Abstract

The limited availability of petroleum fuels and pollution concerns has led to the search for alternative energy sources. The most advantages of utilizing biodiesel are the simultaneous decrease of HC as well as CO emissions. Nevertheless, significant challenges remain, such as extreme NOx and smoke opacity emissions. To mitigate these issues, strategies like premixed charge compression ignition (PCCI) mode have been developed, which can lower NOx and smoke opacity levels. The novelty of the present study was establish to investigates the effects of various blends of waste cooking oil (WCO) biodiesel (B15D85, B30D70, B45D55, and B60D40) on combustion characteristics, emissions, and efficiency in conventional diesel combustion (CDC) and PCCI modes. In PCCI mode, a 20% premix ratio (PR) of diesel is vaporized outside the engine manifold, while the remaining fuel is burned conventionally before reaching TDC. Results reveal that in CDC mode, increasing the proportion of biodiesel in the blends led to decreased brake thermal efficiency (BTE), exhaust gas temperature (EGT), HC, and CO, while brake-specific energy consumption (BSEC), NOx, and smoke opacity increased. In contrast, PCCI mode demonstrated enhanced BTE alongside reductions in NOx and smoke opacity emissions due to the manifold enhancing the homogeneity of the mixture and decreasing combustion temperature. The B60D40 blend in PCCI mode achieved the lowest average NOx at 325 ppm and the minimum EGT at full load at 192 °C, along with reduced HC and CO emissions. While, B15D85 produced the lowest NOx and smoke opacity values, achieving the highest BTE of 34.6% and NOx emissions at 288 ppm in PCCI mode. Finally, using B60D40 PCCI showed BTE almost equal to diesel in CDC with extremely lower NOx and smoke emissions diesel.

Similar content being viewed by others

Introduction

Over the years, there have been concerns about the harmful effects of internal combustion engines on human health and the environment due to their contribution to global warming and air pollution1,2,3. Diesel engines, which are used in various industries and transportation sectors, have advantages such as higher efficiency, and lower maintenance compared to gasoline engines. However, they also produce higher soot and nitrogen oxides (NOX) as a result of diffusion combustion4. The CI engines’ combustion process, according to Srivastava et al.5, comprises three separate phases: “premixed phase - mixing-controlled combustion phase - diffusion phase - controlled combustion phase”. In the high-temperature zones where the A/F ratio approaches stoichiometry, NOX is produced during the mixing-controlled combustion phase. While soot is created in the fuel-rich zones due to the mixture’s heterogeneity, which has comparatively lower temperatures6. Additionally, diffusion combustion makes it difficult for the CI engine to provide cleaner combustion and increases soot formation in fuel-rich zones where air-fuel molecules are unable to compete.

Nowadays, renewable energy sources are not widely used globally since the world still mostly relies on fossil fuels for its energy requirements7. Furthermore, utilizing fossil fuels has a large-scale environmental effect and the world, as it produces greenhouse gases which results in global warming8. Scientists are currently searching for new, sustainable energy sources to replace existing fossil fuels due to the global energy crisis9. One type of biofuel that shows promise as a substitute for fossil fuels is biodiesel. The use of biodiesel in diesel engines doesn’t require modifications to the engine since it is very similar to diesel fuel. It has the advantages of being free of sulfur and polycyclic aromatic hydrocarbons (PAH), additionally having a high Cetane number and around 10% built-in oxygen. Biodiesel is a cleaner fuel that can be mixed with diesel at any ratio to improve its combustion and emission performance10. Biodiesel can be utilized in place of diesel fuel without requiring any additional modifications to the engine’s fuel system. However, compared to mineral diesel, biodiesel has different characteristics such as viscosity, density, and vaporization. These fuel characteristics affect how an air-fuel mixture is formed, which in turn affects how internal combustion (IC) engines burn their fuel.

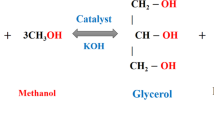

Edible and inedible oils are the two main categories of oils used to produce biodiesel. The primary sources of edible oil are sunflower, rapeseed, palm, and soybean, while WCO and animal fats are commonly used as inedible oils. Using edible oils to produce biodiesel can potentially disrupt the food chain. Vegetable oils are commonly used for frying food11. During the frying process, the oil undergoes hydrolysis, polymerization, and heat deterioration. Hydrolysis occurs due to the presence of moisture in the food, leading to an increase in the amount of free fatty acids in WCO. Polymerization refers to the conversion of smaller molecules into cyclic and acyclic molecules in the presence of heat. Thermal deterioration of the oil also causes chemical and physical changes12. The polar material content of the oil is often used as a measure of oil deterioration, as it has significant implications for human health. Therefore, using WCO to produce biodiesel is a good way to protect human health and avoid disruptions to the food chain. Various techniques such as “pyrolysis - micro-emulsion - transesterification - dilution” have been used to produce biodiesel. Catalytic transesterification is considered the most effective and economical technique13. Transesterification using a similar base catalyst yields a high reaction rate at a low temperature and in a short time, making it the preferred method for commercial biodiesel production.

