Abstract

Carbon nanomaterials, particularly carbon nanotubes (CNTs), have attracted considerable research attention due to their exceptional properties, including high electrical conductivity, stability, and surface area. These properties make CNTs suitable for diverse applications in energy, environment, and biomedicine. However, the conventional methods of synthesizing CNTs are energy-intensive, expensive, and environmentally harmful. Moreover, the reliance on traditional non-renewable precursor graphite is another challenge. To address these issues and promote sustainability research, using biomass as a renewable precursor for synthesizing CNTs offers a promising alternative to traditional approaches. This study presents a novel synthesis method for producing multi-walled CNT with an average diameter of 10 nm. The process involves a two-stage pyrolysis of dried orange peel catalyzed by ferrocene and purification with concentrated sulfuric acid. Various characterization techniques, including UV-Vis, FTIR, XRD, Raman Spectroscopy, SEM-EDS, and TEM, were employed to analyze the synthesized carbon nanomaterial. Results indicate that the physiochemical properties of CNTs were influenced by the catalyst quantity applied during pyrolysis. Specifically, the carbon material derived from orange peel, synthesized at 800℃ with a higher catalyst concentration, yielded well-aligned CNTs ranging in size from 8.0 to 15 nm, exhibiting minimal structural defects. This study reveals the feasibility, cost-effectiveness, and environmental sustainability of synthesizing biomass-derived CNTs.

Similar content being viewed by others

Introduction

Carbon nanotubes (CNTs) are the most researched one-dimensional carbon nanomaterial and were discovered by Sumio Iijima in 1991 using the arc discharge evaporation method, which was early detected experimentally using transmission electron microscopy (TEM), and the conditions for the production of significant amounts of them were reported1. Carbon nanotubes consist of several concentric cylinders of graphitic sheets with diameters ranging from 2.00 to 100 nm and lengths up to a few micrometers. Depending upon the number of graphitic layers that are rolled up to form CNTs, they are classified into single-walled CNTs (SWCNTs) with a single graphene layer, double walled CNTs (DWCNTs) with two graphene layers, and multi-walled CNTs (MWCNTs) consist of multiple graphene layers. CNTs have large specific surface areas, theoretical solid mechanical strength, and good electrochemical stabilization. Due to these properties, CNTs are widely used in energy storage applications2,3, bio and photo sensors4, semi-conductor devices and solar panels5, biotechnology industries6,7, and water treatment applications8.

Conventionally, CNTs are produced using different methods, including arc discharge process9, laser ablation10, and chemical vapor deposition11,12. These techniques often rely on graphite as the carbon source, a nonrenewable material such as graphite, petroleum hydrocarbons, and coal tar pitch that emits harmful waste gases11,13 such as toluene, contributing to environmental degradation. Graphite, a key precursor for CNT synthesis, is both costly and finite in addition to being in high demand for Lithium-ion batteries. Furthermore, the difficulty of process control, high-temperature requirements, raw material nature, low yield, and efficiency are the major limitations14. As a result, new innovative preparation methods of CNTs that are safer, more economical, and more sustainable, using renewable and ecologically acceptable resources, are in great demand. The purpose of this study is to explore alternative sources for CNT synthesis, moving away from conventional, costly, and nonrenewable materials.

Biomass, a carbon-rich renewable resource, is a better alternative as a precursor for the synthesis of carbon-based nanomaterials. Significant biomass sources include trees, crops, energy crops, fruits, greenery, wood, algae, aquatic plants, and general municipal and animal waste. They are inexpensive, widely available everywhere, and naturally replenished. Their high carbon content makes them useful as building blocks for creating nano carbons. The global biomass production is 100 billion tons, making biomass waste management a crucial concern. Disposing a significant amount of biomass waste into land and ocean severely threatens human survival, especially for future generations. Value-added materials made from biomass are made possible by recent developments in nanotechnology. This converts biomass waste into carbon-based products that are promising and safe for the environment15,16. It has been demonstrated that lignocellulose biomass is an appropriate bio-feed for CNTs and other carbon-based materials. It has a significant amount of cellulose, which has been shown as the precursor to the formation of CNTs. Various biomass sources have been explored in the literature for the preparation of carbon-based materials. These include rice straw17, coconut husk18, wheat straw19 fruit peels20,21, and sugar cane bagasse22,23. Biomass-derived CNTs have diverse applications in energy, environmental remediation, water treatment, and diagnostics. Their high electrical conductivity, chemical functionalization, and thermal stability make them effective for removing toxic pollutants and heavy metals from water24,25, as electromagnetic wave absorbers26, and in energy storage systems26,27.

In this work, orange peel (OP) was utilized as a precursor for preparing MWCNTs. Oranges, the most widely consumed citrus fruit globally, have an annual production of 72 million tons. Approximately 50% of the fruit, including seeds, peels, and pulp, is discarded as waste28. Orange peel waste is traded internationally at prices ranging from $50 to $450 per hundred tons29, whereas natural graphite costs approximately $450 per ton, making orange peel waste a significantly cheaper alternative as a precursor for CNT preparation. Startups are increasingly capitalizing on OP waste, transforming it into bio-based products such as textiles, pharmaceuticals, bioactive compounds, and biofuels28,29. While detailed cost analysis was beyond the scope of this study, the use of OP waste as a carbon precursor offers cost savings and environmental benefits30,31. In this study, pyrolysis was utilized as a common technique for synthesizing carbon materials from biomass. This process involves heating a biomass precursor to high temperatures in the presence of an inert gas or under vacuum. The introduction of chemical reagents into the pyrolysis reaction can significantly reduce the required temperature and energy consumption27,32. After the carbonization phase the obtained dried OP powder was mixed with different ratios of chemical reagent ferrocene, then subjected to two-stage pyrolysis, and later treated with concentrated sulfuric acid (H2SO4) to produce CNTs. Various techniques, including UV-Vis, FTIR, X-ray, Raman, SEM, EDS, and TEM, were used to characterize and assess the impact of ferrocene on the quality of the resulting carbon-based materials.

