Abstract

This study presents an advanced approach utilizing vacuum distillation (VD) to purify Al from Al–Mg alloys. The activity coefficients of Al-Mg binary alloy components were meticulously determined by applying the molecular interaction volume model (MIVM), non-random two-liquid (NRTL) model, and Wilson equation. Comparative analysis between experimental data and calculated activity coefficients enabled the selection of an optimal model exhibiting high computational accuracy and extensive applicability. The NRTL model, chosen for its precision, was then employed to compute the activity coefficients of Al-Mg alloy across various temperatures, leading to the development of a vapor-liquid equilibrium (VLE) diagram. This VLE diagram provides a robust quantitative foundation for assessing the purification limits of Al within the temperature range of 973–1373 K in the distillation process. Theoretical analyses underscore that VD offers a rapid and efficient method for Al purification. Experimental verification at a kilogram scale, conducted at 1373 K for 120 min, achieved an Al purity level of 99.9989% with a direct recovery efficiency of 97.98%. Notably, this VD process aligns with environmental standards for sustainable metallurgical practices, as it prevents the release of gaseous emissions or effluents, thereby meeting the industry’s growing demand for eco-friendly Al recycling methods.

Similar content being viewed by others

Introduction

Al is extensively utilized across various industries, including aviation, aerospace, automotive, mechanical manufacturing, and shipbuilding, making it the most widely employed non-ferrous metal1,2,3. In recent years, the demand for Al alloys has significantly increased, driven by the rapid development of new energy vehicles, which results in an average consumption of over 225 kg of Al per vehicle4. In 2023, global primary Al production reached 70.593 million tons5,6, while recycled Al production was approximately 40 million tons. Notably, the production of recycled Al now exceeds half that of primary Al. During primary Al production, the Bayer process is initially used to separate Al from bauxite and produce Al2O37. Subsequently, the cryolite molten salt electrolysis method is employed to reduce Al2O3 to metallic Al8. The purity of primary Al is less than 99.85%9. For every ton of primary Al produced using the Bayer-molten salt electrolysis method, approximately 12 ~ 16 tons of carbon emissions are generated10. However, producing an equivalent quantity of recycled Al only requires 5% compared to primary Al production while saving approximately 3.4 tons of standard coal and conserving approximately 14 m3 of water; it also reduces solid waste emissions by approximately 20 tons11. Based on estimations regarding the service life of various Al products, packaging materials including cans and Al foil demonstrate limited durability with an average lifespan not exceeding one year12. Consequently, due to extensive primary and recycled Al production coupled with relatively short product lifespans in case of certain applications, there has been a persistent rise in waste Al alloy generation13.

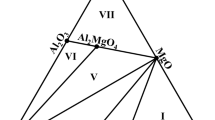

Mg is recognized as one of the primary impurity elements in the smelting of waste Al alloys and the preparation of refined Al14. Refined Al is defined as Al products containing an Al content ranging from 99.99–99.996%14. The efficient separation of Mg from Al is essential for the recycling of Al metal resources15. Currently, four principal methods are employed for the extraction of Mg from Al melts: the high-temperature oxidation technique, the blowing refining method, the three-layer electrolysis refining approach, and the melt adsorption process. The high-temperature oxidation method capitalizes on the superior affinity of Mg for O2 compared to Al at elevated temperatures. During the melting process, Mg reacts with O2 to form MgO, which is subsequently removed as slag. Although this method is simple and easy to implement, it may lead to significant losses of Al and other alloying elements16. The blowing refining method involves the introduction of chlorine gas into Al melt, where it reacts with Mg to produce MgCl2. This MgCl2 then floats on the surface of Al melt, facilitating the removal of Mg as slag. However, the use of chlorine gas in this method poses environmental pollution risks and equipment corrosion challenges, in addition to the complexity and high costs associated with smoke and dust collection and treatment17. The melt adsorption method involves the adsorption of Mg atoms in molten Al through the addition of a specially designed lithium titanium compound18. This method remains in the research phase and has limited industrial applications. Conversely, the three-layer electrolysis refining method is widely utilized; it employs AlF3 to convert Mg in the melt into MgCl2, necessitating the addition of various salt substances such as Na3AlF6, NaCl, KCl, Na2CO3, and K2CO3 into the flux19. The traditional three-layer electrolysis refining method encompasses a series of sequential procedures, including melting, slag removal, electrolyte replenishment, cathode replacement, impurity extraction, and final slag removal19.

