid and ethanol were purchased from Sigma Aldrich. ZnCl2 and potassium ferricyanide were purchased from Merck and Otto Chem India, respectively. DI water was used throughout the experiment to prepare all reagents.

Synthesis of prussian blue analogue of ZnFe(PBA)

0.06 M of ZnCl2 in 100 ml of DI water and 0.04 M of K3[Fe (CN)6] in 100 ml of (12 M) HCl were prepared in two separate beakers. These two solutions were mixed dropwise to induce the co-precipitation process. Then, the formed precipitate mixture was stirred for 5 h in ambient conditions and rested overnight for sedimentation of the residue. The precipitates were centrifuged, washed thoroughly with DI water several times, and dried in a vacuum at 60 °C for 12 h.

Synthesis of Ti3C2Tx

MAX phase sample (Ti3AlC2) was initially treated with hydrofluoric acid (HF) in the ratio of 1:20, followed by 48 h of stirring at room temperature in the fume-hood without any disturbance. The aluminium-etched Ti3C2Tx was then washed with DI water for a neutral pH, dried in a falcon tube, and vacuumed for 24 h to remove moisture from the obtained MXene. The stacked MXene was then taken and delaminated with the help of probe sonication in the ratio of 1:20 of the desired solvent. The probe sonication was done for 60 min in the cold bath. Then, the delaminated Ti3C2Tx supernatant was collected, dried, and used for further studies.

Preparation of ZnFe(PBA)@Ti3C2Tx nanohybrid

The Ti3C2Tx was treated with 10X PBS (Phosphate buffer saline) for 1 h of sonication to get uniform dispersion of Ti3C2Tx on the PBS saline. The ZnFe(PBA) was initially treated with 2% (3-aminopropyl) triethoxysilane (APTES) (in anhydrous ethanol 99.6%) to retain functional groups on its surface. Then, APTES was removed by washing 2 times with ethanol and 1 time with PBS. Once ready, Ti3C2Tx was mixed with ZnFe(PBA) in a 1:10 ratio for uniform dispersion through ultrasonication for 2 h. This was centrifuged, washed with deionized water to remove the unbounded MXene, and dried in a vacuum at 60 °C for 12 h to get ZnFe(PBA)@Ti3C2Tx nanohybrid.

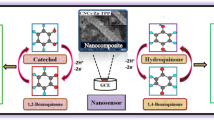

Fabrication of ZnFe(PBA)@Ti3C2Tx coated GCE

The uncoated glassy carbon electrode (GCE) was smoothened using an alumina polish pad with 0.05 m of alumina powder before being cleaned with ethanol and deionized water to remove residue on the electrode surface. The slurry of ZnFe(PBA)@Ti3C2Tx nanohybrid was prepared by mixing 2 mg of the prepared nanohybrid material with Nafion (1 ml of 2% ethanol solution) and eventually homogenized using an ultrasonic process until to get a uniform slurry (Fig. 1). The same fabrication method was employed to coat the screen-printed electrode with the nanohybrid for real-time sweat sample analysis.

Characterization

Physical characterization

X-ray diffractometer (Rigaku, Model: Ultima IV) with nickel-filtered Cu-Kα radiation at the wavelength of 1.540 Å was utilized for understanding the morphologies of ZnFe(PBA), Ti3C2Tx, and ZnFe(PBA)@Ti3C2Tx. The crystallinity and phase purity of the synthesized samples were determined by scanning the sample at a rate of 10° to 80° with a 0.05° increment. The FESEM (Carl Zeiss (USA) Model: Sigma with Gemini column) was used to know the morphologies of ZnFe(PBA), Ti3C2Tx, and ZnFe(PBA)@Ti3C2Tx. The Energy dispersive X-ray analysis (BRUKER, Model: Nano XFlash Detector) was used to observe the elements present in the synthesized ZnFe(PBA), Ti3C2Tx, and ZnFe(PBA)@Ti3C2Tx. A confocal micro-Raman spectrometer (Renishaw RW-2000) utilizing an Ar + laser with a wavelength of 785 nm was used to record the Raman spectra. An X-ray photoelectron spectrometer (Thermo Scientific) using K-Alpha-KAN9954133 was used to evaluate XPS where ZnFe(PBA)@Ti3C2Tx nanohybrid was dispersed in ethanol and then drop cast on 5 × 8 mm silicon/glass slides.