Materials and methods

Materials

This study used the orange peel (citrus reticulate) as the precursor material for synthesizing CNTs. The catalyst ferrocene (C10H10Fe) (Sigma-Aldrich, St Louis, MO 63103, USA), concentrated H2SO4 (95–97%), (EMD, Millipore corporation, 290 Concord Road, Billerica MA, USA), ethanol (C2H5OH, 99.8%), and (Harvey St., Muskegon, USA) were also used in this study.

Methods

Preparation of CNTs from dried orange peel powder

The orange peel was collected from the household waste, washed with tap water, and sundried for a few days. The sundried OP collected from the garbage was dried again using a hot air oven at 70℃ for 24 h to remove further moisture content. After that, the dried orange peel was granulated into fine powder with a mechanical grinder. Further, the OP powder was converted into MWCNTs by two-step pyrolysis. The Pulverized OP is transferred into a quartz boat and then carbonized inside a tubular furnace at 400℃ for 2 h at a heating rate of 3.2 ℃/min under vacuum. The carbonized OP biochar was collected after the furnace cooled to room temperature. 2.5 g of OP biochar was mixed with different ratios (0.5, 1.0 and 1.5 g) of ferrocene catalyst. The pyrolysis was conducted on these samples inside a tubular furnace at 800℃ for 2 h at a heating rate of 10 ℃/min for each. The resultant OP-derived carbon samples were collected in three different vials. We denote these samples as OPDC0.5, OPDC1.0, and OPDC1.5. To wash out the metal catalyst, the OPDC materials were later acid-treated with concentrated H2SO4 using a hotplate at 70 ℃ for 3 h. The samples were diluted with deionized (DI) water to deplete the acid. Subsequently, the solution was discharged, and the remaining residues were drenched multiple times with DI water and centrifuged. For further purification, the materials were washed with ethanol solvent at the end and again centrifuged to remove unwanted impurities. After purification, the OPDC samples were kept under a hot air oven at 90 ℃ till the moisture content was removed. The dried samples were then made to fine powder using a pestle and mortar and collected for further studies.

Material characterization

The size, structure, optical properties, morphology, and composition of the as-synthesized OPDC samples were analyzed using UV- visible spectroscopy (Perkin Elmer LAMBDA 1050 WB, USA), FTIR spectroscopy (Bruker Vertex 80v FT-IR spectrometer, Germany), XRD with Ni-filters Cu Kα radiation (ν = 1.54 Å) at 45 kV and 40 mA PANalytical Empyrean XRD), Raman spectroscopy (Horiba Scientific, LabRam HR Evolution, Japan), FESEM (JEOL, JSM-7610F, Japan), TEM (FEI Titan G2 80–300 ST USA) and EDS (INCA-xart, USA),

The absorption spectra were recorded at ambient temperature by dispersing the sample in ethanol and using a UV–visible spectrometer in the 200–800 nm range with a step size of 0.5 nm. The FT-IR spectra were recorded along the 400–4000 cm−1 wavenumber range. The X-ray diffraction measurements for the prepared OPDC samples were taken within the \(2\theta\) angle range of \(5-{80}^{o}\). The Raman spectra were measured in the 400–4000 cm−1 range, using He–Ne laser source of 633 nm. The microstructure of the samples was analyzed with the aid of FESEM and TEM at different magnifications, followed by qualitative analysis using EDS spectra.

Results and discussion

Synthesis mechanism of OPDC from orange peel

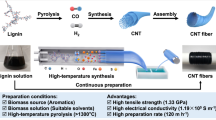

Several studies reported that lignocellulose biomass is an excellent substitute precursor for synthesizing carbon-based materials22,23,33,34,35. The primary composition of orange peel is 19.8% lignin, 69.1% cellulose, and 9.0% hemicellulose, making it suitable for CNT production36. In this study, the two-stage pyrolysis of dried OP was carried out under vacuum at temperatures of around 400 and 800 ℃. Figure 1 depicts the comprehensive approach used in synthesizing OPDC with a graphical representation followed by a flowchart. The dried orange peel powder was subjected to two-step pyrolysis, which is cellulose dominated, along with the pyrolysis of other major components like lignin and hemicellulose. The OP pyrolysis can be divided into three temperature ranges: below 240 ℃, between 300 to 400 ℃, and above 400 ℃. In a pyrolysis reaction below 240 ℃, the hydrogen bonds present in the powdered OP biopolymer disintegrate, and certain bonds become weakened and evolve into water37. Above 250 ℃, the moisture removal phase unfolded, catalyzing the conversion of hemicellulose within the OP into oligosaccharides via depolymerization, while also triggering the initiation of cellulose degradation38. As the temperature increased further (300–400 ℃), the molecular rearrangement, along with the bond fragmentation, resulted in volatilization in OP biochar. Beyond 400 ℃, additional dehydrogenation and cross-linking reactions occur, leading to the carbonization of cellulose and lignin39. The secondary pyrolysis of cellulose occurred at the elevated temperature range, at which point the lignin also started its breakdown process. Elevated temperatures produce dehydrated sugars like levoglucosan and hydroxymethyl furfural. These substances again undergo polymerization and aromatization, which results in the formation of aromatic hydrocarbons40. Due to the substantial polycondensation reaction around 450- 700 ℃, they produced 2-dimensional fused ring structures. When the temperature exceeds 750 ℃, microcrystalline graphitic structures are produced due to excessive graphitization41,42. The addition of ferrocene to the samples accelerates the graphitization process. Heat decomposes ferrocene to free iron atoms and cyclopentadienyl (C5H5)43,44. The condensation and nucleation of free Fe atoms evolve into Fe nanoparticles and disperse across the OP biochar surface. During further heating to 800℃, the carbon atoms in the biochar, which were not directly dissolved into the catalyst, nucleate and grow over the surface of Fe to form CNTs. To purify the as-grown OPDC samples containing CNTs and Fe, the OPDC materials were treated with concentrated H2SO4 for 3 h at 70 ℃, dissolving the Fe from ferrocene and other impurities33.