Numerous research has been conducted to examine how biodiesel affects the engine’s performance, vibration, exhaust emissions, injection process, spray formation, and combustion in addition to blending biodiesel with diesel to enhance its chemical and physical characteristics14. Many researchers generally agree that biodiesel has lower brake thermal efficiency (BTE) than diesel fuel due to its LHV and lower PM emissions because of the fuel’s oxygen content and chemical makeup15,16. Most of the time, an increase in NOx emissions occurs along with a decrease in CO, HC, and PM emissions. The main problems stem from the longer-term deposit formation and material degradation, as well as biodiesel’s higher viscosity than conventional fuels. Biodiesel spray properties were studied by Agarwal et al.17 in a spray chamber with a constant volume and several different ambient pressures. They indicated that when pressure increased, cone angle increased while spray tip penetration reduced. They also indicated that longer spray penetration was associated with higher biodiesel percentage in a blended fuel sample. They identified the greater density and viscosity of the test fuel as the main causes of this phenomenon. The spray outcomes for the biodiesel blends made by Agarwal et al. reported in this study are qualitatively comparable to those reported by Karanja. Another series of studies examined the relationship between ignition delay (ID) and heat release rate (HRR) for diesel and biodiesel. According to the study made by How et al.18, biodiesel blends had shorter ID, lower peak HRR, and longer combustion duration than mineral diesel. Shahabuddin et al.19 claimed in a review study that biodiesel has a shorter ID and an earlier start of combustion than mineral diesel. They explained their results by pointing to biodiesel’s increased cetane number, decreased compressibility, and fatty acid composition. Elkelawy et al.20 discovered that utilizing biodiesel decreased CO and HC emissions. However, after employing biodiesel, significant improvements in particle emissions were seen. According to Zhang et al.21, using biodiesel led to a reduction in particle number and particle mass by 18.8% and 27.3% respectively. Fayad et al.22 investigated performances and emission characteristics of a diesel engine fueled with biodiesel and with nano-additives, subjected to EGR. It concluded that EGR has enhanced engine performance in conjunction with nano-additives, with significant reductions in NOx, soot and particle numbers emissions with the nano blend and higher EGR levels.

Meanwhile, to reduce the intensity of emissions from diesel engines, strength regulations have been implemented. It is imperative to meet the requirements and challenges that have driven engine researchers to improve the features of CI engines. Low-temperature combustion (LTC) methods were established to overcome the problem that CI engines’ high-temperature combustion produces23. These strategies offer lower equivalence ratios and a more homogenous A/F mixture, that enhances the physical properties of fuel and decreases the combustion temperature. LTC can achieve diesel-like efficiency while simultaneously reducing NOx & soot emissions24. To prevent the rich mixture formation in the combustion chamber, which is responsible for the soot production, and to prevent high combustion temperature, which is responsible for the production of NOx emissions, LTC premixes all or the major portion of the fuel.

One of the best promising LTC techniques employed in CI engines for lowering NOx and soot emissions and keeping thermal efficiency constant or even higher is the premixed charge compression ignition (PCCI) strategy25,26. PCCI frequently featured by decreasing the combustion temperature by employing a super lean F/A mixture and improving the homogeneity of the charge, which is accomplished by splitting the fuel amount into 2-stages. The first stage of external injection involves injecting a small amount of fuel early to create a homogenous mixture in the intake manifold using a fuel system that consists of an injector & a fuel evaporator27,28. The remaining part is then injected by the original engine injector in the combustion chamber at the compression stroke’s end, and the injection timing is responsible for controlling the fuel ignition. Horibe et al.29 suggested that PCCI could attain better performance and decrease emissions with the right choice of the quantity and time of injections, together with the EGR requirements for two-stage injections. Additionally, by advancing the time of the first injection and shifting the time of the second near TDC, the relatively better thermal efficiency can be obtained at high loads with a small pressure rise rate and low emissions. Another study has been done by Lu and Su30. used both experimental and computational methods to investigate the impact of injection timing and methods on PCCI performance at low to medium loads. Results indicated that adopting the multiple fuel injection method has lower soot, CO, and HC emissions at medium loads than the single fuel injection method. According to one study, using diesel fuel at varied premixed ratios, the characteristics of DI and PCCI-DI were examined by El Shenawy et al.31. When compared to DI combustion, the results of the study revealed improvements in every parameter during PCCI-DI combustion.

As discussed above using biodiesel reducing CO and HC, but increasing NOx emissions and brake-specific fuel consumption (BSFC). While PCCI is a technique that can decrease BSFC, NOx, and soot emissions, but increase CO and HC emissions. This work investigates a low-cost solution to convert a Compression Ignition (CI) engine, into a Partially Premixed Compression Ignition (PCCI) engine fueled with biodiesel without extensive modification of the main engine subsystems. The study is divided into two sections. The first section evaluates the performance, combustion, and emissions of biodiesel blends (B15D85, B30D70, B45D55, and B60D40) produced from waste cooking oil (WCO) under a Conventional Diesel Combustion (CDC) mode. These blends were compared with using mineral diesel on a CDC mode. The second section explores the impact of the PCCI strategy with a fixed premixed fuel ratio of 20% in the in-cylinder intake manifold, at 110 °C. Five blends of biodiesel (B0D100, B15D85, B30D70, B45D55, and B60D40) were used as the primary fuel, while diesel was used as the pilot fuel in PCCI mode.