Electrochemical characterization

Cyclic voltammetry (CV) and chronoamperometry (CA) were studied in ambient conditions via Metroohm (MultiAuto lab/M204) using a three-electrode system. Modified GCE, silver/silver chloride electrode, and platinum rod were used as working, reference, and counter electrodes. The screen-printed electrode from Metroohm was purchased with the same specifications as the electrode used for the real sample analysis.

Results and discussion

XRD studies

The XRD pattern for 2θ range from 10°-80° is shown in Fig. 2. The XRD pattern of ZnFe(PBA) exhibits a prominent diffraction pattern, which could be accurately matched with the cubic phase (Fm3-m) of zinc hexacyanoferrate hydrate (JCPDS Card No-98-001-3332)18. The X-ray diffraction pattern of ZnFe (PBA) reveals distinct peaks at 14.80°, 17.13°, 24.32°, 34.66°, 38.91°, 52.29°, 53.08°and 56.20° and their corresponding planes are (111), (002), (022), (004), (024), (135), (006) and (026), respectively19. The peaks at 19.49°, 22.19°, 28.30°, and 42.82° correspond to the secondary phase of tri-zinc bis (hexacyanoferrate (III)), which is confirmed with JCPDS No-98-011-0335 with planes (024), (122), (220), and (054)20. In the XRD pattern, peaks at 18.34° and 27.40° contribute to the (006) and (008), crystallographic planes of Ti2C321,22. Additionally, from the JCPDS No 98-008-5845 peaks at 35.89°, 41.68°, 60.42°, 72.31°, and 76.08° correspond to the (111), (002), (022), (113), and (222) planes, respectively23,24, confirming the presence of Titanium Carbide. The nanohybrid XRD pattern confirms the presence of ZnFe(PBA) and Ti3C2Tx. The Scherrer formula is applied to calculate the sample’s average grain size as follows:

Where, K is a constant (K = 0.89), λ is the wavelength of the radiation (\(\:\lambda\) = 1.54178 Å), D is the grain size, \(\:\beta\) is the width at the half maximum on a 2\(\:\theta\) scale, and \(\:\theta\) is the angle of the considered Bragg reflection. The average particle size is ~ 26 ± 3 nm for the in-situ sonicated ZnFe(PBA)@Ti3C2Tx.

Raman studies

Figure 3 represents the Raman spectra of ZnFe(PBA), Ti3C2Tx, and ZnFe(PBA)@Ti3C2Tx nanohybrid. Anharmonic frequency shift and quasi-harmonic lattice expansion are the main causes of the Raman band shift. The resonance peak observed at 120 cm⁻¹ exhibited a blue shift of 127 cm⁻¹ due to probe sonication of the flakes for delamination25. Two Raman active modes, 364 and 387 cm−1, are in the monolayered Ti3C2Tx sheet. The peak at 380 cm−1 obtained from spectra perfectly matches these two modes, suggesting that the terminal groups are delaminated or heterogeneous26,27. The vibration of Ti3C2Tx consists of Eg (in-plane) and A1g (out-of-plane) peaks, both of Ti and C atoms, where the A1g peak observed at 205 cm⁻1 is attributed to vibration originating from titanium surface groups. Furthermore, the Eg and A1g peaks at 580/622 cm−1 and 725 cm−1 are assigned to carbon vibration28. The ZnFe(PBA) of characteristic bands was noted at 517 and 602 cm−1 (attributed to Fe − C stretching) and at 2119, 2161 and 2191 cm−1, assigned to A1g, totally symmetrical stretching of CN29. For C ≡ N vibration, 2119 and 2161 cm−1 are because of cyanide stretching coordinated iron-cyanide (FeII−CN), while 2191 cm−1 is cyanide stretching near oxidized iron (FeIII − CN)30. In the region at (100–700 cm⁻¹), isolated bands corresponding to the CN and NO groups are observed. The three peaks at 238, 491, and 655 cm⁻¹ are assigned to the Fe–C–N–Fe vibrational modes. The peak at 500 cm⁻¹ exhibits A₁ symmetry, indicative of longitudinal acoustic (LA) overtones. The peak at 275 cm⁻¹ is also attributed to interstitial zinc clusters, where the involved Zn atoms reside in neighbouring interstitial sites31.

