Abstract

Despite the abundant production of fruits and vegetables in Xinjiang, there is an increasing trend in waste rates. Gas-controlled packaging techniques are employed post-harvest to enhance freshness and extend shelf life. However, the multi-gas mixing system at the core of this equipment often encounters challenges such as insufficient stability, limited precision, high costs, and inadequate intelligence. In this context, we have developed and designed a multi-gas mixing system for gas-conditioned packaging. The system integrates Internet of Things technology, uses a programmable controller as the core, proposes a ternary gas distribution model based on the ideal gas equation and Dalton’s law of partial pressures, and utilizes RS-485 bus, TCP/IP protocol, among others. This ensures communication between the equipment and data transmission with the cloud server while enabling remote control of the gas mixing and blending process via a mobile phone terminal. The system runs stably through testing, with the average relative deviations of CO2 and O2 gas concentrations being 0.86% and 0.72%, respectively. This fulfills the technical prerequisites for achieving a gas concentration precision of less than 1%, addressing challenges related to inadequate precision in gas blending, unstable performance, and limited visual representation. Moreover, it significantly reduces equipment costs and operational complexities while serving as a valuable reference for advancing multivariate gas mixing and blending technology in Xinjiang’s fruit and vegetable gas-conditioned packaging.

Similar content being viewed by others

Introduction

In recent years, the fruit and vegetable cultivation industry in Xinjiang has experienced continuous growth with a consistent increase in production. However, there has been a concerning rise in post-harvest losses which not only significantly impacts growers’ motivation and income but also impedes the progress of the local agricultural economy. The high rate of vegetable loss can be attributed to the relatively underdeveloped local storage and preservation technology for fruits and vegetables. According to statistics, gas-conditioning preservation technology is employed for fruit and vegetable storage in 90% of developed countries, indicating a significant disparity in the adoption of this technology between China and these developed nations. In the 1980s, foreign countries pioneered the research and implementation of air-conditioned packaging technology, thereby significantly contributing to the advancement of the global fruit and vegetable industry. Despite China’s prominent role in this industry, its preservation efforts still lag behind. In Europe and the United States, more than 90% of storage facilities employ air conditioning in conjunction with comprehensive post-harvest preservation treatments and cold chain technologies1,2,3. If the gas-conditioning preservation technology is widely applied to the preservation of fruits and vegetables in Xinjiang, it will greatly reduce the rate of spoilage to some extent. The gas-conditioning packaging technology is also part of the wider application of gas-conditioning preservation technology. Gas-conditioning packaging technology refers to the preservation of different fruits and vegetables based on their freshness characteristics, using gases (O2, CO2, N2) in specific proportions. These gases are mixed to create a freshness-maintaining atmosphere and then filled into gas-barrier packaging containers. This process slows down physical, biological, and chemical changes in the fruits and vegetables during storage, thereby extending their freshness and shelf life.

Gas-conditioning packaging technology refers to the preservation of different fruits and vegetables based on their freshness characteristics, using gases (O2, CO2, N2) in specific proportions. These gases are mixed to create a freshness-maintaining atmosphere and then filled into gas-barrier packaging containers. This process slows down physical, biological, and chemical changes in the fruits and vegetables during storage, thereby extending their freshness and shelf life. The gas adjustment ratio varies among different fruits and vegetables. To ensure the effectiveness of gas-conditioned packaging in preserving fruits and vegetables, the multi-gas mixing system within the packaging plays a crucial role4,5,6,7. In 2017, Dhalsamant, K., et al. evaluated the performance of air-conditioned packages to assess their ability to establish equilibrium conditions and extend the shelf life of packaged fruits and vegetables at targeted levels8. In 2016, Lepeshinsky et al.9 Designed as a new type of gas dynamic closed mixer, the closed gas dynamic mixing device is a device that uses a two-phase workpiece consisting of liquid and gas, which are premixed and then flow out of the device. In 2017, Li Qi10 set up an S7-200 series PLC-based intelligent proportional mixing instrument for gas conditioning and freshness control. In 2022, Lamberty, A., et al.11 Monitor these parameters using Internet of Things (IoT)-enabled sensors and communication technologies in the supply chain to optimize product quality, thereby reducing rejections and losses. In 2023, Saban, M., et al.12 Proposed a customized smart agriculture system based on the Internet of Things (IoT) and Long Range (LoRa) technology, featuring low cost, low power consumption, and a wide-area wireless sensor network. IoT technology facilitates the interconnection of individuals, objects, and their interactions through communication technologies, enabling intelligent identification, monitoring, and management. It has extensive applications in domains such as agriculture, healthcare, forestry, and other relevant fields. By integrating gas-conditioning preservation technology with IoT capabilities, remote monitoring can be achieved through visualization.

