Abstract

Solar dryers offer a sustainable and efficient method for drying many agricultural products, preserving their quality, color, and medicinal properties while minimizing energy consumption and environmental impact. Current research on henna processing reveals a significant gap in drying engineering studies, creating a critical barrier to process optimization and quality enhancement. While numerous studies have investigated henna’s physical and chemical characteristics, the engineering aspects of drying—including heat and mass transfer mechanisms, equipment design, and process parameter optimization—remain substantially understudied. This knowledge gap hinders the development of efficient, standardized drying methods that could improve product quality, reduce energy consumption, and increase production yields in commercial henna processing. So, during the present study, a direct solar dryer integrated with a photovoltaic system was used for drying Henna leaves at Aswan University, Egypt, during January 2025. Where a comparison study was conducted between the drying of Henna leaves by the developed direct solar dryer (DDSD) and open-air drying (OAD) at three-layer thicknesses of 2 cm, 4 cm, and 6 cm. The comparison study between both drying systems was established in terms of mathematical modeling, drying parameters, EMD, and economic analysis. The obtained results showed that the equilibrium moisture contents of Henna leaves samples dried in OAD and (DDSD) reach ranged between 2.52 and 3.23% (2.17 and 2.69%) on a dry base. Applying the DDSD to dry Henna leaves resulted in a reduction in drying time by approximately 7.14%, 13.33%, and 18.75% for layer thicknesses of approximately 2, 4, and 6 cm, respectively. Additionally, the EMD of the Henna leaves dried using the DDSD ranged from 2.84 × 10–9 to 22.96 × 10–9 m2/s. Furthermore, Lewis (Newton), Weibullian, and Page were the most appropriate mathematical drying models for Henna leaves at layer thicknesses of approximately 2, 4, and 6 cm, respectively, for dried samples by DDSD. On the other hand, the economic analysis revealed that the DDSD has the potential to generate substantial cost savings, amounting to 3,348 USD per year. Additionally, the payback period was calculated to be 0.077 years (less than one month), demonstrating the system’s rapid return on investment and economic viability.

Similar content being viewed by others

Introduction

Henna (Lawsonia inermis) is a powdered plant material traditionally used for medicinal and cosmetic purposes in Asia and the Mediterranean region. In North America and Europe, henna is primarily utilized for coloring hair and creating temporary body art, serving mainly cosmetic and decorative purposes rather than traditional or medicinal uses. This coloring process is due to the action of the secondary metabolite lawsone, which enables Henna to produce orange to red shades of color1. Where Henna powder is popular among people looking for sustainable and environmentally friendly cosmetic products because of its natural, chemical-free characteristics. Market expansion is being driven by rising demand for natural and organic products, more awareness of dangerous chemicals in conventional dyes, and the growing popularity of traditional beauty rituals across worldwide cultures2. The global Henna powder market size will be USD 256.5 million in 2024. Rising demand for natural hair care products is expected to boost sales to USD 391 million by 2031, with a compound annual growth rate (CAGR) of 6.20% from 2024 to 2031. Middle East and Africa had a market share of around 2% of the global revenue and was estimated at a market size of USD 5.13 million in 2024 and will grow at CAGR of 5.9% from 2024 to 2031. Additionally, Egypt Henna powder sales revenue 2024 was USD 0.54 million3.

When Henna leaves are dried in the traditional way, it can take two days in direct sunlight with open air and three days in the shade4. This drying method has numerous disadvantages, including degradation from wind-blown debris, rain, insect infestation, and intervention from humans and animals, which can lead to product contamination5,6. Furthermore, over 20% of Henna production is squandered throughout conventional harvesting and drying procedures because of the absence of advancements in agricultural, harvesting, and drying techniques for this plant4. Where the research on solar drying of henna contributes to society by promoting sustainable, energy-efficient drying methods, reducing post-harvest losses, and improving product quality. It supports rural livelihoods, enhances income for farmers, and minimizes environmental impact by replacing conventional drying techniques, fostering eco-friendly practices in the henna industry.

Dryers provide an effective substitute for solar drying of agricultural products, mitigating the issues associated with OAD7,8,9,10. Dryers can be classified as conventional or non-conventional based on their energy source. Traditional dryers depend on fossil fuels, leading to elevated operational expenses and environmental contamination. Non-conventional dryers utilize solar energy to reduce drying expenses, environmental degradation, and energy consumption11,12,13,14,15,16. Utilizing solar drying techniques, agricultural goods can be desiccated within enclosed facilities, thereby mitigating the challenges linked to conventional OAD17,18,19. The utilization of solar energy in the drying process diminishes reliance on fossil fuels (such as coal, gas, and oil), leading to a reduction in pollutant emissions20. Solar drying is regarded as a viable technique for food preservation due to its effective utilization of solar energy21. In comparison to conventional OAD, solar dryers significantly reduce drying duration, save product losses, and enhance product quality22. The use of solar energy for drying agricultural products in Aswan, Egypt, is very permissible, where in 2024, Aswan recorded the highest temperature around the world. This extreme heat provides an ideal environment for solar drying techniques, which can significantly reduce MC in crops while preserving their quality. Farmers in the region are increasingly adopting these methods to enhance their productivity and reduce reliance on traditional drying processes. Furthermore, Egypt, characterized by a substantial annual daily average solar radiation on a horizontal plane (8 kW h/m2 day) and an average daily sunlight duration of approximately 11 h, presents significant potential for harnessing solar energy as an effective resource for food drying23,24,25.

The development of drying systems, compliance with quality standards, and energy efficiency depend on evaluating the final product’s quality and forecasting the drying behavior of food under various conditions. Mathematical modeling is a cornerstone of drying technology, playing a crucial role in designing and operating dryers under ideal conditions. Since drying affects the physical, chemical, and quality traits of products, process control strategies often involve modeling drying kinetics26,27,28. Additionally, drying kinetics helps in understanding and quantitatively analyzing the thermal and physical factors involved in the process29,30. Key influences on drying kinetics include air temperature, humidity, product size, and drying duration31,32,33. Each factor must be carefully considered, as their effects can vary, making manual dryer operation highly inefficient. Thus, developing a model that incorporates multiple variables is vital for researchers. Over the years, various drying models—such as the Page, Midilli, and logistic models—have been developed and widely used to simulate food drying behavior34,35,36,37. Grasping the material transport mechanisms in thin-layer drying is critical, as it enables effective process simulation or scaling to fine-tune operating parameters. Studies indicate that relying solely on experimental drying methods, without integrating mathematical drying kinetics, can reduce dryer efficiency, increase costs, and compromise product quality. Therefore, a robust model is necessary for process design, optimization, energy management, and control. Applying mathematical models to determine the drying kinetics of agricultural products is indispensable38,39.

Many researchers developed many types of photovoltaic-thermal (PVT)-Based solar dryers for drying many types of agricultural crops such as Gupta et al.40 analyzed the performance of a hybrid PVT solar air dryer for drying green chilis; Tiwari et al.41 presented an attempt to explore the best PV technology suitable for PVT solar drying system through environmental and economic feasibility; Bayrak et al.42 analyzed a novel PVT dryer using a sustainable control approach for drying apple slices; Veeramanipriya, and Sundari43 evaluated the performance of hybrid PVT solar dryer for drying of cassava; Tiwari et al. 44 evaluated the performance of PVT mixed mode greenhouse solar dryer; Elwakeel et al.45 designed and implemented of a PVT-integrated solar dryer based on IoT and date fruit quality monitoring and control; and Elwakeel et al.32 studied the drying kinetics and thermo-environmental analysis of a PVT-operated tracking indirect solar dryer for tomato slices.

