Abstract

Improving highway bases is the most crucial step that enhances pavements’ performance and long-term durability. Lime and Portland cement are commonly used in soil stabilization endeavors. Nevertheless, the substantial carbon emissions associated with cement and lime manufacturing have led to a growing interest in researching environmentally friendly additives. Through standard proctor compaction tests and one-dimensional consolidation tests, this research investigates the consolidation behavior of fine-grained soil stabilized with various content of additives such as fly ash (FA), volcanic ash (VA), marble powder (MP), cement, and lime and their combination at different curing times (7, 14, 28, and 90 days). Furthermore, to evaluate the characteristics of materials, tests such as Atterberg limits, soil grain size distribution, X-ray fluorescence (XRF), scanning electron microscope (SEM), particle size analysis (PSA), and energy dispersive spectroscopy (EDS) have been performed on the selected materials. Various stabilizing agents have different effects on consolidation and compaction behavior, with maximum dry density (MDD) decreasing with higher additives content and optimum moisture content (OMC) values generally increasing, except for MP-stabilized samples. The results indicate that the addition of FA, VA, MP, cement, and lime results in compressibility reductions. By raising the proportion of FA, VA, and MP additives to 20% and extending the duration of curing to 90 days, the compression index (Cc) coefficients decreased by 63%, 42%, and 54%, while the swelling index (Cs) coefficients decreased by 89%, 90%, and 81%, respectively. Since the samples enhanced with cement and lime showed superior performance, this study explored substituting a proportion of the cement or lime with FA, VA, and MP, as well as the simultaneous effect of 2 additives. Substituting cement with MP produces better consolidation outcomes compared to VA and FA in cement-stabilized samples. Furthermore, replacing lime in VA-stabilized samples has shown significantly better results than using cement or MP instead.

Similar content being viewed by others

Introduction

Clayey soils often present geotechnical problems, including excessive settlements, swelling, and dispersivity, which can pose significant challenges. The high cost and impracticality of replacing these soils in construction sites make it essential to improve their properties instead1. Soil improvement and stabilization is a valuable and cost-efficient approach to promote the sustainability of roads2. According to Sabzi3, the utilization of soil stabilization methods helps protect and maintain soil quality in areas where the subsoils have inadequate engineering properties. Chemical stabilization is a frequently utilized method for enhancing soil quality and performance. Cementitious materials like cement and lime have been extensively used for the chemical improvement of soils. Unconfined compressive strength (UCS) tests measure the strength of soil samples, while consolidation tests provide an indication of their stiffness. Uddin et al.4 studied the effect of cement treatment on the consolidation characteristics of soft clays. Adding 15% cement leads to the highest coefficient of consolidation (Cv) and the best results for the compression index (Cc). A notable drawback of Portland cement is its manufacturing process, which releases a substantial amount of carbon dioxide (CO2), resulting in significant environmental pollution and depletion of natural resources5. Therefore, researchers have shifted their focus toward the utilization of environmentally friendly materials such as fly ash6, volcanic ash7, marble powder8, and waste glass powder9. Using these additives presents numerous benefits due to their affordability, local availability, and eco-friendly nature10. The utilization of these materials, either individually or in combination, has a significant impact on enhancing the properties of fine-grained soil.

Waste marble powder (MP) generated from industrial processes results in various issues, including environmental contamination and limited storage space availability. The long-term solution lies in finding ways to recycle MP. It is commonly utilized in areas such as brick production11, building material development12, ceramic manufacturing13, and infiltration processes14. Finding new ways to use waste marble dust can help protect the environment and reduce storage costs15. One such recycling method involves the incorporation of MP in soil stabilization, providing an alternative way to utilize and reduce waste marble powder16,17. Also, by-products of coal-fired furnaces, known as fly ashes (FA), and ashes produced from volcanic eruptions, referred to as volcanic ashes (VA), have been identified as suitable alternatives to cement/lime. These materials have demonstrated their effectiveness as soil stabilizers, offering viable solutions for soil stabilization18.

Many studies have been conducted on the application of green materials in soil stabilization19,20,21,22. In the study conducted by Sayyah et al.7, the researchers examined the influence of VA as an additive material, at varying concentrations of up to 20%, on the behavior of clayey soil. The inclusion of VA has a more significant impact on reducing the recompression index (Cr) compared to the Cc. The swelling index (Cs) is minimally affected by the addition of VA. The impact of additional VA on consolidation parameters is negligible in the short term (up to 28 days) but becomes more significant in the long term. Hossain et al.2 and Hossain and Mol23 employed VA as a stabilization method for clayey soils. To assess the long-lasting performance of the stabilized soil, they examined the effects of soaking on its strength, ability to absorb water, and tendency to shrink during drying. The results demonstrated that incorporating a substantial proportion of VA (up to 20%) had a more pronounced influence compared to using a combination of cement and VA. Cheng et al.24 investigated the properties of stabilized expansive soil with various percentages of VA, lime, and their combination. The findings indicated that VA reduced the swell percentage from 15.8% to 7.8% and 7.3% with the additions of 15% and 20%, respectively. The addition of 3% lime reduced the swelling percentage of the VA-stabilized expansive soil from 7.8% and 7.3% to 2.3% and 2.0% when 15% and 20% VA was added, respectively. They explained that the stimulation of alkali and the presence of Ca(OH)2 in lime triggered the pozzolanic reaction between soil and the combination of stabilizers.

Okoro et al.25 explored the consolidation characteristics of soils stabilized with fly ash and plastic waste. The findings indicated that the incorporation of FA and plastic waste in soil stabilization led to a reduction in soil compressibility. Furthermore, the application of FA and plastic waste stabilization resulted in decreased values of both the Cc and Cs. Mir and Sridharan26 also examined the impact of adding extra fly ashes on the compressibility index of clayey soil mixtures. In the long-term scenario, it was determined that the optimal percentage of additional fly ash for improving compressibility properties was approximately 20%. Suneel et al.27 examined the long-term behavior of consolidation and strength in soft marine clay, with a focus on the use of 0%, 5%, 10%, 20%, and 25% fly ash as an additive to enhance its properties. The inclusion of fly ash led to a reduction in both the Cc and secondary compression index values. Additionally, there was a decrease in the Cv as the percentage of fly ash increased.

Sivrikaya et al.15 studied the effect of adding waste MP with fine-grained soils. As the content of waste MP increased, the values of Cc and Cs decreased. Soil samples that were stabilized with waste MP exhibited a more notable improvement in their ability to resist swelling under compression. In Oncu and Bilsel’s28 study, tests were performed on mixtures of expansive soil and sand, with varying amounts (5%, 10%, and 20%) of waste marble added. The study revealed that the optimal proportions for minimizing swell-shrink potential and Cc were determined to be 10% marble powder, based on the dry mass of the mixture. In recent years, various studies have explored the potential of using FA, VA, and MP in soil stabilization29,30,31,32.

