Abstract

There are several difficulties to overcome when integrating electric vehicles (EVs) into power distribution networks, especially when it comes to preserving power quality (PQ) because of the harmonic distortion produced throughout battery charging. These issues are not sufficiently addressed by conventional charging algorithms like Constant Current Constant Voltage (CCCV), which frequently leads to higher Total Harmonic Distortion (THD), decreased system efficiency, and generally insufficient performance PQ. The Constant Power Constant Voltage (CPCV) charging algorithm, which is a revolutionary approach to addressing these issues, dynamically modifies the charging power according to the battery’s state of charge (SoC). Compared to conventional techniques, this creative technology efficiently controls harmonic emissions and enhances power quality. Three distinct EV models—the Tesla Model 3, the BYD ATTO 3, and the Kia EV3 Long Range—were used in simulations to assess the algorithm’s performance. The findings show that the CPCV algorithm works noticeably better than the CCCV method with respect to of lowering harmonic distortion; for the 3rd, 5th, 7th harmonics, THD values were lowered to as low as 0.41%. Furthermore, comparing to the greater loss seen in CCCV (3.85 kWh to 5.89 kWh), the CPCV algorithm also demonstrated significant decreases in energy losses, ranging from 2.72 kWh to 3.51 kWh. Furthermore, the CPCV method boosted efficiency by guaranteeing a power factor that was almost constant throughout all charging conditions. These results demonstrate the CPCV algorithm’s efficacy in improving power quality, maximizing energy use, and facilitating the smooth integration of EVs into contemporary distribution systems. In order to meet the increasing demand for EV charging infrastructure and guarantee an additional dependable and sustainable power system, CPCV offers an attractive option by reducing harmonic distortion and increasing general charging efficiency.

Similar content being viewed by others

Introduction

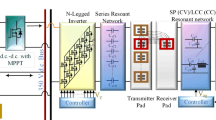

Power systems are being significantly impacted by the quick development of technology and the growing need for eco-friendly solutions. The increasing use of EVs, which is being pushed by environmental concerns, is one of the biggest shifts. As a greener substitute for traditional oil-powered cars, EVs have been increasingly popular over the last five years in a number of different nations. While there are financial advantages to the growing use of EVs, there are also serious PQ issues. Harmonic distortion is one of the most urgent PQ issues, and it becomes especially important when many EVs are linked to the grid throughout peak charging hours. Increased harmonic currents, transformer and feeder overloads, and voltage variations might result from this unexpected rise in load. Because of its non-linear properties, EV chargers introduce harmonics into the power source when charging. These harmonics impair PQ, interfere with delicate equipment, and lower the stability and effectiveness of the system as a whole. The inconsistencies of EV charging—where cars are plugged in and out at various times, resulting in unexpected harmonic variations. A simplified schematic of an EV charging procedure is shown in Fig. 1, emphasizing the production of harmonic distortion and how it affects PQ. It lays the groundwork for the necessity of creating better charging algorithms in order to successfully handle these PQ problems1.

There are a number of strategies that can be used to lessen these difficulties and guarantee the seamless integration of EVs into the electrical grid. Promoting smart charging systems that time EV charging to best align with times of low demand or renewable energy generation is one strategy. By doing so, PQ can be raised, and the grid’s workload can be lessened. In addition, by installing bidirectional charging infrastructure, EVs can serve as mobile energy storage devices by contributing to the grid during times when renewable energy is abundant. Additionally, grid operators can effectively identify and resolve PQ concerns by investing in sophisticated mon- itoring and control systems. By detecting such issues early on and taking appropriate action before they worsen, these technologies can help guarantee a dependable and steady power supply for both EV users and other customers. Furthermore, the creation and implementation of energy storage technologies, like pumped hydro storage or batteries, can facilitate the integration of EVs into the power grid and offer more flexibility. DSOs are interested in learning how charging EV can affect their networks. The effectiveness of distribution networks can be greatly impacted by the special features of EV charging, such as the sporadic nature of plugging and unplugging, the layout of charging stations, and the integration of EV storage systems. Because EV charging is sporadic, there may be abrupt variations in load, which could cause voltage swings and overload distribution transformers. Furthermore, the distribution network may be further taxed by the concentration of charging stations in residential neighborhoods or public charging hubs, which might result in isolated hotspots with high demand2.

One more factor that may affect the distribution system is the kind of charging infrastructure—a single- phase or three-phase system. Transformer overloading risk and load imbalances may worsen as a result of three- phase charging’s increased demand on the grid. The distribution system may also become more complex as a result of the incorporation of EV storage systems. Peak shaving and frequency regulation are two useful grid support functions these systems can offer, but they can also present additional difficulties like reactive power flow and voltage management. Achieving good performance and stability of EV storage systems requires close coordination between the distribution systems. It is crucial to take into account the various traits of car owners, the automobiles themselves, and the distribution grid’s constraints when comparing EVs and charging stations. In order to successfully integrate EVs into the power system and mitigate potential problems, a comprehensive approach is required. The varying harmonic distortion levels brought up by EVs and charging stations are an essential area to look into. Non-sinusoidal currents called harmonics have the ability to alter the power waveform and cause a number of problems, including higher losses, equipment overheating, and interference with delicate loads. Various factors, including the type of EV, the charging infrastructure, and the operating conditions, might affect the degree of harmonic distortion. Standardized procedures and policies for EV charging must be established in order to solve these issues and advance interoperability. Harmonic limitations, charging ports, and communication protocols should all be covered by these standards. In order to guarantee a smooth and effective integration of EVs into the power grid, the automobile industry, DSOs, vehicle users, and regulatory bodies can cooperate by complying with these guidelines. Additionally, additional study and development work is required to provide cutting-edge charging solutions that reduce harmonic distortion and enhance EV charging systems’ overall effectiveness. This entails investigating cutting-edge charging techniques that can maximize distribution grid use and improve user experience, such as bidirectional charging and smart grid integration.

EVs have the potential to lower fuel and greenhouse gas emissions, but as their use increases, power networks may be strained. The best management practices are necessary to deal with this problem. Because it can efficiently manage EV charging, minimize load variability, and optimize power distribution, centralized coordination is a potential strategy. Including renewable energy sources can reduce system stress even more and improve charging effectiveness3. The effect of EV chargers on distribution transformers and voltage quality is examined in this study. It evaluates the impact of EV charger harmonic currents on transformer aging and losses by computing the harmonic currents generated at various states of charge. In order to increase voltage quality and prolong transformer lifespan, it also examines the voltage quality of a distribution system with several EV charging stations and suggests a new harmonic power flow algorithm. A case study is presented to illustrate the efficacy of this approach4. When used in EV charging systems, the suggested ACHR approach efficiently reduces the third harmonic component in the PFC circuit’s input current. It uses an analytical model to determine the dominant third harmonic magnitude and a multilevel filter design to block high-order odd harmonics. The method preserves fundamental harmonic properties while optimizing for a closed-loop system that operates with stability and robustness. According to experimental results, third harmonic magnitude and THD have been decreased, increasing system efficiency and grid compatibility overall5.

Using partial CV charging data, the suggested method calculates the SOH of lithium-ion batteries. After analyzing many health indicators, it is concluded that CV capacity is the most solid and useful. In order to effectively assume the CV capacity, a unique reconstruction method is put forth to handle the problem of partial CV charging. Lastly, an accurate estimation of the battery SOH is obtained using the extracted CV capacity. Long-term deterioration experiments on NCA cells are used to validate the approach, which shows excellent robustness against cell inconsistency, low charging completeness requirements, and high accuracy6. Utilizing power exponential functions, the effect of time aggregation on the current harmonics of aggregated EV loads was examined. The findings demonstrated that 10-minute RMS aggregation produced a considerable deviation of more than 30% in terms of maximum current harmonic magnitude, although 3-second and 1-minute RMS aggregations had only a negligible effect on the result. This implies that in order to properly record the dynamic phenomena related to the large-scale integration of EVs, lower temporal aggregation periods could be required7. There will likely be a large rise in the stress on power distribution systems as EVs become more commonplace. Charging stations provide EV drivers with an option, but because it converts AC power to DC power, it can also add harmonics to the system. Filters can be used to decrease harmonics in order to lessen this problem. The effectiveness of KY and buck-boost converters in charging stations is compared in this study, which also examines the ripple characteristics, battery behavior, and harmonic generation of each. Furthermore, a working model of a charging station is emulated to offer insights into practical applications8.

