Abstract

Hydrogen, as a renewable zero-carbon fuel, is an ideal alternative to internal combustion engine fuels. The paper numerically investigates the effect of piston geometry on lean combustion in hydrogen engines, focusing on early and late injection strategies. Two novel piston bowl designs, referred to as the right-concave piston and left-concave piston, were analyzed for their interaction with hydrogen jets during mixture formation and combustion processes. Validation of the numerical outputs were conducted using an experimental testbench. Results reveal that the right-piston had a stronger and larger scale tumble, compared to the flat-top piston, facilitating hydrogen diffusion. However, due to their early injection timing, mixture distribution at ignition timing was relatively uniform, resulting in comparable indicated thermal efficiency (ITE) and NOx emissions. Conversely, the left-concave piston demonstrated inferior ITE and higher emissions under single injection but achieved superior performance with an optimized dual injection strategy. This strategy improved mixture stratification increased thermal efficiency, and significantly reduced NOx emissions. The key findings highlight the critical role of piston geometry and injection strategy in optimizing hydrogen combustion engines for higher efficiency and lower emissions.

Similar content being viewed by others

Introduction

As global fossil energy reserves dwindle and environmental issues such as the greenhouse effect intensify, global nations are actively seeking solutions to alleviate the energy crisis and reduce carbon emissions. Internal combustion engines (ICEs), which are significant consumers of fossil fuels, are currently being explored for their potential to use zero-carbon alternative fuels, such as hydrogen. Currently, hydrogen has emerged as a promising energy source, with applications primarily in ICEs1,2, Hydrogen`s unique properties, such as its fast combustion rate, wide combustible limit, fast diffusion rate, and near-zero pollutant emissions, hydrogen has emerged as a viable fuel for ICEs, as illustrated in Table 1. Hydrogen direct injection (HDI) engines exhibit an overall thermal efficiency of over 35%, which can exceed 40% under lean burn conditions. Potential reductions in heat loss could boost thermal efficiency to over 50%1,2. An innovative approach reported by Boretti3 involves a two-stroke hydrogen engine that uses oxygen instead of air. This design engine achieves zero carbon dioxide and nitrogen oxide emissions, boasts a remarkable power density of 220 kW/L, and operates at an efficiency of over 70%, these advancements set a new benchmark for the performance and environmental impact of hydrogen engines.

Certainly, there are still several obstacles that need to be overcome to achieve high efficiency and power density, such as the wider combustible limit and lower ignition energy, which make it easier for the occurrence of preignition, knock, and a notable decrease in combustion rate for ultra-lean combustion. So, there has been an increasing amount of research on knock, preignition, and ultra-lean combustion strategies of hydrogen ICEs in recent years1,7.

Hong et al.8 studied the effects of stratified combustion, injection strategy, and the Miller cycle on knock in hydrogen internal combustion engines (HICEs). Using these technologies, the engine operated smoothly under full load with a knock intensity below 0.5 bar. A stratified mixture—richer near the spark plug and leaner at the edges—enhanced combustion while suppressing knock by reducing end-gas autoignition. Delayed injection minimized hydrogen heating time, preventing preignition, while the Miller cycle alleviated knock by lowering the effective compression ratio without compromising efficiency. Lai et al.9 also found that when the start of injection (SOI) is slightly later than the intake valve closing timing, there was a significant decrease in knock intensity. Both exhaust gas regulation (EGR) and lean combustion had a certain effect on suppressing knocks by reducing combustion temperature and mitigating the reaction kinetics. Salvi et al.10 investigated the effects of different operating conditions on the combustion performance of a hydrogen engine. It was found that a greater compression ratio could improve thermal efficiency while both NOx emissions and knock were worsened. Knock and NOx issues were alleviated by delayed ignition and EGR. Unfortunately, combustion performance was also sensitive to ignition timing, equivalence ratio, and compression ratio11, which meant that alleviating knock in this way would sacrifice performance or thermal efficiency.

One of the significant challenges associated with HICEs is the nitrogen oxide (NOx) emissions. While these engines produce nearly zero carbon emissions, the high-temperature combustion process leads to the formation of NOx, such as NO and NO2, due to the oxidation of nitrogen in the air at high temperatures. The generation of NOx are primarily influenced by three factors: (a) high temperature, (b) oxygen availability, and (c) the duration of exposure to high temperature, and the temperature is the most significant factor12. The NOx emissions in HICEs are mainly thermal NOx, with a critical formation temperature of 1800 K. When the critical temperature is exceeded this threshold, the rate of NOx generation rises exponentially. At temperature above 2000 K, the primary driver of NOx generation is the extreme heat13. The level of NOx emissions is also strongly correlated to the air-fuel ratio (lambda: λ). When λ exceeds 2.5, NOx emissions drop to nearly zero14. To minimize emissions, it is advisable to use lean combustion (λ > 2) under low-loads conditions and rich combustion (λ < 1) under heavy loads, additionally the operating within the high NOx emissions range (λ = 1.1–1.5) should be avoided. Simultaneously, NOx emissions can be significantly reduced using hydrogen and a three-way catalyst, which has been shown to achieve a maximum conversion efficiency of 99.5%13,15.

