Abstract

The present study deals with the development of a new separator for the separation of iron ore and coal of a size fraction of -4 + 0 mm individually. Particles of iron ore with size fraction − 2 + 0 mm and finer coal were separated separately using screen mesh with an aperture size of 2 mm. The operating characteristics of the screen’s upward slope and the screen’s vibration frequency of the new separation equipment can be easily modified. In this study, moist iron ore and coal segregation have been carried out for various separation angles and frequencies, and test results of moist iron ore and coal were compared based on their moisture content and density. Also, for the prediction of results, artificial neural network (ANN) modeling and regression analysis were implemented. The R-square value for regression analysis of experimental results was found higher than 85.60% and 88.50% for coal and iron ore respectively. The R-square value for the ANN mathematical model of experimental results was found higher than 99.10% and 98.24% for coal and iron ore respectively. The comparison of the regression model, the ANN model’s mathematical modeling results, and the test results for the separation of moist iron ore and coal hold a strong correlation. For validation, residual analysis was also performed on the separation of moist iron ore and coal regression and ANN models. Including improved accuracy, reduced computational time, and enhanced predictive capabilities. The residual probability plot’s results for homoscedasticity, low standard deviation, normality, and independence demonstrate that, under all experimental settings for iron ore and coal, the developed artificial neural network (ANN) model outperforms the regression model in terms of prediction accuracy.

Similar content being viewed by others

Introduction

Indian iron ore and coal must go through a number of beneficiation processes in order to be cleaned up and ready for use. Large amounts of water are used in wet processing, and the tailings must be processed in a plant wastewater treatment circuit. Water shortage made it difficult to process materials in various parts of India. Therefore, it makes sense to create a very effective dry-processing technology. Although wet beneficiation has been used, it has a number of drawbacks, including the need for a large amount of separation liquid for the process, and issues with tailings treatment. When comparing dry beneficiation to wet beneficiation, there are many advantages. Reducing water use, getting rid of garbage, and treating tailing water are a few of the major benefits. There aren’t many dry processing methods available for iron ore and fine coal. In 2020, India utilized a total of 946.42 million tonnes of coal. Coal is a major energy source used worldwide to generate electricity. High energy-efficient clean coal is created when the amount of ash is reduced. Similar to this, gangue material decreases and high-grade material is created by processing iron ore with a size of less than 2 mm. Wet treatment was first used to separate the material. The growing need for clean iron ore and coal has led to a rising need for efficient separator equipment. Therefore, the best way to separate materials will be through the development of appropriate dry technology for processing.

Numerous efforts were undertaken to examine the dry separation capabilities of the current linear separator equipment for screening. The angular location, frequency, and screen mesh size of conventional linear separator equipment are all set once and are maintained for years until they break down. The main issues with the linear separator equipment are decreased performance and clogging. The material’s moisture content and the presence of near-size particles cause screen blockage. When a screen becomes clogged, particles flow through it inefficiently and small particles become misplaced with coarse particles that are released from the screen deck. The work of Dong et al.1 demonstrates the necessity of using the screen’s circular motion. The job involves creating a DEM model for the several screening vibrating modes, including circular and linear screen vibration. It was discovered that when there was a linear motion on the screen, the particle’s travel rate was greater, and when there was a circular vibration, it was lower. It is evident from the many studies carried out by different researchers like reference1 that screen clogging can be prevented by employing circular vibration in the separator equipment. The main issues with the current linear separator equipment are low residence duration, high velocity, clogged screens that impair efficiency, and rigidity when adjusting the screen’s frequency and angular position. The work of Akbari et al.2 demonstrates the experimental analysis of dry screening using a flip-flop screener. The work clearly shows the methodology of grouping the sample size for dry screening. Production must be halted in order to use a wire brush to remove any material that has become lodged in the screen mesh because of issues with the current linear separator equipment, Bardhan et al.3. However, when the feed material’s moisture content rises, the machine experiences more stoppage, which lowers efficiency, raises production costs, and uses fewer high-grade materials in smaller size fractions.

It has also been observed that near-size fine particles were present in linear separator equipment from the input end to the output end. The screen blinding from the input end to the output end of the screen caused by near-size particles from the input end will lower the screening efficiency. By accumulating near-sized small particles solely at the screen’s discharge end, the circular separator equipment lowers screen blindness and boosts screening effectiveness. According to Feller et al.4, combining the two forces—vertical and horizontal—will lessen screen blindness and improve screening effectiveness. The suggested separator equipment will consider both vertical and horizontal forces. A few additional significant disadvantages of the conventional linear separator equipment include their increased number of parts, which increases friction and vibration.

