Abstract

In the Ordos mining area of China, composite effects between adjacent thick and weak sandstone strata increase the risk of rock burst. Understanding the mechanism of rock bursts under these conditions and developing targeted prevention and control measures are prerequisites for ensuring mine safety. This study theoretically analyzed the formation conditions of composite key strata and revealed the mechanism of rock bursts, through the variations of the roof characteristics and dynamic responses in different drilling control areas of the 3− 1402 working face. Numerical simulations were conducted to investigate the influence of thickness ratios and intercalation thickness on composite effects. The results indicate that the formation conditions of the composite key strata require synchronous movement of the key strata, with no shear slip at the contact surface of strata and the maximum shear stress position of the model. Both the peak and range of the advance abutment stress increase, accompanied by intense dynamic load release, which is consistent with field data, supporting the conclusion that rock bursts induced by the composite key strata effect are triggered by the superposition of high static loads and strong dynamic loads. Furthermore, the closer the thickness of the upper and lower strata, and the thinner the intercalation, the more obvious the composite effect between the key strata. The optimized prevention and control schemes effectively reduce the risk of rock burst under composite key strata effects.

Similar content being viewed by others

Introduction

In recent years, the exploitation of coal resources in China has undergone significant regional shifts. Traditional mining areas in the central and eastern regions face increasingly depleted coal reserves and stringent environmental protection policies. Consequently, mining activities have gradually migrated to western regions, such as Inner Mongolia, Shaanxi, and Xinjiang1,2,3. The Ordos mining area, one of largest coal production bases in China, has entered been in a deep mining mechanical state as a result of intensive coal resource development4,5. At greater depths, the rock mass encounters high ground stress, elevated temperatures, substantial karst water pressure, and frequent mining disturbances. These factors lead to notable changes in geological conditions, dynamic characteristics, and strata movement compared to shallower rock masses6,7,8. Such conditions have frequently contributed to disasters, including large tunnel deformations, rock bursts, and mining tremors. Several severe rock bursts have been closely associated with the deposition and movement of thick sandstone key strata above coal seams5,9,10.

Significant advancements have been made in the theory of key strata. Qian et al. first proposed the key strata theory, suggesting that thick and hard rock strata above the stope play a critical role in controlling the deformation and failure of the overlying rock11,12. According to this theory, prior to breaking, these strata act as a “plate or beam” structure, serving as the primary load-bearing component of the upper rock. Following fracture, the resulting masonry beam structure influences ground pressure and strata movement. Han et al. established a mechanical model describing the spatial distribution and evolution of stope stress based on the key strata structure13,14,15,16. They proposed that the loads from the key strata and its supporting rock can be transferred to the surrounding rock of the mining area through fracture zones and bending subsidence zones. Xu et al. utilized key strata damage characteristics as indicators to distinguish between overburden and surface movement patterns, determining necessity of protective coal pillars17,18. Additionally, other scholars have examined the evolution of stress, the energy release characteristics associated with strata breakage, and the rupture mechanisms underlying mining tremors under the influence of key strata. Using dynamic and static load superposition theory, overlying rock movement, the rock burst mechanism under the influence of thin and hard key strata in the central and eastern regions was revealed19,20,21,22.

Based on key strata theory, scholars have expanded fundamental concepts to include composite key strata and the composite effect of key strata11. When two or more rock strata exist in the overburden, the movement, deformation, and fracture of the upper and lower strata interact, significantly increasing the strength and stiffness of the rock strata. Miao et al.23 proposed criteria to identify thin and hard composite key strata. Using composite material structure mechanics, Ren et al.24 developed a Winkler model and employed FLAC 3D simulations to compare the fracture characteristics of composite and non-composite key strata.

The sandstone strata in mining areas of central and eastern regions generally have a strength greater than 60 MPa, characterized by calcareous cementation and few natural fractures. These strata exhibit high strength and strong cementation. The movement of the roof strata exhibits hysteresis, prone to forming suspended roof structures above the working face. Unlike previous research focused on central and eastern mining areas of China, the sandstone strata of the Jurassic Zhiluo Formation in the Ordos mining area exhibit different characteristics due to influences such as sedimentation and diagenesis24,25,26,27. The sandstone strata generally have a strength below 30 ~ 40 MPa, with a total thickness ranging from approximately 90 ~ 190 m, and a distance from the coal seam of 10 ~ 100 m. The spatial distribution varies significantly, with some areas showing interbedded thick sandstone strata. The rock strata in western mining areas exhibit uneven particle distribution, high porosity, and well-developed natural fractures. These characteristics result in low strength and poor cementation. However, during mining in regions with these interbedded sandstone strata, high-energy microseismic (MS) events frequently occur in the weakly cemented sandstone within 100 m of the coal seam, accompanied by the synergistic movement and fracturing of key strata. The traditional hierarchical fracture-induced rock burst theory of key strata fails to adequately explain these phenomena, leaving the rock burst mechanisms in weakly cemented strata unclear and existing prevention measures largely ineffective.

On the basis of these issues, using the 3− 1402 working face of a mine in the Ordos mining area as an engineering case study, this research analysed the distribution of MS events, the evolution of advanced stress, and rock burst manifestations to determine variations in rock burst risk under different Zhiluo Formation sandstone strata. A theoretical model of thick-weak sandstone composite key strata was established, proposing formation criteria of composite key strata and identifying factors influencing composite effectiveness. Targeted prevention strategies were developed for thick and weak strata conditions. This study resolves the theoretical gap in mining-induced rock burst mechanisms within weakly cemented strata by analysing dynamic-static loading evolution under composite key strata conditions.

Overview of the case study mining site

Geological and mining conditions

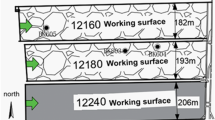

The 3− 1402 working face, located in a rock burst-prone mine in the Ordos mining area, is the second working face of the fourth mining area, separated from the 3− 1401 goaf on the southeast side by a 40 m coal pillar. The strike length of the working face is 3616 m, and the inclination length is 246 m. The coal seam depth decreases from the open-off cut to the stop line, with an average mining depth of 710 m. The layout plan of the working faces is presented in Fig. 1. The 3 − 1 coal seam has an average thickness of 6.25 m and a dip angle of 2°. It exhibits a strong bursting liability, with a uniaxial compressive strength of 29.56 MPa, while the roof and floor show weak bursting liability.

