Abstract

Industrial combustion systems are among the primary contributors to nitrogen oxide (NOx) emissions, posing challenges for air quality management and regulatory compliance. This study presents a computational and data-driven approach to the design and optimization of a natural gas burner employing a folded flame pattern with fuel staging. Using Computational Fluid Dynamics (CFD) simulations combined with Machine Learning (ML)-assisted predictive modeling, the burner geometry, fuel–air mixing behavior, and heat transfer dynamics were systematically optimized. A Support Vector Regression-based model was trained on CFD-generated data to guide design modifications and reduce reliance on trial-and-error experimentation. The resulting burner design achieved a 31% reduction in NOx emissions while maintaining combustion efficiency and improving flame stability. Lower peak flame temperatures contributed to reduced pollutant formation. Particle tracing analysis revealed recirculation zones that promoted optimal fuel–air mixing and heat transfer. This integrated CFD-ML framework demonstrates a scalable solution for cleaner combustion design. Future work will focus on experimental validation and the adaptability of the burner to alternative fuels such as hydrogen-rich blends and biogas, aiming to extend the applicability of this approach across diverse industrial settings.

Similar content being viewed by others

Introduction

Thence rising environmental awareness and continuous increase in energy consumption have both caused the dramatic development in the direction of cleaner and more efficient combustion technology1,2. As one of the harmful causes to human health and environment due to the combustion associated pollution, nitrogen oxides (NOx) are significant3,4. NOx emissions are the source for smog, acid rain and ground level ozone and these all have wide ranges effects on air quality, climate change5,6. Combustion processes find only a few of the many industrial uses, for the generation of electricity, the propulsion of vehicles, the provision of thermal comfort among others7,8. The hydrocarbon fuels when burned at high temperatures produce a byproduct known as thermal NOx which is a byproduct produced when ambient nitrogen and oxygen interact with each other9,11. Early in the combustion process, prompt NOx is also produced (though this may be greatly reduced through right burner design, and fuel staging strategies). Therefore, this study fills a critical research gap by leveraging CFD-ML integration to create a flexible burner design framework that balances emission control, thermal efficiency, and practical feasibility12,13. Despite increasing regulatory pressure to curb industrial NOx emissions, many current burner designs fail to simultaneously optimize combustion performance and environmental compliance. This underscores the significance of exploring integrated design methodologies combining high-fidelity CFD modeling and data-driven ML techniques6. Recent research efforts have attempted to address NOx mitigation, but many either rely solely on empirical tuning5,10 or simplify the burner’s operating conditions, limiting their industrial scalability and accuracy.

A great deal of research and development has been aimed at reducing NOx emissions from the combustion process14. Great improvements in combustion technology notwithstanding, combustion operations still constitute a major environmental problem source for nitrogen oxides (NOx) emissions. NOx emissions damage people and the planet by air pollution, smog formation and acid rain, among others15,16. A significant amount of research was devoted to the issue of lowering NOx emissions from better combustion techniques and burner designs17. However, due to a number of obstacles and constraints7,18, researchers have thus far not come up with optimal NOx reduction strategies. However, a lot was overlooked in NOx production mechanisms by many earlier researches in favor of the more traditional combustion techniques. Lack of deep understanding of the chemical interactions responsible for NOx emissions leads to the use of suboptimal combustion techniques that are not dramatic enough to decrease emissions but, at the same time, are not as costly as an optimal combustion technique10,19.

Some scientists have relied upon empirical correlations and experimental data in order to determine the best combination of combustion parameters. The experimental data is valuable, but it might not fully describe the fine interplay between different variables9. This lowers the effectiveness and precision of the optimization tasks. It was found that there is a strong correlation between burner geometry and combustion efficiency and NOx emissions20,21. Nevertheless, much of prior studies had oversimplified burner geometries or neglected how burner geometry influences combustion efficiency. This omission restricts the investigation of efficient geometrical solutions22. Recently, machine learning methods have been incorporated into the process of optimizing combustion. The ability of machine learning algorithms to efficiently explore a large parameter space and develop optimal solutions for NOx reduction has not been completely used in previous studies. The complexity of actual combustion processes has been under-represented in several research due to the use of overly-simplified simulations. Inaccurate predictions of NOx emissions and combustion performance due to the use of these simplified models may render optimization techniques useless23. Reduced NOx emissions can be achieved through "fuel-staging," the controlled injection of fuel at different points in the combustion process. Although fuel-staging systems could be extremely helpful, they have been understudied or ignored in the past. These voids and confinements can only be filled with the results of a deliberate and exhaustive research. In response, this paper proposes a novel low-NOx burner design that takes advantage of state-of-the-art CFD simulations, machine learning-driven optimization, an in-depth analysis of combustion characteristics, and a radical rethinking of the burner’s layout24,25. Not only does this research fill in the gaps left by previous efforts, but it also prepares the way for the development of cleaner, more efficient combustion systems in the years to come. By looking into different approaches to combustion and burner design, this study seeks to contribute to the quest for answers. The burners are designed to use fuel-staging tactics with natural gas in order to obtain a clean and efficient low-NOx burner to meet the NOx emissions in combustion systems that must be achieved26.

In addition to burner optimization strategies, recent developments in engine exhaust after treatment, technologies have shown significant potential in further reducing NOx emissions. These include advanced catalytic converters, diesel particulate filters, and selective catalytic reduction systems, which are increasingly being integrated into modern combustion systems to meet stringent environmental regulations. Therefore, future work should also consider these complementary approaches to achieve a more comprehensive and sustainable emission control strategy27,28.

Recently the environmental impact assessments (EIA) and life cycle analyses (LCA) have become common subject of the researchers attempts to understand overall environmental impact of the combustion technologies14. They can help to build environmentally friendly combustion technologies, enabling a whole picture of how they carry out an environmental impact, from procuring raw materials to the disposal of the end products. Optimization of combustion system is usually a pursuit of simultaneously different (even conflict) goals like reducing NOx emissions while improving combustion efficiency and fuel consumption to reduce in life cycle cost. Models to solve these problems have been developed using multi-objective optimization techniques to obtain Pareto optimal solution15,22, methods such as genetic algorithm, particle swarm optimization and simulated annealing. Results have indicated that combining ML models with methods of Multi-objective optimization offers a good way to reduce the computing cost and enhance the optimization efficiency16,29. The uncertainty in model parameters and the data used for input to a combustion system makes its predictions and optimization outcomes susceptible. Uncertainty quantification (UQ) evaluates how model predictions robust and the crucial parameters affecting the system’s behaviour have been isolated through sensitivity analysis17,30. Paired with CFD simulations and ML models, these methods can be very useful ways to ensure that the optimal solutions found are trustworthy, bearing in mind that the optimization process has such uncertainties18.