One of the most important steps in dividing iron ore and coal into various size fractions is a prominent process for beneficiation5. The most challenging separation technique, which calls for extensive development, is dry separation. New dry-separating technologies have been developed as a result of the need to reduce excessive water usage through dry separation. Clean iron ore and coal may be produced using effective dry separation equipment, which can save production costs and boost profits. It is challenging to separate moist iron ore and coal for size fractions less than 6 mm. However, less work was carried out on experimental analysis of screening. The work of Akbari et al.2 demonstrates the experimental analysis of dry screening using a flip-flop screener. The work clearly shows the methodology of grouping the sample size for dry screening. The work of Dong et al.1 and Akbari et al.2 was the basis for attempting the present work with the proposed methodology. Therefore, a new separation equipment was created to separate the moist iron ore and coal of − 4 + 0 mm, which is difficult to separate. This separation equipment also provides flexibility to modify the operating parameters such as vibration frequency and inclination angle of the screen that can be sloped in an upward direction. The separation efficiency of the new separator for dry separation and the challenges of separating moist iron ore and coal are presented in this paper. This paper examines the performance of separation of newly developed equipment for the dry iron ore and coal with a size fraction of -4 + 0 mm. The comparative analysis of the impact of operating parameters such as vibration frequency and inclination was determined using separation equipment.

In the existing literature, it was identified that a limited amount of experimental results are available for physical equipment, which makes it challenging to compare and evaluate the actual real-world operational challenges of screen clogging and particle mobility under varying conditions. The present work addresses this gap by conducting a comprehensive experimental study using a physical screen machine to assess its performance in separating iron ore and coal under different operating moisture conditions. By directly testing the equipment, this work provides practical insights into the impact of moisture content, and efficiency, offering a more realistic assessment of screen performance. Additionally, the integration of experimental data with ANN-based predictive modeling further strengthens the reliability of the findings, bridging the gap between theoretical predictions and real-world applications.

Experimental details

Material used

JSW Steels Ltd., Ballari, India, owned iron ore and coal were used in this investigation. Prior to separation, the raw iron ore and coal were crushed using a jaw crusher. Two manual size fractions of − 2 + 0 mm and − 4 + 2 mm were obtained from iron ore and coal. Following the filtering of the mixture, a 30% −2 + 0 mm and 70% −4 + 2 mm mixture was created. To get the required variation in moisture, − 4 + 0 mm of iron ore and coal was mixed with water. The Moisture Analyser - MX 50 was used to measure the moisture content. Three distinct iron ore and coal feeds, each with a different moisture percentage of 4%, 6%, and 8%, were made separately.

Machine used

Low separation performance is typically the outcome of separation equipment with rigid operating conditions. A small number of works on separation equipment with adjustable operating parameters were discovered through a review of the literature. Thus, the authors designed a separation equipment for separating moist iron ore and coal that has a circular vibration mode and operational flexibility. Figure 1 displays a schematic of the new separation equipment.

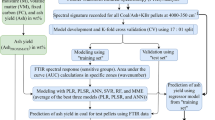

Separation equipment tests

The present work has considered a new methodology for testing the separation performance of the separation equipment. The methodology for testing the separation performance is given in flow sheets, as shown in Fig. 2. Figure 2 shows that in the present study, the Coal and iron ore samples were collected from JSW Steels, Ballari. The materials were initially crushed and sieved to obtain a -4 mm + 0 mm size fraction. Further manual sieving was conducted to separate the samples into − 4 mm + 2 mm and − 2 mm + 0 mm fractions. Feed samples were then prepared by mixing 70% oversized particles (-4 mm + 2 mm) and 30% undersized particles (-2 mm + 0 mm). The moisture content of the samples was varied at three levels: 4%, 6%, and 8%. The prepared feed samples were individually screened using a screener machine to assess screening performance. Screen efficiency was determined for each screening condition, followed by a comparative analysis of the screening performance of coal and iron ore. To enhance predictive accuracy, regression and artificial neural network (ANN) techniques were employed to estimate screen efficiency. Finally, the prediction performances of regression and ANN models were compared to evaluate their effectiveness in predicting screening outcomes.

