Abstract

Access to electricity is a key indicator of a country’s development. In developing nations like Ethiopia, this metric is particularly crucial for assessing progress. Currently, about 45.8% of Ethiopia’s population lacks access to electricity, with rural areas experiencing even higher rates, reaching 57.2%. The Southern Nations, Nationalities, and People’s (SNNP) region faces the greatest challenge, with 62.1% of its population lacking electricity. Ethiopia aims to achieve universal electricity access by 2030, and microgrid (MG) development is expected to play a pivotal role in meeting this goal. This study employs a multi-tier framework (MTF) to categorize village households based on electricity access, considering factors like income level and willingness to pay, to support the MG development process. Three villages—Toba, Koza, and Womba—in the SNNP region were selected for optimal MG sizing. Sensitivity variables such as global horizontal irradiance (GHI) variation, photovoltaic (PV) and battery prices, battery usage limits, and capacity shortage levels were analyzed for their impact on net present cost (NPC), initial capital cost, and cost of energy (COE) using HOMER Pro software. For example, in the Toba MG, increasing the capacity shortage from 0 to 10% reduced the COE from 0.1195 $/kWh to 0.09104 $/kWh, a 23.82% decrease. Additionally, fluctuations in PV and battery prices had a direct impact on the system’s NPC. The study also explored the impact of clustering the microgrids by interconnecting the three individual systems and conducting a techno-economic analysis. The comparison between standalone MG operation and clustered microgrids revealed that, despite the added cost of interconnection, the benefits in terms of technological, economic, and reliable operation of the clustered system were comparable to standalone microgrids. Finally, a feasibility study was conducted for the potential grid extension of the Toba MG, which is located 130 km from the nearest substation in Sawla.

Similar content being viewed by others

Introduction

Access to electricity plays a crucial role in determining a country’s level of development. In 2021, it was reported that approximately 45.8% of Ethiopia’s population lacked access to electricity, with this figure rising to around 57.2% in rural areas1. Various initiatives are underway to improve this situation. The Ethiopian National Electrification Program (NEP 2.0) has been updated with a target of achieving 100% electrification by 2025. As part of this effort, MG development is expected to provide electricity to about 35% of the population, which equates to approximately six million customers2. Table 1 shows the population size and percentage of energy access across different regions of Ethiopia. Notably, despite having a large population, 62.1% of the Southern Nations, Nationalities, and People’s (SNNP) region (before its division into four regions) remains without electricity, the highest rate in the country. Therefore, in this study, three villages—Toba, Koza, and Womba—were selected from this region to analyze the optimal development of microgrids and microgrid clusters.

Literature review

The growing demand for electricity, concerns over environmental emissions, the high risk of fossil fuel depletion, and the challenges of grid expansion to supply remote villages due to economic and technical constraints make renewable energy source (RES)-based microgrids (MGs) the most effective solution for electrifying both rural and urban areas. In addition to providing lighting, access to electricity plays a crucial role in the sustainable development of the country as a whole.

Microgrid

A microgrid (MG) is a small, active distribution system that incorporates RES3. MGs consist of components such as wind generation (WG), photovoltaic (PV) power, flexible loads, and an energy storage system (ESS) that serves as a buffer between electric demand and distributed generation. It is described as an aggregation of distributed energy sources, energy storage systems, and loads4. MGs also have the potential to provide electricity to areas affected by natural disruptive events, thereby enhancing the reliability and resilience of the system5.

MGs can operate in either standalone or grid-connected modes. In the event of a fault or other condition that interrupts power from the main grid, the MG disconnects and begins autonomous operation, supplying local loads. Once the fault is cleared, the isolated MG reconnects and resumes grid-connected operation. During autonomous operation, critical loads are prioritized, while other loads are supplied based on the availability of resources5. Critical loads refer to those that must remain uninterrupted under any circumstance.

Severe weather conditions can impact the power system, causing frequency deviations from the standard. While the extent of the impact varies depending on several factors, it is often difficult for the system to recover from such natural disasters. MGs have emerged as a promising source of resilience in such situations6.

Although increasing the penetration of RES into existing systems offers many benefits, it also introduces stability challenges. The intermittent nature of renewable resources (e.g., variations in solar radiation and wind speed) can lead to an imbalance between supply and demand, causing reliability issues, voltage fluctuations, and stability problems in the grid. Additionally, these fluctuations may result in power losses7. However, properly planned and developed MGs tend to have a more positive impact. According to a study in8, MGs can enhance system stability and reduce the levelized cost of energy (LCOE), although challenges remain due to the intermittent nature of RES.

The solution to the challenges posed by integrating RES into the system is the use of ESS. According to numerous studies, it is generally more cost-effective for MGs to utilize a single shared ESS rather than multiple individual ESS units7,8. To achieve a viable solution considering both environmental and economic factors, attention must be paid to the technology and cost of batteries, which are crucial components in standalone MGs9. Proper sizing of the Battery Energy Storage System (BESS) is essential; an oversized capacity results in unnecessary costs, while an undersized capacity fails to meet demand. In addition to sizing, the charging and sharing strategy should account for the intermittent nature of RES and avoid charging the battery during periods of limited resource availability5,10.

The work presented in11 examines the impact of simultaneously considering battery size, cycle life, and technology in MGs during both standalone and grid-tied operations. It also highlights how the depth of discharge (DOD) affects the battery’s service life. The authors developed a model that quantifies the equivalent number of complete cycles a battery can undergo over its lifetime, illustrating the difference between a full cycle (complete discharge of a fully charged battery) and a partial cycle. Another study12 explores a different configuration of storage systems, including PV, diesel generators (DG), and a hybrid energy storage system (HESS), which combines batteries and supercapacitors (SCs). This arrangement improves the service life of the battery by incorporating SCs.

For rural areas where expanding the distribution network is either uneconomical or infeasible, renewable energy-based MGs offer a promising solution for providing electricity. Autonomous MGs with RES ensure system security and reliability while offering cost-effective solutions13.

Optimization in microgrids

Optimization involves achieving the best possible outcome while meeting specified targets, whether they are maximum or minimum. In the context of MG planning, optimization refers to determining the ideal size, location, and technology of MG components while adhering to various constraints such as investment costs, BESS lifecycle, reliability, greenhouse gas (GHG) emissions, and electricity prices. Researchers employ different optimization techniques based on the specific objectives and constraints of their projects.

Proper sizing of MG components is crucial for enhancing system reliability and cost-efficiency. Oversized systems lead to excess energy and higher operational costs, while undersized systems fail to meet demand. To maximize the benefits of RES-based MGs, optimal sizing and effective energy management are essential14. The importance of optimal sizing is highlighted in5, which examines the island operation mode of a MG with only a PV source. In such a system, if the supply falls short of demand, the bus bar voltage decreases, while an excess supply can result in reverse power flow (RPF), loss of voltage control, and increased risk of short circuits. To mitigate these imbalances, optimal sizing of components is necessary. Additionally, incorporating BESS into the system helps manage energy from intermittent sources, ensuring a reliable supply during deficits.