The key strata theory11,28 holds that one or more strata of rock above the working face play a primary controlling role during the overburden movement in the mining area. The fracturing of the key stratum triggers either partial or overall movement of the overlying strata. Assuming that rock stratum n is the key stratum, according to the composite beam theory, the load resulting from its control over the superimposed overburden rock strata can be calculated using composite beam theory, as shown in Eq. (1).

When the load of stratum m + 1, which overlies stratum n, is less than that of stratum m, and the broken length of stratum m + 1 exceeds that of stratum n, it suggests that stratum m + 1 possesses a strong bearing capacity and moves independently of stratum n. Under these conditions, stratum n can be controlled up to stratum m, designating stratum m + 1 as a new key stratum, as represented in Eqs. (2) and (3).

where (qm)n is a load from stratum m to stratum n; m, n, and i are sequence of overlying roof strata; Ei, hi, and γi are the elastic modulus, strata thickness, and bulk density of the corresponding strata; Ln, Lm+1 are the initial breaking length of stratum n and stratum m + 1, the calculation formula is:

where Rtn, hn is tensile strength and thickness of stratum n.

The physical and mechanical parameters of 3 − 1 coal measure strata are presented in Table 1. The mechanical parameters of distinct lithological types were derived as mean values from experimental measurements conducted under standardized laboratory conditions. Considering the attenuation characteristics of key strata breaking energy and its influence on the working face, combined with the key strata identification principle and the exploration results of drill holes 16 − 4 to 16 − 10, the key strata distribution characteristics within the range of 0 ~ 100 m above the 3 − 1 coal seam were analyzed, as shown in Fig. 2.

The results indicate the presence of at least one sandstone key stratum with a thickness exceeding 30 m (ranging from 34.6 ~ 70.0 m), located within the Jurassic Zhiluo Formation at a distance of 6.4 ~ 31.8 m from the 3 − 1 coal seam. Influenced by diagenetic age and sedimentation, the macroscopic structure of the Zhiluo Formation strata is relatively loose, predominantly comprising weakly cemented rocks with compressive strength below 40 MPa25,26,27.

Monitoring data analysis

Distribution characteristics of MS events

Microseismic (MS) events are small-scale seismic activities induced by mining operations, blasting, hydraulic fracturing, and other engineering activities29,30,31,32. By analysing the spatiotemporal evolution patterns of monitored MS events, it is possible to effectively understand the movement and fracturing of roof strata. During the mining of 3− 1402 working face, ARAMIS M/E monitoring system was used to monitor MS events and rock bursts. MS events with energy ≥ 5 × 104J are usually defined as high -energy MS events. When the 3− 1402 working face was mined to 1850 m, a total of 118 high-energy MS events were monitored, with the following distribution characteristics:

-

(1)

Vertical Distribution: MS events were mainly distributed in the Zhiluo Formation sandstone key strata, located 30 ~ 80 m above the coal seam, as shown in Fig. 3(b). It indicates that high activity in the thick sandstone strata near the coal seam during mining, marking it as a key stratum for inducing rock bursts and significant roadway deformation.

-

(2)

Horizontal Distribution: As the 3− 1402 mining face was adjacent to the 3− 1401 goaf, a notable trend of high-energy MS events developed toward the 3− 1402 tailgate and the 40 m coal pillar, as shown in Fig. 3(c).

As shown in Fig. 4, high-energy MS events within the control range of drill holes 16 − 7 to 16 − 10 were compared and statistically analyzed, with total frequency recorded as 40 times, 20 times, 28 times, and 30 times, with corresponding total energy of 8.90 × 10⁶ J, 3.41 × 10⁶ J, 5.36 × 10⁶ J, and 4.17 × 10⁶ J, respectively. The intensity of MS events induced by the multiple thick sandstone key strata fracture in the control area of drill hole 16 − 7 is significantly higher than in adjacent drill holes.

Evolution characteristics of advanced abutment stress

Stress meters 41# and 71# were installed in the 3− 1402 tailgate at mileage of 2340 m and 1875 m, respectively, as shown in Fig. 3(c). These meters were positioned within the control areas of drill holes 16 − 8 and 16 − 7. The shallow borehole depth was 7 m, while the deep borehole depth extended to 13 m. By analyzing stress values at different distances from the working face, the distribution characteristics of advance abutment stress in the mining area were inferred, allowing for an understanding of the transmission mechanism of the roof load source.

As illustrated in Fig. 5, the stress evolution trends at the stress meters follow four distinct stages:

-

(1)

In-situ stress zone: Beyond 275 ~ 330 m ahead of the 3− 1402 working face, the stress remained approximately at the initial installation value, indicating that this region was not affected by the disturbance of the working face mining. The coal body remained predominantly in an elastic state.

-

(2)

Stress slowly rising zone: Within 225 ~ 330 m ahead of the working face, stress values began to rise slowly without abnormal increase, suggesting the area was influenced by load transfer from the hanging roof in the goaf, though the effect was relatively minor.

-

(3)

Stress rapidly rising zone: Within 50 ~ 240 m ahead of the working face, the monitored stress values increased significantly, peaking approximately 45 ~ 60 m from the working face. The peak stress, reaching 2.5 to 4.0 times the initial value, indicates a prominent influence from the roof load source and a high overall stress concentration.

-

(4)

Stress decreasing zone: Within the range of 0 ~ 50 m ahead of the working face, the stress values at monitoring points with valid data began to decrease. In this area, the coal body was subjected to plastic failure due to the roof load source, resulting in a decrease in bearing capacity and shifting stress to deeper regions.

The advance abutment stress of the 3− 1402 working face is characterized by a wide distribution range, high peak stress, and distinct stress zoning patterns. Figure 5 also shows that the deep borehole stress meters respond more significantly to the stress transmission from the hanging rock strata in the goaf compared to the shallow borehole meters, with earlier and broader stress fluctuation responses. The range of the stress rapidly zone monitored by the deep borehole stress meter 71# was 101 ~ 235 m ahead of the coal wall, whereas that of the stress meter 41# was 106 ~ 215 m. This difference suggests that load transfer intensity in the control area of drill hole 16 − 7 is slightly higher than in that of drill hole 16 − 8.

