Abstract

Electro-osmotic micromixers constitute a specialized class of active micromixers that apply alternating current (AC) to electrodes. This methodology promotes the formation of vortical structures within the fluid medium, resulting in a substantial increase in mixing homogeneity. In this study, the geometrical parameters of the electro-osmotic micromixer, for which two rigid baffles were implanted at the entrance, were optimized using the Taguchi method and response surface methodology (RSM). Data were obtained through a transient 2D model, simulated using COMSOL software based on the finite element method. After acquiring the optimized geometric parameters, the mixing index was assessed under various conditions, including inlet velocity, frequency, voltage, and phase lag of the alternating current. The optimized values of first baffle angle (\({\beta }_{1}\)), second baffle angle (\({\beta }_{2}\)), baffle length (L), the distance between baffles in the x direction (x), the distance between baffles in the y direction(y), and mixing chamber angle (\(\alpha\)) were obtained \({146.1}^{^\circ },{82.88}^{^\circ },11.78\,{ \upmu \text{m}},18.75\,{ \upmu \text{m}},4.93\,{ \upmu \text{m} } \, \text{and} \,{67.34}^{^\circ }\) and resulted in a 10.58% improvement in the mixing process index. The implementation of rigid baffles improved the mixing index by 8%. Furthermore, increasing the applied voltage from 1 to 3 V resulted in a 27% average enhancement of the mixing index. A maximum mixing index of 99.37% was achieved at a \(\pi /2\) phase lag, representing an average 20.1% improvement compared to the absence of a phase lag. This reflects an approximate 65% increase at the initial stage compared to the scenario without any phase lag.

Similar content being viewed by others

Introduction

In the past couple of years, microfluidic systems have developed into powerful tools in life sciences and chemistry, bringing about great improvement in a lot of diagnostic and therapeutic processes1. Micromixers are one of the most fundamental components in these systems. They were designed to mix samples homogeneously and rapidly at the microscale2. Due to technological progress, various kinds of micromixers have been created to address a wide range of applications. These devices find widespread application in diverse fields, including medical detection3,4, biological engineering5,6, chemical reactions7,8, material synthesis9, cell culture, drug screening and development, biomolecular interactions, and applications in energy and environmental protection and monitoring10,11,12,13,14.

Most of the conventional methods of mixing, such as turbulence or stirring, common on a macroscale, become either impossible to implement or highly inefficient on the microscale. Mixing in microchannels is predominantly governed by molecular diffusion; hence, it is slow and inefficient. To overcome this challenge, various methods have been put forward by the researchers. From a general viewpoint, Micromixers are classified as either passive or active2,14. Passive micromixers apply geometrical designs, such as serpentine channels, serrated configurations, or obstructions in order to make fluid flows turbulent. Active micromixers use moving parts or external energy fields such as electric15, thermal16, magnetic17, acoustic18, and pressure fields19 to accelerate the mixing process. Flexible tunability and high efficiency have made active micromixers widespread in fields such as chemistry, biology, and pharmacy.

Electro-osmotic micromixers are a class of active micromixers that use an electric field as an external power source. An interaction between a low-frequency AC electric field and the inherent charges in the electric double layer (EDL) forms the fundamental operating principle, giving rise to the electro-osmotic effect. It generates a force on the positively charged fluid near the channel walls, aligning in the direction of the electric field20,21,22.

In recent years, many researchers and scientists have conducted wide studies and research to improve the effectiveness and performance of electro-osmotic micromixers. The geometry design of micromixers is a key parameter that significantly affects mixing efficiency. Numerous investigations have been conducted to evaluate the efficacy of various geometric designs. Our study will briefly review related literature and investigations about the geometric designs of electro-osmotic micromixers. Kumar et al.23 introduced a new diamond-shaped split-and-recombine electro-osmotic micromixer. Systematically, they changed both electrode lengths and AC frequencies to investigate their effect on mixing efficiency. Results show a complex interplay between electrode length and the frequency of AC, whereas maximum mixing efficiency is shown for certain combinations of them. Xiong et al.24 performed a numerical study of.

an electro-osmotic micromixer with a rhombic structure that was intended to improve the mixing efficiency in microfluidics. They concluded that changing the rhombic angle and a combination of different rhombic elements can result in mixing efficiencies of over 99% under optimal conditions. Shamloo et al.25 present a groundbreaking electro-osmotic micro-mixer featuring a novel two-ring design for enhanced mixing of Newtonian and non-Newtonian fluids. Through optimization of key parameters including geometric dimensions, fluid flow rates, voltage amplitude, AC frequency, and phase lag, they achieve exceptional mixing efficiencies of up to 99.8%. A comparative study with one-ring and diamond-shaped geometry unequivocally demonstrates the superior mixing performance of the two-ring geometry. Chen et al.26 researched the efficiency of the electro-osmotic micromixer that is featured with cosine profile walls. Optimization of geometrical parameters along with the influence of Reynolds number, voltage, electrode pairs, frequency, and phase lag on mixing efficiency was carried out. The results have shown that a high mixing efficiency of 96% was achieved. Maadi et al.27 investigated the mixing performance of a novel electro-osmotic micromixer. The specially designed mixing chamber has ribs and microelectrodes that help enhance the efficiency of mixing through eddies, flow deviation, and electro-osmotic effects. This paper compares performance and pressure requirements for various rib dimensions both with and without microelectrodes under continuous flow conditions. The result of this paper shows the optimized design can achieve a high mixing quality with less pressure requirements. Zhou et al.28 demonstrated an efficient electro-osmotic micromixer with asymmetric lateral structures to improve the mixing capability in microfluidic devices. Numerical simulations predict that the mixing efficiency achieved by this improved mixer can be greater, with the applied potential reduced and a higher throughput rate. In line with the previous article, Chen et al.29 introduced a novel electro-osmotic micromixer featuring an asymmetrical lateral structure. On embedding the asymmetrical arrays of electrodes on the top and bottom walls of rectangular cross-section microchannel, a device generates flow disturbances with vortexes under an applied DC electric field and thus significantly improves mixing efficiency. The authors also investigate the influence of operational parameters, including the Reynolds number, applied potential, and Peclet number, on mixing efficiency. Wu et al.30 presented a new low-voltage electro-osmotic micromixer with a Cantor fractal structure. The researchers achieved an impressive 95.2% mixing efficiency by strategically placing electrode pairs within the fractal framework. Shamloo et al.31 conducted a numerical simulation in three dimensions of a novel T-shaped electro-osmotic micromixer. Their study investigated several parameters including inlet angle, number, and arrangement of conducting obstacles, and geometries of the obstacle and chamber in which mixing took place. Results show that using two conducting obstacles at a certain angle increases the mixing index significantly. Kumar et al.32 numerically investigated a novel square split-and-recombined electro-osmotic micromixer (SSAR-EM) with non-aligned inlet and outlet channels. The influence of some parameters such as the inlet velocity, the configuration of electrodes, the magnitude of voltage, AC frequency, and phase difference was considered in their work. An optimum design reached 98.26% efficiency under specific conditions. Gong et al.1 investigated numerically the efficiency of electro-osmotic mixing in a contraction–expansion microchannel. The study has been performed on circulation flows and rotating vortices under AC electric field influences that highly enhance the mixing quality. In another study, Gayen et al.33 used the offset inlets and outlets in a square micromixer and numerically studied the effects of several parameters, such as the amplitude of the applied voltage, frequency, Reynolds number, and Debye parameter on mixing. They have performed numerical simulations to demonstrate that optimizing these parameters can significantly enhance mixing quality. Kumar et al.34 suggested a new method to increase mixing performance in circular electro-osmotic micromixers by using cross-reciprocal electrodes. Their work studied some of the important parameters, such as microchamber diameter, inlet velocity, AC voltage amplitude, and frequency, which affect the fluid mixing dynamics. The study showed by numerical analysis that as the diameter in the microchamber decreases, the electro-osmotic forces increase and consequently, the mixing performance is appreciably improved. Feeoj et al.35 investigated the effects of the geometrical shape of the mixing chamber (circular, hexagonal, and octagonal), electric field frequency, inlet velocity, and phase difference on mixing quality. It was found that higher frequencies and smaller chambers increase the mixing efficiency by up to 98.16% for a hexagonal chamber. Ghahfarkhi et al.36 performed an investigation into the effect of different barrier geometries (no barrier, circular, rectangular, diamond, and octagonal) on mixing efficiency in a hexagonal electro-osmotic micromixer. They found that an increase in the applied voltage dramatically enhances mixing efficiency. Interestingly, the obstacle-free configuration in the mixing chamber achieved the highest mixing efficiency, which was estimated to be approximately 97%. Gayen et al.37 developed a ring-shaped micromixer having rigid baffles at its entrance and four microelectrodes in the ring chamber. The study determined the effect of various variables, such as the fluid velocity at the inlet, frequency, voltage magnitude, and baffle position on mixing performance. The results showed that the highest mixing quality (99.67%) occurs when the inlet velocity is 0.05 mm/s. It can be seen that higher speeds and frequencies result in less effective mixing. The study, therefore, concluded that the use of baffles improves the mixing quality significantly by creating small whirlpools near charged surfaces. Majhi et al.38 performed a numerical study to improve the mixing of non-Newtonian fluids in electro-osmotic micromixers. The current study examines the effects of shape and flow factors such as mixing chamber design, inner obstacle size, and angle of the nozzle-diffuser channel on mixing efficiency and pressure drop. By using the Cauchy momentum equations from the Poisson–Nernst–Planck framework, the authors proved that internal obstacle size, the Debye–Huckel parameter, and the channel slope are dominant controlling parameters of the mixing quality. The results indicate that shear-thickening fluids can result in mixing efficiencies as high as 96%, much larger than those obtained for shear-thinning fluids.