This paper describes the laboratory scale trial of the separation equipment to individually separate iron ore and coal material of size fraction − 4 mm + 0 mm. The screen deck used in the equipment was 600 mm long and 300 mm wide. The bed depth was maintained as 20 mm, i.e., five times the size of the oversized material6. The screen mesh with an aperture size of 2 mm is fixed to the separating equipment. The screen hole opening area maintained in the separating equipment was 60%, and the shape of the particles used was irregular. The amplitude maintained in the present study was 2 mm. After preparing the samples, the feed material is poured through the hopper of the vibrating feeder. The material was fed at a rate of 500 kg per hour. With the angle bolts on the separation equipment, the angular position can be adjusted to 1, 3, and 5 degrees on an upward slope. The separation equipment is connected to the frequency drive, which can change the frequency from 4 Hz to 12 Hz with an interval of 0.25 Hz, leading to 33 experimental trials for each angular and moisture condition.

During testing, the angular position of the machine was set by rotating the angle bolts. Then, the separation equipment was started, and a variable frequency drive set the frequency. Once the separation equipment was started, it was set to run for 2 min to reach the steady-state condition. However the steady-state maintained used was 20 s in some literature, such as the reflux classifier7. The precision of the experiment was obtained by maintaining the steady-state time for each trial as 2 min. The motor can achieve a consistent rotating force on the screen at both the inlet and outlet zones during the steady-state time. The vibratory feeder is used to pour the material through. As the material comes into contact with the screen mesh, the rotational force of the screen transfers to it, pushing it in the direction of the outlet zone. During this rotational motion, the feed material is vibrated on the screen deck. The vibration allows the undersized material to separate from the oversized material by passing through the screen mesh. The duration of the particle movement on the screen is known as the residence time of the material. A portion of the smaller particles will go through the screen mesh during this movement, and the remaining smaller particles will be misdirected with the larger particles through the output zone. As the amount of undersized particle misplacement is increased, the separating equipment’s efficiency will be minimized. After separation, the undersized material is collected from the collector box, which is placed below the screen mesh, and the oversized material is collected from the outlet zone of the screen deck.

Data processing and analysis

From the literature, it was evident that very limited work was carried out by researchers such as Grozubinsky et al.,8 on the estimation of efficiency of the separating equipment. Moreover, studying separation performance and addressing associated issues are hard efforts; thus, it is essential to employ numerical and analytical methods9. Consequently, the efficiency prediction was conducted utilizing numerical methods, including regression analysis and ANN models.

Based on the consistent success rate and potential, the utilization of regression and ANN analysis for predictions is growing. The literature indicates that limited research has been conducted on the development of regression and ANN models concerning separation performance; for instance, Guerreiro et al.10 and Barbosa et al.11 have employed regression analysis in this context. Yadav et al.12 created an artificial neural network model to assess the efficacy of coal agglomeration. Lawal et al.13, Onifade et al.14, and Lawal et al.15 created an artificial neural network model for the study of coal combustion.

The utilization of regression and artificial neural network prediction models has been progressively rising for addressing intricate issues and establishing a mathematical correlation between input and output data. This project aims to construct a regression and artificial neural network prediction model to forecast the performance of separation equipment for iron ore and coal separation. This study provides a comprehensive discussion on the creation of the prediction model. This study will facilitate the creation of an effective system for predicting the performance of separation equipment.

The data for the regression and ANN prediction model development was acquired through a series of tests including iron ore and coal in the separation apparatus. The frequency was altered during experiments, and the efficiency was measured. Thirty-three distinct trials were conducted for each angle and moisture condition in the separation of iron ore and coal. The prediction model was developed with frequency as an input parameter and efficiency as the output parameter. So, the present study provides the regression and ANN prediction model in terms of frequency for all the angular and moisture conditions of separating iron ore and coal in the developed separation equipment.

Regression model

For analyzing and predicting outcomes, the regression model is frequently utilized. Regression modeling develops a mathematical equation for the indirect estimation of output data. The developed mathematical equation simplifies the complexity of the problem. The primary purpose of regression modeling is to develop a relationship between the input data and the output data. In the present study, the mathematical modeling of efficiency for separating iron ore and coal for all the inclination and moisture conditions was developed. In industries, the separating equipment will be provided with the variation in only frequency. So, the mathematical model was developed for frequency as the input data and efficiency as the output data.

