Abstract

Spray drying is a standard method for preserving bioactive ingredients and enhancing their storage stability. This study aimed to produce entirely plant-based spray-dried powders by using hemp, canola, and flax seed proteins, combined with maltodextrin, as wall material, while chokeberry extract from wine waste served as core material. We conducted a thorough analysis of the oil-seed proteins, examining their nitrogen solubility index, emulsification, and foaming capacities. The encapsulation process was evaluated based on its yield and efficiency. The spray-dried powders were further assessed through colour analysis, particle morphology and size distribution, hygroscopicity, and storage stability measurements. The encapsulation yield with oil-seed proteins ranged from 75.0 ± 6.2 to 78.5 ± 1.3%, and the efficiency from 58.4 ± 0.8 to 77.5 ± 1.9%. These plant-based spray-dried powders exhibited similar colour parameters, morphology, and stability to those of whey protein powders. The study highlights the significant potential of oil-seed proteins in producing plant-based spray-dried powders.

Similar content being viewed by others

Introduction

Microencapsulation is a widespread technique for facilitating the handling and packaging of bioactive fluidic ingredients and protecting the core material from degradation and oxidation1,2,3.

For the efficient protection of bioactive compounds, the wall material used for encapsulation should form emulsions stabilizing the active component during the liquid atomization4,5. The selection of wall material is crucial in achieving the desired encapsulation efficiency, protection, and functionality of the encapsulated product, and depends on the specific application6. The commonly used component of wall material is maltodextrin (MD), derived from rice, wheat, or potato starch7,8. MDs are mixtures of oligo- and polysaccharides typically containing 3–20 D-glucose units9. MDs are cheap, highly soluble in water, and exhibit excellent drying properties helping to convert liquid formulations into dry powders10. The presence of MD influences the particle size and morphology of the spray-dried powder11. MD also acts as a bulking agent, aiding in the formation of larger particles and helping to improve powder flowability12. In addition, MDs can improve the sensory quality of the encapsulated product13.

However, as MD has no surface-active properties required for the formation of particle walls14, it should be combined with other materials, which possess good emulsifying and film-forming properties, like proteins. Proteins and MDs form synergistic combinations allowing for better coverage and protection of the core material15. Proteins can also provide a barrier that controls the release of the encapsulated substance, regulating its diffusion or degradation rate16. Proteins and MDs are generally compatible and form a homogeneous mixture, facilitating the encapsulation process. Due to similar solubility, the distribution of the wall material around the core material is uniform. MD prevents the aggregation or collapse of the protein matrix during drying. This can result in the production of spherical or porous particles with improved powder characteristics but also enhanced stability12. The specific interactions between MD and proteins include weak interactions like hydrogen bonding and electrostatic interactions. During the spray dry process when proteins and MD are exposed to high temperatures, the Maillard reaction occurs between the amino groups of proteins and the reducing sugars. This can lead to the development of brown colour, aroma, and flavour compounds, but also to the deterioration of nutritional properties and stability17.

The choice of proteins for spray-drying wall materials is multifaceted, encompassing factors such as protein emulsifying properties, encapsulation efficiency, functional and sensory attributes, origin, availability, cost, and safety. While whey protein and casein from milk are commonly used, there’s a growing trend of using plant-based proteins from soybeans, peas, legumes, oats, rice, and wheat18,19,20. Several legume proteins have been tested as wall material for the microencapsulation of lipophilic compounds as their physicochemical properties including hydrophobicity, surface charge, and structure flexibility play an important role in adsorption and retention at the oil–water interface21. Chickpea and lentil protein isolates were used in combination with MD for the spray drying of flax seed oil22and pea protein isolates were also combined with MD for the microencapsulation of triglyceride and α-tocopherol18. In addition, legume proteins have been reported for their efficiency in the microencapsulation of hydrophilic compounds such as ascorbic acid spray drying using MD and pea protein isolate23, and anthocyanins using soy protein isolate in combination with MD or starch24,25. Oil-seed proteins from hemp-, canola- and flaxseed show significant potential for the development of functional foods due to excellent functional characteristics like emulsifying and foaming capacity26. These proteins contain an essential amount of 11 S globulins with MW 〜300 kDa, like linin (up to 85% of total flaxseed protein)26, edestin (60–80% of hempseed protein)27, and cruciferin (60% of canola seed protein)28, which are organized into tetramer or hexamer forms29. Unlike albumins, globulins are water-insoluble, whereby their solubility is significantly improved by the presence of salts26. Compared to whey proteins, 90% of which have a molecular weight below 20 kDa, oil-seed protein molecules are significantly bigger30,31. A summary of the main characteristics of oil-seed proteins is provided in Table 1.

The choice of wall material components is important for achieving the expected performance of the core material. The combined use of polysaccharides and proteins for encapsulation has a stabilizing effect for anthocyanins, polyphenolic compounds that present promising health effects, but have poor stability limiting their application in the food industry32. The stability of anthocyanins can be improved by glycosylation and/or acylation caused by sugars at different pH values33, and by the interaction of different protein structures with anthocyanin molecules34. Furthermore, wall material has an impact on the morphology of microparticles and the stability of the encapsulated core material. The morphology of spray-dried microparticles (roughness of the surface, presence of hollow particles, presence of aggregates) and particle size distribution affect the powder characteristics, influencing its potential applications12,35.

The current study aimed to explore the utilization of oil-seed proteins recovered from the hemp, canola, and flax oil-seed cakes, combined with maltodextrin (MD) as wall material for the microencapsulation of black chokeberry extracts based on the hypothesis that whey protein can be replaced by oil-seed proteins to obtain 100% plant-based spray-dried powders. These powders can be used both as dry powders in instant products to provide the retention of encapsulated compounds36, or after reconstitution in water to achieve the desired texture and functionality37. They ensure the effectiveness of bioactive components38, potentially fortify foods with bioactive compounds39, and are natural preservatives due to their antimicrobial properties extending the shelf life of food products40. The obtained powders were characterized by their key physicochemical and functional properties, such as microparticle size and morphology, hygroscopicity, encapsulation efficiency, colour, and storage stability.