Another area of research focuses on the optimization to enhance mixing performance. Shah et al.39 have worked on improving fluid mixing in microfluidic systems. They proposed three configurations: passive, active, and a hybrid model combining both approaches; simulations showed that the active mixer has the best mixing performance. By using the Taguchi method, they optimized the frequency, voltage, and velocity inlet; an optimum mixing index of 99.6% could be achieved at the optimized parameters. Deng et al.14 researched topology optimization of electrode patterns in electro-osmotic micromixers. They worked on how electrode shape and position affect electric field distribution and fluid flow in microchannels. Using topology optimization, they designed the electrode pattern for the optimization of fluid behavior to improve the efficiency of micro-mixing. Jalili et al.40 numerically optimized an electro-osmotic micromixer with a rhombus-like chamber and four microelectrodes to maximize the mixing efficiency by varying operational parameters including inlet velocity, phase lag, frequency, and voltage amplitude. All these parameters have shown very strong effects on mixing quality, and it was recognized that better performances could hopefully be obtained under optimal conditions. Surprisingly, the obstacle shape in the chamber had only a small influence on the mixing at optimum parameters. Chen et al.41 explore a novel micromixer, designed using coastal zone fractals, for producing controllable-sized liposomes. The mixing index is used as the objective function, and four parameters pertaining to the geometric form of the coastal fractal inside the microchannel are used as design variables. They optimize the primary wall-type fractal baffle micromixer under four Reynolds number conditions and find the optimal structural configuration. The results indicate that the double-sidewall cross micromixer, which is optimized, enhances chaotic convection and mixing efficiency, achieving 99% efficiency at both Reynolds numbers of 0.1 and 100, a 50.44% enhancement over the reference structure. The authors conclude that the wall-type fractal micro-mixer has great potential for widespread applications due to its high mixing efficiency.

Based on the reviewed studies, the optimization of micromixer geometry has frequently been approached by varying geometric parameters and subsequently analyzing their effects on mixing performance. A considerable portion of these studies do not employ a specific optimization method or algorithm to rigorously determine the optimal geometry. Within the literature referenced in these papers, only the work by Shah et al.39 utilizes the Taguchi method, and their micromixer geometry exhibits significant differences compared to the geometry under consideration in this study.

A key conclusion from the literature review is that the vortex created by the electric field in the micromixer is very crucial to the mixing process. The micromixer design along with the shape and placement of electrode pairs will influence the electric field and the vortex formed inside the micromixer. Although numerous studies have been performed on electro-osmotic micromixers, there is a lack of research on the effect of solid baffles in these systems. Specifically, the effect of the presence and orientation of rigid baffles on the quality of mixing in a diamond-shaped chamber micromixer has not been extensively investigated. Consequently, it is necessary to develop a micromixer with a relatively simple design that can be easily manufactured and at the same time optimized to achieve high mixing quality.

The current study aims to enhance the mixing performance of a micromixer by introducing a novel geometric design that includes two rigid baffles at the entrance. To find the optimal values for the geometric parameters; the first baffle angle (\({\beta }_{1}\)), second baffle angle (\({\beta }_{2}\)), baffle length (L), the distance between baffles in the x direction(x), the distance between baffles in the y direction(y), and mixing chamber angle (\(\alpha\)), the Taguchi method, and response surface methodology (RSM) will be applied. Also, the effects of inlet velocity, frequency, and applied voltage on the optimized geometric configuration will be considered.

The electro-osmotic micromixer studied here has wide applications, from chemical analysis to chemical synthesis, in various biomedical fields. These biomedical applications include cell culture, drug screening, DNA analysis, biomolecular interactions, biomedical diagnostics, and environmental control and monitoring.

Physical description and mathematical modeling

Geometric configuration

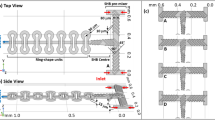

Figure 1 shows the schematic representation of the micromixer used in the present study. The device has a Y-shaped channel with a rhombus-shaped mixing chamber. Two different fluid streams of varying concentrations are introduced into the microchannel via two separate inlets. Mixing is enhanced by applying a time-varying sinusoidal electric field to four electrodes that are embedded in the interior rhombus-shaped barrier. This particular field causes vortex formation in the mixing chamber. The mixed fluid is then expelled out of the microchannel from a single outlet. The physical dimensions of the micromixer are listed in Table 1.