In recent years, many studies have focused on the combination of environmentally friendly additives (like FA, VA, and MP) with cement or lime24. Salimi et al.33 examined the potential of VA to improve the properties of cement-stabilized clay soil. The UCS and CBR values increased almost twice as much in samples with the optimal 6% cement and 15% VA mixture compared to samples with 6% cement alone after 28 days. Furthermore, VA additions to the cement-soil mixtures increased the samples’ durability. Nguyen and Phan34 investigated the engineering properties of soil stabilized with cement and FA for sustainable road construction. The optimal mixture, containing 8% cement and 2% FA, provided superior UCS and elastic modulus values compared to a mixture containing 10% cement, while also being more economical. The use of cement and MP to improve clayey soils was the subject of a study by Hammad et al.35. A series of cement-MP mixtures, with cement/MP ratios of 100/0, 90/10, 70/30, 50/50, 30/70, and 0/100, were employed as the binder. A UCS of 5.26 MPa was obtained for the clayey soil when mixed with a binder consisting of 70% cement and 30% MP, representing the highest value achieved. Boukhatem et al.36 assessed the efficacy of the combination of lime and MP in improving the properties of clayey soils. The most effective soil stabilizer was found to be a blend of 6% MP and 3% lime, significantly improving soil strength.

According to existing literature, most studies have focused on single additive soil stabilization, while the impact of adding two stabilizers simultaneously on the consolidation behavior of fine-grained soils is not well investigated. FA, VA, and MP, unlike industrial materials like cement and lime, lack the necessary activity and reactivity due to their different processing methods. FA and VA are primarily composed of SiO2, with minimal CaO, while MP exhibits an opposite trend, boasting high CaO content and low SiO2. Therefore, these sustainable materials, rich in Si and Ca, require assistance to form strong bonds. This assistance can be achieved using the geopolymer process for FA and VA, employing artificial heating, or through a simpler approach of combining with cement and lime. Cement, while individually active and containing both silica (SiO2) and calcium oxide (CaO), is an excellent stabilizing material, but its use raises significant environmental concerns. The combination approach will a) reduce environmental concerns associated with using high contents of cement or lime, b) activate FA, VA, or MP to form strong bonds by combining with cement or lime, and c) prevent using high contents of FA, VA, or MP to achieve significant stabilization (because of practical challenges). Consolidation characteristics of the stabilized clay are vital issues for pavement construction. This research aims to fill existing gaps in understanding and comparison of the consolidation behavior of stabilized soil mixtures made with varying proportions of additives such as cement, lime, FA, VA, and MP and their combinations at different curing durations. Furthermore, the consolidation characteristics, including the Cc, Cs, and Cr under saturated conditions, are evaluated for different curing times.

Materials

The research incorporates several materials that will be described below, including fine-grained soil, volcanic ash, fly ash, cement, lime, and marble powder.

Fine-grained soil

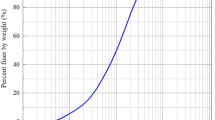

The research utilized soil was obtained from the center of Mashhad city, Iran. To determine the characteristics and classification of the soil, various tests were conducted, including sieve analysis tests based on ASTM D691337, hydrometry according to ASTM D792838, and Atterberg limits following ASTM D431839. Based on the results, the soil sample consisted of approximately 4.5% sand, 16.5% gravel, and 79% fine grains. Additionally, the soil had a plasticity index (PI) of around 5% and a liquid limit (LL) of about 26%. By analyzing the particle size distribution and plasticity properties, the soil was classified as belonging to the clay and silt category (CL-ML) according to the Unified Soil Classification System (USCS)40 specified, as illustrated in Fig. 1 of the chosen soil grain size distribution curve.

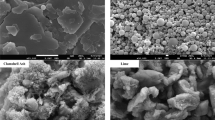

To accurately determine the compounds that make up the materials as well as to image the structure of the materials, energy dispersive spectroscopy (EDS) and scanning electron microscope (SEM) tests were performed on selected samples of the materials in the central laboratory of Ferdowsi University. The soil sample utilized in the study was imaged using the SEM method at varying magnifications, and pictures of the sample are displayed in Fig. 2. The figures reveal that the soil particles employed in the research have uneven polygonal surfaces.

Table 1 illustrates the report of the EDS spectrum produced from the soil sample depicted in Fig. 3, along with the average percentage of its constituent elements. The EDS analysis was conducted on two different points of the soil sample. As indicated in the table, a considerable portion of the soil comprises SiO2 and aluminum oxide (Al2O3).

Additives

Figure 4 illustrates all the materials utilized in this study. To facilitate a comparison of the particle sizes of the additive materials, the grain size distribution curve resulting from particle size analysis (PSA) on all of the additive materials has been shown in Fig. 5. The figure demonstrates that the soil stabilizers employed possess smaller particle sizes compared to cement, while the fly ash utilized in the study exhibits smaller particle sizes than all other additive materials. Consequently, the particle size of all stabilizing materials was deemed appropriate.

To analyze the chemical composition of both clayey soil and additives, X-ray fluorescence (XRF) spectrometry was utilized. The results, shown in Table 2, revealed that SiO2, CaO, and Al2O3 were the dominant oxides in the clayey soil, comprising 47.9%, 12.41%, and 11.01% respectively.

A sample of the materials used in the research was imaged using the SEM method at different magnifications and the sample images are shown in Fig. 6. The pictures show the shape of the particle surfaces.

Table 3 presents the EDS spectrum report of the materials sample depicted in Fig. 7, along with the average proportion of its elemental components. The process of EDS analysis involved conducting measurements at multiple points across the samples to ensure comprehensive evaluation.

Volcanic ashes possess cementitious properties that enable their application as a soil stabilizer. The volcanic ash was obtained from the Chekneh mine, located in Neishabur City, Iran. Furthermore, the widespread abundance and accessibility of fly ash on a global scale present an opportunity to effectively utilize this coal combustion by-product to improve the performance of soil. The fly ash was obtained from Isfahan City, Iran. Based on Table 2, the fly ash displayed a significantly higher SiO2 content (83.63%) compared to the clayey soil but contained a negligible amount of calcium oxide. Based on the chemical analysis, the fly ash used in this study falls under the class-F category according to the ASTM C618 standard41. This classification is due to its low CaO content (0.92%), which is below 6%, and its high combined content of SiO2, Al2O3, and Fe2O3, exceeding 70%.

Waste marble dust finds application in various contexts and serves as a reinforcement or raw material. The marble powder is sourced from Behboodi stonecutting, Shandiz City, Iran. The cement used in this study is Type I Portland cement. Soil cement stabilization refers to the process of soil particles bonding together through the hydration of cement particles, leading to the formation of interlocking crystals. Lime offers a cost-effective approach to soil stabilization42. The lime used in this study is of the type of hydrated lime. The marble powder and lime were primarily composed of CaO, while Type I Portland cement contained a significant amount of both SiO2 and CaO. Table 3 demonstrates similar results for the elements and chemical compositions of studied materials.

Experimental program

Standard proctor compaction test

To determine the soil compaction characteristics, including parameters such as dry specific gravity, maximum dry unit weight (γdmax), and optimum moisture content (ωopt), the compaction test was conducted using the standard Proctor method according to ASTM D698 guidelines43. These tests were performed on the manufactured soil samples. Initially, the compaction test was conducted on the untreated soil sample to determine the existing soil compaction parameters. Subsequently, various additives were introduced to the soil at different stages and in varying quantities. The samples comprising the soil-stabilizer mixture underwent the standard Proctor compaction test. By performing these tests on the manufactured samples, it became possible to ascertain the compaction parameters for each sample. This facilitated the examination of how different types and amounts of additives influenced the soil’s compaction behavior. Additionally, the compaction parameters obtained for each sample were utilized to create specimens for consolidation tests. Table 4 presents the program of compaction tests conducted in this study.