In response to the aforementioned challenges, it is essential to develop a sustainable and technically viable process for the direct synthesis of refined Al from Al-Mg alloy. Vacuum distillation (VD) is a metallurgical technology that enables the separation, enrichment, and purification of metals within a controlled, low-pressure environment. This method is characterized by its environmental compatibility, operational simplicity, and high production efficiency20,21,22. VD technology has been extensively utilized in the preparation of high-purity metals, the recovery of valuable metals, and the treatment of non-ferrous solid waste23,24,25. The underlying principle of this technology is based on the high saturation vapor pressures of metals and metal compounds, which allows for their more efficient evaporation into the gas phase under vacuum conditions as opposed to atmospheric pressure. The principle of VD technique can be succinctly articulated as leveraging the differences in saturated vapor pressure among various substances at a given temperature to facilitate the separation of impurity elements within the material and to enhance the enrichment of the target metal26.

This study proposes the application of VD for the treatment of Al-Mg alloys and the purification of metallic Al. A thorough analysis was conducted to explore the underlying mechanisms associated with VD of Al-Mg alloys, utilizing calculations of activity coefficients and vapor-liquid equilibrium (VLE) analysis. The theoretical feasibility of separating Mg metal using VD to obtain refined Al was convincingly demonstrated. Building upon this theoretical framework, successful experimental trials of VD were conducted to effectively separate Mg from Al-Mg alloy and produce refined Al.

VD experiments

Experimental device

The primary apparatus utilized in VD experiment consisted of a small upright cylindrical furnace (Fig. 1). The entire VD process was executed within a hermetically sealed system, wherein the internal furnace pressure was effectively maintained between 2 Pa and 10 Pa through the use of a rotary vane vacuum pump (TRP-24, Beiyi-Woosung, China). Heat generated by graphite resistance was radiated to the crucible and subsequently transmitted from the exterior to the core of the sample. A temperature control mechanism, integrated with a thermocouple, was employed to facilitate precise adjustments of the operational temperature during VD process. Under elevated temperatures and vacuum conditions, Mg was continuously vaporized and subsequently condensed on a designated condensation plate located atop the furnace chamber. Following a thorough cooling period of the furnace, both the volatilized components and residual materials were collected for further analysis. To ascertain their chemical composition, three analytical methods, including chemical titration and atomic absorption spectroscopy (AAS), were employed. To improve the accuracy of characterization, the analysis and detection of each sample were conducted three times in a randomized manner.

Experimental methods

The primary objective of this investigation was to achieve the separation of Mg while comprehending the impact of distillation temperature and duration on the purity and recovery efficiency of Al. Firstly, Al-Mg alloy was subjected to vacuum drying at 423 K for a duration of 2 h prior to VD experiments. Secondly, 2000 g of the dried Al-Mg alloy was placed in a high-density graphite crucible for the purpose of Mg separation using VD. As previously mentioned, the core apparatus utilized was an internally heated VD furnace. The rotary vane vacuum pump was activated to evacuate the air, thereby reducing the system pressure to below 10 Pa. The temperature was then elevated to the designated distillation temperature and maintained for a predetermined period. A series of ten experimental runs were conducted, during which the distillation temperature was varied between 973 K and 1373 K, and the distillation duration oscillated between 30 min and 150 min. In Fig. 227, which illustrates the phase diagram of Al-Mg alloy, a distillation temperature exceeding 933 K is necessary to melt an Al-Mg alloy containing 5% Mg. Following each experimental run, volatile substances adhering to the condenser and residues remaining in the crucible were collected, weighed, and sampled. The following equations were employed to analytically assess both the volatilization rate of the alloy and the recovery efficiency of Al as follows:

where m0 is the mass of Al-Mg alloy (g); m1 is the mass of the residues component (g); ω0 is the content of Al (wt %) in the Al-Mg alloy; and ω1 is the content of Al (wt %) in the residues.