The main objective of7 is to minimize daytime electricity costs. To achieve this, the study focuses on the economic dispatch of a MG with a shared ESS and employs a Mixed-Integer Linear Programming (MILP) approach for optimization. The algorithm regulates the power outputs of PV generators, the shared ESS, the main grid, and controllable loads to maintain the supply-demand balance and reduce energy costs. The performance of this approach is demonstrated through three scenarios: (I) without MILP optimization, (II) with MILP optimization, and (III) with both MILP optimization and a demand response strategy. The results show a significant cost reduction in scenario II and an even greater reduction in scenario III, highlighting the benefits of using MILP optimization and demand response strategies in the shared ESS of the MG. This approach has been evaluated and validated in a green and smart building park in Benguerir, Morocco.

In5, the MG components considered include PV, BESS, and loads. The study uses Genetic Algorithm (GA) to optimize the capacity of these components, select a charging strategy, and determine optimal locations while meeting requirements for minimum investment costs, maximum energy supply, and minimal reverse power flow (RPF). The research emphasizes the importance of ESS management and proper MG configuration to meet energy demand and optimize costs in autonomous MGs, which serve as backup power during extended disruptions.

For cost optimization of MGs, factors such as the initial state of charge (SoC), load profile, and operating costs of ESS and RESs are taken into account. By applying optimization techniques, it is possible to achieve efficient use of available resources and minimize operational costs15.

Economic concern in MG optimization

Demand Side Management (DSM) is a method that influences customers’ electricity consumption behavior by minimizing peak loads and utilizing price signals. It should be considered during the system’s planning stage. Flexible loads, such as electric vehicle charging, washing machines, and disinfection cabinets, can be shifted to off-peak periods or times with lower tariffs. A study presented in3 analyzes the economic scheduling of renewable energy sources within MGs through a demand management strategy that considers peak-valley tariff mechanisms. The optimization method employed is based on a price-based demand response. In the study, an improved War Strategy Optimization (WSO) algorithm is proposed, considering three scenarios: (1) without a battery, (2) with a battery, and (3) with a battery and demand response. Additionally, demand response optimization is performed using both Particle Swarm Optimization (PSO) and WSO for the battery and demand response scenarios. The results are compared with four other optimization techniques, revealing that the improved WSO performs better in solving the scheduling model. Besides achieving optimal scheduling, WSO also reduces overall costs and alleviates power supply pressure during peak hours.

A paper presented in16 developed a realistic power scheduling approach using meteorological data and annual electrical load demand. The feasibility and productivity of the system are demonstrated by analyzing its techno-economic performance. The study focuses on a residential MG with the primary goals of achieving reliability and maximizing economic benefits. To optimally size the components and determine the best configuration in terms of cost, a techno-economic analysis of three cases is conducted using the MILP optimization technique. In Case 1, the proposed MG configuration consists of PV panels and a BESS. In Case 2, PVs, BESS, and a diesel generator (DG) are used, while in Case 3, these same components are combined with grid connectivity to meet the demand. The analysis indicates that Case 2 is preferred due to its independence from grid power and its lower life cycle cost (LCC). Compared to the other cases, the LCC value of Case 2 is reduced, highlighting the effectiveness of using PVs, BESS, and DG together.

An improved Bacterial Foraging Optimization (BFO) technique is employed for optimal dispatching of the MG with a focus on economic efficiency17. The proposed optimization method enhances economic benefits, reduces environmental emissions, and lowers operational costs. The techno-economic advantages, energy dispatch, and optimal capacity of autonomous MGs are discussed in13, where PVs, wind turbines (WT), BESS, and DG are considered. For optimization, the Hybrid Optimization Model for Electric Renewables (HOMER) software is utilized. The study also considers load-side management by evaluating the impact of demand response (DR) on system optimization. In this context, elastic loads—such as shiftable and curtailable loads—are included to provide MG operators with the flexibility to flatten the load profile, thereby improving MG reliability.

To determine the optimal configuration of hybrid energy sources, eight different MG energy source configurations are evaluated based on the cost of energy (COE) and annual net present cost (NPC), considering seasonally varying commercial and residential loads with different renewable energy fractions. The analysis finds that the PV + BESS configuration is the most economical compared to other simulated feasible combinations. The study also notes that the renewable penetration fraction is inversely related to COE and NPC, meaning that as the fraction of renewable sources decreases, COE increases.

During the planning phase, careful consideration should be given to accurately sizing MG components, assessing required network upgrades, and incorporating flexible components that impact cost optimization to reduce overall expenses. Various optimization techniques can be employed with different constraints to achieve this goal.

Optimization techniques focusing on capacity sizing and the optimal upgrade of generation resources are proposed in18. By considering the flexibility of different distributed assets during the planning phase, investment costs can be reduced by varying the operation scenarios. In this study, PVs and BESSs are used as generation sources, while Electric Vehicles (EVs) serve as flexible assets. The problem formulation includes storage, generation capacity, and network upgrades, and is solved using a mixed integer piecewise linear approach.

In4, the optimal sizing of a standalone MG, considering load variability, renewable sources, various battery types, and battery life cycle energy, and their impact on costs in the Indian context is analyzed. A multi-objective optimization method is presented, balancing cost-effectiveness and energy sustainability through the selection of different batteries. The MG in question includes WT, PVs, and BESS, and the Genetic Algorithm (GA) is used for optimal component sizing, factoring in environmental concerns, energy efficiency, and life cycle costs.

The study in12 proposes a PV model suited for areas without historical operational data, highlighting its impact on the MG sizing process and the inclusion of critical loads. The requirement for zero Energy Not Supplied (ENS) is balanced with economic considerations, and a sensitivity analysis based on an energy storage system is presented. In19, the environmental impact is taken into account in the optimization of microgrid component sizing, comparing the benefits of using either a grid-only system or a microgrid incorporating PV, WT, BESS, and DG to meet demand. The latter approach is found to be more economical.

The environmental and techno-economic impacts of island MGs, considering different levels of renewable energy penetration, are explored in14. The system analyzed includes PVs, BESS, a bio-gasifier, WT, DG, and loads, with the goal of minimizing the total number of components while prioritizing demand supply.