The UV-visible absorption spectra of synthesized OPDC samples were acquired by dispersing the samples in ethanol, as depicted in (Fig. 2). Increasing the catalyst amount results in a higher absorption peak in the UV-Vis spectra. OPDC1.5 exhibits the highest peak at 285 nm, consistent with literature findings indicating that the intensity of the absorption peak increases with higher CNT concentration45,46, and the peak for the other samples is around 282 nm. These peaks arise from the π—π* transitions in the aromatic carbon47. The slight shift from 282 to 285 nm suggests that as the catalyst amount increases, more graphitic structures form due to the augmented catalyst added during the synthesis process. The intensities of absorbance peaks rise from OPDC0.5 to OPDC1.5, suggesting an increase in the CNT concentrations.

A shoulder peak is observed in the OPDC0.5 sample at ~ 340 nm, attributed to the n-π* transitions of C=O48. According to Beer-Lambert law, the concentration of absorbing substance in a solution is directly proportional to the intensity of incident radiation19. Hence, the higher number of absorbing molecules leads to the greater extent of absorption of radiation.

The surface functional groups of OPDC samples are studied using FTIR, and the results are shown in (Fig. 3). The spectra reveal the presence of various functional groups, including C-O, C=H, C–H, C=C, and OH. The peak at ~ 656 cm−1 is assigned to the stretching vibration of Fe–O, resulting from the added ferrocene to the samples. The higher amount of catalyst used in preparing OPDC1.5 led to a notable increase in transmittance peak intensity for this sample49. Conversely, the lowest peak intensity is observed in OPDC0.5 due to its lower iron content, as will be confirmed later through qualitative analysis of synthesized samples. The peak at 1064 cm−1 is associated with aromatic ethers, with a notably high intensity for the samples with a high amount of catalyst. Moreover, the band attributed to 1400 cm−1 is due to the presence of C-H2, which is absent in OPDC0.5 while more prominent in OPDC1.5 compared to OPDC1.0.

The stretching vibrations of C=C are present in the range of 1534- 1694 cm−1, with the intensity of the peaks increasing from OPDC0.5 to OPDC1.5. Additionally, peaks located between 1996 and 2119 cm−1 indicate the presence of C=H, while a peak at 2342 cm−1 in the spectrum of OPDC1.5 is attributed to its interaction with atmospheric carbon dioxide. More pronounced peaks indicate the stretching vibration modes of SP2 C–H and SP3 C–H at 2993 and 2892 cm−1. The intense peaks around 3739 cm−1 are attributed to the formation of hydroxyl groups on synthesized OPDC samples50. The presence of these functional groups confirms the formation of CNTs from orange peel biomass. Overall, the transmittance intensity is higher for the sample with the highest ferrocene concentration (OPDC1.5), consistent with the literature findings51.

The XRD pattern of the samples (Fig. 4) shows two dominant diffraction peaks at \(2\theta ={26}^{o}\) and \(2\theta ={43}^{o}\), corresponding to the (002) and (100) plane reflections from graphitic carbon, respectively. The results reveal a slight narrowing of the main peak with increasing catalyst concentration. This trend can be attributed to the enhanced nucleation and growth of carbon-based materials facilitated by the addition of the catalyst, consistent with previous literature findings52. The d002-spacing of the graphitic surfaces was determined as 0.351 nm for OPDC0.5, 0.346 nm for OPDC1.0, and 0.342 nm for OPDC1.5. The crystallite size of the dominant peak of the samples was calculated using Scherer’s formula, \(L=\frac{K\lambda }{\beta Cos\theta }\) where L is the crystalline size, \(K\) is the shape factor (0.9), \(\lambda\) is the wavelength of the X-ray source (\(\lambda =1.54 nm\) ), \(\beta\) is the full width at half maximum of the main peak, and \(\theta\) is the diffraction angle53,54. The crystalline sizes are 0.30 nm for the OPDC0.5 sample, 0.36 nm for OPDC1.0, and 0.76 nm for the OPDC1.5 sample, indicating an increase in size with higher catalyst quantities. This phenomenon can be attributed to the intense fragmentation of iron present on the catalytic surface55,56,57.

The peak at \({37}^{o}\) is observed in both OPDC1.0 and OPDC1.5, accompanied by two additional shoulder peaks at \({42}^{o}\) and \({45}^{o}\), indicating the persistence of iron residues in these samples55. Notably, the intensity is significantly higher in OPDC1.5. These results imply that the complete removal of iron from the OPDC materials during H2SO4 washing might not have been attained. The increase in catalyst concentration in synthesizing biomass-derived CNTs leads to improved crystallinity, reduced structural defects, and enhanced alignment of nanotube structures, resulting in sharper and more pronounced XRD peaks58,59.