Most researches on Henna are oriented towards its chemical composition1,46,47, its anti-bacterial, anti-inflammatory48,49, antipyretic and analgesic effects48, while only some researches on Henna are oriented towards drying process, such as, Bennamouna et al.50 studied the effect of forced convective solar drying on the biological activities, Bennamouna et al.51 explored solar drying of Henna and its effect on the bioactivities, Bennaceur et al.52 studied the effect of ultrasound on Henna leaves drying and extraction of lawsone. However, no research has yet examined how solar and natural drying affect drying characteristics, EMD, drying kinetics, and the economics of the drying process. This gap in literature highlights the need for comprehensive studies that explore these variables in detail. Understanding the interplay between drying methods and their economic implications could lead to more efficient and sustainable practices in various agricultural sectors.

So, this research paper aims to investigate the mathematical modeling, drying kinetics, EMD, and economic analysis of a hybrid photovoltaic-thermal (PVT)-based direct solar dryer for Henna leaves and compare the obtained data with traditional drying methods in open air. To determine whether the DDSD offers significant advantages over open sun drying in terms of mathematical modeling, drying parameters, effective moisture diffusivity, and economic analysis to identify the optimal layer thickness for drying Henna leaves. This study will furnish pertinent data to identify the optimal drying model that can improve the drying process of Henna leaves on a commercial basis. The results of this study will benefit specialists in postharvest technology seeking to enhance the efficacy of their drying techniques. Furthermore, the findings may also contribute to the development of industry standards that ensure consistent quality in the final product. By optimizing the drying process, producers can achieve higher yields and greater marketability for Henna leaves.

Materials and methods

Experimental setup

Henna leaves were cultivated at the research farm of Aswan University in Aswan, Egypt. Post-harvest, the Henna leaves were conveyed from the research farm to the Faculty of Agriculture and Natural Resources at Aswan University under average temperature 25 °C. Subsequently, Henna leaves samples were preserved in plastic bags at 5 ± 1 °C until the drying trials, Then, the fresh Henna leaves were distributed at three-layer thicknesses of 2, 4, and 6 cm as reported in previous studies53,54. Where during the current study two different drying methods were used for drying Henna leaves, the first system is a DDSD, and the other one is OAD. All field tests related to drying of fresh Henna leaves were conducted at the roof of Faculty of Agriculture and Natural Resources, Aswan University, Egypt, during January 2025. Figure 1 shows fresh and dried Henna leaves. All raw data are comprehensively presented in the Supplementary Materials, spanning Tables S1 through S5.

Description of the developed direct solar dryer (DDSD)

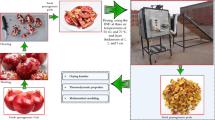

The direct solar dryer was developed and used to achieve the current study’s aims. As shown in Fig. 2, the DDSD consists of many components such as, (1) two DC air exhaust fans, (2) Henna leaves, (3) glass cover, (4) measuring and data logger unit, (5) volt regulator, (6) two DC air suction fans, (7) metallic frame, (8) 100 W PV panel, (9) direct solar dryer, and (10) laptop. The DDSD has dimensions of 300 cm in length and 100 cm in width and 20 cm in depth. It was covered with a glass cover with a 3 mm in thickness. The absorber plate is made from corrugated black aluminum plate and insulated with thermal wool 3 cm in thickness. The DDSD accomplishes three drying trays, each of them has a dimension of 100 cm in length and 100 cm in width. And it was integrated with four DC brushless fan (12 V and 0.20 A, China), to distribute the air evenly around the Henna leaves to create a homogeneous MC throughout the drying trays. Where two DC fans were used to force the ambient air to the DDSD, while the other DC fans were used to exhaust the hot air from the DDSD to the outside. The DDSD was integrated with an IoT-based measuring circuit for measuring both air temperature and relative humidity of air inside and outside the DDSD. The measuring unit consists of an Arduino board (model: Uno, China), dry temperature and humidity sensor (model: DHT-22, China), micro-SD card reader module (data logger, China). The DDSD was operated with a photovoltaic (PV) system, as shown in Fig. 2. The PV system consists of a PV panel (100 W, India), and a voltage converter (12–5 V, China). Figure 3 illustrates the schematic diagram showing the position of DHT sensors within the ADSD and control circuit.

This PV system showing in Fig. 4, consisting of a 100 W polycrystalline solar panel, a 30 A solar charge controller (RBL-30A), and a 12 V/70 Ah sealed lead-acid battery, was effectively used to power an air exhaust fan and other electronic components in a solar dryer setup. The solar panel, with its maximum power voltage of 18 V and current of 5.56A, generated sufficient electricity to charge the battery through the charge controller, which regulated the charging process with specific voltage setpoints (14.4 V for equalization, 13.7 V for float) while protecting the system from over-discharge (cut-off at 10.7 V). The 12 V battery then supplied stable power to the exhaust fan (drawing less than the controller’s 10A discharge limit) and other low-power electronics, with the controller’s USB output (5 V/3A) potentially powering sensors or monitoring devices. The system’s robust operating temperature range (− 35 to + 60 °C) ensured reliable performance in varying environmental conditions, making it ideal for continuous solar dryer operation while maintaining energy efficiency.

Evaluations processes

Drying parameters

Moisture content (MC)

Using the procedure outlined by AOAC55, the fresh Henna leaves sample was heated to 105 ± 1 °C in an electrical oven for three hours in order to determine the MC of the Henna leaves under laboratory conditions. According to Eke56, the initial MC on a dry basis (d.b.) was then determined using Eq. (1).

where \(\mu_{d}\) is the MC (d.b.); \(W_{w} and W_{d}\) are the weight of fresh and dried Henna leaves sample, g. Drying rate (DR).

The drying rate is the velocity at which moisture is extracted from a Henna leaves during the drying process to achieve equilibrium moisture content (EMC) in a certain amount of time, usually quantified in mass per unit area per unit time. This parameter is essential in numerous drying methods and apparatus, affecting energy usage and product quality. Comprehendinthe drying rate facilitates process optimization by determining the optimal conditions for effective moisture elimination and ensuring that the final product adheres to specified standards. The DR was calculated using Eq. (2), as described by Etim et al.57.

where the weight loss of henna sample (in g) was measured by subtracting the henna sample weight at the later time (\(M_{wt2}\)) from the henna sample weight at the earlier time (\(M_{wt1}\)), and \(\Delta t\) is the interval time, h.

Moisture ratio (MR)

MR is the proportion of the MC at a certain time to the original MC of the Henna leaves sample. Consequently, it possesses no unit. The drying rate refers to the velocity at which interior moisture dissipates into the environment9,22,32,33,58. The MR of the dried Henna leaves samples under different drying methods and layer thicknesses was calculated according to Eq. (3), as mentioned by Rabha et al.59.

where: \(M_{0}\) is the initial MC in %, \(M_{e}\) is the EMC in %, and \(M_{t}\) is the MC at any time in %.

The MR was employed to examine the drying kinetics of Henna leaves using suitable mathematical models. The value of \(M_{e}\) can be neglected, as it is relatively little compared to the values of \(M_{t}\) and \(M_{0}\). Consequently, as per Doymaz et al.60, the MR of Henna leaves can be expressed as depicted in Eq. (4).