The black chokeberry (Aronia melanocarpa (Michx.) Elliott) has been appreciated as raw material for beverage production for decades, it is widely cultivated in Estonia and its popularity is still increasing41. Therefore, the extract, known for its exceptionally high anthocyanin content42,43, and possessing high antioxidant activity44, was chosen as the core material for encapsulation. Anthocyanins are water-soluble pigments existing in various forms depending on pH. They predominantly exist as red flavylium cations in acidic conditions, while in slightly acidic to neutral conditions they form colourless hemiketals and blue quinoidal bases45. Extracted anthocyanins can be used as natural colorants in food products, offering an eco-friendly alternative to synthetic dyes. They also exhibit high antioxidant activity, which can be beneficial in food preservation and health applications46,47,48. Additionally, anthocyanins can be incorporated into edible films and coatings, providing pH-sensitive packaging solutions47.

The study underscores the importance of valorizing agri-food waste and by-products for sustainable food production. By-products from fruit processing, including berries, are a rich source of bioactive compounds, often found in higher concentrations than in the edible or processed parts of the fruit49. In this context, the anthocyanin-rich extract used in the present study was prepared from chokeberry pressing residue, a by-product of chokeberry wine production, obtained from a local wine industry.

Materials and methods

Materials

The chokeberry extract was prepared from chokeberry wine waste obtained from Rüüp OÜ (Ala-Juusa farm, Kanepi Parish, Estonia, 58o01’N 26o40’E) in Sept. 2021. The berries were smashed and fermented with Enartis Red Fruit wine yeast for five days. After juice removal, the residues were air-dried and stored at − 18 oC. Air drying was chosen because it is a more scalable and affordable technology compared to freeze-drying for local producers. For the preparation of extracts, the material was thawed at room temperature and ground.

The oil-seed protein concentrates Hempein (hemp protein), Canolein (canola protein), and Flaxein (flax protein) were procured from Vegetein AS (Estonia); the whey protein concentrate WHEY100 was from SportLife Nutrition®, Finland, (Table 2).

All chemicals used were of laboratory grade and purchased from Sigma-Aldrich (Steinheim, Germany).

Preparation of extracts for encapsulation

Anthocyanin-rich chokeberry extracts were obtained via ultrasound-assisted extraction from ground, dried berry residues. Extraction was performed using a UP 400St ultrasonic processor (⍉18 mm titanium horn; Hielscher Ultrasonics GmbH, Germany). Dry powder (10 g) was mixed with ethanol–water solution (70:30, v/v, 250 mL). The extraction was performed at 30% amplitude (power 56 W) for 15 min. The extracts were separated from the residual material by vacuum filtration, and ethanol was removed by vacuum rotary evaporation at 40 °C. The concentrated aqueous extracts served as the core material for encapsulation.

Determination of protein functional properties

For the determination of Nitrogen Solubility Index (NSI), protein aqueous dispersion (100 mL, 1 g/100 mL, pH 7.00) was prepared and mixed for 2 h at 150 rpm, and 35 mL of solution was transferred to a 50-mL centrifuge tube and centrifuged 10 min at 3000 x g at room temperature. The supernatant was collected, filtered through Whatman paper filter no.1, and nitrogen content was determined by the Kjeldahl method according to the Association of Official Analytical Chemists (AOAC) method 2001.11, SFS EN ISO 20483:2013 and EN ISO5983-2. The nitrogen content of the remaining protein dispersion before centrifugation was also determined by the Kjeldahl method. The correction factor of 6.25 was used in protein content calculations50. The NSI was calculated as follows:

Emulsification capacity was determined by measuring the amount of oil (g) emulsified by protein concentrate dispersed in water until the emulsion turned from oil-in-water to water-in-oil emulsion. The turning point of the emulsion was detected by the increase in the emulsion’s resistance monitored using an ohmmeter (Digital Multimeter, Fluke Corporation, Washington, USA). The protein concentrate dispersion (50 mL, 0.01 g protein contained in the concentrate/100 mL, pH7.0) was poured into the reaction cylinder and mixed using Ultra-Turrax homogenizer (IKA®-Werke GmbH & Co., Staufen, Germany) at 13,000 rpm and canola oil was gradually pumped to the solution (25 mL/min). When the emulsion’s resistance increased over the detection limit of the ohmmeter the oil pump was stopped and the amount of added oil was determined. Emulsification capacity was calculated as follows:

Foaming capacity was determined by measuring the volume of foam obtained after whipping of protein solution. Briefly, 150 mL of protein concentrate dispersion (4.5 g protein contained in the concentrate /100 mL, pH 7.0) was whipped using Hobart equipment on full power for 5 min. The volume of the foam was recorded and the foaming capacity was calculated as follows:

Preparation of encapsulation wall material

Protein concentrate dispersions were prepared by mixing 30 g protein concentrate powder with 300 mL Milli-Q water (w/w 1:10), and the mixture was stirred overnight at room temperature. Soluble protein extracts were separated from the insoluble residue by vacuum filtration. For flax-seed protein extract separation, we used centrifugation (3000 x g; 15 min.) as the presence of mucilage in the solution resulted in filters clogging. The dry matter content in 100 mL extract was as follows: hemp 1.20 ± 0.04 g, canola 4.12 ± 0.09 g, and flax 3.10 ± 0.10 g. For whey protein solution, 2.5 g of whey protein concentrate powder was solubilized in 100 mL Milli-Q water. Maltodextrin (3 g) was added to 80 mL protein extract and mixed.

Conducting and evaluating the spray-drying process

The formulation (140 mL, including 80 mL protein extract, 60 mL chokeberry extract, and 3 g MD) was converted into powders using a Büchi Mini Spray Dryer B-290 (Switzerland). The spray –dry feed composition is detailed in Table 3.