Hong et al.16 explored the impact of variable valve timing (VVT) collaborative control on the combustion and emissions and found that delaying the intake valve closing (IVC) could improve intake efficiency, but it led to an increase in NOx emissions. Delaying exhaust valve opening (EVO) could appropriately reduce NOx due to the internal EGR, but it was not conducive to the increase in intake efficiency. Zhao et al.17 conducted experimental and numerical simulations on the optimization of injection strategies to achieve near-zero emissions. It was found that early injections could increase turbulence kinetic energy, while late injections could result in hydrogen accumulation and an increase in local combustion temperature and NOx emissions. EGR technology was also identified as one of the means to reduce NOx, which could increase specific heat capacity and reduce combustion rate and temperature. However, using EGR would adversely impact combustion stability18. Tang et al.19 studied the effects of EGR components on combustion and found that increasing the proportion of N2 significantly reduced NOx emissions, while the combustion rate and heat release rate (HRR) also decreased. However, the in-cylinder pressure, temperature, and HRR increased with the proportion of Ar increasing. Rustemi et al.20 studied numerically the influences of intake pressure and sparking timing on combustion and NOx emissions during lean combustion. A single-zone thermodynamic model coupled with a laminar flame velocity sub-model was applied to study the combustion process21, and the extended Zel’dovich NO reaction mechanism was used to study NOx emissions. It was found that when λ was above 1.82, NO emissions decreased to near zero. Therefore, lean combustion with high inlet pressure can achieve low NOx emissions while ensuring power density22 and increasing intake pressure reduces the sensitivity of thermal efficiency to EGR rate23, which requires a higher turbocharging ability of the turbocharger. Due to the significant difference in the exhaust composition between hydrogen and gasoline engines, there are also significant differences in the matching of the turbocharger. The variable geometry turbine (VGT) is expected to be a suitable selection for hydrogen engines because of its wide flow-rate range at different speeds24.

The wider combustible limit of HICEs contributes to stratified combustion. Compared to port fuel injection (PFI), HDI not only achieves higher thermal efficiency, but also proves higher combustion rate and pressure rise rate25,26, essential for achieving stratified combustion. Fu et al.27 conducted a numerical study to analyze mixture formation and combustion under various injection strategies. They achieved a maximum thermal efficiency of over 49% by forming a stratified mixture. Especially in ultra-lean combustion mode, the combustion process was heavily influenced by the hydrogen concentration near the spark plug. Similarly, Lee et al.28 also explored stratified combustion in a single-cylinder research engine, proving that optimal injection and ignition timing could extend the lean combustion limit. Additionally, secondary injection was found to improve the process of flame kernel formation, accelerate the flame propagation process, and significantly improve cyclic fluctuations29. Huang et al.30 systematically investigated the impact of injection strategies on the combustion performance of HICEs through experimental methods. Their findings revealed that delaying hydrogen injection timing and optimizing secondary injection could significantly improve thermal efficiency while reducing NOx emissions under ultra-lean combustion conditions. Pan et al.31 conducted a more detailed investigation into four hydrogen injection strategies for lean combustion. They compared stratified, premixed, and partially premixed hydrogen mixtures formed by hydrogen direct injection, hydrogen intake port injection, split hydrogen direct injection, and no hydrogen addition, respectively. The thermal efficiency of the partially premixed mixture distribution was the highest thermal efficiency due to its fast combustion rate. However, it also resulted in higher NOx emissions compared to the premixed hydrogen mixture, which had the lowest NOx emissions due to the uniform hydrogen distribution. The stratified mixture, formed by secondary injection, improved the formation of the flame kernel, reduced cyclic fluctuations, and shortening flame propagation process. Oh et al.32 investigated the impacts of piston shape and nozzle parameters on combustion under partial load conditions. They found that a bathtub-shaped combustion chamber facilitated flame propagation in the squish volume, while improving heat transfer losses and reducing emissions. Similarly, Praveena et al.33 also optimized the nozzle and piston crown shapes for diesel engines from the perspectives of energy and exergy, guiding valuable insights for combustion chamber design. Han et al.34 found the knock limit was effectively extended and emissions were reduced by multiple injections in a single-cylinder engine. Comparing with the number of injections, the injection region was more important due to the maximized charge cooling effect. Hydrogen`s mixture formation process has a significant differs from that of traditional fuels. Therefore, the combustion system for HICEs also needs to be redesigned and optimized.

While previous studies have explored knock characteristics, emissions, and injection strategies in HICEs, the collaborative optimization of combustion chamber geometry and hydrogen jet dynamics remains insufficiently understood. The intricate interplay between chamber shape and jet behavior, crucial for improving combustion efficiency and emissions performance, has received limited research attention. This study addresses this gap by focusing on ultra-lean combustion in hydrogen ICEs. It aims to investigate the impact of different combustion chamber designs on the combustion process and to optimize mixture formation and combustion by integrating injection strategies with piston geometry.