In this study, to find the optimal location and geometry of baffles as well as mixing chamber angle, six parameters were designated as design variables: L (baffle length), x (horizontal center-to-center baffle spacing), y (vertical baffle offset from the central horizontal axis), and \({\beta }_{1}\) and \({\beta }_{2}\) (angles of first baffle and second baffle relative to the horizontal axis, respectively) and \(\alpha\) (mixing chamber angle). The mixing quality served as the objective function. In other words, x and y define the positional coordinates of the baffles, \({\beta }_{1}\) and \({\beta }_{2}\) dictate their orientation, L determines their length and \(\alpha\) governs the mixing chamber angle. The range of variations for these variables is listed in Table 1. L was varied from 10 μm to 15 μm in increments of 1.25 μm. x ranged from 10 μm to 20 μm, with a step size of 2.5 μm. y was varied from 0 to 5 μm with a step of 1.25 μm. \({\beta }_{1}\) and \({\beta }_{2}\) were adjusted from 10° to 170° in 40° increments. Finally, \(\alpha\) was varied from 50° to 90° in increments of 10°. The specific values for these parameters were determined using the Taguchi technique and are shown in Table 4.

These parameters significantly impact mixing performance. The first baffle angle \(\left({\beta }_{1}\right)\) and second baffle angle \(\left({\beta }_{2}\right)\) play a significant role in flow deviation in a micromixer. These angles are optimized for enhanced vortex creation for better mixing. Fluid residence time is affected by baffle length (L), with a longer baffle enhancing mixing at the expense of higher pressure drop and lower efficiency. The distance between baffles in the x-direction (x) controls fluid flow distribution, preventing dead spaces and ensuring constant interaction, which favors mixing. Likewise, y-direction spacing (y) affects the interaction of fluid streams, such that optimum separation leads to improved vortices and mixing rate enhancement. Finally, the mixing chamber angle (\(\alpha\)) is accountable for establishing the direction and turbulence of flow and is optimized for improved kinetic energy distribution and mixing efficiency.

Governing equations

The velocity vector field and pressure distribution were obtained through the solution of the continuity and Navier–Stokes equations42:

where \(\overrightarrow{U}\) is the flow velocity vector, \(\rho\) shows the density of the fluids, P represents the pressure, \(t\) is time,\(\mu\) indicates the viscosity of the fluids, and \({\rho }_{e}, \overrightarrow{E}\) denotes the electric charge density and the electric field intensity, respectively. The electric potential \(\left(\varphi \right)\) has a relationship with \(\overrightarrow{E}\)42:

and \(\varphi\) is described by the Poisson equation:

The permittivity \(\left(\varepsilon \right)\) is given by \(\varepsilon ={\varepsilon }_{0}{\varepsilon }_{r}\), where \({\varepsilon }_{0}\) is the vacuum permittivity and \({\varepsilon }_{r}\) is the dielectric constant (or relative permittivity).

The electric double layer thickness \(\left({\lambda }_{D}\right)\) (The electric double layer (EDL) is a structure that forms at the interface between two phases, typically a solid surface and a liquid solution when one of the phases has an electrical charge) is given by42:

where F is Faraday’s constant, R is the gas constant, T is the temperature, \({z}_{i}\) is the charge number of species i, and \({c}_{i\infty }\) is the average concentration of species i. Also, the charge density is given by:

One can separate the electric field from the fluid field and decompose the potential \(\left(\varphi \right)\) into a potential due to the external electric field \(\left(\Phi \right)\) and a potential due to the ζ potential \(\left( \psi \right)\)42:

And \(\Phi\) is governed by:

The fluid velocity in the electric double layer is given by42:

where the electric field intensity E is defined by:

In situations where the Debye length is much less than the channel’s width, the terms accounting for the curvature may be neglected. The one-dimensional form of Eq. 9, appropriate for electro-osmotic flow in a long channel, is obtained through simplification42:

For electro-osmotic flow in a uniform channel with a thin electric double layer (EDL), the Helmholtz-Smoluchowski equation provides a simplified relationship between the electro-osmotic velocity and the tangential component of the applied electric field, under the assumption of a dominant electric field within the thin EDL42.

where ζ₀ denotes the zeta potential at the channel wall and \({E}_{x}\) represents the tangential component of the electric field. This equation is applicable at all boundaries excluding the inlet and outlet. Within the bulk of the fluid, where ψ vanishes, the fluid motion is described by the Navier–Stokes equation42:

The convection–diffusion equation presented below1 governs the concentration field within the micromixer:

where \(D\) represents the diffusion coefficient, \(c\) is the concentration, and \(u\) is the flow velocity. The following advection–diffusion equation gives the distribution of concentration in the fluid1:

where \(j\) is the mass flux and given by1:

A diffusion equation can be used to model the current balance within the channel by neglecting concentration gradients of current-carrying ions and assuming near-equilibrium conditions in the diffuse double layer1:

where σ stands for the solution’s conductivity \((\text{S}/\text{m})\), The mixing efficiency \((MI)\) is defined by1:

where, \(c\) is the concentration of each element, \(\overline{c}\) is the average concentration in the selected cross-section, and \({{\sigma }^{2}}_{max}\) shows the maximum value of standard deviation. The mixing index \((MI)\) of 0 indicates complete segregation, while a value of 1 signifies a homogeneous mixture.

Assumptions

This numerical investigation simulates transient, laminar electroosmotic flow through a microchannel at low Reynolds numbers. The working fluid is approximated as incompressible and Newtonian with constant thermophysical properties. For simplicity in electrostatics calculation, ions are presumed to be point charges with no steric effects, and the electric double layer (EDL) thickness is assumed to be much smaller than the channel width. This thin EDL approximation allows the application of the Helmholtz-Smoluchowski slip velocity boundary condition at the walls of the channel, which are assumed to be electro-osmotic and non-conductive, hence simplifying the electrical boundary conditions. The electric field body force is hence assumed negligible in the bulk fluid. Joule heating and buoyancy forces are also neglected, which implies low electrical fields and slight density changes. Finally, it is also presumed that there are no chemical reactions taking place, with initial concentrations set at 1 mol/m3 and 0 mol/m3 at the upper and lower inlets, respectively.

Boundary conditions

The solution of the above equations was subject to the following boundary conditions:

Two electrode-pairs:

Outlet of the micromixer:

Micromixer inlets: fully developed flow.

Micromixer outlet: \(P={P}_{a}\) with suppressing backflow.

Micromixer walls and baffles: electro-osmotic slip velocity (In a microfluidic device driven by electroosmosis, the slip velocity at the walls, is known as the electro-osmotic slip velocity).

Insulation is applied to all other boundaries, with the following condition at the wall:

Table 2 presents the material parameters employed in this study.

Numerical simulation

The transport equations and their boundary conditions are numerically solved by the finite element-based solver COMSOL Multiphysics. This numerical simulation discretizes three critical physical phenomena: laminar flow, electric currents, and transport of diluted species. The proposed model is implemented through a two-phase simulation process. Initially, a stationary simulation is conducted to determine the amplitude of the electric current voltage. Following this, flow and concentration fields are assessed during the transient phases. At the beginning of the transient phase (t = 0), the initial condition is derived from the results of the stationary simulation.

Grid independency

Figure 2 shows the unstructured triangular grid developed inside the micromixer. It has a higher density near the four electrodes, where significant gradients are present. By carefully choosing the grid size and considering solution variations, convergence was achieved at a relative tolerance of \({10}^{-4}\), thereby ensuring the reliability of the simulation results. In addition, a network independence analysis was performed to ensure that element size did not influence the results. Our investigation of the average concentration and mixing index at the exit of the microchannel at \(t= 2\text{ s}\), as shown in Table 3 and Fig. 3, shows the minimum deviations when the number of elements exceeds 11,479. Therefore, the element size 11,479 was chosen for further calculations.