Improper electrical harmonics on the DC bus might result from the electronic parts and electric machines that control the energy flow found in the powertrain of EVs. The onboard battery may degrade as a result of the ripple currents produced by these harmonics. Studies usually look at the effects of one AC frequency placed on DC. However, actual data show that the battery is affected by a larger range of ripple frequencies (50 Hz to 4 kHz). There is a need for more research as the first results reveal little variation in battery degradation among pure DC and DC having superposed ripple current9. EVs are becoming more and more popular due to a number of reasons, including reduced costs, government incentives, energy independence, and environmental concerns. On the other hand, uncontrolled EV charging may have detrimental effects on the electrical grid, such as elevated peak demand, phase imbalance, voltage variations, harmonic distortion, overloading, and power losses. On the other hand, managed EV charging and discharging can provide advantages, including better PQ, congestion management, frequency and voltage regulation, and congestion control. Subsequent investigations have to concentrate on refining EV charging tactics in order to minimize adverse effects and optimize beneficial contributions to the electrical system10. The suggested on-board charger speeds up battery charging by making use of the current propulsion machine motor system. This novel method makes use of the electrical machine’s high power rating and the motor-drive voltage source converter to enable quick charging. To guarantee dependable performance, the system is tested in real-time and built to run in a variety of operating modes11.

Due to the ease of use and absence of public charging infrastructure, EV charging is expected to rise dra- matically. Higher harmonic emissions in the distribution network will be a result of this nonlinear load. This requires an upgrade or management of the power system. This study uses a randomized EV load model to evaluate the harmonic emissions of EV charging at various voltage distortions and examines the effects on the distribution transformer12. Whenever the bidirectional EVSE is integrated into the smart grid, it can support grid stability and open up new economic opportunities. Its efficiency, PF, high-frequency grid impedance, and harmonic and supraharmonic emissions are all examined in this research. At optimum power, the EVSE shows low THD and good efficiency; at low power, the converse happens. Supraharmonic emissions are invariant to power levels of charging and discharging. The EVSE’s increased capacitance has a substantial effect on the high-frequency grid impedance, which causes resonance sites13. Lithium plating on the anode of LIBs can happen at low temperatures or throughout fast charging, posing a danger to safety and capacity loss. A three-electrode ECM with aging and temperature models was created in order to address this. A self-adaptive multi-stage CcCV approach was suggested using NSGA-II optimization. By preserving a safe anode potential, it strikes a balance between rapid charging and aging. The balanced approach decreased aging by 11.5% without sacrificing charging speed as compared to conventional CCCV14.

The low-order and high-order harmonics produced by rapid charging stations are evaluated in this research. To measure this effect, new three-phase effective power values were created. Significant differences in harmonic current distortion levels were found in measurements conducted at stations employing chargers from two different manufacturers in Canada. The system-level distortion reached 18%. A time-frequency study revealed that the harmonic current distortion of chargers made by various manufacturers varied significantly. The chargers that contributed significantly to both low-order and high-order harmonics were successfully recognized by the new power amounts, which offered important insights into the management of harmonic interference in the infrastructure used for charging EVs15. Lithium-ion batteries are the primary power source for EVs because of their high energy density, but issues with charging time, efficiency, and battery lifespan are impeding EV adoption worldwide. Fast-charging protocols are divided into two groups in this paper: material aspects protocols, which concentrate on changes to the physical and chemical makeup of the battery, and power management procedures, which regulate temperature, voltage, and current. On the basis of efficiency, cycle life, charging time, and temperature rise, it assesses and contrasts different protocols emphasizing how they can maximize charging efficiency and longevity16. Air pollution and global warming concerns are the main drivers of the EV market’s rapid adoption. While EVs are a more environmentally friendly option than conventional fossil-fuel cars, integrating them into the current electrical system presents serious PQ issues. It is anticipated that problems, including harmonic distortion, volt- age imbalance, and transformer failure, would surface as EV penetration rises. In order to guarantee a seamless transition to a more electrified transportation sector, this study examines these obstacles and examines possible mitigating measures17.

For effective and high-quality power transfer, the suggested on-board EV battery charger uses a three-level DC-DC SEPIC converter in conjunction with a diode bridge rectifier. In order to achieve a unity PF, a duty cycle feed-forward control technique eliminates THD in the ig and guarantees precise voltage regulation. Both the CV and CC modes are used to assess the system’s performance. The reliability and effectiveness of the converter are evaluated by recording the PQ indices, such as PF and THD, under different vs changes18. Traditional CC-CV charging extends the overall charging time by using a quick CC phase followed by a slower CV phase. An innovative approach that uses real-time temperature, SoH, impedance, and SoC data to optimize the CC-to-CV transition is presented in this study. It improves battery health and shortens charging times by dynamically modifying parameters. For environmentally friendly transport, the strategy encourages safer, quicker, and more intelligent EV charging19. By using lithium-ion batteries that are charged efficiently, electric vehicles contribute to reducing pollution, prices, and global warming associated with fossil fuels. The impact of several charging technologies, such as CCCV, on battery performance and longevity is examined in this research. Battery capacity (48 V, 72Ah), SoC, and voltage are taken into account while designing a charger. Several methods are tested using MATLAB simulations to determine which is best for onboard charging. The results demonstrate that CCCV provides a well-rounded strategy, whereas the suggested approach improves battery longevity and efficiency20.

Efficient battery charging is becoming increasingly important as EV adoption rises, particularly for systems that use several batteries. Although it decreases system size, traditional CC-CV charging with a single converter has drawbacks such as voltage imbalance and longer charging time. In order to get over the CC-CV constraints in parallel charging, this study suggests a pulse charging technique. Batteries with various SoCs can be charged independently and effectively thanks to the technique’s brief bursts of high current. It enhances system performance, balance, and charging speed21. In this study, a switched-mode rectifier and boost converter are used to create an effective EV charging/discharging system with input-side power factor adjustment. Dual modes of charging and load supply are made possible by a non-isolated bidirectional DC-DC converter. The best battery charging is achieved by integrating the CC-CV approach. Despite fluctuating loads, the system ensures a steady output voltage22. A new method for improving the PQ and efficiency of EV battery charging is provided by the bridgeless PFC converter, which is being suggested. It lowers input/output current ripple, enhances PQ, and lessens device stress by doing away with the conventional diode-bridge converter. The control system is made simpler by the single sensor component, which guarantees unity PF and steady dc load voltage. Longer battery life, lessened device stress, and enhanced efficiency in EV charging applications are all benefits of this novel design23.