Characteristic of rock burst

According to the records from the MS monitoring system, a rock burst occurred at the 3− 1402 working face mined to 1750 m, with a MS event energy of 2.55 × 105J. The MS event source was approximately 85 m horizontally from the 3− 1402 tailgate, and about 60 m vertically from the 3 − 1 coal seam. The damage area at tailgate caused by the rock burst was located 50 ~ 90 m ahead of the coal wall, with significant floor heave on the side near the working face. The maximum floor heave reached 0.8 m, with a roof subsidence of 0.25 m. Four safety valves of the supports were damaged, some anchor plates fell off, and the rock burst caused dust to rise along with a strong airflow. The on-site rock burst damage and affected area are shown in Fig. 3(a).

In summary, the primary factor inducing high-energy MS events is the failure and instability of the thick sandstone key stratum located within 100 m above the 3− 1402 working face. Variations in MS event activity and stress distribution are fundamentally influenced by the differing occurrence states of the key strata near the coal seam. The rock burst risk in the area controlled by drill hole 16 − 7 is higher than that in the area controlled by drill holes 16 − 8 to 16 − 10.

Mechanical analysis of key strata composite effect

Determination criteria of composite key strata

A mechanical model for analyzing the load on composite key strata has been established11,23, as shown in Fig. 6. In light of the potential influence of joints and weak planes on interlayer interactions, coupled with the strength-weakening effects induced by ground temperature33 and groundwater34, the model idealizes the lithological units as homogeneous materials and explicitly excludes thermal and hydrogeological weakening mechanisms to decouple these geological factors from the mechanical responses.

The model primarily examines a composite beam with a rectangular cross-section, comprising an upper key stratum, a lower key stratum, and an intercalated stratum between them. In the model, the thicknesses and elastic modulus of the rock strata, from bottom to top, are represented by h1, h12, h2, and E1, E12, E2 respectively. It is assumed that the neutral axis of the composite beam is located in the intercalation. The distances from the neutral axis to the lower and upper key strata are denoted as ha, hb, respectively. The variable q represents the vertical load per unit area carried by the key strata.

Based on the static relationship of the composite beam cross-section, the following can be derived:

By applying the model conditions into Eq. (5), the distance ha b between the neutral axis and the lower key stratum is determined.

The stress distribution above and below the neutral axis of the composite beam are different: above the neutral axis is the compression zone, while below is the tension zone. Shear stress for each zone is expressed as follows:

The tension zone: -L/2 ≤ x ≤ L/2, 0 ≤ y ≤ ha,

The compression zone: -L/2 ≤ x ≤ L/2, 0 ≤ y≤-hb,

where L and q is the ultimate initial breaking length and overburden load of key stratum.

The formation conditions for composite key strata require synchronous movement of each rock stratum, with no shear slip occurring at the rock stratum contact surfaces and at the maximum shear stress points in the model.

The shear stress distribution curves of the composite key strata mechanical model were constructed based on Eqs. (7) and (8) using MATLAB software, as schematically shown in Fig. 7. It can be observed that the maximum shear stress τ12max in the model is distributed at both ends of the neutral axis, while the maximum shear stresses τ1max and τ2max on the rock stratum contact surfaces are distributed at both ends of the contact surface. Thus, the formation condition for the composite key strata is expressed in Eq. (9):

where the maximum shear stress τ in Eq. (9) is negative, it only indicates that the shear stress at this location is in the opposite direction to the coordinate axis; τz is the shear strength of the rock stratum at the neutral axis; τg1, τg2 are the shear strengths along the bedding planes of the rock strata, the calculation formula35,36,37 is:

where σ is the vertical stress on the bedding planes between rock strata.

To analyze, the medium-grained sandstone o 36.8 m and fine-grained sandstone of 34.6 m above the 3 − 1 coal seam in drill hole 16 − 7 were selected. The mechanical parameters of these sandstones were substituted into Eqs. (1), (4), (5), and (6) to calculate the neutral axis position, as shown in Table 2. Results indicate that the neutral axis is located in the lower key stratum, while the contact surface between the two key strata is located in the compression zone above the neutral axis.

Since there is no intercalation between the upper and lower key strata, forming the composite key strata only requires satisfying the last two terms of Eq. (9). According to Table 2, the maximum shear stresses at the contact surface between the key strata (τ2max) and at the neutral axis (τ12max) are calculated as 0.76 MPa. In the study area, the vertical stress σ in the key strata region is 16.8 MPa, which is substituted into Eq. (10) to calculate the shear strength τg2 at the contact surface of the key strata as 7.98 MPa. Additionally, by the experiments, that the shear strength τz of the medium-grained sandstone in the lower key stratum is 5.24 MPa.

It is observed that the shear stresses at the neutral axis and contact surface of the two thick key strata within 100 m of the drill hole 16 − 7 area are below their shear failure strengths, thus meeting the formation conditions for composite key strata.

Dynamic and static load characteristics

When the overlying strata of the mining stope satisfy the formation conditions for composite key strata, they can be replaced with an equivalent homogeneous stratum11,38. This substitution yields the equivalent parameters, such as thickness he, moment of inertia Ie, elastic modulus Ee, and unit weight γe, as shown in Eq. (11).

In this paper, the static load increment caused by composite key strata structure prior to initial fracture, and the dynamic load induced by the initial fracture are analyzed. By substituting the equivalent parameters into key strata theory, the overlying load qe on the composite key strata, and the initial ultimate fracture length Le are calculated, as shown in Eq. (12).

The parameters of the composite key strata from drill hole 16 − 7, as listed in Tables 1 and 2, are substituted into Eq. (11), yielding equivalent values for a single homogeneous stratum: he=71.4 m, Ie=30332.86 m3, Ee =0.90 GPa, and γe = 22.75 kN/m3. Further substitution of these values into Eq. (12) results in an overlying load qe =2.08 MPa, and a controlled strata thickness h = 127.4 m. Since the fracture of the lower key stratum is a prerequisite for the fracture of the composite key strata, the tensile strength RT=1.6 MPa is introduced into the calculation, resulting in an initial fracture length Le =88.6 m for the composite key strata. Compared to the single key strata analysis in Table 2, the composite effect significantly enhances the bearing capacity of the upper and lower key strata, increasing the controlled rock height and initial fracture length.