Drying constant (k)

The drying constant in thin layer drying is obtained from a combination of many drying transport characteristics, including mass coefficients, density, specific heat, thermal conductivity, and interface heat61. The drying constant is ascertained using the exponential correlation between LnMR and drying time. Moreover, the drying constant is obtained from the identical relationship for two drying methods (DDSD and OAD) with a three-layer thickness of the Henna leaves. Although drying constants are essential for thoroughly characterizing the drying kinetics of dried product62,63, it is imperative to account for the various transport parameters involved. The drying constant was calculated using Eq. (5).

where A is the initial dry basis moisture content, gwater/gdry matter, k is the drying constant, and t is the interval time, h.

Effective moisture diffusivity (EMD)

Fick’s second law of diffusion relates the diffusive flux to the gradient of the concentration in absence of any chemical reactions. It postulates that the flux goes from regions of high concentration to regions of low concentration, with a magnitude that is proportional to the concentration gradient (spatial derivative), or in simplistic terms the concept that a solute will move from a region of high concentration to a region of low concentration across a concentration gradient. EMD is a measure of how efficient moisture can diffuse through a material. It’s influenced by factors like the material’s porosity, density, and the presence of moisture-absorbing components. Fick’s Second Law provides a framework for understanding and predicting moisture diffusion behavior in materials. Fick’s second law of diffusion describes how moisture concentration changes over time during drying processes. It states that the rate of change of moisture concentration at a point is proportional to the second derivative of concentration with respect to space. This law is applied in drying studies to model moisture diffusion in materials like food, agricultural products, and porous media, helping optimize drying conditions and predict drying rates64,65,66.

The calculation of EMD using Fick’s second law of diffusion relies on several key assumptions. These assumptions simplify the complex drying process and make mathematical modeling feasible. Here are the main assumptions including; (1) Moisture Diffusion is the Dominant Mechanism: Moisture transfer occurs primarily through diffusion, and other mechanisms (e.g., capillary flow, evaporation) are negligible or secondary; (2) Uniform Initial Moisture Content: The material (e.g., Henna leaves) has a uniform initial moisture distribution at the start of the drying process; (3) Isotropic Material: The material is isotropic, meaning its properties (e.g., diffusivity) are the same in all directions; (4) Constant Diffusivity: The effective moisture diffusivity (EMD) is assumed to be constant throughout the drying process, even though it may vary with moisture content and temperature in reality; (5) Negligible Shrinkage: The material does not undergo significant shrinkage or changes in shape during drying, which could otherwise affect the diffusion process; (6) One-Dimensional Moisture Transfer: Moisture transfer is assumed to occur primarily in one dimension (e.g., thickness of the material), simplifying the mathematical model; (7) Negligible External Resistance: The external resistance to mass transfer (e.g., boundary layer effects) is negligible compared to the internal resistance within the material; (8) Constant Drying Conditions: The temperature, humidity, and airflow around the material remain constant during the drying process; (9) Equilibrium at Surface: The surface of the material is assumed to be in equilibrium with the surrounding air, meaning the surface moisture content is directly related to the ambient relative humidity; and (10) Negligible Heat Transfer Effects: The impact of heat transfer on moisture diffusion is considered negligible, or the process is assumed to be isothermal.

Also, there are many conditions for applying Fick’s Second Law: (1) The material is homogeneous and has a well-defined geometry (e.g., slab, cylinder, or sphere); (2) The drying process occurs under controlled environmental conditions (e.g., constant temperature and humidity); (3) The boundary conditions (e.g., surface moisture content) are clearly defined and consistent throughout the process. By explicitly stating these assumptions and conditions, the application of Fick’s second law for calculating EMD becomes transparent, and the limitations of the model are clearly understood. This ensures the results are interpreted correctly within the context of the study67,68,69,70,71,72,73.

By applying Fick’s Second Law and considering the specific properties of a material, researchers and engineers can predict how moisture will move through a material over time, under different conditions. Fick’s Second Law of Diffusion is a powerful tool for understanding and predicting moisture diffusion behavior in materials. By applying this principle, researchers and engineers can gain valuable insights into EMD, leading to advancements in various fields that rely on controlling moisture transport74, as follows:

Diffusion analysis typically relies on several key assumptions, including, (1) The material starts with a consistent moisture level throughout. (2) The primary barrier to moisture movement occurs within the material itself. (3) Factors like air movement and surface conditions minimally impede moisture transfer. (4) The material’s ability to allow moisture to pass through remains unchanged during the process75. Using Eq. (7), the EMD can be calculated,

where \({\text{D}}_{{{\text{eff}}}}\) is the effective moisture diffusivity, m2/s, n is the term number, t is the time in s, and \({\text{L}}\) is the half slab thickness.

Mathematical modeling of drying process

Experimental data from each drying process was analyzed using eleven drying models (Table 1). Subsequently, non-linear regression analysis was conducted utilizing Microsoft Excel (version 2016) to estimate the coefficients of the provided models and statistical measures listed in Eqs. (8–10). The optimal model was identified based on the criterion of minimal root mean squared error (RMSE) values and maximal coefficient of determination (R2) and adjusted coefficient of determination (\({R}_{adj.}^{2}\))76,77,78.

where \(MR_{obs, i}\) and \(MR_{pre, i}\) are the ith experimental and predicted values; \(\overline{M}R_{pre}\) is the average predicted values; N is the number of observations; n is the number of constants in a model84.

Uncertainty analysis

Where the uncertainties in measuring instruments are estimated using Eq. (11), according to Suraparaju et al.85:

The initially evaluated uncertainty of moisture content (MR), moisture ratio (MR) and drying rate (DR) was about 1.12%. The research also examined measurement errors for temperature, humidity, wind speed, and solar radiation, which were 0.32%, 0.28%, 0.24%, and 0.13%, respectively. Upon evaluating these factors, the comprehensive assessment of solar dryer efficiency was estimated to possess a cumulative uncertainty of around ± 2%. This signifies that, notwithstanding the intrinsic measurement uncertainties, the sun drying system continues to be dependable and efficient in its functioning. The accumulation of imprecision highlights the system’s resilience in practical scenarios.

Economic analysis

Economic analysis plays a crucial role in assessing solar dryers, as it determines whether a proposed system is financially viable, cost-efficient, sustainable, and worthy of investment. For the DDSD, the economic feasibility was evaluated using Eqs. (12–23). Table 2 outlines the key assumptions used in the economic analysis, based on the Egyptian economic context.

The annual investment cost (\(C_{a}\) in USD/year) of the DDSD was calculated using Eq. (12).

where the annual capital cost (\(C_{ac}\)) of the DDSD was calculated according to Eqs. (13) and (14), as follows,

where \(C_{cc}\) is the capital cost of the DDSD, \(F_{c}\) is the recovery factor.

The drying cost per kg of Henna leaves using the DDSD (\(C_{s}\)), was calculated using Eq. (15), according to Mohammed et al.91 and Singh et al.91,92.

The amount of dried Henna leaves using the DDSD per year (\(M_{y}\)) is calculated using Eq. (16), where the amount of Henna leaves using the DDSD per batch (\(M_{d}\)) was equal 3 kg, 6 kg, and 9 kg at layer thicknesses of 2 cm, 4 cm, and 6 cm, respectively. Additionally, the number of days available for drying per year (\(D_{d}\)) assumed to be 300 days.