As an EV charger and a grid support device, the suggested modular inverter system provides a full solution for residential applications. Through effective power flow management between the grid, residential loads, and the EV battery, the system improves grid stability and dependability. The outcomes of the simulation show how well it supports peak demand, integrates renewable energy sources, and provides backup power during blackouts24. Infrastructure for charging EVs is becoming more and more necessary as a result of the rising demand for EVs. EV charging, however, has the potential to cause power outages, decreased efficiency, and harm to devices by introducing harmonic distortion to the electrical distribution network. Utilizing harmonic reduction, an EV charging system was created to guarantee a steady and effective charging procedure. To assess the effectiveness of the suggested system, the research methodology was comprised of creating a mathematical model and running simulations. The project’s results showed how well the suggested solution worked to lower harmonic distortion, enhance PQ, and guarantee a steady and successful charging procedure25. The problems with EV fast charging at different battery operating circumstances and SOC are successfully addressed by the suggested gain ASMC with a redesigned phase-shift algorithm. Through the use of a strong phase estimation technique and dynamic control gain adjustments, the ASMC improves the front-end AC-DC charging performance while guaranteeing accurate power transfer and reducing power-mismatch. Despite sacrificing utility PQ, this method facilitates smooth bi-directional charging and supports either V2G or G2V modes of operation26. Shanmugam et al.27 discuss solar-powered quasi-dynamic charging for slow-moving vehicles, emphasizing renewable energy integration to enhance efficiency and grid compatibility, resonating with the sustainable objectives of the proposed CPCV algorithm. Abraham et al.28 extend this by using a fuzzy-based control for PV-energized DC microgrids, highlighting intelligent system configurations that align with goals for power optimization and minimal harmonic distortion. The review by Ravindran et al.29 identifies key challenges in fast-charging infrastructure, such as energy loss and grid impact, providing a backdrop for the necessity of algorithms like CPCV to address these issues effectively. Feng et al.30 and Li et al.31 both propose strategies for optimizing station placement and cooperative scheduling, which reflect the broader application of research in system-level coordination and efficiency. Kumar et al.32,33 propose hybrid algorithms and strategic planning for network resilience and efficient station placement, underpinning the practical applicability of predictive and adaptive models like CPCV. Similarly, Sabyasachi et al.34 advocate for holistic business models to integrate mobility solutions, aligning with the systemic approach needed for the study. The work by Ramakrishnan et al.35 on high misalignment tolerance in wireless chargers and Cui et al.36 on coordinated charging schemes underline the importance of adaptability and priority-based charging solutions, which the algorithm could further enhance by addressing PQ under variable conditions. Al-Alwash et al.37 provide an overview of optimization scheduling, reinforcing the relevance of robust and efficient algorithms like CPCV. Singh et al.38 and Salam et al.39 explore grid integration strategies and charge scheduling optimization, emphasizing the role of systematic and secure methodologies in achieving sustainable e-mobility. The predictive analysis by Kumar et al.40 on charging patterns highlights the need for precise algorithms to reduce inefficiencies. Varghese et al.41 and Aggarwal et al.42 focus on energy management and load optimization in fast-charging stations, echoing the themes of minimizing grid impact and enhancing system reliability, which the CPCV algorithm also targets. Finally, Lepolesa et al.43 delve into dynamic pricing strategies for load balancing, showcasing the interplay of economic and technical factors in achieving grid stability, a consideration the algorithm implicitly addresses. Zhang et al. (2022)44 introduced a PBI-based multi-objective optimization framework using a deep reinforcement elite learning strategy for micro-grid dispatch while accounting for frequency dynamics. This approach could potentially be extended to optimize EV charging schedules within micro-grids, ensuring stable grid operations and efficient energy utilization. Meng et al. (2024)45 presented an optimization strategy for multi-power supply startups to enhance distribution system stability and efficiency in the context of new energy integration. Their findings can be adapted to improve EV charging infrastructure stability, especially in scenarios involving renewable energy sources. A thorough analysis of the literature review on electric vehicle charging algorithms is provided in Table 1.

According to the evaluation of the literature, some research gaps were found; it describes a gain ASMC with CC-CV charging for EVs, but it doesn’t explain how the suggested algorithm manages harmonic distortions in different battery SOC and charging options. Uncertainty surrounds the CC-CV control’s efficacy in higher har- monic content situations26. THD is significantly reduced in this study, with an emphasis on harmonic reduction. It still fails to provide information on whether the CC-CV control technique specifically affects harmonic distor- tion in various EV charging circumstances, such as shifting the state of charge or charging at various rates25. While a grid-tied modular inverter allowing bidirectional charging using CC-CV control is covered in this study, the impact of harmonic distortions on the functioning of the system is not examined. There is no analysis of the relationship between harmonic disturbances and CC-CV control, particularly in residential settings24. A power.

A converter with CC-CV control is assessed in the study to reduce THD and increase PQ. It does not, how- ever, provide a thorough examination of the effects of the CC-CV algorithm’s operation and various harmonic situations on the converter’s future dependability18. The impact of ripple currents on battery deterioration is investigated in this study; however, the contribution of CC-CV management to reducing these ripple currents is not taken into account. The study emphasizes the importance of more research on how to handle the whole range of harmonics impacting battery health through CC-CV charging9.

Traditional charging techniques, including CCCV, frequently don’t adjust effectively to variations in the battery’s SoC, which leads to low power factor, higher THD, and wasteful energy use. This poses a significant research question: How can a charging algorithm be developed to reduce harmonic emissions, boost power factor, and increase energy efficiency throughout the charging process? Given the growing popularity of EVs, answering this question is essential to maintaining grid stability. So, the charging technique known as CPCV is not wholly novel; it has been suggested before. The management of harmonic distortion during EV battery charging, which has not been thoroughly investigated in previous studies, is one of the significant research gaps that our work fills. The research’s primary objective is to formulate and implement a CPCV algorithm that will enhance PQ when charging EV batteries which means this study offers a substantial advancement over traditional CC-CV techniques, which generally fall short in reducing harmonic distortions, particularly in high-harmonic situations and with fluctuating battery SOC. To ensure better PQ, the CPCV algorithm is tuned to control and minimize harmonic distortions during the charging process. In contrast to previous studies that either ignored the impact of CC-CV control across high harmonic situations or did not investigate its performance under various SOC levels, this study provides a comprehensive analysis of these variables. Because of the algorithm’s capacity to regulate voltage while keeping a steady power output, harmonic distortions are lessened, improving PQ overall. Additionally, the CPCV approach fully eliminates THD, whereas earlier studies have only partially addressed this problem. It efficiently controls harmonics in a range of charging situations, guaranteeing steady charging current and reducing harmonic disruptions, especially in residential areas with high penetration because these problems can be very problematic. Furthermore, this study examines the impact of harmonic distortions on battery health and system performance, an important topic that has frequently been ignored in earlier research. By mitigating ripple currents and reducing harmonic effects, the CPCV algorithm enhances the long-term robustness of power converters and the battery system. The comprehensive approach ensures that the CPCV technology lowers harmonic content with improving EV charging systems’ performance and reliability.

A structured methodology for the proposed CPCV algorithm is shown in Fig. 2. Section 2 depicts the Charging Infrastructure: Key to EV Adoption, and Sect. 3 depicts the EVB Charger. Section 4 gives a brief explanation of the EV charging algorithms. Section 5 provides the Results and Discussion, and Sect. 6 presents the Comparison of Charging Algorithms. Section 7 depicts the Conclusion.

Charging infrastructure: key to EV adoption

EV adoption depends on the establishment of a reliable and easily available infrastructure for EV charging. The lack of charging facilities is now a major obstacle to the adoption of EVs. The industry is concentrating on two main charging paradigms—off-board and on-board systems—to address this difficulty. Integrated into the EV itself, on-board charging systems usually consist of a mix of DC-to-DC and AC-to-DC converters. The task of converting grid-supplied AC into DC appropriate for battery charging falls to the AC-to-DC converter. In order to optimize charging effectiveness and security, the DC-to-DC converter is utilized to control the voltage and current delivered to the battery. For residence charging or charging at commercial stations with lesser power outputs, on-board charging is typically utilized. The EV and the charging station must physically be connected for off- board charging systems, which are external to the car. The AC and DC charging systems are the two groups into which these devices fall. After receiving AC electricity from AC charging stations, the EV’s on-board charger converts it to DC power. Bypassing the necessity for on-board conversion, DC charging stations provide the EVB with straight DC electricity. When fast battery replacement is required, DC charging is usually utilized for fast-charging applications. Charge speed, cost, and simplicity are some of the elements that influence the decision among on-board and off-board charging systems. Investing in a complete charging infrastructure that includes both on-board and off-board solutions is essential to accelerating the adoption of EVs. This will give EV drivers the simplicity and adaptability required to make the switch to electric cars with confidence. Furthermore, new developments in charging technologies, such as wireless and bidirectional charging, have the potential to improve charging even more and solve problems with the infrastructure that now supports it46.

AC bus distribution system

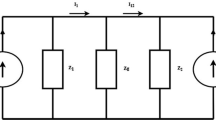

A three-phase AC bus running at a lower voltage, usually between 250 V and 480 V line-to-line, is interfaced with the distribution network in AC-connected systems via a step-down transformer. The station’s multiple chargers, each with its own AC/DC stage, is then powered by this AC bus. Although there are some benefits to this strategy, there are also new complications and possible downsides. System complexity and expense are increased when additional conversion stages are used among the DC port of the EV or RES and the distribution network. The efficiency of the system decreases with each conversion stage that is introduced.

