Abstract

Mining geological disasters occur frequently in Guizhou, with mine mining and rainfall-induced avalanche geological disasters mainly, the investigation concluded that the hard rock of the overlying slide body is mostly sandstone, and it is crucial to study the physical and mechanical properties of sandstone under the action of mine mining (hereinafter referred to as the action of mining) and water action. The paper analyzes the deterioration characteristics of sandstone hydrophysical and mechanical properties under the action of mining and water. The main research results are as follows: (1) The water absorption rate of sandstone increased by 0.056% under the action of mining, the water absorption rate of sandstone increased with a good exponential relationship under the action of dry and wet cycles, the swelling rate of sandstone increased by 0.3% under the action of mining, and the index of disintegration resistance decreased by 0.3% in 5 cycles; (2) The damage rate of uniaxial compressive strength of sandstone after being subjected to mining was 6.367%. The total deterioration rate increases with the number of wet and dry cycles, the stage deterioration rate and the average stage deterioration rate first decrease and then increase, and the degree of fragmentation gradually increases; (3) According to the microscopic test results, the microstructural evolution of “mining cracking → water adsorption → water–rock interaction” model was established.

Similar content being viewed by others

Introduction

Guizhou region to develop a large number of soft and hard interlayered rock body slopes1, the hard rock layer in the mining area is mostly sandstone layer, the large-scale mining of underground ore layer on the surface sandstone irreversible changes2, long-term underground mining to make the sandstone physical and mechanical properties of the deterioration, coupled with the role of precipitation, resulting in the destabilization of the rock body, which can lead to geological hazards.

At present, the research of sandstone physico-mechanical tests under the action of water is more mature and perfect3,4, mainly focusing on the study of sandstone under the physical action of water–rock water content, dry and wet cycles, freeze–thaw cycles, etc., and many research results have been achieved. Hale et al.5, in order to study the treatment that has the greatest effect on the strength of sandstone, sandstone has been subjected to different numbers of hot and cold, dry and wet, freeze and thaw cycles under uniaxial compressive strength tests. Liang et al.6,7 investigated the effects of acid solution pH and immersion time on the deterioration characteristics of sandstone, conducted a series of physical and mechanical tests, and studied the deterioration law of acid corroded sandstone. Wang et al.8 studied some red sandstone samples with different water absorption rates and concluded that the tensile strength of red sandstone decreases with the increase of water absorption rate; Liang et al.9 established the interrelationship between water content and soaking time and sandstone mechanics by conducting triaxial compression tests on sandstone in different water-bearing conditions; Vásárhelyi et al.10 and Yuan et al.11 analyzed the relationship between water content and the change in strength of sandstone by conducting static and dynamic uniaxial compressive strength tests on sandstones under different water content conditions, respectively. conducted static and dynamic uniaxial compressive strength tests on sandstone under different water content conditions to analyze the relationship between water content and sandstone strength changes.Huang et al.12,13 and Du et al.14,15,16 carried out conventional mechanical tests on sandstone after dry and wet cycling, and researched the variation rules of mechanical parameters based on the test results to summarize the deterioration effect of sandstone under the dry and wet cycling; Hua et al.17,18 investigated the effect of wet and dry cycling on fractured specimens of sandstone and concluded that sandstone becomes softer and more ductile after several cycles of wet and dry cycling. Wu et al.19 used a self-made humidity environment control simulation device to study the mechanical properties and deterioration mechanism of sandstone specimens under uniaxial compression under different relative humidity conditions. Li et al.20 carried out a series of triaxial compression tests under hydrodynamic coupling conditions in order to study the effects of perimeter pressure and pore water pressure on the peak damage strength characteristics, energy storage state and energy release strength of sandstone. Li et al.21 conducted mechanical tests on freeze-thawed sandstone under graded loading in order to study the deterioration characteristics of sandstone under long-term freeze–thaw cycles and loading.

The indexes of rock hydrophysical properties mainly include water absorption, permeability, swelling, softening, disintegration, etc.22, and there are more studies considering the effect of water absorption in the current research on the deterioration law of sandstones, while there are fewer studies on other hydrophysical properties. Zhang et al.23 carried out a splitting test on the red sandstone of Majiagou landslide in the Three Gorges Reservoir area under the combined effect of water pressure and dry–wet alternation, and investigated the deterioration mechanism of the sandstone by combining the analysis of the microfabrication, water absorption, and the measured analysis of the mineral composition and content; Zhou et al.24 derived from the test that the water absorption and porosity of sandstone also increase gradually with the increase of dry–wet cycling, and that the density, the velocity of the longitudinal wave, the dynamic compressive strength, etc. all decrease with dry and wet cycling; Xu et al.25 considered natural water absorption and saturated water absorption respectively when conducting mechanical tests, and analyzed in detail the characteristics of hydrometallurgical deterioration and the deterioration mechanism of the studied sandstones according to the test results.

As can be seen from the above literature, there is a breakthrough in the research on sandstone in terms of influencing factors, physical and mechanical properties and their deterioration mechanisms, while there are fewer researches considering sandstone subjected to mining action in actual engineering. And when water has a greater impact on the physical and mechanical properties of rocks, its hydrophysical properties should be the key index, the above studies on sandstone water content, dry and wet cycle treatment and freeze–thaw cycle treatment, considering the water absorption of sandstone, ignoring other hydrophysical properties, such as swelling, disintegration and so on.

In response to the above problems, based on the sandstone of the Meidongpo in Duyun City, Guizhou Province, adjacent sandstone rock samples that were sandstone without mining action and Sandstone under mining action (hereinafter referred to as unmined sandstone and mining sandstone) were selected as specimens before and after the intrusion of underground mining, which refers to the mining disturbing effect of the mining of underground coal seams on the overlying rock strata26,27, and unmined refers to the sandstone rock samples that did not go through the action of disturbing by the underground mining to carry out the subjected to the action of mining- Carry out tests on the hydrophysical and mechanical properties of sandstone before and after being subjected to mining and water action, and study the deterioration patterns of the hydrophysical and mechanical properties.