XPS studies

In this spectrum (Fig. 4), spin orbit-splitting gives rise to the doublets Ti 2p3/2 (binding energy 459.4 eV) and Ti 2p1/2 (binding energy 464.4 eV)32. Zn2+ peaks at 1044.7 eV and 1021.5 eV are denoted as Zn 2p1/2 and 2p3/2, respectively33. For the Fe 2p spectra, the peak at 708.9 eV corresponded to the lower-energy spin-orbital of Fe 2p3/2. The peak in the higher-energy spin-orbital (2p1/2) region is at 721. eV is assigned to Fe 2p1/2. The C 1s spectrum displayed three distinct peaks at 284.4 eV, 284.9 eV, and 286.4 eV, respectively, assigned to C = C, C = N, and C ≡ N bonding. The presence of the C ≡ N group was further confirmed by the N 1s spectrum, which showed a peak at 398.2 eV, characteristic of this functional group. The O 1s spectrum exhibited prominent peaks at 531.4 eV and 532.6 eV binding energies, corresponding to C-O-C and C = O functional groups, respectively34,35,36,37.

FE-SEM and EDAX studies

The FE-SEM analysis illustrates the morphology of ZnFe(PBA), Ti3C2Tx, and ZnFe(PBA)@ Ti3C2Tx nanohybrid. The FESEM pictures of ZnFe(PBA) and Ti3C2Tx, as seen in Fig. 5a, and b, clearly depict the cubic structure of ZnFe(PBA), whereas nanosheet structures were verified for Ti3C2Tx. As seen in Fig. 5c, ZnFe(PBA)@Ti3C2Tx nanohybrid and a ZnFe(PBA) nanocubic structure were injected into Ti3C2Tx sheets. The Energy Dispersive X-ray analysis (EDAX) of the ZnFe(PBA)@ Ti3C2Tx nanohybrid confirms the presence of several elements, including zinc (Zn), iron (Fe), oxygen (O), Titanium (Ti), nitrogen (N), fluoride (F), and carbon (C). This is evident from the EDAX spectra presented in Fig. 6a. Additionally, Fig. 6b provides a visual representation of the distribution of each element through elemental mapping.

Electrochemical studies

The electrochemical performances are performed in a three-electrode setup with GCE as a working electrode. The glucose analyte, which diffused in the prepared electrolyte of varying concentrations ranging from 0.01 to 1 mM concentration, is analyzed by using the electrolyte of 0.1 M KOH and the prepared ZnFe(PBA)@Ti3C2Tx nanohybrid electrode. Continuous oxidation and reduction in the composites were studied in the presence and absence of glucose. When ZnFe(PBA)@Ti3C2Tx is synthesized, it presents an oxidation peak at around 0.4 V, representing the oxidation of glucose to gluconate and a reduction at 0.3 V, representing the reduction of gluconate to glucose. Figure 7a shows the electroanalytical performance of GCE, ZnFe(PBA), Ti3C2Tx and ZnFe(PBA)@Ti3C2Tx in the absence of glucose at a scan rate of 25 mVs−1.

Similarly, Fig. 7b represents the presence of glucose at a concentration of 0.75 mM containing electrolyte. The Ti3C2Tx coated electrode shows no electroanalytical behaviour in the electrolyte, clearly showing that it lacks the catalytic capacity for glucose38,39,40,41. The sensor shows a linearity redox peak magnitude versus scan rate (30 mVs−1- 140 mVs−1) in the presence of 0.75 mM of glucose-containing electrolyte in the potential window of -0.1 to 0.8 as shown in Fig. 7c. The Iap and Icp. are illustrated by calibrating the plot of anodic oxidation and cathodic reduction as shown in Fig. 7d which illustrates the diffusion-controlled electrochemical42 behaviour which is in a Randles-Sevcik Plot, which displays the peak current of the redox reactions versus the scan rate’s square root, where R2 is 0.9974 and 0.9983, correspondingly.

Additionally, the formula for determining the glucose sensor’s sensitivity (S) and limit of detection (LOD) is LOD = 3σ/m, where m is the linear plot’s slope and σ is the steady-state current signal’s standard deviation (S/N ratio = 3). Sensitivity is calculated by slope/electrode area43. The development of a non-enzymatic electrochemical glucose sensor with enhanced sensitivity of 973.42 µA mM−1 cm−2 and a limit of detection (LOD) of 3.036 µM (S/N = 3). The CV is conducted over the glucose concentration range of 0.01 mM−1 mM of both hypoglycaemic and hyperglycaemic patients (0.02–0.6 mM)44 showing a sensitivity of 973.42 µA mM−1 cm−2 with good selectivity and better reproducibility with a linear detection range (LDR) of 0.01 to 1 mM.