AC-connected systems provide a number of benefits despite these disadvantages. These systems’ rectifier and inverter technologies have been thoroughly researched and developed, guaranteeing dependable and effective performance. Furthermore, AC switchgear and protective devices are widely accessible, giving the system essential security and protection. Moreover, AC power distribution systems’ structure, installation, and upkeep are made easier by accepted standards and procedures46.

DC bus distribution system

DC-connected systems use a single central front-end AC/DC converter to generate a DC bus, which results in a more energy-efficient method of charging EVs. Therefore, instead of requiring separate AC/DC converters in each charger, this DC bus serves as a shared power supply for numerous chargers. A single-stage transformer that performs isolation, voltage step-down, and rectification duties is usually placed after a low-frequency transformer in a central front-end converter. In order to fit the 400 V voltage range found in current EV batteries, the DC bus voltage usually stays within 1000 V. Comparing DC-connected systems to AC-connected systems, the former has higher system efficiency since it uses a DC bus to lower the number of conversion stages. Furthermore, chances for load diversification are presented by the single connection to the utility via the central front-end. This reduces the possibility of system costs for installation by enabling the system to improve the functioning of the grid connection and AC/DC converter depending on the different charging demands of varied EVs.

The lack of reactive power in DC-connected systems minimizes losses and simplifies control, among other benefits. The addition or removal of chargers as needed is also made simpler by the scalability and modularity of DC systems. The need for particular requirements, system cost, and desired charging speed are some of the elements that influence the decision between AC-connected and DC-connected systems. DC-connected systems might be more suited for applications that value fast charging times and low power losses, even though AC-connected systems have specific benefits in terms of standards and technology development.

Modern fast charging stations usually run at up to 480 V line-to-line over three-phase low-voltage distribution grids. A specialized MV to LV service transformer is typically used to provide this voltage. On the other hand, the charging station’s size, cost, and installation difficulty may all be greatly increased by this transformer46. In order to overcome these obstacles, SSTs that utilize power electronics can be utilized to link the MV grid directly, negating the requirement for a large service transformer. SSTs are essentially power electronic converters that use high-frequency transformers to deliver galvanic isolation and voltage conversion, thereby replacing conventional line-frequency transformers. SSTs are superior to conventional line-frequency transformers in a number of ways. It is easier to regulate, making it possible to change the voltage and current precisely. Additionally, it will be equipped with built-in current limiting features that guard against the system being harmed by excessive currents. SSTs also frequently have superior efficiency, particularly under light loads.

Numerous SSTs that are suggested for use in fast-charging applications are converted in three steps. After converting the line-frequency MV AC input towards DC voltage in the first stage, an active front-end rectifier is used. The second stage is an isolated DC/DC converter that maintains galvanic isolation while converting the DC voltage to a specified level. The DC voltage is finally reversed into a line-frequency LV AC output by the third stage, shown in Fig. 3.

Electric vehicle battery (EVB) charger

There is a vast array of models of EVs, each with distinct features of its own. These differences can have a major effect on both the general outcome and the charging process. For instance, certain EVs can go farther between charges because of their superior battery capacities. Some could be able to accelerate more quickly and reach greater top speeds due to their larger power outputs. Furthermore, the voltage and current ratings of EVs are distinct, which has an impact on charging efficiency and infrastructure availability. The swift development of EVs as a feasible mode of transportation may be primarily ascribed to the continuous progress in energy storage technology. Because of their superior driving characteristics, lithium-ion batteries have become the preferred option between the different battery chemistries accessible to EVs. Because of their high energy density, lithium- ion batteries have a greater driving range between charges. It might also have excellent rates of charging and discharging, which facilitates speedy refilling and minimizes wait periods.

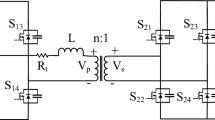

In addition, when compared with other battery types, lithium-ion batteries have a comparatively longer lifespan, which guarantees their dependability and endurance throughout prolonged usage. Due to their combined benefits, lithium-ion batteries are now the technology of choice for EV powering, which has fueled their broad adoption and helped in the shift to more environmentally friendly modes of transportation47. An AC-DC converter and a DC-DC converter are usually the two converters in the topology of the on-board charger. An external power source, such as a charging station, provides AC, which must be converted into DC by an AC-DC converter. The DC-DC converter then adjusts this DC voltage to the battery’s precise specifications. The on-board charger can guarantee effective energy transfer, avoid overcharging or undercharging the battery, and shield it from harm by carefully regulating the charging and discharging cycles. Advanced algorithms and electrical circuitry that track the battery’s voltage, current, and SOC and modify the charging or discharging rate accordingly are used to attain this regulation46.

Electric vehicle battery (EVB) charger

There is a vast array of models of EVs, each with distinct features of its own. These differences can have a major effect on both the general outcome and the charging process. For instance, certain EVs can go farther between charges because of their superior battery capacities. Some could be able to accelerate more quickly and reach greater top speeds due to their larger power outputs. Furthermore, the voltage and current ratings of EVs are distinct, which has an impact on charging efficiency and infrastructure availability. The swift development of EVs as a feasible mode of transportation may be primarily ascribed to the continuous progress in energy storage technology. Because of their superior driving characteristics, lithium-ion batteries have become the preferred option between the different battery chemistries accessible to EVs. Because of their high energy density, lithium-ion batteries have a greater driving range between charges. It might also have excellent rates of charging and discharging, which facilitates speedy refilling and minimizes wait periods.

An AC-DC converter and a DC-DC converter are usually the two converters in the topology of the on-board charger. An external power source, such as a charging station, provides AC, which must be converted into DC by an AC-DC converter. The DC-DC converter then adjusts this DC voltage to the battery’s precise specifications. The on-board charger can guarantee effective energy transfer, avoid overcharging or undercharging the battery, and shield it from harm by carefully regulating the charging and discharging cycles. Advanced algorithms and electrical circuitry that track the battery’s voltage, current, and SOC and modify the charging or discharging rate accordingly are used to attain this regulation46. The need for ideal charging techniques that guarantee speed and dependability without compromising battery life is fueled by the growing use of Li-ion batteries in EVs. With an emphasis on active optimum charging techniques, this study examines recent attempts to develop such solutions. It assesses the advantages and disadvantages of mathematical controllers and emphasizes the battery models that are utilized as well as the main architectures of charging algorithms. Along with discussing practical applications, the evaluation makes suggestions for enhancements to overcome current drawbacks47. Since the efficiency of charging and discharging lithium-ion batteries is largely reliant on current, these batteries are essential to electric vehicle and power systems. This study presents a novel approach to calculating battery capacity that takes into consideration energy losses that occur during both charging and discharging. To precisely quantify stored and extracted energy, one-way efficiencies are measured in experimental tests conducted under various situations. Because of its efficiency and temperature concerns, the system works better than current methods, particularly in varying ambient temperatures. It supports more accurate and dependable energy management throughout charging, which is in line with CPCV goals48.

Moreover, the efficiency and duration of an EV’s charging can be affected by the battery’s SOC. More often than not, a battery with a lower SOC will charge more quickly. Another important consideration is an EV’s range, which establishes the extent to which the car can go between charges. The range is influenced by variables like driving conditions, energy efficiency, and battery size. The variety of EVs found in real life offers potential as well as issues for the advancement of charging infrastructure and the uptake of EVs. Setting up for the development of electric mobility and making educated judgments regarding EV ownership requires recognition of these variances. In order to fully evaluate how charging methods affect harmonic current distortion in EVs, a variety of EV models should be taken into account. A range of parameters, such as battery capacity, charging rate, and onboard charging system design, should be included in these models. This study can record the variation in charging characteristics and spot any harmonic distortion developments or patterns by choosing three distinct EV models: Tesla Model 349, BYD ATTO 3 EV50, and Kia EV 3 Long Range51. Idealistically, these models ought to cover a variety of EV market segments, including luxury, mid-size, and compact cars. EVs with various battery chemistries (such as Li-ion and NiMh) and charging capacity also need to be taken into account. These three EV models were selected, each of which ought to cover a different market niche for EVs and include a range of battery types and charging speeds. This research may cover a wide variety of EV types and characteristics, such as battery capacity, charging rate, and onboard charging system setup, by choosing these three EV models. These will make it possible to analyze the performance of various charging algorithms and the factors driving harmonic current distortion in more detail.