Distribution of abutment stress under composite key strata

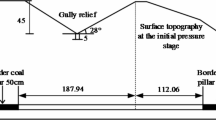

The distribution of the abutment stress in front of the coal wall at the working face is determined by several factors. Assuming that the composite key strata are in a fully suspended state prior to initial fracture, the structural model for stress transfer is illustrated in Fig. 8.

The self-weight stress of the suspended composite key strata structure (rock mass in the OADF range) is jointly borne by the solid coal on both sides. This stress results in a forward-transmitted stress increment, Δσ, which can be considered the total stress conveyed by the OABC structure on the right side. The distribution of the abutment stress increment can be approximately fitted into a triangular distribution39, as expressed by the following equation:

where the peak stress σmax transmitted by the suspended OABC rock mass is given by the following equation:

where α is the movement angle of the composite key strata.

Based on the monitoring data of the overburden movement in the 3− 1402 working face, the rock strata movement angle α = 64° is obtained. Substituting the parameters of the composite key strata into Eqs. (13) and (14), the peak value of the abutment stress increment caused by the composite strata structure is calculated to be 3.52 MPa, located 62.1 m in front of the coal wall. In contrast, based on the parameters of the two key strata mentioned in Table 2, without considering the composite effect, the superimposed peak abutment stress increment transmitted by the key strata is 2.76 MPa, positioned 45.8 m ahead of the coal wall. The distribution of the advance abutment stress under composite or non-composite conditions is shown in Fig. 9.

The distribution characteristics of advance abutment stress indicate that the stress transmitted by suspended rock strata to the front of the working face has a significant positive correlation with the thickness and length of these strata. Consequently, compared to individual key strata, the ultimate fracture length and bearing thickness of the rock strata increase under the composite key strata effect. It leads to a greater advance abutment stress increment of the working face, and a broader stress influence range.

Characteristics of fracture energy release under composite key strata

The primary source of elastic energy released during the initial fracture of the composite key strata structure is the bending elastic energy of the roof. According to the energy storage model of the suspended rock strata system, the energy released during the initial fracture of the composite key strata structure can be expressed as40:

where Ufw is the elastic energy released during the initial fracture of the composite key strata structure; η is the seismic efficiency, representing the proportion of energy released as seismic waves relative to the elastic energy released by the fractured rock strata, typically ranging from 0.26% ~ 3.6%; b is the fracture length of the key strata along the inclination direction.

With η taken as 0.26% and b as 82 m (1/3 of the 3− 1402 working face width), substituting into Eq. (15) yields an energy release of 3.20 × 10 5 J during the initial fracture of the composite key strata. In comparison, the energy released from asynchronous fracture of key strata without the composite effect is 9.17 × 104 J. This indicates a significantly higher energy release intensity when the composite key strata structure fractures.

Overall, the thickness of the overlying rock, enhanced load-bearing capacity, and extended initial fracture length are characteristic of the composite effect of key strata.

Based on monitoring data and theoretical analysis results, the rock burst process and mechanism under the influence of the key strata composite effect are described through static and dynamic load superposition theory, as illustrated in Fig. 10.

Before the fracture of the composite key strata, the static load ahead of the working face rises due to load transfer from the suspended rock strata, evidenced by a high abutment pressure peak and an expanded stress influence range. When the composite key strata reach the ultimate strength and fracture, the resulting strong dynamic load propagates as seismic waves toward the coal-rock mass ahead. Under the combined effects of static and strong dynamic loads within the composite key strata structure, the working face is prone to dynamic manifestations, such as rock burst and strong ground pressure.

Numerical simulation of influencing factors under the key strata composite effect

The sandstone strata combinations within the Zhiluo Formation of the Ordos mining area vary due to diagenetic age and sedimentation processes. These variations influence the composite effects across stratigraphic combinations, which, in turn, affect rock burst risk at the working face. In this study, the UDEC numerical simulation software was used to select two factors: the strata thickness ratio and intercalation thickness, to analyze the synchronicity of rock strata fracture and the evolution law of peak advance abutment stress. The aim is to investigate the strength of composite effects across different combinations of thick and weak strata.

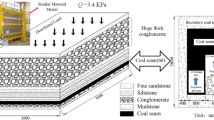

Simulation scheme of influencing factors

A numerical model based on drill hole 16 − 7 was constructed to evaluate the strength of composite effects across different strata combinations, as illustrated in Fig. 11. The model dimensions are 500 m × 250 m, with a coal seam thickness of 6 m. An equivalent uniformly distributed load of 12.25 MPa is applied to the top of the model, while the bottom is fixed, and the remaining surfaces are rolling support boundaries. The lateral stress coefficient is set to 1.4, and gravitational acceleration is 9.8 m/s². The block material follows the Mohr-Coulomb plastic constitutive model, while the contact surfaces are modeled using the Coulomb slip constitutive model.

The determination and adjustment of the mechanical parameters used in the numerical model were conducted as follows41,42:(1) Parameters such as Poisson’s ratio, cohesion, friction angle, elastic modulus, and compressive strength of coal and rock samples were obtained through laboratory tests; (2) The elastic modulus Em of the engineering rock mass was calculated using the RQD method43, as shown in Eq. (16). The compressive strength σmc of the engineering rock mass was determined using the method proposed by Singh and Seshagiri Rao44, as indicated in Eq. (17). The tensile strength of the engineering rock mass was assumed to be 1/10 of its compressive strength, while other parameters remained consistent with those of standard samples; (3) The bulk modulus and shear modulus of the block material were calculated using Eqs. (18) and (19), respectively. The normal stiffness kn and shear stiffness ks of the joints were also determined using these equations; (4) A trial-and-error approach was employed to validate the calculated parameters through a series of uniaxial compression tests. The simulation parameters were then fine-tuned to ensure consistency with experimental results. The mechanical parameters used in the numerical model are listed in Table 3.

where Em is the elastic modulus of rock mass; Er is the elastic modulus of rock; RQD is a rock quality index.

where σmc is the compressive strength of rock mass; σc is the compressive strength of rock; n is the coefficient, the values of n are 0.56, 0.66 and 0.72, respectively. In this paper, n is 0.56.

where Em, K and G are the block elastic modulus, bulk modulus and shear modulus respectively, and µ is the Poisson ratio of the block. Mechanical parameters of rock mass. where kn and ks are the normal stiffness and shear stiffness of the contact. ΔZmin is the smallest length of zone and n is a scaling factor (usually set 1 ~ 10).