Experiment program

Preparation of rock samples

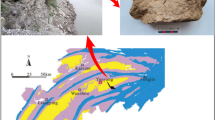

The raw materials of the experimental sandstone were taken from Meidongpo, Duyun City, Guizhou Province, the geographical range is 107° 17.50′ − 107° 18.47′ E and 26° 10.58′ − 26° 11.48′ N.At present, the underground coal mining in this area has a history of 50 years, and the main deformation and damage are two places, as shown in Fig. 128, namely the coal cave slope deformation body and the Madaling landslide.On May 18, 2006, the Madaling Mountain experienced a large-scale landslide with a volume of 1.39 × 106 m3. Prior to the landslide, the local area experienced continuous heavy rainfall for over 120 h, which was a typical landslide induced by the combined effect of mining and heavy rainfall29. The distance between the Madaling landslide and the coal cave slope is 160 m, and they have similar geological strata, rock structure, and mining history. The sandstone of the Xiangpai Formation in the coal cave slope can be regarded as the sandstone that has not been subjected to mining action, and the sandstone of the already occurred Madaling mining landslide can be regarded as the sandstone that has been subjected to mining action. The physical and mechanical degradation law of sandstone under mining water action can be carried out.

Immediately send the retrieved block sandstone to the geotechnical sample processing center to process it into a standard rock sample (a cylinder with a diameter of 50 mm and a height of 100 mm). The sample size and accuracy meet the requirements of the "Engineering Rock Mass Test Method Standard" (GB/T50266-2013)30, and some samples are shown in Fig. 2.

The surface sandstone is not continuously immersed in water, but undergoes a process of periodic rainfall and rainwater evaporation. Under the action of mining and the repeated water absorption and loss environment, the sandstone deteriorates, leading to rock instability and geological disasters. According to the experimental design, sandstone was divided into 5 groups, unmined sandstone as Group A, and mining sandstone with 0, 1, 5, and 10 dry wet cycles as Group B, C, D, and E, respectively. During each experiment, corresponding hydraulic properties, uniaxial compressive strength, scanning electron microscopy, and X-ray diffraction tests were completed. The corresponding experimental scheme flowchart is shown in Fig. 3.

Water physical property test

Water absorption

The water absorption test was performed on the unmined sandstone using the free immersion method; the mining sandstone was subjected to 0, 1, 5, and 10 dry and wet cycles, respectively, and the water absorption test was completed during the dry and wet cycle treatments. After the wet-dry cycle treatment, the sandstone was sealed and wrapped with cling film to prevent water evaporation from affecting the uniaxial compression test. Calculate its water absorption rate according to Eq. (1):

where \({\omega }_{n}\)—the water absorption rate corresponding to n cycles; \({m}_{a}\)—the mass of water immersion for 48 h; \({m}_{d}\)—the mass of drying.

Expansion test

The free expansion rate meter was selected to test the axial free expansion rate (hereinafter referred to as expansion rate) of the unmined sandstone and mining sandstone. Test steps are: ① sandstone into the free expansion rate instrument, placed in the top of the sandstone metal spacer, adjust and fix the position of the micrometer, placed in the metal spacer above the micrometer to record the initial readings; ② slowly to the free expansion rate instrument into the water, added to the top of the rock samples just missed about 2 cm; ③ the first hour every 10 min to record the number of times, and then every hour to record; ④ according to the formula (2) calculation Calculate the free expansion rate of sandstone according to Eq. (2).

where—\({V}_{H}\)sandstone axial expansion rate (%); \(\Delta H\)—The deformation of the dial indicator reading; H—Initial reading of the dial indicator.

Disintegration test

The disintegration tester was selected to carry out disintegration test. The test process is as follows: put the specimen into the oven at 105 °C for 12 h and then put it into the sieve of the disintegration tester, and then pour the water into the water tank to submerge the specimen, and then finally activate the switch of the tester to carry out the test; the sieve speed is set at 20 r/min, and stop the test after 10 min./min, stop the test after 10 min; put the removed sandstone into the oven at 110 °C to dry for 12 h, the suspension in the water tank is left to stand for 24 h, then pour out the upper part of the water tank, and dry the lower part of the liquid to complete a cycle of disintegration resistance, and record the residual mass of the sandstone mn. Each group of sandstone specimens need to repeat the above steps for 5 times, and record and organize the relevant data. The disintegration resistance index was calculated according to Eq. (3) after n cycles of the test:

where \({I}_{{d}_{n}}\)—the resistance index to disintegration obtained after n cycles of disintegration.

Mechanical properties test

Uniaxial compression tests were conducted on five groups of sandstone with three specimens in each group, Groups A and B were to study the effect of mining action, and Groups B, C, D, and E were treated with 0, 1, 5, and 10 dry and wet cycles to study the effect of water action, respectively. The loading system adopts stress–strain triaxial shear penetration tester.

Test results and analysis of water physical properties

Water absorbency analysis

The results of water absorption tests of sandstone under the action of mining and wet dry cycling are shown in Table 1.

From Table 1, it can be seen that there is not much difference in water absorption between Group A and Group B. The average water absorption of the unmined sandstone is 1.631%, and the average water absorption of the mining sandstone is 1.676%, which indicates that the action of mining has increased the water absorption of the sandstone by 0.056%.