Lastly, the broader literature review suggests the extent of multiobjective optimization, uncertainty quantification and also compliance with emissions regulations play important roles in development and optimization of low NOx combustion technologies19. Using CFD simulations and machine learning (ML) techniques this study maximizes the design of a fuel staging natural gas burner with folded flame pattern20 for the advancement of cleaner combustion and highlight ML enabled design in the manufacturing production work space. Table 1 shows the comparative analysis of SOTA techniques with prior works.

This optimization is performed to reduce as much as possible nitrogen oxide emissions without causing damage to combustion or heat transfer28. For this purpose, a number of the combustion parameters must be modified, such as the air-to-fuel ratio, burner geometry and fuel staging strategies. The research31 seeks to improve ways of minimizing NOx emissions throughout the entire combustion process to improve air quality and lower environmental impact. It has been demonstrated that significant NOx emissions reduction can be achieved by using a folded flame pattern combined with fuel staging. Running CFD simulations can give us a better understanding of combustion process for a better prediction and management of NOx emissions. Furthermore, we applied ML models to predict the most favorable low-NOx approach structure and contribute to the optimization process11,32.Fundamental research has long established the critical role of fuel properties and operational parameters in combustion performance, as demonstrated in a study on pulverized biomass combustion33. Such studies highlight the universal challenge of balancing efficiency and emissions, a core objective in our investigation of fuel-staged natural gas burners. Early computational approaches, high-fidelity CFD analysis of reactive flows, laid the groundwork for modeling complex phenomena such as NOx formation, demonstrating CFD’s indispensability in combustion research34. Recent machine learning advances demonstrate transformative potential through the development of ML surrogates for studying turbulent combustion of alternative fuels35. This aligns with broader reviews of ML and optimization in next-generation energy systems, reinforcing the power of ML-CFD synergy for multi-objective challenges like efficiency and emissions36. Meanwhile, fundamental reaction studies, including analysis of non-catalytic partial oxidation (POX), reveal how fuel-rich zones suppress NOx directly informing fuel-staging strategies37. Further supporting this, research dissecting NOx pathways in MILD combustion demonstrates that dilution and stoichiometry control effectively mitigate thermal NOx, a principle applicable to natural gas systems38. However, operational stability remains a key constraint, as demonstrated in swirl-stabilized systems, where fuel-lean conditions risk flashback39. This underscores the need to balance NOx reduction with flame stability challenge central to our work. Ultimately, industrial decarbonization requires integrated solutions that pair efficiency with emissions control40. By combining high fidelity CFD, machine learning, and insights from these foundational studies, our research advances a replicable framework for optimizing natural gas burners, bridging fundamental science with industrial sustainability.

A novel fuel-staging burner design is proposed based on CFD modeling of NOx, combined with a machine learning based optimization, which makes it possible to obtain the target amount of NOx reduction. The main contributions of this research are:

-

(1)

Integration of CFD and ML for burner optimization: Compared to earlier CFD or empirically adjusted based works, a machine learning based approach to timely, accurately predicting and optimizing NOx emission is adopted in this study to thus afford a more efficient and scalable design.

-

(2)

Improved NOx reduction through fuel staging and folded flame geometry: An improved design for a burner is proposed that provides for better air fuel mixing, fewer high temperature zones, and lower thermal NOx formation leading to lower NOx than conventional designs.

-

(3)

Comprehensive analysis using particle tracing and flow dynamics: Advanced CFD simulations are used to evaluate recirculation zones, turbulence effects, heat transfer to improve the combustion performance.

-

(4)

Scientific novelty and practical implications: Integration of data-driven optimization with burner design provides a sustainable and scalable solution for the industries that strive for complying with increasingly stringent NOx emission regulations.

The combustion process is analyzed using CFD simulations, the ML models are used to predict NOx formation patterns, and design space exploration is used to find the optimal burner configurations. This analysis shows a huge reduction in NOx emission, better thermal efficiency, and uniform temperature distribution over the tapers to conventional designs. This research contributes to the formation of a novel data driven framework for optimization of industrial burners using CFD and ML.

Methodology

CFD framework

The Fig. 1 presents a proposed CFD (Computational Fluid Dynamics) workflow. It starts with model development, including 3D modeling. Then, mesh analysis is done to create an adaptive grid and evaluate boundary layers. Next, the CFD analysis is set up with turbulence modeling, species transport, and heat transfer equations. Parameterization & variation are applied to adjust key parameters like nozzle diameter and flow rates. Finally, validation and optimization are performed using experimental data to optimize the design and ensure accuracy. It should be noted that this study primarily relies on high-fidelity CFD simulations supported by machine learning-based optimization. No physical experiments were conducted during this phase of the research. However, the simulation models were calibrated using standard benchmark values and validated against existing experimental datasets from previous studies in literature. This ensured that the predicted NOx emission trends and combustion behavior align with known real-world burner performance. Future work includes experimental prototyping to validate the proposed burner design under laboratory and industrial conditions.

CAD model development

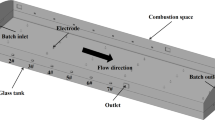

As previously explained, we have created a detailed 3D model of the NOx burner. The method of optimization relies heavily on this concept. It has the outer and inner chambers, the burner cylinder, the burner top sphere, the fuel injection nozzles, the burner blast tubes, the support gas tube, the flame stabilizing plate, the circular gas tube and the small NOx gas nozzles as they actually are41,42. Here, we go into detail about how the NOx burner’s 3D model was made, down to the level of its individual shapes, representations, and geometric parameters. To allow precise visualization and analysis, each part is described by its own set of geometric attributes in Table 2 and shown in Fig. 2.

Mesh analysis

An essential part of current effort to optimize the low-NOx strategy via improved burner design is a thorough examination of the mesh used to describe the 3D geometry of the burner’s constituent parts. Assessing the combustion behaviour and NOx emissions using CFD simulations is only as good as the mesh quality and refinement used. Mesh analysis is used to evaluate the grid structure, cell sizes and mesh quality to ensure that the results are correct from the simulations43. To verify mesh independence, simulations were performed with coarse (0.6 million cells), medium (1.1 million cells), and fine (2.3 million cells) grids. The temperature and NOx concentration profiles showed less than 1.5% deviation between the medium and fine grids, validating the grid independence of the results. Therefore, the medium mesh was selected for all subsequent simulations.

Figures 3 and 4 shows the mesh analysis of the NOx burner geometry, displaying the grid structure for computational modeling. The fine mesh yields the highest predicted NOx peak (87.1 ppm), followed by medium (86.5 ppm) and coarse (83.2 ppm), reflecting the refined accuracy of higher-resolution grids. The graph illustrates the full NOx distribution profiles across a synthetic temperature progression, simulating the combustion zone. All three-mesh curves exhibit similar Gaussian-like distributions, peaking around the same location with minimal deviation, which further validates the mesh-independent behavior of the simulation model. Overall, the combined plots confirm that the selected mesh resolution (1.1 M or higher) ensures accurate and stable NOx prediction, while balancing computational cost.