The study focuses on the effects of the thickness ratio between the upper and lower key strata, as well as the intercalation thickness, on the strength of composite effects. The simulation scheme is as follows. A simulation calculation is conducted each 10 m of excavation along the working face.

Thickness ratio between the upper and lower key strata: Numerical models were constructed with the lower stratum located at a distance of 0 m from the coal seam, an intercalation thickness of 0 m, and a total composite strata thickness of 70 m. The thickness ratios of the upper to lower strata were set to 5:2, 4:3, 1:1, 3:4, and 2:5, respectively.

Intercalation thickness: Numerical models were constructed with the lower stratum located at a distance of 0 m from the coal seam, both the upper and lower strata having a thickness of 35 m. The intercalation composed of sandy mudstone, was modeled with thicknesses of 0 m, 10 m, 20 m, 30 m, and 40 m, respectively.

The influence of key strata thickness ratio

Whether the upper and lower strata can subside and fracture synchronously is the criterion for judging the strength of the composite effect. The Y displacement and the roof strata fracture characteristics are analyzed when the working face is mined to 70 m and 90 m.

Figure 12 shows that with a thickness ratio of 5:2, the fracture length of the lower stratum is 70 m. The upper stratum displays a maximum displacement of approximately 2.10 m, with a peak separation of 0.65 m between the upper and lower strata. When the working face is mined to 90 m, the upper stratum begins to fracture, increasing the maximum separation to 0.95 m. It indicates relatively independent movement and fracture of the upper and lower strata at this thickness ratio. For thickness ratios of 4:3, 1:1, and 3:4, the movement and fracture laws of the overburden are similar. When the working face is mined to 70 m, neither stratum fractures, and the maximum roof displacement is about 2.0 m. As the working face advances to 90 m, both strata fracture and collapse into the goaf without significant separation. With a thickness ratio of 2:5, the lower stratum fractures at 70 m, forming an ‘inverted arch’ shape as the bottom of the lower stratum collapses into the goaf, accompanied by substantial displacement and separation. However, the top section of the lower stratum maintains strong integrity with the upper stratum, creating a relatively stable structure suspended above the goaf. As the working face advances to 90 m, both strata break as a unified structure, exhibiting fracture characteristics similar to those at thickness ratios of 4:3, 1:1, or 3:4.

The overall strength increases when a composite effect forms between the upper and lower strata, resulting in stronger stress transmission to the coal body when the rock structure is suspended. To ensure comparability of advance stress across different schemes, the stress at a mining length of 60 m was selected for analysis, with the measurement line positioned at y = 27 m. At this stage, the roof in each of the five thickness ratio models remained unbroken.

As shown in Fig. 13, as the thickness ratio between the upper and lower strata decreases, the peak advance support stress on the working face shows a trend of initially increasing and then decreasing. When the thickness ratio is 1:1, the peak stress is the highest, reaching 23.3 MPa, indicating the strongest composite effect at this scheme. In contrast, when the thickness ratio is 5:2, the peak stress is the lowest, with a peak stress of 22.7 MPa.

It is observed that when the lower stratum is relatively thin, the composite effect between key strata weakens or disappears, and the upper and lower strata exhibit distinct step-by-step movement and fracture characteristics. As the thicknesses of the upper and lower strata become more similar, the composite effect strengthens, resulting in an increase in peak advance support stress and fracture length, thereby raising the rock burst risk in the working face. However, when the lower stratum is significantly thicker than the upper stratum, it exhibits characteristics of a single key stratum, though the composite effect is reduced.

The influence of intercalation thickness

The Y displacement and the roof strata fracture characteristics are analyzed when the working face is mined to 70 m and 90 m.

Figure 14 shows that with the intercalation thickness of 0 m, 10 m, or 20 m, the fracture patterns of the strata remain relatively similar. When the working face is mined to 70 m, both the upper and lower strata fracture and collapse into the goaf, with no significant separation between the two strata.

However, as the intercalation thickness increases to 30 m and 40 m, the upper and lower strata no longer move synchronously. When the working face is mined to 70 m, the lower stratum begins to break, with portions collapsing into the goaf. At this stage, the separation between the lower stratum and the intercalation is minimal. As the working face advances to 90 m, the lower stratum fracture and collapse entirely, creating a distinct separation space from the intercalation, with maximum separation gaps of 1.5 m and 2.2 m, respectively. The upper stratum, constrained by the intercalation, resulting in the small displacements of 1.1 m and 0.9 m, respectively.

The stress at a mining length of 60 m was selected for analysis, with the measurement line positioned at y = 27 m. As shown in Fig. 15, when the intercalation thickness is 0 m, 10 m, or 20 m, the peak advance abutment stress values of the working face remain identical at 23.3 MPa, indicating a strong composite effect. However, as the intercalation thickness increases to 30 m and 40 m, the peak advance stress decreases to 22.9 MPa and 22.4 MPa, respectively.

It is observed that as the intercalation thickness approaches or exceeds that of the upper and lower strata, the lower stratum fractures and collapses into the goaf earlier, creating a distinct separation space from the intercalation and upper strata. This reduces the concentration of advance stress, resulting in a lower peak stress and the disappearance of the composite effect. Thus, the presence of the intercalation disrupts the connection between the upper and lower strata, diminishing the potential of forming the composite effect.

Prevention and control of rock burst under composite key strata

The parameters of the key strata, consisting of coarse-grained sandstone with a thickness of 47.58 m and medium-grained sandstone with a thickness of 53.79 m in drill hole 16 − 5 of the 3− 1402 working face, were substituted into Eq. (1) ~ (10). The maximum shear stresses calculated at the contact surface and neutral axis of the key strata are 0.96 MPa, which are below the shear failure strength of the rock. Thus, these strata meet the conditions for forming composite key strata. To weaken the risk of rock burst during mining in the control area of drill hole 16 − 5, targeted preventive measures should be implemented in advance to reduce the likelihood of rock burst.

Prevention and control scheme

Based on the geological characteristics of the rock strata in drill hole 16 − 5, an optimized prevention and control scheme is proposed, to mitigate the strong composite effects between the upper and lower rock strata. This scheme combines overall roof weakening with coal seam stress relief.