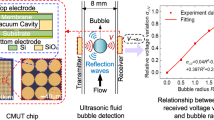

Validation

To ensure the accuracy of our numerical method in the current study of the electro-osmotic micromixer, our results were compared with the experimental and numerical analyses conducted by Wu and Li43 and the numerical analysis performed by Gayen et al.37. Figure 4 displays Wu and Li’s research’s experimental and numerical Mixing of two liquid streams (concentrations: 0.1 and 0 \(\text{mol}/{\text{m}}^{3}\)) in a microchannel featuring non-conductive walls and incorporating two conductive, symmetric triangular obstacles, under the application of 50 V/cm electric field. Additionally, Fig. 5 illustrates the numerical concentration profiles from Biswajit Gayen et al.'s study (Outlet concentration of the microchannel at t = 1 s with three pairs of aligned baffles at \(U_{0} = 0.05 \,{\text{mm/s}},{\text{ f}} = 4 \,{\text{Hz}}, V_{0} = 0.2 {\text{V}},{\text{ and}}\,{ }\alpha = 45^\circ\) compared to our method. The comparisons presented in these figures show an excellent resemblance, which validates the accuracy of our numerical approach.

Results of current numerical data comparison with Wu and Li experimental and numerical data43.

The present numerical results are compared with the numerical data reported by Gayen et al.37.

Results and discussion

Optimization geometry by Taguchi and RSM method

The Taguchi technique is a widely applied method in engineering and industry for optimizing design parameters. Two crucial concepts form the basis of this method: firstly, high-quality products should be built into the design economically, and secondly, the losses in quality need to be quantified as deviations from targets rather than arbitrary specifications.

The study encompasses three dimensions \(\left(x, y, L\right)\) and three angles \(\left({\beta }_{1}, {\beta }_{2}, \alpha \right)\). A complete factorial design involving six components at five levels would require \({5}^{6}=15625\) runs. In contrast, the Taguchi method reduces this to only 25 runs, as illustrated in Table 4. This optimization technique uses RSM, a combination of statistical and mathematical approaches to analyze complex situations. RSM tries to minimize numerical noise and reduce costs associated with more expensive analysis methods like Computational Fluid Dynamics (CFD) and the Finite Element Method (FEM). Research by Venter et al.44 proves the effectiveness of RSM in design optimization applications. This study explores an optimized design for the electro-osmotic micromixer using the Taguchi method alongside RSM. The L25 orthogonal array was utilized in the Taguchi approach to pinpoint key factors affecting solidification time, examining six variables \(x, y, L, {\beta }_{1}, {\beta }_{2}\) and \(\alpha\) across five levels each. This approach enhances the reliability of our findings and promotes better micromixer performance.

RSM effectively analyzes how response variables influence outputs and defines the relationships between adjustable input parameters and these responses. Errors in RSM, such as those from value rounding, non-convergence, and iteration counts, can be minimized to nearly zero. For accuracy, start with a good approximation of first or second-order polynomials. Second-order models are beneficial when variables interact, and surfaces are curved. RSM’s experimental design strictly investigates the relationships of responses with explanatory variables; therefore, it is widely used for process optimization and determining adequate parameter settings. Being one of the core assets in engineering, manufacturing, and research, RSM aids in providing a strong framework for the analysis of variations of inputs in trying to develop significant innovations and improvements. A second-order model is generally described as follows45:

This model represents the design variables as \({x}_{i}\) and \({x}_{j}\). The factor to be used for optimization is written as \(a\), while \(m\) represents the number of consideration factors, and ξ stands for the error.

The Taguchi optimization method offers benefits like improved quality and reduced process variations, but it also faces challenges. A major issue is the incorrect selection of parameters and their levels, leading to inaccurate results. Additionally, complex parameter interactions may be overlooked, and employing Orthogonal Arrays might not adequately capture these interactions. Sensitivity to environmental changes can also affect accuracy. Therefore, engineers and researchers must carefully select parameters, analyze interactions, and consider environmental factors when using this method.

The analysis of variance (ANOVA) is an effective tool for determining how adequate our model is and validating the mathematical soundness of the results. Variance analysis is shown in Table 5, highlighting the differences between predicted and actual values. Analysis of the interaction among different variables with the response variable increases the accuracy and reliability of our models. Rigorous methodology strengthens our conclusions and points out the resilience of our evaluation.

Figure 6 shows that the interaction of parameters with each other enhances the mixing index with results that closely match the predicted values. Response variables are evaluated in terms of quantitative scores using desirability functions, and hence, a composite score is obtained. The successful optimization of parameters is based on a trade-off balance and understanding the relationships among the variables.

The attractiveness of a process measures its effectiveness in achieving goals and is influenced by key parameters. Identifying these variables and systematically varying them, often using methods like RSM, allows for mathematical modeling of relationships. Surface plots illustrate how parameters impact desirability. The numerical data obtained earlier are compared to the relevant mixing index estimations derived from the associated Eq. (24):

Table 6 gives the best-fit parameter values used in this correlation. With these values, one can solve Eq. (24) to get the maximum mixing index. It is the reciprocal relationship between mixing index and \(x, y, L,{\beta }_{1}, {\beta }_{2}\) and \(\alpha\). Equation (24) describes their mutual relation with the mixing index.

The interactions between the various factors significantly affect mixing index, as shown in Fig. 7. It can be perceived that mixing index could be significantly decreased through changing angles and dimensions, which was proved by the 3D diagrams. These display the linkages among dimensions and angles by showing the best values of parameters \(x, y, L, {\beta }_{1}, {\beta }_{2}\) and \(\alpha\), for which mixing index has the maximum value. the trends and patterns pointed out here are very helpful in learning the best combinations with the highest mixing index value. The effect of geometric parameters L and β1 on mixing index can be seen from Fig. 7a. As can be observed, the effect of parameter L is greater than that of β1. It is because increasing L enhances interaction time and the evolution of the flow, leading to better mixing, whereas β1 simply affects local flow structure with a relatively lower contribution to total mixing efficiency. The effect of geometric parameters y and x on the mixing index is shown in Fig. 7b. As is evident, the effect of parameter y is greater than that of x. This is because by raising y, the length of the flow path is increased, and fluid stretching and folding are increased, thus improving mixing. Conversely, parameter x affects merely the horizontal displacement of the fluid layers, which has comparatively lesser control over the total efficiency of mixing. The effect of geometric parameters β2 and α on the mixing index is shown in Fig. 7c. As seen from there, the effect of parameter α is greater than that of β2. This is because the increase in α increases the shear and rotational effects in the flow, leading to greater mixing. Whereas, β2 predominately affects local direction of the flow, its impact on total mixing efficiency is relatively low compared to other characteristics. The data presented in Fig. 8 demonstrates that the micromixer, engineered with optimal parameters, outperforms the other four selected cases. At every instance throughout the simulations, the mixing index for the optimal case is significantly higher than that of the remaining cases, thereby indicating its enhanced efficiency. the concentration field (\(\text{mol}/{\text{m}}^{3}\)) in the instant of 0 s, 0.5 s, and 2 s and streamline in the instant of 0.55 s and 0.7 s at \(U_{0} = 0.05\,{\text{mm}}/{\text{s}},{\text{f}} = 4\,{\text{Hz}},V_{0} = 1\,{\text{V}}\) is presented in Figs. 9 and 10 for four selected cases and an optimized case. The comparative analysis of contour plots demonstrates that the optimized configuration substantially enhances the mixing process by employing the most effective parameters. This improvement leads to a notable augmentation in mixing quality and efficiency, particularly reducing mixing time. The streamlines surrounding the baffles demonstrate heightened turbulence, which engenders supplementary vortices and promotes swift momentum. Furthermore, the contour plots depict a more uniform distribution of fluid characteristics, signifying enhanced mixing efficiency compared to non-optimized scenarios. The optimized configuration significantly augments mixing effectiveness and decreases processing duration.