Based on local markets in Egypt, the cost of fresh Henna leaves (\(C_{fd}\)) was about 2.0 USD per kg. And the cost of one kilogram of the dried Henna leaves was calculated using Eq. (17), as recommended by Mohammed et al.91 and Singh et al.91,92.

where \(C_{dp}\) is the cost of fresh Henna leaves per kg of dried product, which is calculated using Eq. (18),

where \(M_{f}\) is the quantity of fresh Henna leaves loaded inside the DDSD.

Based on local markets in Egypt, the selling price of dried Henna (\(SP_{c}\)) is about 7.2 USD per kg. Also, the cost savings obtained per kg of dried Henna leaves (\(S_{kg}\)) are given by Eq. (19),

The savings obtained from the DDSD per batch (\(S_{b}\)) are given by Eq. 20,

While the savings obtained from the DDSD per day (\(S_{d}\)) are given by Eq. 21,

The savings obtained from the DDSD after “j” number of years is given by Eq. (22),

The payback time (Ŧ) for the DDSD is calculated using Eq. (23), as recommended by Mohammed et al.91 and Singh et al.91,92.

where \(S_{1}\) is the savings obtained from the DDSD after the first year.

Results and discussion

The fresh Henna leaves were dried during January 2025 at the roof of the Faculty of Agriculture and Natural Resources, Aswan University, Egypt. Where during the current study two different drying methods were used for drying Henna leaves, the first system is a direct solar dryer, and the other one is OAD at three-layer thicknesses of 2, 4, and 6 cm. Three repetitions of the MC laboratory tests revealed an average initial MC of 144.65% of fresh Henna leaves on a dry base (d.b.). During the drying process, the average ambient air temperature (in shadow), solar radiation intensity, and wind speed ranged from 10.6 to 25.72 °C, 96 to 677.5 W/m2, and 0.1–0.4 m/s, respectively. Also, inside the DDSD the air temperature and relative humidity ranged from 21.2 to 58.5 °C and 7.4 to 44.3%, respectively. Figure 5 shows solar radiation intensity, wind speed, temperature and humidity inside and outside the ADSD during the experiment period. Additionally, all drying experiments were conducted at fixed air velocity of 0.5 m/s.

Effect of drying method and layer thickness on MC and drying coefficient of Henna leaves

Figure 6 illustrated the impact of the drying techniques (OAD and DDSD) and layer thickness (2 cm, 4 cm, and 6 mm) on the MC of Henna leaves. Henna leaves samples dried in OAD achieved EMCs of 3.23%, 2.69%, and 2.52% (d.b.) for layer thicknesses of 2, 4, and 6 cm, respectively. While different Henna leaves samples dried by the DDSD achieved EMCs (d.b.) of 2.69%, 2.17%, and 2.69% for layer thicknesses of 2, 4, and 6 cm, respectively. The moisture extraction rate from the analyzed Henna leaves increased due to the elevated air temperature within the DDSD compared to the OAD. This results in an elevated rate of moisture evaporation from the surface layer of Henna leaves, leading to an increased drying rate93,94,95,96,97. Figure 6 illustrated that significant moisture loss transpired throughout the falling rate period, corroborating findings from numerous other investigations98,99,100.

Table 3 presents the drying coefficient (k) and determination coefficient (R2) for Henna leaves at various layer thicknesses, along with their respective drying methodologies. As the drying air temperature within the DDSD rises, the (k) concurrently increases relative to the OAD, as corroborated by previous studies66,101,102,103. There exists an inverse correlation between the (k) and the layer thickness of Henna leaves samples, as evidenced by the calculated (k) diminishing from 0.23 to 0.19 while the layer thickness escalated from 2 to 6 cm, as depicted in Table 3. This impact may result from a reduction in the internal temperature of the Henna leaves samples concomitant with an increase in layer thickness.

Effect of drying method and layer thickness on MR of Henna leaves

Figure 7 illustrates the relationship between moisture ratio (MR) and drying time for Henna leaves at three different layer thicknesses in both drying methods. Initially, the MR was high across all thickness levels. As solar radiation increased from 96 to 653 W/m2 during the day, the MR gradually declined. Due to the high initial moisture content in the Henna leaves and the greater thermal energy absorbed by the DDSD plate, the MR decreased faster in this system compared to open-air drying (OAD). However, as solar radiation diminished, the required drying time for moisture evaporation increased. The drying process for high-moisture agricultural products like Henna leaves typically occurs in two distinct phases. In the first stage, moisture removal is accelerated because of the high surface moisture content. Part of the thermal energy is used to evaporate surface moisture, while the rest penetrates the samples, raising their internal temperature. Under these conditions, capillary forces act between the internal water molecules, facilitating internal mass transfer, while surface moisture is simultaneously removed through external mass transfer. The reduction in the thickness of Henna leaves results in a more rapid attainment of EMC and a decreased drying duration. According to the duration required to attain the EMC, Henna leaves samples dried using the DDSD method achieve this MC after 14, 15, and 16 h for layer thicknesses of 2, 4, and 6 cm, respectively. In contrast, Henna leaves samples dried via OAD reach the EMC after 15, 17, and 19 h for layer thicknesses of 2, 4, and 6 cm, respectively. The application of DDSD for drying Henna leaves resulted in a reduction of drying time by approximately 7.14%, 13.33%, and 18.75% for layer thicknesses of 2, 4, and 6 cm, respectively.

Effect of drying method and layer thickness on drying rate of Henna leaves

Figure 8 presents the drying rate profiles of Henna leaves for both drying methods at different layer thicknesses, while Fig. 9 shows the relationship between moisture content (MC) and drying rate (DR) across both systems. For the DDSD method, initial/maximum drying rates were 40.02, 57.28, and 20.13 kgwater/kgdry matter/h at 2 cm, 4 cm, and 6 cm thicknesses respectively, compared to 31.29, 29.04, and 29.78 kgwater/kgdry matter/h for open-air drying (OAD). The peak drying rate (57.28 kgwater/kgdry matter/h) occurred with 4 cm layers in DDSD. High initial MC facilitates rapid surface moisture transfer and evaporation. However, as cellular water depletes, moisture migration becomes progressively slower, particularly in later stages when fiber contraction at elevated temperatures further impedes moisture diffusion. Consequently, internal diffusion emerges as the rate-limiting factor governing the overall drying process. The drying rate increases for certain thicknesses because of an optimal balance between surface evaporation, internal moisture diffusion, and heat transfer. Thicker materials often dry more slowly due to increased internal resistance, while very thin materials might dry too quickly on the surface, hindering further evaporation. These findings align with previous research, such as Elshehawy et al.104, who demonstrated that higher air temperatures promote faster moisture migration from a product’s core to its surface, boosting both surface evaporation and overall drying rate. Similarly, Darvishi et al.105 observed that the drying rate (DR) progressively declines as moisture content (MC) decreases throughout the process. The maximum DR occurred during initial drying stages when free moisture was rapidly eliminated from the Henna leaves, followed by a gradual reduction. For all tested thicknesses, drying mainly proceeded through a falling rate period, with only a brief initial constant rate phase. This pattern indicates that internal mass transfer resistance primarily governs the total drying duration. Additionally, Elshehawy et al.104 reported that moisture ratio (MR) reduction occurs more slowly at the experiment’s onset compared to its conclusion.