Raman spectroscopy was used to study the structural properties of synthesized OPDC samples, with results shown in Fig. 5. The two primary peaks at 1326 and 1590 cm−1 correspond to the disordered and ordered carbon atoms, respectively. The G band represents the vibrations of sp2-bonded graphitic carbon, while the D band signifies defects in the synthesized material, indicating the presence of amorphous carbon and catalyst particles52. Additionally, another broad peak observed at 2670 cm−1, is attributed to the 2D band, indicating the growth of multiple layers or MWCNTs with long-range arrangement of crystalline structures. The intensities of the observed peaks in Raman spectra are utilized to measure the degree of order and graphitization60,61. The ratio of the intensity of the D band to that of the G band or 2D band (ID/IG or I2D/IG) provides insight into the crystalline order of OPDC samples18. These results are shown in Fig. 6. The ID/IG ratio indicates the degree of defects and disorder in the synthesized OPDC materials. In contrast, the I2D/IG ratio measures the graphitization level. A higher ID/IG indicates greater disorder, whereas a higher I2D/IG value suggests enhanced graphitization62,63. The ID/IG ratios of OPDC samples are noted as 1.25, 1.10, and 1.07 for OPDC0.5, OPDC1.0, and OPDC1.5, respectively.

Similarly, the I2D/IG values are recorded as 0.75, 0.91, and 0.92 for OPDC0.5, OPDC1.0 and OPDC1.5. The declining trend in ID/IG ratios and the ascending trend in I2D/IG ratios suggest an increase in crystallinity corresponding to the rise in catalyst quantity. The OPDC1.5 sample exhibits enhanced graphitization and crystallization compared to the other samples, leading to a higher abundance of CNTs. This is further confirmed through morphological characterization of the samples.

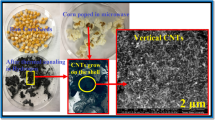

Morphological analysis of the synthesized OPDC samples was conducted using FESEM, as illustrated in Figs. 7–9, along with elemental analysis. Figure 7a–f shows the images of OPDC0.5 with different magnifications, revealing porous surfaces with sheet-like graphitic structures. These graphitic surfaces consist of nanosheets of graphitic carbon and exhibit a rippled surface along with smaller particles and pores, as reported earlier23,64,65. Moreover, at a scale of 100 nm, we observed irregular solid surfaces composed of disordered clusters with interconnected thin layers. Specifically, the images of (Fig. 7b,c) show the flake-like structures of graphitic carbon due to the graphitization in the presence of ferrocene, revealing the multilayer property of synthesized OPDC. Additionally, images in Fig. 7d–f demonstrate the presence of numerous pores with diameters below 50 nm as analyzed using Image J-software. Overall, the surface of OPDC0.5 exhibits irregular flake-like carbon with multiple micro-pore matrices signaling incomplete graphitization that was already initiated. Notably, no CNTs were observed in the OPDC0.5 samples, only amorphous carbon within an interconnected and incomplete sheet-like matrix, consistent with other characterization results.

The EDS spectra of the OPDC0.5 sample, shown in Fig. 7g, exhibits a significant intensity of carbon (82.36% by weight) due to the graphitic structure inherent in OPDC, with the presence of oxygen atoms comprising 13.17% by weight. Other elements such as Mg, K, C, and S are also detected, originating from the orange peel biochar. Despite being present in negligible amounts, Fe is observed, likely stemming from the catalyst51,58 which underwent thorough washing with H2SO4. The carbon-to-oxygen ratio of OPDC0.5 is determined to be 6.26.

Figure 1S, in the supplementary information (SI), shows the FESEM images of OPDC1.0 alongside elemental analysis and mapping. At low magnification, as shown in (Fig. 1Sa), the image displays an irregular graphitic structure similar to hard carbon. However, upon a slight increase in magnification, the presence of CNT clouds becomes evident across the surface, accompanied by a few graphitic flakes. Long clusters of CNTs are observable in Fig. 1Sb through (f), with diameters ranging from 20 to 50 nm. The irregular alignment of these CNT structures suggests the presence of some structural defects19. The addition of ferrocene facilitates the conversion of bulk carbon materials within the orange peel biochar into CNTs. Compared to the OPDC0.5 sample, surface irregularities such as incomplete graphitization and irregular graphitic flakes are reduced, leading to more crystalline structures. This observation aligns with other structural characterizations, such as XRD and Raman spectroscopy. Higher ferrocene concentrations cause the biomass to melt and fuse into a mass of vesicles, resulting in improved graphitization and crystallization66,67,68, consequently promoting the growth of CNTs32.

The elemental analysis of the OPDC1.0 sample is shown in (Fig. 1Sg), in which carbon accounts for approximately 78.43%, while oxygen makes up 10.45%. The EDS findings also identify additional elements such as Si, K, and Ca, which are inherent metallic species in orange peel biochar. These may have facilitated the growth of CNTs under suitable temperatures and catalyst conditions during pyrolysis66. The higher Fe content in this sample is due to an increased catalyst amount used during synthesis. Moreover, the carbon-to-oxygen ratio of OPDC1.0 is calculated to be 7.5, exceeding that of OPDC0.5.

The morphological analysis of the OPDC1.5 sample and its EDS qualitative analysis are shown in Fig. 2S (in SI). As shown, even at low magnification, as seen in (Fig. 2Sa), the presence of CNTs is evident, and in Fig. 2S (b), dense CNT clouds are visible. Images in Fig. 2Sc,d reveal twisted, curved, and threadlike CNTs interspersed with other carbon structures along the OPDC. At higher magnification, as shown in (Fig. 2Se,f), long, entangled, and vertically aligned CNTs are visible, in agreement to the literature44. The CNTs’ diameters are between 10 and 30 nm. This indicates that increasing the catalyst amount during the synthesis of OPDC1.5 results in the production of well-aligned rope-like CNTs of superior quality compared to the other samples.