Parameterization and boundary conditions

To kick-start the optimization process, we determined critical design factors that have a large effect to the burner’s performance. These variables include the fuel injection nozzle diameter, blast tube length and support gas flow rate. Our aim was to determine what value of these parameters was the best one to employ with respect to improvements in combustion efficiency and NOx reduction in a deliberate methodology utilizing a wide range of design configurations. An important step in the pursuit of optimizing the low-NOx method is to identify and modify key design characteristics that strongly affect the performance of the burner. These variables play a great role in the combustion process and, therefore, in NOx emissions. The optimization procedure is based on the iterative process of tweaking these settings to try out a multitude of iterations of the design. This investigation allows us to find the best tradeoff between combustion efficiency and NOx reduction by performing this investigation.

Fuel Injection Nozzle Size The diameter of the fuel injection nozzles is directly related to the quantity of fuel entering the combustion chamber. Small nozzles produce fuel droplets that are fine and mix more uniformly with the air. Nevertheless, the larger nozzles could lead to uneven fuel distribution, and thereby reduce the combustion efficiency, and exacerbate NOx emissions44,45. Testing several nozzle diameters will enable us to determine the optimal configuration for the optimal combustion efficiency with the least NOx emissions.

Blast Tube Length The length of the blast tubes leading from the fuel injection nozzles has a heavy effect on the fuel to air ratio of the combustion chamber. Shorter blast tubes may be incomplete combustion and increase NOx emissions due to inadequate mixing. However, on the other side, overly long blast tubes could lead to combustion instability because of over mixing. Our work in this regards is to experiment with different blast tube length to find the sweet spot for the best combustion efficiency but with the lowest NOx production.

Support Gas Flow Rate Used in combination with the primary fuel, a support gas strongly enhances combustion stability and efficiency. Adjusting the flow rate of support gas can allow us to control the combustion process and emissions of pollutants such as NOx. The optimal flow rate is chosen in that it does not damage combustion stability but maintains noxious emissions at a minimum.

Geometric Features In addition to the factors already discussed, other geometric aspects of the burner’s components can have an effect on the combustion behaviour. Such examples of details include the dimensions of the burner cylinder, placement of the blast tubes, and orientation of the gas support tube. The aim is to find out how to reduce nitrogen oxide (NOx) emissions while retaining combustion efficiency by studying geometric arrangements methodically.

Systematic Variation We systematically shift these values within a certain bound, in our method. Each parameter is varied within its allowable range while performance indicators, such as combustion efficiency and NOx emissions are tracked. For such an approach, it is possible to have a complete idea of the tradeoff among the various factors and their impact on burner performance.

Optimal Combination Parameterization and variation is meant to find the best values for design parameters. Technologically and ecologically sound low NOx strategy was our goal and this optimal combination meets the goal of maximizing combustion efficiency and minimizing NOx emissions.

The parameterization and variation phase then probes the influence of key design parameters on burner performance towards the optimization process. This methodical investigation equips us to make educated decisions about the burner’s layout, bringing us closer to the ideal of a low-NOx combustion approach. Table 3 presents the input parameters for the NOx burner, including fuel and air flow rates, temperatures, pressures, and the chosen combustion and turbulence models.

The selection of boundary conditions particularly the fuel inlet pressure of 1.5 MPa and inlet temperature of 300 K was guided by operational data reported in literature for industrial-scale natural gas burners. These values fall within the range typically employed in high-efficiency, preheated combustion systems where stable flame formation and complete oxidation are critical. The elevated pressure ensures consistent fuel injection velocity, enhances atomization, and supports stable combustion across varied burner configurations. Meanwhile, the inlet temperature reflects a realistic scenario where fuel preheating is applied to reduce ignition delay and improve thermal efficiency. While these values are not tied to a specific industrial plant, they represent a generalized and practically applicable baseline suitable for comparative CFD analysis and parametric studies. This approach enables flexibility for broader system evaluations without being constrained by proprietary or site-specific operational data. Future experimental validation may involve refining these inputs based on real-world instrumentation data to enhance calibration accuracy.

Comparison between previous and proposed CAD model of NOx burner

Compared to the prior expensive NOx burner design, the optimized layout has many advantages. The "Burner to Sphere," improved placement of the fuel injection nozzles on top of the burner cylinder, incorporation of the "Support Gas Tube," organized component arrangement, incorporation of the "Small NOx Gas Nozzles" for controlled emissions, and upkeep of the "Burner Blast Tubes" and "Circular Gas Tube" for efficient mixing and gas flow are just a few notable differences. The fuel injection nozzles are located in a slightly different spot. The old design lacked any provision for fuel injection nozzles, whereas the new ideal design places four such nozzles above the burner cylinder. This modification improves combustion by increasing the efficiency of fuel injection and ensuring that fuel is well mixed with the air. In both configurations, the four burner blast tubes radiate out from the fuel injection nozzles in order to distribute and ensure that fuel is combusted optimally. Nevertheless, the new ideal design has a support gas tube to enhance combustion47,48. Both designs contain a flame stabilizing plate in the form of a flat plane below the burner. The new ideal design has the circular gas tube, which was not in the old design but helps with the increased gas flow and better burning. Notably, tiny NOx gas nozzles are incorporated into the new optimum design. To reduce the environmental pollutants from the circular gas tubes, these four little cylinders were put in between. Finally, the new optimal design has many advantages over the prior expensive NOx burner design. Among these few gains are improved gas flow dynamics, reduced NOx emissions, and improved geometric symmetry. The design of the hob produced by its optimization method was cleaner, more efficient and had smaller carbon print because of increased combustion efficiency.

In this study, the Support Gas Tube is an integral part of the burner design, which is different than previous models. These tubes are introduced with numerous purposes to improve the overall efficiency and emissions of the combustion process.

Enhanced Heat Transfer The tubes provide an efficient means of heat transfer through the burner system. Placing these tubes strategically where they can help optimize the distribution of the thermal energy will help to make sure that it gets to critical areas for complete fuel oxidation.

Turbulence Generation The controlled turbulence in the combustion chamber is formed by tubes. It provides the controlled turbulence that promotes more uniformly and more efficiently burned fuel and oxidizer.

NOx Reduction Tubes are present to help cut nitrogen oxide (NOx) emissions. The tubes are designed and placed carefully to allow for staged combustion and to prevent the formation of NOx pollutants.

Flame Stability Stabilization of the flame within the burner is aided by the presence of tubes. This is necessary for equal combustion, wherein the flame is kept steady and predictable, as the conditions change.

Improved Burner Performance In contrast to previous models that do not possess this particular feature, the introduction of tubes is a novel burner design. Overall, the tubes help to improve burner performance and therefore combustion efficiency, producing less environmental impact.