Effect of drying method and layer thickness on EMD of Henna leaves

Figure 10 illustrates the correlation between LnMR and the drying time of Henna leaves for OAD and DDSD across various layer thicknesses. For DDSD-dried Henna leaves at 2, 4, and 6 cm layer thicknesses, EMD values ranged from 2.84 × 10−9 to 22.96 × 10−9 m2/s, while OSD-dried samples showed values between 2.59 × 10−8 and 18.22 × 10−9 m2/s (Fig. 11). As no prior studies have reported EMD values for Henna leaves, our results were compared with other agricultural products in Table 4. Notably, DDSD consistently yielded higher EMD values than OAD at equivalent thicknesses (Fig. 11). This phenomenon can be explained by temperature effects: increased air temperature accelerates water molecule movement, enhancing both diffusion rates and heat/mass transfer between the Henna leaves’ solid–liquid interface and surrounding air. The resulting reduction in surface moisture content and water vapor pressure promotes faster internal evaporation and moisture migration, ultimately increasing EMD106.

Mathematical modeling

Tables 5 and 6 present the constant values of mathematical models and the goodness of fit indices for Henna leaves in OAD and DDSD across various layer thicknesses. Standard computations and methodologies were employed to analyze the MC data gathered from Henna leaves samples dried using both drying processes at varying layer thicknesses. Subsequently, the MC was transformed into a MR expression, and twenty distinct drying models were employed for curve fitting calculations. The results of the statistical analysis indicate that all drying models had a good overall correlation coefficient (R2) (Tables 5, 6). In the present study, R2, R2adj., and RMSE are statistical metrics employed to evaluate the quality of the fitted models. Previous studies76,77,78 indicated that the model best appropriate for characterizing thin layer drying was the one exhibiting the highest R2, and R2adj., values, together with the lowest RMSE values. Several models demonstrated a strong fit to the experimental data from several samples of Henna leaves dried using DDSD and OAD techniques. The models encompassed Aghbashlo, Henderson–Pabis, Lewis (Newton), Logarithmic (Asymptotic), Midilli, Modified Midilli (I), Modified Midilli (II), Page, Modified Page, Wang-Sigh, Weibullian, and Weibullian (I). According to Table 5, among all evaluated models on the OAD, the Modified Midilli (I) was the best suitable drying model for Henna leaves at layer thicknesses of 4 cm and 6 cm, but the Weibullian (I) drying model was the most suitable for Henna leaves at a layer thickness of 2 cm. Conversely, as demonstrated in Table 6, the Lewis (Newton), Weibullian, and Page models were the most suitable drying models for Henna leaves at layer thicknesses of 2, 4, and 6 cm, respectively, for samples dried by DDSD. Figure 12 illustrates the contrast between the observed and expected MRs derived from the relevant drying models for several samples of Henna leaves subjected to both drying techniques at varying layer thicknesses.

Economic analysis

The primary objective of the economic analysis conducted in this study was to assess the viability of combining the DDSD with a PV system for economically beneficial operation. The study utilized Eqs. (12–23), which addressed the life cycle savings technique and the simple payback methodology. Significant considerations were considered, as illustrated in Tables 7 and 8, while also evaluating the present condition of the Egyptian economy and the anticipated expenses of the DDSD components. The results indicate that using the DDSD for drying Henna leaves could yield substantial annual savings of 3348 USD. The payback period, representing the duration required to recover the initial investment, was determined to be 0.077, 0.115, and 0.228 years for layer thicknesses of 6, 4, and 2 cm, respectively. In contrast to the projected 30-year lifespan of the DDSD and the expected 20-year lifespan of the PV system. This indicates that, assuming no unexpected hazards, the DDSD will recoup its initial capital expenditure of $50.35 USD in approximately one month, demonstrating its cost-effectiveness. Table 8 presents the economic analysis of the DDSD and the PV system.

Conclusions and future work

During the current study, a comparison study between the drying of Henna leaves by the DDSD and OAD was conducted at three-layer thicknesses of 2 cm, 4 cm, and 6 cm. Where the drying process was conducted at an average initial MC of 144.65% on a dry basis. The findings showed that the EMC of Henna leaf samples dried in OAD (DSD) was 3.23% (2.69%), 2.69% (2.17%), and 2.52% (2.69%) for layer thicknesses of 2, 4, and 6 cm, in that order. Additionally, the DDSD-dried samples demonstrated a maximum drying rate of 57.28 kgwater/kgdry matter/h at a 4 cm layer thickness. Using DDSD to dry Henna leaves reduced the drying time by approximately 7.14%, 13.33%, and 18.75% for layer thicknesses of 2, 4, and 6 cm, respectively. Additionally, the EMD of the dried Henna leaves dried using the DDSD ranged from 2.84 × 10–9 to 22.96 × 10–9 m2/s. Furthermore, Lewis (Newton), Weibullian, and Page were the most appropriate drying models for Henna leaves at layer thicknesses of 2, 4, and 6 cm, respectively, for dried samples by DDSD. Finally, the economic analysis of the DDSD showed that the annual cost of the DDSD integrated photovoltaic system is 50.35 USD; and the drying of henna leaves at a layer thickness of 6 cm led to maximizing the savings after one year to 3348 USD and minimizing the payback period to less than one month. In conclusion, drying henna leaves in a 2 cm thick layer reduced the drying time. However, the economic analysis revealed that drying henna leaves in a 6 cm thick layer was more cost-effective.

It is essential to recognize the limitations of the current study, which was conducted over a single season and focused exclusively on one crop. Furthermore, the study did not account for air speed and temperature as variables during the experimental process. Consequently, future research endeavors should prioritize the development and optimization of dryer designs, as well as their integration with hybrid renewable energy sources and exploration of potential industrial applications. Additionally, it would be beneficial to examine the effects of varying temperature and air speed levels, along with the drying of diverse products.

Data availability

All data will be made available upon request from the first author.

References

Sienkiewicz-Szłapka, E., Janysz, A. & Wróbel, M. H. Quantification of lawsone and p-phenylenediamine in natural henna products for hair colouring available in Poland. Contact Dermat. 92, 261–272 (2025).

Daleen Hassan. Emirati henna artist launches natural henna brand & rolls out ‘risqué’ designs. https://www.africanews.com/2020/10/23/uae-henna-artist-launches-natural-henna-brand-rolls-out-risque-designs/ (2024).

Manoj Phagare. Henna Powder Market Report 2025 (Global Edition). https://www.cognitivemarketresearch.com/henna-powder-market-report?srsltid=AfmBOoqbp8yt7a436WDD7hh2jG2s8BTqqZ-7cfTr_BfOsZSNaWY347X2 (2024).

Labed, A., Moummi, N., Aoues, K. & Benchabane, A. Solar drying of henna (Lawsonia inermis) using different models of solar flat plate collectors: An experimental investigation in the region of Biskra (Algeria). J. Clean Prod. 112, 2545–2552 (2016).

Benhamza, A., Boubekri, A., Atia, A., Hadibi, T. & Arıcı, M. Drying uniformity analysis of an indirect solar dryer based on computational fluid dynamics and image processing. Sustain. Energy Technol. Assess. 47, 101466 (2021).

Safri, N. A. M. et al. Current status of solar-assisted greenhouse drying systems for drying industry (food materials and agricultural crops). Trends Food Sci. Technol. 114, 633–657 (2021).