Although some range loss and degradation are unavoidable with EV batteries in time, these impacts can be greatly reduced by maximizing charging efficiency. It is feasible to reduce energy loss and increase battery life by customizing the charging procedure to the unique features and ability of the battery. The sudden burst of energy following fast charging may cause the battery cells to internally stress and produce more heat. These elements may hasten the aging process and lower battery capacity. Yet, the charging process can be optimized, and these negative impacts can be minimized by employing intelligent charging algorithms that consider the temperature, other pertinent parameters, and the battery’s current state of charge. This research suggests that the CPCV charging method should be improved52.

Figure 4 depicts block diagram of EVB fed from Grid utilizing the CPCV algorithm. Figure 5 depicts block diagram of EVB fed from Grid utilizing the CCCV algorithm.

Constant current constant voltage algorithm (CCCV)

One common way for charging energy storage devices, such as EV batteries, is the CCCV charging method. With this method, the charger starts off by keeping the battery’s terminal voltage at a CC till it hits a predefined threshold, usually the Voc at 100% SOC. Throughout the CC phase, the terminal voltage rises as the SOC grows because the battery’s internal resistance reduces. The charger enters CV mode when the terminal voltage hits the voltage limit, progressively lowering the current but keeping the terminal voltage. This shift guarantees safe functioning and protects the battery against overcharging. The increase in terminal voltage that occurs throughout the CC phase is a reflection of the battery’s internal electrochemical reactions. The charging current needs to be precisely controlled to avoid going over the battery’s safeguarding limitations. However, unbalanced energy distribution throughout battery cells is a possible drawback of the CCCV approach. There could be imbalances and possible decreased capacity if specific cells charge higher than elsewhere as the terminal voltage rises. Furthermore, the small rise in terminal voltage and charging current in the CC mode results in a tiny rise in the charged power. Gradually, this marginal benefit could lead to imbalanced energy distribution and capacity loss. To prevent overcharging and preserve battery safety, the charging current progressively drops in the CV mode following an exponential decay. Throughout the CC phase, the power provided to the battery grows as a function of charging current and terminal voltage. Large-capacity batteries may experience a notable increase in power after injection52. Changes to the charging current or terminal voltage might be required to maximize the charging process and preserve a steady power supply. By making these adjustments, the battery’s lifespan and effectiveness can be increased, and its general charging performance can be improved. A brief CCCV algorithm is shown in Fig. 6.

Constant power constant voltage algorithm (CPCV)

In EVs, the problem of useful energy loss occurs when charging in the CV mode. The reason for this is that the continuous power supply provided throughout the CV phase may lead to a boost in energy loss, which eventually lowers charging efficiency. Because a CP phase prevents such inefficiencies by keeping the power level more stable during the charge, it can boost efficiency if it is used early in the process52.

Comparing the CCCV and CPCV charging techniques, it can minimize useful energy loss by delivering the same amount of energy at a steady power level. This can be quantified using the CPCV algorithm’s equations:

-

Step 1: Energy Input during CP Phase:

-

Step 2: Energy Input during CV Phase.

-

Step 3: Total Energy Input:

The total energy supplied to the battery is useful for determining the charging efficiency and evaluating how well the charging algorithm works.

-

Step 4: Useful Energy Stored:

-

Step 5: Useful Energy Loss:

The energy loss throughout the charging process is computed using this equation. The energy that is effectively stored in the battery is subtracted from the overall energy that is delivered. Switching losses, converter losses, heat dissipation, and other charging system inefficiencies could be the cause of this energy loss.

Before entering the CV phase, it presents a modified charging method that substitutes a CP phase for the conventional CC phase. This sequence modification attempts to solve the inefficiencies seen in the first case, where extended CV mode may result in needless energy losses, and enhance overall charging efficiency. Therefore, the suggested strategy minimizes inefficiencies during the CV phase and gives priority to consistent power output during the CP period. A brief CPCV algorithm is shown in Fig. 7.

This adjustment is based on the finding that useful energy loss can be significantly influenced by the amount of time spent in the CV mode. The charging process can be enhanced to lower energy losses and raise the general effectiveness by utilizing a CP phase. This study conducts test cases with three different EV models, Tesla Model 3, BYD ATTO 3 EV, and Kia EV 3 Long Range, and uses the suggested CP-CV charging method for a wide range of EV charging settings. These models, which differ in aspects like battery capacity, charging rate, and onboard charging system setup, probably reflect a wide range of EVs. Through the simulation of these diverse EV models over varying charging conditions, this study is able to assess the CP-CV method’s efficacy in a broad range of application scenarios. This strategy improves the study’s generalizability by ensuring that the conclusions apply to a wide variety of EVs. The main objective of these test cases is to offer solid evidence of the advantages of the CP-CV charging technique. In order to further EV charging technology and encourage the use of EVs, the study highlights potential enhancements in charging efficiency, battery life, and general EV performance.

Results and discussion

In order to determine the optimal CPCV algorithm for PQ enhancement in EVB charging, a simulation was conducted using MATLAB 2018a. The results section uses the CPCV method in an EVB system to thoroughly examine the harmonic content throughout the charging process. With a PFC converter, this grid-powered system is operational. By examining the harmonic distortion in the ib, the analysis’s main goal is to ascertain whether the PFC converter is actually present and operating in the EV charging system.

The 3rd, 5th, and 7th harmonics magnitude —which are identifiers of the quality of the current waveform and the existence of PFC—are the main odd harmonics that are the subject of the harmonic analysis. With the goal of minimizing THD and lower-order harmonics, especially the third harmonic magnitude, a PFC converter must be activated in order to guarantee that the current generated by the grid is in phase with the input voltage.

When there is no effective PFC present in a system, the ib third harmonic magnitude often takes center stage, signifying not enough PF and poor waveform quality. Indicating that the PFC converter is either missing or not operating properly is the harmonic’s presence above the 5, 7 harmonics magnitude. The 5th and 7th harmonic magnitude, on the other hand, are usually more noticeable than the 3rd harmonic magnitude in a well-operating system with PFC, indicating an additional balanced harmonic distribution and better PQ. Thus, the findings show the staggered shape of the harmonics produced by the CPCV charging algorithm and offer an in-depth description of the changing harmonic content over the charging process. It is possible to figure out that the PFC converter is effectively trying to lower THD while maintaining excellent PQ during the charging process by looking at the harmonic content in the ib.

In order to ensure the reliability and consistency of the results in evaluating the existence and efficacy of the PFC converter in the EV charging system, the harmonic content analysis was confirmed across three distinct EV models with three test cases. The EVB charging procedure utilizing the CPCV algorithm is depicted in the flowchart shown in Fig. 8 shows the general layout of the suggested EV charging system, in which the Ferdowsi PFC converter provides energy from the grid to the battery. In order to increase power factor and decrease harmonic distortion while charging, the Ferdowsi PFC converter controls the input current taken from the grid. The battery’s charging behaviour in this configuration is controlled by the CPCV algorithm. The charging current Icharge is dynamically determined using the instantaneous battery voltage (V), as the control logic illustrates. A steady power charging profile is maintained by the controller. In order to maintain steady power, the algorithm raises the current whenever the battery voltage falls below a predetermined threshold. The current is suitably decreased to preserve the same power level whenever the battery voltage exceeds this threshold. Stable power delivery, less grid strain, and effective charging are all supported by this CPCV current management technique. The relationship among the grid, the PFC converter, and the CPCV-controlled battery charging mechanism is summarized in Fig. 8, which also highlights advancements in control logic and PQ. When used for EV charging, a typical DC–DC converter results in low power factor, excessive harmonics, and poor PQ, which reduces battery life and efficiency. The Ferdowsi Converter is suggested as a solution to this problem. It uses two interleaved Buck-Boost converters with a shared inductor. Utilizing a streamlined PT control approach, it functions in DCM. Under various circumstances, this configuration guarantees a power factor of almost unity and maintains THD below 5%. In addition to synchronizing input current with mains voltage, the design minimizes the number of components53.