The total dry matter content in the feed was kept below 10% due to the low dry matter content in the chokeberry extract, which we couldn’t evaporate further to avoid the degradation of anthocyanins51. In addition, a lower dry matter content helps to preserve the bioactivity of the anthocyanin-rich extracts during spray-drying processes52. The parameters of the spray-drying process were as follows: spray nozzle tip diameter 0.5 mm; atomization pressure 5.0 bar; inlet temperature 190 oC; material feed rate 3.8 ± 0.2 mL/min; aspirator 50%. All processes were carried out in triplicate, and the powders obtained were kept in closed vessels at room temperature until analysis on the same day.

The process yield, indicating process performance, was calculated as follows:

The encapsulation efficiency, the percentage of active core material (anthocyanins for chokeberry extract) encapsulated, was calculated as follows:

Determination of total anthocyanins: spray-dried powder sample (100 mg) was dispersed in 2 mL methanol/acetic acid/water solution (50:8:42 v/v/v), homogenized using a vortex mixer for 1 min, and incubated for 20 min in sonication bath. After sonication, samples were centrifuged at 12,000 rpm for 15 min.

Determination of surface anthocyanins: spray-dried powder sample (100 mg) was dispersed in 2 mL methanol/ethanol mixture (1:1 v/v), homogenized using a vortex mixer for 1 min, and then centrifuged at 12,000 rpm for 5 min.

After centrifugation, the supernatant was recovered to measure total and surface anthocyanins content using the pH differential method53. The supernatant was pipetted into two different 4 ml spectrophotometric cuvettes, where two different buffer solutions, pH 1.0 (potassium chloride, 0.025 M) and pH 4.5 (sodium acetate, 0.4 M) were added respectively. The mixtures were left for 20–50 min in dark at room temperature, and after that the samples were measured using Shimadzu UV 1200 spectrophotometer at two different wavelengths, 520 and 700 nm. Calculation of anthocyanin pigment concentration, expressed as cyanidin-3-glucoside equivalents, was as follows:

where: A= (A520nm – A700nm)pH1.0 – (A520nm – A700nm)pH 4.5; MW (molecular weight) = 449.2 g/mol for cyanidin-3-glucoside (cyd-3-glu); DF = dilution factor; l = path length in cm; ε = 26 900 molar extinction coefficient in L×mol–1×cm–1 for cyd-3-glu; and 103 = factor for conversion from g to mg.

Spray-dried powder analyses

Particle Morphology Study: The particle morphology was examined using a scanning electron microscope system EVO LS15 (Zeiss, Germany). Before the examination, powder specimens were fixed on specimen stab with adhesive double-sided carbon tape and sputter-coated with Au using a modified vacuum chamber. Images were taken in back-scattered electron (BSE) mode at a working distance of 9 mm, and an accelerating voltage of 4.45 kV.

Particle size distribution: The particle size distribution of spray-dried powders was determined using a Malvern Mastersizer 3000 analyzer (Malvern Instruments Ltd., Malvern, UK). About 0.1 mL of sample was suspended with 1 mL of Milli-Q water (conductivity 0.055 µS/cm) in 2 mL Eppendorf tubes and briefly vortexed before transfer into the particle size distribution analyzer’s dispersion tank containing the same quality water. The material (cellulose, refractive index 1.47) and dispersant (water, refractive index 1.33) were selected as proposed by Mastersizer software, and the speed of the stirrer was 2,000 rpm. The size distribution of the extracts was measured after adding a sufficient amount of sample to achieve an obscuration of 5 to 8%. Size by volume distribution–-based percentiles (Dv10 as the first decile, Dv50 as the median, Dv90 as the last decile) and D3,4(volume moment mean) were derived from Mastersizer software. D3,4 was defined as follows:

where Ni is the number of particles in a size class of di.

Colour values: Colour values (L, a, b) were determined using a Minolta colourimeter CR-400 (Konica Minolta, Germany). The samples were packed into the granular sample attachment CR-A50 for measurement. The L value, ranging from 0 to 100, is the indicator of the degree of lightness; a value stands for the red (a > 0) and green (a < 0) colours; b value measures yellow (b > 0) and blue (b < 0) colours. The overall colour difference ΔE*abwas calculated according to the CIE 1976 formula54,55:

where L*1, a*1, and b*1 characterize the average of reference sample, in our experiment the powder prepared with whey protein. Five measurements per sample were taken.

Hygroscopicity Determination: To determine the hygroscopicity of spray-dried powders, 0.25 g of powder was weighted onto plastic plates, which were placed into a Climacell 707 (MMM Medcenter Einrichtungen GmbH; MMM Group) at 23 oC at 70% humidity for 24 h. Afterward, the samples were reweighted, and the hygroscopicity was expressed as the mass of water absorbed per 100 g of sample dry weight.

Storage Stability Test: To test the storage stability of spray-dried powders and non-encapsulated extract, approximately 1.2 g of sample was weighed into 50 ml transparent white plastic screw cap cups and stored in darkness at room temperature or + 50 °C, as elevated temperatures help to simulate long-term storage conditions in a shorter period56. The total anthocyanin content was measured every two weeks as described in Sect. 2.5.

Data analyses

Spray drying using different proteins as wall material was performed in duplicates and further analyses were in triplicates. Results are expressed as mean ± standard deviation. The statistical analysis was conducted using Prism 5 (GraphPad Software, San Diego, CA, USA). Data were analyzed by one-way analysis of variance (ANOVA), followed by Tukey’s test.

Results and discussion

Functional properties of oil-seed proteins

Surface-active properties are vital for selecting proteins as wall materials for microencapsulation, as they allow for improved encapsulation efficiency and stability when combined with polysaccharides such as maltodextrin or starch57. The functional properties most relevant to encapsulation, including nitrogen solubility, emulsification capacity and foaming capacity of the studied oilseed proteins, are shown in Table 4.

Emulsification capacity is known to play an important role in the encapsulation efficiency of lipophilic compounds by stabilizing the oil/water interface, while in the case of hydrophilic compounds such as anthocyanins the emulsifying properties of proteins play an important role in enhancing the film-forming capacity of MD and enhance the encapsulation efficiency25. The addition of MD as wall material offers good protection for the core material against oxidation, thus improving the powder stability58. The protein foaming capacity potentially affects encapsulation efficiency preventing bubble coalescence and guaranteeing the stability of the encapsulated products.

