Abstract

This study examines the stability of a spoiled heap along the Guigu Expressway. Through onsite investigations, laboratory tests, numerical analyses, and onsite monitoring, this case study evaluates the reinforcement effect of a multistep method for disposing of spoiled heaps. The results show that applying the multistep method to treat spoiled heaps significantly improves their stability, as demonstrated by numerical simulation. The results of the circular sliding surface method (fs = 1.56) and the fold line sliding surface method (fs = 1.58) both satisfy the stability requirements of the current standard (fs > 1.3). The cost of using the multistep method to treat medium-sized spoiled heaps is 1.11 million CNY, effectively improving the economic efficiency of construction. According to the results of onsite monitoring, no significant deformation occurred in the spoiled slope, with both the final settlement and maximum displacement measuring less than 10 mm.

Similar content being viewed by others

Introduction

In mountainous regions, landslides are common geological hazards that often have serious consequences for human activities1. Landslides can be categorized into natural soil slopes and artificial soil slopes. Artificial soil slopes mainly consist of tall, man-made formations created during construction activities, with slopes formed from abandoned soil being the most hazardous2,3. This is mainly because spoiled soil slopes are often deposited in valleys after engineering excavation, usually without special treatment. These artificial slopes have a loose texture, have been naturally settling in the field for decades, and have lush weeds covering their surface. The newly deposited spoiled soil is separated from the original soil surface by weeds, resulting in ineffective bonding between the new and old soil layers. With rainwater infiltration, the weight of the upper soil increases, causing the lower interlayer to slide, ultimately leading to landslides.

Since the 1970s, scholars have studied methods for reinforcing the stability of spoiled soil sites, achieving effective results4,5,6. Xu et al.7 classified damage to spoiled soil sites into three categories: debris flow, consolidation compression deformation, and landslides.Adamczyk et al.8 and Rassam and Williams9 analyzed the stability of abandoned soil sites and proposed recommendations for their geometric shapes. Poulsen et al.10, Steiakakis et al.11, Igwe and Chukwu12, and Gao et al.13 analyzed the factors affecting the stability of spoiled soil sites by studying their raw materials. Among these factors, rainfall is the most important in affecting slope stability. Cho and Song14, Mahesh et al.15, and Bao et al.16 conducted a series of studies on rainwater infiltration into the soil at waste disposal sites, establishing relationships between rainfall and slope deformation.

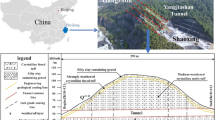

The Guigu Expressway is a crucial route connecting Guizhou Province to Sichuan Province. Located in the Yunnan–Guizhou Plateau, its route often involves high slopes and high cuttings. This study uses the Guigu Expressway as a case study, employing onsite surveys, laboratory tests, numerical simulations, and onsite monitoring to systematically analyze the stability of spoiled soil. The application of a multistep method to reinforce high spoiled slopes can serve as a reference for similar projects.

Case study project and its geological engineering conditions

Engineering geology in the Guigu expressway

The Guigu Expressway originates in the Guanshanhu district of Guiyang city, passes through Jinsha County, and terminates at the border of Gulin County in Luzhou city, Sichuan Province. It is the most convenient expressway connection between Guiyang and Chengdu. The highway spans approximately 158 km in length, with a bridge-to-tunnel ratio of 62.1%. The expressway has a width of 33 m, featuring six lanes in both directions, and is designed for a maximum speed of up to 100 km/h.

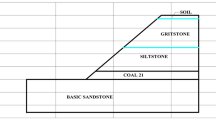

The construction section is characterized by tectonic erosion in a low to medium mountain terrain, with a relative elevation difference of approximately 118 m (see Fig. 1). The thickness of the covering layer generally ranges from 0 to 12 m but can reach up to 15 m in some areas. In certain locations, the rock mass is fragmented, whereas the lower middle weathered layer remains relatively intact. The rock occurrence varies between 12° and 155°, and the mechanical properties of the rock mass are good. The Karst landscape in this section is generally weakly to moderately developed, with strong development in other areas.