Based on a comprehensive analysis of the literature and system control objectives, it is evident that despite achieving mixing control within a specific range of fresh gas proportions, the current multivariate gas mixing system still exhibits deficiencies in terms of precision, stability, operational complexity, cost-effectiveness, internal structure intricacy, and limited visualization capabilities. Therefore, to solve the aforementioned problems, this study proposes achieving remote control of the multi-gas mixing process from a mobile phone terminal through a series of logical control methods based on the ideal gas equation of state and Dalton’s law of partial pressures. This is combined with an Internet of Things (IoT) cloud platform, with the programmable controller at its core. In this study, we first conducted a demand analysis of the gas-conditioned packaging multi-gas mixing system, followed by the overall structural design of the system, IoT system design, control method design, remote monitoring module design, and so on. The gas mixing process for O2, CO2, and N2 was finally tested. The analysis of the results demonstrated that the process is stable, efficient, accurate, highly visual, easy to operate, and allows remote control via a mobile phone terminal. This contributes to the enhancement of fruit and vegetable storage and preservation. The implementation of the remote control system has improved the storage and preservation of fruits and vegetables.

Methods

Overall system framework design

Demand analysis

In order to solve the problems existing in the gas distribution process of gas-conditioned packaging multi-gas, combined with the control requirements of the gas distribution system of fruit and vegetable gas-conditioned packaging assembly, we need to carry out a systematic analysis of its gas distribution process. According to the analysis, the designed gas distribution system can realize the real-time monitoring of the mixing process of the preservation gas by cell phone, and the gas distribution ratio of the ternary gas can be adjusted and set according to the requirements of different fruits and vegetables, and it is also required that the system is safe and reliable, and the operation is convenient and efficient, so the developed and designed system has the function of remote control, high-precision decision-making ability of the system, and the function of data management13,14,15,16.The system transmits the data information detected during the gas distribution process to the cell phone, PC and touch screen through the cloud to realize real-time remote monitoring. At the same time, operators and managers can set the gas concentration value and control the working status of solenoid valves, push-button switches and other equipments at any time according to their needs, realizing the remote control function; system realizes the automatic decision-making function of the system according to the parameter setting, data acquisition and feedback, software control algorithm, and program of the programmable controller in order to improve the speed, precision, and reliability of the gas mixing to realize the high-precision decision-making capability of this system; At the same time, the data such as concentration and pressure value of the gas collected during the gas distribution process and the working status of each component are uploaded to the cloud platform in real time and stored in the database, which is convenient for the operator to manage, retrieve and view the past data records and realize the systematic management of the data.

The aforementioned demand analysis serves as the foundation for developing a gas mixing method that integrates the mobile client, IoT cloud platform, and programmable logic controller (PLC) in a scientifically and logically designed manner. The system undergoes functional structure design, software design, hardware device integration, as well as testing and improvements to meet the requirements and functionalities of the system.

IoT framework architecture design

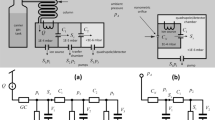

The architecture of the gas-conditioned packaging multi-gas mixing system can be classified into three layers17,18,19,20: the data acquisition layer, the data transmission layer, and the remote monitoring layer, as shown in Fig. 1.

The data acquisition layer serves as the fundamental component of the entire system, employing sensor technology to gather CO2 and O2 gas concentrations, along with pressure values of the mixed gases. Subsequently, it integrates and processes this information before transmitting it to the transmission layer. Additionally, this layer is responsible for executing control commands to regulate gas concentration mixing ratios according to specific requirements.