Artificial neural network model

Artificial neural network modeling provides the prediction of the output data using a nonlinear mathematical equation. The Regression and ANN modeling was carried out using Minitab V1716 and Matlab 2024b17, respectively. The artificial neural network model consists of interconnected nodes called neurons. The neurons receive the input data, perform a nonlinear operation, and provide prediction results. The artificial neural network (ANN) model consists of three layers, i.e., input layer, hidden layer, and output layer, as shown in Fig. 3. Similar to regression modeling, the mathematical model was developed for frequency as the input data and efficiency as the output data. A feedforward backpropagation technique was used for ANN modeling. This technique allows the model to adjust the weights, such as error decreases with iteration. Out of 33 experimental results, For evaluating the ANN model, the splitting of the sample data into training, testing, and validation was carried out in 70%, 15%, and 15%, respectively18. The correlations between input and output parameters were analyzed using residual analysis. The performance validation of the ANN model is not required as the model provides both validation and prediction results. The input and output parameters considered in the present work to build the model were frequency and screening efficiency. The predictive model using frequency was developed for different angles and moisture content. The practicability and efficiency of the developed model show the Interpretability of the input and output parameters. After the regression model and ANN model’s prediction results are obtained, a comparative study using the residual analysis will be carried out to evaluate the most efficient modeling technique for predicting the separation performance of iron ore and coal in the separation equipment. The residual analysis of the developed model verifies the robustness of the regression and ANN models which also shows the noisy data.

Results and discussion

Influence of separating iron ore and coal at 4% moisture for different inclinations and frequency

The efficiency variation for the separation of 4% moisture iron ore and coal at different frequencies is illustrated in Fig. 4a and b, respectively. The deck’s angle on an ascending slope was modified to various degrees, specifically (1, 3, and 5). Particles exhibited effective circular motion with a 1-degree spacing, leading to enhanced fine coal infiltration into the mesh aperture. The separation occurred on an incline, allowing the particles additional time to traverse the aperture, resulting in an extended duration of coal particles on the deck1. Extended separation periods and circular particle motion have yielded efficiency rates of 87.45% for iron ore and 85.96% for coal separation. The separation efficiency for coal decreased to 71.63% and 78.71%, respectively, when the deck tilt was modified to 3 and 5 degrees. This occurred by the upward separation, which makes the coal particles travel against gravity. It was discovered that when the angle was changed from 1 to 5 degrees, the efficiency dropped from 85.96 to 71.63%. This happened as a result of some coal particles on the deck rolling back, reducing the possibility that fine coal would pass through the mesh aperture. To separate iron ore, The separation efficiency rose to 90.13% and 94.56%, respectively, when the deck’s tilt was changed to 3 degrees and 5 degrees. It was found that the efficiency rose from 87.45 to 94.56% when the angle was adjusted from 1 to 5 degrees. Based on the results of both material separations, iron ore has the highest efficiency. For the iron ore particles on the screen, good rotating motion, mixing, loosening, and stratification were observed19. Therefore, iron ore had a better separation efficiency than coal.

Influence of separating iron ore and coal at 6% moisture for different inclinations and frequency

The efficiency variation for separating 6% moist iron ore and coal at various frequencies is depicted in Fig. 5a, b, respectively. The highest separation efficiencies of coal were 75.64%, 70.24%, and 65.23% at 1, 3, and 5 degrees, respectively. The highest iron ore separation efficiencies at 1, 3, and 5 degrees were 82.35%, 86.43%, and 90.45%, respectively. From the data, it was evident that when the angular position was raised from 1 to 5 degrees, iron ore’s efficiency peaked. However, when the inclination rose, coal’s efficiency decreased. It was demonstrated that the main cause of the variations in separation behavior between iron ore and coal was the material’s density differential. When iron ore was separated instead of coal, it was found that the particles moved from the intake zone to the outflow zone more quickly and at a lower frequency. Particle mobility in iron ore has led to more chances for the particles to pass through the opening of the screen20. The coal’s mobility was reduced when the inclination was raised to 5 degrees, which led to an increase in the accumulation of coal particles in the inlet zone. Additionally, it stopped some of the coal particles that were too small from getting through the screen openings.

Influence of separating iron ore and coal at 8% moisture for different inclinations and frequency

The efficiency variation for separating 8% moist iron ore and coal at various frequencies is depicted in Fig. 6a and b, respectively. The highest separation efficiencies of coal were 63.46%, 59.74%, and 56.97% at 1, 3, and 5 degrees, respectively. The highest separation efficiencies of iron ore were 78.64%, 83.91%, and 80.39% at 1, 3, and 5 degrees, respectively. The results demonstrated that a higher fall in coal performance at 5 degrees was brought on by screen blockage and a high buildup of coal particles next to the intake zone, as shown in Fig. 7. With an increase in coal moisture content, it was discovered that efficiency, particle transit into the screen hole, and particle stratified all declined.