This study employs a comprehensive approach combining numerical simulations and experimental validation to investigate the impact of combustion chamber design and injection strategies on hydrogen-fueled internal combustion engines. The research addresses three specific objectives: (1) evaluating the influence of two distinct combustion chamber geometries on hydrogen distribution, flow dynamics, and combustion characteristics; (2) examining the synergistic effects of piston design and injection strategies on combustion efficiency and emissions control; and (3) establishing a foundational framework for optimizing hydrogen combustion systems.

Methodology

Experimental setup

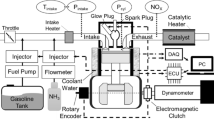

A four-cylinder HDI engine was used for the planned experimental and numerical investigations. The engine`s specifications, including key operational parameters, are listed in Table 2, and the layout of the developed test bench is illustrated and shown in Fig. 1.

The output torque and speed of the engine are measured using an electric dynamometer (AVL, accuracy: ±1 rpm, ± 0.01 N∙m). Engine coolant temperature and intake temperature are maintained at 90 ± 5 ℃ and 30 ± 3 ℃, respectively, by a constant temperature control system. The cylinder pressure is measured using a pressure sensor (Kistler 6054, range: 0-200 bar, sensitivity: -9.772 pC/bar). The crank angle signal is provided by an AVL angle marker (365 C) with a resolution of 0.1°CA. A combustion analyzer (AVL INDICOM 602) is used to acquire and process the cylinder pressure and crank angle signals at a sampling resolution of 0.1 ° CA. To minimize the measurement error, 200 cycles were recorded and averaged. Emissions are then analyzed using a motor exhaust gas analyzer (HORIBA, MEXA-7400DEGR). Hydrogen production via anaerobic digestion and purification was conducted following the methodology outlined in the previous work35. The engine is supplied with hydrogen from a gas bottles group (40 L×16, 15 MPa). A hydrogen flow meter (Rheonik, RHM03L) is used to measure hydrogen mass flow, and a flame arrester is added to prevent backfire. A single-hole nozzle with a diameter of 0.5 mm is used to inject hydrogen for greater hydrogen flow. The precision and uncertainty of the main equipment are shown in Table 3.

To avoid ambiguity, CA10, CA50, and CA90 are referred as crankshaft angles when the cumulative heat release reaches 10%, 50% and 90%, respectively. The ignition delay and combustion duration are defined as the crank angle from the ignition timing to CA10, and from CA10 to CA90, respectively.

Numerical modeling

The numerical simulation work in the paper is carried out using the CONVERGE (Version 3.0) platform. CONVERGE has a distinct advantage in the computational fluid dynamics for ICEs. The solver-based fully automatic mesh generation method can automatically generate regular hexahedral meshes, which greatly improves the efficiency of pre-processing. At the same time, the flexible grid control function, such as fixed embedding, adaptive mesh refinement (AMR), and grid scaling can improve the calculation efficiency while ensuring the calculation accuracy. The geometry model is built based on the proposed engine using SolidWorks 2023 SP 0.1, as shown in Fig. 2. In order to balance between the computational accuracy and efficiency, local fixed embedding and AMR strategies are adopted, as shown in Table 4. Accurate boundary conditions are also important for the accuracy of the simulation. The detailed boundary conditions are set according to real working conditions, as shown in Table 5. The modified Pressure Implicit with Splitting of Operator (PISO) method is used for the solution of mass, momentum, energy, and species transport. The PISO algorithm as implemented in the CONVERGE starts with a predictor step where the momentum equation is solved. And then a pressure equation is derived and solved, which leads to a correction. The correction is applied to the momentum equation correction. This process of correcting the momentum equation and re-solving will be repeated as many times as necessary to achieve the desired accuracy. After the momentum predictor and first corrector step have been completed, the other transport equations are solved in series.

(The mesh size after encrypting with level of n is \({d \mathord{\left/ {\vphantom {d {{2^n}}}} \right. \kern-0pt} {{2^n}}}\), where d is base size, 4 mm.)

The exploited numerical models are listed in Table 6. G equation model coupled with SAGE is selected as the combustion model, which assumed that premixed turbulent flames always occurred in the corrugated flame-let or thin reaction zone. The detailed hydrogen-oxygen chemical reaction mechanism is employed based on the previous work Li et al. (2004)33. Flame propagation is described by a transport equation of non-reactive scalar G, as shown in Eq. (1). The flame front is defined by solving G while the computational domain is distinguished as unburned zone (G < 0), burned zone (G > 0) and flame front (G = 0).

In the above equations, St is the turbulent flame speed, ρu is the density of the unburned mixture. The turbulent flame speed St is necessary for solving Eq. (1). The turbulent flame speed is solved by the Eq. (2) in the RANS turbulence model:

In the above equation, Sl is the laminar flame velocity, u’ is the root mean square of the turbulent pulsation velocity, a4, b1, and b3 are model coefficients, and Da is the Damkohler number.