One-dimensional consolidation test

The produced samples underwent the one-dimensional soil consolidation test according to ASTM D243544. The purpose was to obtain the stress-porosity ratio diagram and determine the soil consolidation parameters, which included the Cc, Cs, and Cr. As a preparatory step for the experiments, the clayey soil was subjected to an oven-drying process at 105 °C for 48 h to eliminate any residual moisture. Specimens with dimensions of approximately 74 mm diameter and 20 mm height were prepared and underwent curing for different periods. Specimens were cured in a controlled environment with a relative humidity of 80% ± 2% and a temperature of 25 °C ± 2 °C. To ensure the saturation of the sample, a preliminary investigation was conducted on some treated and untreated test samples before commencing the main tests. After 24, 48, 72, and 96 h of saturation process, the degree of saturation of the test samples was measured. It was observed that there was a slight difference between the measurements taken at 72 h and those taken at 96 h, and the test samples were almost saturated. As a result, samples were subjected to flooding with a saturation time of 72 h. It was determined that the submerged samples achieved complete saturation after 72 h. Figure 8 depicts the process of manufacturing the samples and the equipment employed for the consolidation test.

The consolidation tests conducted in this research followed the schedule outlined below. Following the specifications outlined in Table 5, different chemical and pozzolanic additives were individually introduced to the soil at various percentages, and consolidation tests were then conducted on the samples. The reason for choosing the unsaturated curing condition was due to the attempt to replicate real-world conditions. Due to the fine-grained nature of the soil, it is practically impossible to keep it saturated during curing time. Moreover, to examine the consolidation behavior under the worst conditions in terms of hardness, the sample was loaded in saturated conditions.

In this study, the program of consolidation tests incorporated high percentages of additives (i.e., up to 20%) which has potential practical challenges in field applications. These challenges primarily involve the cost and logistical complexities related to the sourcing, transport, and mixing of large additive volumes. Ensuring uniform consistency across extensive material quantities is also problematic. Furthermore, increased viscosity and modified rheological properties can complicate the compaction processes, often necessitating specialized equipment or techniques. Environmental and regulatory considerations concerning the high usage of cement or lime may affect project feasibility and compliance, requiring thorough planning and management strategies. Consequently, this study proposes a straightforward approach to integrating FA, VA, and MP with cement or lime, aiming to achieve significant stabilization without high percentages of FA, VA, and MP, thereby reducing cement and lime content to address environmental concerns.

Samples were created by combining two different additives as specified in Table 6. These samples were processed under unsaturated conditions and subjected to three days of saturation with swelling control. Following this, the samples were loaded under saturated conditions. As mentioned in the introduction section, FA, VA, and MP are environmentally friendly and cost-effective materials, but they have limited reactivity and bonding capabilities when used individually. Besides, FA and VA dominated by SiO2 and low in CaO, contrasts significantly with MP, which has a high CaO content and low SiO2 content. Therefore, the consolidation test program explored two types of additive combinations: (1) a silica-rich material with a calcium-rich material, and (2) a low-activity, environmentally friendly material with a high-activity material. The combination of cement and lime was excluded as they are both destructive to the environment. Furthermore, the combination of FA and VA was not considered due to their insufficient CaO content and limited activity. Additionally, because employing VA alone yielded the worst results between individually treated samples in this study and due to the availability of VA mines in different regions of Iran, a combination of 50% lime, cement, or MP was utilized to activate VA.

Microstructural analysis

Further investigations were performed to thoroughly understand the microstructural and morphological properties of the samples made with a combination of two additives. SEM imaging allows for the detailed analysis of sample microstructure by revealing its microscopic morphology. In addition to morphological analysis by SEM, the results of EDS analysis provide a quantitative assessment of the elemental composition of the samples. A gold–palladium coating was applied to the cubic samples, extracted from the center of stabilized samples, using an SC720 model machine for 180 s. The samples underwent SEM imaging with a LEO1450VP model (made in Germany) that provided 2.5 nm resolution and a maximum voltage of 35 kV. Images were produced at magnifications of 1000× and 2000×. The samples, mounted on a specialized stub with adhesive, were imaged at various magnifications under a 20 kV voltage after proper coating.

Results and discussion

Effect of additives on OMC and MDD

The compaction tests summarized in Table 4 result in the variation of dry density with the moisture content for clayey soil and different FA, VA, MP, cement, and lime percentages. Optimum Moisture Content (OMC) and Maximum Dry Density (MDD) values of 14.1% and 18.6 kN/m3 were obtained for the clayey soil, respectively. Figure 9 illustrates the variation of MDD and OMC with different stabilizer contents. As the percentage of additives increases, a slight decrease in MDD can be noticed. By increasing the percentage of additives to 20%, it is possible to see a decrease in MDD amount to approximately 2%, 6%, 2%, 3%, and 9% respectively in the samples containing FA, VA, MP, cement, and lime. This pattern may be explained by the specific gravity of additives and the particle size distribution of the mixture, as noted by Hossain and Mol23 and Sayyah et al.7. Conversely, the trend of OMC values increases with the rise in additive quantities, except for samples that include MP. Adding additives to the soil causes the particles to aggregate. This aggregation increases the void spaces between the granules, necessitating more water to fill them. Moreover, the additives (except MP) absorb more water than soil, leading to an increased moisture absorption tendency. Cement and lime absorb more water than VA, FA, and MP due to their high activity. Turan et al.45,46 also reported that as the percentage of FA increased, the MDD of the mixture decreased, while the OMC rose.

One-dimensional consolidation test results

Consolidation behavior of untreated soil

Figure 10 illustrates the outcome of the one-dimensional consolidation test conducted on untreated soil in saturated conditions. The compression index reflects the soil’s capacity to settle when subjected to external loads and the swelling coefficient indicates the soil’s ability to expand for the initial loading path. The recompression coefficient plays a crucial role in determining the behavior of soil under loading and unloading conditions. It represents the rate at which the soil recompresses when the load is removed. In this study, the untreated soil’s compression, swelling, and recompression indices are measured at 0.182, 0.031, and 0.020, respectively. It is important to mention that all the tests were performed at a relative standard proctor compaction (RC) of 90%.

Effect of fly ash (FA)

Based on Table 5, specimens containing varying weight proportions of fly ash at 5%, 10%, 15%, and 20% were tested at curing durations of 7, 14, 28, and 90 days. Supplementary Fig. S1 online displays the consolidation curves of soil specimens enhanced using varying quantities of FA. Comparing the porosity graphs under different stress levels for untreated soil samples and soil treated with FA shows that the addition of FA decreases settlement (compressibility). This is due to: (1) cementing bonds that were developed due to FA stabilization and (2) fine clay particles that were replaced with nonplastic fines25. The degree of reduction, however, depends on the stabilizer content and curing duration. For example, the porosity ratio for the sample treated with 5% FA was 0.553 at the stress level of 1 kg/cm2 and 0.43 at the stress level of 8 kg/cm2 after 7 days of curing, while the corresponding values for the untreated sample were 0.499 and 0.403, respectively. This indicates a reduction in compressibility of approximately 7%. Extending the curing time of treated samples leads to a decrease in compressibility. This decrease is particularly notable in samples with 90 days of curing time. For instance, the porosity ratio of the sample treated with 15% FA after 90 days of curing at the stress level of 8 kg/cm2 was 0.502, while the corresponding value for the sample treated with 15% FA after 7 days was 0.450. This indicates an approximately 11% reduction in compressibility with higher curing duration.