In20, a hybrid Grey Wolf with Cuckoo Search Optimization (GWCSO) method is applied to optimally size MG components at minimal cost. The simulation results show that GWCSO outperforms GA, Grey Wolf Optimization (GWO), Cuckoo Search Optimization (CSO), Particle Swarm Optimization (PSO), and Ant Lion Optimization (ALO) in terms of robustness, deviation, annual cost, LCOE, and component sizing. The study uses real-time economic models to optimize the dispatching of ESS, factoring in future operational profit and past acquisition costs. The Alternating Direction Multiplier Method (ADMM) is used to find the optimal solution.

The emission-free nature and low operational costs of renewable energy sources make them ideal for carbon-neutral electric power grids. Effective capacity sizing is crucial for ensuring reliability and sufficient power generation at reasonable operating costs. According to21, demand response programs can improve the reliability and stability of the power grid by rescheduling flexible loads to coincide with periods of excess renewable power supply. The study also examines cost-benefit advantages based on various demand response strategies and the dependency of energy storage systems in MGs with variable energy sources. The suggested cost-effective optimal planning method for autonomous MGs employs power capacity-based dynamic pricing demand response programs (PCDP DRP), integrating both optimal capacity sizing and operational planning. The goal is to minimize total annual costs while maximizing the installed capacity of components and ensuring the best operational strategy. Four simulation scenarios are solved using the MILP optimization solver in MATLAB.

The optimal sizing of photovoltaic, diesel, and battery components for island MGs, considering both economic and reliability factors, is analyzed in22. A tradeoff between economy and reliability is necessary, as achieving detailed reliability often incurs higher costs. The study concludes that larger-sized RES are needed to meet reliability criteria in MG planning. An autonomous MG with BESS, PVs, and DG is considered, with optimal sizing performed using the MILP algorithm.

Optimal sizing of storage systems plays a significant role in the economic performance of MG systems. ESS must be properly sized to avoid the high costs of oversizing or the reliability issues caused by undersizing. As discussed in10, key factors to consider in ESS optimization include energy storage configuration methods (single or composite), operational modes (standalone or grid-tied), optimization analysis techniques, and the impact on customers’ income and system economy. Harmonized planning of BESS and PVs with demand-side resources is also explored in the study.

In the context of MG planning, a low-carbon economy is becoming increasingly important. The double-layer optimization technique proposed in23 determines the optimal capacity and location of MG components while minimizing carbon emission costs. A carbon subsidy policy to encourage the use of clean energy (such as PV and wind) and a carbon tax system for carbon-emitting sources (such as diesel generators) are incorporated to address climate change. This optimization method significantly reduces carbon emissions and promotes the development of renewable energy sources.

Microgrid cluster

A MG is a small-scale electrical grid consisting of distributed generation and loads. It can operate in either standalone mode or grid-connected mode. Standalone MGs function autonomously, isolated from the main grid, and typically include RES along with BESS and/or diesel or gas generators. Due to the intermittent nature of RES (such as solar radiation and wind speed), MGs are prone to issues like overloading and overgeneration.

Overloading occurs when the generated power is insufficient to meet the load demand, which can be mitigated by load shedding. Overgeneration, on the other hand, refers to a situation where power generation exceeds demand, and in such cases, curtailing non-dispatchable renewable sources can be a solution. Both overloading and overgeneration can impact the frequency and voltage stability of the MG.

Curtailment of renewable energy sources and load shedding are commonly used to address short-term overgeneration and overloading in standalone MGs. However, these solutions are not economical. An alternative is the use of energy storage systems, which can resolve these issues but come with high installation and operational costs. Therefore, finding an optimal solution to this problem is essential.

One such solution is to interconnect nearby MGs to allow power exchange between them. This configuration, where two or more neighboring MGs are interconnected, is known as a coupled microgrid (CMG) or microgrid cluster (MGC). In a CMG, each MG is responsible for meeting its own local load demand, but excess generation can be shared with other interconnected MGs in need. By sharing power within the cluster, both the curtailment of renewable sources and the need for load shedding are reduced, thereby enhancing the overall reliability of the system.

In24, MGs within a cluster are interconnected via a 3-phase AC link and a back-to-back converter. The effectiveness of the proposed power exchange and control strategy is demonstrated through simulation analysis using PSIM.

The interconnection of a commercial MG with a residential MG to form an MGC is discussed in8. These MGs experience different load patterns throughout the week: residential MGs typically see peak loads during weekends, while commercial MGs experience peak loads on weekdays. By leveraging the differing power requirements of residential and commercial loads, the surplus power from the commercial MG can be used to meet residential peak loads during weekends, thereby increasing the reliability of the cluster. As with any power system, maintaining voltage and frequency within standard limits requires balancing supply and demand within the cluster.

Figure 1(a) shows a standalone MG that includes PV, micro-hydro, batteries, and various types of loads, while Fig. 1(b) illustrates a MG cluster composed of three individual MGs.

Research gap

The aforementioned studies on MGs have typically focused on a limited set of factors, such as capacity shortages and economic impacts, or the economic benefits of MG clustering. In contrast, this work addresses a broader range of factors, including the optimal sizing of MGs using HOMER Pro, sensitivity analysis considering variations in Global Horizontal Irradiance (GHI), the price of PV and battery systems, battery lifetime and state of charge (SOC), and the impact of different capacity shortage levels. Additionally, it examines the interconnection of standalone MGs to form an MG cluster, analyzes the performance of MGs when operated individually versus in a clustered form, and conducts a feasibility study of grid extension to a microgrid. This study focuses solely on renewable energy sources, and the economic, technical, and reliability impacts of these influencing factors are thoroughly analyzed and discussed.

Contributions of the research

Based on the research gaps, this research has the following contributions:

-

This study introduces a method for accurately sizing MG components by categorizing households based on income levels rather than relying on average energy consumption. This Multi-Tier Framework (MTF) approach addresses the potential overestimation of MG component requirements in low-income areas, which can lead to higher initial costs and impede MG development. By tailoring component sizing to the actual income distribution of households, the study promotes cost-effective MG implementation and supports the NEP 2.0 goal of universal electricity access.

-

A comprehensive techno-economic and reliability analysis is performed to assess the development and performance of MGs and their clusters. This analysis highlights the effectiveness of the MTF method in optimizing component sizing.

-

The study evaluates the advantages of MG clustering from economic, technical, and reliability perspectives, demonstrating that interconnecting neighboring MGs into clusters provides mutual benefits compared to standalone MGs.

-

A comparative analysis between standalone MGs and MG clusters is conducted, revealing the trade-offs and benefits of each configuration and underscoring the enhanced performance of clustered MGs.

Organization of the manuscript

The remaining sections of this paper are organized as follows: Sect. 2 presents the proposed methodology; Sect. 3 covers the results and discussion; and Sect. 4 concludes the paper.

Methodology

Projects focused on MG development face challenges in achieving sustainability due to the need to balance high reliability requirements with shorter implementation periods, efficiency, and affordability. To address these challenges, the MTF has been developed. This method supports the achievement of universal access in both urban and rural areas25.