Al-Mg alloy phase diagram27.

Experimental results and discussion

Experimental materials

Mg content in Al-Mg alloys typically ranges from 3 to 5%. Therefore, this study selected a recycled Al-Mg alloy with an approximate Mg content of 5% for the purpose of VD. Al-Mg alloy under investigation was sourced from a recycling Al facility located in Guangdong Province, China. To quantify the composition of the recycled Al-Mg alloy, chemical titration and flame AAS were utilized. Al content was determined through ethylenediaminetetraacetic acid (EDTA) titration. Two concentration testing methods were employed to ascertain Mg content. Cyclohexane-1,2-diaminetetraacetic acid (CDTA) titration was conducted to estimate Mg content range, followed by a more precise determination using flame AAS (WFX-320, Beijing Beifen-Ruili, China). The results indicated that the contents of Al and Mg were 95.02% and 4.98%, respectively, with Mg content being higher than that typically found in standard Al-Mg alloys. The elemental distribution within the recycled Al-Mg alloy was analyzed using scanning electron microscopy (SEM, SU5000, HITACHI, Japan), as illustrated in Fig. 3. The mapping results revealed that the concentration of Al in Al-Mg alloy was significantly greater than that of Mg. Furthermore, the spatial distributions of Al and Mg exhibited overlapping regions (i.e., indicated by circled areas), which provide evidence for the existence of intermediate phases between Al and Mg.

Phase identification was performed using X-ray diffraction (XRD) on a Rigaku/D-MAX/2600 diffractometer, utilizing Cu Kα radiation at 40 kV. The diffraction spectra covered an angular range from 10° to 90°. X-ray phase analysis of the experimental materials was conducted with a retrieval and analysis software suite, which included a specialized search/match module aimed at identifying both major and minor phases. A representative XRD pattern is depicted in Fig. 4. The recycled Al-Mg alloy primarily consists of elemental Al, elemental Mg, and intermediate phases such as Mg4Al23, Mg9Al31, and Mg19Al12. The presence of these intermediate phases significantly complicates the separation of Mg from Al-Mg alloy using the conventional three-layer electrolysis refining method14. Additionally, X-ray photoelectron spectroscopy (XPS) was utilized to investigate the chemical valence states of Al and Mg (Fig. 5). The analysis of the high-resolution spectra for Al 2p (Fig. 5a) and Mg 1s (Fig. 5b) indicates that both Al and Mg exist in a metallic state within Al-Mg alloy.

VD experiments results

An investigation was conducted to assess the effect of distillation temperature on the production of refined Al at pressures ranging from 2 Pa to 10 Pa over a continuous duration of 60 min. To optimize recovery efficiency, it is necessary to maximize Al content in the residues while appropriately evaporating Mg. The experimental results are illustrated in Fig. 6. It indicates that increasing the distillation temperature from 973 K to 1373 K resulted in a slight decrease in Al recovery efficiency, from 99.994 to 98.11%, while Al content in the residues increased from 98.5527 to 99.9780%. Notably, when the distillation temperature exceeded 1173 K, there was a progressive increase in Al content within the residues accompanied by a minor decline in Al recovery efficiency. These observed variations can be attributed to an increased amount of Al vaporizing into the gas phase at elevated temperatures. The volatilization behavior of metals is significantly impacted by distillation temperature. Economically efficient recovery of high-purity Al is attainable at a distillation temperature of 1173 K. However, for achieving even higher purity levels, a temperature of 1373 K is recommended.