Cyclic voltammetry is performed for the different concentrations of glucose. Figure 8a shows a different oxidation and reduction current response for other concentrations. Chronoamperometry measures the response to the sequential addition of glucose at low and high concentrations in PBS electrolytes. Chronoamperometry measured glucose concentration changes, varying from low to high (Fig. 8b). The analysis identified 1 mM is the optimal applied potential (Eapp) for maximizing glucose oxidation sensitivity due to its high response current and rapid reaction time. The sensor responded within two seconds, suggesting efficient electrocatalysis and fast electron transfer within ZnFe(PBA)@Ti3C2Tx. Interestingly, the calibration plot exhibited two distinct linear ranges: low concentrations (Fig. 8c) and high concentrations (Fig. 8d), which have coefficient (R) values of 0.98 and 0.99, respectively. Table 1 shows the comparison of the sensitivity, limit of detection, and linear range of the fabricated ZnFe(PBA)@Ti3C2Tx glucose sensor with previously reported materials. It is observed from Table 1 that the prepared ZnFe(PBA)@Ti3C2Tx system has a higher sensitivity of 973.4 µA mM−1 cm−2 than the other reported system.

As shown in Fig. 9a, the current responses to the increase in glucose concentration signify its sensing ability. The selectivity of the nanohybrid is simulated with the artificial human sweat concentration prepared in the lab, where we use 1 M PBS (pH 7.4) to measure the current response, as shown in Fig. 9b. Subsequently, we injected glucose, ascorbic acid, uric acid, dopamine, NaCl and lactic acid one by one. Glucose elicited a significantly higher current response than other interferents, indicating excellent selectivity for glucose detection over other common components in human sweat. The long-term stability of the prepared ZnFe(PBA)@Ti3C2Tx nanohybrid is performed for 12 days. It is determined by the current values acquired from chronoamperometry in 0.1 mM of glucose, as shown in Fig. 9c. The nanohybrid electrode demonstrates excellent stability and retains 97% of its initial signal (Fig. 9d).

Analysis of glucose in real samples

The real-time performance of the non-enzymatic glucose sensor is assessed through the analysis of glucose concentrations in human sweat. The sweat from the hand seems to be a more promising site than all the other parts of the human body due to its relatively high sweat gland density and natural sweating rate52,53. Sweat samples from three people are collected and applied to the three-electrode screen-printed electrode, where non-enzymatic activity is observed (Table 2). The sensor has a portable potentiostat for decentralized analysis, as depicted in Fig. 10a-c. The working electrode, ZnFe(PBA)@Ti3C2Tx, facilitates glucose oxidation and ensures selective glucose detection with a commendable repeatability of 1.91% reative standard deviation (RSD).

The corresponding blood and sweat glucose concentrations were detected in three different persons. Our fabricated sensor’s glucose concentration is similar to a commercial glucometer (Tecan Sunrise Plate Reader), showing high potential for its practical application in detecting blood glucose.

Conclusion

We have introduced an innovative non-enzymatic glucose sensor utilizing a screen-printed electrode with electrochemical oxidative ZnFe(PBA)@Ti3C2Tx nanohybrid material. This creative combination leverages the excellent electrocatalytic activity of the Prussian blue analogue-derived metal-organic framework ZnFe(PBA) with the ultra-high conductivity of 2D delaminated titanium MXene. Our investigation evaluated its electrochemical performance in detecting glucose in human sweat. This sensor demonstrates remarkable characteristics in electrochemistry, including a notably large active surface area and elevated electrocatalytic activity for the electro-oxidation of glucose. The sensor exhibits an excellent sensitivity of 973.42 µA mM−1 cm−2. This underscores the sensor’s commendable attributes, such as sensitivity, linearity, selectivity, and stability for electrochemically detecting glucose. This study highlights the effective synergy between a cubic metal-organic framework derived from a Prussian blue analogue with excellent electrocatalytic activity and a 2D delaminated Ti3C2Tx with ultra-high conductivity. This combination emerges as a promising approach to developing high-performance electrochemical biosensors. The sensor response’s RSD (relative standard deviation) is 1.91%, indicating good reproducibility for detecting human sweat glucose.