Figure 11 illustrates the variation of consolidation coefficients with the FA percentage at different curing times measured from conventional consolidation curves (Supplementary Fig. S1 online). The addition of fly ash to the soil has resulted in a notable decrease in Cs and Cc similar to the results of Mir and Sridharan26. For instance, the Cs and Cc values for the sample treated with 20% FA after 90 days of curing were 0.003 and 0.067, respectively, whereas these values were 0.031 and 0.182 for the untreated sample, indicating a significant reduction in the treated sample. Suneel et al.27 and Noaman et al.47 also reported that FA was very effective in reducing compressibility. Increasing the FA content and curing time continuously reduces the Cs and Cc. Moreover, in a specific proportion of FA, the values of Cc and Cs exhibit a notable decline as the curing time increases. Similarly, Turan et al.45,46 stated that class F fly ash reduced both Cc and Cs coefficients compared to untreated soil, and this effect was enhanced with longer curing times.

This impact was almost negligible for Cr. This behavior is attributed to the breakage of particle bonds due to increased pressure. When these particle bonds are broken, all Cr values are similar to each other and to those of the untreated soil. This pattern is also observed with other additives. As a result, the Cr has not been explored in this study.

Effect of volcanic ash (VA)

According to Table 5, samples with varying percentages of volcanic ash (5%, 10%, 15%, and 20%) were examined at curing durations of 7, 14, 28, and 90 days. Supplementary Fig. S2 online depicts the consolidation behavior of soil samples treated with different amounts of VA similar to the results of Sayyah et al.7. Through analyzing the porosity trends in relation to the stress levels of unmodified soil samples and soil treated with VA, it is evident that the addition of VA results in a reduction in compressibility. For instance, when comparing the porosity ratios of soil samples enhanced with 5% VA after 7 days versus unmodified samples at the stress levels of 1 and 8 kg/cm2, the improved sample exhibited porosity ratio of 0.587 and 0.44, respectively, while the unmodified sample showed ratios of 0.542 and 0.403, respectively. This difference highlights an approximate 8% decrease in compressibility due to the incorporation of VA into the soil. The level of compressibility diminishes with an increase in the curing duration of treated samples. This decrease is particularly notable after 90 days, where the duration of curing played a significant role, especially in cases of higher VA content like samples containing 20% VA. As an example, consider the porosity ratios of the sample enhanced with 20% pozzolan after 90 days of curing at stresses 1 and 8 kg/cm2, which were recorded as 0.579 and 0.491, respectively. The comparison with the unmodified sample results highlights an approximate 18% reduction in compressibility due to the extended curing period for samples with higher VA content. It is evident that in samples with higher additive content (e.g., 20%), the impact of longer curing time on reducing compressibility becomes more pronounced. The results align with the results of Hossain et al.2, Hossain and Mol23, and Cheng et al.24 studies and exhibit similar percentages of reduction by adding VA to clayey soil.

Figure 12 demonstrates how the consolidation coefficients change with different percentages of VA at varying curing durations. As the proportion of VA rises, there is a consistent reduction in the coefficients of Cc and Cs. The value of Cs of the improved sample with 20% VA at the curing age of 90 days was 0.003, but this value for the untreated sample was 0.031, which indicates about 90% reduction in the improved sample. The samples tested at 90 days demonstrate lower compressibility and consolidation coefficients, indicating that as curing time increases, the improved sample will experience less settlement. Sayyah et al.7 also noted that VA significantly strengthens the soil’s stiffness characteristics. In their study, the inclusion of VA decreased both Cc and Cs coefficients.

Effect of marble powder (MP)

Supplementary Fig. S3 online presents the consolidation curves at the log scale (e–log σ′) for the samples with different amounts of MP (5%, 10%, 15%, and 20%) at different curing durations (7, 14, 28, and 90 days). It can be seen that the compressibility decreased with the increasing MP content and curing duration. For example, when comparing the porosity ratios of soil samples treated with 5% MP after 7 days with untreated samples under stress levels of 1 and 8 kg/cm2, the treated sample showed porosity ratios of 0.54 and 0.426, respectively, while the untreated sample displayed ratios of 0.499 and 0.403, respectively. This discrepancy indicates an approximate 7% decrease in compressibility resulting from the addition of MP to the soil. This reduction becomes more pronounced after 90 days, where the curing duration becomes particularly significant. For instance, the porosity ratio of the sample treated with 10% MP after 90 days of curing at the stress level of 8 kg/cm2 was 0.479, while the corresponding value for the sample treated with 15% FA after 7 days was 0.439. A comparison with the untreated sample data reveals an approximate 9% decrease in compressibility attributed to the longer curing period. This reduction demonstrated a continuous tendency, suggesting that the stiffness of the MP-stabilized samples increased as a result of the pozzolanic reaction occurring throughout the stabilization process. Similar results have been observed in Agrawal and Gupta48, Abdulla and Majeed49, and Saygili50 studies.

With the increase of MP percentage and curing time, the Cc and Cs values continuously decrease, as illustrated in Fig. 13. At 90 days of curing time, according to Fig. 13a, the Cc values for samples containing 5%, 10%, 15%, and 20% MP are 0.128, 0.104, 0.097, and 0.084, respectively, while the value of Cc for the untreated sample is equal to 0.182. Based on Fig. 13b, the Cs values decreased from 0.031 (for the unmodified sample) to 0.0078, 0.0079, 0.0066, and 0.0058 for samples with 5%, 10%, 15%, and 20% MP after 90 days, respectively, showing up to 82% reduction in Cs values. Jalal et al.51 revealed that adding marble dust to soil significantly reduced the compression index. Jain et al.52 also reported that the addition of marble dust typically raises the alkalinity of the soil. Similar findings can be found in studies conducted by Zorluer and Muratoglu53, Oncu and Bilsel28, and Abdelkader et al.54.

Effect of cement (C) and lime (L)

As shown in Table 5, specimens with different proportions of cement and lime were tested after curing for 7 and 28 days. Supplementary Fig. S4 online illustrates the consolidation characteristics of soil samples that have been treated with varying quantities of cement or lime. By comparing the porosity curves of untreated soil samples with those treated with cement or lime, it becomes evident that both cement and lime additives lead to a substantial decrease in the compressibility of the soil. The enhanced impact of cement on soil consolidation behavior can be attributed to the rise of calcium silicate hydrate (CSH) gels that are produced during hydration19. For instance, the porosity ratios of the sample treated with 5% cement and 5% lime after 7 days under stresses 1 and 8 kg/cm2 were 0.587 and 0.544, and 0.587 and 0.520, respectively. In contrast, the untreated sample had porosity ratios of 0.542 and 0.403, showing a significant reduction in compressibility for the cement and lime-treated samples, respectively, even under high stresses. This is consistent with Huey and Eng55’s results. Zidan56 demonstrated that cement stabilization significantly enhanced the consolidation characteristics and compressibility of the soil.