A single cylinder, 4-stroke, Direct Injection (DI) diesel engine with air cooled arranged operated at a constant speed of 1500 rpm with different running loads. Each blend was analyzed for performance and emission characteristics of the engine.

Materials and procedures

This study aims to investigate how using biodiesel blends (B15D85 - B30D70 - B45D55 - B60D40) affects combustion, performance, and emission properties in CDC mode. In addition, how PCCI mode affects the performance and emissions properties of biodiesel. In PCCI mode, the combustion chamber is directly injected with the prepared biodiesel blends at a pressure of 220 bar through the main fuel injector, while diesel is introduced through the secondary injector operating at low pressure in the suction manifold. Finally, the results of the PCCI mode are mapped and compared with those of conventional combustion fueled with mineral diesel.

Experimental setup

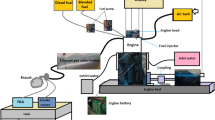

Figures 1 and 2 show a schematic and an actual illustration of the PCCI engine configuration, respectively. The tests were carried out using an air-cooled, single-cylinder, 4-stroke, DI diesel engine called “DEUTZ FL 511/W”. The engine was kept operating at a constant 220 bar fuel injection pressure at 32º CA bTDC, and the compression ratio was maintained at 17. In the tests, a speed-detection sensor was installed in the engine, controlling the engine load was done with switches, and instruments were used to record temperatures and flow rates. Table 1 provides a detailed description of the conventional CI engine that was employed in this experiment. The amount of intake air entering the engine was measured using an orifice system, and the suction stroke-induced pulsations were removed by using a damping reservoir. A generator connected to the engine allowed for the adjustment of torque and speed. Figure 3 illustrates the two main components of the generator model dynamometer. The first component is an AC generator with a 5-kW output that is attached to the engine’s crankshaft. The second component is the load circuit used to control the dynamometer, which consists of 6 lamps and a voltage variac unit to regulate the generator’s output. Voltmeters and ammeters were used to measure the power of the lamps.

The engine has already undergone some modifications to run in PCCI mode. Specifically, the intake system was modified to provide an efficient external mixture formation technology, which forms a homogeneous A/F mixture. This mechanism consists of a pre-chamber with 2-inlet ports and one outlet. The first inlet is connected to a blower that supplies a small quantity of fresh air, which then passes over a heater to increase its temperature. The second inlet port is for fuel coming from an electrical injector. To control the injector, there is an electrical circuit that includes an Arduino microcontroller and a tachometer sensor. This circuit keeps the injector open for 8°CA (crank angle) per engine cycle. The quality of the mixture is controlled by the quantity of air and its temperature. The amount of air is controlled by using a variac attached to the blower, while the temperature is controlled using another variac attached to the heater. Once the homogeneous air/fuel mixture is formed, it is discharged from the outlet port at the bottom of the pre-chamber into the suction line. There, it is mixed with fresh air in the intake manifold before entering the engine. Additionally, there is a vent in the pre-chamber that is used to drain any condensed fuel. Based on the above discussion, it is clear that there are two distinct techniques for supplying fuel: the main technique of the engine’s direct injection (DI) and the external technique used to create the external mixture. Also, there are two distinct methods for supplying air: the main air method that flows through the manifold, and the external air supply method used to create the premixed homogeneous mixture. Table 2 provides details on the number of samples used and their proportions. A K-type thermocouple was used to measure the temperature with an accuracy of 1 °C. GASBOARD-5020 emission gas analyzer was used for the measurements of exhaust emissions (CO2, CO, O2, HC and NOX). Measurements NOX and HC were made in ppm, whereas Calculations for CO2, CO, and O2 were made in %Vol. While GASBOARD-6010 opacity meter was used to measure soot emissions.

Experimental errors

The uncertainties throughout the experiment could be attributed to various factors, including the measurements taken by each device. Equations (1) and (2) can be used to determine the degree of uncertainty for recorded and computed quantities32. The coefficient of variation (COV) for each measurement value is calculated to evaluate the precision and repeatability of the procedures, and it is found to be within an acceptable range of less than 2%. To determine the limiting errors associated with each measured value, an accurate uncertainty analysis is conducted. Since the limiting errors of the measurements are influenced by both the values of the measurements and the accuracy of the instruments, Table 3 shows the accuracy and uncertainty of the various instruments utilized in this experimental study. From Table 3, it is clear that the uncertainty of the measurement instruments does not affect the conclusions. Figure 4 shows that Vibration and vaporizer fuel circuit schematic diagram

Where \(\:\varvec{\upsigma\:}\) is the standard deviation, \(\:{\:\mathbf{X}}_{\mathbf{m}}\) is the mean of \(\:\left(x\right)\:\)variable, n is the cycle of sample numbers.