Data availability

No crystallographic data, as we used powder XRD patterns. Other data is provided within the manuscript files.

References

Wang, J. Electrochemical glucose biosensors. Chem. Rev. 108, 814–825 (2008).

Clark, L. C. & Lyons, C. Electrode systems for continuous monitoring in cardiovascular surgery. Ann. N. Y. Acad. Sci. 102, 29–45 (1962).

Yang, J., Jiang, L. C., De Zhang, W. & Gunasekaran, S. A highly sensitive non-enzymatic glucose sensor based on a simple two-step electrodeposition of cupric oxide (CuO) nanoparticles onto multi-walled carbon nanotube arrays. Talanta. 82, 25–33 (2010).

Hassan, M. H., Vyas, C., Grieve, B. & Bartolo, P. Recent advances in enzymatic and non-enzymatic electrochemical glucose sensing. Sensors 21, 4672 (2021).

Kim, J. H. et al. Diboronic-Acid-based Electrochemical Sensor for enzyme-free selective and sensitive glucose detection. Biosens. (Basel) 13, 248 (2023).

Blasques, R. V. et al. Disposable prussian blue-anchored electrochemical sensor for enzymatic and non-enzymatic multi-analyte detection. Sens. Actuators Rep. 4, 100118 (2022).

di Dottorato di Amicucci Chiara, T. Synthesis of Silver Nanowires and Fabrication of Substrates for Surface Enhanced Raman Spectroscopy for Detection of Biomolecules Chap Vol. 1 (Silver Nanowires, an Overview, 2022).

Bandodkar, A. J. & Wang, J. Non-invasive wearable electrochemical sensors: a review. Trends Biotechnol. 32, 363–371 (2014).

Zafar, H., Channa, A., Jeoti, V. & Stojanović, G. M. Comprehensive Review on Wearable sweat-glucose sensors for continuous glucose monitoring. Sensors 22, 638 (2022).

Chu, M. et al. In situ growth of CoFe-prussian blue analog nanospheres on ferrocene-functionalized ultrathin layered Ti3C2Tx MXene frameworks for efficient detection of xanthine. Chem. Eng. J. 469, (2023).

Li, J., Li, Y., Zhang, Y. & Wei, G. Highly sensitive molecularly imprinted electrochemical sensor based on the double amplification by an inorganic prussian blue catalytic polymer and the enzymatic effect of glucose oxidase. Anal. Chem. 84, 1888–1893 (2012).

Li, W. J. et al. Chemical Properties, Structural Properties, and Energy Storage Applications of Prussian Blue Analogues. Small 15 (2019).

Yao, L. et al. Partially oxidized Ti3C2Tx MXene-sensitive material-based ammonia gas sensor with high-sensing performances for room temperature application. J. Mater. Sci.: Mater. Electron. 32, 27837–27848 (2021).

Tian, S. et al. Recent advances in MXenes-based glucose biosensors. Chin. Chem. Lett. 34, 108241 (2023).

Naguib, M., Mochalin, V. N., Barsoum, M. W. & Gogotsi, Y. 25th anniversary article: MXenes: a new family of two-dimensional materials. Adv. Mater. 26, 992–1005 (2014).

Li, Q. F., Chen, X., Wang, H., Liu, M. & Peng, H. L. Pt/MXene-Based flexible wearable non-enzymatic Electrochemical Sensor for continuous glucose detection in sweat. ACS Appl. Mater. Interfaces. 15, 13290–13298 (2023).

Neravathu, D., Paloly, A. R., P., S., M., S. & Bushiri, M. J. Hybrid nanomaterial of ZnFe2O4/α-Fe2O3 implanted graphene for electrochemical glucose sensing application. Diam. Relat. Mater. 106, 107852 (2020).

Gravereau, P. & Garnier, E. Structure de la phase cubique de l’hexacyanoferrate(III) de zinc: Zn3[Fe(CN)6]2.nH2O. Acta Crystallogr. Sect. C. 40, 1306–1309 (1984).

Silva, M. N. T., Ardisson, J. D., Fabrisa, J. D. & Nossol, E. Zinc Hexacyanoferrate/Multi-Walled Carbon nanotubes films for rechargeable aqueous batteries. J. Braz Chem. Soc. 31, 1787–1795 (2020).

Rodríguez-Hernández, J. et al. An atypical coordination in hexacyanometallates: structure and properties of hexagonal zinc phases. J. Phys. Chem. Solids. 68, 1630–1642 (2007).