As the middle layer of the entire system, the data transmission layer plays the role of both uploading and downloading data. The main function is to upload the real-time data collected in the sensing layer to the application layer, while simultaneously transmitting the control instructions from the application layer back to the controller in the sensing layer. In order to achieve real-time monitoring and ensure high-speed data transmission, we employ a hybrid network that combines field bus communication technology with wireless transmission. The primary approach involves utilizing cloud boxes to transmit data to the cloud server, which is subsequently relayed to the user’s mobile device.

The remote monitoring layer represents the highest level within the overall system, primarily responsible for data visualization and functional applications to facilitate user interaction. It predominantly comprises mobile phone terminals, PC terminals, and HMIs. The system administrator can access the cloud platform through a cellphone or webpage to observe real-time gas distribution processes, issue control commands for remote operations, ensure optimal efficiency in gas distribution procedures, and achieve superior outcomes. Simultaneously, operators can utilize the HMI user interface to monitor gas distribution processes.

Structural design of gas mixing systems

The gas sources for gas mixing in this system are CO2, O2, and N2. based on the principle of ideal gas equation of state and Dalton’s law of partial pressure21,22,23, and according to the technical and control requirements, the overall structure of the designed gas distribution system for gas conditioning and preservation is shown in Fig. 2.

The system mainly includes a carbon dioxide tank, an oxygen tank, a nitrogen tank, a pressure-reducing valve, electrical proportional valves, solenoid valves, check valves, a PLC controller, a mixing tank, an HMI touch screen, a gas concentration sensor, a pressure sensor, a cloud box, etc. The PLC controller model is the Siemens S7-200 SMART ST30, which inherits the advantages of the previous generation S7-200 PLC and, at the same time, adds many functions. Adds a lot of functions. The gas distribution system sensors and solenoid valves are analog inputs and outputs, choosing PLC’s analog conversion module EM AM06; Kunlun Tongshi TPC1061Ti touch screen as the human-machine interaction module.

According to Dalton’s law of partial pressure, a gas blend in a container, without chemical interactions between elements, results in uniform distribution of each gas throughout the container, creating the same pressure as if it were contained in the whole container, as outlined by the formula:

When an ideal gas is in equilibrium, the ideal gas equation of state is:

Where P represents the pressure of the ideal gas; V represents the volume of the ideal gas; T represents the thermodynamic temperature of the ideal gas; n represents the amount of gas substance; and R represents the ideal gas constant.

Hardware design of the system

CO2, O2, N2 three kinds of gases from the high-pressure cylinder through the pressure reducing valve control at 0.4 ~ 0.6 MPa, according to the software control system set the pressure of each gas by the electrical proportional valve ( ITV 2030-312LB ) control. Electromagnetic valve (4V210-08) to open the gas washed into the high-pressure gas mixing tank, gas mixing tank device with a pressure sensor (QBE2103-P16), gas concentration sensors, mixing gas information continuously feedback to the software control system to adjust the equipment, to achieve high-precision gas mixing of ternary gases, gas mixing and mixing is completed and transported to the gas-conditioning packaging equipment standby. The tank diameter of the gas mixture tank is 220 mm, the size is 220 mm x 220 mm x 800 mm, and the concentration detection structure of the system consists of an oxygen concentration sensor FMS-51, a nitrogen concentration sensor PET10, and a carbon dioxide concentration sensor SW-302FL, respectively.

In order to ensure the overall functionality of the gas distribution system, it is essential for each component to be equipped with parameters that meet the specified technical requirements. The technical specifications of the primary hardware equipment are presented in Table 1, while Fig. 3 illustrates the schematic diagram depicting the selection process for these hardware components.

Design of system control

The system adopts a software control system combined with a PLC for control. It has a user-friendly interface on both the mobile phone and touch screen sides, through which the target value of the gas mixing concentration ratio is set. The sensor detects the real-time pressure of the gas tank during the gas mixing process and sends the detected information to the control system, which calculates the actual gas concentration ratio and the deviation of the gas pressure value from the set target value22,23,24,25. The control system adjusts the pressure value by controlling the electric proportional valve based on the calculated results, forming a closed-loop control process with information feedback to achieve high-precision gas mixing.