The power law formula proposed by Metghalchi et al.36 is widely adopted to calculate laminar flame velocity, as shown in Eqs. (3)-(5). While the reference laminar flame velocity Sl_ref is usually calculated by applying either Metghalchi model, Gulder model, or table file, in this analytical investigation, Gulder model37 is exploited, shown as Eq. (6).

In the above equations, Sl_ref is the reference laminar flame velocity, Tu is the unburned temperature, υTu_ref is the reference unburned temperature (298 K), P is the pressure, Pref is the reference pressure (0.1 Mpa), \(\Upsilon_{dil}\) is the dilute gas mass fraction, aT and aP are the temperature and pressure exponent, respectively, ω, η, ξ, γ, β are the parameters associated with fuel. ω is the basis velocity reflecting the molecular structure and reactivity of the fuel, η is the modifying factor for the equivalence ratio, reflecting the influence of the equivalence ratio on the laminar flame velocity, and ζ is a nonlinear correction term for the equivalence ratio, which is used to correct for flame velocities when deviating from the stoichiometric ratio (ϕ = 1). γ and β are the sensitivity coefficients for temperature and pressure.

The renormalization group (RNG) k-ε model is widely used in turbulence simulation of internal combustion engines, and the model has also been widely validated for hydrogen engines38,39. The turbulent Schmid t number, defined by Eq. (7), needs to be optimized for a high diffusion coefficient of hydrogen. Therefore, the RNG k-ε model is used to simulate the turbulent combustion with a Schmidt number of 0.5. From the result of Y + value in Fig. 3, it can be seen that the Y + values for the near-wall are in the range of 60–150, so the standard wall function is used for near-wall flow in turbulent model.

Where νt is the turbulent kinematic viscosity and Dt is the turbulent coefficient of molecular diffusion. The molecular diffusion compared to jet viscosity can be increased by reducing the Schmidt number and consequently increasing the fuel dispersion over convection.

The operating conditions for model validation and model parameters of reference laminar flame velocity in Eq. (6) are shown in Tables 7 and 8. The model parameters in Table 8 were obtained through nonlinear fitting based on the experimental data of other scholars. The parameters are used in laminar flame velocity model for calculating flame velocity, as shown in Eq. (6). But the parameters themselves have no specific physical meaning. Figure 4a illustrates that the calculated laminar flame velocity in this study closely matches the test data. It is considered that the laminar flame velocity model can accurately calculate the laminar flame velocity under the condition that the equivalence ratio is less than 1.5, which is crucial for the G equation combustion model.

In order to balance the computational accuracy and efficiency, the combustion process under different grid encryption levels was calculated (fuel: hydrogen, speed: 2000 rpm, relative air-fuel ratio: 2.5), as shown in the Fig. 4b. With the decrease of the grid size, the cylinder pressure and HRR curves gradually tends to converge, especially when the encryption level increases from 2 to 3. The difference between in-cylinder pressures and HRRs is found negligible. Therefore, the grid with Level 2 encryption is considered to be computationally accurate and efficient. Furthermore, considering the fluctuation of the combustion cycle, the average of experimental data collected over 200 consecutive cycles was selected to verify the model, as shown in Fig. 4c,d. It demonstrates that the numerical pressure and HRR align well with the experimental results at different loads and air-fuel ratios, indicating that the numerical model is able to accurately predict the combustion process of HICEs. Despite some remaining errors, given the simplifications in the numerical model and experimental uncertainties, these discrepancies are deemed acceptable.

Validation of numerical models and comparison with experimental data. (a) The calculated laminar flame velocity, (b) the cell independence validation under different encryption levels, (c) comparison of experimental and simulated cylinder pressure and heat release rate at operating condition (1) and (d) comparison of experimental and simulated cylinder pressure and heat release rate at operating condition (2).

Results and discussions

The effect of combustion chamber shape

In ultra-lean combustion, the combustion velocity of hydrogen decreases significantly, leading to a reduction in thermal efficiency. To counteract this, enhancing in-cylinder turbulence through the effective utilization of the hydrogen jet is a promising approach to improve combustion velocity. However, achieving this requires careful optimization of both the injection timing and the combustion chamber geometry, as these factors play a crucial role in shaping the intensity and distribution of turbulence within the cylinder. To investigate the synergy between combustion chamber geometry and the hydrogen jet, three distinct piston designs were developed using SolidWorks, as illustrated in Fig. 5. The flat-top piston in Case 1 (Fig. 5a) represents the baseline design, modeled after a conventional gasoline engine piston. The right-concave piston in Case 2 (Fig. 5b) was designed to generate a counterclockwise tumbling flow, optimized for early injection. In contrast, the left-concave piston in Case 3 (Fig. 5c) was designed to create a clockwise tumbling flow, tailored for late injection. These designs enable a comparative analysis of how piston geometry influences in-cylinder flow dynamics and mixture formation under varying injection strategies.

The effect of chamber shape on the mixture performance

For the performance comparison of the three combustion chamber shapes, specific operating conditions were carefully planned and shown in Table 9. For case 1 and case 2, early injection timing was set to form a homogeneous mixture, while late injection timing was chosen for case 3 to form a stratified mixture. The ignition timing was optimized to position the combustion center (CA50) at approximately 8°CA after top dead center (ATDC).