Effect of different parameters

In this study, a numerical simulation was conducted to assess the interaction of two different fluid flows of concentration 1 and 0 \(\text{mol}/\text{m}^2\) by considering electrokinetic effects, such as electro-osmotic flow. Two rigid baffles were introduced at the entrance of the micromixer to enhance the mixing index. All essential influential variables were investigated: angle, length, baffle placement, and internal mixing chamber angle. Using simulations to collect data and the Taguchi optimization method, our study aimed to find the most advantageous values for these parameters to maximize the mixing index. All simulations were carried out under equal speed, frequency, and voltage conditions \(\left[{U}_{0}=0.05 \text{mm}/\text{s},\text{f}=4\text{ Hz}, {V}_{0}=1 \text{V}\right]\). Once the best parameters were found, the influence of speed \({U}_{0} \left(0.05, 0.1, 0.2, 0.3, 0.4 \text{mm}/\text{s}\right)\), frequency \(\text{f} \left(4, 8, 12, 16, 20\text{ Hz}\right)\), and voltage \({V}_{0} \left( 1, 1.5, 2, 2.5, 3\text{ V}\right)\) were examined on the system’s performance under this optimal scenario. In addition, the velocity profile were studied at three specific sections at different velocities. The influences of frequency and voltage were examined on the concentrations at three distinct points in the micromixer’s outlet zone. The performance was compared in the presence and absence of the electro-osmotic effect and electrode phase lags and considered the pressure drop at different velocities.

Assessment of micromixer performance in different operating condition

The mixing index for the proposed micromixer has been evaluated under four distinct conditions: with baffles, with EOF, with both baffles and EOF, and without either component. The results of this comparison are illustrated in Fig. 11. The electro-osmotic effect significantly enhances mixing efficiency about 13% at 0.05 mm/s and 36% at 0.1 mm/s compared to the micromixer, which relies solely on mechanical agitation obstacles. When an electric field is applied, the fluid mixture moves toward one pair of electrodes on opposite sides. This creates shear stress, which changes the fluid flow. As a result, pulling and twisting together form many vortices near the electrode pairs, improving mixing quality. The integration of baffles at the entrance of the micromixer substantially improves mixing efficiency, resulting in enhancements of approximately 8% at a velocity of 0.05 mm/s and 6% at a velocity of 0.1 mm/s, in comparison to a standard micromixer. This improvement can be ascribed to the effective convective mixing effects of the baffles.

The influence of electrode phase lags

The current subsection explores the influence of phase lags on the mixing index, as illustrated in Fig. 12. Three various values of phase lag \(\left(\uppi , \frac{\pi }{2}, \frac{\pi }{4}\right)\) were imposed on the electrodes. It has been observed that a phase lag of \(\frac{\pi }{2}\) exerts the most substantial influence on the mixing process index. Since the applied voltage to the electrodes is sinusoidal, introducing a phase delay enables the electrodes to operate at an elevated voltage during the initial mixing process stages. Consequently, this results in a rapid mixing enhancement in the micromixer. Specifically, when the phase delay is \(\frac{\pi }{2}\), it improves the performance by about 65% compared with the case without a phase lag. Furthermore, the phase lag results in an increased mixing index at each stage in comparison to the scenario without lag, thereby facilitating the micromixer’s attainment of nearly complete mixing in the final stages of the process.

Mixing index (%) of micromixers with various electrode phase lags \(\left( { {\raise0.7ex\hbox{$\pi $} \!\mathord{\left/ {\vphantom {\pi 2}}\right.\kern-0pt} \!\lower0.7ex\hbox{$2$}}, {\raise0.7ex\hbox{$\pi $} \!\mathord{\left/ {\vphantom {\pi 4}}\right.\kern-0pt} \!\lower0.7ex\hbox{$4$}} \;{\text{and}}\; \pi } \right)\) with the progress in time at outlet \({U}_{0}\) = 0.4 mm/s, \({V}_{0}\) = 2 V and f = 12 Hz.

The influence of inlet velocity

Figure 13 provides a detailed analysis of the influence of different inlet velocities. (0.05, 0.1, 0.2, 0.3, and 0.4 mm/s) on the micromixer’s mixing index within a period of time, at a frequency f = 12 Hz and \({\text{V}}_{0}\)= 2 V. From the data, it is evident that the smaller the inlet velocity, the higher the mixing index within the period under consideration. In contrast, increasing the inlet velocity leads to a poorer mixing index, with the most rapid deterioration in performance at high velocities. This loss in mixing quality can be attributed to comparative effects due to inertia force for electro-osmotic force on the fluid streams. With increases in fluid velocities, inertia force becomes the dominant influence, superseding that of electro-osmotic force, reducing the mixing index at the initiation of the process.

To explain this occurrence, the concentration field in mol/m3 is given in Fig. 14 at different inlet velocities for some specific time instants, which are 0, 0.5, and 2 s. When the electro-osmotic force dominates, fluid components are continuously stretched and folded in the transverse direction in the microchannel at a frequency that is the same as the externally applied electric field. besides, the fluid particles undergo electro-osmotic recirculation owing to forming two micro-vortices close to each electrode. Such a technique achieves a better mixing index, which is considerable and relevant in practical applications. The Fig. 15 illustrates three lines extending from the micromixer to specific locations. These locations represent the points of convergence for the two streams following their passage through the first and second baffles. The flow velocity profiles at these three positions are presented in Fig. 16 for three distinct velocities 0.05, 0.2 and 0.4 mm/s. Streamlines are presented in Fig. 17 at time intervals of 0.55 and 1.7 s.

The streamline field illustrates the baffles’ impact on the mixing process. Upstream of each baffle, vortices emerge due to the disturbance created by the walls within the boundary layers. These generated vortices facilitate the remixing of two fluids with differing concentrations, thereby enhancing the uniformity of the fluid mixture entering the mixing chamber.

The influence of alternating current frequency

This report delineates the anticipation that an elevated AC frequency will enhance the mixing index of the electro-osmotic mixer. A comparative analysis of various AC frequencies has been performed to examine their effects on mixing efficiency. Preliminary results, as illustrated in Fig. 18, demonstrate that an AC frequency of 8 Hz generates a more uniform mixing of liquids relative to both lower and higher frequencies.