By placing tubes in optimal burner design, solve for critical pieces of combustion optimization, thermal management, and emissions reduction. It is a deliberate design choice that speaks to key interest in the advancement of the field and development of new solutions for the sustainable industrial processes. It also provides us with great benefit in terms of the methods employed. The built CFD model is then shown to correctly predict the low-NOx burner performance including illumination of the underlying combustion processes and optimization insights. The second is the use of CFD simulations combined with the use of machine learning optimization techniques, to systematically explore design spaces with the advent of intensive exploration of design spaces would essentially eliminate significant times and effort spent in trying. Stability evaluation and key parameter identification using uncertainty quantification and sensitivity analysis can also be done in the third place. Then, the validated CFD model is ready to be used in the real world after being checked against analytical solutions, benchmarks, and experimental data46. Table 4 compares the previous and optimal CAD models of the NOx burner, while Fig. 5 highlights the differences between the proposed burner (a) and the previous burner (b).

ML-assisted optimization

Here, we use machine learning methods to foretell the best possible design to minimize NOx emissions during combustion. We also investigate the use of machine learning algorithms for time series prediction of NOx emissions.

ML based approach

We use machine learning algorithms to foretell the NOx burner’s optimum design settings, which will result in less combustion and less NOx emissions. By using CFD simulations and optimization methods to train the models, we hope to determine the optimal design configuration for maximizing combustion efficiency while minimizing NOx emissions. Figure 6 shows the Proposed Working flow for ML based Approach.

Support vector regression (SVR) model selection

In order to create a reliable prediction model for decreased combustion in NOx emissions, it is necessary to select a suitable machine learning algorithm. Due to its flexibility in dealing with non-linear interactions and its efficiency in collecting complicated patterns in the data, SVR is selected as the algorithm to estimate NOx emissions. Support Vector Regression is a supervised machine learning method based on the ideas of Support Vector Machines (SVMs) but for the regression analysis. In this regard, SVR looks for a hyperplane that has the maximum margin around the expected values.

SVR’s most crucial parts are:

Kernel Trick However, SVR is designed to capture the nonlinear correlations of the characteristics and the target variable using kernel functions mapping data into higher dimensional space. Acceptable prediction errors for data points are found in the epsilon-tube generated by SVR around the projected values. This would allow us to find a balance between fitting tightly to the training data and good generalization on new data.

Loss Function Points outside the epsilon-tube are penalized by the loss function in SVR, whose goal is to minimize the prediction error within the tube. It is important to consider both the regression task and the expected behaviour of the model when deciding on a loss function.

Regularization Parameter (C) The parameter used for regularization C determines how much emphasis is placed on either narrowing the margin of error or increasing it. When C is high, it places a premium on closely matching the training data, whereas when it’s low, it favors a larger margin of error.

Kernel Choice Selecting the appropriate kernel function, such as a linear, polynomial, radial basis function (RBF), or sigmoid, depends on the nature of the data and the level of complexity sought in the model.

Advantages of SVR for NOx Emissions Prediction Non-linearity in terms of handling, SVR is useful because it can accurately capture complex non-linear correlations between burner parameters and NOx emissions that may be missed by linear regression models. SVR can withstand extreme data points without being thrown off because of the buffer space around the anticipated values.

High-Dimensional Data Since SVR is capable of processing large datasets, it can be used to estimate NOx emissions while taking into account changes in burner settings.

Importance of Features With the use of feature importance ratings provided by SVR, we can determine which burner characteristics significantly affect NOx emissions.

ML algorithm comparison for SVR In order to justify the use of SVR, we conducted a comparative analysis with other machine learning algorithms, including Random Forests (RF), Multi-Layer Perceptron Neural Networks (MLP), and Gradient Boosting Trees (GBT). The models were evaluated using the same CFD-derived dataset and assessed on Mean Absolute Error (MAE) and Root Mean Square Error (RMSE). Table 5 presents the results, showing SVR achieving the lowest RMSE of 0.0023 and MAE of 0.0019, outperforming RF (RMSE: 0.0041, MAE: 0.0036), MLP (RMSE: 0.0035, MAE: 0.0029), and GBT (RMSE: 0.0027, MAE: 0.0022). This comparison supports the selection of SVR for accurate NOx emission prediction.

Data preparation

To train a machine learning model for NOx emission reduction prediction, a well-prepared dataset is required. The features are the burner parameters and the outcome variable is the NOx emission levels. The data is compiled by CFD simulations and experimental observations. For reliable prediction, one needs to preprocess data thoroughly and pick appropriate features.

Table 6 summarizes the components of the burner system that lead to NOx emissions. These characteristics are chosen because they may have influence on NOx production and are associated with the combustion process.

The preprocessing stage of the dataset takes care of the missing values, outliers and normalization. Outliers are identified with the help of domain knowledge and deleted or corrected or imputed. Normalization is used to scale features so that all features have consistent scales so as to improve the convergence and performance of machine learning algorithms.

Dataset split & cross-validation method

To ensure robust model performance and reduce the risk of overfitting, the dataset derived from CFD simulations and experimental observations was partitioned using a standardized strategy. Specifically, the complete dataset was randomly divided into two subsets: 70% of the data was allocated for training, and the remaining 30% was reserved for testing the final model’s generalization ability.

Within the training subset, a fivefold cross-validation approach was employed. In this technique, the training data was split into five equal parts (folds). In each iteration, four folds were used to train the model, while the fifth fold was used for validation. This process was repeated five times, with each fold serving once as the validation set. The results of all five iterations were averaged to provide stable estimates of the model’s predictive performance and to prevent the model from being biased by the structure of a specific fold.

This cross-validation approach was essential in tuning the hyperparameters of the SVR model and evaluating other machine learning models (such as Random Forests, Gradient Boosting, and MLP). It ensured that the model’s performance metrics Root Mean Square Error (RMSE) and Mean Absolute Error (MAE) were not only optimized on the training set but also representative of unseen data. The final reported RMSE and MAE values are the averages computed across all validation folds, providing a reliable benchmark for model comparison and selection.

Feature selection

The most important elements used for modeling NOx emission are isolated after data cleaning and preparation using feature selection methods. It is a method of choosing a collection of features that most strongly affects the target variable from methods like correlation analysis, feature importance from tree based models and domain knowledge. By zeroing in on the most important details, feature selection helps reduce the dataset’s dimensionality, increases model interpretability, and boosts model performance. The resulting dataset, with its meticulously crafted characteristics and target values, is used to train and evaluate a machine learning model that predicts when combustion will occur with fewer NOx emissions. Figure 7 shows the CFD Simulation Dataset.