The tumble ratio for different piston designs is shown in Fig. 6. The tumble ratio_X+, tumble ratio_X- and tumble_ratio_X are the positive, negative and average tumble ratio about the X axis, respectively. The tumble ratio in x direction is defined as the ratio of the angular speed of the flow about the center of mass in the x direction, ω1, to the angular speed of the crankshaft, ωcrankshaft. It is evident that the tumble ratio increases significantly during the injection, primarily due to the influence of the hydrogen jet.

In Cases 1 and 2, the hydrogen jet induces a predominantly counterclockwise tumbling flow, aligning with the natural tumble direction in the cylinder. However, Case 2 exhibits a stronger tumble intensity than Case 1. In contrast, Case 3 generates a dominant clockwise tumbling flow due to the combined effects of the hydrogen jet and the piston geometry. This interaction reverses the overall tumble ratio from positive to negative during injection. As shown in Fig. 7a, b, the tumble scale in Case 2 is larger, with its center shifted farther to the right compared to the flat-top piston in Case 1. This is attributed to the guidance provided by the concave piston design, which minimizes kinetic energy loss from jet collisions with the cylinder wall. Consequently, Case 2 achieves higher in-cylinder flow velocity and faster hydrogen diffusion. At -65°CA ATDC, hydrogen in Case 2 has already diffused toward the right side of the cylinder, whereas in Case 1, most hydrogen remains on the left. By -10°CA ATDC, the larger tumble scale in Case 2 results in a wider hydrogen diffusion range and a more uniform mixture. In Case 3, the later injection timing creates a smaller but more intense clockwise tumbling flow guided by the piston’s concavity. Hydrogen diffuses clockwise along the piston surface, resulting in a stratified mixture. At -5°CA ATDC (ignition timing), the mixture in Case 3 is richer near the cylinder center and leaner near the walls.

For more accurate evaluation of the uniformity of the mixture, a quantitative index is proposed, uniformity index (UI), which is defined as follows:

Where mi and φi are mass and equivalence ratio in cell i, \(\:\stackrel{-}{\phi\:}\) is average equivalence ratio, M is total mass in the cylinder.

In Case 1 and Case 2, the equivalence ratio distribution is notably more concentrated, with the majority of mixtures falling between 0.3 and 0.4, as shown in Fig. 7 (c). This indicates a relatively homogeneous mixture. Conversely, Case 3 exhibits a more dispersed distribution, spanning mainly from 0 to 1.2. This trend is further evident in the UI results, with Case 1 and Case 2 boasting UI values exceeding 0.9, which is significantly higher than the UI of Case 3 at 0.69.

The effect of chamber shape on the combustion performance

Figure 8a shows the in-cylinder pressure and the pressure rise rates for the three cases. It can be observed that the cylinder pressure curves of case 1 and case 2 are relatively close, but the maximum cylinder pressure and maximum pressure rise rate of case 2 are slightly higher than those of case 1. This is mainly due to the richer mixture near the spark plug. Therefore, case 2 exhibits a higher HRR, as shown in Fig. 8b.

In Case 3, most of the mixture is located near the spark plug, coupled with a higher intensity of in-cylinder turbulence. This results in the fastest combustion rate among the three cases, with the highest pressure rise rate and heat release rate (HRR). The flame propagation process, as shown in the temperature-field distribution (Fig. 9), highlights distinct differences between the cases. In Cases 1 and 2, the flame propagates uniformly outward from the spark plug, with Case 2 demonstrating a slightly faster flame propagation rate than Case 1. However, in Case 3, the flame propagation is the fastest, reaching the cylinder wall within 14°CA after ignition, compared to approximately 32°CA and 28°CA for Cases 1 and 2, respectively.

The temperature within the cylinder in Case 3 is significantly higher than in the other two cases due to the concentrated mixture distribution, as shown in Table 10. This elevated temperature leads to substantially higher NOx emissions, exceeding those of Case 2 by more than 300 times. Additionally, increased heat transfer losses contribute to Case 3’s slightly lower thermal efficiency compared to the other cases. Among the three, Case 2 achieves the best overall performance, combining a more homogeneous mixture distribution and strong tumble intensity. This results in the highest indicated thermal efficiency (ITE) and the lowest NOx emissions.

The effect of the injection strategy on mixture formation and combustion performance

Although the piston shape in Case 3 performs poorly with late injection, particularly due to the significantly higher NOx emissions, late injection plays a crucial role in avoiding pre-ignition and knock. Additionally, it facilitates the formation of a stratified mixture, offering considerable potential for performance improvement.