Table 1 shows the angle and optimized frequency for the highest screening efficiency of iron ore and coal. From Table 1, It was clear that the highest separator efficiency obtained for coal was 85.96% at 4% Moisture and 10 Hz frequency. From Table 1, It was clear that the highest separator efficiency obtained for iron ore was 94.56% at 4% Moisture and 9 Hz frequency.

The results of the separator efficiency of coal correlated well with the results of Akbari et al., 2017, which had a separator efficiency of 85.1% for separating coal in flip flop screener. From the work of Dong et al.1, the simulation results show that the separator efficiency of the circular motion screener has yielded up to 78%. In comparison with the previous literature results, it was clear that the developed separator equipment is highly efficient for separating coal and iron ore.

From Table 1, it was clear that Iron ore separated at 5 degrees was also discovered to be less efficient than iron ore separated at 3 degrees. The main causes of this were the decreased buildup of iron ore particles on the screen deck as well as the decreasing mobility. Additionally, it was found that separating iron ore resulted in decreased screen clogging, as seen in Fig. 8. Therefore, iron ore was more efficient than coal.

The high density of iron ore also contributed to its increased efficiency. It was discovered that, in comparison to low-density coal, the increased density of iron ore also corresponds to the handling of a small amount of material. There were fewer near-sized, fine, and coarse particles in iron ore because there was less material handling. Thus, the stratification of iron ore particles occurred faster than with coal. Additionally, it was noted that the iron ore particles moved well during separation at a higher inclination on an upward slope. All of the iron ore particles had more possibilities to pass through the screen holes as a result of this particle mobility than coal.

For all moisture circumstances, separating coal at higher inclination decreased in efficiency; however, separation of coal at a 1-degree increased efficiency. The optimal bed depth has made optimum particle segregation and particle mobility on the screen deck possible21.

The material moved from the screen deck’s inlet to outflow zones due to the rotational force’s horizontal motion4. Additionally, the bigger particles are moved horizontally, making it easier for the smaller particles to fit through screen holes. The rotational force’s vertical motion stirred the particles, mixed them, and cleared the screen holes, which prevented clogging4. The separating equipment will have a high residence time of the material on the screen due to the intermediate horizontal and vertical motion of the rotational force, which results in a high transit of particles through the screen4. The results indicated that iron ore may be screened more efficiently than coal regarding screen clogging. This suggests that the high-density material demonstrated superior separation performance for the separation apparatus. Furthermore, it was determined that iron ore separated at 5 degrees exhibited lower efficiency compared to iron ore screened at 3 degrees. The primary factors contributing to this were the reduced accumulation of particles on the screen and diminished mobility. Additionally, it was discovered that separating iron ore resulted in decreased screen clogging. Therefore, iron ore was more efficient than coal.

The high density of iron ore also contributed to its increased efficiency. It was discovered that, in comparison to low-density coal, the increased density of iron ore also corresponds to the handling of a small amount of material. There were fewer near-sized, fine, and coarse particles in iron ore because there was less material handling. In comparison to iron ore, more water was used during sample preparation to alter the moisture content of coal. This was brought about by the low density of coal, which causes a significant amount of material to absorb moisture content due to its increased surface area. As a result, a large volume of water is needed to increase the moisture content of coal. Therefore, compared to coal, the stratification of iron ore particles happened more quickly. All of the iron ore particles on the screen had more possibilities to pass through the screen holes as a result of this particle mobility than coal. Separating coal at 3 and 5 degrees showed a decrease in efficiency for all moisture conditions; however, separating coal at a lower inclination in an upward slope produced higher efficiency. It was noted that the screen’s rotational motion and ideal bed depth produced excellent efficiency22. The material moved from the screen deck’s inlet to outflow zones due to the rotational force’s horizontal motion. Additionally, the bigger particles are moved horizontally, making it easier for the smaller particles to fit through screen holes. The rotational force’s vertical motion stirred the particles, mixed them, and cleared the screen holes, which prevented clogging. The separating equipment will have a high duration for material residence on the screen deck due to the intermediate horizontal and vertical motion of the rotational force, which results in a high transit of particles through the screen hole. The findings demonstrated that iron ore material may be separated more easily than coal in terms of screen clogging. This indicates that high-density materials, such as iron ore, exhibited better anti-logging behavior for the designed separation equipment.

Prediction of efficiency using the regression model

After the experimentation, the predictive regression model was developed for efficiency with respect to the frequency variation for each moisture and angular condition. For each predictive model, P-value and R-squared values were obtained. P-value is a significant value that has to be less than 0.005. The P-value was 0.00 for all iron ore and coal settings. This indicates that the model was of high quality. The R-squared value shows the closeness in the correlation of the experiment results and prediction results in percentage.