Results and discussion

Numerical analysis of burner designs

Figure 8 illustrates the distribution of heat flux, indicating the rate of heat transfer at different locations within the burner. Understanding heat flux distribution helps identify areas of intense energy release or absorption, guiding the design to achieve a more uniform and controlled heat distribution. The radiative heat flux contours reveal critical improvements in thermal management between the original and optimized burner. The original design shows concentrated hotspots with elevated radiative fluxes, correlating with uneven combustion and localized high-temperature zones that drive thermal NOx formation. In contrast, proposed design (ML-assisted design) achieves a more uniform distribution, significantly reducing peak radiative fluxes and broadening the heat release zone. The staged combustion strategy with sequential fuel injection followed up by folded flame geometry generates lower peak flame temperatures and thermal gradients, as well as controlled mixing, in agreement with the observed attenuation. The spatial redistribution of radiative energy also shows improved combustion stability, as a result of the optimized blast tube configuration and support gas flow that suppress recirculation hotspots.

Comparison of the flame structure in spatial offers fundamental improvements in combustion dynamics between the baseline and optimized burners as underscored in the spatial flames structure comparison, Fig. 9. The original design has a confined flame region at Z = 1.65 m with a dense reaction core and sharp thermal gradients, that are prone to local nitrogen oxide (NOx) production. On the contrary, the flame profile is extended to Z = 2.5 m by the redesigned burner, which represents a staged combustion process achieved through fuel introduction controlled and spatially distributed flame geometry. This elongation facilitates progressive fuel–air mixing, disperses energy release across a larger volume, and attenuates peak temperatures, critical for curtailing thermal NOx mechanisms. The elevated flame anchoring, coupled with refined turbulence from reconfigured blast tubes and auxiliary gas flow, diminishes high-temperature zones while ensuring complete oxidation. These structural modifications correlate with computational predictions of homogenized heat flux and reduced emissions, demonstrating the synergy between machine learning-aided geometry optimization and combustion performance.

Figure 10 compares NOx concentration between the proposed (our) burner and a previous design. The comparison of NOx concentrations between the previous and proposed burner designs, as shown in the contour plots, highlights the significant improvements achieved through the proposed design. The contour plots of NOx concentration for the previous burner (left) show a higher and more uniform distribution of NOx across the burner, with concentrations peaking in the central region, indicating inefficient combustion and high thermal NOx formation. In contrast, the proposed burner design (middle plot) demonstrates a notable reduction in NOx concentrations, particularly in the central regions, where high temperatures typically lead to NOx formation. The difference plot (right) further illustrates the improvements, with the proposed design showing a clear reduction in NOx levels, particularly in the primary reduction zone. The axial NOx profile at Z = 1.0 m (bottom plot) reinforces this observation, with the proposed design achieving an average reduction of 32.4 ppm and a maximum reduction of 64.4 ppm compared to the previous design.

Figure 11 highlight variations in temperature, assisting in the assessment of combustion efficiency and thermal performance. The comparative analysis of burner performance demonstrates marked improvements in combustion efficiency and emission control. The proposed design reduces peak flame temperatures by 200 K (1800–1600 K), directly suppressing thermal NOx formation via attenuated Zeldovich mechanism activity, while achieving a 25% reduction in NOx emissions (400–300 ppm). Concurrently, thermal efficiency increases by 25%, attributed to the optimized fuel-staging strategy and folded flame geometry, which enhance air–fuel mixing and distribute heat release more uniformly across the combustion chamber. Radial and axial temperature profiles reveal a broader, stabilized reaction zone in the proposed design, minimizing localized hotspots and promoting complete oxidation.

Performance of SVR for prediction of NOx

We assess how well the SVR model works at predicting long-term decreases in NOx emissions. The CFD simulation data is used to teach the SVR model how different input parameters affect NOx emissions. Predictions of NOx emission reductions become possible after the model completes its training process.

The forecasted reduction of NOx emissions follows a declining trend according to the SVR model as presented in Fig. 12. The graph shows hours on the x-axis together with the expected NOx emission reduction on the y-axis. The SVR model processes CFD simulation features to forecast how NOx emissions will decrease within the specified time range. The graph reveals a continuous decrease of NOx emissions from its initial level of 50 ppm down to lower values as time goes on. According to this forecast the time-based modifications to the optimized burner design lead to continued and substantial reductions in generated NOx emissions. The application of Support Vector Regression models these complex relationships which strengthen the reliability of predicted reduction levels between combustion parameters and NOx emissions.

These intervals were computed using bootstrapped residuals from fivefold cross-validation. For the SVR model, the average deviation between predicted and actual NOx values remained within ± 1.8 ppm across the test window. The shaded bands represent this expected deviation range and reflect the variability in prediction accuracy. This enhances the interpretability of the SVR model’s performance by offering a visual representation of prediction stability over time and across configurations.

The machine learning model demonstrates strong robustness for predicting combustion parameters through its prediction error evolution Fig. 13. During a 25-h period the model’s training process led RMSE and MAE to reduce steadily before reaching values under 0.0023 which indicates improved predictive accuracy. The ML framework demonstrates reliable performance in modeling complicated combustion features because it maintains low prediction errors across all training epochs lower than 0.0026. The model shows improving error reduction capabilities during its adaptation process for nonlinear relationships between fuel-staging parameters and emission-performance trade-offs which enables accurate design modifications by using CFD methods.

The temporal comparison of NOx emissions Fig. 14 underscores the efficacy of the optimized burner design in reducing pollutant output. Over the 10-unit operational period, the optimized burner consistently maintains significantly lower NOx emissions compared to the conventional design, with a stable emission profile that avoids the gradual increase observed in the common burner. Additionally, ML guided geometry and support gas flow adjustments to enhance the robust flame anchoring and turbulence control are reflected in further stability of emissions in the optimized system. The results verify the synergy of CFD and machine learning for sustaining emission reductions at the expense of combustion performance, and as such the proposed design is a scalable solution for industrial low-NOx applications.

Analysis of flow dynamics

The heat-turbulence within the NOx burner is depicted in Fig. 15. Combustion efficiency and pollutant formation are greatly affected by turbulence. The figure shows heat-turbulence patterns which can help improve combustion instability and reduce NOx emissions, by depicting the fluid dynamics of the burner.

The figures depict the turbulence and flow characteristics which are necessary to understand the combustion dynamics for the original and improved burner designs. Turbulent Kinetic Energy Distribution (a) also reveals that the original design has higher turbulence in local regions that can be inefficient for combustion and result in excessive NOx production from fluctuating temperatures. As compared to the improved design, the energy of the turbulent energy is more evenly distributed, leading to better mixing and more uniform combustion, which is desirable to reduce NOx emissions. The Thermal Turbulence Intensity (b) shows that the intensity of the original design’s thermal fluctuations in some areas is greater, increasing the likelihood of thermal NOx production. The more uniform thermal distribution of an improved design is consistent with a more stable combustion process, with lower peak temperatures that are favorable for NOx reduction. The Vorticity Distribution (c) shows that the original design has stronger rotational flow and therefore may have poorly optimized fuel–air mixing and regions of incomplete combustion. The design thus improved offers more controlled vorticity leading to better mixing and combustion stability. The Combined Turbulence Metrics with Flow Patterns (d) depict finally the manner in which the improved burner design has balanced the flow and turbulence characteristics to increase the stability and efficiency in the combustion process. As a result, peak temperatures are reduced and complete combustion is achieved, which in turn, lowers NOx emissions. Overall, better flow dynamics and combustion stability are provided, together with a great reduction in NOx formation, which is in agreement with the aim of developing a cleaner and more efficient combustion system.