-

(1)

The depth of deep-hole pre-splitting blasting in the roof should be increased. Fracturing should target the middle-top section of the 47.58 m coarse-grained sandstone key stratum and the bottom section of the 53.79 m medium-grained sandstone key stratum. This approach weakens the integrity of both key strata and reduces the fracture length in the lower stratum, facilitating asynchronous breaking of the strata. In the tailgate and headgate of the control area under drill hole 16 − 5, fan-shaped groups of blasting holes are arranged every 10 m, with 5 holes per group in the tailgate and 3 holes per group in the headgate. Each blasting hole has a diameter of 90 mm with positive charging. To ensure effective fracture propagation, the charge quantity is increased from 2 ~ 3 kg·m− 1 to 4 kg·m− 1. The blasting parameters are shown in Table 4.

-

(2)

Large-diameter pressure relief boreholes should be applied to weaken the coal seam strength in the advance region of the working face. This approach reduces the concentration of advance stress in the coal seam. Each borehole has a diameter of 153 mm, and the spacing between boreholes has been reduced from 1.0 ~ 2.0 m to 0.8 ~ 1.6 m. The drill hole depth has been increased from 20 m to 25 m.

The pressure relief scheme is shown in Fig. 16. Considering the variation in rock burst hazards between the tailgate and headgate, attributed to factors such as suspended roof areas in the goaf and the irrational design of the coal pillar, the pre-pressure relief range should not be less than 350 m for the tailgate and 200 m for the headgate.

Inspection of prevention and control effect

For simplicity, the control areas of drill holes 16 − 7 and 16 − 5 are designated as Region 1 and Region 2, respectively. Both regions represent the influence zones of the composite key strata. As shown in Fig. 17, the implementation of the optimized prevention and control scheme in Region 2 resulted in reductions in both the frequency and total energy of high-energy MS events (with energy ≥ 5.0 × 104 J), which decreased to 10 times and 1.0 × 106 J, respectively. In contrast, Region 1, which did not apply this optimized scheme, experienced 40 MS events with a total energy of 8.90 × 106 J. This outcome reflects a reduction of approximately 75% in event frequency and 88.2% in total energy in Region 2. Conversely, the activity of low-energy MS events in Region 2 increased compared to Region 1. These results indicate that the optimized prevention and control scheme effectively disrupted the connection between the upper and lower key strata, thereby significantly weakening their composite effect. Consequently, the MS event pattern shifted from a “low-frequency, high-energy” strong risk profile to a “high-frequency, low-energy” medium-low risk profile, reducing the influence of strong dynamic loads caused by the collaborative breaking of composite key strata.

Energy density clouds can reflect the development of microcracks and energy release, with high-energy density areas indicating regions where microcracks are concentrated and coal-rock mass fractures are validated. Additionally, the nucleation of the energy density clouds can represent the evolution of localized high-stress concentration regions before rock bursts occur45,46. MS event data during the mining of the working face in both regions are used to generate energy density cloud maps, as shown in Fig. 18.

The results indicate that during the mining in Region 1, the maximum energy density is 78.5 J·m− 2, with a large and concentrated nucleation area for the energy density cloud, aligning with the distribution of strong MS events shown in Fig. 3. In contrast, during mining in Region 2, the maximum energy density is 58.4 J·m− 2, marking a reduction of approximately 25.6%. Additionally, the nucleation area in Region 2 is smaller, more dispersed, and positioned farther from the adjacent goaf side of the 3− 1402 tailgate. These findings suggest that the optimized prevention and control scheme in Region 2 weakens the capacity of the coal-rock mass to accumulate elastic energy, reduces stress concentration, and demonstrates a significant pressure-relief effect.

Discussion

Applicability of the composite key strata theory model

The mechanical model of the composite key strata, based on idealized assumptions, provides a theoretical framework and quantitative analytical tools for understanding the mechanical behavior of composite key strata. While it holds theoretical significance and guiding value, its applicability in practice is influenced by variations in geological and mining conditions encountered in underground operations. To ensure its practical relevance, the theoretical model must be validated and adjusted using geological data, on-site monitoring results, and other specific engineering conditions.

Proposed improvements for prevention and control methods

In practical mining conditions, implementing control measures for composite key strata often encounters challenges and limitations, such as significant interference with construction effectiveness, difficulty in evaluating pressure relief effects, and the limited applicability of roof blasting. To address these issues, the following improvements are proposed:

-

(1)

When utilizing deep-hole roof blasting to mitigate rock bursts, real-time monitoring of MS parameters: event frequency, energy, scalar seismic moment, and moment magnitude, which should be conducted during the mining of the working face. It helps evaluate the effectiveness of pressure relief from the blasting47,48. In areas where construction effectiveness is insufficient, roof blasting parameters should be promptly adjusted, and supplementary blasting measures should be implemented.

-

(2)

If roof blasting is constrained by underground conditions, alternative techniques such as surface hydraulic fracturing49 or surface blasting can be employed. These methods significantly reduce the structural integrity of the roof strata, weaken mining-induced stresses, and lower the intensity of MS event activities during the mining of the working face.

Conclusions

Taking the 3− 1402 working face of a rock burst coal mine in the Ordos mining area as the research background, the data analysis, theoretical modeling, and numerical simulation were employed to investigate the formation conditions of composite key strata between thick and weak key strata and the mechanism inducing rock burst. The study also examined the varying strength of the composite effect under different influencing factors, and proposed a prevention and control scheme to mitigate the intensity of this effect. The main conclusions are as follows.

-

(1)

The field data indicate that during the mining in areas with thick, multi-layered sandstone key strata, the frequency of high-energy MS events is greater, the energy release is higher, and the events are more concentrated. Additionally, advance stress monitoring meters show stronger responses to disturbances caused by working face mining. The variation in key strata characteristics account for the differing rock burst risks across regions.

-

(2)

A criterion for the formation conditions of composite key strata is proposed, based on a structural mechanics model of the composite effect between thick and weak key strata. The mechanism of rock bursts under the composite effect of key strata: the peak advance support stress and its influence range increase, and the dynamic load released by the fracture of composite key strata is intense, which are prone to rock burst under the combined effects of static load and multiple rounds of strong dynamic load.