Figure 9 a-i shows the regression data fitting results of efficiency for all experimental conditions of separating coal. For 4% moisture content, the R-squared value for 1 degree, 3 degrees, and 5 degrees was 78.7%, 96.5%, and 97.3%, respectively. The R-squared value of 3 degrees and 5 degrees was found to be more accurate compared to 1 degree. 78.7% R-squared value for predicting separation results at 1 degree was in an acceptable range. For 6% moisture content, the R-squared value for 1 degree, 3 degrees, and 5 degrees was 91.7%, 97.9%, and 97.1%, respectively. For 8% moisture content, the R-squared value for 1 degree, 3 degrees, and 5 degrees was 87.3%, 85.6%, and 95.3%, respectively. All the predictive values of separating coal with 6% and 8% moisture, the R squared value, were found to be highly accurate for the developed regression model.

Figure 10 a-i shows the regression data fitting results of efficiency for all experimental conditions of separating iron ore. For 4% moisture content, the R-squared value for 1 degree, 3 degrees, and 5 degrees was 93.4%, 89.8%, and 88.5%, respectively. For 6% moisture content, the R-squared value for 1 degree, 3 degrees, and 5 degrees was 89.8%, 94.2%, and 93.3%, respectively. For 8% moisture content, the R-squared value for 1 degree, 3 degrees, and 5 degrees was 92.5%, 92.4%, and 94.9%, respectively. Figure 9 a-i and Fig. 10 a-i observed that the regression prediction results of iron ore had provided more accurate results than the prediction results of coal.

Prediction of efficiency using the artificial neural network model

Figure 11 a-i and 12 a-i show the artificial neural network data fitting results for all the conditions of separating iron ore and coal, respectively. The predictive model was developed using an artificial neural network for efficiency with respect to the frequency variation for each moisture and angular condition. For each predictive model, R-value validation, R-value overall, and R-squared value were obtained. R-value overall shows the closeness in the correlation between the experimental results and prediction results. From Fig. 11 a-i and 12 a-i, it was clear that the prediction data fit well with experimental data.

Table 2a, b show ANN prediction results of efficiency for all experimental conditions of separating iron ore and coal, respectively. Table 2a, b showed that the R squared value obtained was more than 98% for all the separation conditions. This shows that the modeling with an artificial neural network results in developing a highly accurate model for separating iron ore and coal. The closeness in R-value validation with the R-value overall provides the validation of the predictive model. Table 2a, b, it was clear that the developed model was valid and accurate.

Validation of regression and ANN model using probability plot of residuals

Figure 13a, b show the probability plot of residual of regression models for all the experimental conditions of iron ore and coal. From Fig. 13a, b, it was clear that the residuals are within the normal line and also are independent of one another. Figure 13a, b also show that the standard deviation value indicates the overall spread of errors ranging from 0.4 to 1.3. The standard deviation value was low but in the acceptable range. The normality, independent, and standard deviation results of the probability plot show that the developed regression model for all the experimental conditions of iron ore and coal fits well with the data.

Figure 14a, b show the probability plot of residual of ANN models for all the experimental conditions of iron ore and coal, respectively. From Fig. 14a, b, it was clear that the residuals are within the normal line and also are independent of one another. Additionally, Figs. 14a, b demonstrate that the ANN model’s standard deviation value was substantially lower than the regression model, with a range of 0.1. The criteria of homoscedasticity are satisfied by Fig. 14a, b illustrate that the vertical dispersion of the data around the normal line appears to remain rather constant as the X-axis varies23. The probability plot results for homoscedasticity, low standard deviation, normality, and independence indicate that, across all experimental conditions for iron ore and coal, the developed artificial neural network (ANN) model outperforms the regression model in predictive accuracy. Overfitting generally results in elevated variance and significant dispersion in prediction errors. The probability plot of residuals in this investigation exhibited less data scatter, signifying alignment between expected and actual values. This verifies that the constructed model is optimal and unaffected by overfitting14,24,25.

The regression and artificial neural network prediction results clearly indicated that the R-squared value of the artificial neural network model outperformed that of the regression model. The findings of the regression and artificial neural network residual analysis clearly indicated that the data fitting performance of the artificial neural network model was better than that of the regression model. This signifies that the artificial neural network-based prediction model has performed better than the predictive regression model. The intricate challenge of segregating iron ore from coal is more effectively addressed by the prediction model of artificial neural networks.