To further examine the effect of distillation time on Al enrichment during VD process, a series of experiments were conducted with a distillation time ranging from 30 min to 150 min, a temperature of 1173 K, and a residual pressure between 2 Pa and 10 Pa. The results of these experiments are depicted in Fig. 7. An increase in distillation time resulted in a decrease in the efficiency of Al recovery at a constant temperature, while the concentration of residue increased. This phenomenon can be attributed to the enhanced volatilization of alkali metals and Mg as the distillation time was extended. Notably, the volatilization of Mg was more pronounced than that of Al, which led to an accumulation of Al in the residue. Furthermore, no significant increase in Al content was detected when the distillation time exceeded 120 min. Therefore, a duration of 120 min is optimal for Al enrichment throughout VD process. A refined product with an Al content of 99.9989% was achieved at an optimized temperature and duration of 1373 K and 120 min, respectively, resulting in a direct recovery of up to 97.98% from the original Al-Mg alloy. The refined Al meets the standards for “first-class refined product”17 distribution is illustrated in Fig. 8, where the minimal concentration of Mg indicates effective separation from the primary Al metal using VD method. Additionally, Fig. 9 presents an XRD pattern that illustrates the elemental state of the refined Al.

VD theoretical analysis

Saturated vapor pressure determination

The saturated vapor pressures of various metallic substances within Al-Mg alloy were theoretically calculated to assess the feasibility of Mg separation. The relationship between the saturated vapor pressure (P*, Pa) and temperature (T, K) for a specific metal can be expressed by Eq. (3):

where A, B, C, and D are the evaporation constants for each metal28. The results of the investigation into the relationship between metal pressure and temperature (Fig. 10) demonstrate that the pressures of Mg are significantly higher than those of Al within the temperature range of 973 K to 1373 K. At a distillation temperature of 1373 K, the saturated vapor pressure of Al is recorded at a mere 2.36 × 10− 4 Pa, in contrast to 6.97 × 104 Pa observed for Mg. Consequently, Mg is preferentially evaporated and separated from Al-Mg alloy at relatively low temperatures. In contrast, Al, characterized by its low saturation vapor pressure, is more challenging to evaporate and tends to remain in the residues. The removal of Mg and the enrichment of Al from Al-Mg alloy can be effectively accomplished at elevated temperatures. Furthermore, the judicious application of VD process can significantly enhance the purification of Al from Al-Mg alloy.

Maximum volatilization rate dynamics

A comprehensive investigation was conducted to examine the dynamics of VD process as it pertains to Al-Mg alloy. The maximum volatilization rates of Al and Mg were assessed at various distillation temperatures utilizing the Langmuir Eq. 28. This equation serves to characterize the maximum rate at which a particular element can evaporate:

where ν is the maximum volatilization rate (g/(cm2∙min)); α is the accommodation coefficient, which is generally considered to be close to 1; P* is the saturated vapor pressure (Pa); M is the molar molecular weight (g/mol); and T is the melt temperature (K). The maximum volatilization rates of Al and Mg at different temperatures are depicted in Fig. 11.

Figure 11 illustrates the maximum volatilization rates of Al and Mg across a range of temperatures. As the distillation temperature increases, the maximum volatilization rate for each metal also rises correspondingly. The ranking of these rates at a given temperature reflects the order observed in saturated vapor pressures. Within the distillation temperature range of 973 K to 1373 K, the disparity in peak volatilization rates among the substances is significant. Notably, the maximum volatilization rate of Mg surpasses that of Al by an five orders of magnitude. At a distillation temperature of 973 K, the maximum volatilization rate for Al is measured at only 1.811 × 10–11 g/(cm2∙min), which is substantially lower than the rate of 2.264 g/(cm2∙min) for Mg. This considerable difference indicates that the initial phase of VD predominantly features the volatilization of Mg, while Al’s volatilization occurs at a slower rate. As the distillation temperature continues to rise, the evaporation of Mg intensifies, concurrently leading to an increase in the evaporation loss of Al. Therefore, it is essential to determine an appropriate duration for the distillation process based on empirical research. This strategy ensures the efficient recovery of Al, reduces energy consumption, and minimizes the processing time required for Al purification.