Liu, N. et al. Ti3C2-MXene partially derived hierarchical 1D/2D TiO2/Ti3C2 heterostructure electrode for high-performance capacitive deionization. Adv. Sci. 10, 2204041 (2023).

Gao, Y. et al. Hydrothermal synthesis of TiO2/Ti3C2 nanocomposites with enhanced photocatalytic activity. Mater. Lett. 150, 62–64 (2015).

Mahmood, M. et al. Synthesis of ultrathin MnO2 nanowire-intercalated 2D-MXenes for high-performance hybrid supercapacitors. Energy Fuels. 35, 3469–3478 (2021).

Norton, J. T. & Mowry, A. L. Solubility relationships of the refractory monocarbides. JOM. 1, 133–136 (1949).

Sarycheva, A. & Gogotsi, Y. Raman Spectroscopy Analysis of the structure and Surface Chemistry of Ti3C2Tx MXene. Chem. Mater. 32, 3480–3488 (2020).

Kaipoldayev, O. et al. Studying of 2D Titanium Carbide structure by Raman Spectroscopy after Heat Treatment in Argon and hydrogen atmospheres. Eurasian Chem. Technol. J. 19, 197–200 (2017).

Hu, T. et al. Vibrational properties of Ti3C2 and Ti3C2T2 (T = O, F, OH) monosheets by first-principles calculations: a comparative study. Phys. Chem. Chem. Phys. 17, 9997–10003 (2015).

Emerenciano, A. A. et al. Ti3C2 MXene membranes for gas separation: influence of Heat Treatment conditions on D-Spacing and Surface Functionalization. Membr. (Basel) 12, 1025 (2022).

Coupry, C., Lautie, A. & Revault, M. Contribution of Raman Spectroscopy to Art and History. J. Raman Spectrosc. 25, 89-94 (1994).

Steen, I. A., Jeerage, K. M. & Schwartz, D. T. Raman Spectroscopy of Redox Activity in Cathodically Electrodeposited Nickel Hexacyanoferrate Thin films. Applied Spectroscopy 56, 1021-1029 (2002).

Momot, A. et al. A novel explanation for the increased conductivity in annealed Al-doped ZnO: an insight into migration of aluminum and displacement of zinc. Phys. Chem. Chem. Phys. 19, 27866–27877 (2017).

Bharti, B., Kumar, S., Lee, H. N. & Kumar, R. Formation of oxygen vacancies and Ti3+ state in TiO2 thin film and enhanced optical properties by air plasma treatment. Sci. Rep. 6, 32355 (2016).

Chiu, F. C. & Chiang, W. P. Trap exploration in amorphous boron-doped ZnO films. Materials. 8, 5795–5805 (2015).

Pires, B. M. et al. Characterization of porous cobalt hexacyanoferrate and activated carbon electrodes under dynamic polarization conditions in a sodium-ion pseudocapacitor. J. Energy Chem. 54, 53–62 (2020).

Ahmed, J. et al. Mn2O3 nanoparticle-porous silicon nanocomposite based amperometric sensor for sensitive detection and quantification of Acetaminophen in real samples. Ceram. Int. 49, 933–943 (2023).

Ahmed, J., Faisal, M., Jalalah, M., Alsareii, S. A. & Harraz, F. A. Novel polypyrrole-carbon black doped ZnO nanocomposite for efficient amperometric detection of hydroquinone. J. Electroanal. Chem. 898, 115631 (2021).

Ahmed, J. et al. An efficient amperometric catechol sensor based on novel polypyrrole-carbon black doped α-Fe2O3 nanocomposite. Colloids Surf. Physicochem Eng. Asp. 619, 126469 (2021).

Muthukutty, B. et al. Progress and Perspective in harnessing MXene–carbon-based composites (0–3D): synthesis, performance, and applications. Chemosphere. 355, 141838 (2024).

Shobana, B., Kumar, S., Renugadevi, P., Prakash, P. & K. & Sensing the invisible: Ultra-low-level electrochemical detection of the microbe (Pseudomonas aeruginosa) on cobalt ferrite-doped silver nanocomposite (CoFe2O4/AgNPs) surfaces. Food Chem. 439, 138073 (2024).