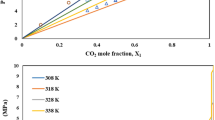

The known volume of the gas storage tank V′, based on the ideal gas equation and Dalton’s partial pressure law algorithm, set the concentration ratio of the three gases of nitrogen, carbon dioxide and oxygen for mixing as n1:n2:n3 = 90:2:8, and the pressure of the three gases into the mixing tank as P′1、P′2、P′3, real-time detection of the dynamic temperature T′ and the dynamic total pressure of the gas tank P123, when the three gases enter the mixing tank, the following equation is satisfied:

According to Eq. (3) ~ (7), combined with the concentration ratio of the three gases, using the initial value of the pressure of the first gas, the second and third gas partial pressures can be calculated, and the pressure ratio equation is:

Based on the results of the calculation, the partial pressure value is set according to the electrical proportional valve, and the control system starts the filling and mixing action, monitors the parameters in the gas distribution process in real time, and makes repairs and corrections.

The control process is shown in Fig. 4, according to the required gas conditioning ratio of fruits and vegetables gas conditioning preservation, set the target value of gas concentration, and then the gas mixing tank for gas pressure detection, the use of the first gas sub-pressure initial set value, through the software calculates the second, third gas sub-pressure, control of electrical proportional valves for the sub-pressure value setting. Open the solenoid valve 7, close the solenoid valve 8, 9, 10, filling the first gas; when the gas pressure sensor detects that the gas pressure reaches its set value, open the solenoid valve 8, close the solenoid valve 7, 9, 10, for the second gas inflatable; when the gas pressure sensor detects that the total pressure of gas reaches the sum of the two kinds of gas and the concentration of the second kind of gas reaches the set value, open the solenoid valve 9, close the solenoid valve 7, 8, 10, for the third gas inflatable; when the gas pressure sensor detects that the total gas pressure reaches the total set value, and the concentration of the third gas reaches the set value, close the solenoid valve 7, 8, 9, to complete the mixing of the gas, and then the solenoid valve 10 can be opened for the use of the gas conditioning equipment.

Configuration design of remote monitoring module

Configuration design of touch screen

According to the control requirements of the system design, the data acquisition layer of the system completes data acquisition, controls the solenoid valves, and transmits the collected information to the touch screen in real time to enable remote monitoring of the gas distribution process26,27,28.The operator can establish communication and realize the system’s human-computer interaction control function by operating the touch screen, the programmable controller, and connecting them through Ethernet. The MCGS configuration software is selected for designing the monitoring screen, as shown in Fig. 5.

The MCGS configuration software has powerful data acquisition and monitoring functions. The control interface design is relatively simple, and its interactivity and visibility better meet the design requirements and operation and management needs. At the same time, MCGS features a strong real-time database function, which aids in the debugging and maintenance of the system. The system’s touchscreen operation screen is shown in Fig. 6. The main screen includes the operation buttons for the fruit and vegetable gas blending processes, the operation status of each instrument and piece of equipment, and displays the real-time data detected by each sensor.

Design of the configuration interface for cell phones

The design of the cell phone interface is realized through the configuration design function in the cloud platform, which provides users with a configuration editor, through which the configuration editor completes the design of the remote control screen on the cell phone, and the bound data variables are displayed visually29,30,31,32.The cell phone remote monitoring system consists of on-site device side, data transmission layer, and remote mobile client, and the framework diagram of cell phone remote monitoring is shown in Fig. 7.

The Suk-Box-4G cloud box executes the data transmission layer via TCP/IP protocol, enabling bidirectional data transfer between the cloud server and PLC. The controller enters the necessary gas conditioning ratio for maintaining gas in the mobile phone interface. Concurrently, the cloud server transmits and scrutinizes the data via the cloud box, recording the established value in the PLC’s respective register. Concurrently, the CO2 and O2 gas concentration and pressure sensor data are processed through the cloud box and transferred to the cloud server.

The design of the cell phone interface primarily involves three phases: system project establishment, interface configuration design, and consideration of related variables.