Test case 1: Tesla model 3

With an emphasis on battery features and critical performance metrics, Table 2 provides comprehensive Tesla Model 3 EV specs. The vehicle’s capabilities are comprehensively outlined, including essential parameters like charging capacity, battery type, acceleration, and range. According to Table 2, in which Depending on the battery’s state of charge, the 400 V architecture is the total system voltage that powers the motor, inverter, and powertrain components.

This test scenario involved using a Ferdowsi PFC converter for charging an EVB with a nominal voltage of 340 V using a grid supply of 230 V/32A. Through the analysis of harmonic distortion in both ib and ig, the CPCV algorithm was used during the charging process to evaluate the Ferdowsi PFC converter’s functionality thoroughly. Throughout the charging process, the Ferdowsi PFC converter efficiently configured the PQ. The battery required 20.21 A of current to be charged to a high voltage of 366.2 V, is shown in Fig. 9. A UPF has been detected by the vs and ig aligning in phase. The almost sinusoidal current waveform that results from the Ferdowsi PFC converter’s effective reduction of reactive power and harmonics is indicated by this in-phase position, which is shown in Fig. 10. A spectrum of the battery’s SoC was used throughout the simulations, with the 50–70% SoC range being of particular interest. The ib harmonics for the 3, 5, and 7 orders were measured at 0.59 over this range, as shown in Fig. 11. The harmonic analysis of the ib during charging is shown in Fig. 11. The various harmonic components, namely the 3rd, 5th, 7th orders, are analyzed to see when a PFC converter is operational. When the 3rd is higher than 5th, 7th, it is a clear sign that a PFC converter is not present. On the other hand, the PFC converter is confirmed to be functioning when the 3rd is less than 5th, 7th. Figure 11 illustrates the measurement of the 3rd, 5th, 7th harmonic orders of ib at 0.59 in this test example. This suggests that the Ferdowsi PFC converter was functioning and operating, successfully lowering harmonic distortion in the battery charging current, because the 3rd, harmonic is not dominant and equivalent to the higher orders. In order to confirm the existence and efficacy of the PFC converter under varied EV charging conditions, this evaluation criterion has been consistently carried out throughout all test instances.

The fact that the harmonic level remains constant throughout these orders implies that the PFC converter is operating as intended to keep any particular harmonic—like the three from taking center stage. In the 50–70% SoC range, the ig harmonics for the identical orders held steady at an extremely low level of 0.01.

The ig negligible harmonic distortion further improves the Ferdowsi PFC converter’s efficient operation. Its UPF functioning and ability to keep up an almost sinusoidal ig are essential for reducing harmonic interruptions.

In general, the findings demonstrate that independent of the SoC level, the Ferdowsi PFC converter is operating at peak efficiency inside the EV charging system, delivering reliable PQ and successfully lowering THD. The Results confirm the Ferdowsi PFC converter’s function in attaining UPF and effective harmonic management by showing that it sustains excellent PQ during the charging process.

Test case 2: BYD ATTO 3 EV

The BYD Atto 3 EV model’s primary specs are outlined in Table 3, which also highlights the model’s cutting-edge battery and performance attributes. This EV stands out from the competition in the EV market because of its high-capacity Li-ion battery and outstanding acceleration and range characteristics.

Utilizing a Ferdowsi PFC converter, a BYD Atto EV battery with a 403 V nominal voltage was charged in this test scenario utilizing a 230 V/32A grid supply. The CPCV technique was used during the charging process to analyze harmonic distortion in both ig and ib, allowing for a comprehensive assessment of the PFC converter’s effectiveness.

Effective PQ management was achieved throughout the charging phase using the Ferdowsi PFC converter. The battery consumed 17.05 A of current at its highest voltage of 434.1 V, which is shown in Fig. 12. Ferdowsi PFC converter maintained UPF by ensuring that the supplied voltage and current stayed in phase, as shown in Fig. 13. With respect to an almost sinusoidal current waveform, this relationship indicates that the Ferdowsi PFC converter was successful in reducing reactive power and harmonics.

The battery’s SOC, with an emphasis on the harmonic content, was monitored during the charging process. The 3rd, 5th, 7th order ib harmonics were observed at 0.7. The harmonic levels of the 3rd -order magnitude were seen to be lower than or equivalent to those of the 5th, 7th, indicating that the Ferdowsi PFC converter is effectively controlling and regulating harmonics in accordance with its intended function, as shown in Fig. 14.

At 0.01 for each order, the ig harmonics for the 3rd, 5th, 7th orders continued to be always low. The Ferdowsi PFC converter’s efficiency in reducing harmonic disturbances is supported by the ig little distortion. In the end, the findings show that the BYD Atto EV charging system’s Ferdowsi PFC converter is successfully controlling PQ. The converter’s ability to minimize harmonic distortions and guarantee effective energy transfer is demonstrated by the constant harmonic content in the grid and ib as well as the measured UPF. The Ferdowsi PFC converter’s existence and efficacy in preserving PQ is reinforced by its capacity to control the 3rd harmonic magnitude while keeping it in line with or below the 5th, 7th harmonic magnitude.

Test case 3: Kia EV3 long range

The Kia EV3 Long Range’s technical details and charging parameters, such as battery capacity, nominal voltage, and charging efficiency, are compiled in Table 4. In this test scenario, a 230 V/32 A grid supply was used to charge the car’s battery, which has a nominal voltage rating of 343 V. As shown in Fig. 15, the charging procedure raised the battery voltage to an ideal level of 369.4 V with a charging current of 20.1 A.

A Ferdowsi PFC converter was utilized to guarantee PQ throughout the charging procedure. By actively regulating the grid current waveform, this converter reduces harmonic distortion. ith the harmonic analysis of both ib and ig, the efficacy of this PFC control can be seen. In particular, Fig. 16 illustrates that the 3rd, 5th, 7th harmonic components of ib were all limited to 0.41%. Remarkably, the 3rd harmonic continuously stayed below or equal to the 5th, 7th harmonics, demonstrating the converter’s effective behaviour and correct operation. Furthermore, all measured components had a very low harmonic content ig of 0.01% in the grid current. As seen in Fig. 17, this demonstrates that ig stayed almost sinusoidal and in phase with the grid voltage, satisfying the criterion for UPF. By eliminating harmonic distortion, the Ferdowsi PFC converter successfully preserved good PQ, irrespective of the battery’s charge level, as these findings show.

Comparison of charging algorithms

The extensive system parameters and configuration utilized during the computations assist in clarifying the advantages of the CPCV charging algorithm over the CCCV algorithm, including lower harmonics and enhanced PQ. The Ferdowsi PFC Converter system configuration53, particularly was installed in the system for this research, was essential in controlling the power flow and reducing harmonic distortion. The simulation was used to examine the PQ over combination CPCV and CCCV charging algorithms. The main system parameters included the vs 230 V, vb, motor power, and particular EV models (Tesla Model 3, BYD ATTO 3, and Kia EV3 Long Range). Fast Fourier Transform analysis of the is frequency spectrum was used to determine the harmonic magnitudes (3rd, 5th, and 7th harmonics). The separation of distinct harmonic components and a comparison of the effects of each method on harmonic distortion during the charging process were made possible by this procedure.

In the findings section of the CPCV and CCCV charging algorithms, notable differences were found when analyzing the ib harmonic magnitude for the three test cases. In comparison to the CCCV method, which showed significantly more harmonic distortion, these variations demonstrate the level of effectiveness and PQ provided by the CPCV algorithm in Table 5.

Comparison of charging Algorithms - CPCV/CCCV over harmonics magnitude in test case 1- Tesla model 3

For the 3rd, 5th, 7th harmonics magnitude, each calculated at 0.5, the CPCV algorithm produced a uniform ib harmonic distortion in Test Case 1, which has been presented in Table 5, highlighted in red color. The success of the CPCV technique in reducing harmonics and guaranteeing PQ is demonstrated by this consistent and low level of distortion. The ib harmonics, on the other hand, demonstrated a noticeable rise when the CCCV algorithm was utilized in the identical test scenario; the 3rd harmonic magnitude is 125.13, the 5th harmonic magnitude is 124.13, and the 7th harmonic magnitude is 122.55 in Table 5. There could be problems with PQ, which could result in increased harmonic distortions when charging, as shown by the CCCV algorithm’s notably greater harmonic levels.