According to the Ethiopian NEP2.0, the MTF significantly advances the national electrification goal. Figure 2 illustrates household energy consumption across different regions of Ethiopia based on the MTF25. It shows that the majority of consumers fall into Tiers 0–3, with Tier 0 comprising 62% of households in the SNNP region, which represents the largest percentage in this tier.

MTF-based household consumption by regions in Ethiopia25.

Figure 3 clearly shows that in the SNNP region, the percentages of electricity access are as follows: 30.1% for grid access, 7.8% for off-grid access, and 62.1% for no access. This places the region in the worst access status compared to other regions. Therefore, this research focuses on the SNNP region, selecting three villages (Toba, Koza, and Womba) for the optimal development of the MG and MG cluster.

Categorization of household electricity access based on MTF

The MTF is a method for categorizing households based on various criteria related to electricity access. This electrification approach involves detailed measurements of energy access to provide people-centric energy services at different household levels, taking into account energy consumption patterns, economic conditions, and willingness to pay26. Rather than relying on a generalized average for a village’s electricity usage, MTF categorizes households hierarchically from Tier 1 to Tier 5.

In this study, the MTF-based energy access matrix is employed to categorize demands according to the type of service and the amount of energy consumed, aiming for an optimal solution. Table 2 presents the MTF-based energy access matrix, which illustrates how Tiers are categorized based on attributes such as power capacity, availability, supported appliances, reliability, and affordability.

The MTF-based categorization framework offers several advantages, including considering household income to assess affordability, evaluating outages per week to indicate reliability, and defining specific energy access services for each Tier.

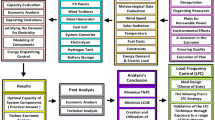

The procedure used to achieve the objectives of this study is illustrated in Fig. 4 as a flowchart. The procedure begins with a literature review, followed by site selection and data collection. In the data collection phase, categories include gathering electrical load data based on MTF-based household categorization, natural resource data such as GHI, and costs of various system components.

Using this information, optimization analysis will be conducted with HOMER Pro software to determine the optimal component sizes, considering factors such as cost, reliability, and affordability. In addition to the base case, sensitivity analysis will be performed to assess the impact of variable sensitivity on optimal sizing. Based on this analysis, a configuration will be selected that balances cost, reliability, and affordability, allowing for the choice of the most effective architecture based on different trade-offs.

Subsequently, MGs will be developed using the obtained values, and this process will be repeated for all three selected MGs. These individual MGs will be interconnected to form an MG cluster. The next step involves comparing individual MGs with MG clusters from both techno-economic and reliability perspectives.

Finally, a feasibility study of grid extension will be conducted to determine whether to connect the MG to a nearby substation based on the results obtained.

Microgrid development (Case study: Toba Village)

-

A.

Site description

The proposed villages for this study, namely Toba, Koza, and Womba, are situated in the SNNP region, specifically within the Gofa zone. Table 3 provides details regarding the population count, number of households, latitude and longitude coordinates, classification of village households based on income levels as low, middle, or high, and the presence of available rivers for micro-hydro installations.

In these villages, electricity access is nonexistent, and their considerable distance from the nearby substation suggests that obtaining electricity from the grid is likely a long-term aspiration.

Toba Village is located at a latitude of 60° 28’ N and a longitude of 360° 40’ E. The village has a population of 4,882, living in 976 households. The households are classified into three income groups: low-income (58%), middle-income (26%), and high-income (16%). The village is also home to the Toba River, which has potential for micro-hydro power generation.

-

B.

Solar energy assessment of Toba village

In Toba village, the monthly average solar GHI data is shown in Fig. 5.

In this village, the annual average GHI is 5.67 kWh/m²/day. The maximum average GHI is 6.24 kWh/m²/day, occurring in March, while the minimum average GHI is 4.89 kWh/m²/day, occurring in July.

-

C.

Electrical loads of Toba microgrid

In this work, instead of using identical load data for each day and within-day time variations, random variability inputs are applied to the load profile. This introduces randomness to the load data, making it more realistic. The random variabilities are introduced as day-to-day and time-step inputs. By incorporating day-to-day variability, the load profile for each day changes by a random amount, while time-step variability alters the shape of the load profile without affecting its overall size25,26,27.

In this study, a 10% random variability for both day-to-day and time-step inputs is considered. The resulting load summary for the Toba MG is presented in Table 4.

Based on the MTF household categorization, the households in Toba Village are classified from Tier 1 to Tier 3. Table 5. presents the residential load profiles for Tiers 1, 2, and 3 in the Toba MG, detailing the type of load, quantity, daily operating hours, power ratings, and daily energy consumption. Similarly, the commercial loads are shown in Table 6..

By aggregating the Tier 1, Tier 2, and Tier 3 residential loads for each household at different hours of the day, the authors derive the village’s residential load profile. Similarly, by summing the various commercial loads at different hours of the day, the commercial load profile is obtained. Figure 6 illustrates the total residential and commercial load profiles of the Toba MG over a 24-hour period.

-

D.

Toba MG Deferrable Load (Pump)

In Toba Village, pumps are considered for irrigation and drinking purposes, and Fig. 7 shows the deferrable load demand. During the rainy season, this demand decreases, as clearly observed from May to October. Table 7 presents the storage capacity and peak load of the system.

E.Micro-Hydropower of Toba MG

The electrical output power of a hydroelectric turbine is determined using the following equation:

Where, \(\:{P}_{hyd}\) is the power output of the hydro turbine (W), \(\:{\eta\:}_{hyd}\) is the efficiency of the hydro turbine (%), \(\:{\rho\:}_{water}\) is the density of water (1000 kg/m3), \(\:g\) is the acceleration due to gravity (9.81 m/s2), \(\:{h}_{net}\) is the effective head (m) and \(\:{Q}_{turbine}\) is the flow rate of hydro turbine (m3/s).

Substituting these values, the power output of the Toba Micro Hydro is calculated to be 51.79 kW. The input data required for the analysis of Toba MG Micro-hydro Power is provided in Table 828,29.

F. Photovoltaic systems in the Toba MG

Table 9 provides the PV input data required for the optimal analysis of the Toba MG.

-

G.

Converter systems in the Toba MG

Table 10 provides the converter input data required for the optimal analysis of the Toba MG.

-

H.

Battery systems in the Toba MG

Table 11 provides the battery input data required for the optimal analysis of the Toba MG.

In addition to the aforementioned costs, MG distribution network costs are also considered. For the Toba MG, the capital costs amount to $94,000, and the O&M costs are $4,700 for the distribution network.