Groundwater mainly comprises loose-layer pore water, bedrock fissure water, and karst water. Due to the steep terrain and fast discharge, groundwater is generally abundant. Apart from coal mines and caves along the route, no other adverse geological formations have been observed. The geological strata in the road section are complex, groundwater is abundant, and the overall site is relatively stable, making it suitable for route layout and structural construction.

The landslide location and soil layers

The landslide site is located between K19 + 505 and K19 + 575. It features a middle to low mountain slope landform with steep slopes and a natural gradient of 15°–40°. Vegetation on the slope is not developed, and the terrain is undulating. The detected soil layers at the site include plain fill, strongly weathered limestone, and moderately weathered limestone. To determine their basic mechanical parameters, a series of lab tests were conducted following an in situ investigation of the spoiled slope. The physical parameters of the soils and rocks are shown in Table 1. No surface or fissure water was found in the base section; water was mainly present in the fissures of the bedrock. According to the Seismic Ground Motion Parameter Zoning Map of China (GB18306-2015)17, the peak ground acceleration at this site is 0.05 g, the characteristic period of the dynamic response spectrum is 0.35 s, and the corresponding seismic basic intensity is grade VI.

Multistep method and the retaining wall design

Multistep method

Compared with that of natural slopes, the stability of artificial spoiled slopes is influenced by multiple factors. Different stacking methods significantly affect the stability of spoiled slopes under rainfall conditions. When the single-step method is used to excavate spoiled slopes, it often results in a high slope, making landslides more likely during heavy rain. As shown in Fig. 2, the multistep method divides a high step into several smaller steps, increasing friction between new and old layers. This approach increases the contact area between the spoil and original soil, reducing the likelihood of landslides.

Original retaining wall design

The section of the Guigu Expressway from K19 + 505 to K19 + 575 passes through an existing unprotected soil dumping site with a dumping period of approximately eight years and a depth ranging from 6 to 10 m. The unstable layer is thick and consists of a sliding, unstable soil mass. The landslide section from K19 + 505 to K19 + 575 adopts pile foundation retaining walls (Fig. 3). To prevent overall sliding of the fill soil, double-row piles are installed at the base of the retaining wall for support. The wall height ranges from 8 to 11 m, and its lower section comprises 7 pile foundation caps, each measuring 10 m × 6 m × 1.5 m. Each cap contains 4 reinforced concrete bored piles (C30) with a diameter of 1.5 m, a longitudinal spacing of 5 m, and a transverse spacing of 3.5 m. Each pile extends 20 m in length, with a total of 28 piles.

Changes in the retaining wall design

During the construction of the pile foundation retaining wall, the geological conditions at the site did not match the original design. Some piles were unable to penetrate the rock even after drilling to a depth of 35 m, failing to provide the intended antisliding effect. To ensure the safety of subsequent operations, the design was immediately revised. In order to ensure the economy and safety of the design, two consulting firms provided their own solutions.

-

1.

One suggestion design.

On the left side of the line, the pile foundation retaining wall remains unchanged, but the pile length is increased from the original 20–30 m. On the right side, a road-cut retaining wall is added for protection. The original abandoned soil is stabilized with a slope ratio of 1:2.5, and the slope surface is protected by arched skeleton grass. Concrete interception and drainage ditches are installed on both sides of the abandoned soil. This design requires the acquisition of more than 30 acres of additional land.

-

2.

Another suggestion design.

To ensure safe and reliable operation in the later stages, all dumped miscellaneous fill soil within the mainline red line and on the left slope will be excavated and removed from the site. A retaining wall will be constructed at the foot of the roadbed slope, and the roadbed will then be filled following the half-filling, half-excavation construction process, starting from the foot of the slope.

-

3.

The final design.

To ensure the safety and reliability of future operations and completely eliminate the threat of landslides, the final design combines elements of designs A and B (Fig. 4). First, all dumped and miscellaneous fill soil on the main slope will be excavated and removed. Second, a retaining wall will be constructed at the foot of the roadbed slope, with back pressure applied. Third, soil layers will be filled according to the standard excavation of large steps on the roadbed to ensure the stability of the lower slope. Finally, greening will be implemented on each slope.

Reinforcement analysis

Analysis methods

According to the manual of geotechnical engineering.