Eissa, A. S., Gameh, M. A., Mostafa, M. B. & Elwakeel, A. E. Some engineering factors affecting utilization of solar energy in drying tomato fruits introduction. Aswan Univ. J. Environ. Stud. 5, 52–68 (2024).

Thakur, A. K. et al. Advancements in solar technologies for sustainable development of agricultural sector in India: A comprehensive review on challenges and opportunities. Environ. Sci. Pollut. Res. 29, 43607–43634 (2022).

El-Mesery, H. S. et al. Optimization of dried garlic physicochemical properties using a self-organizing map and the development of an artificial intelligence prediction model. Sci. Rep. 15, 3105 (2025).

Farag Taha, M. et al. Emerging technologies for precision crop management towards agriculture 5.0: A comprehensive overview. Agriculture 15, 582 (2025).

Prakash, O. & Kumar, A. Historical review and recent trends in solar drying systems. Int. J. Green Energy 10, 690–738 (2013).

Sharma, A., Chen, C. R. & Lan, N. V. Solar-energy drying systems: A review. Renew. Sustain. Energy Rev. 13, 1185–1210 (2009).

Elwakeel, A. E. et al. Development, drying characteristics, and environmental analysis of a PV operated automatic solar dryer for drying date. Front. Sustain. Food Syst. https://doi.org/10.3389/fsufs.2025.1531601 (2025).

Elwakeel, A. E. et al. Quality evaluation of dried tomato fruit and optimization of drying conditions using a modified solar dryer integrated with an automatic solar collector tracker. Sci. Rep. 15, 7659 (2025).

Younis, O. S. et al. Drying characteristics, environmental and economic analysis of a solar dryer with evacuated tube solar collector for drying Nile Tilapia slices. Sci. Rep. 15, 9822 (2025).

Ghanem, T. H. M. et al. Thin-layer modeling, drying parameters, and techno-enviro-economic analysis of a solar dried salted tilapia fish fillets. Sci. Rep. 15, 5073 (2025).

El-Sebaii, A. A., Aboul-Enein, S., Ramadan, M. R. I. & El-Gohary, H. G. Experimental investigation of an indirect type natural convection solar dryer. Energy Convers. Manag. 43, 2251–2266 (2002).

Elwakeel, A. E., Gameh, M. A., Eissa, A. S. & Mostafa, M. B. Recent advances in solar drying technology for tomato fruits: A comprehensive review. Int. J. Appl. Energy Syst. 6, 37–44 (2024).

Elwakeel, A. E. et al. Development and techno-economic analysis of a tracked indirect forced solar dryer integrated photovoltaic system for drying tomatoes. Sustainability 16, 7008 (2024).

Santos, B. M., Queiroz, M. R. & Borges, T. P. F. A solar collector design procedure for crop drying. Braz. J. Chem. Eng. 22, 277–284 (2005).

Sekyere, C. K. K., Forson, F. K. & Adam, F. W. Experimental investigation of the drying characteristics of a mixed mode natural convection solar crop dryer with back up heater. Renew. Energy 92, 532–542 (2016).

Khater, E.-S.G. et al. Assessment of a LPG hybrid solar dryer assisted with smart air circulation system for drying basil leaves. Sci. Rep. 14, 23922 (2024).

El-Beltagy, A., Gamea, G. R. & Essa, A. H. A. Solar drying characteristics of strawberry. J. Food Eng. 78, 456–464 (2007).

Kishk, S., El-reheem, S. A. & Elgamal, A. Experimental and mathematical modeling study for solar drying of mint. Misr J. Agric. Eng. 35, 1327–1344 (2018).

Shams, M. Y. et al. Automated on-site broiler live weight estimation through YOLO-based segmentation. Smart Agric. Technol. 10, 100828 (2025).

Khazaei, J., Chegini, G. & Bakhshiani, M. A novel alternative method for modeling the effects of air temperature and slice thickness on quality and drying kinetics of tomato slices : Superposition technique. Dry. Technol. https://doi.org/10.1080/07373930802046427 (2008).

Natarajan, S. K., Suraparaju, S. K., Muthuvairavan, G., Elangovan, E. & Samykano, M. Experimental analysis and development of novel drying kinetics model for drying grapes in a double slope solar dryer. Renew. Energy 236, 121508 (2024).

Natarajan, S. K., Muthuvairavan, G., Suraparaju, S. K., Elangovan, E. & Samykano, M. Innovative insights into solar drying of Kola fish: Mechanisms, modeling, and optimization. Appl. Solar Energy 59, 887–902 (2023).

Tunde-Akintunde, T. Y. Mathematical modeling of sun and solar drying of chilli pepper. Renew. Energy 36, 2139–2145 (2011).

Murugavelh, S., Anand, B., Prasad, K. M., Nagarajan, R. & Pravin, S. A. Environmental effects exergy analysis and kinetic study of tomato waste drying in a mixed mode solar tunnel dryer. Energy Sources Part A Recov. Util. Environ. Eff. 00, 1–17 (2019).

Rajkumar, P., Kulanthaisami, S., Raghavan, G. S. V., Gariépy, Y. & Orsat, V. Drying kinetics of tomato slices in vacuum assisted solar and open sun drying methods. Dry. Technol. 25, 1349–1357 (2007).

Elwakeel, A. E. et al. Drying kinetics and thermo-environmental analysis of a PV-operated tracking indirect solar dryer for tomato slices. PLoS ONE 19, e0306281 (2024).

Elmessery, W. M. et al. Deep regression analysis for enhanced thermal control in photovoltaic energy systems. Sci. Rep. 14, 30600 (2024).

Sacilik, K., Keskin, R. & Elicin, A. K. Mathematical modelling of solar tunnel drying of thin layer organic tomato. J. Food Eng. 73, 231–238 (2006).

Doymaz, I. Air-drying characteristics of tomatoes. J. Food Eng. 78, 1291–1297 (2007).

Movagharnejad, K. & Nikzad, M. Modeling of tomato drying using artificial neural network. Comput. Electron. Agric. 59, 78–85 (2007).

Machado, M. F., Oliveira, F. A. R. & Cunha, L. M. Effect of milk fat and total solids concentration on the kinetics of moisture uptake by ready-to-eat breakfast cereal. Int. J. Food Sci. Technol. 34, 47–57 (1999).

Inyang, U. E., Oboh, I. O. & Etuk, B. R. Kinetic models for drying techniques—Food materials. Adv. Chem. Eng. Sci. https://doi.org/10.4236/aces.2018.82003 (2018).

Buzrul, S. Reassessment of thin-layer drying models for foods. Processes 10, 118 (2022).

Gupta, A., Das, B. & Mondol, J. D. Experimental and theoretical performance analysis of a hybrid photovoltaic-thermal (PVT) solar air dryer for green chillies. Int. J. Ambient Energy 43, 2423–2431 (2022).

Tiwari, S. et al. Environmental and economic sustainability of PVT drying system: A heat transfer approach. Environ. Prog. Sustain. Energy 40, e13535 (2021).

Bayrak, F. et al. Analysis of a novel PVT dryer using a sustainable control approach. Renew. Energy 245, 122728 (2025).

Veeramanipriya, E. & Sundari, A. R. U. Performance evaluation of hybrid photovoltaic thermal (PVT) solar dryer for drying of cassava. Sol. Energy 215, 240–251 (2021).