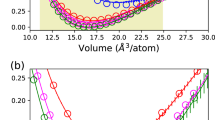

Prediction of activity coefficients

To evaluate the separation efficiency of VD process at a specific temperature, it is necessary to understand the activity coefficients of the constituents within the liquid alloy28,29, as represented in a VLE diagram. This study employed the most widely recognized molecular interaction volume model (MIVM)30,31, non-random two-liquid (NRTL) model32,33, and Wilson Eqs. 34, 35 to calculate the activity coefficients of Al and Mg components. To assess the reliability of the model calculations, the research introduced average standard error (S\(_{i}^{*}\)) and average relative error (Si) between the calculated and experimental values36. Table 1 outlines a comparison of the computed activity coefficients from each model against the experimental data. The results indicate that Al-Mg melt behaves as a non-ideal solution, exhibiting a negative deviation, which suggests the presence of reciprocal suppression between Al and Mg atoms during VD process. In Table 1, NRTL model exhibited the least fitting deviations when comparing the observed and calculated activity coefficient values for Al-Mg alloy. This result implies that NRTL model is more accurate and stable than Wilson and MIVM models, which are the other two local composition models considered. This phase of the investigation provides further insights into the thermodynamic properties of Al-Mg melt. Therefore, NRTL model was selected to predict the activity coefficients of Al-Mg alloy within the temperature range of 973 K to 1373 K for distillation purposes. The calculated activity coefficient values for Al-Mg alloy components, as derived from NRTL model, are detailed in Table 2.

VLE diagram of Al-Mg alloy

VLE diagrams serve as intuitive and effective instruments for comparing saturation vapor pressure and VD capabilities. These diagrams are utilized to assess the efficacy of a process in separating impurity elements and purifying metals37-39. By applying the selected NRTL model to calculate activity coefficients, along with Eqs. (5) and (6), one can obtain VLE data for Al-Mg alloy as follows:

where P*Al and P*Mg are the saturated vapor pressures of Al and Mg related to temperature, respectively; γAl and γMg are the activity coefficients of Al and Mg, respectively, which both had been calculated (Table 2); ωAl,l and ωMg,l are the mass fractions of Al and Fe in the Al-Fe binary alloy system, respectively. Based on Eqs. (5) and (6), the mass fraction of Mg and Al in the vapor phase (ωMg,g and ωAl,g) can be calculated quantitatively (Fig. 12).

In Fig. 12, even a minimal concentration of Mg in the liquid phase tends to evaporate almost entirely into the gas phase. For instance, at a distillation temperature of 1373 K, a liquid phase containing 9.09% Mg results in a vapor phase concentration of 99.9999987% Mg. The concentration of Mg in the gas phase ωMg,g decreases with increasing temperature, indicating that a greater amount of Al evaporates into the vapor phase at a constant ωAl,l. Additionally, as the concentration of Al in ωAl,l increases at a constant temperature, ωMg,g gradually decreases. The precise prediction of VLE diagram demonstrates that VD can effectively separate Mg from Al-Mg alloys, thereby yielding high-purity Al.