Comparison of charging Algorithms - CPCV/CCCV over harmonics magnitude in test case 2- BYD ATTO 3

Comparable patterns were seen in Test Case 2, where the CPCV algorithm maintained a low and consistent harmonic profile by providing ib harmonic magnitude of 0.7 for the 3rd, 5th, 7th harmonic orders presented in Table 5 highlighted in red color. The 3rd harmonic magnitude was obtained at 144.41, the 5th harmonic magnitude at 143.25, and the 7th harmonic magnitude at 142.14; however, the CCCV algorithm produced far larger harmonic distortion in this test scenario depicted in Table 5. The CCCV algorithm may have introduced considerable harmonic information, as indicated by these high harmonic levels. This could have detrimental effects on the battery’s functionality and charging efficiency.

Comparison of charging Algorithms - CPCV/CCCV over harmonics magnitude in test case 3- Kia EV3 long range

Similar to the above Test Cases, the CPCV algorithm produced lower balance ib harmonics of 0.41 for the 3rd, 5th, 7th harmonic magnitude orders in Test Case 3 is presented in Table 5 highlighted in red color. In contrast, the 3rd, 5th, 7th harmonic magnitude of the CCCV algorithm were all at high harmonic values—125.06, 124.91, and 124.47, respectively, as depicted in Table 5. These outcomes support the finding that, in comparison to the CPCV method, the CCCV algorithm significantly improves harmonic distortion. The CPCV method continuously outperformed in terms of lowering ib harmonic magnitude and preserving low, constant distortion levels. This shows that throughout the charging process, the CPCV method manages PQ better. On the other hand, the 3rd, 5th, 7th harmonic magnitude significantly increased in all test scenarios where the CCCV algorithm produced substantially larger harmonic distortion. The CPCV algorithm is a better option for maintaining PQ during EV charging because the CCCV algorithm’s increasing harmonic level may lead to decreased charging performance and possible long-term impacts on battery health. The. The CCCV approach produced larger energy losses of 3.856 kWh, 4.819 kWh, and 5.894 kWh than the CPCV method, which measured 3.507 kWh, 2.724 kWh, and 3.507 kWh, as shown in Table 5, highlighted in red color The results demonstrated that the CPCV algorithm enhanced PQ by dramatically reducing harmonic magnitudes when compared with CCCV. Simulations of energy loss, which show how effective each charging algorithm is, have been gathered from the charging conditions of the system. The energy losses for both CPCV and CCCV were computed for comparison by taking into account the supply voltage, battery voltage, charging current, and converter efficiency. The findings showed that CPCV resulted in lower energy losses than CCCV because of its more steady charging profile. Therefore, based on the given system architecture and characteristics, these computations offer a clear foundation for comprehending the benefits of CPCV over CCCV in terms of lowering harmonics and enhancing PQ.

This article’s main strength is its comparative analysis and actual demonstration of the Constant Power CPCV charging method over several models of electric vehicles, which highlights how well it works to reduce harmonic distortion and improve PQ. The research provides a thorough understanding of how the CPCV approach improves grid stability, lowers energy losses, and maintains a power factor close to unity by combining simulation-based information with harmonic order analysis (3rd, 5th, and 7th). The suggested approach’s flexibility and dependability are reinforced by the results’ consistency across several EV models. The current study can be expanded upon in a number of ways for future research: CPCV effectiveness during dynamic grid and load situations will be validated by implementing real-time hardware-in-the-loop testing; (2) CPCV integration with renewable energy sources, such as solar PV, will be investigated to create a greener and more sustainable EV charging system; (3) creating machine learning-based adaptive CPCV algorithms to maximize charging behaviour according to grid conditions and user habits; and (4) Carrying out extensive field tests at both public and private charging stations to evaluate system responsiveness, user impact, and practicality. These additions will strengthen the CPCV method’s resilience and suitability for use in upcoming smart grid scenarios.

Conclusion

The utilization of the Constant Power CPCV charging algorithm is presented in this paper as an important breakthrough in resolving PQ issues brought on by the incorporation of EVs into power distribution networks. Significant gains in harmonic mitigation, energy efficiency, and system stability are shown by the CPCV algorithm when compared to conventional CV charging techniques. The CPCV algorithm successfully lowers THD to as low as 0.41% across the 3rd, 5th, 7th harmonic orders, according to simulation results throughout three distinct EV models: the Tesla Model 3, BYD ATTO 3, and Kia EV3 Long Range. Furthermore, independent of the battery’s SOC, the CPCV technique minimizes energy losses during charging and guarantees near- UPF functioning. The CPCV algorithm successfully lowers THD to as low as 0.41% across the 3rd, 5th, 7th harmonic orders, according to simulation results throughout three distinct EV models: the Tesla Model 3, BYD ATTO 3, and Kia EV3 Long Range. Furthermore, independent of the battery’s SOC, the CPCV technique minimizes energy losses during charging and guarantees near UPF functioning. In situations with high EV penetration, where preserving grid stability and reducing PQ degradation are crucial, these enhancements are vital. The CPCV algorithm guarantees steady power delivery by continuously modifying the charging current in response to the battery voltage in real time. This avoids the inefficiencies and harmonic emissions that are sometimes seen with preset charging methods.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- i b :

-

Battery current

- i g :

-

Grid current

- V oc :

-

Open cIrcuit voltage

- V s :

-

Supply voltage

- ηcoul :

-

Coulombic efficiency of the battery

- E input,CV :

-

Energy input during the constant voltage phase

- E loss :

-

Energy loss

- E stored :

-

Useful energy stored in the battery

- I(t):

-

Time-varying current during the CV phase

- P CP :

-

Constant power during the CP phase

- t CP :

-

Duration of the CP phase

- V CV :

-

Constant voltage during the CV phase

- AC:

-

Alternating current

- ACHR:

-

Active compensation-based harmonic reduction technique

- APD:

-

Active power decoupling

- ASMC:

-

Adaptive sliding mode control

- BMS:

-

Battery management system

- CC:

-

Constant current

- CCCV:

-

Constant current constant voltage

- CP:

-

Constant power

- CPCV:

-

Constant power constant voltage

- CV:

-

Constant voltage

- DC:

-

Direct current

- DSO:

-

Distribution system operators

- EV:

-

Electric vehicles

- EVB:

-

Electric vehicle battery

- EVCS:

-

EV charging station

- EVSE:

-

Electric vehicle supply equipment

- G2V:

-

Grid-to-vehicle

- GA:

-

Genetic algorithm

- HEV:

-

Hybrid EV

- Li ion:

-

Lithium ion

- LV:

-

Low voltage

- MSS:

-

Maximum sensitivity selection

- MV:

-

Medium-voltage

- NCA:

-

Nickel-Cobalt-Aluminum

- NiMh:

-

Nickel-Metal Hydride

- OBIEV:

-

On-board Integrated Electric Vehicle

- PF:

-

Power factor

- PFC:

-

Power factor correction

- PQ:

-

Power quality

- PR:

-

Propulsion

- PWM:

-

Pulse-width modulation

- RES:

-

Renewable energy source

- SOC:

-

State of charge

- SOH:

-

State of health

- SSC:

-

Switched shunt capacitors

- SST:

-

Solid state transformer

- THD:

-

Total harmonic distortion

- UPF:

-

Unity power factor

- V2G:

-

Vehicle-to-grid

References

Wang, L., Qin, Z., Slangen, T., Bauer, P. & Van Wijk, T. Grid impact of electric vehicle fast charging stations: trends, standards, issues and mitigation measures—an overview. IEEE Open. J. Power Electron. 2, 56–74 (2021).

Affolabi, L. et al. DSO market for transactive scheduling of electric vehicle charging stations in constrained hierarchical power distribution and urban transportation networks. IEEE Trans. Transp. Electrification. 10 (1), 1788–1801 (2023).