Hemp protein concentrate displayed the lowest solubility with only 9.44 ± 0.79% of total nitrogen soluble, while canola and flax protein concentrates exhibited 3 to 5-fold higher solubility, with 32.95 ± 5.3% and 54.31 ± 4.2%, respectively. Malomo et al.. also described the low solubility of hemp protein isolate at pH 7.0 (< 10%) which is explained by the aggregation of hemp seed major protein edestin below pH 7.059. A previous study on protein solubility of defatted meals from different species of oilseed canola reported a somewhat higher solubility ranging between 45.9 and 60.6% at pH 7.060. Kaushik et al.. reported similar results regarding the solubility of flax protein isolate with 57% of total nitrogen soluble at pH 7.061.

All oil-seed proteins exhibited good emulsifying capacity ranging between 14.68 and 67.76 g oil/mg protein contained in protein concentrate, with flax protein showing the highest capacity followed by hemp protein and canola protein. A previous study on whey protein isolate (WPI) emulsifying properties reported that WPI emulsifying capacity at pH 6.8 was 145 mL oil/100 mg protein62, which is equivalent to 1.33 g oil/ mg protein. Other studies also reported that plant proteins exhibit a higher emulsifying activity index compared to whey protein including hemp and flax protein isolates61,63. Emulsifying properties of proteins are affected by their solubility and surface hydrophobicity63, which play a crucial role in the migration and adsorption of protein molecules on the oil-water interface due to the increased hydrophobic interaction of the molecular surface with oil droplets. Increased surface hydrophobicity, attributed to the high degree of exposure of hydrophobic amino acids on the surface of the molecule, promotes the formation of a viscoelastic film surrounding oil droplets, preventing their agglomeration.

The foaming capacity of a protein is measured as the volume increases (% overrun) resulting from the entrapment of air in the continuous liquid phase after whipping of protein suspension64. Hemp and flax protein concentrates exhibited low foaming capacity with 113% and 167% overrun respectively. A recent study reported that the foaming capacity of hemp protein isolates from different hemp cultivars ranged between 52.9% and 84.9% for 1% protein solution at pH 7.0, this difference between different cultivars was correlated with the difference in their protein composition (content of edestin) which affected protein solubility65. Lan et al.. examined the foaming capacity of flax protein concentrate and flax protein isolate, which were 92% and 170% respectively66. On the other hand, canola protein concentrate exhibited 9 to 10-fold higher foaming capacity compared to hemp and flax protein. These results align with recent studies highlighting the exceptional foaming properties of rapeseed (canola) protein and its two main components, napin and cruciferin67,68. Isolated cruciferin and napin displayed high foaming capacity with 320% and 410% overrun, respectively. The mixtures at different ratios of both proteins displayed a similar foaming capacity as napin, between 400% and 420%. Their results also showed that due to its smaller particle size, napin exhibited higher foamability, while cruciferin displayed higher foam stability as it formed a stiff and solid-like film in the air-water interface. Whey protein isolate (WPI) has also high foamability: e.g. 6.5 g/100 mL WPI solution displayed 1300% overrun at pH 6.862.

Process yield and encapsulation efficiency

Figure 1 shows the yield and efficiency of the microencapsulation process of chokeberry extract using the mixture of different oil-seed proteins with MD as wall material.

The process yield varied between 71.7 ± 8.6 and 78.5 ± 1.3% (Fig. 1). The difference in process yield between different wall materials was not statistically significant. Previous studies on microencapsulation of anthocyanin-rich extracts have reported a process yield of 58.9% for purple potato extract encapsulated with MD, while the process yield of chokeberry extract with a mixture of MD and skim milk powder was 31.9%, and 39.9% with a mixture of MD and whey protein69,70, which is considerably lower compared to the present study and can be attributed to different encapsulation conditions.

Encapsulation yield and efficiency of anthocyanin-rich chokeberry extract using hemp, canola, flax, and whey proteins added to maltodextrin as wall material. (A) Encapsulation yield based on dry matter content and (B) Anthocyanins encapsulation efficiency. All values are means ± standard deviation, n = 3. Means with different letters differ significantly at p < 0.05.

Total and surface anthocyanin content in spray-dried powders was determined using the pH differential method. Total anthocyanin content values were 7.6 ± 0.7, 5.4 ± 0.2, 6.1 ± 0.2, and 6.3 ± 0.2 µg/mg of powder for samples spray-dried with hemp, canola, flax, and whey protein concentrates, respectively. Surface anthocyanin content values were 2.1 ± 0.2, 2.22 ± 0.1, 1.3 ± 0.1, and 2.4 ± 0.2 µg/mg of powder for samples spray-dried with hemp, canola, flax, and whey protein concentrates, respectively. The highest encapsulation efficiency 77.5 ± 1.9 and 71.5 ± 1.0% was obtained when flax and hemp protein concentrates were added to MD, respectively. Encapsulation with canola and whey protein concentrates exhibited lower efficiency with 58.4 ± 0.8 and 60.1 ± 3.6%, respectively. These results correlate with the proteins’ emulsifying properties of protein concentrates (Table 4) as flax and hemp protein concentrates exhibited significantly higher emulsification capacity compared to canola protein concentrate as well as whey protein according to the data available in the literature62. The encapsulation efficiency is influenced by the interaction of anthocyanins with the wall material through hydrogen bonds and/or electrostatic interactions69. In addition, proteins with higher emulsifying properties exhibit better encapsulation efficiency as their surface-active properties result in enhanced film-forming ability71. Patel et al. reported that increasing the emulsifier content in wall material resulted in an increased encapsulation efficiency of anthocyanins while the emulsifier concentration did not have a significant effect on anthocyanin content in the spray-dried powder25. In the study by Tzatsi and Goula, the encapsulation efficiency of chokeberry extract was 99.57% for MD/Skim milk powder and 96.77% for MD/whey protein concentrate70. The higher encapsulation efficiency compared to our results is likely related to the wall/core material ratio (9/1 vs. 3–4.8/1 in the present study as shown in Table 3). The authors also indicated that encapsulation efficiency increases by increasing the wall/core material ratio, which is partly explained by the increase of the solution viscosity that hinders anthocyanin diffusion to the particle surface.