Conclusions

This study thoroughly investigated the separation efficacy of iron ore and coal under different moisture circumstances utilizing a separation apparatus. The findings indicated that a reduced moisture content of 4% resulted in optimal separation efficiency. Both coal (85.96%) and iron ore (94.56%) exhibited reduced efficiency due to increasing moisture content, which caused screen clogging and diminished particle mobility, especially in coal.Moreover, iron ore demonstrated enhanced mobility at elevated angular locations and increased separation efficiency relative to coal, owing to the screen deck’s rotational force.

The research further validated that the anti-clogging efficacy of the separation apparatus was more pronounced for high-density iron ore compared to low-density coal, enhancing the performance of iron ore separation. To improve predictive accuracy, regression and artificial neural network (ANN) models were employed, with the ANN model exhibiting superior prediction accuracy, attaining R² values of 99.10% for coal and 98.24% for iron ore. The ANN model outperformed the regression analysis in forecasting separation efficiency, as confirmed by residual probability plot analysis. These findings underscore the capability of machine learning models in enhancing separation procedures. The research findings showed the significance of diverse iron ore and coal characteristics in predicting the efficacy of separator equipment utilized for their separation. The study, grounded in experimental analysis and ANN-based predictions, found moisture content and the density differential between coal and iron ore as critical determinants of separation efficiency. These qualities substantially influence the behavior of materials throughout the separation process. The findings from this investigation endorse the refined selection and functioning of separator equipment, enhancing total separation efficiency. The residual probability plot indicates that the developed artificial neural network (ANN) model outperforms the regression model in prediction accuracy across all experimental conditions for iron ore and coal, demonstrating homoscedasticity, low standard deviation, normality, and independence. The authors will investigate various predictive modeling techniques for the separation studies of coal and iron ore, and they also intend to examine the separation studies of different materials using the developed separator equipment as potential future research directions in the field. Future study may concentrate on optimizing separation equipment design to reduce coal clogging problems and using real-time AI-driven monitoring systems to improve operational efficiency.

Data availability

The necessary data used in the manuscript are already present in the manuscript.

References

Dong, H., Liu, C., Zhao, Y. & Zhao, L. Influence of vibration mode on the screening process. Int. J. Min. Sci. Technol. 23 (1), 95–98 (2013).

Akbari, H., Ackah, L. & Mohanty, M. Performance optimization of a new air table and Flip-flow screen for fine particle dry separation. Int. J. Coal Prep. Util. 40 (9), 581–603. https://doi.org/10.1080/19392699.2017.1389727 (2017).

Bardhan, A., Singh, R. K., Alatiyyah, M. & Alateyah, S. A. An Effective Hybrid Model of ELM and Enhanced GWO for Estimating Compressive Strength of Metakaolin-Contained Cemented Materials. CMES Comput. Model. Eng. Sci. (2024).

Feller, R., Zion, B. & Pag, J. Accurate sizing without cumulative screen clogging. J. Agri. Eng. Res. 35, 235–244 (1986).

Fu, J., Jialiang, Z. & Fengshuang, L. Enhanced Sieving mechanism of novel cleaning screen and investigation of particle movement characteristics on the screen. Powder Technol. 431, 19043. https://doi.org/10.1016/j.powtec.2023.119043 (2024).

Li, J., Webb, C., Pandiella, S. S. & Campbell, G. M. A numerical simulation of separation of crop seeds by screening—effect of particle bed depth. Food Bioprod. Proc. 80 (2), 109–117. https://doi.org/10.1205/09603080252938744 (2002).

Amariei, D., Michaud, D., Paquet, G. & Lindsay, M. The use of a reflux classifier for iron ores: assessment of fine particles recovery at pilot scale. Miner. Eng. 62, 66–73. https://doi.org/10.1016/j.mineng.2013.11.011 (2014).

Grozubinsky, V., Sultanovitch, E., Lin, I. & J Efficiency of solid particle screening as a function of screen slot size, particle size and duration of screening: the theoretical approach. Int. J. Min. Process. 52 (4), 261–272. https://doi.org/10.1016/S0301-7516(97)00069-0 (1998).

Zhovtiuk, G. V. Wet sizing of coals on stationary screens. Coal Prep. 5 (3–4), 229–241. https://doi.org/10.1080/07349348808945567 (1988).

Guerreiro, F. S., Gedraite, R. & Ataíde, C. H. Residual moisture content and separation efficiency optimization in pilot–scale vibrating screen. Powder Technol. 287, 301–307. https://doi.org/10.1016/j.powtec.2015.10.016 (2016).