Results and discussion

Optimal sizing results of Toba microgrid

In the optimal sizing of the Toba MG, the primary objective is to meet the predefined MTF-based load demand with a minimum-cost solution. The optimization process focuses on balancing three key factors: cost, reliability, and affordability. For cost minimization analysis, the NPC, COE, initial capital cost, operating cost, annual capacity shortage, and state of charge are considered. This study evaluates the optimal MG configuration needed to meet various load demand levels ranging from 0 to 10% capacity shortage. Since only clean energy sources are utilized, the renewable fraction is 100%.

A capacity shortage is a shortfall that occurs between the required operating capacity and the actual amount of operating capacity the system can provide. Figure 8 illustrates the optimal sizing of PV systems, batteries, micro-hydro (assumed constant), and converters for different levels of capacity shortage in the Toba MG.

Figure 8 clearly shows that the sizes of the components vary depending on the capacity shortage. For example, with a capacity shortage of 3%, the capacities of the PV systems and batteries are 85.81 kW and 104 kWh, respectively. As the capacity shortage increases to 4%, their capacities change to 62.35 kW and 144.0 kWh, respectively. This indicates a reduction in PV size and an increase in battery capacity. Since the size of the micro-hydro power is assumed to be constant, the sizes of the PV systems, batteries, and converters adjust to meet the specified load demand with minimal cost. Therefore, the variation in component sizes for different levels of capacity shortage is necessary to achieve the specified load with the minimum overall NPC or COE for the system.

Figure 9 displays the NPCs, initial capital costs, capital costs of PV systems, batteries, converters, and COE of the Toba MG as the capacity shortage increases from 0 to 10%.

In this MG, the NPC, initial capital cost, and combined capital costs of the PV systems, battery, and converter are reduced by 27.77%, 28.72%, and 58.83%, respectively, as the capacity shortage increases from 0 to 10%. Additionally, the COE, which is $0.1195/kWh at 0% capacity shortage, decreases to $0.09104/kWh at a 10% capacity shortage, representing a 23.82% reduction. This reduction in various system costs with increased capacity shortages highlights the benefits of developing MGs.

The impact of capacity shortages on reliability is reflected in terms of unmet electrical loads. For the reliability analysis, July is chosen due to its minimal GHI. Figure 10a shows the hourly power supply and demand for a 10% capacity shortage in July. During this month, there are a total of seven outages per week, four of which are major outages, as illustrated in Fig. 10b. Thus, for a 10% capacity shortage, the MG experiences between 4 and 7 outages per week.

Figure 11 clearly shows that as the capacity shortage increases, the number of unmet electrical loads also rises. For example, with a capacity shortage of 10%, there are 16 major power outages per month compared to only 2 outages with a 1% capacity shortage.

The COE for capacity shortages of 1%, 4%, 7%, and 10% is $0.102/kWh, $0.0963/kWh, $0.0927/kWh, and $0.09104/kWh, respectively. This demonstrates a reduction in cost. However, this reduction in cost comes with an increase in unmet electrical loads.

Therefore, as capacity shortage increases, the number of unmet electrical loads rises, indicating a decrease in reliability. According to NEP2.0, grid-connected households experience 4 to 14 outages per week, with outage levels for Tier 1 and Tier 2 households—who are predominant in standalone MGs—exceeding 14 outages per week. In contrast, Tier 3 households experience fewer than 14 outages per week. Therefore, considering existing reliability, a 10% capacity shortage can be chosen for the reliability versus cost trade-off.

On average, the cost of electric power generation, transmission, and distribution is $0.09/kWh. However, the current tariff in Ethiopia ranges between $0.04/kWh and $0.06/kWh, which is the lowest in Africa. According to the Ethiopian Electric Utility (EEU), the tariff should be between $0.08/kWh and $0.10/kWh for the EEU to be profitable30. With a 10% capacity shortage, the COE is $0.09104/kWh, which falls within the EEU’s planned tariff range.

The optimal techno-economic results for the Toba MG are detailed in the following section. Tables 12 and 13 present the technical and economic results of the Toba MG, respectively, while Table 14 summarizes the detailed MG costs under a 10% capacity shortage.

Table 13 categorizes the cost analysis of the MG over a 25-year project lifetime into Capital Costs, Operation and Maintenance (O&M) Costs, and Salvage Costs.

Capital Costs refer to the initial investment required for the procurement and installation of MG components. For example, the capital cost for the PV system is $49,053.32. This expense is a one-time cost incurred at the beginning of the project, covering the purchase and installation of the PV panels.

O&M Costs encompass the annual expenditures necessary for the ongoing operation and upkeep of the MG components. For the PV panels, the total O&M cost over the 25-year period is projected to be $12,682.75. This figure includes costs associated with routine servicing, minor repairs etc. necessary to maintain the PV system’s efficiency and reliability.

Replacement Costs are considered for components with a limited lifespan. While the PV panels, having a lifespan equal to the project’s duration, do not incur replacement costs, the battery system—having a shorter lifespan of 15 years—will require replacement once during the project’s lifetime. This replacement cost is anticipated at the end of the battery’s useful life.

Sensitivity analysis

The sensitivity analysis is a crucial methodological approach used to evaluate how variations in key variables impact the overall costs and performance of MG systems. This study focuses on several critical sensitivity variables, including GHI, PV prices, battery prices, and allowed battery usage levels. To assess their influence on optimal MG sizing and system economics, the analysis method involves varying one parameter at a time while keeping others constant. This approach isolates the effects of each variable on key economic metrics such as NPC, initial capital cost, and COE. By systematically examining changes in solar irradiation, fluctuations in battery and PV prices, and variations in battery SOC, this sensitivity analysis aims to provide valuable insights into the robustness of the MG design. The results guide more effective decision-making and optimize system performance by identifying which variables most significantly impact the microgrid’s economic outcomes.

GHI plays a pivotal role in determining the energy output of PV panels, thereby influencing the overall performance and cost of a microgrid. Variations in GHI directly affect the energy production of the system, which can lead to significant changes in both operational efficiency and total costs. According to31, GHI predictions can vary from 20 to 63% over the long term (48 h to 7 days). To account for this variability, a ± 25% range in GHI was considered for the Toba MG study.

Figure 12 illustrates the sensitivity analysis results for GHI variations, demonstrating how adjusting GHI by ± 25% from the optimization value impacts MG costs. Specifically, a 25% reduction in GHI results in increases of 4.96% in NPC, 4.89% in initial capital cost, 16.34% in PV and battery capital costs, and 4.51% in COE. Conversely, a 25% increase in GHI leads to reductions of 2.83% in NPC, 2.79% in initial capital cost, 11.17% in PV and battery capital costs, and 2.97% in COE. This analysis underscores the sensitivity of MG economics to fluctuations in solar irradiation and highlights the importance of considering GHI variability in system optimization.