This suggests the existence of an optimal frequency at which mixing efficiency reaches its maximum, specifically at velocity of \({\text{U}}_{0}=0.2\text{ mm}/\text{s}\). To substantiate this assertion, an analysis of the concentration field was conducted over 0 s, 0.5 s, and 2 s interval encompassing a range from a very low to a very high frequency in Fig. 19. The results reveal the existence of a specific frequency at which mixing achieves optimal conditions. Applying alternating current at a frequency of 8 Hz resulted in an impressive mixing efficiency of 97.70%. This efficiency notably exceeds the values observed at other frequencies, including 2.25% at 4 Hz, 6.7% at 12 Hz, 14.43% at 16 Hz, and 22% at 20 Hz. This phenomenon can be attributed to the voltage polarity reversal at the electrodes. With increasing flow velocity, inertial forces begin to surpass electro-osmotic forces, diminishing the effectiveness of low-frequency operations and necessitating the adoption of higher frequencies to enhance the mixing index. Variations in frequency impact the stretching and folding dynamics of fluid layers, contributing to effective mixing after a specific number of cycles. It is crucial to acknowledge that the mixing index undergoes a significant decline once the frequency exceeds 8 Hz, which results from the increased magnitude of vortices that arise from augmenting the frequency beyond this threshold. While the mixing index decreases with intermediate inlet velocity values, the influence of electro-osmotic forces prevails; conversely, in scenarios of elevated fluid velocity, inertial forces intensify, leading to improved mixing indexes when higher frequencies are utilized within the system. This is evidenced by Fig. 20. observed at different time intervals (0.55 s and 1.7 s) at \({\text{U}}_{0}=0.2 \text{mm}/\text{s}\) and \({\text{V}}_{0}=2\text{ V}\), where the fluid flow direction is in the frequency of the AC electric field. The mixing index resulting from higher frequencies due to rapid flow direction changes shows oscillating patterns. Higher frequencies improve the mixing index, but only marginally; these improvements become especially useful at higher fluid velocities.

The influence of alternating current voltage

The influence of varying electrode voltage amplitudes (1, 1.5, 2, 2.5, and 3 V) on the mixing index is depicted in Fig. 21. This figure illustrates the evolution of mixing as a function of time at an inlet velocity of \(0.2\text{ mm}/\text{s}\) and frequency of \(12\text{ Hz}\). Increasing the voltage from 1 to 1.5 V resulted in an average increase of 12% in the mixing index. An increase in the amplitude of the sinusoidal electric field results in a marked enhancement of the mixing index at the channel exit, with this improvement remaining stable over time. The pronounced electro-osmotic effect associated with elevated voltage amplitude induces the formation of additional flow vortices, which directly contribute to the increase in the mixing index. However, the data indicate that the effectiveness of increasing the voltage on the mixing index diminishes with higher voltages. Raising the voltage from 2.5 to 3 V only leads to a 2.65% increase in the mixing index.

Furthermore, Concentration fields illustrated in Fig. 22 have been noted that at reduced inlet velocities, higher voltage amplitudes \(\left({\text{V}}_{0}\right)\) correlate with more consistent growth in the mixing index over time than lower voltage amplitudes. In contrast, increasing the velocity of the incoming fluid from \({\text{U}}_{0}=0.05\text{ to }0.4\text{ mm}/\text{s}\) results in oscillatory behavior in the mixing quality over time. These oscillations become more noticeable at elevated voltage amplitudes \(\left({\text{V}}_{0}\right)\) and fluid inlet velocities. Figure 23 presents streamlines with varying voltage at time intervals of [0.55 s and 1.7 s]. With increased voltage intensity, the fluid elements encounter a more significant electro-osmotic force, facilitating electro-osmotic recirculation near each electrode. This phenomenon commonly manifests as the formation of two micro vortices, which promote the equalization of fluid streams with unequal compositions.

Pressure drop

Incorporating rigid baffles generates an increased quantity of flow vortices upstream of the mixing chamber, consequently enhancing the quality of mixing. These vortices promote a more thorough and uniform mixing of the fluids, improving the efficiency of the micromixer. Nevertheless, the presence of these baffles impedes the flowing fluids, resulting in a more significant pressure drop within the channel. As the flow encounters the baffles, additional resistance is created due to friction, and the flow becomes more turbulent, contributing to a higher loss of pressure. Figure 24 illustrates the correlation between the micromixer’s pressure loss and inlet velocities. As the velocity increases, the pressure drop becomes more pronounced, as detailed in fluid dynamics principles, such as the increase in frictional resistance and the transition to a more turbulent flow regime. Previous observations indicate that micromixers featuring baffles demonstrate enhanced mixing efficiency; however, they experience a more pronounced pressure drop due to these additional resistances and the alteration of the flow characteristics.

Time history of concentration

Three control points are set in the outlet section of micromixers, located at \(y=-10 \mu \text{m}\), \(y=0 \mu \text{m}\), and \(y=10 \mu \text{m}\). The time history of concentration variation at these points is presented in Fig. 25 for the parameters f [4 Hz, 12 Hz, 20 Hz] and Fig. 26 for the parameters \({\text{V}}_{0}\) [1 V, 2 V, 3 V]. Initially, a distinct interface is observed at the microchannel centerline, separating the two fluids of differing concentrations, with the higher-concentration fluid occupying the upper section and the lower-concentration fluid occupying the lower section. Upon applying an AC electric field, oscillations in concentration are observed. It is inferred that the chaotic advection and electro-osmotic recirculation within the fluid are consequence of the sustained application of the AC field. Furthermore, the transient characteristics of the AC field influence the fluctuations in output concentration, where a more negligible concentration difference results in more uniform mixing. As shown in Fig. 25 The performance of micromixers decreases as the AC frequency increases. Importantly, each inlet velocity demonstrates optimal performance at a specific frequency. Conversely, an increase in voltage amplitude is correlated with enhanced performance, as indicated in Fig. 26.

Conclusion

The present work explores the implementation of baffles as a strategy for improving the mixing index in a micromixer. Previous research has shown that recirculation flow patterns, often called vortices, may appear near the baffles’ leading edge. This phenomenon increases the convective mixing process before occurring in the mixing chamber. Two baffles were introduced at the entrance of the micromixer, and a comprehensive study of some critical geometrical parameters was conducted along with the collection of simulation data. The Taguchi optimization method was applied to determine the optimum values of such parameters. Then, the effects of inlet velocities, voltage magnitudes, AC frequency, and phase lags on the overall performance of the optimized micromixer were studied. The following summary presents the key findings.

-

The optimized geometric parameters \(\left({\beta }_{1}={146.1}^{^\circ },{\beta }_{2}={82.88}^{^\circ },L=11.78\, {\upmu \text{m}},x=18.75\, {\upmu \text{m}},y=4.93\, {\upmu \text{m}} ,\alpha ={67.34}^{^\circ }\right)\) were determined, resulting in a minimum 10.58% increase in the mixing index compared to other cases, demonstrating the effectiveness of geometric optimization.

-

Rigid baffles enhance vortex formation upstream of the mixing chamber, enhancing the mixing index by approximately 8% at \(0.05\, \text{mm}/\text{s}\) and 6% at \(0.1\, \text{mm}/\text{s}\) in comparison to a standard electro-osmotic micromixer. However, their presence also causes a greater pressure drop in the fluid flow.

-

Increasing the amplitude of the electrode voltage generates a liquid vortex that facilitates a more uniform concentration and enhances the mixing index. A voltage increase from 1 to 3 V corresponds to an average improvement of 27% in the mixing index, which can rise to 97.17%. This enhancement was due to the formation of additional flow vortices driven by the stronger electro-osmotic effect.