Comparative assessment of the VD process

The results of this research demonstrate that VD significantly enhances the purification of Al. By adhering to the core principles of energy conservation, efficient purification, and environmental protection, the application of VD is consistent with sustainable development policies and provides considerable environmental advantages. A comparative analysis of VD technique and the traditional three-layer electrolysis refining process is presented in Table 3. In the latter method, the direct recovery efficiency of Al is less than 98%, often leading to the generation of oxidizing slag and fluorides40,41. In contrast, VD process, which operates in an air-isolated environment, prevents Al loss due to combustion. In the conventional three-layer electrolysis refining process, the impurity Mg enters the liquid electrolyte layer beneath the refined Al as Mg2+ ions. However, VD facilitates the direct separation of Mg from Al in its elemental form, rather than as compounds. Furthermore, VD eliminates the necessity for fluxing agents, slagging agents, oxidizing agents, and other auxiliary materials, while also preventing the emission of toxic gases and dust. This innovative process produces refined Al with an Al concentration as high as 99.9989%. By removing unnecessary oxidation and reduction steps in Al production, it not only accelerates the overall process but also improves Al recovery rates.

Conclusion

The study proposes employing VD for effective Mg separation and high-purity Al production from recycled Al-Mg alloys. Independent experiments and theoretical analysis confirmed its feasibility, providing scholarly guidance on Al recycling and purification. Activity coefficients for components in Al-Mg alloy were calculated using Wilson, NRTL, and MIVM models. The activity coefficients obtained from NRTL model showed the closest resemblance to experimental values. Subsequently, activity coefficients at temperatures ranging from 973 K to 1373 K were predicted using NRTL model. VLE phase diagram of Al-Mg indicated that high-purity metallic Al could be obtained by vacuum distilling almost all Mg from the alloy. Optimal conditions for purifying Al through kilogram-scale VD process were determined based on analysis of ten experimental runs: a distillation temperature of 1373 K, a distillation time of 120 min, and a pressure range of 2 ~ 10 Pa. This procedure achieved direct recovery of Al with an efficiency rate of 97.98% and refined it to a concentration level as high as 99.9989%. In contrast to conventional approaches for treating Al-Mg alloys, VD offers several advantages including streamlined operation flow, absence of gas or wastewater discharge, preservation of Al’s oxygenation state, improved resource utilization efficiency, and enhanced working conditions. Furthermore, VD meets the demand for cleaner production in the recycling Al industry.

Data availability

We declare that the data supporting the findings of this study are available within the article.

References

Wan, Z. et al. Novel weld composition to improve mechanical properties of 2219-T8 aluminum alloy joint using double-wire tig welding. Mater. Charact. 209, 113764. https://doi.org/10.1016/J.MATCHAR.2024.113764 (2024).

Morshed-Behbahani, K., Rayner, A. J., Bishop, D. P. & Nasiri, A. Perspectives on the unusual electrochemical corrosion of nickel aluminum bronze (nab) alloy fabricated through laser-powder bed fusion additive manufacturing. Corros. Sci. 228, 111846. https://doi.org/10.1016/J.CORSCI.2024.111846 (2024).

Zhu, H., Zhao, J. & Li, Z. Investigations on the hydration characteristics of blended ferroaluminate cement containing granulated blast furnace slag. Constr. Build. Mater. 417, 135243. https://doi.org/10.1016/J.CONBUILDMAT.2024.135243 (2024).

Wang, Z. China’s renewable aluminum industry advancing bravely towards the summit of the world. Resource Regener. 03, 12–14 (2023).

World Bureau of Metal Statistics. Global Primary Aluminum Production in 2023. Available online (2024). http://www.lseg.com/en/data-analytics/market-data/data-feeds

National Bureau of Statistics. Production Data of Major Industrial Products in 2023. Available online (2024). http://www.stats.gov.cn/sj/zxfb/202401/t20240117_1946624.html.

Pietrantonio, M. et al. Vanadium recovery from bayer process liquor residue. Jom 76, 1531–1538. https://doi.org/10.1007/SLL837-023-06336-X (2024).

Cui, L., Wang, W., Chao, X., Gao, J. & Cheng, F. Efficient lithium recovery from electrolytic aluminum slag via an environmentally friendly process: Leaching behavior and mechanism. J. Clean. Prod. 439, 140800. https://doi.org/10.1016/J.JCLEPRO.2024.14080 (2024).