The price of PV decreased annually by nearly 20% up to 2020, as shown in32. However, by the end of 2020, the price rose by 15%, and it is expected to continue rising in the coming years due to increasing material and shipping costs33. To account for this in the sensitivity analysis, a variability of ± 15% and + 20% in PV module price is considered.

Figure 13 illustrates the impact of PV price on various system costs, showing the price variation of ± 15% and + 20% from the value used for system optimization. When the PV price decreased by 15%, the NPC, initial capital cost, and COE dropped by 1.62%, 2.37%, and 1.95%, respectively. Conversely, when the PV price increased by 20%, these same costs rose by 2.16%, 3.16%, and 1.83%, respectively. This result demonstrates that changes in PV costs can significantly affect the overall system economy.

Figure 14 presents the cost trends for Li-ion LFP batteries across different capacities from 2020 to 205034.

The cost trend of Li-ion LFP battery from 2020 to 205034.

Figure 15 shows the reduction in various MG system costs as the allowed battery usage level increases. When the battery usage level increases from 50 to 100%, the NPC, initial capital cost, and PV plus battery capital cost decrease by 3.17%, 6.58%, and 22.8%, respectively, while the COE drops from $0.09361/kWh to $0.09054/kWh.

As explained in Table 15, the cost reduction is attributed to a decrease in the number of batteries required as the allowed usage level increases. Conversely, when the allowed battery usage level decreases from 100 to 50%, the number of required battery strings rises.

At the 100% allowed battery usage level, the fewest battery strings are required. However, it is important to note that 100% usage is not advisable as it reduces the battery’s lifetime. Therefore, a balance must be achieved between cost and battery longevity.

Battery price variation significantly affects the economics of the MG system. As battery prices decrease, the various costs associated with the MG also decline. This is clearly illustrated in Fig. 16, which shows the impact of a 10% and 20% reduction in battery price. percent.

With a 20% price reduction, the battery capital cost decreases by $5,760, and the COE falls from $0.09104/kWh to $0.08999/kWh.

Microgrid cluster

A microgrid cluster consists of neighboring, independently operating MGs that collaborate to function as a cohesive unit. In this research, for the development of the cluster, a hypothetical location was created that integrates the combined load profiles (both primary and deferrable) of the three case study villages, the average GHI of these villages, a micro-hydro power system with a capacity equal to the combined capacities of the Toba and Ergino micro-hydro systems, the distribution network costs for the three villages combined, and the costs associated with interconnecting the villages. Table 16 presents the details of the three individual MGs used to develop the MG cluster.

Figure 17 illustrates the distances between the villages and their near-linear, cascaded positioning. Consequently, from an economic standpoint, this study focuses on interconnections from Toba to Koza and from Koza to Womba.

Techno-Economic analysis of microgrid cluster

Figure 18 displays the load profile of the MG cluster, including the combined residential and commercial loads for each MG. Figure 19 illustrates the total residential and commercial loads across all three MGs.

Table 17 presents the daily energy consumption and peak power for residential, commercial, and deferrable loads for both individual MGs and MG cluster.

Distribution network and interconnection costs for microgrid cluster

In the optimal planning of MGs, accounting for distribution network costs is crucial for making techno-economic analysis more realistic. In addition to distribution networks, the cost of interconnection systems between individual MGs should also be considered in the development of MG cluster. Tables 18 and 19 present the costs associated with the distribution network and interconnection systems for the MGs.

Optimal sizing result of microgrid cluster

In MG cluster analysis, it is essential to account for both the distribution costs of each MG and the costs of interconnecting them, which typically results in a higher overall initial cost compared to independent operation. However, this additional cost must be evaluated from a different perspective to determine its value.

For the analysis, the procedure used to develop the optimal Toba MG is applied to the development of the Koza and Womba MGs. A hypothetical MG, combining all residential, commercial, and deferrable loads from the three villages, is considered. Additionally, parameters such as the micro-hydro power potential (aggregating Toba and Ergino micro-hydro), the average GHI of the three villages, the combined distribution network costs, and the interconnection costs are used for the optimal analysis. This study also considers a 10% capacity shortage for both individual and clustered MGs.

To provide a comprehensive evaluation, this study compares the results from the hypothetical MG cluster with those of three standalone, non-interconnected MGs, referred to as ‘Three Ind. MG.’ The comparison is conducted from technical, economic, and reliability perspectives to assess the impact and benefits of clustering MGs.

Economical analysis

To develop cluster, it is necessary to interconnect the individual MGs, which introduces additional costs but can also provide economies of scale. As shown in Table 20, while the initial capital cost increases by 10%, MG clustering results in a reduction in capital costs for PV systems, batteries, and converters by 32.44%, 45.12%, and 35.17%, respectively, compared to three independent MGs. Additionally, the NPC and operating costs also exhibit reductions. Furthermore, the COE for the cluster is lower than the average COE of the three individual MGs, highlighting the benefits of clustering.

Technical analysis

It Table 21.a indicates that the PV capacity, initially 300 kW in the three independent MGs, is reduced to 203 kW in the clustered MG. Similarly, battery capacity decreases from 656 kWh to 360 kWh. These reductions are primarily attributed to the Koza MG, which, while operating independently, relied solely on PV and batteries to meet its load requirements. With the introduction of interconnecting lines, Koza now benefits from additional renewable energy sources provided by the other MGs. Consequently, excess hydropower from Toba or Womba MGs can be supplied to Koza during the night, reducing its reliance on batteries. This arrangement allows for a more efficient sharing of resources within the cluster.

Table 21.b further demonstrates that clustering the MGs reduces unmet load and excess energy by 6.85% and 73.4%, respectively. As a result, excess power in the cluster is effectively transferred to other connected MGs experiencing power deficits.

Reliability analysis

When analyzing reliability, it is important to consider whether the benefits of clustering impact the system’s reliability beyond acceptable levels or if it remains within standard thresholds. As noted earlier, clustering reduces unmet load, which can serve as a positive indicator of improved reliability.

Grid extension

Grid extension involves connecting individually operating MGs to the national grid system, potentially enhancing system reliability and power access. This section analyzes the feasibility of extending the grid to the Toba MG, which is situated 130 km from the Sawla substation. The feasibility study assesses whether this connection is economically viable by comparing the costs of grid extension with the anticipated benefits. The information required for this analysis is presented in Table 22. This evaluation aims to determine if the investment in extending the grid to such a distance offers sufficient economic benefits to justify the costs.

The feasibility is assessed by comparing the costs of extending the grid to the MG with the potential economic benefits. The breakeven distance, where the costs of extension are balanced by the benefits, is calculated and illustrated in Fig. 20, showing a breakeven distance of 15.02 km. Since the Toba MG is 130 km from the Sawla substation, this distance greatly exceeds the breakeven point, indicating that extending the grid is not economically justified in this case.