Tested fuels

Five test fuels were used in our study: B0D100, B15D85, B30D70, B45D55, and B60D40. The fuels were obtained by mixing biodiesel with diesel in volumetric ratios of 0%, 15%, 30%, 45%, and 60%, respectively. The characteristics of the test diesel and biodiesel fuels are listed in Table 4. As shown in Fig. 5, the transesterification process was used to produce the biodiesel from WCO. The WCO was filtered to remove contaminants and impurities before transesterification. In the transesterification step, a round flask with an electrical heater and an electrical stirrer was initially filled with 6 L of WCO, with 200 ml of methanol (alcohol) per liter of oil and NaOH (catalyst) at a weight of 1% of oil. The mixture was stirred for one hour at 550 rpm, and a control unit was used to keep the temperature below 65 °C to prevent the burning of the oil. Then, the mixture was left in a conical flask to separate naturally under gravity for a day, during which glycerin separated at the bottom of the flask. The last step is the washing stage, which is used to remove any dirt and unsolved fatty substances from the biodiesel. In this step, hot water at 100 °C is used in a 1:1 volume ratio with the biodiesel. This step is repeated three times until pure biodiesel is obtained after washing.

Experimental conditions

The tests in this work were carried out under several load conditions, including partial, full, and no load, and the engine speed was kept constant. The experiments were divided into two stages. The first stage studied the effect of using biodiesel blends (B15D85, B30D70, B45D55, and B60D40) in CDC mode. The second stage investigated the impact of using biodiesel in PCCI mode. The results of the two stages on the performance and emissions properties were compared to those obtained with CDC fueled with mineral diesel. In PCCI mode, the premixed ratio is determined using Eq. (3). The fuel injected directly flow rate is obtained by calculating the time for the engine to consume 10 cm3 of the fuel.

The volume flow rate of the premixed fuel is determined using Eq. (4)33. The flow rate of fuel injected in the pre-chamber is already known depending on the number of opening crank angle degrees of the electrical injector. The flow rate of fuel condensed in the pre-chamber is calculated by collecting the condensed fuel through a specified time in a tank then it is pumped to a graduated cylinder before it back to its separated external tank.

Results and discussion

Based on the given information, it appears that using biodiesel in PCCI mode is an effective strategy for achieving improved combustion and reducing emissions compared to using diesel in CDC (Conventional Diesel Combustion) mode. This strategy may result in higher BTE or at least the same level of BTE as diesel, while also reducing emissions.

Engine performance

Engine performance refers to the overall efficiency and effectiveness of an engine about power output, fuel consumption, and emissions. In the context of engine emissions characteristics, three important factors are often considered: BTE, BSFC, and Exhaust Gas Temperature (EGT). (1) BTE: is a measurement of an engine’s efficiency at converting fuel combustion energy into effective work. It is expressed as a percentage and represents the ratio of the engine’s brake power (power output at the crankshaft) to the energy content of the fuel consumed. Higher BTE values indicate better engine efficiency. (2) BSFC: is a measurement of the quantity of fuel an engine consumes to generate one unit of power. It is typically expressed in units of mass of fuel per unit of power (e.g., grams per kilowatt-hour). Lower BSFC values indicate better fuel efficiency, as it means the engine can produce more power with less fuel consumption. (3) EGT: refers to the temperature of the exhaust gases exiting the engine’s combustion chamber. It is an important parameter to monitor as it can indicate the engine’s operating conditions and combustion efficiency. Higher EGT values may suggest incomplete combustion or excessive engine load, while lower EGT values may indicate poor engine performance or cooling system issues. By analyzing and optimizing these engine performance parameters, engineers can enhance overall engine performance and reduce emissions.

Brake thermal efficiency

The engine performance is expressed by using BTE. The variation in BTE for the various tested fuels in CDC mode and PCCI mode under various loads is shown in Fig. 6. The results demonstrated that the BTE of all operating conditions increased with increasing engine load as the heat transfer loss decreased. From Fig. 6a it can be understood that the BTE is marginally reduced when increasing biodiesel percentage. The higher cetane number of biodiesels decreases the formation of fuel-rich zones, additionally, O2 content in biodiesel leads to smoothening and improves its combustion but higher density and viscosity results in a decreased rate of vaporization, volatility, atomization, and larger droplet size and thus deteriorate combustion. This agrees with the results achieved by Elkelawy et al.34. From Fig. 6b PCCI mode showed higher BTE due to the diesel injection in the manifold providing enough time for mixing with air to achieve better homogenous mixture formation that helps in producing complete and better combustion. The BTE at full load in CDC mode for diesel, B15D85, B30D70, B45D55, and B60D40 are 38.6, 37.4, 35.6, 34.8 and 33.8% respectively and in PCCI mode for B15D85, B30D70, B45D55, and B60D40 are 40.5, 39.2, 37.6 and 36.5% respectively. Among all fuels, B15D85 in PCCI mode has the maximum BTE while B60D40 in PCCI mode has almost the same BTE. As shown in Fig. 6c the mean value of BTE increased with using PCCI mode by 2.6%, 2.9%, 2.3%, and 2.3% for B15D85, B30D70, B45D55, and B60D40 respectively.