Comparing the average water absorption rates of Groups B, C, D, and E, the overall average water absorption rate showed an increasing trend with the number of wet and dry cycles, and the average water absorption rate of the mining sandstone with the number of wet and dry cycles in Table 1 was fitted to the relationship Equation (0 ≤ n ≤ 10) as shown in Fig. 4:

where \(\overline{{\omega }_{n}}\)—water absorption (%); n—number of wet and dry cycles; R2—correlation coefficient.

Referring to the analytical method of the previous31 on the change of water absorption rate under dry and wet cycles, the change of water absorption rate of mining sandstone under dry and wet cycle conditions was studied to calculate the increment of water absorption rate of sandstone in each cycle stage, and to calculate the stage increment of water absorption rate of sandstone and the average stage increment after each stage of cycling, and the formula of calculation is shown in Eq. (5), and the results of the calculations are shown in Table 2.

where \({\Delta }_{\omega }\) is the stage increment; \(\overline{{\omega }_{i+1}}\), \(\overline{{\omega }_{i}}\) is the average water absorption rate corresponding to stages i + 1 and i, respectively; and is the number of wet and dry cycles corresponding to stage i.

As shown in Table 2, the stage increment of the water absorption rate of mining sandstone is 0.048% at n = 1, 0.24% at n = 5, and 0.058% at n = 10. The trend indicates an initial increase followed by a decrease. Specifically, the average stage increment at n = 1 is 0.048%, which rises to 0.06% at n = 5 before decreasing to 0.01% at n = 10. This suggests that when the dry and wet cycles reach a certain point, the water absorption rate of sandstone no longer continues to increase and tends toward equilibrium. Therefore, the effect of dry and wet cycling on the water absorption of sandstone is primarily concentrated in the initial dry and wet cycling period. The water absorption rate exhibits an exponential decreasing trend, with the average increment rising to 0.06% after five cycles. Subsequently, the change in the water absorption rate decreases as the number of cycles increases, with the average stage increment falling to 0.01% at n = 10.

Expansion analysis

The test data of sandstone expansion rate are shown in Table 3. The maximum expansion rate of unmined sandstone is 0.4%, while the maximum expansion rate of mined sandstone is 0.7%. The expansion rate of sandstone increases by 0.3% after mining, mainly due to cracking caused by mining, which increases the porosity of sandstone and enhances its expansibility.

The curves of sandstone expansion versus time at different times are plotted according to Table 3 and are shown in Fig. 5.

Based on Table 3 and Fig. 5, the expansion law can be divided into three stages: ① Rapid expansion stage: sandstone expands immediately after immersion in water, and the expansion rate increases rapidly with time and is basically constant. The two types of sandstone maintain the same duration in this stage, both between 0 and 60min. The slope rate of the mined sandstone is greater than that of the unmined sandstone, that is, the growth rate of the expansion rate is greater than that of the unmined sandstone. ② Slow expansion stage: The expansion rate increases slowly with time and the growth rate becomes slower and slower. The unmined sandstone takes 60–360 min, and the mined sandstone takes 60–720 min. The slow expansion time of the mined sandstone is 360 min longer than that of the unmined sandstone Expansion stability stage: The expansion rate reaches the expansion limit and is basically stable. The unmined sandstone expands and deforms stably after 360 min, while the mined sandstone expands and deforms stably after 720 min. The expansion rate does not continue to increase and the deformation reaches stability. The two types of sandstone have the same time in the rapid expansion stage, but there is a large time difference between the slow expansion stage and the stable expansion stage. The slow expansion time required for mining sandstone is longer, mainly due to the increase in porosity and dispersion of particles caused by mining, resulting in a faster expansion rate and stronger expansibility of sandstone.

Disintegration analysis

The disintegration test data are shown in Table 4.

According to Table 4, after 5 cycles of disintegration, the disintegration resistance index of the two sandstones is above 99%, and the suspension becomes turbid without sediment after standing, indicating that both unmined and mined sandstones are not prone to disintegration. The fivefold collapse resistance index of unmined sandstone is 99.8%, while that of mined sandstone is 99.5%. The collapse resistance index of unmined sandstone is slightly higher than that of mined sandstone, and mining action reduces the collapse resistance index of sandstone by 0.3%.

Figure 6 shows a plot of the number of disintegration-resistant cycles of sandstone versus the residual mass of the specimen, which yields a model for the damage degradation of disintegration-resistant residual mass under mining and water action as shown in Eq. (6):

From Fig. 6, it can be seen that as the number of disintegration cycles increases, the residual mass of the sample decreases exponentially, and the rate of decrease slows down. The residual mass of the sample becomes closer to the horizontal line. The initial mass of the mined sandstone is lower than that of the unmined sandstone, but the rate of decrease is faster. The time required for the unmined sandstone to reach the horizontal level is shorter, indicating that the unmined sandstone has stronger resistance to disintegration. After 5 cycles of dry wet cycles, there was no significant decrease in the residual mass of unmined sandstone, indicating that the sandstone had reached a stable state of disintegration.

Mechanical property testing results and analysis

Stress–strain curve

Make the stress–strain curve of each sandstone, as shown in Figs. 7 and 8a–d, the uniaxial compressive strength of each sandstone has been marked in the figure, and the uniaxial compressive strength of each sandstone is summarized in Table 5.

As shown in Table 5, the mean uniaxial compressive strength of unmined sandstone is 111.987 MPa, the mean uniaxial compressive strength of mining sandstone is 104.854 MPa, and the uniaxial compressive strength of unmined sandstone is higher than that of mining sandstone by 7.133 MPa. With the increase of the number of dry and wet cycles, the mean uniaxial compressive strength of extracted sandstone gradually decreases, and its change curve is shown in Fig. 9, which shows that its fitting is good, the corresponding damage deterioration model is shown in Eq. (7). The effect is good, the uniaxial compressive strength decreases with an exponential trend, and the corresponding damage deterioration model is shown in Eq. (7):

Deterioration pattern analysis

Mining effects

Define the degree of reduction of mechanical parameters of sandstone in the process of mining as the damage rate D, which reflects the degree of damage of sandstone after experiencing the action of mining. Its calculation formula is:

where \(\text{D}\)-the damage rate;\({\sigma }_{cA}\)-the uniaxial compressive strength of unmined sandstone; \({\sigma }_{cB}\)-the uniaxial compressive strength of mining sandstone without wet and dry cycles.