-

A phase lag of π/2 can significantly influence the mixing index, leading to an initial 65% enhancement with the potential for the mixing index to attain levels as high as 99.36%

-

At lower inlet velocities, the electro-osmotic force predominates over the inertial force, resulting in a higher mixing index compared to higher inlet velocities.

-

Each inlet velocity is linked to a specific frequency that optimizes mixing. With an inlet velocity of 0.2 mm/s, the micromixer achieves 97.7% effectiveness when operated at 8 Hz. While higher frequencies improved mixing, their effects were more pronounced at greater fluid velocities.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- AC:

-

Alternating current

- EDL:

-

Electric double-layer

- ANOVA:

-

Analysis of variance

- RSM:

-

Response surface methodology

- MI :

-

Mixing efficiency

- \(\overrightarrow{E}\) :

-

Electric field intensity (V/m)

- \(\overrightarrow{U}\) :

-

Velocity vector (m/s)

- \({U}_{slip}\) :

-

Electro-osmotic velocity (m/s)

- u:

-

Velocity (m/s)

- V:

-

External voltages (V)

- D:

-

Diffusion coefficient (\({\text{m}}^{2}\)/s)

- P:

-

Pressure (Pa)

- \({\text{P}}_{\text{a}}\) :

-

Atmospheric pressure

- F:

-

Faraday’s constant

- R:

-

Gas constant

- T:

-

Temperature

- j :

-

Mass flux

- f:

-

Frequency (Hz)

- \(c\) :

-

Concentration

- \(\overline{c }\) :

-

Average concentration

- n:

-

Normal vector

- z:

-

Charge number

- t:

-

Time (s)

- \(\rho\) :

-

Density of fluid (kg/\({\text{m}}^{3}\))

- \({\uprho }_{\text{e}}\) :

-

Electric charge density

- \(\upmu\) :

-

Dynamic viscosity (Pa s)

- \({\lambda }_{D}\) :

-

Electric double-layer thickness

- \(\sigma\) :

-

Conductivity of the solution (S/m)

- \(\varepsilon\) :

-

Electric permittivity of fluid (F/m)

- \({\varepsilon }_{0}\) :

-

Vacuum permittivity

- \({\varepsilon }_{r}\) :

-

Relative permittivity

- \(\varphi\) :

-

Electric potential (V)

- \(\Phi\) :

-

External electric field

- Ѱ:

-

ζ Potential (V)

- ζ:

-

Zeta potential (V)

- \(\xi\) :

-

Error

- i :

-

Ith species

- x:

-

Coordinate direction

- y:

-

Coordinate direction

References

Gong, Y. & Cheng, X. Numerical investigation of electroosmotic mixing in a contraction–expansion microchannel. Chem. Eng. Process. Process Intensif. 192, 109492. https://doi.org/10.1016/j.cep.2023.109492 (2023).

Wang, X., Liu, Z., Wang, B., Cai, Y. & Song, Q. An overview on state-of-art of micromixer designs, characteristics and applications. Anal. Chim. Acta https://doi.org/10.1016/j.aca.2023.341685 (2023).

Qi, W. et al. A finger-actuated microfluidic biosensor for colorimetric detection of foodborne pathogens. Food Chem. https://doi.org/10.1016/j.foodchem.2021.131801 (2022).

Sayad, A. A. et al. A microfluidic lab-on-a-disc integrated loop-mediated isothermal amplification for foodborne pathogen detection. Sens. Actuators B Chem. 227, 600–609. https://doi.org/10.1016/j.snb.2015.10.116 (2016).

Conde, A. J., Keraite, I., Ongaro, A. E. & Kersaudy-Kerhoas, M. Versatile hybrid acoustic micromixer with demonstration of circulating cell-free DNA extraction from sub-ml plasma samples. Lab Chip 20(4), 741–748. https://doi.org/10.1039/c9lc01130g (2020).

Lin, M. X. et al. Continuous labeling of circulating tumor cells with microbeads using a vortex micromixer for highly selective isolation. Biosens. Bioelectron. 40(1), 63–67. https://doi.org/10.1016/j.bios.2012.06.016 (2013).

Jalal Sahandi, P., Kazemeini, M. & Sadjadi, S. Simulation of continuous catalytic conversion of glycerol into lactic acid in a microreactor system: A CFD study. J. Ind. Eng. Chem. 104, 258–271. https://doi.org/10.1016/j.jiec.2021.08.027 (2021).

Zhang, J., Tan, J., Wang, K., Lu, Y. & Luo, G. Chlorohydrination of allyl chloride to dichloropropanol in a microchemical system. Ind. Eng. Chem. Res. 51(45), 14685–14691. https://doi.org/10.1021/ie301816k (2012).

Shrimal, P., Jadeja, G. & Patel, S. A review on novel methodologies for drug nanoparticle preparation: Microfluidic approach. Inst. Chem. Eng. https://doi.org/10.1016/j.cherd.2019.11.031 (2020).

Han, W., Li, W. & Zhang, H. A comprehensive review on the fundamental principles, innovative designs, and multidisciplinary applications of micromixers. Am. Inst. Phy https://doi.org/10.1063/5.0238393 (2024).

Enders, A., Siller, I. G., Urmann, K., Hoffmann, M. R. & Bahnemann, J. 3D printed microfluidic mixers—a comparative study on mixing unit performances. Small https://doi.org/10.1002/smll.201804326 (2019).

Elmas, S. et al. Photometric sensing of active chlorine, total chlorine, and ph on a microfluidic chip for online swimming pool monitoring. Sensors (Switzerland) https://doi.org/10.3390/s20113099 (2020).

Elkady, M. F., Zaatout, A. & Balbaa, O. Production of biodiesel from waste vegetable oil via KM micromixer. J. Chem. https://doi.org/10.1155/2015/630168 (2015).

Chen, X. & Chen, X. A novel electrophoretic assisted hydrophobic microdevice for enhancing blood cell sorting: design and numerical simulation. Anal. Methods 16(15), 2368–2377. https://doi.org/10.1039/d4ay00196f (2024).

Deng, Y. et al. Topology optimization of electrode patterns for electroosmotic micromixer. Int. J. Heat Mass Transf. 126, 1299–1315. https://doi.org/10.1016/j.ijheatmasstransfer.2018.06.065 (2018).

Ng, W. Y., Goh, S., Lam, Y. C., Yang, C. & Rodríguez, I. DC-biased AC-electroosmotic and AC-electrothermal flow mixing in microchannels. Lab Chip 9(6), 802–809. https://doi.org/10.1039/b813639d (2009).

Xiao, X. & Kim, C. N. Numerical analysis of an MHD micro-device with simultaneous mixing and pumping capability. J. Ind. Eng. Chem. 38, 23–36. https://doi.org/10.1016/j.jiec.2016.04.001 (2016).

Bachman, H. et al. An Acoustofluidic device for efficient mixing over a wide range of flow rates. Lab Chip 20, 1238–1248 (2020).

Jännig, O. & Nguyen, N. T. A polymeric high-throughput pressure-driven micromixer using a nanoporous membrane. Microfluid Nanofluidics 10(3), 513–519. https://doi.org/10.1007/s10404-010-0685-1 (2011).