Initiate a project for the system. Access the cloud platform’s project management center, choose the equipment monitoring module to access the platform’s configuration interface, and then proceed to set up the PC terminal and mobile terminal interfaces accordingly.

The cloud platform offers various advantages, including storage, computing capabilities, and flexibility. Additionally, it provides the flexibility to configure cloud servers and customize the interface configuration to meet specific system design requirements. By utilizing the configuration editor to create the mobile client’s cell phone configuration screen, significant cost reductions can be achieved in terms of user development and maintenance.

Establish connections between the configuration buttons and switches on the cell phone’s screen, the data display box, and the instruments and meters displayed on the screen with their respective variables. The synchronization of mobile phone remote monitoring with on-site operations and management is crucial because it allows operators to remotely access the gas conservation and distribution system via a mobile app. The controller can perform relevant configuration tasks on the mobile app while also providing real-time tracking of CO2 and O2 levels, as well as the total pressure in the combined gas tank. Additionally, it offers controls for various devices, such as switches and solenoid valves, and provides information about their operational conditions. This functionality is illustrated in Fig. 8, which shows the interface of the mobile app.

Testing and analysis

According to most of the fruits and vegetables gas-conditioned packaging gas-conditioned preservation of the three gases ( CO2, O2, N2 ) mixing technical requirements, the general situation of O2 gas volume concentration ratio of 5–30%, CO2 gas volume concentration ratio of 0% to 30.According to the control requirements of the system, 10 groups of experimental tests are carried out based on this, and 10 groups of different gas mixing ratios are set up, corresponding to 10 groups of different gas partial pressures. During the test, the gas pressure value of the gas mixing tank and the partial pressure value of each gas are set in the operation control interface, and the precise control of the mixing concentration is realized by constantly adjusting the partial pressure values of CO2 and O2 gases. Real-time detection of CO2 and O2 gas concentration value after mixing in each group, and calculate the relative deviation from the set value, through the information feedback to adjust the software gas partial pressure value, the relative deviation is gradually reduced, the mixing accuracy is gradually improved, the test data are shown in Tables 2 and 3; Figs. 9, 10, 11 and 12.

The formula for the relative deviation of gas concentration is:

Where P represents the relative deviation rate; R represents the real-time measurement value of gas concentration; M represents the target value of gas concentration.

Based on the data in Table 2, the starting partial pressure for each gas was determined by the concentration levels of the three gases, finalizing the gas-mixing procedure. The average deviation of the gas concentration of CO2 was 1.56% and the average deviation of the gas concentration of O2 was 1.45% after the completion of the mixing process. From the data in Table 3, it was concluded that the average deviation of the gas concentration of CO2 was 0.86% and the average deviation of the gas concentration of O2 was 0.72% after the completion of the second gas mixing process after the adjustments were made based on the initial gas mixing process and the mixing accuracies were all improved.

Analyzing the data on carbon dioxide levels in the gas mixture shown in Fig. 9 indicates that, after the second mixture, these levels align more closely with the initial value. Conversely, a comparative analysis of carbon dioxide gas variations in Fig. 10 reveals that the differences in carbon dioxide gas levels between the groups after the second mix are significantly smaller than those in the first.

The comparison of the oxygen concentration data during the gas-mixing process is shown in the Fig. 11, it can be analyzed that the concentration of oxygen after the second mixing is closer to the initial set value; from the analysis of the relative deviation of oxygen gas concentration in Fig. 12, it is concluded that after the second mixing, the relative deviation of the concentration of oxygen gas in each group is significantly reduced compared with the deviation of the initial mixing.

Therefore, through the analysis of the test data from the above figure and table, it can be seen that the gas mixing system is complete. After the average deviation of CO2 and O2 gas concentrations is low, with both being less than 1%, it meets the technical requirements for gas conditioning in fruit and vegetable packaging. This indicates that the system is suitable for gas blending in fruit and vegetable packaging.