From Table 5, \({\sigma }_{cA}\)=111.987 MPa, \({\sigma }_{cB}\)=104.854 MPa, which is brought into Eq. (8) to calculate the damage rate of 6.367%, indicating that the damage rate of uniaxial compressive strength of sandstone after being subjected to mining action is 6.367%.

Wet and dry cycle effects

The uniaxial compressive strength of the mining sandstone showed a gradual decrease with the increase of the number of wet and dry cycling, in order to study the influence of the strength of the mining sandstone under the wet and dry cycling, the degree of reduction of the mechanical parameters of sandstone in the process of wet and dry cycling is defined as the degree of deterioration32, which reflects the degree of damage of sandstone after experiencing the process of wet and dry cycling to a certain extent. Taking the uniaxial compressive strength of the mining sandstone at n = 0 as the benchmark, the total deterioration rate, stage deterioration rate and stage average deterioration rate were calculated by Eq. (9), and the specific calculation results are shown in Table 6.

where \({\sigma }_{n}\)-the uniaxial compressive strength corresponding to a dry and wet cycle of n; \({N}_{n}\), \({N}_{n-1}\)-the compressive strength corresponding to the n and n-1 stages, respectively.

According to Table 6, when n = 1, the uniaxial compressive strength of the mined sandstone is 80.296 MPa, a decrease of 24.558 MPa, and the total degradation rate is 22.33%; When n = 5, the uniaxial compressive strength was 76.006 MPa, a decrease of 4.29 MPa, and the total degradation rate was 26.24%; When n = 10, the uniaxial compressive strength was 59.468 MPa, a decrease of 17.88 MPa, and the total degradation rate was 43.29%. It can be seen that as the number of wet dry cycles increases, the total degradation rate of the mined sandstone also increases. The pattern of stage degradation and stage average degradation is roughly the same, showing an overall trend of first decreasing and then increasing. From the analysis of stage degradation rate, it can be seen that the damage is the highest when n = 1, and the damage decreases to the lowest when n = 5. The essence of this pattern is that under the action of water, the reaction between sandstone and water is concentrated at 5 times or earlier, and mineral particles and water exchange substances, making the internal structure of the specimen loose. New pores are generated inside the sandstone, and the number of pores increases, which is manifested macroscopically as a decrease in uniaxial compressive strength; And the increase in damage with n = 10 is due to the weakening of the cohesion between sandstones due to the number of wet dry cycles. At this time, under external forces, the degree of sandstone damage will be strengthened.

Epimorphological analysis

After completing the uniaxial compression test, the typical damage specimens were photographed to obtain their typical apparent morphology diagrams (Figs. 10 and 11), in which the sandstone cracks were outlined and numbered along the cracks with a red line, and the damage patterns of each sandstone were judged according to the damage apparent morphology (Table 733).

Mining effects

Figure 10 shows the morphology of the unmined sandstone and mining sandstone (n = 0) at the end of the uniaxial compressive strength test. When the unmined sandstone is damaged, the specimen is intact, no debris is generated, and there are two cracks, in addition to axial crack ①, there is also a crack along the diagonal cross-section of 60°②, and the damage form is tensile-shear composite damage, see Fig. 10a; when the mining sandstone (n = 0) is damaged, the specimen is intact, there is a small amount of debris generated, and there are two cracks, in addition to axial cracks ①, but also accompanied by parallel cracks ②, see Fig. 10b, and the damage form is tension-shear composite damage. See Fig. 10b, the damage form is tension and shear combined failure.

Wet and dry cycle effects

Figure 11 shows the typical specimens of sandstone damaged after uniaxial compression test under different cycle times. n = 1, less surface spalling phenomenon occurs, with a total of 4 cracks, crack ① is an arc-shaped crack connecting the top surface and the top surface, crack ② is an axial surface crack, accompanied by the appearance of parallel cracks (③), cracks (④) and crack ① in the upper part of the sandstone intersected, which means that the damage is in the form of composite damage of tensile-shear, see Fig. 11a; n = 5, the damage surface is relatively dispersed, there are 5 cracks, crack ① sandstone connected to the top surface and the top surface of the arc crack, the upper part of the axial crack, the lower part of the arc crack connected with the parallel crack ⑤, crack ②, ③, ④ for the axial crack not connected to the top surface and the top surface of the arc crack, the form of damage is tension and shear combined failure, see Fig. 11b; n = 10, the sandstone has been broken, there are 4 cracks At n = 10, the sandstone has been cracked, and there are 4 cracks, all of which are axial rupture cracks through the top surface of sandstone and the bottom surface of sandstone, the cracks penetrate into the sandstone, and the damage surface is cracked along the axial direction, and the damage is in the form of tensile damage, see Fig. 11c.

Dry and wet cycle 5 times and before the number of cracks were 2, 4, 5, respectively, the number of cracks gradually increased, the sandstone damage morphology is more incomplete, the degree of fragmentation is stronger, the form of damage for tension and shear combined failure; and dry and wet cycle 10 times, there are 4 cracks, the sandstone internal fracture, block cracking, the form of damage for tensile damage. In the process of dry and wet cycling, water molecules enter the sandstone interior through the pores between particles and dissolve the mineral particles, leading to the softening of sandstone and weakening the cohesion between particles, at this time in the role of external forces, it will accelerate the rate of damage deterioration, which will lead to a decrease in the degree of sandstone crushing and the overall strength.