-

(3)

Simulation results indicate that the closer the thickness of the upper and lower strata, the stronger the composite effect becomes. The peak abutment stress is highest when the thickness ratio of the rock strata is 1:1. Additionally, the presence of an intercalation weakens the synergy between the upper and lower strata. When the thickness of the intercalation nears or exceeds that of the upper and lower strata, the composite effect diminishes or even vanishes entirely.

-

(4)

An optimized prevention and control scheme is proposed to manage the energy and load release between the roof and coal seam. This approach effectively reduces high-energy MS event intensity and stress concentration in the coal and rock mass, thereby weakening the rock burst risk caused by the composite key strata on the working face.

Data availability

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

References

Chen, W. C. et al. Impact of mining-induced bed separation spaces on a cretaceous aquifer: a case study of the Yingpanhao coal mine, Ordos basin, China. Hydrogeol. J. 30, 691–706. https://doi.org/10.1007/s10040-022-02455-y (2022).

Pan, W. et al. Coal burst prevention technology and engineering practice in Ordos deep mining area of China. Sustainability 15, 159 (2023).

Zhang, L. & Ponomarenko, T. Directions for sustainable development of China’s coal industry in the post-epidemic era. Sustainability 15, 6518 (2023).

Ranjith, P. G. et al. Opportunities and challenges in deep mining: a brief review. Engineering 3, 546–551. https://doi.org/10.1016/J.ENG.2017.04.024 (2017).

Zhang, J., Li, Q., Zhang, Y., Cao, Z. & Wang, X. Definition of deep coal mining and response analysis. J. China Coal Soc. 44 (5), 1314–1325. https://doi.org/10.13225/j.cnki.jccs.2019.6018 (2019).

Lou, C. et al. Dynamic mechanical characteristics of deep Jinping marble in complex stress environments. J. Rock. Mech. Geotech. 16, 630–644. https://doi.org/10.1016/j.jrmge.2023.08.005 (2024).

Xie, H. et al. Study on mechanical properties and mechanical response of coal mining at 1000 m or deeper. Rock. Mech. Rock. Eng. 52, 1475–1490. https://doi.org/10.1007/s00603-018-1509-y (2019).

Xie, H. et al. Experimental study on rock mechanical behavior retaining the in situ geological conditions at different depths. Int. J. Rock. Mech. Min. 138, 104548. https://doi.org/10.1016/j.ijrmms.2020.104548 (2021).

Guo, W. et al. Mechanism and evolution control of wide coal pillar bursts in multithick key strata. Shock Vib. 2021 (4696619). https://doi.org/10.1155/2021/4696619 (2021).

Zhao, Y. et al. Failure mechanism of gob-side roadway in deep coal mining in the Xinjie mining area: theoretical analysis and numerical simulation. J. Cent. South. Univ. 30, 1631–1648. https://doi.org/10.1007/s11771-023-5315-7 (2023).

Qian, M., Shi, P. & Xu, J. Underground Pressure and Strata Control (China University of Mining and Technology, 2003).

Qian, M., Miu, X., Xu, J. & Mao, X. Key Strata Theory in Ground Control (China University of Mining and Technology, 2000).

Han, H. et al. Mining stress formation and distribution: predictive model based on overburden key strata structure. Energy Sci. Eng. 12, 1551–1568. https://doi.org/10.1002/ese3.1686 (2024).

Han, H., Xu, J., Wang, X., Xie, J. & Xing, Y. Method to calculate working surface abutment pressure based on key strata theory. Adv. Civ. Eng. 2019 (7678327). https://doi.org/10.1155/2019/7678327 (2019).

Kuang, T. et al. The impact of key strata movement on ground pressure behaviour in the Datong coalfield. Int. J. Rock. Mech. Min. 119, 193–204. https://doi.org/10.1016/j.ijrmms.2019.04.010 (2019).

Xie, J. & Xu, J. The corresponding relationship between the change of Goaf pressure and the key stratum breaking. J. Geophys. Eng. 16, 913–925. https://doi.org/10.1093/jge/gxz054 (2019).

Chen, L. et al. Analysis of the impact of key strata failure on overlying strata and surface transport patterns. Eng. Fail. Ana. 163, 108532. https://doi.org/10.1016/j.engfailanal.2024.108532 (2024).

He, C., Xu, J., Wang, F. & Wang, F. Movement boundary shape of overburden strata and its influencing factors. Energies 11, 742 (2018).

Cunhan, H. et al. Development rule of ground fissure and mine ground pressure in shallow burial and thin bedrock mining area. Sci. Rep. 15, 10065–10065. https://doi.org/10.1038/s41598-024-77324-7 (2025).

Feng, X. et al. The dynamic impact of rock burst induced by the fracture of the Thick and hard key stratum. Procedia Eng. 26, 457–465. https://doi.org/10.1016/j.proeng.2011.11.2192 (2011).

Wang, C. et al. Mechanism of rock burst induced by fault slip in an Island coal panel and hazard assessment using seismic tomography: a case study from Xuzhuang colliery, Xuzhou, China. Geosci. J. 21, 469–481. https://doi.org/10.1007/s12303-016-0065-2 (2017).

Zhou, K. et al. Coal burst mechanism in large-scale panel under extra-thick key strata. Geomat. Nat. Haz Risk. 15, 2347420. https://doi.org/10.1080/19475705.2024.2347420 (2024).

Miao, X., Mao, X., Sun, Z. & Pu, H. Formation conditions of compound key strata in mining overlayer strata and its discriminance. J. China Univ. Min. Technol. 34, 547–550 (2005).

Ren, H., Li, S. & Pan, H. Analysis of numerical simulation on breaking law of the composite key stratum affected by coal mining. AMR 2012, 616–618. https://doi.org/10.4028/www.scientific.net/AMR.616-618.350 (2012).

Wang, Z. et al. Relationships between the petrographic, physical and mechanical characteristics of sedimentary rocks in jurassic weakly cemented strata. Environ. Earth Sci. 78, 131. https://doi.org/10.1007/s12665-019-8130-6 (2019).

Zhang, G. et al. Mechanical properties and failure mechanism of the weakly cemented overburden in deep mining. Minerals 12, 1276 (2022).

Zhang, L. et al. Characteristic developments of the water-conducting fracture zones in weakly cemented overlying strata of jurassic coal mines in Western China. Water 15, 1097 (2023).