Figure 2Sg displays the EDS spectra of this sample, revealing a carbon content of 71.47%, oxygen at 6.10%, and the presence of other inherent elements found in orange peel biochar, such as K and Ca. Despite washing the samples with H2SO4, complete removal of the catalyst from the OPDC1.5 sample was not achieved. Notably, the carbon-to-oxygen ratio for these samples is calculated to be 11.72, significantly higher compared to the other two samples.

Ferrocene, widely used as a catalyst in the synthesis of CNTs, serves a dual purpose as it provides iron nanoparticles and acts as a carbon source51,69,70. During pyrolysis, at temperatures above 300 °C, ferrocene undergoes thermal decomposition, releasing iron (Fe) nanoparticles and hydrocarbon derivatives such as methane, hydrogen, and cyclopentadiene. These Fe nanoparticles act as catalytic centers, facilitating the breakdown of carbon sources from both ferrocene and biomass. When combined with orange peel biomass, which is rich in carbon content, the process is further enhanced as ferrocene liberates Fe and C atoms within the biochar matrix, initiating CNT growth44. The C atoms released from the orange peel biochar diffuse into the Fe nanoparticles, which condense on the biochar substrate44. During supersaturation, the dissolved C atoms re-crystallize as CNTs on the Fe surface, while undissolved C atoms nucleate and contribute to CNT growth. The Fe nanoparticles are dispersed throughout the biochar and remain encapsulated within the CNT walls68,71, ensuring effective catalytic activity. Barreiro et al.70 has demonstrated that the optimal temperature for ferrocene decomposition is around 400 °C, ensuring efficient interaction between ferrocene-derived catalysts and biomass carbon, resulting in high-quality CNTs.

To further examine the quality of the CNTs, we have conducted TEM characterizations, and the results are shown in Figs. 8, 9.

Figure 8 depicts the TEM micrographs of OPDC1.0, showing the multiwalled-CNTs with diameters between 10 and 20 nm, determined using ImageJ software. An encapsulated iron catalyst is prominent in all images from (Fig. 8a–f), confirmed by the EDS elemental analysis. The presence of other carbon structures is also evident in (Fig. 8a,b). A closer examination of OPDC1.0 reveals the presence of long CNTs ranging from 100 -300 nm in length. In Fig. 8f, the lattice fringe measures around 0.354 nm, indicating the (002) plane of graphitic carbon59. This result aligns well with the calculated d-spacing obtained from XRD analysis. All the images reveal that the synthesized materials are MWCNTs from orange peel biochar. The wall thickness of these MWCNTs was determined to be 6.7 and 6.9 nm. Furthermore, the presence of irregularities in the shape and size of CNTs in OPDC1.0 are noticeable in the TEM images in (Fig. 8).

The TEM micrographs displayed in Fig. 9a–f provide insights into the characteristics of CNTs in the OPDC1.5 sample. In Fig. 9a, a low-magnification TEM image reveals a dense cloud of CNTs, with a noticeably smaller proportion of other carbonaceous materials compared to OPDC1.0. Long CNTs with diameters around 10 nm are observed. Notably, the OPDC1.5 samples exhibit CNTs with smaller dimensions than those in OPDC1.0. The CNTs in OPDC1.5 display varying diameters, ranging from 8 to 15 nm, with MWCNT thickness measured at 10.9 and 10.4 nm, respectively. It is worth highlighting that achieving CNT diameters below 10 nm through the pyrolysis method is a noteworthy outcome.27,72. Moreover, the encapsulation of Fe nanoparticles within the synthesized CNTs is observed along their length, which signifies that the acid wash procedure with H2SO4 couldn’t eliminate the catalyst during purification19,73. In Fig. 9f, the lattice fringe measures around 0.34 nm, indicating the (002) plane of graphitic carbon, which agrees with the calculated d-spacing acquired from XRD analysis59. Both ordered and disordered structures are observed in OPDC1.5 samples, with amorphous carbon between the crystalline carbons. Notably, the CNT structure and diameter irregularities are less pronounced in OPDC1.5 compared to OPDC1.0. The calculated surface areas, obtained from nitrogen adsorption–desorption isotherms (Fig. 3S) are 6.0 and 11.0 m2/g for OPDC1.0 and OPDC1.5, respectively, which are consistent with reported values in the literature (Ref.17,19,74). Results from the previous experiments indicate that OPDC1.5 predominantly comprises MWCNTs with a higher degree of graphitization and good thermal stability, confirmed from the carbon to oxygen ratio from EDS. Varied amounts of chemical reagents affected the growth of CNTs and the accumulation of amorphous carbon, resulting in varied morphologies15,32. These findings support the conclusion that increased ferrocene catalyst quantity used in OPDC material synthesis enables the successful production of MWCNTs51,75. It shows the necessity for an appropriate amount of chemical reagent in synthesizing CNTs from biomass.