Microstructure analysis

Microstructure analysis

Scanning electron microscope tests were carried out on sandstone specimens taken from cracks after uniaxial compression tests were done. The test results are shown in Fig. 12 (the main pore sizes have been labeled in the figure, and H indicates the average pore size).

Based on the results of the SEM images, it can be seen that the action of wet and dry cycles affects the sandstone microstructure and pore size as follows:

-

1.

When n = 0, the internal structure of sandstone is dense, the surface is smooth, the mineral particles and intergranular cement are relatively intact, with fewer pores and a small amount of debris attached, and the average pore size is 7.16mm, see Fig. 12a;

-

2.

When n = 1, the smoothness is poor, the mineral particles begin to become loose, the intergranular cement begins to be eroded by water, there are a small amount of debris attached to the damage surface, the sandstone pores and cracks begin to develop gradually, there are obvious secondary pores and cracks on the surface, and the average pore size increases to 12 mm, see Fig. 12b;

-

3.

When n = 5, with the increase of the number of wet and dry cycles, the gravel on the surface of sandstone obviously increased, the number of pores in sandstone increased, and some of the pores began to connect, and the average pore size was 12 mm, see Fig. 12c;

-

4.

When n = 10, the gravel is softened by water erosion into a large number of smaller shaped particles clinging to the sandstone surface, and the pore space continues to increase, with an average pore space of 17.5 mm, see Fig. 12d.

With the increase of the number of dry and wet cycling, the damage of sandstone subjected to dry and wet cycling gradually intensified. The microstructure of sandstone gradually evolves from the initial dense state to a loose porous and fissured structure, and the average pore size gradually expands. The cement between the mineral particles gradually dissolved, forming many pores and connected cracks, resulting in the microstructure no longer complete.

EDS surface energy spectroscopy was performed on selected surfaces of sandstone samples under the use of sandstone before and after the action of mining, and the graphical results of the energy spectrometer are shown in Fig. 13a,b.The vertical coordinates of the EDS energy spectrograms indicate the intensity values or the number of counts of X-rays in the different energy ranges, and the intensity values of O and Si of the unmined sandstone are much greater than those of mining sandstone, which indicates that the unmined sandstone has a better crystallization than that of the mining sandstone.

The composition and proportion of corresponding elements are shown in Table 8, and the detection results of the spectra of the unmined sandstone and mining sandstone show that there are only three elements, K, O and Si, in the detection area, of which K is a component of the conductive tape that belongs to the sample making process. The atomic number of oxygen element in the unmined sandstone accounted for 64.8%, oxygen element accounted for 51.58% of the total mass of the sample, the atomic number of silicon element accounted for 35.2%, and silicon element accounted for 48.82% of the total mass of the sample; the atomic number of oxygen element in the mining sandstone accounted for 70.45%, the atomic number of oxygen element accounted for 57.59% of the total mass of the sample, the atomic number of silicon element accounted for 29.55%, and the silicon element accounted for 42.41% of the total mass of the sample. The fact that the Si element content of the unmined sandstone is higher than that of the mining sandstone and the O element content is higher than that of the mining sandstone is due to the fact that the pore space generated by the sandstone due to the action of mining makes the O element in the air enter into the interior of the sandstone, and the purity of the sandstone is reduced.

Mineral composition testing and analysis

X-ray diffraction is currently the most widely used and effective mineral analysis technique, which has been widely used in materials science, chemistry, physics, and a variety of engineering and technological sciences34. In this experiment, X'pert Pro type X-ray diffractometer was used to analyze the mineral composition of sandstone.

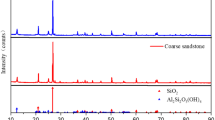

The experimental data were processed using Origin software and MDI Jade6 post-processing software to obtain the XRD diffraction patterns of five groups of rock samples, as shown in Fig. 14. The spectra were analyzed by searching peaks and comparing with the standard PDF cards, and the results showed that the crystallinity of sandstone was relatively good, and no diffraction peaks of other crystalline minerals appeared in the diffraction spectra except for the quartz crystalline phase, indicating that the mineral composition of sandstone contained only quartz (SiO2), and that the mining action and dry and wet cycling did not change the mineral composition of sandstone.

There is an obvious peak at diffraction angle 2 = 20°–30°, which corresponds to the 002 surface of the microcrystalline structure, and the peak obtained at diffraction angle 2 = 10°–35° is generally called the 002 peak. The strongest diffraction peak of each sandstone in Fig. 13 appeared at about 26.6°, so the strongest diffraction peak is 002 peak. From the comparison of curve A and curve B in Fig. 14, it can be seen that the 002 peak of the unmined sandstone is sharper than that of the extracted sandstone, and the diffraction intensity is larger, and from the comparison of curves B, C, D, and E, it can be seen that the diffraction intensity of the 002 peak of the extracted sandstone is also reduced with the increase of the number of dry and wet cycles, which indicates that the extracting and the dry and wet cycling will make the sandstone more sensitive. dry and wet cycling will reduce the sandstone in peak 002.