Tiwari, S., Tiwari, G. N. & Al-Helal, I. M. Performance analysis of photovoltaic–thermal (PVT) mixed mode greenhouse solar dryer. Sol. Energy 133, 421–428 (2016).

Elwakeel, A. E. et al. Design and implementation of a PV-integrated solar dryer based on internet of things and date fruit quality monitoring and control. Int. J. Energy Res. 2023, 7425045 (2023).

S’hih, Y., Hinad, I., Loukili, A., Mesfioui, A. & Ouahidi, M. L. Evaluation of hypoglycaemic, hypolipidemic and glucose tolerant effect of Henna leaves on fructose-induced metabolic syndromes in Wistar rats. Pharmacol. Res. Nat. Prod. 6, 100150 (2025).

Salah, A. A. S. & Mofleh, S. M. Q. The HPLC and FTIR analytical techniques to determination of para-phenylenediamine in some black hair dyes. J. Sci. Technol. 30, 47–59 (2025).

Humaish, H. Study comparison analgesic, antipyretic and anti-inflammatory activity of aqueous and alcoholic leaves extract of Lawsonia inermis L. (Henna) with ketoprofen in male albino rats. Kufa J. Vet. Med. Sci. 8, 88–100 (2017).

Alkhalaf, M. I., Alansari, W. S., Ibrahim, E. A. & Elhalwagy, M. E. A. Anti-oxidant, anti-inflammatory and anti-cancer activities of avocado (Persea americana) fruit and seed extract. J. King Saud Univ. Sci. 31, 1358–1362 (2019).

Bennamoun, L. et al. Exploring forced convective solar drying of henna (Lawsonia inermis) and its effect on the biological activities: Comparison with open sun dried product. Dry. Technol. 42, 1540–1551 (2024).

Bennamoun, L. et al. Exploring solar drying of henna (Lawsonia inermis) and its effect on the bioactivities (2024).

Bennaceur, S. et al. Effect of ultrasound on henna leaves drying and extraction of lawsone: Experimental and modeling study. Energies (Basel) 14, 1329 (2021).

Imbabi, A. T., Abdel-Galil, H. S. & Abdel-Kader, T. Design, construction and performance evaluation of a solar drying unit of basil leaves. Misr J. Agric. Eng. 33, 75–100 (2016).

Babu, A. K., Kumaresan, G., Raj, V. & Velraj, R. Experimental investigations of thin-layer drying of leaves in a heat-pump assisted tray-type batch drying chamber. J. Mech. Eng. 66, 254–265 (2020).

Int, A. Official methods of analysis of AOAC Int. Preprint at (2007).

Eke, A. B. & Simonyan, K. J. Development of small scale direct mode passive solar dryers for effective drying of tomato. J. Appl. Agric. Res. 6, 111–119 (2014).

Etim, P. J., Eke, A. B. & Simonyan, K. J. Effect of air inlet duct features and grater thickness on cooking banana drying characteristics using active indirect mode solar dryer. Niger. J. Technol. 38, 1056–1063 (2019).

Elwakeel, A. E. et al. Design and implementation of a PV-integrated solar dryer based on internet of things and date fruit quality monitoring and control. Int. J. Energy Res. 2023, 1–17 (2023).

Rabha, D. K., Muthukumar, P. & Somayaji, C. Experimental investigation of thin layer drying kinetics of ghost chilli pepper (Capsicum Chinense Jacq.) dried in a forced convection solar tunnel dryer. Renew. Energy 105, 583–589 (2017).

Doymaz, İ. Drying characteristics and kinetics of okra. J. Food Eng. 69, 275–279 (2005).

Marinos-Kouris, D. & Maroulis, Z. B. Transport properties in the drying of solids. Handb. Ind. Dry. 2, 113–159 (2020).

Temple, S. J. & Van Boxtel, A. J. B. Thin layer drying of black tea. J. Agric. Eng. Res. 74, 167–176 (1999).

Karathanos, V. T. & Belessiotis, V. G. Application of a thin-layer equation to drying data of fresh and semi-dried fruits. J. Agric. Eng. Res. 74, 355–361 (1999).

Diffusivity, M., Moringa, P., Using, L. & Bed, F. Mathematical modeling of thin layer drying kinetics and moisture diffusivity study of pretreated Moringa oleifera leaves using fluidized bed dryer. Processes 10, 2464 (2025).

Pandey, S., Kumar, A. & Sharma, A. Sustainable solar drying: Recent advances in materials, innovative designs, mathematical modeling, and energy storage solutions. Energy 1, 132725 (2024).

Metwally, K. A. et al. The mathematical modeling, diffusivity, energy, and enviro-economic analysis (MD3E) of an automatic solar dryer for drying date fruits. Sustainability 16, 3506 (2024).

Dak, M. & Pareek, N. K. Effective moisture diffusivity of pomegranate arils under going microwave-vacuum drying. J. Food Eng. 122, 117–121 (2014).

Kara, C. & Doymaz, İ. Effective moisture diffusivity determination and mathematical modelling of drying curves of apple pomace. Heat Mass Transf. 51, 983–989 (2015).

Mokhtarian, M., Tavakolipour, H., Kalbasi-Ashtari, A. & Koushki, F. The effects of solar drying on drying kinetics and effective moisture diffusivity of pistachio nut. Food Health 4, 7–12 (2021).

Waramit, P., Krittacom, B. & Luampon, R. Experimental investigation to evaluate the effective moisture diffusivity and activation energy of cassava (Manihot Esculenta) under convective drying. Appl. Sci. Eng. Prog. 15, 5518 (2022).

Mathematical modeling, effective moisture diffusivity, activation energy and environmental assessment of an hybrid solar dryer compared with oven dryer for marjoram leaves.

Aghbashlo, M. & Samimi-Akhijahani, H. Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energy Convers. Manag. 49, 2865–2871 (2008).

Zeng, Z. et al. Analysis of drying characteristic, effective moisture diffusivity and energy, exergy and environment performance indicators during thin layer drying of tea in a convective-hot air dryer. Front. Sustain. Food Syst. https://doi.org/10.3389/fsufs.2024.1371696 (2024).

Doymaz, İ & İsmail, O. Drying characteristics of sweet cherry. Food Bioprod. Process. 89, 31–38 (2011).

Crank, J. The Mathematics of Diffusion (Oxford University Press, 1975).

Midilli, A. & Kucuk, H. Mathematical modeling of thin layer drying of pistachio by using solar energy. Energy Convers. Manag. 44, 1111–1122 (2003).

Akpinar, E. K. & Bicer, Y. Mathematical modeling and experimental study on thin layer drying of strawberry. Int. J. Food Eng. https://doi.org/10.2202/1556-3758.1045 (2006).

Akpinar, E. K., Bicer, Y. & Cetinkaya, F. Modelling of thin layer drying of parsley leaves in a convective dryer and under open sun. J. Food Eng. 75, 308–315 (2006).

Öksüz, H. B. & Buzrul, S. DrYFiT: An excel freeware tool to describe thin layer drying of foods. J. Food Process. Eng. 47, e14748 (2024).

Buzrul, S. Reassessment of thin-layer drying models for foods: A critical short communication. Processes 10, 118 (2022).

Inyang, U. E., Oboh, I. O. & Etuk, B. R. Kinetic models for drying techniques—Food materials. Adv. Chem. Eng. Sci. 8, 27 (2018).