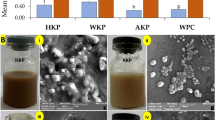

Microparticle morphology

The particle morphology is an important parameter of spray-dried powder that affects the powder’s application behavior, particularly flowability72. The particle morphology itself is in turn influenced by the feed composition. It is proposed that powders with higher MD/whey protein ratios include more wrinkled particles, while the increase in protein content leads to more hollow particles12.

In the current study, the protein/MD ratio was between 0.3 and 1.1 / 1 (Table 3), and the morphology of the spray-dried powders was studied using scanning electron microscopy (SEM). All powders, prepared using oil-seed or whey proteins as wall material, consisted mainly of spheroidal structures. Most particles had non-smooth wrinkled surfaces, but there were also bigger smooth ball-shaped particles, especially when canola protein was used as a wall material component (Fig. 2). With flax protein in wall material, a few bigger structures (> 20 μm) were detected in the powder indicating the potential presence of agglomerates. Some larger wall cavities may be attributed to air bubbles entrained during homogenization or atomization or being a result of foaming during vacuole formation.

Particle size analyses of spray-dried powders

The chokeberry extract and all spray-dried powders exhibited particle size distributions with two sub-distributions (smaller around 0.5 μm and larger around 10 μm) (Fig. 3). Larger sub-distributions dominated in all samples, except for the chokeberry whey encapsulation, where both sub-distributions had similar shares. Smaller particles suggest a thinner encapsulation coating when the amount of added encapsulation material remains constant (smaller particles, larger surface area).

The largest volume mean particle size was observed when canola protein was used for encapsulation, followed by hemp, flax, and whey protein (D3,4 = 11.44, 8.52, 5.14, and 4.28 μm, respectively) (Table 5).

The volume mean particle size (D3,4) increases with a smaller percentage of hollow particles12. Our results show that the value of D3,4 was higher if hemp and canola proteins were used (Table 5). Therefore, for applications where smaller particle sizes are desirable, flax may be the preferred encapsulation material when maintaining a consistent amount of encapsulation material.

Colour analyses

Colour analysis provides valuable information about the composition and quality of a powder, as particle size and surface geometry have influence on reflectance resulting in differences in colour. In the CIELAB colour space73, the minimal colour difference perceived is defined as ∆E*ab=1, while a distinguishable difference is proposed to be around 2.355. The colorimetric analyses revealed some colour variations between the powders with different proteins (Fig. 4).

The whey protein, used as standard, resulted in the powders with the highest L* values (55.21 ± 0.03) and the lowest a* and b* values (21.33 ± 0.24 and − 5.28 ± 0.04, respectively, Table 6). Powders with hemp protein, on the contrary, had the lowest L* value (46.76 ± 0.18), and highest a* and b*values (27.12 ± 0.23 and − 2.95 ± 0.07, respectively), while the colour space values for spray-dried powders with canola and flax proteins remained between these limits (Table 6). Tukey’s Multiple Comparison Test indicated no statistically significant colour difference between different spray-dried powders (p < 0.05).

Hygroscopicity

The hygroscopicity of different samples was characterized, as this attribute impacts the powders’ stability, storage, and other technical properties. Powders with lower hygroscopicity are easier to handle74,75. Spray-dried powders prepared using oil-seed proteins as wall material had somewhat higher hygroscopicity than powders prepared with whey protein, particularly if hemp protein was used (Fig. 5). However, all powders can be considered as only slightly hygroscopic, as the hygroscopicity was ≤ 20% for all samples. This low hygroscopicity is also achieved due to the relatively low protein/MD ratio because compared to proteins, MD is less hygroscopic76.

Storage stability

We studied the stability of spray-dried powders produced with different proteins both at room temperature and at 50 oC. Figure 6 shows the evolution of anthocyanin content (as % of initial anthocyanin concentration) during storage at different temperatures for non-encapsulated chokeberry extract and encapsulated extracts with MD and different proteins.

The initial anthocyanin concentrations in spray-dried powders were 7.6 ± 0.7, 5.4 ± 0.2, 6.1 ± 0.2, and 6.3 ± 0.2 µg/mg of powder for samples encapsulated with hemp, canola, flax, and whey protein concentrates, respectively. After 90 days, all spray-dried powders retained 90.0 ± 3.5 to 97.3 ± 3.7% of their initial anthocyanins content at room temperature and 80.9 ± 2.8 to 89.2 ± 4.2% at 50 °C. Statistically, there was no difference between the stability of spray-dried powders produced using oil-seed or whey proteins. In contrast, the non-encapsulated extract initially containing 780.3 ± 3.8 µg/mL lost approximately 60% of its anthocyanins content after 90 days at room temperature and underwent complete degradation after 34 days at 50 °C, losing about 85% of its initial content after 8 days. Anthocyanins are known to have low stability, which is influenced by environmental factors including pH, temperature, oxygen, and light. The fast degradation of anthocyanins limits their effectiveness as bioactive food ingredients77. The rapid degradation of anthocyanins in liquid extract underscores the importance of encapsulation to stabilize and preserve their bioactivity.

Conclusions

This study evaluated hemp, canola, and flax seed proteins as encapsulating agents in microencapsulation. The proteins exhibited distinct functional properties, with flax and hemp proteins showing higher encapsulation efficiency than canola protein. The oil-seed protein spray-dried powders, comparable in colour and particle morphology to whey protein powders, retained a significant portion of their anthocyanin content after 90 days. The obtained results regarding the physicochemical and functional properties of oil-seed proteins underscore their significant potential in producing 100% plant-based spray-dried powders of anthocyanins from wine waste.

Data availability

Data that support the findings of this study are available via Estonian University of Life Sciences online data repository: http://hdl.handle.net/10492/8811.

References

Sosnik, A. & Seremeta, K. P. Advantages and challenges of the spray-drying technology for the production of pure drug particles and drug-loaded polymeric carriers. Adv. Colloid Interface Sci. 223, 40–54 (2015).