Conclusions

With the continuous improvement of people’s living standards, consumers have higher and higher requirements for the types and quality of fruits and vegetables, so the requirements for the fruits and vegetables air-conditioned packaging air-conditioned freshness gas distribution have been gradually increased, system stability, precise control, timely feedback, easy to maintain and low-cost has become the basis for the design of the control system. Based on the Internet of Things technology, computer technology and network communication technology, based on the ideal gas equation and Dalton’s law of partial pressure, with the data collection, storage, management and other basic services provided by the cloud platform and various cloud service interfaces as the core, it realizes the connection between the equipment layer and the application layer through the cloud box, and realizes the remote monitoring and controlling of the preservation gas dispensing process by the cell phone and the touch screen.

In the process of gas distribution, the system collects the pressure and concentration of the mixed gas in real time through the sensing layer, analyzes, judges and adjusts, and controls the programmable controller to execute the corresponding filling action; at the same time, it adjusts the opening of the electric proportional valve according to the feedback of the real-time information to adjust the mixing ratio of the gas, forming the closed-loop control of the system. The pilot test demonstrates that the system significantly enhances gas mixing accuracy, while maintaining excellent stability, real-time performance, and human-computer interaction capabilities. Furthermore, it effectively reduces management and maintenance costs, mitigates daily usage challenges, and facilitates subsequent system enhancements to achieve a higher level of gas mixing precision. However, the integration of the system is not sufficient; it needs more types of electronic components. I hope that in the future, the system will be more concise and intelligent. At the same time, it can be further improved based on the successful implementation of fruits and vegetables cleaning, gas mixing and blending for preservation, and the integrated intelligent control of the packaging production line.

Data availability

The data presented in this study are available on request from the corresponding author.

References

Ma, X. et al. Overview of fresh-keeping methods for fruits and vegetables. Chin. Fruits Vegetables. 35, 4–9 (2016).

Xu, P., Wu, Y. & Liu, M. The present situation and development trend of controlled atmosphere preservation technology and equipment for fruits and vegetables in our country. Packaging Food Mach. 34, 51–54 (2016).

Huang, L. et al. The development status of fresh-keeping technology of fruits and vegetables under controlled atmosphere. Agric. Technol. 38, 163–166 (2018).

Fang, Y. & Wakisaka, M. A review on the modified atmosphere preservation of fruits and vegetables with cutting-edge technologies. Agriculture 11, 992 (2021).

Prange, R., DeLong, J. M. & K. & Controlled-atmosphere related disorders of fruits and vegetables. Stewart Postharvest Rev. 5, 1–10 (2006).

Brecht, J. et al. Maintaining optimal atmosphere conditions for fruits and vegetables throughout the postharvest handling chain. Postharvest Biol. Technol. 27, 87–101 (2003).

Ghidelli, C. & Pérez-Gago, M. B. Recent advances in modified atmosphere packaging and edible coatings to maintain quality of fresh-cut fruits and vegetables. Crit. Rev. Food Sci. Nutr. 58, 662–679 (2018).

Dhalsamant, K., Mangaraj, S. & Bal, L. M. Modified atmosphere packaging for mango and tomato: an appraisal to improve shelf life. J. Packaging Technol. Res. 1, 127–133 (2017).

Lepeshinsky, I. et al. Experimental research of the closed-type gas-dynamic mixer. Vestnik Samara Univ. Aerosp. Mech. Eng. 15, 70–80 (2016).

Li, Q., Zhao, H. & Tian, L. Based on S7-200 series PLC, the design of a kind of intelligent proportional mixing instrument for regulating atmosphere preservation. Autom. Technol. Appl. 36, 148–150 (2017).

Lamberty, A. & Kreyenschmidt, J. Ambient parameter monitoring in fresh fruit and vegetable supply chains using internet of things-enabled sensor and communication technology. Foods 11, 1777 (2022).

Saban, M. et al. A smart agricultural system based on PLC and a cloud computing web application using LoRa and LoRaWan. Sensors 23, 2725 (2023).

Chong, J. L., Chew, K. W., Peter, A. P., Ting, H. Y. & Show, P. L. Internet of things (IoT)-Based environmental monitoring and control system for home-based mushroom cultivation. Biosensors 13, 98 (2023).

Zhang, Q. Design of intelligent agriculture remote monitoring system based on internet of things technology. South. Agricultural Mach. 54, 84–86 (2023).