Simulation of water molecule adsorption by sandstone

Model building and simulation methods

Model building

Sandstone models with different pore structures were built with the help of Materials Studio software, the models were derived from the crystal structure database35, and supercell structures were built in the unit cell on x × y, see Fig. 15a, based on which a space was added between the 2 supercell structures, i.e., in the z direction, so as to construct sandstone structures with different porosities. According to Section "Stress–strain curve", the average pores of sandstone specimens after different wet and dry cycles were 7.16 μm, 12 μm, and 17.5 μm, respectively, and the number of atoms required for micrometer-scale simulation was too large, so the pores were reduced by 2000 times for the study, and the sandstones with 3 nm, 6 nm, and 9 nm pores, respectively, were selected for the simulation of water molecule adsorption. The constructed model was first optimized geometrically using the Forcite module in MS software to eliminate the unreasonable overlap between atoms, and the force field was selected as the Dreiding force field, and the constructed model is shown in Fig. 15b. On the basis of constructing the sandstone model, it is also necessary to construct the water molecule model, the water molecule model is shown in Fig. 15c, and the bond length of the water molecule is 1.813 nm and the bond angle is 109.471°.

Monte Carlo simulation

Sandstone adsorption of water molecules simulation is an important part of the study of water adsorption properties of sandstone with different porosity, Monte Carlo simulation has been widely used in the study of adsorption properties of materials36,37, the simulation steps are as follows: firstly, the operation of water molecules adsorbed at constant pressure in the pores of sandstone of three groups is carried out through the Sorption module based on the principle of Monte Carlo, and the adsorption quantities of the three groups of models at room temperature and pressure are calculated, and the heat of adsorption is calculated simultaneously; after calculating the adsorption quantity, the adsorption location of H2O is calculated through Sorption locate module; finally, the adsorption of adsorption models is calculated. The heat of adsorption is calculated; after calculating the adsorption quantity, the adsorption location of H2O is calculated by Sorption locate module; finally, the adsorption is calculated for the adsorption model. The type of force field in the simulation was chosen as Dreiding force field, Ewald&Group method was used for the calculation of Coulomb force interaction, and Atom Based method was used for the calculation of Van der Waals force interaction.

Results and analysis

Adsorption energy distribution

The energy distribution curves of adsorbed water molecules in sandstone models with different porosities are shown in Fig. 16, from which it can be seen that the energy distribution among water molecules in the three pore models shows a single peak state, which indicates that the adsorption of water molecules within the same pore space is homogeneous, they are adsorbed in a random way in the pore space and the adsorption state is the same, and there is no obvious adsorption difference, i.e., there is no situation in which pores in the sandstone have different adsorption sites, which means that all the pores in sandstone have the same ability to adsorb water molecules. That is, there is no situation where the pores in the sandstone have different adsorption sites, which means that all the pores in the sandstone have the same ability to adsorb water molecules38. In addition, it can be seen from Fig. 16 that the energy corresponding to the peak value of water molecules increases with the increase of the pore space, which indicates that the adsorption of water molecules gradually shifts from the adsorption sites with lower energy to the adsorption sites with higher energy with the increase of the pore space.

Average equivalent heat of adsorption

The average equivalent heat of adsorption of water molecules in each pore sandstone is shown in Table 9, the maximum equivalent heat of adsorption of water molecules corresponding to a pore size of 3 nm is 0.834 kcal/mol, whereas the equivalent heat of adsorption of water molecules corresponding to a pore size of 9 nm is reduced to 0.645 kcal/mol, and it can be found that the average equivalent heat of adsorption decreases gradually with the increase of the pore size at room temperature and pressure.

Under the action of mining, the pores become larger and larger, the heat of adsorption required to adsorb an equal amount of water molecules becomes smaller and smaller, and the sandstone’s ability to adsorb water is enhanced, and the number of adsorbed water molecules during the simulation is shown in Fig. 17.

From Fig. 17, the average number of water molecules adsorbed by a single crystal cell is stabilized at about 1.6 when the pore size is 3 nm, at about 2.7 when the pore size is 3 nm, and at about 3.8 when the pore size is 9 nm. It can be seen that the increase in the average number of adsorbed water molecules of individual crystal cells is the same, both are 1.1, and the average number of adsorbed water molecules of individual crystal cells also tends to increase in equal amount for every 3 nm increase in the pore space.

Combining the above analyses, it can be concluded that the increase in pore space leads to a decrease in the average equivalent heat of adsorption, and an increase in the number of water molecules adsorbed by the sandstone and the total energy of adsorption, which suggests that the sandstone’s ability to adsorb water is enhanced in large pore space, and water molecules have a wetting effect on the sandstone pore space, whereas the water molecules’ atoms are more tightly arranged in small pore space, which is conducive to the saturating of pore space.

Patterns of microstructural evolution in sandstone

Comprehensive analysis of the previous test results, sandstone are continuously deteriorating in their physical and mechanical properties under mining and water action, the establishment of microstructural evolution of "mining cracking → water adsorption → water–rock action" mode, as shown in Fig. 18.

-

(1)

mining cracking: as shown in Fig. 18a, sandstone under the action of mining will produce micro-cracks, micro-pores and loose internal structure. The force produces gravel around the pore, the mineral composition remains unchanged, and the elemental content changes, which is consistent with the results of the energy spectrum test of sandstone in the lower EDS surface before and after the mining action in section "Microstructure analysis".

-

(2)

Water adsorption: as shown in Fig. 18b, water molecules flow into the sandstone pore space generated by the cracking action of mining, through the micro-cracks, micro-pore penetration of the sandstone interior, the sandstone began to adsorb water molecules, the adsorption capacity of different pore sandstone is different, from the simulation of the different pore sandstone adsorption of water molecules in section "Simulation of water molecule adsorption by sandstone" of the MS software is known that the increase in the pore space can increase the number of water molecules adsorbed by the sandstone, the adsorption capacity is increased, pore large when When the pore space is large, it is favorable to wet the sandstone pore space, and when the pore space is small, the atomic arrangement of water molecules is more compact, which is favorable to saturate the pore space.