To optimize the combustion performance of Case 3 while mitigating NOx emissions, a split injection strategy is employed to enhance the stratified mixture. In this strategy, the start of the first injection (SOFI) is set at 90°CA BTDC to create a homogeneous mixture, while the start of the second injection (SOSI) is set at 30°CA BTDC. This timing leverages the combined effects of the hydrogen jet and piston design to increase the mixture concentration near the spark plug and strengthen tumble flow. To evaluate and optimize combustion performance, three different mass fractions of the second injection (MFSI) are tested. The operating conditions and parameters are detailed in Table 11. For reference, MFSI values of 0% and 100% correspond to single injections with SOI at 90°CA BTDC and 30°CA BTDC, respectively.

The distribution of the mixture in the cylinder of different MFSIs is shown in Fig. 10a. It is notable that after the first injection, the mixture distribution of the three MFSIs is remarkably similar at -30°CA ATDC, with a relatively homogeneous mixture distribution. After the second hydrogen injection, the hydrogen distribution in the cylinder is stratified. Following the second hydrogen injection, the hydrogen distribution in the cylinder becomes stratified, with the mixture near the center of the cylinder being richer and the mixture near the cylinder wall leaner. However, upon observing the hydrogen distribution at ignition timing (-5°CA ATDC), it is observed that for the MFSI of 20%, the richer mixture is predominantly distributed to the right side of the center. As the MFSI gradually increases, the distribution of the richer mixture in the cylinder gradually shifts from right to left.

As depicted in the flow field distribution in Fig. 10b, the hydrogen jet of the second injection moves in the opposite direction to the tumbling flow in the cylinder, forming a notable convection, which causes large velocity duo to fluid viscosity. Therefore, with MFSI increases, the overall tumble ratio at ignition timing significantly decreased, as shown in Fig. 11. However, the convection is conducive to mixing of hydrogen and air. As the MFSI increases, the kinetic energy of the hydrogen jet of the second injection increases, and the hydrogen jet becomes more and more dominant in connection with the mixture, which can be seen in the flow field at -20°CA ATDC. Thus, when MFSI increases from 20 to 40%, the hydrogen-rich zone gradually shifts from the right side of the cylinder to the left, as shown in Fig. 10a.

The temperature distribution in the cylinder is shown in Fig. 10c. Corresponding to the hydrogen distribution in Fig. 10a, when the MFSI increases from 20 to 40%, the distribution of the high-temperature area in the cylinder shifts from the right to the middle and left of the cylinder. Moreover, in comparison to the combustion temperature of the single injection in Fig. 9 (Case 3), the combustion temperature of the dual injection is significantly lower and the temperatures rises with MFSI increasing.

Compared with a single early injection (MFSI = 0), the dual injection can significantly shorten the ignition delay and combustion duration, as shown in Fig. 12a. As the MFSI increases, the combustion duration increases slightly. It was recorded that, the ignition delay reaches a minimum at MFSI of 30%. When the MFSI reaches 100%, meaning that all hydrogen is injected in a single injection with SOI of 30°CA BTDC, the combustion duration and ignition delay are further shortened. As shown in Fig. 12b, compared with single injection (MFSI = 0 and 100%), the ITE of the dual injection becomes higher and reaches a maximum of 46.3% at MFSI of 30%, which is mainly benefiting from the faster combustion rate and lower heat transfer losses and NOx emissions are much lower than the single late injection (MFSI = 100%). This is primarily because of the stratified mixture distribution from dual injection, leading to fewer hydrogen-rich areas. Consequently, the high temperature areas is lower, leading to reduced NOx emissions. With the increase in MFSI, NOx emission increases gradually.

Figure 13 depicts the in-cylinder pressure, pressure rise rate and HRR curves of different MFSIs. Compared with late single injection (MFSI=100%), the maximum pressure rise rate and HRR decrease by more than 38% and 35%. In other words, split injection can ameliorate the combustion process of late injection, which is beneficial to reduce combustion noise and NOx emissions. Compared with early single injection (MFSI=0), the heat releasing processes of dual injection are more concentrated.

Conclusions

This study systematically investigated the coupling mechanisms between hydrogen jet dynamics and combustion chamber geometry, focusing on their combined impact on mixture formation and combustion characteristics. Through comparative analysis of three chamber configurations (flat top piston, right concave piston, and left concave piston), the main findings are summarized as follows:

-

(1)

The concave pistons designs significantly improved tumble flow, particularly the right-concave piston in Case 2, which enhanced hydrogen transport and diffusion due to its larger-scale tumble flow. This design also enriched the mixture near the spark plug, leading to faster combustion and higher heat release rates while maintaining low NOx emissions and competitive thermal efficiency.

-

(2)

The left-concave piston of case 3, despite generating strong tumble flow, resulted in hydrogen-rich zones due to late injection, causing high combustion temperatures, rapid combustion, and significantly higher NOx emissions.

-

(3)

Dual injection strategies addressed these challenges of case 3 by optimizing mixture distribution, increasing thermal efficiency, and reducing NOx emissions. Increasing the proportion of the second injection further improved hydrogen transport and combustion efficiency, demonstrating the potential of split injections for enhancing hydrogen engine performance.