Calderón-Oliver, M. & Ponce-Alquicira, E. The role of Microencapsulation in Food Application. Molecules. 27, 1499. https://doi.org/10.3390/molecules27051499 (2022).

Wang, L. et al. Study on preparation and properties of camellia oleifera seed oil microcapsules by complex coacervation and spray drying. LWT. 184, 115056. https://doi.org/10.1016/j.lwt.2023.115056 (2023).

Kim, Y. D., Morr, C. V. & Schenz, T. W. Microencapsulation properties of Gum Arabic and several Food proteins: Liquid Orange Oil Emulsion Particles. J. Agric. Food Chem. 44, 1308–1313 (1996).

Prata, A. S., Garcia, L., Tonon, R. & Hubinger, M. Wall Material Selection for Encapsulation by Spray Drying. J. Colloid Sci. Biotechnol. 2, 86–92 (2013).

Xu, Y. et al. The application of encapsulation technology in the food industry: classifications, recent advances, and perspectives. Food Chem. X. 21, 101240. https://doi.org/10.1016/j.fochx.2024.101240 (2024).

Jimenez-Hernandez, J., Salazar-Montoya, J. A. & Ramos-Ramirez, E. G. Physical, chemical and microscopic characterization of a new starch from chayote (Sechium edule) tuber and its comparison with potato and maize starches. Carbohydr. Polym. 68, 679–686 (2007).

Antonio-Estrada, C. et al. Enzymatic production of maltodextrins from taro (Colocasia esculenta) starch. CyTA-J Food. 7, 233–241 (2009).

Hofman, D. L., van Buul, V. J., Brouns, F. J. P. H. & Nutrition Health, and Regulatory aspects of Digestible Maltodextrins. Crit. Rev. Food Sci. Nutr. 56, 2091–2100 (2016).

Klinjapo, R. & Krasaekoopt, W. Microencapsulation of Colour and Flavor in confectionery products in Handbook of Food Bioengineering, Natural and Artificial Flavoring Agents and Food Dyes (eds Grumezescu, A. M. & Holban, A. M.) 457–494 (Academic, (2018).

Sansone, F. et al. Maltodextrin/pectin microparticles by spray drying as carrier for nutraceutical extracts. J. Food Eng. 105, 468–476 (2011).

Both, E. M., Boom, R. M. & Schutyser, M. A. I. particle morphology and powder properties during spray drying of maltodextrin and whey protein mixtures. Powder Technol. 363, 519–524 (2020).

Yang, S. et al. The improving effect of spray-drying encapsulation process on the bitter taste and stability of whey protein hydrolysate. Eur. Food Res. Technol. 235, 91–97 (2012).

McNamee, B. F., White, L. E., O’Riordan, E. D. & O’Sullivan, M. Effect of partial replacement of gum arabic with carbohydrates on its microencapsulation properties. J. Agric. Food Chem. 49, 3385–3388 (2001).

Özbek, Z. A. & Ergönül, P. G. Optimisation of wall material composition of freeze–dried pumpkin seed oil microcapsules: Interaction effects of whey protein, maltodextrin, and gum arabic by D–optimal mixture design approach. Food Hydrocoll. 107, 105909. https://doi.org/10.1016/j.foodhyd.2020.105909 (2020).

Talón, E. et al. Encapsulation of eugenol by spray-drying using whey protein isolate or lecithin: release kinetics, antioxidant and antimicrobial properties. Food Chem. 295, 588–598 (2019).

Zhou, Z. & Langrish, T. A review of Maillard reactions in spray dryers. J. Food Eng. 305, 110615. https://doi.org/10.1016/j.jfoodeng.2021.110615 (2021).

Nesterenko, A., Alric, I., Silvestre, F. & Durrieu, V. Vegetable proteins in microencapsulation: a review of recent interventions and their effectiveness. Ind. Crops Prod. 42, 469–479 (2013).

Sridhar, K. et al. Application of high-pressure and ultrasound technologies for legume proteins as wall material in microencapsulation: new insights and advances. Trends Food Sci. Technol. 127, 49–62 (2022).

Islam, F. et al. Vegetable proteins as encapsulating agents: recent updates and future perspectives. Food Sci. Nutr. 11, 1705–1717 (2023).

Chang, C. & Nickerson, M. T. Encapsulation of omega 3-6-9 fatty acid-rich oils using protein-based emulsions with spray drying. J. Food Sci. Technol. 55, 2850–2861 (2018).

Karaca, A. C., Low, N. & Nickerson, M. Encapsulation of flaxseed oil using a benchtop spray dryer for legume protein-maltodextrin microcapsule preparation. J. Agric. Food Chem. 61, 5148–5155 (2013).

Pereira, H. V. R. et al. Legume seeds protein isolates in the production of ascorbic acid microparticles. Food Res. Int. 42, 115–121 (2009).

Robert, P. et al. Encapsulation of polyphenols and anthocyanins from pomegranate (Punica granatum) by spray drying. Int. J. Food Sci. Technol. 45, 1386–1394 (2010).

Patel, A. S., Kar, A. & Mohapatra, D. Development of microencapsulated anthocyanin-rich powder using soy protein isolate, jackfruit seed starch and an emulsifier (NBRE-15) as encapsulating materials. Sci. Rep. 10, 10198. https://doi.org/10.1038/s41598-020-67191-3 (2020).

Ye, X. P. et al. Flaxseed protein: extraction, functionalities and applications. Food Sci. Technol. 42, e22021. https://doi.org/10.1590/fst.22021 (2022).

Sun, X. et al. Identification and characterization of the seed storage proteins and related genes of Cannabis sativa L. Front. Nutr. 8, 678421. https://doi.org/10.3389/fnut.2021.678421 (2021).

Perera, S. P., McIntosh, T. C. & Wanasundara, J. P. Structural Properties of Cruciferin and Napin of Brassica napus (Canola) Show Distinct Responses to Changes in pH and Temperature. Plants 5, 36; (2016). https://doi.org/10.3390/plants5030036

Cruz-Torres, L. F. et al. Physicochemical and functional properties of 11S globulin from Chan (Hyptis suaveolens L. poit) seeds. J. Cereal Sci. 77, 66–72 (2017).