-

(3)

Water–rock interaction: As shown in Fig. 18c, according to the X-ray diffraction results in section "Mineral composition testing and analysis", the mineral composition of the sandstone used in the test is quartz, and the mineral composition did not change after interaction with water, but it will promote the development and expansion of cracks, providing more paths for water–rock interaction. Water–rock interaction will affect the hydrophysical properties of sandstone, one is to enhance the water absorption, water molecules will soften the mineral particles around the pore space and make the gravel around the pore space increase, increasing the sandstone porosity, water absorption performance enhancement; the second is the weakening of the resistance to disintegration, some mineral particles in contact with water, as well as cementation by the water erosion dissolved in the water, and with the migration of water diffusion out of the sandstone, so that the resistance to disintegration of the index is reduced, the density is reduced, and the number of pore spaces Increase; Third, some minerals in contact with water to produce expansion, expansion of the pore wall extrusion, resulting in the further expansion of some of the pores at the same time, there will be a fine tension cracks, promoting the development and expansion of sandstone micro-cracks, increase and expand the water in and out of the sandstone internal channels.

Conclusion

-

(1)

The quarrying action increased the water absorption rate of sandstone by 0.056%, and the water absorption rate of quarried sandstone increased with dry and wet cycles in a good exponential relationship; the expansion rate of sandstone increased by 0.3% by the quarrying action, and the expansion pattern of sandstone could be divided into three stages: rapid expansion stage, slow expansion stage and expansion stabilization stage, in which the slow expansion stage and the expansion stabilization stage required a longer slow expansion time; the quarrying action reduced the 5 times disintegration resistance index of sandstone by 0.3%. The time gap between the expansion and stabilization stages is large, and the slow expansion time required by the quarried sandstone is longer; the 5 times disintegration resistance index of sandstone decreased by 0.3% by the quarrying action.

-

(2)

The damage rate of uniaxial compressive strength of sandstone after quarrying is 6.367%; the uniaxial compressive strength of quarried sandstone decreases exponentially with the number of wet and dry cycles; there are 2 cracks in the damage of unquarried sandstone and quarried sandstone (n = 0), one is axial crack, the other is the crack along the diagonal cross section of 60° and the parallel crack, and both of them are in the form of tensile-shear composite damage. The number of cracks were 2, 4 and 5 before 5 times of wet and dry cycling, the number of cracks increased gradually, the sandstone was incomplete, and there were 4 cracks in 10 times of wet and dry cycling, the sandstone was broken inside, and it was cracked in the form of block, and the form of damage was tensile damage.

-

(3)

The damage of the quarried sandstone is gradually strengthened with the dry and wet cycle, and the pore size is gradually increased; the composition of sandstone before and after quarrying only has two kinds of elements, Si and O. The content of Si in un-quarried sandstone is higher than that in quarried sandstone, and the content of O is lower than that in quarried sandstone. According to the microscopic test results, the microstructural evolution of “mining cracking → water adsorption → water–rock interaction” model was established, and the internal structure weakening speed was accelerated and the physical and mechanical properties were deteriorated by the action of mining-water cycle.

Data availability

The data used to support the findings of this study are included within the article.

References

Song, Y. Y. Failure Models and Instability of Slopes with Soft and Hard Rock Interbedded Laminated Structure in Southwest China (Chengdu University of Technology, 2011).

Fan, L. M. et al. Geological disasters and control technology in high intensity mining area of western China. J. Coal Soc. 42(02), 276–285. https://doi.org/10.13225/j.cnki.jccs.2016.6002 (2017).

Wang, J. J., Xiao, L. L., Zhang, J. & Zhu, Y. B. Deformation characteristics and failure mechanisms of a rainfall-induced complex landslide in Wanzhou County, Three Gorges Reservoir, China. Landslides 17, 419–431 (2020).

Li, J. et al. Research on rainfall infiltration models of slopes and formation mechanism of rock landslides in red stratum in the east of sichuan province. Chinese J. Rock Mech. Eng. 35(S2), 4053–4062. https://doi.org/10.13722/j.cnki.jrme.2015.1784 (2016).

Hale, P. A. & Shakoor, A. A laboratory investigation of the effects of cyclic heating and cooling, wetting and drying, and freezing and thawing on the compressive strength of selected sandstones. Environ. Eng. Geosci. 9(2), 117–130 (2003).

Liang, Y. L. et al. Macro-meso deterioration characteristics and statistical damage constitutive model for acid-corroded sandstone. J. Build. Eng. 71, 2352–7102. https://doi.org/10.1016/j.jobe.2023.106499 (2023).

Liang, Y. L. et al. Effect of the surface-area-to-volume ratio on dissolution and deterioration of acid-corroded sandstone. J. Build. Eng. 86, 2352–7102. https://doi.org/10.1016/j.jobe.2024.108789 (2024).

Wang, M. et al. Effect of water absorption ratio on tensile strength of red sandstone and morphological analysis of fracture surfaces. J. Central South Univ. 24, 1647–1653. https://doi.org/10.1007/s11771-017-3570-1 (2017).

Liang, X. et al. Influence of Water on the Mechanical Properties and Failure Behaviors of Sandstone Under Triaxial Compression. Rock Mech. Rock Eng. 56(2), 1131–1162 (2022).

Vásárhelyi, B. & Ván, P. Influence of water content on the strength of rock. Eng. Geol. 84(1), 70–74 (2006).

Yuan, P. & Ma, R. Q. Split Hopkinson pressure bar tests and analysis of coalmine sandstone with various moisture contents. Chin J Rock Mech Eng 34(S1), 2888–2893. https://doi.org/10.13722/j.cnki.jrme.2014.0534 (2015).

Huang, S. Y. et al. Effects of cyclic wetting-drying conditions on elastic modulus and compressive strength of sandstone and mudstone. Processes 6(12), 234 (2018).