Ambrová, M., Korenko, M. & Szatmáry, L. Influence of the Sulfur species on the current efficiency and Carbon Consumption in the aluminum electrolysis process. Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 54, 2541–2551. https://doi.org/10.1007/S11663-023-02855-9 (2023).

Shen, A. & Zhang, J. Technologies for Co2 emission reduction and low-carbon development in primary aluminum industry in China: A review. Renew. Sustain. Energy Rev. 189, 113965. https://doi.org/10.1016/J.RSER.2023.113965 (2024).

Reyes-Bozo, L. et al. Green Hydrogen integration in aluminum recycling: Techno-economic analysis towards sustainability transition in the expanding aluminum market. Energy Convers. Management: X. 22, 100548. https://doi.org/10.1016/J.ECMX.2024.100548 (2024).

Wan, B. et al. Review of solid state recycling of aluminum chips. Resour. Conserv. Recycl. 125, 37–47. https://doi.org/10.1016/j.resconrec.2017.06.004 (2017).

Gaustad, G., Olivetti, E. & Kirchain, R. Improving aluminum recycling: A survey of sorting and impurity removal technologies. Resour. Conserv. Recycl. 58, 79–87. https://doi.org/10.1016/j.resconrec.2011.10.010 (2012).

Zhang, L., Lv, X., Wiredu Damoah, L. N. & Bai, C. Mathematical modeling on the removal of impurity elements from molten aluminum. Min. Process. Extr. Metall. Rev. 33, 1–54. https://doi.org/10.1080/08827508.2010.542210 (2012).

Gotenbruck, M. et al. Static crystallization, an alternative methodology for synthesis of high-purity aluminum. Met. (Basel). 13, 280. https://doi.org/10.3390/MET13020280 (2023).

Wan, H. et al. Zone melting under vacuum purification method for high-purity aluminum. J. Mater. Res. Technol. 17, 802–808. https://doi.org/10.1016/J.JMRT.2022.01.010 (2022).

Wang, K. Aluminum Smelting Process (Chemical Industry, 2010).

Curtolo, D. C., Xiong, N., Friedrich, S. & Friedrich, B. High- and ultra-high-purity aluminum, a review on technical production methodologies. Metals 11, 1407. https://doi.org/10.3390/MET11091407 (2021).

Feng, N. Modern Aluminum electrolysis – Theory and Technology (Chemical Industry, 2020).

Zhou, Z. et al. A Novel vacuum distillation method for preparing high purity antimony trisulfide from antimony minerals. Sep. Purif. Technol. 300, 121935. https://doi.org/10.1016/J.SEPPUR.2022.121935 (2022).

Ma, J. et al. Separation and recovery of tin and copper from tin refining sulfur slag using a new process of airtight sulfuration – Vacuum distillation. J. Clean. Prod. 378, 134553. https://doi.org/10.1016/J.JCLEPRO.2022.134553 (2022).

Pu, Z. et al. A Universal study of liquid metal cathodes for direct extraction of titanium within a closed loop. J. Clean. Prod. 368, 133135. https://doi.org/10.1016/J.JCLEPRO.2022.133135 (2022).

Chen, L. et al. Modeling and measurement of vapor-liquid equilibrium of in–Pb and in–Pb–Sn alloy systems in vacuum distillation. Vacuum 207, 111556. https://doi.org/10.1016/j.vacuum.2022.111556 (2023).

Zha, G. et al. Evaporation regularities of elemental selenium in the vacuum distillation process. Metall. Mater. Trans. B. 53, 3856–3864. https://doi.org/10.1007/S11663-022-02647-7 (2022).

Zha, G. et al. New vacuum distillation technology for separating and recovering valuable metals from a high value-added Waste. Sep. Purif. Technol. 209, 863–869. https://doi.org/10.1016/j.seppur.2018.09.038 (2019).