In Fig. 16, the temperature variations and thermal gradients in the burner are explored in terms of thermal effects inside the burner. A fine view of how thermal loads affect the burner components is provided and it allows for designing the materials to withstand high temperatures and optimize the thermal performance of the system as a whole. Critical insights into burner’s operational and design tenability are brought forth by the thermal analysis. Radial gradients of the temperature distribution, in particular near the center, have extremely well localized primary hotspot (flame core) and this is needed to control the local material degradation. Finally, the contours of thermal stress are very closely related to these gradients, peaking at hot zones, implying the need for advanced material selection for handling cyclic loading. Radially this thermal gradient magnitude attenuates, reflecting the optimized geometry’s role in heating distribution and is steepest at the flame core, and is mimicked by the thermal gradient magnitude measured at the probe position. Notably, the critical thermal load index remains below failure thresholds across all components, validating the design’s ability to operate safely under extreme conditions.

Figure 17 offer a comprehensive view of flow patterns, aiding in the identification of areas with turbulence, stagnation, or uneven flow. Optimization efforts can be directed toward achieving more uniform and controlled velocities. In (a) Velocity Vector Field, the vector directions and magnitudes indicate the movement of gases through the combustion chamber, with higher velocities concentrated near the fuel injection region. The highlighted “stagnation zone” represents areas of lower velocity, which are critical to assess as these regions can potentially lead to poor fuel–air mixing, affecting combustion efficiency. These stagnant regions can cause incomplete combustion and lead to the formation of localized hotspots, which may increase NOx emissions.

The (b) Turbulence Intensity plot complements this by showing the distribution of turbulence across the burner. High turbulence intensity is concentrated in certain zones, particularly near the recirculation region. This is beneficial for improving fuel–air mixing and stabilizing the combustion process. However, regions with excessively high turbulence can result in instability or uneven combustion, contributing to higher NOx emissions due to fluctuating temperatures. The plot focuses on the areas of “high turbulence zones,” which refers to locations where the mixing is intense and in turn leads to more uniform combustion.

The concentration distribution obtained from particle tracing is shown in Fig. 18 Subfigure (a) and points of interest and potential pollutant concentrations are highlighted. In the case of subfigure (b), the movement of particles over time is used to analyze residence times and flow dynamics within the burner. The concentration distribution of particles in the burner is shown in Fig. 18a where high pollutant accumulation areas were revealed. The warmer colors in these areas represent potential hotspots of incomplete combustion or inefficient mixing in which additional pollutant formation may take place. Thus, we reduce the concentrated regions in the burner design to achieve better fuel–air mixing and combustion efficiency, and minimize NOx emissions. The residence times and flow dynamics can be illustrated in Fig. 18b where particles are moved over time. The particle trajectories reveal how long particles stay in and interact with the flow, which is important to complete combustion.

Figure 19 illustrates the time evolution of OH chemiluminescence intensity, a key indicator of heat release and combustion dynamics. The red-shaded region (0–50 ms) represents the ignition phase, characterized by increasing intensity as the flame develops. The green-shaded region (100–200 ms) corresponds to steady-state combustion, where heat release stabilizes. Understanding transient combustion behavior is essential for designing low-emission, high-efficiency burners that operate under variable industrial conditions.

Figure 20 displays the turbulence kinetic energy (TKE) distribution, which influences flame stability, mixing, and NOx formation. High-TKE zones (in red and yellow) indicate regions of intense turbulence and strong mixing, leading to efficient combustion. Low-TKE zones (in blue) correspond to stable recirculation regions where the flame stabilizes. The optimization of turbulence characteristics plays a crucial role in reducing pollutant formation and enhancing combustion efficiency.

Figure 21 optimize tube geometries and placements, ensuring efficient heat transfer and minimizing NOx formation in regions prone to flow disturbances. The velocity vector field depicted in the figure provides critical insight into the fluid flow dynamics within the combustion system, particularly in regions influenced by tube geometries and placements. This indicates the high velocity zones-indicated by warmer colors-indicating flow that has more turbulent flow from which fuel–air mixing and overall combustion efficiency is enhanced. But they can also give rise to higher isolated temperatures, which can then result in increased NOx formation. On the other hand, the colder regions, attributed to the blue to purple colors, indicate slow flowing regions where stagnation may occur, poor mixing and potential hot spots. The refinement of the tube geometries and their placement is a requirement to improve heat transfer efficiency and reduce the stagnant areas in order to optimize burner performance. The system can reduce the formation of thermal NOx, and thus more efficient, environmentally friendly combustion, by providing a more uniform flow distribution.

The efficiency of the burner in converting fuel nitrogen to nitrogen oxides is represented in Fig. 22 by proportional NOx conversion. The figure of the NOx conversion proportional to fuel nitrogen clearly gives an idea about the efficiency of the burner in converting the fuel nitrogen to nitrogen oxides (NOx). The color gradient is a color gradient where the warmer colors mean higher NOx conversion and the cooler colors mean lower NOx conversion. The analysis reveals how the burner design influences the NOx formation process across the combustion chamber. High NOx conversion regions, particularly near the fuel injection zone, suggest that areas with elevated temperatures are promoting the oxidation of nitrogen. However, these regions can also contribute to higher NOx emissions, which is undesirable. The goal of optimizing burner design is to minimize these high-conversion zones while maintaining efficient combustion.

Sensitivity analysis

Although uncertainty quantification (UQ) is acknowledged as a crucial aspect in combustion modeling, a focused sensitivity analysis was also conducted to assess the influence of key design parameters on NOx emission levels. Specifically, two critical parameters fuel injection nozzle diameter and support gas flow rate, were selected based on their strong correlation with combustion behavior and pollutant formation. The nozzle diameter was varied within a ± 5% range of its baseline value, while the support gas flow rate was altered by ± 10% to reflect possible deviations encountered in practical scenarios. For each configuration, CFD simulations were performed to evaluate the resulting NOx concentrations and combustion stability. The results revealed that the variation in NOx output due to these parameter changes remained within a 3–5% margin, suggesting a moderate sensitivity of the system to these inputs. This confirms the robustness and stability of the optimized burner design under small perturbations in operational parameters. These findings reinforce the reliability of the presented optimization strategy and validate its applicability in real-world combustion systems where input variability is inevitable. Figure 23 shows the sensitivity analysis.