Hussain, M. T., Sulaiman, N. B., Hussain, M. S. & Jabir, M. Optimal management strategies to solve issues of grid having electric vehicles (EV): A review. J. Energy Storage. 33, 102114 (2021).

Alame, D., Azzouz, M. & Kar, N. Assessing and mitigating impacts of electric vehicle harmonic currents on distribution systems. Energies 13 (12), 3257 (2020).

Kazemtarghi, A., Chandwani, A., Ishraq, N. & Mallik, A. Active compensation-based harmonic reduction technique to mitigate power quality impacts of EV charging systems. IEEE Trans. Trans- Portation Electrification. 9 (1), 1629–1640 (2022).

Ruan, H., He, H., Wei, Z., Quan, Z. & Li, Y. State of health Estimation of lithium-ion battery based on constant-voltage charging reconstruction. IEEE J. Emerg. Sel. Top. Power Electron. 11 (4), 4393–4402 (2021).

Foskolos, G. & Lundenga˚rd, K. The impact of aggregation interval on current harmonic simu- lation of aggregated electric vehicle loads. In 2020 19th International Conference on Harmonics and Quality of Power (ICHQP) (pp. 1–6). IEEE. (2020), July.

Megha, A., Mahendran, N. & Elizabeth, R. Analysis of harmonic contamination in electrical grid due to electric vehicle charging. In 2020 Third International Conference on Smart Systems and Inventive Technology (ICSSIT) (pp. 608–614). IEEE. (2020), August.

Amamra, S. A., Tripathy, Y., Barai, A., Moore, A. D. & Marco, J. Electric vehicle battery perfor- Mance investigation based on real world current harmonics. Energies 13 (2), 489 (2020).

Nour, M., Chaves-A´ vila, J. P., Magdy, G. & Sa´nchez-Miralles, A. Review of positive and negative impacts of electric vehicles charging on electric power systems. Energies 13 (18), 4675 (2020).

Gupta, J., Maurya, R. & Arya, S. R. Improved power quality on-board integrated charger with reduced switching stress. IEEE Trans. Power Electron. 35 (10), 10810–10820 (2020).

Iqbal, M. N., Ku¨tt, L., Daniel, K., Asad, B., Ghahfarokhi, S. & P Estimation of harmonic emission of electric vehicles and their impact on low voltage residential network. Sustainability 13 (15), 8551 (2021).

Grasel, B., Baptista, J. & Tragner, M. Supraharmonic and harmonic emissions of a bi-directional V2G electric vehicle charging station and their impact to the grid impedance. Energies 15 (8), 2920 (2022).

Villuri, R. T., Singh, M. & Beck, Y. Experimental analysis of electric vehicle’s Li-ion battery with constant pulse and constant voltage charging method. Int. J. Energy Res. 46 (15), 22365–22385 (2022).

Basta, B. & Morsi, W. G. Low and high order harmonic distortion in the presence of fast charging stations. Int. J. Electr. Power Energy Syst. 126, 106557 (2021).

Makeen, P., Ghali, H. A. & Memon, S. A review of various fast charging power and thermal protocols for electric vehicles represented by lithium-ion battery systems. Future Transp. 2 (1), 15 (2022).

Srivastava, A., Manas, M. & Dubey, R. K. Electric vehicle integration’s impacts on power quality in distribution network and associated mitigation measures: A review. J. Eng. Appl. Sci. 70 (1), 32 (2023).

Gupta, J., Maurya, R. & Arya, S. R. On-board electric vehicle battery charger with improved power quality and reduced switching stress. IET Power Electron. 13 (13), 2885–2894 (2020).

Rajawat, S. P., Moorthi, S., Soni, L. & Jain, S. A Multivariable Function Based Optimised Charging Algorithm for Electric Vehicle Battery Management Systems (No. 2024-28-0228). SAE Technical Paper. (2024).

Koli, A., Mundotiya, P., Tiwari, H. & Dave, V. An improved cccv controlled charging technique for electric vehicles. In 2023 International Conference on Computer, Electronics & Electrical Engineering & their Applications (IC2E3) (pp. 1–5). IEEE. (2023), June.

Venkat, K. S., Chandra, M. S. S. & Mohapatro, S. Pulse charging scheme for multiple battery charging in electric vehicle applications. In 2023 IEEE 3rd International Conference on Smart Technologies for Power, Energy and Control (STPEC) (pp. 1–6). IEEE. (2023), December.

Parichha, P., Parida, J. K., Chaudhary, M. & Namrata, K. On-Board EV Charging with Switched Mode Rectifier-Based Bidirectional Converter in CC-CV Mode. In Smart Energy and Advancement in Power Technologies: Select Proceedings of ICSEAPT 2021, Volume 2 (pp. 375–385). Singapore: Springer Nature Singapore. (2022).

Karneddi, H. & Ronanki, D. Reconfigurable battery charger with a wide voltage range for universal electric vehicle charging applications. IEEE Trans. Power Electronics (2023).

Jaman, S., Abdel-Monem, M., Geury, T. & Hegazy, O. Development and validation of an integrated EV charging station with grid interfacing inverter for residential application. IEEE Access (2023).

Gonzalez, M. et al. Vehicle- to-grid charging control strategy aimed at minimizing harmonic disturbances. Int. J. Energy Res. 45 (11), 16478–16488 (2021).

Mishra, D., Singh, B. & Panigrahi, B. K. Bi-directional EV charging with robust power controlled adaptive phase-shift algorithm. IEEE Trans. Veh. Technol. 72 (12), 15491–15501 (2023).

Shanmugam, Y. et al. Solar-powered five-leg inverter-driven quasi-dynamic charging for a slow-moving vehicle. Front. Energy Res. 11, 1115262 (2023).

Abraham, D. et al. Fuzzy-based efficient control of DC microgrid configuration for PV-energized EV charging station. Energies 16.6 : 2753. (2023).

Ravindran, M. et al. A novel technological review on fast charging infrastructure for electrical vehicles: challenges, solutions, and future research directions. Alexandria Eng. J. 82, 260–290 (2023).

Feng, J., Yao, Y. & Liu, Z. Developing an optimal Building strategy for electric vehicle charging stations: automaker role. Environment Dev. Sustainability : 1–61. (2024).

Li, P., Jiang, M. & Zhang, Y. Cooperative optimization of bus service and charging schedules for a fast-charging battery electric bus network. IEEE Trans. Intell. Transp. Syst. 24 (5), 5362–5375 (2023).

Kumar, B. et al. A novel strategy towards efficient and reliable electric vehicle charging for the realisation of a true sustainable transportation landscape. Sci. Rep. 14 (1), 3261 (2024).

Kumar, B. et al. Hybrid genetic algorithm-simulated annealing based electric vehicle charging station placement for optimizing distribution network resilience. Sci. Rep. 14 (1), 7637 (2024).

Sabyasachi, S. et al. Reimagining E-mobility: A holistic business model for the electric vehicle charging ecosystem. Alexandria Eng. J. 93, 236–258 (2024).

Ramakrishnan, V. et al. Design and implementation of a high misalignment-tolerance wireless charger for an electric vehicle with control of the constant current/voltage charging. Sci. Rep. 14 (1), 13165 (2024).

Cui, D. et al. Coordinated charging scheme for electric vehicle Fast-Charging station with Demand-based priority. IEEE Trans. Transp. Electrification (2023).

Al-Alwash, H. M. et al. Optimization schedule schemes for charging electric vehicles: overview, challenges, and solutions. IEEE Access (2024).

Singh, A. R. et al. Electric vehicle charging technologies, infrastructure expansion, grid integration strategies, and their role in promoting sustainable e-mobility. Alexandria Eng. J. 105, 300–330 (2024).

Salam, S. S. et al. Charge scheduling optimization of electric vehicles: A comprehensive review of essentiality, perspectives, techniques and security. IEEE Access (2024).

Kumar, B. et al. Enhancing EV charging predictions: a comprehensive analysis using K-nearest neighbours and ensemble stack generalization. Multiscale Multidisciplinary Model. Experiments Design : 1–27. (2024).

Varghese, S., Susan, S. Q., Ali & Joos, G. Energy management of fast charging and ultra fast charging stations with distributed energy resources. IEEE Access (2024).