Brake-specific energy consumption

BSFC measures the amount of fuel consumed to generate a unit of braking power, it depends on the fuel’s calorific value. This dependency makes BSFC unsuitable for indicating combustion performance when using multiple fuels. Instead, brake-specific energy consumption (BSEC) is used, as it represents the total energy released to generate brake power and is independent of the fuel’s calorific value. Equation (5) calculates the BSEC value in MJ/kW.hr. Figure 7 illustrates the fluctuations in BSEC for the tested fuels in both CDC and PCCI modes under various load conditions. It is observed that BSEC decreases with increasing load, as higher loads result in faster combustion at higher temperatures, improving combustion quality and controllability, reducing heat losses, and producing more energy. Figure 7a showed that the BSEC for biodiesel blends is increased with increasing biodiesel percentage in blends than that of conventional diesel. As a result of LHV and the increment in viscosity of biodiesel, the engine consumption of fuel increased under the same load. As indicated in Fig. 7b for all tested fuels, PCCI mode decreased the BSEC for each tested fuel when compared to conventional mode because the diesel injection through the manifold enhances the homogeneity of the mixture which results in better combustion and reduces fuel consumption. Among all fuels, B15D85 in PCCI mode show the minimum BSEC with an average reduction of 5.82% than diesel in CDC mode. As shown in Fig. 7c the average value of BTEC decreased by using PCCI mode by 2.2, 2.3, 2.4, and 2.3 MJ/kw.hr for B15D85, B30D70, B45D55, and B60D40 respectively.

Where, BSEC in terms of (MJ/kW.hr), m° in terms of (kg/sec), LHV in terms of (MJ/kg), Power in terms of (kw).

Exhaust gas temperature

EGT is defined as the temperature of exhaust gases resulting from the combustion process, so it refers to the energy lost in the exhaust gases and the thermal stress on the engine body. The fluctuation of the EGT of the engine with the tested fuels in CDC mode and PCCI mode under various load conditions is shown in Fig. 8. It is seen from Fig. 8 that in all cases the EGT raised with increasing the load because of increasing the burned fuel, that results in increasing energy released. It is comprehended from Fig. 8-a that, the EGT for biodiesel blends is decreased with increasing biodiesel percentage in blends than that of diesel because of LHV of biodiesel and the increment in its viscosity. It is obvious from Fig. 8b that, the PCCI mode for all tested fuels showed a decrement in EGT due to the diesel injection in the manifold providing enough time for mixing with air to achieve better homogenous mixture formation that helps in controlling the combustion process and reducing the diffusion phase combustion. As shown in Fig. 8c the mean value of EGT decreased by using PCCI mode by 2.8, 2.4, 3.7, and 6.9 ºC for B15D85, B30D70, B45D55, and B60D40 respectively.

Engine emissions

The engine emissions characteristics are discussed in terms of NOx emissions, HC emissions, CO emissions and smoke emissions.

NOx emission

Various variables affect NOx formation including high combustion temperature, reaction time, and the availability of O2 and N2 content in fuel. As CI engines are usually run with a moderately lean mixture, they are ever more likely to produce higher levels of NOx. The variation of NOx emissions of the engine with the various tested fuels in CDC mode and PCCI mode under various load conditions are demonstrated in Fig. 9. It is comprehended from the figure that in all cases, the NOx emissions increased with increasing load due to higher combustion chamber temperature as more energy released. Figure 9a indicates that NOx emissions increased with higher biodiesel concentrations compared to conventional diesel. This is due to the high oxygen content in biodiesel, which facilitates more reactions between oxygen and nitrogen, even though the combustion temperature is lower when using biodiesel35. As indicated in Fig. 9b, NOx emission decreased for all tested fuels in PCCI mode due to the diesel injection through the manifold enhancing the homogeneity of the mixture which results in decreasing combustion temperature. Among all fuels, B15D85 in PCCI mode produced the minimum NOx emission while B60D40 in CDC mode produced the maximum NOx emission. As indicated in Fig. 9c the mean value of NOX decreased by using PCCI mode by 36.4, 39.7, 37.3, and 40.4 ppm for B15D85, B30D70, B45D55, and B60D40 respectively.

HC emission

Unburned hydrocarbons refer to fuel particles that remain unburnt due to incomplete combustion, which can occur for several reasons, including low combustion temperatures, inefficient fuel-air mixing in over-lean or rich mixtures, poor fuel atomization, fuel trapped in cleft volumes, and liquid fuel films on the combustion chamber wall. Figure 10 illustrates the differences in HC emissions for various tested fuels in CDC and PCCI modes across all load conditions. The figure shows that HC emissions decrease with increasing engine load, as higher loads improve combustion efficiency. At higher loads, the combustion chamber temperature rises, leading to more complete fuel combustion and reduced HC emissions. According to Fig. 10a, it is seen that in all cases the HC emissions decrease for biodiesel blends with increasing biodiesel ratio compared to conventional diesel due to the availability of O2 in the chemical composition of biodiesel which results in the fuel burning completely. It can be understood from Fig. 10b that for all tested fuels in all the operating ranges, PCCI mode has higher HC emission for each tested fuel when compared to the same fuel in CDC mode because of lower combustion temperature and fuel trapped in cleft volumes and the fuel film wetted on the cylinder wall. Among all the fuels tested, B60D40 in CDC mode exhibited the lowest HC emissions. In comparison, B60D40 in PCCI mode had the lowest HC emissions compared to diesel fuel, with only a slight increase relative to B60D40 in CDC mode. Figure 10c shows that in PCCI mode, the average HC emissions increased by 9.8 ppm and 10 ppm for B15D85 and B30D70, respectively. However, they decreased by 5.2 ppm and 12.6 ppm for B45D55 and B60D40, respectively.