Figures 14 and Fig. 15 indicate the results of consolidation coefficients measured by the e–log σ'v compression curves for different percentages of cement and lime, respectively, used as the stabilization agent. Adding higher amounts of cement and lime to the untreated soil and longer curing time causes a decrease in Cc and Cs. According to the results in Fig. 15a, with the application of 15% lime after 28 days, the compression index shows an 84% reduction compared to the untreated sample. In addition, with the use of 15% cement as a stabilizer additive, the compression index is reduced to 0.0235, which means an 88% decrease in this coefficient for the clayey soil. Based on Fig. 14b and Fig. 15b, both cement and lime additions to the soil have demonstrated a significant impact on reducing Cs. For instance, the Cs value for the sample treated with 5% cement after 28 days was 0.004, while for the sample treated with 5% lime, the Cs value was 0.0035. In comparison, the untreated sample had a Cs value of 0.031. This indicates a reduction of about 87% and 89% in Cs for the cement and lime-treated samples, respectively, compared to the untreated sample. Uddin et al.4 and Zidan56 studies show similar results about the influence of adding cement to soft clay. They revealed that adding 15% cement leads to the lowest values of Cc and Cs. The significant decrease in compression index can be attributed to the pozzolanic reaction between lime and the clay fraction of the soil sample, resulting in the formation of CSH and calcium aluminate hydrates (CAH) cementing gels that provide resistance against external loads19.

Comparing the effect of different stabilizing additives

The initial void ratio for all samples is roughly between 0.58 and 0.6. However, how the void ratio changes with stress varies based on the type of additive (leading to different soil fabrics or structures), the percentage of the additive, and the curing time. The change in void ratio from the initial level to under stress of 8 kg/cm2 was approximately 0.138, 0.160, 0.139, 0.020, and 0.053 for 7-day samples containing 15% FA, VA, MP, cement, or lime, respectively. The changes in void ratios are significantly smaller in samples stabilized with cement or lime compared to those stabilized with FA, VA, or MP. This is due to the fact that samples stabilized with cement or lime possess a dense structure with robust bonds between particles formed by CSH or CAH gels, resulting in fewer pores. Additionally, cement typically creates an even denser and stronger structure than lime. However, samples stabilized with only FA, VA, or MP exhibit a looser gel formation and significantly more pores in their structure compared to those stabilized with cement or lime, resulting in more substantial changes in void ratio when subjected to stress. The results clearly indicate that samples stabilized with FA or MP experience smaller changes in void ratio compared to those stabilized with VA, as VA has a less pronounced ability to create strong bonds between particles because of its compounds and low activity.

Compared to other studied additives, cement exhibited the highest efficiency in reducing consolidation coefficients due to its superior activity, reactivity, and rich SiO2 and CaO composition. Conversely, VA had the worst performance among the additives (especially in Cs coefficient), which is due to its low activity, lack of CaO, and low percentage of SiO2 compared to FA. After 90 days of curing, the soil treated with 20% FA, VA, and MP showed significant reductions in Cc values, reaching 0.068, 0.105, and 0.084, respectively, compared to the untreated sample’s Cc value of 0.182. While all three additives improved outcomes, FA was superior to MP, and MP was superior to VA, especially when using higher percentages. After 28 days of curing, the addition of up to 15% cement or lime to untreated soil significantly reduces the consolidation coefficient, reaching a reduction of up to 88% and resulting in Cc values of 0.023 and 0.028, respectively. Samples stabilized with VA or lime show the most significant changes in response to variations in curing time. Cement and lime have emerged as the top performers among the additives, but their environmental concerns motivate us to investigate alternatives. The following section focuses on using FA, VA, and MP as partial substitutes.

Effect of combination of two additives on the consolidation behavior

Consolidation tests have been performed on the samples containing the combination of cement with FA, VA, or MP according to Table 6 with 7 and 28 days of curing time. Supplementary Fig. S5a and Fig. S5b online show the consolidation characteristics of soil samples treated by a combination of cement with VA and FA, respectively. The substitution of cement with MP in cement-stabilized samples leads to superior outcomes compared to the use of FA, as illustrated in Supplementary Fig. S5c online, and substituting FA produces better results than using VA. Furthermore, the reduction in compressibility increased with higher proportions of cement and MP. As stated before, increasing curing duration decreases compressibility and consolidation coefficients.

Figure 16 indicates the compression and swelling indices of samples made by incorporating cement and VA, FA, or MP with a curing duration of 7 and 28 days. The findings of this study demonstrate that utilizing cement alone yields superior outcomes compared to all other samples mixed with cement. Compression and swelling indices of the sample containing only 10% cement after 28 days were 0.0262 and 0.0037, respectively. By substituting half of the cement content with VA, FA, and MP at 5% each, the Cc values were recorded as 0.0381, 0.0348, and 0.0328, respectively, after 28 days. Also, the Cs values for VA, FA, and MP were measured as 0.0083, 0.0047, and 0.0038, respectively. As mentioned earlier, replacing MP with a portion of cement has proven to yield better results than replacing FA and VA, but its performance was weaker than that of cement alone. The variation in Cc and Cs coefficients between the sample containing 10% cement and the sample where 5% cement was substituted with MP is 25% and 3%, respectively. This slight difference in results suggests that for creating an environmentally friendly sample, a portion of the cement can be replaced with MP, yielding nearly identical outcomes. Furthermore, when 5% cement is present, replacing 2.5% with either VA or MP leads to similar results, with MP demonstrating better replacement performance than FA and VA. Substituting a portion of cement with VA, FA, or MP yields improved outcomes compared to using VA, FA, or MP alone. For instance, S90C5VA5, S90C5FA5, and S90C5MP5 mixtures demonstrated approximately 70.3%, 76.2%, and 74.3% lower Cc values compared to S90VA10, S90FA10, and S90MP10 mixtures after 28 days of curing, respectively. For 7-day cured mixtures, these reductions were about 65.9%, 75.3%, and 71.3%, respectively. A similar trend can be observed between the S95C2.5VA2.5, S95C2.5FA2.5, and S95C2.5MP2.5 mixtures and S95VA5, S95FA5, and S95MP5 mixtures. However, the consolidation coefficients are notably higher than when using cement alone. This observation suggests that the chemical interaction between VA and cement does not result in significantly stronger bonds. Consequently, in this study, the impact of replacing a portion of VA with lime and MP has been investigated.