Conclusion

This work presented the optimal planning and sizing of microgrid cluster for performance enhancement. Based on the research, the following points can be concluded:

-

Using the MTF-based strategy, the categorization of households’ energy access varied based on income and willingness to pay the bill, which helped increase the accuracy of optimal sizing and gave more economical results than taking the assumption of average consumption for all households.

-

In this research, the households fall between Tier 1 and Tier 3, and the disruption times for Tier 3 are less than 14 times a week, and for the majority of the neighboring national grid, around 4–14 times a week. Therefore, without leaving this level of reliability, the consideration of a capacity shortage has a high economic benefit. For example, if we compare a capacity shortage of 0% and 10% in Toba MG, the COE is reduced by 23.82%, which gives economic benefit without missing the required reliability level.

-

Prediction of GHI has some result variation, so consider that ± 25% of GHI is taken. As the percentage of irradiance reduces, different costs of the system increase, and as the irradiance percentage increases, system costs decrease. Therefore, accurate measurement values and consideration of site location with higher irradiance for PV installation have an impact on the economy of the system.

-

The price of PV modules varies. It was reducing toward 2020, but starting at the end of 2020, it is increasing. Price changes have a direct impact on the economy of the system. Taking Toba MG, a 20% increment in PV price resulted in a 3.16% increment in initial capital cost; therefore, during the design stage, it is necessary to know the time of implementation so that module price can be predicted in order to have a good economic estimation.

-

The price of batteries is decreasing, and this one also has a direct impact on the economy of the system. In Toba MG, for a price reduction of 20%, the battery capital cost is reduced by $5,760. Therefore, for batteries too, it is necessary to know the time of implementation during the design stage to predict what its price would be by then in order to have a good economic estimation.

-

A high usage level of batteries reduces the quantity required and so does the cost, but such an advantage comes with a payback of faster battery degradation, which results in the requirement of replacement earlier than expected, so a tradeoff is needed to benefit from an optimal usage level.

-

MG clustering requires an additional cost of interconnection between individual MGs, but the advantages it brings in the form of reduced unmet load, excess energy, component size, and reliability enhancement weigh the additional initial cost.

-

In Toba MG, due to the calculated NPC and its distance from the nearby Sawla substation, grid extension is not economically feasible.

As a future enhancement of this work, individual microgrid and microgrid cluster control can be incorporated into the system to make system performance better.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Change history

20 February 2025

A Correction to this paper has been published: https://doi.org/10.1038/s41598-025-91000-4

References

Access to electricity, rural (% of rural population) - Ethiopia | Data. [Online]. Available: https://data.worldbank.org/indicator/EG.ELC.ACCS.RU.ZS?end=2020&locations=ET&start=2000&view=chart . (Accessed: Jan. 8, 2023).

Lighting to All: National Electrification Program 2.0: Integrated Planning for Universal Access, Themat. Progr. Doc., no. Ministry of Water, Irrigation & energy & October p. 49, [Online].Available: (2019). (Accessed: Jan. 13, 2023).

He, Y. et al. Economic optimization Scheduling based on load demand in Microgrids considering source network load storage. Electronics. 12 (12), 2721. https://doi.org/10.3390/electronics12122721 (Jun. 2023).

Das, J. Optimal component sizing of an isolated PV-Wind-battery microgrid in India using Multi Objective Optimisation. 2020 IEEE 17th India Counc. Int. Conf. INDICON 2020. 1 https://doi.org/10.1109/INDICON49873.2020.9342122 (2020).

Li, X. & Jones, G. Optimal sizing, location, and assignment of photovoltaic distributed generators with an Energy Storage System for Islanded Microgrids. Energies. 15 (18). https://doi.org/10.3390/en15186630 (Sep. 2022).

Borghei, M. & Ghassemi, M. Optimal planning of microgrids for resilient distribution networks. Int. J. Electr. Power Energy Syst. 128 https://doi.org/10.1016/j.ijepes.2020.106682 (Jun. 2021).

Barkouki, B. E. et al. Jun., An Economic Dispatch for a Shared Energy Storage System Using MILP Optimization: A Case Study of a Moroccan Microgrid, Energies, vol. 16, no. 12, p. 4601, doi: (2023). https://doi.org/10.3390/en16124601

Dinkhah, S., Salazar Cuellar, J. & Khanbaghi, M. Optimal Power and Frequency Control of Microgrid Cluster with mixed loads. IEEE Open. Access. J. Power Energy. 9, 143–150. https://doi.org/10.1109/OAJPE.2022.3148375 (2022).

Edisson Garcia Vera, Y., Dufo-Lopez, R., Daniel DIaz, O. & Castillo Oct., Optimization and feasibility of standalone hybrid diesel-pv-battery microgrid considering battery technologies, in 2020 IEEE ANDESCON, ANDESCON 2020, Institute of Electrical and Electronics Engineers Inc., doi: https://doi.org/10.1109/ANDESCON50619.2020.9272144. (2020).

Shen, W. & Zeng, M. Collaborative Planning Model of PV-Battery Storage System for Microgrid considering demand response. J. Phys. Conf. Ser. 2433 (1). https://doi.org/10.1088/1742-6596/2433/1/012008 (2023).

Masaud, T. M. & El-Saadany, E. F. Correlating optimal size, cycle life estimation, and Technology Selection of batteries: a two-stage Approach for Microgrid Applications. IEEE Trans. Sustain. Energy. 11 (3), 1257–1267. https://doi.org/10.1109/TSTE.2019.2921804 (2020).

León, L. M., Romero-Quete, D., Merchán, N. & Cortés, C. A. Optimal design of PV and hybrid storage based microgrids for healthcare and government facilities connected to highly intermittent utility grids. Appl. Energy. 335, 120709. https://doi.org/10.1016/j.apenergy.2023.120709 (2023).

Murty, V. V. V. S. N. & Kumar, A. Optimal energy management and techno-economic analysis in microgrid with hybrid renewable energy sources. J. Mod. Power Syst. Clean. Energy. 8 (5), 929–940. https://doi.org/10.35833/MPCE.2020.000273 (2020).

Jasim, A. M., Jasim, B. H., Baiceanu, F. C. & Neagu, B. C. Optimized sizing of Energy Management System for Off. Mathematics. 11 (5). https://doi.org/10.3390/math11051248 (Mar. 2023). -Grid Hybrid Solar/Wind/Battery/Biogasifier/Diesel Microgrid System.