Unregulated emissions, such as polycyclic aromatic hydrocarbons (PAHs), are byproducts of incomplete combustion in internal combustion engines, particularly in diesel engines operating under low-load conditions36. PAHs contribute to carbon buildup and wet stacking, which can lead to efficiency losses and engine damage. In Partially Premixed Compression Ignition (PPCCI) engines, fuel and air are mixed more homogeneously than in conventional diesel combustion (CDC) engines, leading to lower combustion temperatures and reduced formation of PAHs and soot. Unlike CDC engines, which rely on direct injection with a diffusion-controlled combustion phase, PPCCI operates with a pre-mixed charge that enhances combustion efficiency and reduces unregulated emissions, striking a balance between fuel stratification and controlled ignition timing to optimize performance and emissions.

CO emission

CO is a key byproduct of incomplete combustion, resulting from partial oxidation of carbon atoms, which hinders the formation of CO2. CO production occurs due to insufficient oxygen in rich zones and lower in-cylinder combustion temperatures. Figure 11 illustrates the fluctuations in CO emissions for various tested fuels in both CDC and PCCI modes across different loads. The figure indicates that CO emissions decrease with increasing engine load in all cases, attributed to higher combustion temperatures. It is seen from Fig. 11a that biodiesel produced lower CO emissions than those of diesel because oxygen content in biodiesel completes combustion. For PCCI mode, it is demonstrated from Fig. 11b that CO emissions decreased for B15D85 and B30D70 but it increased for B45D55 and B60D40. It may be due to the PCCI mode enhancing the homogeneity of the mixture for B15D85, and B30D70 but for B45D55, and B60D40 more fuel was injected, and more rich zones were formed which led to incomplete combustion. Among all fuels, B60D40 in CDC mode has the minimum CO emission. As demonstrated from Fig. 11c the mean value of CO increased by using PCCI mode by 0.018, 0.011, and 0.013% for B15D85, B45D55, and B60D40 respectively.

Smoke opacity

Figure 12 shows the variation in smoke opacity for different fuels in both CDC and PCCI modes under various load conditions. The figure indicates that smoke opacity increases with higher loads for all fuel types, attributed to the formation of a richer air-fuel mixture37. From Fig. 12a, the results demonstrated that smoke opacity increased with increasing biodiesel percentage than that of conventional diesel in all load ranges. This increment is because biodiesel has a higher viscosity and heavier molecules. As indicated in Fig. 12b for all tested fuels, PCCI mode decreased the smoke opacity for each tested fuel when compared to CDC mode due to the diesel vapour enhancing the homogeneity of the mixture which results in combustion improvement and so decreased smoke opacity. Among all fuels, B15D85 in PCCI mode has the minimum smoke opacity emission while B60D40 in CDC mode produces the maximum smoke opacity emission. As shown in Fig. 12c the mean value of NOX decreased for PCCI mode by 3.8, 4.4, 3.1, and 1.4% for B15D85, B30D70, B45D55, and B60D40 respectively.

Conclusion

The present study investigated the effects of four conventional biodiesel blends (B15D85, B30D70, B45D55 and B60D40) on the performance and emissions of an engine operated both in the CDC and PCCI modes. The key findings are:

-

BTE decreased with biodiesel blends but increased with the PCCI strategy due to better mixture homogeneity. The best improvement was seen with B30D70 in PCCI mode (from 30.5 to 33.4%), while B15D85 in PCCI mode achieved the highest average BTE (34.6%).

-

Owing to the LHV of biodiesel, the BSEC increased by increasing biodiesel percentage. Using PCCI decreased BSEC due to the diesel injection through the manifold enhancing the homogeneity of the mixture which results in better combustion and reduced fuel consumption.

-

NOx Emissions: Increased with biodiesel blends due to higher oxygen content but decreased in PCCI mode due to lower combustion temperatures. The most significant reduction was observed with B60D40 in PCCI mode (from 366 ppm to 325 ppm).

-

EGT decreased with biodiesel blends due to lower heating value and higher viscosity, and further decreased in PCCI mode due to reduced diffusion phase combustion.

-

HC & CO Emissions: Decreased with biodiesel blends due to higher oxygen content but increased in PCCI mode due to lower combustion temperatures and fuel trapped in cleft volumes. The lowest HC & CO emissions were observed with B60D40 in CDC mode.

-

Smoke Opacity increased with biodiesel blends due to higher viscosity and heavier molecules but decreased in PCCI mode due to improved mixture homogeneity. The best reduction was observed with B30D70 in PCCI mode (from 17.1 to 12.7%), while B15D85 in PCCI mode had the lowest smoke opacity.

Overall, biodiesel in PCCI mode shows promise for achieving comparable or slightly higher efficiency and lower HC, CO, NOx, and smoke opacity emissions compared to diesel in CDC mode by combining the benefits of both fuels.