Li, D. Y. et al. Influence of water content and anisotropy on the strength and deformability of low porosity meta-sedimentary rocks under triaxial compression. Eng. Geol. 126, 46–66 (2012).

Du, B. et al. Experimental study on the dynamic tensile properties of red-sandstone after cyclic wetting and drying. Chin. J. Rock Mech. Eng. 37(07), 1671–1679. https://doi.org/10.13722/j.cnki.jrme.2018.0039 (2018).

Yao, H. Y. et al. Experimental study of mechanical properties of sandstone under cyclic drying and wetting. Rock Soil Mech. 31(12), 3704–3708. https://doi.org/10.16285/j.rsm.2010.12.017 (2010).

Jiang, Y. D. et al. Experimental study on mechanical properties of rock under the conditions of wet and dry cycles. China Min. Mag. 20(05), 104–106 (2011).

Hua, W. et al. Effect of cyclic wetting and drying on the pure mode II fracture toughness of sandstone. Eng. Fract. Mech. 153, 143–150 (2016).

Hua, W. et al. The influence of cyclic wetting and drying on the fracture toughness of sandstone. Int. J. Rock Mech. Min. Sci. 78, 331–335 (2015).

Wu, Q. H. et al. Uniaxial compression mechanical properties and deterioration mechanism of sandstone under different humidity conditions. J. Central South Univ. 30, 4252–4267. https://doi.org/10.1007/s11771-023-5521-3 (2023).

Li, F. et al. Strength and energy exchange of deep sandstone under high hydraulic conditions. J. Central South Univ. 27, 3053–3062. https://doi.org/10.1007/s11771-020-4528-2 (2020).

Li, J. L. et al. Non-linear creep damage model of sandstone under freeze-thaw cycle. J. Central South Univ. 28, 954–967. https://doi.org/10.1007/s11771-021-4656-3 (2021).

Cai, M. F. Rock Mechanics and Engineering (China Science and Technology Press, 2002).

Zhang, Z. H., Huang, X. & Cui, Q. Experimental study on deterioration of the tensile strength of red sandstone during the operation of reservoir. Chin. J. Rock Mech. Eng. 36(11), 2731–2740. https://doi.org/10.13722/j.cnki.jrme.2017.1180.(inChinese) (2017).

Zhou, Z. L. et al. Influence of cyclic wetting and drying on physical and dynamic compressive properties of sandstone. Eng. Geol. 220, 1–12 (2017).

Xu, B. T. et al. Effect of void characteristics on deteriorating rules of sandstone due to water. Rock Soil Mech. 40(02), 561–569. https://doi.org/10.16285/j.rsm.2017.1296 (2019).

Di, J. Y. Influence of repeated excavation on surface moving deformation. J. Mine Press. Roof Manag. 04, 74–75 (2000).

Xiong, F. et al. Instability failure mechanism of karst mountain with deep and large fissures under the mining-fissure water coupling. J. Coal Soc. 46(11), 3445–3458. https://doi.org/10.13225/j.cnki.jccs.2020.1690.(inChinese) (2021).

Zhao, J. J. et al. Physical modeling on deformation characteristics of overlying rock mass above mined-out area in gently inclined coal seam. J. Coal Soc. 41(06), 1369–1374. https://doi.org/10.13225/j.cnki.jccs.2015.1408 (2016).

Zhao, J. J. et al. Experimental study on failure process of mining landslide induced by rainfall. J. Coal Soc. 45(02), 760–769. https://doi.org/10.13225/j.cnki.jccs.2019.0188 (2020).

National Standard of the People’s Republic of China. Standard for engineering rock test methods(GB/T 50026–2013).

Wang, K. J. Mechanism of Black Rock Deterioration and Water-Rock Interaction Under Dry-Wet Cycle (Southwest Jiaotong University, 2020).

Chen, G. B. et al. Timeliness of damage and deterioration of mechanical properties of coal-rock combined body under water-rock interaction. J. Coal Soc. 46(S2), 701–712 (2021).

Ma, C. Y. et al. Optimal Proportion of Similar Materials and Rockburst Tendency of White Sandstone. Adv. Mater. Sci. Eng. 2021, 1–17 (2021).

Zhou, Y. & Wu, G. H. Materials Analysis and Testing Technology (Harbin Institute of Technology Press, 1998).

COD. Crystallography Open Database, http://www.crystallography.net/cod/

Xiong, J., Liu, X. J. & Liang, L. X. Adsorption of methane in quartz by Grand Canonical Monte Carlo simulation. J. Nat. Gas Geosci. 27(08), 1532–1540 (2016).

Sun, X. Y. et al. Adsorption of Benzene and Propene in β Zeolite by Grand Canonical Monte Carlo Simulation. J. Chem. 15, 1810–1814 (2008).

Zhang, L. et al. Molecular simulation investigation on the effect of pore structure on the wettability of low-rank coa. J. China Univ. Min. Technol. 51(06), 1117–1127. https://doi.org/10.13247/j.cnki.jcumt.001424 (2022).

Acknowledgements

The work is supported by the National Natural Science Foundation of China (Nos. 52264005).

Funding

This work was supported by the National Natural Science Foundation of China 52264005.

Author information

Authors and Affiliations

Contributions

Z.D.: carried out experiments, collated and analyzed data, and wrote papers; T.X.: supervised experiments, provided paper writing guidance, revised and polished manuscripts; W.M. and Q.L.: put forward ideas and theoretical analysis; H.B.and Y.C.: participated in the experiment and assisted in sorting out data and pictures. All authors agreed to the format and presentation of the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Dai, Z., Xia, T., Meng, W. et al. Deterioration characterization of sandstone physical and mechanical properties under mining and water action. Sci Rep 14, 30340 (2024). https://doi.org/10.1038/s41598-024-81552-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-81552-2