Chandran, B. et al. Cerium Zirconium Oxide-decorated reduced Graphene Oxide Nanocomposite for low potential voltammetric detection of N-Hydroxysuccinimide. ACS Appl. Nano Mater. 7, 6839–6850 (2024).

Alagumalai, K. et al. Improved electrochemical detection of levofloxacin in diverse aquatic samples using 3D flower-like Co@CaPO4 nanospheres. Environ. Pollut. 343, 123189 (2024).

Ahmed, J., Faisal, M., Harraz, F. A., Jalalah, M. & Alsareii, S. A. Development of an amperometric biosensor for dopamine using novel mesoporous silicon nanoparticles fabricated via a facile stain etching approach. Phys. E Low Dimens Syst. Nanostruct. 135, 114952 (2022).

Han, X. et al. A novel electrochemical sensor for glucose detection based on a Ti3C2Tx/ZIF-67 nanocomposite. RSC Adv. 12, 20138–20146 (2022).

Bae, C. W. et al. Fully stretchable Capillary Microfluidics-Integrated Nanoporous Gold Electrochemical Sensor for Wearable continuous glucose monitoring. ACS Appl. Mater. Interfaces. 11, 14567–14575 (2019).

Zahed, M. A. et al. A Nanoporous Carbon-MXene Heterostructured Nanocomposite-based epidermal Patch for real-time biopotentials and sweat glucose monitoring. Adv. Funct. Mater. 32, 2208344 (2022).

Myndrul, V. et al. MXene nanoflakes decorating ZnO tetrapods for enhanced performance of skin-attachable stretchable enzymatic electrochemical glucose sensor. Biosens. Bioelectron. 207, 114141 (2022).

Alanazi, N. et al. Cu2O/MXene/rGO ternary nanocomposites as sensing electrodes for nonenzymatic glucose sensors. ACS Appl. Nano Mater. 6, 12271–12281 (2023).

Cui, F. et al. Laser-induced graphene (LIG)-based Au@CuO/V2CTx MXene non-enzymatic electrochemical sensors for the urine glucose test. Chem. Eng. J. 457, 141303 (2023).

Shang, L. J. et al. A non-invasive glucose sensor based on 3D reduced graphene oxide-MXene and AuNPs composite electrode for the detection of saliva glucose. J. Appl. Electrochem. 54, 1807–1817 (2024).

Pan, Y., He, M., Wu, J., Qi, H. & Cheng, Y. One-step synthesis of MXene-functionalized PEDOT: PSS conductive polymer hydrogels for wearable and noninvasive monitoring of sweat glucose. Sens. Actuators B Chem. 401, 135055 (2024).

Li, C., Xiong, J., Zheng, C. & Zhao, J. Screen-Printing Preparation of High-Performance Nonenzymatic glucose sensors based on Co3O4 nanoparticles-embedded N-Doped Laser-Induced Graphene. ACS Appl. Nano Mater. 5, 16655–16663 (2022).

Lin, P. H., Sheu, S. C., Chen, C. W., Huang, S. C. & Li, B. R. Wearable hydrogel patch with noninvasive, electrochemical glucose sensor for natural sweat detection. Talanta 241, 123187 (2022).

Ravitchandiran, A. et al. Development of ZnFe(PBA)@Mo3C2Tx nanohybrid based Non-enzymatic Sensor for the detection of glucose in human sweat. Chem. Select 9, e202401553 (2024).

Subramania, A. K. et al. NiCo2O4/Ti2NbC2 (double MXene) nanohybrid-based non-enzymatic electrochemical biosensor for the detection of glucose in sweat. Bioprocess. Biosyst Eng. 46, 1755–1763 (2023).

Acknowledgements

The authors gratefully acknowledge the CIF-Pondicherry University for extending their instrumentation facility.

Author information

Authors and Affiliations

Contributions

AR contributed to Methodology, investigation, and writing - original draft; SAG and MSA reviewed & Editing the manuscript; RR contributed to Reviewing & Editing the manuscript; TM contributed to Reviewing & Editing the manuscript; SA contributed to Resources, Supervision, Funding Acquisition, Reviewing & Editing. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ravitchandiran, A., AlGarni, S., AlSalhi, M.S. et al. ZnFe(PBA)@Ti3C2Tx nanohybrid-based highly sensitive non-enzymatic electrochemical sensor for the detection of glucose in human sweat. Sci Rep 14, 23835 (2024). https://doi.org/10.1038/s41598-024-75623-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-75623-7