Future research direction

The investigation of the effects of using biodiesel in CDC and PCCI mode on engine emissions, performance, and combustion characteristics has recommended future research as listed below.

-

For higher BTE, more controllability, and more optimization of engine design, using gaseous fuels with high heating value as a premixed fuel may be an effective method.

-

Using nanoparticles as an additive in biodiesel fuel may be more effective in reducing smoke and NOX emissions in addition to increasing BTE.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Balasubramanian, K. et al. Utilization of biodiesel blended fuel in a diesel engine – Combustion engine performance and emission characteristics study. Fuel 311, 11–13 (2021).

Srivastava, D. K., Agarwal, A. K., Datta, A. & Maurya, R. K. Advances in Internal Combustion Engine Research (Springer, 2018).

Fayad, M. A. et al. Influence of renewable fuels and nanoparticles additives on engine performance and soot nanoparticles characteristics. Int. J. Renew. Energy Dev. 11 (4), 46294 (2022).

Bastawissi, H. A. E., Elkelawy, M., Panchal, H. & Sadasivuni, K. K. Optimization of the multi-carburant dose as an energy source for the application of the HCCI engine. Fuel 253, 15–24 (2019).

Elkelawy, M. et al. Numerical and Experimental Investigation of Ethyl Alcohol as Oxygenator on the Combustion, Performance, and Emission Characteristics of Diesel/cotton Seed Oil Blends in Homogenous Charge Compression Ignition Engine 0148–7191 (SAE Technical Paper, 2018).

Dey, S., Reang, N., Das, P. & Deb, M. A comprehensive study on prospects of economy, environment, and efficiency of palm oil biodiesel as a renewable fuel. J. Clean. Prod. 286, 124981 (2021).

Elkelawy, M. et al. Study of performance, combustion, and emissions parameters of DI-diesel engine fueled with algae biodiesel/diesel/n-pentane blends. Energy Convers. Manage. X. 10, 100058 (2021).

Choe, E. & Min, D. Chemistry of deep-fat frying oils. J. Food Sci. 72 (5), R77–R86 (2007).

Prabu, A., Premkumar, I. I. & Pradeep, A. An investigation on the performance, combustion and emission characteristics of CI engine on the addition of antioxidants, oxygenates and nanoparticles as additives in Jatropha biodiesel. Int. J. Ambient Energy. 41 (2), 121–128 (2020).

Atabani, A. E. et al. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew. Sustain. Energy Rev. 16 (4), 2070–2093 (2012).

Jiaqiang, E. et al. Effects of fatty acid Methyl esters proportion on combustion and emission characteristics of a biodiesel fueled diesel engine. Energy. Conv. Manag. 117, 410–419 (2016).

Sun, J., Caton, J. A. & Jacobs, T. J. Oxides of nitrogen emissions from biodiesel-fuelled diesel engines. Prog. Energy Combust. Sci. 36 (6), 677–695 (2010).

Elkelawy, M., Almeldinmohamad, H. & El-Gamal, M. A. Experimental investigation of the biodiesel direct injection and diesel fuel as premixed charge on CI-Engine emissions, performance, and combustion characteristics. J. Eng. Res. 7(1), 177–187 (2023).

Agarwal, A. K., Chaudhury, V., Agarwal, A., Shukla, P. C. Comparative study of macroscopic spray parameters and fuel atomization behaviour of SVO (jatropha), its biodiesel and blends. Thermal Sci. 17(1), 217–232 (2013).

How, H., Masjuki, H., Kalam, M. & Teoh, Y. An investigation of the engine performance, emissions and combustion characteristics of coconut biodiesel in a high-pressure common-rail diesel engine. Energy 69, 749–759 (2014).

Shahabuddin, M., Liaquat, A., Masjuki, H., Kalam, M. & Mofijur, M. Ignition delay, combustion and emission characteristics of diesel engine fueled with biodiesel. Renew. Sustain. Energy Rev. 21, 623–632 (2013).

Elkelawy, M. et al. Experimental studies on the biodiesel production parameters optimization of sunflower and soybean oil mixture and DI engine combustion, performance, and emission analysis fueled with diesel/biodiesel blends. Fuel 255, 115791 (2019).

Zhang, Y., Lou, D. & Tan, P. Z. Hu Particulate emissions from urban bus fueled with biodiesel blend and their reducing characteristics using particulate after-treatment system. Energy 155, 77–86 (2018).

Fayad, M. A. et al. Reducing soot nanoparticles and NOX emissions in CRDI diesel engine by incorporating TiO2 nano-additives into biodiesel blends and using high rate of EGR. Energies 16(9), 3921 (2023).

Mohammed Elbanna, A. et al. Fuel reactivity controlled compression ignition engine and potential strategies to extend the engine operating range: A comprehensive review. Energy Convers. Manag X. 13, 100133 (2022).

Bhurat, S. S., Pandey, S. & Chintala, V. Combined effect of external mixture formation and cooled exhaust gas recirculation on engine performance and emissions characteristics of partially pre-mixed charged compression ignition engine. Environ. Progr. Sustain. Energy 40(1), e13470 (2021).