San, T. et al. Highly efficient separation of Ag, Cu and Sn by Vacuum cracking to prepare Ultra-pure Energy Metal lead materials. Sep. Purif. Technol. 124549 https://doi.org/10.1016/j.seppur.2023.124549 (2023).

Durham, R. N., Gleeson, B. & Young, D. J. Factors affecting chromium carbide precipitate dissolution during alloy oxidation. Oxid. Met. 50, 139–165. https://doi.org/10.1023/A:1018880019395 (1998).

Dai, Y. & Yang, B. Vacuum Metallurgy of Nonferrous Metal Materials (Metallurgical Industry, 2000).

Dai, Y. & Yang, B. Vacuum Metallurgy of Nonferrous Metal, 2nd edn (Metallurgical Industry, 2000).

Dai, H. Improvement of MIVM and its Application in Liquid Alloys and Organic Solutions (Kunming University of Science and Technology, 2021).

Dai, H. & Tao, D. P. A statistical thermodynamic model with strong adaptability for Liquid mixtures. Fluid Phase Equilib. 473, 154–165. https://doi.org/10.1016/j.fluid.2018.06.001 (2018).

Prausnitz, J. M., Lichtenthaler, R. N. & Azevedo, G. D. Molecular Thermodynamics of fluid-phase Equilibria, 3rd edn (Prentice-Hall, 1999).

Tao, D. P. A New Model of thermodynamics of Liquid mixtures and its application to Liquid alloys. Thermochim Acta. 363, 105–113. https://doi.org/10.1016/S0040-6031(00)00603-1 (2000).

Sandeepa, K. et al. Thermodynamic models for determination of solid–liquid equilibrium of para-tert-butylbenzoic acid in Binary and Ternary Solvent System. J. Mol. Liq. 369, 120888. https://doi.org/10.1016/J.MOLLIQ.2022.120888 (2023).

Saunders, N., Rivlin, V. G. A. & Critical Review Thermodynamic calculations for the Al-Rich portion of the Al-Cr-Fe phase diagram. Int. J. Mater. Res. 78, 795–801. https://doi.org/10.1515/IJMR-1987-781107 (1987).

Lida, T. & Guthrie RIL the Physical Properties of Liquid Metals (Clarendon, 1988).

Yi, J. et al. Effective separation and recovery of valuable metals from high value-added lead anode slime by sustainable vacuum distillation. J. Clean. Prod. 319, 128731. https://doi.org/10.1016/J.JCLEPRO.2021.128731 (2021).

Cheng, K. et al. Separation behavior of as, Zn and Cd Trace impurities in the Deep Vacuum purification process of Refined lead. Sep. Purif. Technol. 278, 119531. https://doi.org/10.1016/j.seppur.2021.119531 (2021).

Jiang, W. et al. Application of vacuum distillation in refining crude indium. Rare Met. 32, 627–631. https://doi.org/10.1007/s12598-013-0169-z (2013).

Hua, Y. Introduction to Nonferrous Metallurgy (Metallurgical Industry, 2014).

Li, H. & Gu, S. Technology Handbook of Aluminum Production (Metallurgical Industry, 2021).

Author information

Authors and Affiliations

Contributions

Conceptualization, J.Y. and J.S. and L.C.; Methodology, J.Y. and J.S. and L.C.; Formal analysis and investigation, J.Y. and B.H. and A.C. and P.Q.; Writing—review and editing, J.Y. and B.H. and J.S. and A.C.; Supervision, J.S. and J.X.; Resources, J.Y. and X.Z. and J.X.; Funding acquisition, J.Y. and X.Z. and J.X. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yi, J., He, B., Sun, J. et al. Innovative vacuum distillation technology for preparing refined Al from Al–Mg alloy. Sci Rep 14, 29823 (2024). https://doi.org/10.1038/s41598-024-81018-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-81018-5