Bai, X. et al. Rock burst mechanism induced by stress anomaly in roof thickness variation zone: a case study. Geomat. Nat. Haz Risk. 13, 1805–1830. https://doi.org/10.1080/19475705.2022.2100832 (2022).

Dong, L. J., Wesseloo, J., Potvin, Y. & Li, X. B. Discriminant models of blasts and seismic events in mine seismology. Int. J. Rock. Mech. Min. 86, 282–291. https://doi.org/10.1016/j.ijrmms.2016.04.021 (2016).

Maxwell, S. C., Rutledge, J., Jones, R. & Fehler, M. Petroleum reservoir characterization using downhole microseismic monitoring. Geophysics 75 https://doi.org/10.1190/1.3477966 (2010). A129-A137, doi.

Wesseloo, J., Woodward, K. & Pereira, J. Grid-based analysis of seismic data. J. S Afr. I Min. Metall. 114, 815–822 (2014).

Wilkins, A. H., Strange, A., Duan, Y. & Luo, X. Identifying microseismic events in a mining scenario using a convolutional neural network. Comput. Geosci-UK. 137 https://doi.org/10.1016/j.cageo.2020.104418 (2020).

Lin, H. X., Liu, W. D., Zhang, D., Chen, B. & Zhang, X. S. Study on the degradation mechanism of mechanical properties of red sandstone under static and dynamic loading after different high temperatures. Sci. Rep. 15 https://doi.org/10.1038/s41598-025-93969-4 (2025).

Wang, J. C., Wang, W., Chen, G. Q. & Wang, Y. K. Effect of moisture content on the rockburst intensity of sandstones. Geomech. Geophys. Geo. 10 https://doi.org/10.1007/s40948-024-00807-4 (2024).

Sanei, M. et al. Shear strength of discontinuities in sedimentary rock masses based on direct shear tests. Int. J. Rock. Mech. Min. 75, 119–131. https://doi.org/10.1016/j.ijrmms.2014.11.009 (2015).

Zhang, Q., Shen, M., Ding, W. & Clark, C. Shearing creep properties of cements with different irregularities on two surfaces. J. Geophys. Eng. 9, 210–217. https://doi.org/10.1088/1742-2132/9/2/210 (2012).

Zhang, Y. Instability and Control Mechanism of Layered Compound Roof in Consideration of Shear Behavior of Bedding Plane (China University of Mining and Technology,Xuzhou,China, 2015).

Sayyad, A. S. & Ghugal, Y. M. Bending, buckling and free vibration of laminated composite and sandwich beams: A critical review of literature. Compos. Struct. 171, 486–504. https://doi.org/10.1016/j.compstruct.2017.03.053 (2017).

Zhu, S., Feng, Y. & Jiang, F. Determination of abutment pressure in coal mines with extremely Thick alluvium stratum: a typical kind of rockburst mines in China. Rock. Mech. Rock. Eng. 49, 1943–1952. https://doi.org/10.1007/s00603-015-0868-x (2016).

Wang, S. et al. Study on mechanism of rock burst in horizontal section mining of a steeply inclined extra-thick coal seam. Lithosphere 2022 (7058797). https://doi.org/10.2113/2022/7058797 (2022).

Cao, J. R. et al. Mechanism of the coal bursts in the working face during mining of steeply inclined and extra Thick coal seam. Geomat. Nat. Haz Risk. 14 https://doi.org/10.1080/19475705.2023.2206511 (2023).

Guo, F. et al. A Three-Dimensional supporting technology, optimization and inspiration from a deep coal mine in China. Rock. Mech. Rock. Eng. 57, 655–677. https://doi.org/10.1007/s00603-023-03576-w (2024).

Zhang, L. Y. & Einstein, H. H. Using RQD to estimate the deformation modulus of rock masses. Int. J. Rock. Mech. Min. 41, 337–341. https://doi.org/10.1016/S1365-1609(03)00100-X (2004).

Singh, M. & Rao, K. S. Empirical methods to estimate the strength of jointed rock masses. Eng. Geol. 77, 127–137. https://doi.org/10.1016/j.enggeo.2004.09.001 (2005).

Frankel, A. Mapping seismic hazard in the central and Eastern united States. Seismol. Res. Lett. 66, 8–21. https://doi.org/10.1785/gssrl.66.4.8 (1995).

Wang, G. F. et al. Understanding rockburst-generating behaviors and associated seismicity by using a spatial calculation methodology with an energy density index. Math Probl Eng 6128368, (2018). https://doi.org/10.1155/2018/6128368 (2018).

Wojtecki, L., Mendecki, M. J. & Zuberek, W. M. Determination of destress blasting effectiveness using seismic source parameters. Rock. Mech. Rock. Eng. 50, 3233–3244. https://doi.org/10.1007/s00603-017-1297-9 (2017).

Wu, K. B., Zou, J. P., Jiao, Y. Y., He, S. J. & Wang, G. M. Insight and effectiveness of Working-Face deep-Hole blasting for prevention of strong seismicity induced by deep coal mining. Rock. Mech. Rock. Eng. 56, 8693–8709. https://doi.org/10.1007/s00603-023-03516-8 (2023).

Zhuang, J. X. et al. Multistage hydraulic fracturing of a horizontal well for hard roof related coal burst control: insights from numerical modelling to field application. Int. J. Min. Sci. Techno. 34, 1095–1114. https://doi.org/10.1016/j.ijmst.2024.08.008 (2024).

Acknowledgements

This research is funded by the projects: National Natural Science Foundation of China (52274098, U21A20110), National Key Research and Development Program (2022YFC3004603), Jiangsu Province International Collaboration Program- Key national industrial technology research and development cooperation projects (BZ2023050), Postgraduate Research & Practice Innovation Program of Jiangsu Province (SJCX23_1292), and Graduate Innovation Program of China University of Mining and Technology (2023WLKXJ038). These supports are gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

G. L. and (A) C. wrote the main manuscript text and acquired funding. C. X. and S. W. analyzed the formals. Q. H and N.Z. Conducted numerical simulations. G. L. and C. X. analyzed the theory and simulation results. X. (B) and Y. P. Collected and organized data. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lyu, G., Cao, A., Xue, C. et al. Rock burst mechanisms induced by dynamic and static loading under composite key strata: a case study. Sci Rep 15, 16935 (2025). https://doi.org/10.1038/s41598-025-01591-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-01591-1