The untreated soil is composed predominantly of flaky units exhibiting poor structural arrangement and loose inter-unit contacts. Particle aggregation and micropores are the primary contact mechanisms between particles57. The untreated soil sample exhibits high compressibility and consolidation coefficients, attributable to its microstructure featuring numerous particles and a high degree of void space (large voids and cracks)58. SEM images of samples containing a combination of cement with FA, VA, or MP are depicted in Fig. 17. Although 10% cement alone leads to dense and finely distributed gels, the sample stabilized with 5% cement and 5% MP (as seen in Fig. 17a) exhibits a less uniform structure with a significant number of porous areas. Consolidation test results also confirm the formation of less dense microstructures on MP-cement-stabilized samples, resulting in higher consolidation coefficients compared to cement-stabilized samples. The EDS analysis was employed to identify the compounds within the crystal structure. High calcium and silica levels at specific locations, as depicted in Fig. 18 (for the S90C5MP5 sample; spectrum 3), confirmed the presence of CSH gels. The formation of an imprecise CSH gel and a higher percentage of voids in these samples might have affected their consolidation behavior. Figure 17b and c illustrate the SEM images of S90C5FA5 and S90C5VA5 samples, respectively. Adding water to the soil–cement-FA (or VA) mixture results in the formation of clay clusters59. The samples are non-uniform, exhibiting significant porosity compared to cement-stabilized samples. In some parts, loose gel formation can be observed. The S90C5VA5 sample stands out with untreated soil particles and a significantly larger void percentage compared to the S90C5FA5 and S90C5MP5 samples. This observation aligns with the consolidation test results that the S90C5FA5 and S90C5MP5 samples yielded lower consolidation coefficients and compressibility compared to the S90C5VA5 sample. The SEM findings are consistent with those reported in prior investigations59,60,61,62.

Since using VA alone did not yield satisfactory results and due to the abundance of VA mines in different regions of Iran, a combination of 50% lime, cement, or MP was employed to activate VA in this study. Therefore, consolidation experiments were conducted on samples incorporating VA in conjunction with lime, cement, or MP as outlined in Table 5, with curing times of 7 and 28 days. Supplementary Fig. S6a and Fig. S6b online display the consolidation behavior of soil samples treated with the combination of VA and lime, and VA and MP, respectively. The compressibility of samples where a portion of the VA is substituted with lime or MP is lower compared to samples consisting solely of VA. For instance, the porosity ratio in the enhanced sample with 5% lime replacing VA after 7 days was 0.546 under stress of 8 kg/cm2. In contrast, the unaltered sample with only 10% VA had a value of 0.448 under the same stress, indicating a reduction in compressibility of about 18% at high stresses. Moreover, this reduction in compressibility increased with higher proportions of additives and higher curing duration. Therefore, utilizing lime or MP in conjunction with VA yields superior outcomes compared to using an equivalent quantity of VA alone.

Figure 19 depicts the compression and swelling indices of samples where half of the VA is replaced with lime or MP after 7 and 28 days of curing. Lime substitution has shown significantly better results when contrasted with the use of MP as a substitute. Based on Fig. 19a, instead of using 10% of VA, substituting 5% of it with lime results in a significant reduction in the Cc value for the 28-day samples. Specifically, the Cc value decreases from 0.128 to 0.033, which corresponds to a decrease of approximately 74%. Although this value is lower than the Cc of the S90C5VA5 sample, it remains higher than the corresponding values for samples with 10% cement or 10% lime. The Cs value also decreased from 0.0064 for the S90VA10 sample to 0.0038 for the S90VA5L5 sample according to Fig. 19b. The outcomes are in line with Cheng et al.24 's investigation on how VA addition reduces swelling in lime-stabilized expansive soil. The study highlighted that the interaction between the soil and stabilizers was enhanced by the presence of Ca(OH)2 in lime and the activation of alkali, resulting in decreased swelling percentages. Comparing S95VA5 and S95VA2.5L2.5 samples demonstrates similar results. The substitution of some VA with MP has led to improved outcomes, although not exceptionally remarkable. For example, in the S90VA5MP5 sample, instead of using only 10% of VA, 5% of it is replaced with MP. The results of this sample after 7 days of curing show that this replacement has reduced Cc from 0.132 to 0.128. As a result, the combination of VA and MP or the combination of VA and lime yielded superior outcomes compared to using VA alone and demonstrated weaker results compared to employing lime alone. Furthermore, using a combination of 5% MP and 5% VA leads to lower Cc values and higher Cs values compared to employing 10% MP alone.

SEM images of the S90VA10 sample, shown in Fig. 20a, reveal that fine VA grains coat the clay particles. The spots shown in the image indicate the presence of chemical bonds, which are composed of CSH and CAH, as shown in the result of EDS analysis (Fig. 21). The sample exhibits a uniform structure with minimal voids, but the bonds holding it together are weak. The S90VA5L5 sample, which demonstrated satisfactory results in the consolidation test, exhibits a dense and uniform structure with strong connections between the clay particles (Fig. 20b). The interaction between lime and VA triggers alkali activation, producing Ca(OH)2 and CAH gels that thoroughly encapsulate and firmly adhere to the soil particles24. The S90VA5MP5 sample, depicted in Fig. 20c, exhibits enhanced bonding compared to the S90VA10 sample due to the presence of abundant SiO2 in VA and CaO in MP. The microstructural results are consistent with consolidation test results. The S90VA5L5 sample which demonstrated lower compressibility and Cc values compared to S90VA10 and S90VA5MP5 samples, has a dense and uniform structure with strong connections. The microstructure of S90VA10 and S90VA5MP5 samples are approximately the same, resulting in similar consolidation results. The SEM results align with previous studies7,24.

Conclusion

In this paper, a comprehensive study on the influence of adding different stabilizers such as fly ash, volcanic ash, marble powder, cement, and lime with various percentages (i.e. 5, 10, 15, and 20%) and their combination on consolidation behavior of clayey soil has been investigated. Unlike industrial materials like cement and lime, FA, VA, and MP lack sufficient activity and reactivity. While FA and VA are primarily silica-rich, MP is calcium oxide-rich. Therefore, these sustainable materials require additional processes, such as geopolymerization or combining with cement and lime, to facilitate strong bond formation. While cement and lime proved most effective, their environmental impact raises concerns. Standard proctor compaction tests were carried out to study the OMC and MDD of differently treated soil samples, SEM and EDS tests were carried out to analyze the microstructure characteristics of the soil and additives, and one-dimensional consolidation tests were conducted on different stabilized samples during curing periods varying from 7 to 90 days to achieve consolidation coefficients. The main conclusions are as follows:

-

1.

The influence of different types and contents of stabilizing agents on the consolidation and compaction behavior is quite different. Increasing the additive content to 20% results in a slight reduction of the MDD by around 2%, 6%, 2%, 3%, and 9% in the samples that include FA, VA, MP, cement, and lime, respectively. On the other hand, the pattern of OMC values rises with the increase in additive amounts, except for the samples incorporating MP.

-

2.

Incorporating all the additives has resulted in a reduction in compressibility. Additionally, all consolidation coefficients decreased in comparison to the untreated soil. For example, in the case of the sample treated with 20% FA, VA, and MP after 90 days of curing, the Cc values were 0.068, 0.105, and 0.084, respectively. In contrast, the Cc value for the untreated sample was 0.182. Moreover, adding up to 15% cement and lime to untreated samples after 28 days of curing decreases the Cc values to 0.023 and 0.028, respectively, which shows a reduction of up to 88%. The Cs values displayed comparable variations and trends as a result of incorporating these additives.

-

3.

Concerning the curing periods, for a constant percentage of different additives, changes in consolidation coefficients become more considerable at long-term (i.e. 90 days) compared to short-term curing conditions (7 days). Additionally, an increasing amount of additives leads to a greater reduction in compressibility. VA and lime-stabilized samples are the most affected mixtures by changes in curing time.

-

4.