Henderson, S. M. Progress in developing the thin layer drying equation. Trans. ASAE 17, 1167–1168 (1974).

Ghazanfari, A., Emami, S., Tabil, L. G. & Panigrahi, S. Thin-layer drying of flax fiber: II. Modeling drying process using semi-theoretical and empirical models. Dry. Technol. 24, 1637–1642 (2006).

Wang, Z. et al. Mathematical modeling on hot air drying of thin layer apple pomace. Food Res. Int. 40, 39–46 (2007).

Suraparaju, S. K. et al. Assessing thermal and economic performance of solar dryers in sustainable strategies for bottle gourd and tomato preservation. Sci. Rep. 14, 27755 (2024).

Parrado, C., Marzo, A., Fuentealba, E. & Fernández, A. G. 2050 LCOE improvement using new molten salts for thermal energy storage in CSP plants. Renew. Sustain. Energy Rev. 57, 505–514 (2016).

White, J. A., Grasman, K. S., Case, K. E., Needy, K. L. & Pratt, D. B. Fundamentals of Engineering Economic Analysis (Wiley, 2020).

Newnan, D. G., Eschenbach, T. G. & Lavelle, J. P. Engineering Economic Analysis Vol. 1 (Oxford University Press, 2004).

Harini, S., Kavya, V. S. & Ramana, A. S. Recent developments in design and operations of solar dryer. In IOP Conference Series: Earth and Environmental Science vol. 1100, 012007 (IOP Publishing, 2022).

Sodhi, M., Banaszek, L., Magee, C. & Rivero-Hudec, M. Economic lifetimes of solar panels. Procedia CIRP 105, 782–787 (2022).

Mohammed, I. A. & Al Dulaimi, M. A. K. An economic analysis of the costs of producing tomato under greenhouse in Anbar Governorate For the Agricultural Season 2019–2020. In IOP Conference Series: Earth and Environmental Science vol. 904, 12061 (IOP Publishing, 2021).

Singh, P. & Gaur, M. K. Environmental and economic analysis of novel hybrid active greenhouse solar dryer with evacuated tube solar collector. Sustain. Energy Technol. Assess. 47, 101428 (2021).

Sengkhamparn, N., Chanshotikul, N., Assawajitpukdee, C. & Khamjae, T. Effects of blanching and drying on fiber rich powder from pitaya (Hylocereus undatus) peel. Int. Food Res. J. 20, 1595 (2013).

Deng, L.-Z. et al. High-humidity hot air impingement blanching (HHAIB) enhances drying quality of apricots by inactivating the enzymes, reducing drying time and altering cellular structure. Food Control 96, 104–111 (2019).

Kamal, M. M., Ali, M. R., Shishir, M. R. I. & Mondal, S. C. Thin-layer drying kinetics of yam slices, physicochemical, and functional attributes of yam flour. J. Food Process. Eng. 43, e13448 (2020).

Ambawat, S., Sharma, A. & Saini, R. K. Mathematical modeling of thin layer drying kinetics and moisture diffusivity study of pretreated Moringa oleifera leaves using fluidized bed dryer. Processes 10, 2464 (2022).

Khater, E. G. & Bahnasawy, A. H. Basil drying performance and quality under different drying systems. Benha J. Appl. Sci. 2, 1–9 (2017).

Etim, P. J., Eke, A. B. & Simonyan, K. J. Design and development of an active indirect solar dryer for cooking banana. Sci. Afr. 8, e00463 (2020).

Tesfaye, A. & Habtu, N. G. Fabrication and performance evaluation of solar tunnel dryer for ginger drying. Int. J. Photoenergy 2022, 1–13 (2022).

Babar, O. A., Tarafdar, A., Malakar, S., Arora, V. K. & Nema, P. K. Design and performance evaluation of a passive flat plate collector solar dryer for agricultural products. J. Food Process. Eng. 43, e13484 (2020).

Doymaz, İ. Evaluation of some thin-layer drying models of persimmon slices (Diospyros kaki L.). Energy Convers. Manag. 56, 199–205 (2012).

Kaleta, A., Górnicki, K., Winiczenko, R. & Chojnacka, A. Evaluation of drying models of apple (var. Ligol) dried in a fluidized bed dryer. Energy Convers. Manag. 67, 179–185 (2013).

Meziane, S. Drying kinetics of olive pomace in a fluidized bed dryer. Energy Convers. Manag. 52, 1644–1649 (2011).

Elshehawy, S. M. & Mosad, G. A. Mathematical modeling of tilapia fish fillets dried in thin layer. J. Soil Sci. Agric. Eng. 13, 359–364 (2022).

Darvishi, H., Azadbakht, M., Rezaeiasl, A. & Farhang, A. Drying characteristics of sardine fish dried with microwave heating. J. Saudi Soc. Agric. Sci. 12, 121–127 (2013).

Guan, Z., Wang, X., Li, M. & Jiang, X. Mathematical modeling on hot air drying of thin layer fresh tilapia fillets. Pol. J. Food Nutr. Sci. 63, 25–34 (2013).

Seyedabadi, E. Drying kinetics modelling of basil in microwave dryer. Agric. Commun. 3, 37–44 (2015).

López-Ortiz, A. et al. Energy analysis of drying basil (Ocimum basilicum) leaves in an active greenhouse solar dryer. J. Food Process. Eng. 46, e14257 (2023).

Mbegbu, N. N., Nwajinka, C. O. & Amaefule, D. O. Thin layer drying models and characteristics of scent leaves (Ocimum gratissimum) and lemon basil leaves (Ocimum africanum). Heliyon 7, e05945 (2021).

Altay, K., Hayaloglu, A. A. & Dirim, S. N. Determination of the drying kinetics and energy efficiency of purple basil (Ocimum basilicum L.) leaves using different drying methods. Heat Mass Transf. 55, 2173–2184 (2019).

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research, King Saud University for funding through the Vice Deanship of Scientific Research Chairs; Research Chair of Prince Sultan Bin Abdulaziz International Prize for Water.

Funding

Open access funding provided by University of Pécs. This research was funded by the Deanship of Scientific Research, King Saud University through the Vice Deanship of Scientific Research Chairs; Research Chair of Prince Sultan Bin Abdulaziz International Prize for Water.

Author information

Authors and Affiliations

Contributions

Conceptualization, A.E.E., methodology, A.E.E., software, A.E.E., formal analysis, A.E.E., and K.A.M., investigation, A.E.E., K.A.M., A.A.T.O., T.H.M.G., B.H., A.S., M.E.M., and T.M.E., resources, A.E.E., K.A.M., A.A.T.O., T.H.M.G., B.H., M.E.M., and T.M.E., data curation, A.E.E., K.A.M., A.A.T.O., T.H.M.G., B.H., and T.M.E., writing-original draft, A.E.E., writing—review and editing, A.E.E., and K.A.M., visualization, A.E.E., K.A.M., A.E., A.S., A.Z.D., M.E.M., and A.M.O., supervision, A.E.E., project administration, A.E.E., funding, A.E., A.S., A.Z.D., and A.M.O., All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Elwakeel, A.E., Oraiath, A.A.T., Ghanem, T.H.M. et al. Mathematical modeling, drying kinetics, and economic analysis of a hybrid photovoltaic thermal solar dryer for henna leaves. Sci Rep 15, 21392 (2025). https://doi.org/10.1038/s41598-025-03460-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-03460-3