Campisi, M., Accoto, D., Damiani, F. & Dario, P. A soft-lithographed chaotic electrokinetic micromixer for efficient chemical reactions in lab-on-chips. J. Micro-Nano Mechatron. 5(3), 69–76. https://doi.org/10.1007/s12213-010-0024-3 (2009).

Wu, M., Gao, Y., Ghaznavi, A., Zhao, W. & Xu, J. AC electroosmosis micromixing on a lab-on-a-foil electric microfluidic device. Sens. Actuators B: Chem. 359, 131611 (2022).

Alizadeh, A., Hsu, W. L., Wang, M. & Daiguji, H. Electroosmotic flow: From microfluidics to nanofluidics. Electrophoresis https://doi.org/10.1002/elps.202000313 (2021).

Kumar, A., Manna, N. K. & Sarkar, S. Effect of Electrode Length and AC Frequency on Mixing in a Diamond-Shaped Split-And-Recombine Electroosmotic Micromixer. in Lecture Notes in Mechanical Engineering, Springer Science and Business Media Deutschland GmbH 83–92 (2023). https://doi.org/10.1007/978-981-19-3266-3_7.

Xiong, S., Chen, X., Chen, H., Chen, Y. & Zhang, W. Numerical study on an electroosmotic micromixer with rhombic structure. J. Dispers. Sci. Technol. 42(9), 1331–1337. https://doi.org/10.1080/01932691.2020.1748644 (2021).

Shamloo, A., Mirzakhanloo, M. & Dabirzadeh, M. R. Numerical Simulation for efficient mixing of Newtonian and non-Newtonian fluids in an electro-osmotic micro-mixer. Chem. Eng. Process. 107, 11–20. https://doi.org/10.1016/j.cep.2016.06.003 (2016).

Chen, Z., Wang, Y. & Zhou, S. Numerical analysis of mixing performance in an electroosmotic micromixer with cosine channel walls. Micromachines (Basel) https://doi.org/10.3390/mi13111933 (2022).

Maadi, M. & Golmarz, T. P. Investigation of mixing and simulation of an electroosmotic micromixer. J. Mech. Sci. Technol. 28(8), 3223–3230. https://doi.org/10.1007/s12206-014-0732-z (2014).

Zhou, T., Wang, H., Shi, L., Liu, Z. & Joo, S. W. An enhanced electroosmotic micromixer with an efficient asymmetric lateral structure. Micromachines (Basel) https://doi.org/10.3390/mi7120218 (2016).

Chen, L., Deng, Y., Zhou, T., Pan, H. & Liu, Z. A novel electroosmotic micromixer with asymmetric lateral structures and DC electrode arrays. Micromachines (Basel) https://doi.org/10.3390/mi8040105 (2017).

Wu, Z. & Chen, X. Numerical simulation of a novel microfluidic electroosmotic micromixer with Cantor fractal structure. Microsyst. Technol. 25(8), 3157–3164. https://doi.org/10.1007/s00542-019-04311-8 (2019).

Shamloo, A., Madadelahi, M. & Abdorahimzadeh, S. Three-dimensional numerical simulation of a novel electroosmotic micromixer. Chem. Eng. Process. 119, 25–33. https://doi.org/10.1016/j.cep.2017.05.005 (2017).

Kumar, A., Manna, N. K., Sarkar, S. & Biswas, N. Analysis of a square split-and-recombined electroosmotic micromixer with non-aligned inlet-outlet channels. Nanoscale Microscale Thermophys. Eng. 27(1), 55–73. https://doi.org/10.1080/15567265.2023.2173108 (2023).

Gayen, B., Manna, N. K. & Biswas, N. Enhancing mixing performance in a square electroosmotic micromixer through an off-set inlet and outlet design. Phys. Fluids https://doi.org/10.1063/5.0212356 (2024).

Kumar, A., Manna, N. K., Sarkar, S. & Biswas, N. Enhancing mixing efficiency of a circular electroosmotic micromixer with cross-reciprocal electrodes. Phys. Fluids https://doi.org/10.1063/5.0225659 (2024).

Kalantar Feeoj, R., Alavi Eshkaftaki, S. M., Kazemi Asfeh, I. & Jahangiri, M. Finite-element simulation of electroosmotic mixing: A study of the simultaneous effects of working parameters for optimization. Int. J. Chem. Eng. https://doi.org/10.1155/2022/9957189 (2022).

Ghahfarokhi, N. J., Bayareh, M., Nadooshan, A. A. & Azadi, S. mixing enhancement in electroosmotic micromixers. J. Therm. Eng. 7, 47–57 (2021).

Gayen, B., Manna, N. K. & Biswas, N. Enhanced mixing quality of ring-type electroosmotic micromixer using baffles. Chem. Eng. Process. Process Intensif. https://doi.org/10.1016/j.cep.2023.109381 (2023).

Majhi, M., Nayak, A. K. & Weigand, B. Electroosmotic mixing of non-Newtonian fluid in an optimized geometry connected with a modulated microchamber. Phys. Fluids https://doi.org/10.1063/5.0144762 (2023).

Shah, I., Su Jeon, H., Ali, M., Yang, D. H. & Choi, K. H. Optimal parametric mixing analysis of active and passive micromixers using Taguchi method. Proc. Inst. Mech. Eng., Part E: J. Process Mech. Eng. 233(6), 1292–1303. https://doi.org/10.1177/0954408919862997 (2019).

Jalili, H., Raad, M. & Fallah, D. A. Numerical study on the mixing quality of an electroosmotic micromixer under periodic potential. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 234(11), 2113–2125. https://doi.org/10.1177/0954406220904089 (2020).

Chen, X., Zhai, J. & Chen, X. A novel micromixer based on coastal fractal for manufacturing controllable size liposome. Phys. Fluids https://doi.org/10.1063/5.0239840 (2024).

Chen, H., Zhang, Y., Mezic, I., Meinhart, C. & Petzold, L. IMECE2003–55017 numerical simulation of an electroosmotic micromixer (2003). Available: http://www.asme.org/about-asme/terms-of-use.

Wu, Z. & Li, D. Micromixing using induced-charge electrokinetic flow. Electrochim Acta 53(19), 5827–5835. https://doi.org/10.1016/j.electacta.2008.03.039 (2008).

Venter, G., Haftka, R. T. & Starnes, J. H. Construction of response surface approximations for design optimization. AIAA J. 36(12), 2242–2249. https://doi.org/10.2514/2.333 (1998).

Hosseinzadeh, K. et al. Optimization of antenna-shaped fins configuration for enhanced solidification in triplex thermal energy storage systems with radiative heat transfer. Case Stud. Therm. Eng. https://doi.org/10.1016/j.csite.2024.105488 (2024).

Author information

Authors and Affiliations

Contributions

A.K.: Formal analysis, Writing—Original Draft, Writing—Review & Editing R.S.: Validation, Investigation K.H.: Methodology, Software.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Khoshnod, A., Shahsavandi, R. & Hosseinzadeh, K. Investigation of mixing performance in electro-osmotic micromixers through rigid baffle design and parameter optimization. Sci Rep 15, 16721 (2025). https://doi.org/10.1038/s41598-025-01812-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-01812-7

Keywords

This article is cited by

-

Influence of different electric fields on electroosmotic micromixing performance

Chemical Papers (2025)