Minimal impact on Cr is due to particle bond breakage under increased pressure, resulting in consistent values that are equal to those of untreated soil samples. This pattern is observed for all additives, leading to no exploration of Cr in this study.

-

5.

Substituting a portion of the cement in cement-stabilized samples demonstrates that better results are achieved by replacing some cement with MP compared to FA, and substituting FA performs better than VA. The sample with 10% cement had Cc and Cs of 0.0262 and 0.0037, respectively, after 28 days. When half of the cement was replaced with 5% MP, the Cc and Cs values were 0.0328 and 0.0038 after 28 days. Additionally, the decrease in compressibility became more pronounced with higher amounts of cement and MP.

-

6.

As VA alone did not achieve the desired results, a mixture of 50% lime or MP was used to activate VA in this study. The compressibility of samples in which some of the VA is replaced with lime or MP is lower than that of samples containing only VA. Replacing lime has demonstrated significantly superior outcomes compared to using MP as an alternative. For instance, by replacing 5% of VA with lime instead of using 10% VA alone, the Cc value decreases from 0.128 to 0.033, representing a reduction of around 74%. The lime and VA combination has proven to be more effective than using cement with VA.

-

7.

The findings from SEM and EDS analysis align with the results obtained from consolidation tests. Denser samples with lower void percentages, evident in their homogeneous structure and strong gel formation seen in the SEM and EDS tests, exhibited lower consolidation coefficients in consolidation tests.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Hadi Sahlabadi, S., Bayat, M., Mousivand, M. & Saadat, M. Freeze–thaw durability of cement-stabilized soil reinforced with polypropylene/basalt fibers. J. Mater. Civ. Eng. 33(9), 04021232 (2021).

Hossain, K., Lachemi, M. & Easa, S. Stabilized soils for construction applications incorporating natural resources of Papua New Guinea. Resour. Conserv. Recycl. 51(4), 711–731 (2007).

Sabzi, Z. Environmental friendly soil stabilization materials available in Iran. J. Environ. Friendly Mater. 2(1), 33–39 (2018).

Uddin, K., Balasubramaniam, A. & Bergado, D. Engineering behavior of cement-treated Bangkok soft clay. Geotech. Eng. 28, 89–119 (1997).

Pournoori, P. et al. Experimental exploration of fracture behavior (pure mode III) in eco-friendly steel fiber-reinforced self-compacting concrete with waste tempered glass as coarse aggregates. Sci. Rep. 14(1), 9043 (2024).

Tejasvi, A. & Kumar, S. Impact of fly ash on soil properties. Natl. Acad. Sci. Lett. 35, 13–16 (2012).

Sayyah, M. A., Abrishami, S., Dastpak, P. & Dias, D. Behavior of volcanic ash–soil mixtures under one-dimensional compression testing. Sci. Rep. 12(1), 14524 (2022).

Umar, I. H., Lin, H. & Ibrahim, A. S. Laboratory testing and analysis of clay soil stabilization using waste marble powder. Appl. Sci. 13(16), 9274 (2023).

Baradaran, M. S., Qazanfari, R. & Baradaran, S. Study of soil reinforcement in the east of Mashhad using glass granule. Mater. Res. Express 10(5), 055202 (2023).

Rahgozar, M. A., Saberian, M. & Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transport. Geotech. 14, 52–60 (2018).

Saboya, F. Jr., Xavier, G. & Alexandre, J. The use of the powder marble by-product to enhance the properties of brick ceramic. Constr. Build. Mater. 21(10), 1950–1960 (2007).

Sarkar, R., Das, S. K., Mandal, P. K. & Maiti, H. S. Phase and microstructure evolution during hydrothermal solidification of clay–quartz mixture with marble dust source of reactive lime. J. Eur. Ceram. Soc. 26(3), 297–304 (2006).

Acchar, W., Vieira, F. & Hotza, D. Effect of marble and granite sludge in clay materials. Mater. Sci. Eng. A 419(1–2), 306–309 (2006).

Davini, P. Investigation into the desulphurization properties of by-products of the manufacture of white marbles of Northern Tuscany. Fuel 79(11), 1363–1369 (2000).

Sivrikaya, O., Uysal, F., Yorulmaz, A. & Aydin, K. The efficiency of waste marble powder in the stabilization of fine-grained soils in terms of volume changes. Arabi. J. Sci. Eng. 45, 8561–8576 (2020).

Jassim, N. W., Hassan, H. A., Mohammed, H. A. & Fattah, M. Y. Utilization of waste marble powder as sustainable stabilization materials for subgrade layer. Results Eng. 14, 100436 (2022).

Choksi, R., Mishra, C. & Patel, N. Pursuance of waste marble powder to improve soil stabilization. Int. Res. J. Eng. Technol. (IRJET) 5(5), 1695–1698 (2018).

Rifai, A. & Yasufuku, N. Effect of volcanic ash utilization as substitution material for soil stabilization in view point of geo-environment. In Ground Improvement and Geosynthetics 138–147 (2014).

Ouhadi, V., Yong, R., Amiri, M. & Ouhadi, M. Pozzolanic consolidation of stabilized soft clays. Appl. Clay Sci. 95, 111–118 (2014).

Phanikumar, B. Effect of lime and fly ash on swell, consolidation and shear strength characteristics of expansive clays: a comparative study. Geomech. Geoeng. Int. J. 4(2), 175–181 (2009).

Savaş, H. Consolidation and swell characteristics of dispersive soils stabilized with lime and natural zeolite. Sci. Eng. Compos. Mater. 23(6), 589–598 (2016).

Amirnia, M., Sheikhi, M., Talebi, N., Pournoori, P. & Rajaee, A. Evaluation of hardened properties of structural concrete containing waste tiles and volcanic ash. In Presented at the 5th. International Congress on Engineering, Technology & Applied Sciences, Auckland, New Zealand (2024).

Hossain, K. & Mol, L. Some engineering properties of stabilized clayey soils incorporating natural pozzolans and industrial wastes. Constr. Build. Mater. 25(8), 3495–3501 (2011).

Cheng, Y. et al. Engineering and mineralogical properties of stabilized expansive soil compositing lime and natural pozzolans. Constr. Build. Mater. 187, 1031–1038 (2018).

Okoro, C. C., Vogtman, J., Yousif, A., Agnaou, M. & Khoury, N. “Consolidation characteristics of soils stabilized with lime, coal combustion product, and plastic waste,” in Geo-Frontiers. Adv. Geotechn. Eng. 2011, 1202–1209 (2011).

Mir, B. & Sridharan, A. Volume change behavior of clayey soil–fly ash mixtures. Int. J. Geotech. Eng. 8(1), 72–83 (2014).

Suneel, M., Kwon, J., Im, J.-C. & Jeon, C. W. Long-term consolidation and strength behavior of marine clay improved with fly ash. Mar.Georesourc. Geotechnol. 28(2), 105–114 (2010).

Öncü, Ş & Bilsel, H. Utilization of waste marble to enhance volume change and strength characteristics of sand-stabilized expansive soil. Environ. Earth Sci. 77(12), 461 (2018).

Çadir, C. C. & Vekli, M. Usage of waste marble powder and pumice powder to improve the engineering properties of soft clays. Int. J. Environ. Sci. Technol. 19(7), 6481–6490 (2022).