Barbosa, V. P., Menezes, A. L., Gedraite, R. & Ataíde, C. H. Vibration screening: A detailed study using image analysis techniques to characterize the bed behavior in solid–liquid separation. Miner. Eng. 154, 106383. https://doi.org/10.1016/j.mineng.2020.106383 (2020).

Yadav, A. M., Nikkam, S. & Gajbhiye, P. MH Tyeb. Modeling and optimization of coal oil agglomeration using response surface methodology and artificial neural network approaches. Int. J. Miner. Process.. 163, 55–63 https://doi.org/10.1016/j.minpro.2017.04.009 (2017).

Lawal, A. I. et al. On the performance assessment of ANN and spotted hyena optimized ANN to predict the spontaneous combustion liability of coal. Combust. Sci. Technol. 194 (7), 1408–1432. https://doi.org/10.1080/00102202.2020.1815196 (2020).

Onifade, M. et al. Development of multiple soft computing models for estimating organic and inorganic constituents in coal. Int. J. Min. Sci. Technol. 31 (3), 483–494. https://doi.org/10.1016/j.ijmst.2021.02.003 (2021).

Lawal, A. I. et al. Prediction of mechanical properties of coal from Non-destructive properties: A comparative application of MARS, ANN, and GA. Nat. Resour. Res. 30, 4547–4563. https://doi.org/10.1007/s11053-021-09955-w (2021).

Minitab, L. L. C. Minitab. https://www.minitab.com (2017).

The MathWorks Inc. Statistics and Machine Learning Toolbox Documentation, Natick, Massachusetts: The MathWorks Inc. https://www.mathworks.com/help/stats/index.html (2024).

Kumar, B. R., Vardhan, H., Govindaraj, M. & Vijay, G. S. Regression analysis and ANN models to predict rock properties from sound levels produced during drilling. Int. J. Rock Mech. Min. Sci. 58, 61–72. https://doi.org/10.1016/j.ijrmms.2012.10.002 (2013).

Özer, M., Basha, O. M. & Morsi, B. Coal-agglomeration processes: A review. Int. J. Coal Prep. Util. 37 (3), 131–167 (2017).

Soldinger, M. Interrelation of stratification and passage in the screening process. Min. Eng. 12 (5), 497–516 (1999).

Soldinger, M. Influence of particle size and bed thickness on the screening process. Min. Eng. 13 (3), 297–312 (2000).

Harzanagh, A. A., Caner Orhan, E. & Levent Ergun, S. Discrete element modelling of vibrating screens. Miner. Eng. 121, 107–121. https://doi.org/10.1016/j.mineng.2018.03.010 (2018).

Mohanraj, G. T. et al. Design and fabrication of optimized magnetic roller for permanent roll magnetic separator (PRMS): Finite element method magnetics (FEMM) approach. Adv. Powder Technol. 2021, 0921–8831 https://doi.org/10.1016/j.apt.2021.01.003 (2021).

Aladejare, A. E., Onifade, M. & Lawal, A. I. Application of metaheuristic based artificial neural network and multilinear regression for the prediction of higher heating values of fuels. Int. J. Coal Prep. Util. 42 (6), 1830–1851. https://doi.org/10.1080/19392699.2020.1768080 (2020).

Said, K. O., Onifade, M., Lawal, A. I. & Githiria, J. M. An artificial Intelligence-based model for the prediction of spontaneous combustion liability of coal based on its proximate analysis. Combust. Sci. Technol. 193 (13), 2350–2367. https://doi.org/10.1080/00102202.2020.1736577 (2020).

Acknowledgements

The authors extend their appreciation to King Saud University for funding this work through Researchers Supporting Project number (RSPD2025R711), King Saud University, Riyadh, Saudi Arabia.

Funding

This research was funded by King Saud University through Researchers Supporting Project number (RSPD2025R711).

Author information

Authors and Affiliations

Contributions

BK, HM, RK, AR, SM CDP: Writing original draft, review, editing, methodology, Investigation BK, HM MK, AK, SS, AR, SM: Formal Analysis, Investigation, Writing review, supervision .

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical statement

This study did not involve human participants or animals, and no ethical approval was required. All research procedures adhered to relevant ethical guidelines and best practices for non-human and non-animal research.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shanmugam, B.K., Hanumanthappa, H., Singh, R.K. et al. Separator equipment performance of iron ore and coal using experimental and ANN-based analysis. Sci Rep 15, 18197 (2025). https://doi.org/10.1038/s41598-025-02681-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-02681-w