Goodall, S., Grandison, A. S., Jauregi, P. J. & Price, J. Selective separation of the major whey proteins using ion exchange membranes. J. Dairy. Sci. 91, 1–10 (2008).

Mavropoulou, I. P., Kosikowski, F. V. & Composition Solubility, and Stability of Whey powders. J. Dairy. Sci. 56, 1128–1134 (1973).

Song, J. et al. Advancement of protein- and polysaccharide-based biopolymers for anthocyanin encapsulation. Front. Nutr. 9, 938829. https://doi.org/10.3389/fnut.2022.938829 (2022).

Vidana Gamage, G. C., Lim, Y. Y. & Choo, W. S. Sources and relative stabilities of acylated and nonacylated anthocyanins in beverage systems. J. Food Sci. Technol. 59, 831–845 (2022).

Ren, S., Jiménez-Flores, R. & Giusti, M. M. The interactions between anthocyanin and whey protein: a review. Compr. Rev. Food Sci. Food Saf. 20, 5992–6011 (2021).

Paramita, V., Iida, K., Yoshii, H. & Furuta, T. Effect of additives on the morphology of spray-dried powder. Dry. Technol. 28, 323–329 (2010).

Drozłowska, E. et al. Spray-Drying Impact the Physicochemical Properties and Formation of Maillard Reaction Products Contributing to Antioxidant Activity of Camelina Press Cake Extract. Antioxidants 12, 919; (2023). https://doi.org/10.3390/antiox12040919

Wu, S. & Miao, S. Physical properties and stickiness of spray-dried food powders in Spray Drying for the Food Industry 551–571Woodhead Publishing, (2024).

Banožić, M., Vladić, J. & Jokić, S. Encapsulation of bioactive compounds from herbal extracts using spray drying in Bioactive Compounds and their Importance 37–60Nova Science Publishers, (2021).

Hoskin, R. T., Grace, M. H., Xiong, J. & Lila, M. A. Spray-drying microencapsulation of blackcurrant and cocoa polyphenols using underexplored plant-based protein sources. J. Food Sci. 88, 2665–2678 (2023).

Baghi, F., Ghnimi, S., Dumas, E. & Gharsallaoui, A. Microencapsulation of Antimicrobial trans-Cinnamaldehyde: Effect of Emulsifier Type, pH, and drying technique. Appl. Sci. 13, 6184. https://doi.org/10.3390/app13106184 (2022).

Rätsep, R. et al. Polyphenol composition and antioxidant activity of wine raw materials and pomace from hybrid grapes, aronia, and Japanese quince. Agric. Food Sci. 1–10. https://doi.org/10.23986/afsci.143844 (2024).

d’Alessandro, L. G., Kriaa, K., Nikov, I. & Dimitrov, K. Ultrasound assisted extraction of polyphenols from black chokeberry. Sep. Purif. Technol. 93, 42–47 (2012).

Denev, P., Číž, M., Kratchanova, M. & Blazheva, D. Black chokeberry (Aronia melanocarpa) polyphenols reveal different antioxidant, antimicrobial and neutrophil-modulating activities. Food Chem. 284, 108–117 (2019).

Ovaskainen, M. L. et al. Dietary intake and major food sources of polyphenols in Finnish adults. J. Nutr. 138, 562–566 (2008).

Silva, V. O., Freitas, A. A., Maçanita, A. L. & Quina, F. H. Chemistry and photochemistry of natural plant pigments: the anthocyanins. J. Phys. Org. Chem. 29, 594–599 (2016).

Lapornik, B., Prošek, M. & Wondra, A. G. Comparison of extracts prepared from plant by-products using different solvents and extraction time. J. Food Eng. 71, 214–222 (2005).

Mileti, O. et al. Formulation Study on Edible Film from Waste grape and Red Cabbage. Foods. 12, 2804. https://doi.org/10.3390/foods12142804 (2023).

Trentin, J. et al. Antioxidant ready-to-use grape pomace extracts recovered with natural eutectic mixtures for Formulation of Color-Rich gummies. Foods. 13, 2840. https://doi.org/10.3390/foods13172840 (2024).

Ben-Othman, S., Jõudu, I. & Bhat, R. Bioactives from agri-food wastes: present insights and future challenges. Molecules. 25, 510. https://doi.org/10.3390/molecules25030510 (2020).

Pap, N. et al. Biorefining of legume and grass biomasses: Technological properties and bioactivities of the green juice. Future Foods. 9, 100331. https://doi.org/10.1016/j.fufo.2024.100331 (2024).

Patras, A., Brunton, N. P., O’Donnell, C. & Tiwari, B. K. Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci. Technol. 21, 3–11 (2010).

Radisavljević, M. et al. Optimization of spray drying conditions for production of Achillea millefolium extract powder. Hem Ind. 75, 353–363 (2021).

Lee, J., Durst, R. W. & Wrolstad, R. E. Determination of total Monomeric Anthocyanin Pigment Content of Fruit Juices, beverages, Natural colourants, and wines by the pH Differential Method: collaborative study. J. AOAC Int. 88, 1269–1278 (2005).

Santipanichwong, R. & Suphantharika, M. Carotenoids as colourants in reduced-fat mayonnaise containing spent brewer’s yeast β-glucan as a fat replacer. Food Hydrocoll. 21, 565–574 (2007).

Mokrzycki, W. S. & Tatol, M. Colour difference ∆E - a survey. Mach. Graph Vis. Int. J. 20, 383–411 (2011).

Pasagadi, A. S. et al. Shelf-life prediction of milk-millet powders. J. Food Process. Eng. 46, e14204. https://doi.org/10.1111/jfpe.14204 (2022).

Puttarat, N. et al. Spray-drying microencapsulation using whey protein isolate and nano-crystalline starch for enhancing the survivability and stability of Lactobacillus reuteri TF-7. Food Sci. Biotechnol. 30, 245–256 (2021).