Elkelawy, M., Alm Eldin Mohamad, H., Abd Elhamid, E., El-Gamal. M. A. A critical review of the performance, combustion, and emissions characteristics of PCCI engine controlled by injection strategy and fuel properties. J. Eng. Res. 6(5), 96–110 (2022).

Elkelawy, M., Bastawissi, H., Shenawy, E. E. & El-Gamal, M. Effects of using a novel fuel vaporizer on partially premixed charge compression ignition (PPCCI) engine emissions, performance, and combustion characteristics 012017.

Srihari, S., Thirumalini, S. & Prashanth, K. An experimental study on the performance and emission characteristics of PCCI-DI engine fuelled with diethyl ether-biodiesel-diesel blends. Renew. Energy. 107, 440–447 (2017).

Wissink, M. & Reitz, R. D. Direct dual fuel stratification, a path to combine the benefits of RCCI and PPC. SAE. Int. J. Engines. 8 (2), 878–889 (2015).

Horibe, N., Harada, S., Ishiyama, T. & Shioji, M. Improvement of premixed charge compression ignition-based combustion by two-stage injection. Int. J. Engine Res. 10 (2), 71–80 (2009).

Lu, Y. & Su, W. Effects of the injection parameters on the premixed charge compression ignition combustion and the emissions in a heavy-duty diesel engine. Proc. Insti Mech. Eng. Part D 231(7), 915–926 (2017).

El Shenawy, E., Elkelawy, M., Bastawissi, H. A. E., Panchal, H. & Shams, M. M. Comparative study of the combustion, performance, and emission characteristics of a direct injection diesel engine with a partially premixed lean charge compression ignition diesel engines. Fuel 249, 277–285 (2019).

Moffat, R. J. Describing the uncertainties in experimental results. Exp. Thermal Fluid Sci. 1 (1), 3–17 (1988).

Shim, E., Park, H. & Bae, C. Intake air strategy for low HC and CO emissions in dual-fuel (CNG-diesel) premixed charge compression ignition engine. Appl. Energy. 225, 1068–1077 (2018).

Elkelawy, M., Shenawy, E. E., Bastawissi, H. & El, I. Shennawy. The effect of using the WCO biodiesel as an alternative fuel in compression ignition diesel engine on performance and emissions characteristics 012023.

Rajak, U. et al. Experimental and parametric studies on the effect of waste cooking oil Methyl ester with diesel fuel in compression ignition engine. Sustain. Energy Technol. Assess. (2022).

Yilmaz, N. & Donaldson, A. Examination of Causes of Wetstacking in Diesel Engines. SAE Technical Paper 2005-01-3138. https://doi.org/10.4271/2005-01-3138 (2005).

Gupta, P., Rajak, U., Verma, T. N., Arya, M. & Singh, T. S. Impact of fuel injection pressure on the common rail direct fuel injection engine powered by microalgae, Kapok oil, and soybean biodiesel blend. Ind. Crops Prod. 194, 116332 (2023).

Dash, S. K. et al. Effect of injection pressure adjustment towards performance, emission and combustion analysis of optimal Nahar Methyl ester diesel blend powered agricultural diesel engine. In energy. Elsevier BV. 263, 125831. https://doi.org/10.1016/j.energy.2022.125831 (2023).

Ranjith, P. S. et al. Experimental investigations on gaseous hydrogen supplemented Aleurites Fordii biodiesel in a direct injection diesel engine for performance enhancement and reduction in emissions. Mater. Today Vol. 46, 11140–11148. https://doi.org/10.1016/j.matpr.2021.02.368 (2021).

Dash, S. K., Lingfa, P. & Barik, D. Combined adjustment of injection timing and compression ratio for an agricultural diesel engine fuelled with Nahar Methyl ester. Int. J. Ambient Energy Vol. 43, 1482–1494. https://doi.org/10.1080/01430750.2020.1712250 (2020).

Author information

Authors and Affiliations

Contributions

All the authors are equally contributing to the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Elkelawy, M., Bastawissi, H.AE., El Shenawy, E.A. et al. Enhancing CI engine performance and emissions through PCCI and sustainable combustion solutions with waste cooking oil biodiesel blends a comparative study. Sci Rep 15, 24617 (2025). https://doi.org/10.1038/s41598-025-00437-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-00437-0

Keywords

This article is cited by

-

Validation of experimental and gradient boosting regressor model for predicting performance, combustion, emission, and biomedical implications of cerium oxide (CeO₂)-augmented B20 biodiesel blends derived from used temple oil

BMC Chemistry (2025)

-

Experimental investigation of Al₂O₃ and CeO₂ nanoparticle additives in diesel-cottonseed biodiesel (CSOME) blends for performance and emission mitigation in a CI engine

Scientific Reports (2025)

-

Impact of magnesium oxide nanoparticles and hydrogen enrichment on CI engine performance with Mahua oil biodiesel using machine learning

Heat and Mass Transfer (2025)

-

Comparative analysis of emission characteristics and performance between naturally aspirated and turbocharged engines operating on waste oil biodiesel-diesel blends

Journal of Umm Al-Qura University for Engineering and Architecture (2025)