To develop a combustion system with enhanced efficiency and reduced emissions, the geometric configuration of the combustion chamber, particularly the piston crown and cylinder head profiles, requires more detailed investigation. Given the simplifications inherent in current simulation methodologies and the discrepancies observed between numerical predictions and actual engine operating conditions, systematic experimental research should be conducted to verify the computational models.

Data availability

Data will be made available from the corresponding author upon reasonable request. For data access inquiries, please contact Liangmo Wang at liangmowang_njust@163.com.

Abbreviations

- AUC:

-

Area under the curve

- BNP:

-

B-type natriuretic peptide

- eGFR:

-

Estimated glomerular filtration rate

- ESAS:

-

Edmonton symptom assessment system

- FDA:

-

Food and drug administration

- GNRI:

-

Geriatric nutritional risk index

- HF:

-

Heart failure

- IDI:

-

Integrated discrimination improvement

- KCCQ:

-

Kansas city cardiomyopathy questionnaire

- MAGGIC:

-

Meta-analysis global group in chronic heart failure

- MLHFQ:

-

Minnesota living with heart failure questionnaire

- MMSE:

-

Mini-mental state examination

- NRI:

-

Net reclassification improvement

- NYHA:

-

New york heart association

- QoL:

-

Quality of life

- PRO:

-

Patient-reported outcome

References

Stępień, Z. A comprehensive overview of Hydrogen-Fueled internal combustion engines: achievements and future challenges. Energies 14 (20), 6504 (2021).

Liu, X. et al. Computational study of hydrogen engine combustion strategies: Dual-Fuel compression ignition with Port- and Direct-Injection, Pre-Chamber combustion, and Spark-Ignition. Fuel 350, 128801 (2023).

Boretti, A. A high-efficiency internal combustion engine using oxygen and hydrogen. Int. J. Hydrog. Energy. 50 (Part B), 847–856 (2024).

Hosseini, S. E. & Butler, B. An overview of development and challenges in hydrogen-powered vehicles. Int. J. Green. Energy. 17, 13–37 (2020).

Shahid, M. I. et al. Hydrogen production techniques and use of hydrogen in internal combustion engine: A comprehensive review. Fuel 378, 132769 (2024).

Muhammed, N. S. et al. Hydrogen production, transportation, utilization, and storage: recent advances towards sustainable energy. J. Energy Strorage. 73, 109207 (2023).

Gao, W. et al. Progress of performance, emission, and technical measures of hydrogen fuel internal-combustion engines. Energies 15 (19), 7401 (2022).

Hong, C. et al. Progressive strategies to avoid and exploit knock limit for optimal performance and stoichiometric operation of a DI hydrogen engine with high CR at WOT conditions. Fuel 357, 129849 (2024).

Lai, F. et al. Research on the inducing factors and characteristics of knock combustion in a DI hydrogen internal combustion engine in the process of improving performance and thermal efficiency. Int. J. Hydrog. Energy. 48 (20), 7488–7498 (2023).

Salvi, B. L. & Subramanian, K. A. Experimental investigation on effects of compression ratio and exhaust gas recirculation on backfire, performance and emission characteristics in a hydrogen fuelled spark ignition engine. Int. J. Hydrog. Energy. 41 (13), 5842–5855 (2016).

Salvi, B. L. & Subramanian, K. A. A novel approach for experimental study and numerical modeling of combustion characteristics of a hydrogen fuelled spark ignition engine. Sustain. Energy Technol. Assess. 51, 101972 (2022).

Mogi, Y. et al. Effect of high compression ratio on improving thermal efficiency and NOx formation in jet plume controlled direct-injection near-zero emission hydrogen engines. Int. J. Hydrog. Energy. 47 (73), 31459–31467 (2022).

Jiang, M., Sun, W. & Guo, L. Numerical study of the combustion process and NOx evolution mechanism of ammonia-hydrogen compound fuel engine under different intake conditions. J. Energy Inst. 116, 101759 (2024).

Takagi, Y. et al. Improvement of thermal efficiency and reduction of NOx emissions by burning a controlled jet plume in high-pressure direct injection hydrogen engines. Int. J. Hydrog. Energy. 42 (41), 26114–26122 (2017).

Bao, L. et al. Simulation and experimental study of the NOx reduction by unburned H2 in TWC for a hydrogen engine. Int. J. Hydrog. Energy. 45 (39), 20491–20500 (2020).

Hong, C. et al. Assessment of a synergistic control of intake and exhaust VVT for airflow exchange, combustion, and emissions in a DI hydrogen engine. Int. J. Hydrog. Energy. 48 (53), 20495–20506 (2023).

Zhao, F. et al. Experimental and modeling investigations to improve the performance of the near-zero NOx emissions direct-injection hydrogen engine by injection optimization. Int. J. Hydrog. Energy. 49 (Part B), 713–724 (2024).

Wallner, T. Efficiency and emissions potential of hydrogen internal combustion engine vehicles. (SAE Paper, 2011).

Tang, Y. et al. Simulation study of N2/Ar Dilution gas to improve thermal efficiency and reduce NOX emissions in hydrogen engines. Int. J. Hydrog. Energy. 49 (Part B), 636–651 (2024).