Conclusion

In this study, a process for producing CNTs from orange peel biomass via pyrolysis catalyzed by different concentrations of ferrocene was developed. Increasing the amount of catalyst successfully facilitated the synthesis of CNTs, evidenced by the morphological analysis of OPDC1.0 and OPDC1.5 using FESEM and TEM. The UV-Vis absorption spectra showed a maximum absorbance peak at 285 nm, with increased intensity observed for OPDC1.5. FTIR spectra revealed the surface functional groups of synthesized OPDC materials. XRD analysis showed pronounced peaks for the OPDC1.5 sample compared to OPDC1.0 and OPDC0.5 samples, with a lattice spacing of 0.351, 0.346, and 0.342 nm for the samples OPDC0.5, OPDC1.0, and OPDC1.5, respectively. Moreover, Raman spectra indicated a descending trend in the ID/IG ratio and a rising trend in the I2D/IG ratio with increased catalyst quantity. The FESEM images depicted long rope-like CNT clusters in OPDC1.0 and OPDC1.5, while OPDC1.5 exhibited a higher CNT concentration and better alignment. TEM micrographs confirmed that the synthesized CNTs are multi-walled with diameters ranging from 8–20 nm, in which Fe nanoparticles were encapsulated inside the tube. The lattice spacing of OPDC samples obtained by the TEM analysis, recorded as 0.354 and 0.340 nm for OPDC1.0 and OPDC1.5, matched well with the XRD data. The EDS elemental analysis supported the results by providing a qualitative insight into OPDC material. Overall, samples synthesized with a higher amount of catalyst (OPDC1.5˃OPDC1.0˃OPDC0.5) exhibited a greater degree of wall graphitization and crystallization with diminished defects. This study suggests that lower catalyst levels result in the production of more carbon flakes and 2D carbons. Consequently, a higher catalyst concentration is required to produce biomass-derived CNTs, with low ID/IG ratio, smaller sizes, and higher carbon-to-oxygen ratios.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Iijima, S. Helical microtubules of graphitic carbon. Nature 354, 56–58. https://doi.org/10.1038/354056a0 (1991).

Notarianni, M., Liu, J., Vernon, K. & Motta, N. Synthesis and applications of carbon nanomaterials for energy generation and storage. Beilstein J. Nanotechnol. 7, 149–196. https://doi.org/10.3762/bjnano.7.17 (2016).

Frackowiak, E., Jurewicz, K., Szostak, K., Delpeux, S. & Béguin, F. Nanotubular materials as electrodes for supercapacitors. Fuel Process. Technol. 77–78, 213–219. https://doi.org/10.1016/S0378-3820(02)00078-4 (2002).

Tizani, L., Abbas, Y., Yassin, A. M., Mohammad, B. & Rezeq, M. D. Single wall carbon nanotube based optical rectenna. RSC Adv. 11, 24116–24124 (2021).

Bera, R. K., Mhaisalkar, S. G., Mandler, D. & Magdassi, S. Formation and performance of highly absorbing solar thermal coating based on carbon nanotubes and boehmite. Energy Convers. Manag. 120, 287–293 (2016).

He, H. et al. Carbon nanotubes: applications in pharmacy and medicine. BioMed Res. Int. 2013, 578290 (2013).

Anzar, N., Hasan, R., Tyagi, M., Yadav, N. & Narang, J. Carbon nanotube-A review on synthesis, properties and plethora of applications in the field of biomedical science. Sens. Int. 1, 100003 (2020).

AlOmar, M. K., Alsaadi, M. A., Jassam, T. M., Akib, S. & Hashim, M. A. Novel deep eutectic solvent-functionalized carbon nanotubes adsorbent for mercury removal from water. J. Coll. Interface Sci. 497, 413–421 (2017).

Arora, N. & Sharma, N. Arc discharge synthesis of carbon nanotubes: Comprehensive review. Diam. Relat. Mater. 50, 135–150 (2014).

Yudasaka, M., Komatsu, T., Ichihashi, T. & Iijima, S. Single-wall carbon nanotube formation by laser ablation using double-targets of carbon and metal. Chem. Phys. Lett. 278, 102–106 (1997).

Griffiths, O. G. et al. Identifying the largest environmental life cycle impacts during carbon nanotube synthesis via chemical vapour deposition. J. Clean. Prod. 42, 180–189 (2013).

Patole, S. P., Alegaonkar, P. S., Lee, H.-C. & Yoo, J.-B. Optimization of water assisted chemical vapor deposition parameters for super growth of carbon nanotubes. Carbon 46, 1987–1993 (2008).

Han, S. et al. Emission characteristic and environmental impact of process-based VOCs from prebaked anode manufacturing industry in Zhengzhou China. Atmosph. Pollut. Res. 11, 67–77 (2020).

Ge, L. et al. A review of comprehensive utilization of biomass to synthesize carbon nanotubes: From chemical vapor deposition to microwave pyrolysis. J. Anal. Appl. Pyrolys. 177, 106320 (2023).

Liu, J. et al. Biomass pyrolysis mechanism for carbon-based high-value products. Proc. Combust. Inst. 39, 3157–3181 (2023).

Tripathi, N., Hills, C. D., Singh, R. S. & Atkinson, C. J. Biomass waste utilisation in low-carbon products: harnessing a major potential resource. NPJ Climate Atmosph. Sci. 2, 35 (2019).

Lotfy, V. F., Fathy, N. A. & Basta, A. H. Novel approach for synthesizing different shapes of carbon nanotubes from rice straw residue. J. Environ. Chem. Eng. 6, 6263–6274 (2018).

Araga, R. & Sharma, C. S. One step direct synthesis of multiwalled carbon nanotubes from coconut shell derived charcoal. Mater. Lett. 188, 205–207 (2017).

Hidalgo, P., Navia, R., Hunter, R., Coronado, G. & Gonzalez, M. Synthesis of carbon nanotubes using biochar as precursor material under microwave irradiation. J. Environ. Manag. 244, 83–91 (2019).

Luna-Lama, F., Morales, J. & Caballero, A. Biomass porous carbons derived from banana peel waste as sustainable anodes for lithium-ion batteries. Materials 14, 5995 (2021).

Qureshi, W. A. et al. Antimicrobial activity and characterization of pomegranate peel-based carbon dots. J. Nanomater. 2021, 1–6 (2021).

Thangaraj, B. et al. Synthesis of reduced graphene oxide nanosheets from sugarcane dry leaves by two-stage pyrolysis for antibacterial activity. Nano Mater. Sci. 6, 625–634 (2024).

Thangaraj, B. et al. Synthesis of graphene oxide from sugarcane dry leaves by two-stage pyrolysis. Molecules 28, 3329 (2023).