The circular sliding surface method is based on the principle of limited equilibrium18. It assumes that the fractured soil is a rigid body that rotates around the center of a circle. The interaction forces between soil slices are then considered to calculate the ratio of the sliding force to the antisliding force, also known as the stability safety factor. The fold-line sliding surface method, on the other hand, is suitable for sliding surfaces of any shape18. According to equilibrium conditions, the resultant force of the first soil slice is assumed to be parallel to the surface of the second soil slice. The resultant forces of the soil slices are then calculated sequentially until the resultant force decreases to zero.

Simulation analysis

To ensure the revised design meets the requirements of the Technical Code for Building Slope Engineering (GB 50330-2013)18, the stability of the slope is analyzed using numerical simulation. The simulation is conducted with GEO5 numerical calculation software, and the model parameters are provided in Table 1. To ensure the accuracy and reliability of the results the circular sliding surface method and the fold-line sliding surface method are used for the numerical calculations.

According to the numerical calculation results, the safety factor when using the circular sliding surface method is 1.56, which is 0.26 higher than the required value of 1.30 as specified in the GB 50330-201318, as shown in Fig. 5a. The safety factor when using the fold-line sliding surface method is 1.58, which also exceeds the requirement of 1.30 in the Chinese specifications (GB 50330-2013)18, as shown in Fig. 5b.

Economic analysis

The economic benefit calculation for the spoiled slope failure treatment can include both completed and incomplete work, with canceled work subtracted. Prior to the landslide, the completed work consisted of soil filling, retaining wall pile foundation construction, and gravity retaining wall construction, with a total cost of 0.71 million. According to the new landslide disposal plan, slope protection and pile foundation retaining wall construction will be canceled, reducing expenses by a total of ¥ 3.64 million. Additionally, a total of ¥ 4.04 million is required for slope excavation, step filling, treatment of the new spoil heap, C20 rubble concrete retaining wall construction, and land acquisition. Finally, the total expenditure for all projects is ¥ 1.11 million, and the detailed costs are shown in Table 2.

Construction process

According to the natural roadbed and final design, the first slope ratio was set at 1:1.2, the second slope ratio at 1:1.5, and the third slope ratio at 1:1.75. The slope was protected by an arched skeleton. Next, a C20 rubble concrete retaining wall was constructed at the foot of the slope, and the spoiled soil outside the retaining wall was used to provide counter pressure (Fig. 6).

Monitoring equipment and arrangement

After the construction was completed, the stability of the slope was monitored for long-term assessment. The monitoring was divided into displacement and settlement monitoring, with displacement measured using displacement meters and settlement measured using settlement plates (Fig. 7). The monitoring locations are shown in the figure, with displacement monitoring conducted at the top of the first slope (D1), the foot of the first slope (D2), and the second slope (D3). Settlement monitoring was carried out at the top of the first slope (S1) and the foot of the first slope (S2). During the first 125 days, the monitoring frequency was once a day. After 125 days, the monitoring frequency was reduced based on the results of settlement and displacement.

Monitoring results

The displacement and settlement of the reinforced slope are shown in Fig. 8. After construction, significant deformation occurred immediately at the top of the first slope (D1), the foot of the first slope (D2), and the second slope (D3). After 30 days, the displacement gradually slowed. By 90 days, the displacement stabilized, ranging from 4 to 6 mm, with the maximum value approximately 6 mm at the foot of the second slope. Similarly, the top of the first slope also experienced significant settlement after construction. After 30 days, the settlement rate began to slow, and by 90 days, the settlement rate stabilized, with a settlement value ranging from 5 to 8 mm. The maximum settlement point was at the foot of the first slope (S2). According to long-term monitoring of the spoiled slope, both the displacement and settlement values did not exceed 1 cm, and no significant cracks occurred in this section of the expressway, indicating that the multistep method is effective for spoiled slope treatment (Fig. 9).

Conclusions

This study focused on the treatment of high spoil slopes, using the Guigu Expressway as a case study. Considering both the reinforcement effects and economic benefits, a multistep method for spoiled slope treatment was adopted. To evaluate the reinforcing effects of the slope, a series of simulation analyses and site monitoring methods were conducted. The main conclusions drawn from this study are as follows:

-

1.