Conclusions

This study successfully demonstrates the integration of CFD and ML to optimize a fuel-staging natural gas burner, achieving a 31% reduction in NOx emissions while improving combustion efficiency. Key innovations—such as folded flame geometry and staged support gas injection redistributed thermal energy, reduced peak flame temperatures by 200 K, and enhanced fuel–air mixing, thereby suppressing both thermal and prompt NOx formation mechanisms. The SVR-based ML framework accurately predicted emission patterns with RMSE/MAE values below 0.0023 and optimized burner parameters with high precision. Flow field analysis confirmed improved turbulence uniformity and flame stabilization, validating the performance gains.

While the study focused on natural gas, future work will involve experimental validation and extending the design’s applicability to alternative fuels, including hydrogen-rich blends, syngas, and biogas. These fuels exhibit different combustion behaviors that may affect flame dynamics and emission trends, requiring further CFD-ML simulations and design adjustments. Ultimately, the proposed CFD-ML design framework offers a scalable, reliable pathway for developing low-emission, high-efficiency combustion systems across diverse industrial conditions.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Winkler, B et al. Global sensitivity analysis and uncertainty quantification for simulated atrial electrocardiograms. 1–28 (2023).

Rybaczewska, M. Life cycle assessment (LCA) in environmental impact assessment (EIA): Principles and practical implications for industrial projects. 22(1), 138–153 https://doi.org/10.2478/manment-2018-0010. (2018)

Saadé-sbeih, M. EnvirOnMEntAl lifE CyClE ASSESSMEnt.

Folds 207 (2020).

Liu, Z. et al. Comparison of combustion characteristics of MILD model combustor and multi-nozzle array model combustor fueled hydrogen-methane mixtures. Int. J. Hydrogen Energy 48(81), 31802–31812. https://doi.org/10.1016/j.ijhydene.2023.04.326 (2023).

Brunton, S. L., Noack, B. R., & Koumoutsakos, P. Machine learning for fluid mechanics. (2020).

Bui, K. Q., Perera, L. P. The compliance challenges in emissions control regulations to reduce air pollution from shipping. https://doi.org/10.1109/OCEANSE.2019.8867420 (2019).

The E. Parliament, The Council, of the, and E. Union. Text with EEA relevance 443 (2020).

Karyeyen, S. (2022).

Wang, B., Gupta, R., Bei, L., Wan, Q. & Sun, L. A review on gasification of municipal solid waste (MSW): Syngas production, tar formation, mineral transformation and industrial challenges. Int. J. Hydrogen Energy 48(69), 26676–26706. https://doi.org/10.1016/j.ijhydene.2023.03.086 (2023).

Kozhukhova, A. E., du Preez, S. P. & Bessarabov, D. G. Catalytic hydrogen combustion for domestic and safety applications: A critical review of catalyst materials and technologies. Energies https://doi.org/10.3390/en14164897 (2021).

Ge, H. et al. CFD Optimization of the pre-chamber geometry for a gasoline spark ignition engine. Front. Mech. Eng. 6, 1–18. https://doi.org/10.3389/fmech.2020.599752 (2021).

Yan, P., Fan, W. & Zhang, R. Predicting the NOx emissions of low heat value gas rich-quench-lean combustor via three integrated learning algorithms with Bayesian optimization Predicting the NOx emissions of low heat value gas rich-quench-lean combustor via three integrated learning a. Energy 273, 127227. https://doi.org/10.1016/j.energy.2023.127227 (2023).

Chanphavong, L. & Zainal, Z. A. Characterization and challenge of development of producer gas fuel combustor: A review. J. Energy Inst. 92(5), 1577–1590. https://doi.org/10.1016/j.joei.2018.07.016 (2019).

Saastamoinen, H. & Leino, T. Fuel staging and air staging to reduce nitrogen emission in the CFB combustion of bark and coal. Energy Fuels https://doi.org/10.1021/acs.energyfuels.9b00850 (2019).

Pramudianto, A. life cycle analysis methods on environmental impact assessment (EIA) procedures in the perspective of sustainable development. 11003 (2018).

Industries, M. H. Dry low-NOx combustion technology for novel clean coal power generation aiming at the realization of a low carbon society. 52, 24–31 (2015).

Office, A. M. Energy tips : STEAM upgrade boilers with energy-efficient burners.

Alboshmina, N. A. H. Ammonia cracking with heat transfer improvement technology. 1–165; https://orca.cardiff.ac.uk/126553/1/2019AlboshminaNAPhD.pdf (2019).

Objectives, L. Chapter 3 Fire dynamics and fire pattern development. 53–116.

Ohkubo, Y. Low-NOx combustion technology. 41(1), 12–23.

Banihabib, R. & Assadi, M. A hydrogen-fueled micro gas turbine unit for carbon-free heat and power generation. Sustain. https://doi.org/10.3390/su142013305 (2022).

Yepes, H. A., Obando, J. E. & Amell, A. A. The effect of syngas addition on flameless natural gas combustion in a regenerative furnace. Energy https://doi.org/10.1016/j.energy.2022.124008 (2022).

Faqih, M., Omar, M. B., Ibrahim, R. & Omar, B. A. A. Dry-low emission gas turbine technology: recent trends and challenges. Appl. Sci. https://doi.org/10.3390/app122110922 (2022).

Checa, M., Nogales-Delgado, S., Montes, V. & Encinar, J. M. Recent advances in glycerol catalytic valorization: A review. Catalysts 10(11), 1–41. https://doi.org/10.3390/catal10111279 (2020).

Donskoy, I. Techno-economic efficiency estimation of promising integrated oxyfuel gasification combined-cycle power plants with carbon capture. Clean Technol. 5(1), 215–232. https://doi.org/10.3390/cleantechnol5010013 (2023).

Yu, T. et al. Diesel engine emission after treatment device aging mechanism and durability assessment methods: A review. Atmosphere 14(2), 314. https://doi.org/10.3390/atmos14020314 (2023).

Zuo, Q. et al. Effect of premixed ratio on combustion and emission characteristics in a spark ignition engine with hydrogen-ammonia direct injection. Fuel 393, 135051. https://doi.org/10.1016/j.fuel.2025.135051 (2025).

Zhao, D., Guan, Y. & Reinecke, A. Characterizing hydrogen-fuelled pulsating combustion on thermodynamic properties of a combustor. Commun. Phys. 2(1), 1–10. https://doi.org/10.1038/s42005-019-0142-8 (2019).

Khlifi, S., Lajili, M., Perré, P. & Pozzobon, V. A numerical study of turbulent combustion of a lignocellulosic gas mixture in an updraft fixed bed reactor. Sustain. 14(24), 1–18. https://doi.org/10.3390/su142416587 (2022).