Moallaei, H. et al. Application of Fusarium sp. immobilized on multi-walled carbon nanotubes for solid-phase extraction and trace analysis of heavy metal cations. Food Chem. 322, 126757 (2020).

Hoang, A. T. et al. Heavy metal removal by biomass-derived carbon nanotubes as a greener environmental remediation: A comprehensive review. Chemosphere 287, 131959 (2022).

Yang, M. et al. Dramatically enhanced electromagnetic wave absorption of hierarchical CNT/Co/C fiber derived from cotton and metal-organic-framework. Carbon 161, 517–527 (2020).

Zhou, Y., He, J., Chen, R. & Li, X. Recent advances in biomass-derived graphene and carbon nanotubes. Mater. Today Sustain. 18, 100138 (2022).

Tahir, Z., Khan, M. I., Ashraf, U., Adan, I. R. D. N. & Mubarik, U. Industrial application of orange peel waste; a review. (2023).

Sachidhanandham, A. Textiles from orange peel waste. Sci. Technol. Dev. J. 23, 508–516 (2020).

Janas, D. From bio to nano: A review of sustainable methods of synthesis of carbon nanotubes. Sustainability 12, 4115 (2020).

Verma, S. K. et al. Green synthesis of carbon-based nanomaterials and their applications in various sectors: a topical review. Carbon Letters, 1–29 (2021).

Rangel, M. D. C., Mayer, F. M., Carvalho, M. D. S., Saboia, G. & de Andrade, A. M. Selecting catalysts for pyrolysis of lignocellulosic biomass. Biomass 3, 31–63 (2023).

Saleh, T. A. A review on the technologies for converting biomass into carbon-based materials: sustainability and economy. Bioresour. Technol. Rep. 25, 101771 (2024).

Nor, N. M., Lau, L. C., Lee, K. T. & Mohamed, A. R. Synthesis of activated carbon from lignocellulosic biomass and its applications in air pollution control—a review. J. Environ. Chem. Eng. 1, 658–666 (2013).

Thangaraj, B. et al. Synthesis of reduced graphene oxide from onion peel waste by single-stage pyrolysis, characterization and evaluation of its antibacterial activity. J. Environ. Chem. Eng. 12, 113474 (2024).

Ayala, J. R. et al. Characterization of orange peel waste and valorization to obtain reducing sugars. Molecules 26, 1348 (2021).

Xin, S. et al. Chemical structure evolution of char during the pyrolysis of cellulose. J. Anal. Appl. Pyrol. 116, 263–271 (2015).

Yaashikaa, P., Kumar, P. S., Varjani, S. & Saravanan, A. A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Biotechnol. Rep. 28, e00570 (2020).

Burhenne, L., Messmer, J., Aicher, T. & Laborie, M.-P. The effect of the biomass components lignin, cellulose and hemicellulose on TGA and fixed bed pyrolysis. J. Anal. Appl. Pyrol. 101, 177–184 (2013).

Gao, Z., Li, N., Yin, S. & Yi, W. Pyrolysis behavior of cellulose in a fixed bed reactor: residue evolution and effects of parameters on products distribution and bio-oil composition. Energy 175, 1067–1074 (2019).

Shen, D. & Gu, S. The mechanism for thermal decomposition of cellulose and its main products. Biores. Technol. 100, 6496–6504 (2009).

Chen, Y., Zhang, X., Chen, W., Yang, H. & Chen, H. The structure evolution of biochar from biomass pyrolysis and its correlation with gas pollutant adsorption performance. Biores. Technol. 246, 101–109 (2017).

Zhan, M., Pan, G., Wang, Y., Kuang, T. & Zhou, F. Ultrafast carbon nanotube growth by microwave irradiation. Diam. Relat. Mater. 77, 65–71 (2017).

Baghel, P. & Kaushal, P. Rapid synthesis of carbon nanotubes from Prosopis Juliflora biochar using microwave irradiation. Mater. Sci. Eng. B 286, 115987 (2022).

Algadri, N. A., Ibrahim, K., Hassan, Z. & Bououdina, M. Cost-effective single-step carbon nanotube synthesis using microwave oven. Mater. Res. Express 4, 085602 (2017).

Njuguna, J., Vanli, O. A. & Liang, R. A review of spectral methods for dispersion characterization of carbon nanotubes in aqueous suspensions. J. Spectrosc. 2015, 463156 (2015).

Jiang, L., Gao, L. & Sun, J. Production of aqueous colloidal dispersions of carbon nanotubes. J. Coll. Interface Sci. 260, 89–94 (2003).

Li, D., Müller, M. B., Gilje, S., Kaner, R. B. & Wallace, G. G. Processable aqueous dispersions of graphene nanosheets. Nat. Nanotechnol. 3, 101–105 (2008).

Morsy, M., Helal, M., El-Okr, M. & Ibrahim, M. Preparation, purification and characterization of high purity multi-wall carbon nanotube. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 132, 594–598 (2014).

Aviles, F., Cauich, J., Moo-Tah, L., May Pat, A. & Vargas Coronado, R. Evaluation of mild acid oxidation treatments for MWCNT functionalization. Carbon 47, 2970–2975. https://doi.org/10.1016/j.carbon.2009.06.044 (2009).

Adel, A. M., Martinez-Sabando, J., Al-Shemy, M. T. & Cerveny, S. Effect of ferrocene on physicochemical properties of biochar extracted from windmill palm tree (Trachycarpus Fortunei). Waste Biomass Valor. 15, 1031–1051 (2024).

Gai, L., Li, J., Wang, Q., Tian, R. & Li, K. Evolution of biomass to porous graphite carbon by catalytic graphitization. J. Environ. Chem. Eng. 9, 106678 (2021).