The safety factor for the circular sliding surface method is 1.56, and for the fold line sliding surface method, it is 1.58, according to the simulation results. Both values exceed the current Chinese code requirement of 1.30, meaning that the use of this multistep method provides a strong reinforcement effect.

-

2.

The economic benefit can be attributed to both completed and incomplete work, with canceled work subtracted. The number of completed works has reached 0.71 million, and their cost will total 4.04 million. The canceled work could cost 3.64 million. Finally, all projects require a total expenditure of 1.11 million for slope treatment.

-

3.

According to the in situ monitoring results, the displacement of the reinforced slope ranged from 4 to 6 mm, and the settlement ranged from 5 to 8 mm. The maximum settlement occurred at the slope foot of the first slope. Therefore, the stability of the first slope should receive more attention.

Data availability

The data used and/or analyzed in the current study are available from the corresponding author upon reasonable request.

References

Li, J. et al. Effects of soil texture and gravel content on the infiltration and soil loss of spoil heaps under simulated rainfall. J. Soils Sediments. 7 (20), 3896–3908 (2020).

Zhang, Y. et al. Rock fragments and soil hydrological processes: significance and progress. Catena 147, 153–166 (2016).

Conforti, M. & Ietto, F. Influence of tectonics and morphometric features on the landslide distribution: a case study from the mesima basin (Calabria, South Italy). J. Earth Sci. 31 (2), 393–409 (2020).

Wang, Y. Determination of rational bench height of Open-pit dump. Metal Mine. 02, 24–26 (2004).

Luo, Q. Stability Study of Rock Slope and Anchoring Parametric Analysis (Central south university, 2010).

Zhao, T. Markov Chain Monte Carlo-based Stability Analysis for Pingzishan Landslide (Southwest Jiaotong University, 2014).

Xu, Z. & Zhang, H. The stability research of Waitoushan waste dump. Min. Eng. 01, 12–15 (2007).

Adamczyk, J. et al. Slope stability analysis of waste dump in sandstone open pit Osielec. Stud. Geotech. Mech. 35 (1), 3–17 (2013).

Rassam, D. W. & Williams, D. J. 3-Dimensional effects on slope stability of high waste rock dumps. Int. J. Surf. Min. (13): 19. (1999).

Poulsen, B. et al. Mine overburden dump failure: a case study. Geotech. Geol. Eng. 32 (2), 297–309 (2014).

Steiakakis, E., Kavouridis, K. & Monopolis, D. Large scale failure of the external waste dump at the South field lignite mine, Northern Greece. Eng. Geol. 23 (3–4), 269–279 (2009).

Igwe, O. & Chukwu, C. Slope stability analysis of mine waste dumps at a mine site in southeastern Nigeria. Bull. Eng. Geol. Environ. 78, 2503–2517 (2019).

Gao, S. et al. Mechanical properties of material in a mine dump at the Shengli #1 surface coal mine, China. Int. J. Min. Sci. Technol. 27 (3), 545–550 (2017).

Cho, Y. & Song, Y. Deformation measurements and a stability analysis of the slope at a coal mine waste dump. Ecol. Eng. 68, 189–199 (2014).

Mahesh, J. et al. Management of municipal solid waste open dumps immediately after the collapse: an integrated approach from Meethotamulla open dump. Sri Lank Waste Manag. (2019).

Bao, Y. et al. Numerical assessment of failure potential of a large mine waste dump in Panzhihua City, China. Eng. Geol. 10 (253), 1–13 (2019).

General Administration of Quality Supervision. Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. The Seismic Ground Motion Parameter Zoning Map of China. GB18306-2015, (2015).

Ministry of Housing. and Urban–Rural Development of the People’s Republic of China, State Administration for Market Regulation. Technical Code for Building Slope Engineering. GB 50330-2013, (2013).

Author information

Authors and Affiliations

Contributions

Jingtao Zhang and Han Xia wrote the main manuscript text and Qiaoshan Xing, Xu Du and HuanHuan He prepared figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, J., Xing, Q., Du, X. et al. Stability analysis of a multistep method for excavating high spoiled slopes on the Guigu expressway: a case study. Sci Rep 15, 19317 (2025). https://doi.org/10.1038/s41598-025-03587-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-03587-3