Li, Z. et al. Energy Storage charging Pile Management based on internet of Things Technology for Electric Vehicles. Processes 11, 1561 (2023).

Cheng, F., Jin, H. & Shen, H. Design of real-time monitoring system for CO2, CH4 and various environmental factors in Intelligent Greenhouse. Chem. Eng. Trans. 71, 163–168 (2018).

Mellit, A., Benghanem, M., Herrak, O. & Messalaoui, A. Design of a novel remote monitoring system for smart greenhouses using the internet of things and deep convolutional neural networks. Energies 14, 5045 (2021).

Júnior, A. C. D. S. et al. Internet of water things: a remote raw water monitoring and control system. IEEE Access. 9, 35790–35800 (2021).

Díaz López, D. et al. Developing secure IoT services: a security-oriented review of IoT platforms. Symmetry 10, 669 (2018).

Zhang, L., Li, C., Jia, Y. & Xiao, Z. Design of greenhouse environment remote monitoring system based on android platform. Chem. Eng. Trans. 46, 739–744 (2015).

Smith, W. R. & Missen, R. W. A note on Dalton’s law: myths, facts, and implementation. J. Chem. Educ. 82, 1197 (2005).

Woo, K. W. & Yeo, S. I. Dalton’s law vs, amagat’s law for the mixture of real gases. SNU J. Educ. Res. 5, 127–134 (1995).

Donval, J. P., Guyader, V. & Boissy, E. A simple method for the preparation and injection of gas mixtures into a gas chromatograph using a two-component device. J. Chromatogr. A. 1631, 461579 (2020).

Wang, G. et al. The design of the automatic control system for the fresh-keeping environment of fruit and vegetable with controlled atmosphere based on PLC. Jiangsu Agricultural Sci. 43, 368–372 (2015).

Widhiada, W., Widiyarta, I. M., Antara, I. N. G., Budiarsa, I. N. & Karohika, I. M. G. Remote pressure Water Valve Control System based on PLC. Int. J. Adv. Sci. Eng. Inform. Technol. 11, 981 (2021).

Guo, D. & Zhao, Y. Design of greenhouse environment monitoring system based on MCGS configuration technology. Electr. Autom. 38, 97–99 (2016).

Hu, X. & Lin, X. Design of the temperature and humidity monitoring system for Intelligent Agriculture. Mach. Tool. Hydraulics 48, 129–133 .

Laghmouchi, A., Hohwieler, E., Geisert, C. & Uhlmann, E. Intelligent configuration of condition monitoring algorithms. Appl. Mech. Mater. 794, 355–362 (2015).

Garcia-Sanchez, A. J., Garcia-Sanchez, F. & Garcia-Haro, J. Wireless sensor network deployment for integrating video-surveillance and data-monitoring in precision agriculture over distributed crops. Comput. Electron. Agric. 75, 288–303 (2011).

Liu, Y., Li, J., Cao, S. & Xing, B. Design and application of monitoring system for crab breeding base based on internet of things. Trans. Chin. Soc. Agricultural Eng. 34, 205–213 (2018).

Gao, G., Xiao, K. & Chen, M. An intelligent IoT-based control and traceability system to forecast and maintain water quality in freshwater fish farms. Comput. Electron. Agric. 166, 105013 (2019).

Agarwal, S. & Lau, C. T. Remote health monitoring using mobile phones and web services. Telemedicine e-Health. 16, 603–607 (2010).

Acknowledgements

This work was supported by the National Natural Science Foundation (No. 32160427) and the President’s Fund of Tarim University (No. TDZKSS202015).

Author information

Authors and Affiliations

Contributions

Conceptualization, B.Z.; methodology and software, B.Z. and X.L.; Data curation, D.Y and X.L.; writing—original draft preparation, B.Z; writing—review and editing, X.Z and X.Y; data curation, S.M. supervision, X.L.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, B., Lin, X., zhang, X. et al. Research and design of multiple gas mixing system in modified atmosphere packaging. Sci Rep 14, 30080 (2024). https://doi.org/10.1038/s41598-024-81366-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-81366-2