Theyab, E. J. et al. X-ray diffraction analysis for main peaks and the noises of single and multi-walled carbon nanotubes. J. Eng. Technol. 4, 001–007 (2023).

Iwashita, N., Park, C. R., Fujimoto, H., Shiraishi, M. & Inagaki, M. Specification for a standard procedure of X-ray diffraction measurements on carbon materials. Carbon 42, 701–714 (2004).

Nakayasu, Y., Goto, Y., Katsuyama, Y., Itoh, T. & Watanabe, M. Highly crystalline graphite-like carbon from wood via low-temperature catalytic graphitization. Carbon Trends 8, 100190 (2022).

Xie, M., Yang, J., Liang, J., Guo, X. & Ding, W. In situ hydrothermal deposition as an efficient catalyst supporting method towards low-temperature graphitization of amorphous carbon. Carbon 77, 215–225 (2014).

Michalska-Domańska, M., Bystrzycki, J., Jankiewicz, B. & Bojar, Z. Effect of the grain diameter of Ni-based catalysts on their catalytic properties in the thermocatalytic decomposition of methanol. C. R. Chim. 20, 156–163 (2017).

Le, G. T., Mala, P., Ratchahat, S. & Charinpanitkul, T. Bio-based production of carbon nanotubes via co-pyrolysis of eucalyptus oil and ferrocene. J. Anal. Appl. Pyrol. 158, 105257 (2021).

Sun, Z. et al. Preparation and formation mechanism of biomass-based graphite carbon catalyzed by iron nitrate under a low-temperature condition. J. Environ. Manag. 318, 115555 (2022).

Kosateva, A., Stoycheva, I., Petrova, B. & Tsyntsarski, B. Characterization of some carbon materials by Raman spectroscopy. Bulgarian Chem. Commun. 53, 85 (2021).

Roy, D., Kanojia, S., Mukhopadhyay, K. & Eswara Prasad, N. Analysis of carbon-based nanomaterials using Raman spectroscopy: principles and case studies. Bull. Mater. Sci. 44, 31 (2021).

Bernd, M. G. S., Bragança, S. R., Heck, N. & da Silva Filho, L. C. Synthesis of carbon nanostructures by the pyrolysis of wood sawdust in a tubular reactor. J. Mater. Res. Technol. 6, 171–177 (2017).

Paul, S. & Samdarshi, S. A green precursor for carbon nanotube synthesis. New Carbon Mater. 26, 85–88 (2011).

Zhao, H. et al. Biomass-derived graphene-like porous carbon nanosheets towards ultralight microwave absorption and excellent thermal infrared properties. Carbon 173, 501–511 (2021).

Kong, X. et al. Synthesis of graphene-like carbon from biomass pyrolysis and its applications. Chem. Eng. J. 399, 125808 (2020).

Esohe Omoriyekomwan, J., Tahmasebi, A., Zhang, J. & Yu, J. Synthesis of super-long carbon nanotubes from cellulosic biomass under microwave radiation. Nanomaterials 12, 737 (2022).

Zhao, J.-R., Hu, J., Li, J.-F. & Chen, P. N-doped carbon nanotubes derived from waste biomass and its electrochemical performance. Mater. Lett. 261, 127146 (2020).

Lee, C. J. & Park, J. Growth model of bamboo-shaped carbon nanotubes by thermal chemical vapor deposition. Appl. Phys. Lett. 77, 3397–3399 (2000).

Yah, C. S., Simate, G. S., Moothi, K., Maphutha, K. S. & Iyuke, S. E. Synthesis of large carbon nanotubes from ferrocene: the chemical vapour deposition technique. Trends Appl. Sci. Res. 6, 1270 (2011).

Barreiro, A. et al. Thermal decomposition of ferrocene as a method for production of single-walled carbon nanotubes without additional carbon sources. J. Phys. Chem. B 110, 20973–20977 (2006).

Bajpai, R. & Wagner, H. D. Fast growth of carbon nanotubes using a microwave oven. Carbon 82, 327–336 (2015).

Omoriyekomwan, J. E., Tahmasebi, A., Dou, J., Wang, R. & Yu, J. A review on the recent advances in the production of carbon nanotubes and carbon nanofibers via microwave-assisted pyrolysis of biomass. Fuel Process. Technol. 214, 106686 (2021).

Hong, E. H., Lee, K. H., Oh, S. H. & Park, C. G. Synthesis of carbon nanotubes using microwave radiation. Adv. Func. Mater. 13, 961–966 (2003).

Hidalgo, P. et al. Carbon nanotube production from algal biochar using microwave irradiation technology. J. Anal. Appl. Pyrol. 172, 106017 (2023).

Kumar, M. & Ando, Y. A simple method of producing aligned carbon nanotubes from an unconventional precursor–Camphor. Chem. Phys. Lett. 374, 521–526 (2003).

Acknowledgements

S. F would like to thank Dr. Baskar for providing her with initial training. She also extends her gratitude to Mr. Ali Abdulla and Mr. Yusuf Ibrahim Olatunji for their assistance with some characterization measurements.

Funding

Khalifa University fund number CIRA-2020-051 partially funds this research.

Author information

Authors and Affiliations

Contributions

S. F. and J. H. wrote the main manuscript. The conceptualization, supervision, and project administration of this work were owned by J.H., M.R. TEM images were prepared by S. P. The methodology, validation, and analyses of figures were carried out by S. F., J. H., M.R, S. A., S. P, and D. H. Funding was provided by J.H. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Farsana, S., Rezeq, M., Abedrabbo, S. et al. Effect of catalyst in the synthesis of orange peel biomass derived CNTs. Sci Rep 15, 23024 (2025). https://doi.org/10.1038/s41598-025-07151-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-07151-x