Waheed, A., Arshid, M. U., Khalid, R. A. & Gardezi, S. S. S. Soil improvement using waste marble dust for sustainable development. Civ. Eng. J. 7(9), 1594–1607 (2021).

Wang, C., Liu, H., Wu, D. & Liu, X. Engineering and environmental evaluation of red mud amended volcanic ash as a sustainable subgrade material. J. Clean. Prod. 393, 136353 (2023).

Sengul, T., Akray, N. & Vitosoglu, Y. Investigating the effects of stabilization carried out using fly ash and polypropylene fiber on the properties of highway clay soils. Constr. Build. Mater. 400, 132590 (2023).

Salimi, M., Dordsheykhtorkamani, A., Afrasiabian, A. & Khajeh, A. Incorporation of volcanic ash for enhanced treatment of a cement-stabilized clayey soil. J. Mater. Civ. Eng. 33(2), 04020465 (2021).

Nguyen, D. & Phan, V. Engineering properties of soil stabilized with cement and fly ash for sustainable road construction. Int. J. Eng. Trans C: Aspects 34(12), 2665–2671 (2021).

Hammad, M. A., Mohamedzein, Y.E.-A. & Al-Aghbari, M. Improvement of Sabkha soils using cement and marble powder. Indian Geotech. J. 54(3), 827–836 (2024).

Boukhatem, G. et al. Optimizing properties of clayey soil using lime and waste marble powder: a sustainable approach for engineering applications. Front. Mater. 11, 1392875 (2024).

A. C. D.-o. Soil and Rock, Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis (ASTM International, 2009).

ASTM, D. 7928; standard test method for particle-size distribution (gradation) of fine-grained soils using the sedimentation (hydrometer) analysis. In ASTM International: West Conshohocken (PA) (2017).

A. C. D.-o. Soil and Rock. In Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. (ASTM International, 2010).

Standard, A. D2487–11. InStandard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System), ASTM International, West Conshohocken, PA, (2011).

Standard, A. Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. In ASTM Standard C, vol. 618 (2012).

Fattah, M. Y., Al-Saidi, A. A. & Jaber, M. M. Consolidation properties of compacted soft soil stabilized with lime-silica fume mix. Int. J. Sci. Eng. Res. 5(7), 1675–1682 (2014).

Astm, D. 698; standard test methods for laboratory compaction characteristics of soil using standard effort. In ASTM International: West Conshohocken, PA, USA, no. 19428–2959 (2007).

A. C. D.-o. Soil and Rock. In Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading (ASTM International, 2004).

Turan, C., Javadi, A. A. & Vinai, R. Effects of class C and class F fly ash on mechanical and microstructural behavior of clay soil—a comparative study. Materials 15(5), 1845 (2022).

Turan, C., Javadi, A. A., Vinai, R. & Beig Zali, R. Geotechnical characteristics of fine-grained soils stabilized with fly ash, a review. Sustainability14(24), 16710 (2022).

Noaman, M. F., Khan, M., Ali, K. & Hassan, A. A review on the effect of fly ash on the geotechnical properties and stability of soil. Clean. Mater. 6, 100151 (2022).

Agrawal, V. & Gupta, M. Expansive soil stabilization using marble dust. Int. J. Earth Sci. Eng. 4(6), 59–62 (2011).

Abdulla, R. S. & Majeed, N. Some physical properties treatment of expansive soil using marble waste powder. Int. J. Eng. Res. Technol. 3(1), 591–600 (2014).

Saygili, A. Use of waste marble dust for stabilization of clayey soil. Mater. Sci. 21(4), 601–606 (2015).

Jalal, F. E., Mulk, S., Memon, S. A., Jamhiri, B. & Naseem, A. Strength, hydraulic, and microstructural characteristics of expansive soils incorporating marble dust and rice husk ash. Adv. Civ. Eng. 2021(1), 9918757 (2021).

Jain, A. K. & Jha, A. K. Geotechnical behaviour and micro-analyses of expansive soil amended with marble dust. Soils and Foundations 60(4), 737–751 (2020).

Zorluer, I. & Muratoglu, I. Effect of marble dust on consolidation characteristics of clay soils. In International Symposium on Sustainable Development 514–517 (2010).

Abdelkader, H. A., Hussein, M. M. & Ye, H. Influence of waste marble dust on the improvement of expansive clay soils. Adv. Civ. Eng. 2021(1), 3192122 (2021).

Huey, C. S. & Eng, B. Consolidation characteristics of Iime stabilised soil. J. Civ. Eng. 12, 31–42 (2000).

Zidan, A. F. Strength and consolidation characteristics for cement stabilized cohesive soil considering consistency index. Geotech. Geol. Eng. 38(5), 5341–5353 (2020).

Luo, Y., Meng, J., Wang, D., Jiao, L. & Xue, G. Experimental study on mechanical properties and microstructure of metakaolin based geopolymer stabilized silty clay. Constr. Build. Mater. 316, 125662 (2022).

Hatefi, M. H., Arabani, M., Payan, M. & Ranjbar, P. Z. The influence of volcanic ash (VA) on the mechanical properties and freeze-thaw durability of lime kiln dust (LKD)-stabilized kaolin clayey soil. Results Eng. 24, 103077 (2024).

Olgun, M. Effects of polypropylene fiber inclusion on the strength and volume change characteristics of cement-fly ash stabilized clay soil. Geosynth. Int. 20(4), 263–275 (2013).

Rai, P. et al. Effect of fly ash and cement on the engineering characteristic of stabilized subgrade soil: an experimental study. Geofluids 2021, 11 (2021).

Vardhan, K., Goyal, S., Siddique, R. & Singh, M. Mechanical properties and microstructural analysis of cement mortar incorporating marble powder as partial replacement of cement. Constr. Build. Mater. 96, 615–621 (2015).

Kupwade-Patil, K. et al. Microstructure of cement paste with natural pozzolanic volcanic ash and Portland cement at different stages of curing. Constr. Build. Mater. 113, 423–441 (2016).

Author information

Authors and Affiliations

Contributions

S.S.: Data curation, investigation, resources, writing- original draft. A.R.: Methodology, Data curation, investigation, visualization, writing- original draft, reviewing and editing. S.A.: Methodology, supervision, resources, writing- reviewing and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shojamoghadam, S., Rajaee, A. & Abrishami, S. Impact of various additives and their combinations on the consolidation characteristics of clayey soil. Sci Rep 14, 31907 (2024). https://doi.org/10.1038/s41598-024-83385-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-83385-5

Keywords

This article is cited by

-

Clayey soil stabilization using waste-derived pine needles and marble dust: an experimental evaluation

Journal of Building Pathology and Rehabilitation (2026)

-

Consolidation and Microstructural Behaviour of River Sludge Stabilized with Rice Husk Ash and Cement

Geotechnical and Geological Engineering (2026)

-

Synergistic role of scrap rubber powder and silica fume in enhancing cohesive soil behavior: sustainable soil improvement

Journal of Building Pathology and Rehabilitation (2026)

-

Experimental study on the dynamic properties of low-cement sludge solidified soil under long-term cyclic loading

Scientific Reports (2025)

-

Recycled aggregate size effect on shear and tensile fracture toughness of SCB Eco-friendly cemented specimens

Scientific Reports (2025)