Rustemi, D. N., Ganippa, L. C. & Axon, C. J. Investigation of boost pressure and spark timing on combustion and NO emissions under lean mixture operation in hydrogen engines. Fuel 353, 129192 (2023).

Anticaglia, A. et al. Feasibility analysis of a direct injection H2 internal combustion engine: numerical assessment and proof-of-concept. Int. J. Hydrog. Energy. 48 (83), 32553–32571 (2023).

Novella, R. et al. Optimizing hydrogen spark-ignition engine performance and pollutants by combining VVT and EGR strategies through numerical simulation. Appl. Energy, 376(Part B) 124307 .(2024).

Buzzi, L. et al. Experimental investigation of hydrogen combustion in a single cylinder PFI engine. Int. J. Engine Res. 25 (2), 358–372 (2024).

Lai, F. et al. Research on optimizing turbo-matching of a large-displacement PFI hydrogen engine to achieve high-power performance. Int. J. Hydrog. Energy. 48 (97), 38508–38520 (2023).

Zhang, S. et al. Energy and exergy analysis for a turbocharged direct-injection hydrogen engine to achieve efficient and high-economy performances. Int. J. Hydrog. Energy. 54, 601–612 (2024).

Duan, Y. et al. Combustion characteristics of a turbocharged direct-injection hydrogen engine. Energy. Conv. Manag. 291, 117267 (2023).

Fu, Z. et al. Numerical simulation of the mixture distribution and its influence on the performance of a hydrogen direct injection engine under an ultra-lean mixture condition. Int. J. Hydrog. Energy. 48 (51), 19700–19712 (2023).

Lee, S., Kim, G. & Bae, C. Effect of injection and ignition timing on a hydrogen-lean stratified charge combustion engine. Int. J. Engine Res. 23 (5), 816–829 (2022).

Yu, X. et al. Effects of second hydrogen direct injection proportion and injection timing on combustion and emission characteristics of hydrogen/n-butanol combined injection engine. Int. J. Hydrog. Energy. 47 (75), 32330–32344 (2022).

Huang, Z. M. et al. Experimental study on the impact of hydrogen injection strategy on combustion performance in internal combustion engines. ACS Omega. 8 (42), 39427–39436 (2023).

Pan, S., Wang, J. & Huang, Z. Effects of hydrogen injection strategy on the hydrogen mixture distribution and combustion of a gasoline/hydrogen SI engine under lean burn condition. Int. J. Hydrog. Energy. 47 (57), 24069–24079 (2022).

Oh, S. et al. Effects of piston shape and nozzle specifications on part-load operation of natural gas–diesel dual-fuel RCCI engine and its application to high load extension. Fuel 328, 125361 (2022).

Praveena, V., Leenus Jesu Martin, M. & Varuvel, E. G. Combined effects of nozzle hole variation and piston bowl geometry modification on performance characteristics of a diesel engine with energy and exergy approach. J. Clean. Prod. 375, 133946 (2022).

Abdelqader, A. et al. Application of helium-neon red laser for enhancing biohydrogen production from anaerobic digestion of biowastes. Egy J. Chem. 12, 12345 (2022).

Han, T. et al. Multiple injection for improving knock, gaseous and particulate matter emissions in direct injection SI engines. Appl. Energy. 262, 114578 (2020).

Li, J. et al. An updated comprehensive kinetic model of hydrogen combustion. Int. J. Chem. Kinet. 36 (10), 566–575 (2004).

Gülder, O. Correlations of Laminar Combustion Data for Alternative S.I. Engine Fuels. SAE Technical Paper (SAE International, 1984).

Li, Y. et al. Effects study of injection strategies on hydrogen-air formation and performance of hydrogen direct injection internal combustion engine. Int. J. Hydrog. Energy. 44 (47), 26000–26011 (2019).

Yang, Z. et al. Effects of injection mode on the mixture formation and combustion performance of the hydrogen internal combustion engine. Energy 147, 715–728 (2018).

Acknowledgements

This work was financially supported by Key projects of natural science research in colleges and universities of Anhui Province (Grant No: 2022AH052431) and Major projects of natural science research in colleges and universities of Anhui Province (Grant Nos: 2022AH040312, 2023AH040350).

Author information

Authors and Affiliations

Contributions

Zhaoming Huang: Conceptualization, Funding acquisition, Investigation, Resources.Tianyu Zhu: Funding acquisition, Project administration.Li Wang: Funding acquisition, Supervision, Writing – original draft.Liangmo Wang: Conceptualization, Supervision, Validation.Abdallah S. Ali: Data curation, Formal analysis, Investigation.Mohamed G. A. Nassef: Data curation, Investigation.Tao Wang: Visualization, Writing – original draft.Rasha H. Ahmed: Data curation, Investigation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Huang, Z., Zhu, T., Wang, L. et al. Synergistic optimization of combustion chamber design and hydrogen injection strategies for ultra-lean combustion in hydrogen engines. Sci Rep 15, 23073 (2025). https://doi.org/10.1038/s41598-025-06685-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-06685-4