Ignat, A., Szilagyi, E. & Petreus, D. Islanded Microgrid Simulation and Cost Optimisation, in 2020 IEEE 26th International Symposium for Design and Technology in Electronic Packaging, SIITME 2020 - Conference Proceedings, Institute of Electrical and Electronics Engineers Inc., Oct. pp. 426–429. doi: (2020). https://doi.org/10.1109/SIITME50350.2020.9292153

Tahirou Halidou, I., Or Rashid Howlader, H., Gamil, M. M., Elkholy, M. H. & Senjyu, T. Optimal Power Scheduling and Techno-Economic Analysis of a Residential Microgrid for a Remotely Located Area: A Case Study for the Sahara Desert of Niger, Energies, vol. 16, no. 8, Apr. doi: (2023). https://doi.org/10.3390/en16083471

Zhang, Y., Zhou, H., Xiao, L. & Zhao, G. Research on Economic Optimal Dispatching of Microgrid Cluster Based on Improved Butterfly Optimization Algorithm, Int. Trans. Electr. Energy Syst., vol. pp. 1–16, 2022, doi: (2022). https://doi.org/10.1155/2022/7041778

Essayeh, C. & Morstyn, T. Optimal sizing for microgrids integrating distributed flexibility with the Perth West smart city as a case study. Appl. Energy. 336 https://doi.org/10.1016/j.apenergy.2023.120846 (Apr. 2023).

Bin, L. et al. Scheduling and sizing of campus Microgrid considering demand response and economic analysis. Sensors. 22 (16). https://doi.org/10.3390/s22166150 (Aug. 2022).

Universitetet i Agder IEEE Singapore Section. Industrial Electronics Chapter, IEEE Singapore Section., IEEE Industrial Electronics Society, and Institute of Electrical and Electronics Engineers, Proceedings of the the 15th IEEE Conference on Industrial Electronics and Applications (ICIEA 2020): 9–13 November virtual conference. (2020).

Kiptoo, M. K., Adewuyi, O. B., Howlader, H. O. R., Nakadomari, A. & Senjyu, T. Optimal capacity and operational planning for renewable energy-based Microgrid considering different demand-side management strategies. Energies. 16 (10). https://doi.org/10.3390/en16104147 (May 2023).

Wu, X., Zhao, W., Wang, X. & Li, H. An MILP-Based Planning Model of a Photovoltaic/Diesel/Battery Stand-Alone Microgrid Considering the Reliability, IEEE Trans. Smart Grid, vol. 12, no. 5, pp. 3809–3818, Sep. doi: (2021). https://doi.org/10.1109/TSG.2021.3084935

Zhao, W., Xu, M., Ning, N., Kang, Y. & Cai, Z. A Microgrid Capacity Optimization Method Considering Carbon Emission Cost, in iSPEC 2020 - Proceedings: IEEE Sustainable Power and Energy Conference: Energy Transition and Energy Internet, Institute of Electrical and Electronics Engineers Inc., Nov. pp. 2219–2224. doi: (2020). https://doi.org/10.1109/iSPEC50848.2020.9351276

Ferdous, S. M., Shahnia, F. & Shafiullah, G. M. Power Sharing and Control Strategy for Microgrid Clusters, in 9th International Conference on Power and Energy Systems, ICPES 2019, Institute of Electrical and Electronics Engineers Inc., Dec. 2019. doi: (2019). https://doi.org/10.1109/ICPES47639.2019.9105387

Bhatia, M. & Angelou, N. Beyond Connections: Energy Access Redefined, ESMAP Tech. Rep., vol. 008/15, pp. 1–244, [Online]. Available: (2015). http://hdl.handle.net/10986/24368

Gouthami, P. et al. Beyond connections: Energy access diagnostic report based on the multi-tier framework. Beyond Connect. Accessed 12 May 2024. https://openknowledge.worldbank.org/entities/publication/80924c3d-92d7-51ab-8420-6d58a56786ae (2015).

Energy, H. O. M. E. R. LLC, HOMER Pro 3.1 User Manual, HOMER Energy LLC, Boulder, CO, USA, [Online]. Available: (2014). https://www.homerenergy.com/products/pro/docs/HOMERPro_UserGuide_3.1.pdf. (Accessed: Jan. 17, 2023.).

Ashebir Dingeto Hailu. Ethiopia hydropower development and Nile basin hydro politics[J]. AIMS Energy. 10 (1), 87–101 (2022).

van der Zwaan, B. C. C. et al. Prospects for hydropower in Ethiopia: an energy-water nexus analysis. Energy Strategy Reviews. 19, 19–30 (2018).

Electricity tariffs must double to sustain profits. EEU - Capital Newspaper. [Online]. Available: https://www.capitalethiopia.com/2022/08/21/electricity-tariffs-must-double-to-sustain-profits-eeu/

Ramirez-Vergara, J., Bosman, L. B., Leon-Salas, W. D. & Wollega, E. Ambient temperature and solar irradiance forecasting prediction horizon sensitivity analysis. Mach. Learn. Appl. 6, 100128. https://doi.org/10.1016/j.mlwa.2021.100128 (2021).

IRENA. Renewable power generation costs in 2019 - key findings. Int. Renew. Energy Agency. 160. Accessed 13 May 2024. https://www.irena.org/publications/2020/Jun/Renewable-Power-Costs-in-2019 (2020).

Max Hall. African solar installers feel the pinch of rising panel prices, PV magazine International. Accessed 17 June 2023. https://www.pv-magazine.com/2021/04/26/african-solar-installers-feel-the-pinch-of-rising-panel-prices/ (2021).

BESS costs could fall 47%. by 2030, says NRE. [Online]. Available: (2023). https://www.energy-storage.news/li-ion-bess-costs-could-fall-47-by-2030-nrel-says-in-long-term-forecast-update/. (Accessed: Feb. 6.

Funding

This work was supported by the Ministry of Foreign Affairs of Denmark, Danida Fellowship Centre (Project No. 20-M04AAU).

Author information

Authors and Affiliations

Contributions

AB, BK, MAZ, JMG, SC, JCV and GDAT wrote the main manuscript text. AB, BK, MAZ, JMG, SC, JCV and GDAT prepared figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: In the original version of this Article, Mohamed Ali Zdiri was incorrectly affiliated with ‘Center of Research on Microgrids (CROM), Aalborg University, Aalborg, Denmark’. Consequently, the correct affiliation is as follows: Center for Renewable Energy and Microgrids, Huanjiang Laboratory, Zhejiang University, Zhejiang, 311816, China.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bekele, A., Khan, B., Zdiri, M.A. et al. Optimal planning and sizing of microgrid cluster for performance enhancement. Sci Rep 14, 26653 (2024). https://doi.org/10.1038/s41598-024-75906-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-75906-z

Keywords

This article is cited by

-

Economic dispatch of multimicrogrid interconnected system based on bilevel robust optimization

Scientific Reports (2025)