Number, G. A., Acronym, P., & Project, R. Collection of the abstracts of the developed publications in journals and conferences. 1–18 (2021).

De Robbio, R. Micro gas turbine role in distributed generation with renewable energy sources. Energies https://doi.org/10.3390/en16020704 (2023).

Mohanna, H. Combustion of pulverized biomass : impact of fuel Hassan Mohanna To cite this version : HAL Id : tel-03272429 (2021).

Lim, C. W. UC Irvine UC irvine electronic theses and dissertations UNIVERSITY ! OF ! CALIFORNIA, !. 1982–2004 (2015).

Sadeq, A. M., Moghaddam, A. H., Sleiti, A. K. & Ahmed, S. F. Development of machine learning models for studying the premixed turbulent combustion of gas-to-liquids (GTL) fuel blends. 4, https://ssrn.com/abstract=4335761 (2023).

Li, N. et al. A review of reformed methanol-high temperature proton exchange membrane fuel cell systems. Renew. Sustain. Energy Rev. https://doi.org/10.1016/j.rser.2023.113395 (2023).

Makaryan, I. A., Salgansky, E. A., Arutyunov, V. S. & Sedov, I. V. Non-catalytic partial oxidation of hydrocarbon gases to syngas and hydrogen: A systematic review. Energies https://doi.org/10.3390/en16062916 (2023).

Shi, G., Li, P., Hu, F. & Liu, Z. NO mechanisms of syngas MILD combustion diluted with N2, CO2, and H2O. Int. J. Hydrogen Energy 47(37), 16649–16664. https://doi.org/10.1016/j.ijhydene.2022.03.123 (2022).

Hasan, K. S., Abd Al-Wahid, W. A. & Khwayyir, H. H. S. Flashback and combustion stability in swirl burners: Review paper. IOP Conf. Ser. Mater. Sci. Eng. https://doi.org/10.1088/1757-899X/928/2/022045 (2020).

Branca, T. A. et al. Reuse and recycling of by-products in the steel sector: Recent achievements paving the way to circular economy and industrial symbiosis in Europe. Metals (Basel) https://doi.org/10.3390/met10030345 (2020).

Velidi, G. & Yoo, C. S. A review on flame stabilization technologies for UAV engine micro-meso scale combustors: progress and challenges. Energies https://doi.org/10.3390/en16093968 (2023).

Cecere, D., Giacomazzi, E., Di Nardo, A. & Calchetti, G. Gas turbine combustion technologies for hydrogen blends. Energies https://doi.org/10.3390/en16196829 (2023).

Alnaeli, M. et al. High-temperature materials for complex components in ammonia/hydrogen gas turbines: A critical review. Energies https://doi.org/10.3390/en16196973 (2023).

Zhu, R. & Shin, D. Study on flow and heat transfer characteristics of 25 kW flameless combustion in a cylindrical heat exchanger for a reforming processor. Energies https://doi.org/10.3390/en16207160 (2023).

Giacomazzi, E. et al. Hydrogen combustion: Features and barriers to its exploitation in the energy transition. Energies https://doi.org/10.3390/en16207174 (2023).

Sun, Z. et al. Hydrogen engine operation strategies: Recent progress, industrialization challenges, and perspectives. Int. J. Hydrogen Energy 48(1), 366–392. https://doi.org/10.1016/j.ijhydene.2022.09.256 (2023).

ESTEP The Circular Economy Focus Group. Improve the EAF scrap route for a sustainable value chain in the EU circular economy scenario. vol. 32 73; https://www.estep.eu/assets/Uploads/Improve-the-EAF-scrap-route-Roadmap-Final-V2-3.pdf (2001)

Megia, P. J., Vizcaino, A. J., Calles, J. A. & Carrero, A. Hydrogen production technologies: from fossil fuels toward renewable sources. A mini review. Energy Fuels 35(20), 16403–16415. https://doi.org/10.1021/acs.energyfuels.1c02501 (2021).

Acknowledgements

The authors gratefully acknowledge the financial support provided by the Key Research and Development Program of Jiangsu Province (BE2020114), the “Zhishan Young Scholar” Program of Southeast University (2242021R41112), and the Yangzhou City Science and Technology Three Expense Special Fund Project (YS202103). Additionally, the authors extend their appreciation to the Deanship of Scientific. The authors extend their appreciation to Northern Border University, Saudi Arabia, for supporting. This work through project number (NBU-CRP-2025-2484). This research is funded by European Union under the REFRESH—Research Excellence For Region Sustainability and High-Tech Industries Project via the Operational Programme Just Transition under Grant CZ.10.03.01/00/22_003/0000048; in part by the National Centre for Energy II and ExPEDite Project a Research and Innovation Action to Support the Implementation of the Climate Neutral and Smart Cities Mission Project TN02000025; and in part by ExPEDite through European Union’s Horizon Mission Programme under Grant 101139527.

Funding

The authors gratefully acknowledge the financial support by the Key Research and Development Program of Jiangsu Province (BE2020114), the “Zhishan Young Scholar” Program of Southeast University (2242021R41112), and Yangzhou City Science and Technology Three Expense Special Fund Project (YS202103). The authors extend their appreciation to Northern Border University, Saudi Arabia, for supporting, this work through project number (NBU-CRP-2025-2484). This research is funded by European Union under the REFRESH-Research Excellence For Region Sustainability and High-Tech Industries Project via the Operational Programme Just Transition under Grant CZ.10.03.01/00/22_003/0000048; in part by the National Centre for Energy II and ExPEDite Project a Research and Innovation Action to Support the Implementation of the Climate Neutral and Smart Cities Mission Project TN02000025; and in part by ExPEDite through European Union’s Horizon Mission Programme under Grant 101139527.

Author information

Authors and Affiliations

Contributions

Muhammad Mubashir: Conceptualization, methodology, software, formal analysis, investigation, data curation, writing—original draft, visualization. Conducted CFD simulations, developed the machine learning models, performed data analysis, and drafted the manuscript. Dekui Shen: Supervision, Funding acquisition, project administration, resources, writing—review & editing. Oversaw the research design, secured funding, and provided critical revisions to the manuscript. Habib Kraiem: Validation, resources, writing—review & editing. Contributed to methodology validation and provided computational resources. Aymen Flah: Software, formal analysis, visualization. Assisted in CFD setup, turbulence modeling, and result visualization. Nahar F. Alshammari: Resources, funding acquisition. Supported resource provisioning and funding from institutional grants. Muhammad Mubashar Hanif: Writing—review & editing, visualization. Enhanced manuscript clarity and prepared graphical abstracts. All authors reviewed and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Mubashir, M., Shen, D., Kraiem, H. et al. Machine learning assisted CFD optimization of fuel-staging natural gas burners for enhanced combustion efficiency and reduced NOx emissions. Sci Rep 15, 23547 (2025). https://doi.org/10.1038/s41598-025-05132-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-05132-8