Carneiro, H. C., Tonon, R. V., Grosso, C. R. & Hubinger, M. D. Encapsulation efficiency and oxidative stability of flaxseed oil microencapsulated by spray-drying using different combinations of wall materials. J. Food Eng. 115, 443–451 (2013).

Malomo, S. A., He, R. & Aluko, R. E. Structural and functional properties of hemp seed protein products. J. Food Sci. 79, C1512–C1521 (2014).

Wanasundara, J. P. D., Abeysekara, S. J., McIntosh, T. C. & Falk, K. C. Solubility Differences of Major Storage Proteins of Brassicaceae Oilseeds. J. Am. Oil Chem. Soc. 89, 869–881 (2012).

Kaushik, P. et al. Preparation, characterization and functional properties of flax seed protein isolate. Food Chem. 197, 212–220 (2016).

Firebaugh, J. D. & Daubert, C. R. Emulsifying and Foaming properties of a derivatized whey protein ingredient. Int. J. Food Prop. 8, 243–253 (2005).

Xue, Y. et al. Physicochemical, Structural, and Functional Properties of Hemp Protein vs several commercially available plant and animal proteins: a comparative study. ACS Food Sci. Technol. 2, 1672–1680 (2022).

Narsimhan, G. & Xiang, N. Role of proteins on formation, drainage, and Stability of Liquid Food Foams. Annu. Rev. Food Sci. Technol. 9, 45–63 (2018).

Liu, M. et al. Composition and functional properties of hemp seed protein isolates from various hemp cultivars. J. Food Sci. 88, 942–951 (2023).

Lan, Y., Ohm, J., Chen, B. & Rao, J. Physicochemical properties and aroma profiles of flaxseed proteins extracted from whole flaxseed and flaxseed meal. Food Hydrocoll. 104, 105731. https://doi.org/10.1016/j.foodhyd.2020.105731 (2020).

Shen, P. et al. Cruciferin versus napin – air-water interface and foam stabilizing properties of rapeseed storage proteins. Food Hydrocoll. 136, 108300. https://doi.org/10.1016/j.foodhyd.2022.108300 (2023).

Yang, J., Berton-Carabin, C. C., Nikiforidis, C. V., Van der Linden, E. & Sagis, L. M. Competition of rapeseed proteins and oleosomes for the air-water interface and its effect on the foaming properties of protein-oleosome mixtures. Food Hydrocoll. 122, 107078. https://doi.org/10.1016/j.foodhyd.2021.107078 (2021).

Vergara, C. et al. Microencapsulation of Anthocyanin extracted from Purple Flesh Cultivated Potatoes by Spray Drying and its effects on in Vitro gastrointestinal digestion. Molecules. 25, 722. https://doi.org/10.3390/molecules25030722 (2019).

Tzatsi, P. & Goula, A. M. Encapsulation of Extract from unused chokeberries by spray Drying, co-crystallization, and ionic gelation. Waste Biomass Valorization. 12, 4567–4585 (2021).

Raj, R., Sheikh, S. A., Singh, S. A. & Shetty, N. P. Improvement of storage stability and bioaccessibility of microencapsulated black carrot (Daucus Carota ssp. sativus) anthocyanins using maltodextrin and sericin protein combinations as wall material. Food Biosci. 61, 104666. https://doi.org/10.1016/j.fbio.2024.104666 (2024).

Fu, X. et al. Effect of particle shape and size on flow properties of lactose powders. Particuology. 10, 203–208 (2012).

ISO/CIE 11664-4:2019. Colorimetry - Part 4: CIE 1976 Lab* Colour Space (STANDARD by International Organization for Standardization / CIE, 2019).

Wang, H. et al. Effect of spray-drying and freeze-drying on the properties of soybean hydrolysates. J. Chem. 2020 (9201457). https://doi.org/10.1155/2020/9201457 (2020).

Juarez-Enriquez, E. et al. Effect of water content on the flowability of hygroscopic powders. J. Food Eng. 205, 12–17 (2017).

Kurozawa, L. E., Park, K. J. & Hubinger, M. D. Effect of carrier agents on the physicochemical properties of a spray dried chicken meat protein hydrolysate. J. Food Eng. 94, 326–333 (2009).

Enaru, B. et al. Anthocyanins: factors affecting their Stability and Degradation. Antioxidants. 10, 1967. https://doi.org/10.3390/antiox10121967 (2021).

Acknowledgements

The authors would like to acknowledge the help provided by Märt Rahi from the Estonian University of Life Sciences with SEM micrographs.

Funding

This research was funded by the European Union’s Horizon 2020 Research and Innovation Program project VALORTECH under grant agreement No. 810630, the Mobilitas Pluss ERA Chair support (no. MOBEC006), and the European Regional Development Fund’s project “PlantValor—full-scale product development service in synergy with the traditional activities of Polli Horticultural Research Centre” 2020–2023.

Author information

Authors and Affiliations

Contributions

Sana Ben-Othman, Uko Bleive, and Toonika Rinken made the spray-dried powders; Sana Ben-Othman, Nora Pap, and Eila Järvenpää determined the protein functional properties; Hedi Kaldmäe, Reelika Rätsep, and Alar Aluvee made all the analyses; Andres Sats carried out the particle size measurements. Toonika Rinken wrote the main manuscript text and prepared Figs. 2 and 4, and 6; Sana Ben-Othman prepared Figs. 1 and 5; Andres Sats prepared Fig. 3. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ben-Othman, S., Bleive, U., Kaldmäe, H. et al. Characterization of Plant based spray dried powders using oil seed proteins and chokeberry extract from wine byproduct. Sci Rep 14, 27429 (2024). https://doi.org/10.1038/s41598-024-79223-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-79223-3

Keywords

This article is cited by

-

Functional and Structural Performance of Canola, Black Caraway, and Soy Proteins in Anthocyanin Microencapsulation

Food and Bioprocess Technology (2025)

-

Dry particles obtained from jabuticaba peel extracts: impact of acid type in ultrasound-assisted chemical hydrolysis on morphostructural properties, thermal stability, and in vitro digestibility

Journal of Food Measurement and Characterization (2025)