Abstract

This study examines the mechanical and durability behaviors of cement mortar containing sesame shells (SS) as partial substitutes of cement and sand with regard to sustainable construction using an agricultural by-product. Three types of SS—raw powder, vinegar-treated powder and vinegar-thermal-treated powder (250 °C)—were used as the fine aggregate replacements at 1%, 2%, and 3% by weight. Mechanical performances (compressive strength, dry density) and durability (UPV, water absorption, water porosity, workability) of the composites were investigated in a systematic manner. Results show that substituting sand with SS causes a significant decrease in the compressive strength (up to 54% at 3%of replacement) and the increase in porosity and water absorption that compromised the durability. On the contrary, the use of SS, particularly the treated one, caused strength decrease (up to 42.3%) with improved durability properties specifically lower porosity (8.84%) and lower water absorption (1.7%). UPV of all mixes were above 4.2 km/s representing good internal consistency. Error bars were included in all test figures with replicate specimens to properly demonstrate the variation and to reinforce the reliability of the data. The findings suggest that the optimal use of SS is as a 3% cement replacement in treated form, offering an environmentally friendly alternative with acceptable mechanical performance and significantly improved durability.

Similar content being viewed by others

Introduction

The cement industry is a major contributor to global carbon emissions, accounting for approximately 8% of anthropogenic CO2 emissions worldwide, with nearly 0.9 tons of CO2 released per ton of cement produced. This environmental burden, coupled with the depletion of natural sand resources due to escalating concrete demand, underscores the urgency of developing sustainable alternatives1,2,3,4. Agricultural waste materials, such as sesame shells (SS), offer a dual opportunity to mitigate these challenges by reducing cement dependency and repurposing underutilized biomass5,6,7. Over 6 million tons of sesame are harvested annually, generating vast quantities of SS that are typically burned or discarded, exacerbating air pollution and waste management issues8,9,10,11. Roman builders utilized ash leftovers from burning agricultural trash; they combined the ashes with lime and clay and kneaded the mixture for about two days to create a cement-like substance with extremely strong bonds12,13,14. Leveraging SS in cementitious systems not only addresses these environmental concerns but also aligns with circular economy principles by transforming waste into value-added construction materials.

The increasing demand for concrete globally poses significant environmental challenges, particularly due to the production of Portland cement, which accounts for approximately 7–8% of global CO2 emissions. Every ton of cement produced emits nearly 0.9 tons of CO2, largely due to calcination and fuel combustion during manufacturing. In light of escalating environmental concerns and the depletion of natural resources, sustainable alternatives to conventional cement and fine aggregates have become a research priority. This study specifically addresses these challenges by investigating the use of SS—an underutilized agricultural by-product—as partial replacements for both cement and sand in mortar production. Unlike prior research which has predominantly focused on sesame shell ash (SSA) or fiber applications, this work explores the mechanical and durability performance of mortars incorporating untreated and treated SS, providing new insights into their synergistic behavior when used as dual replacements. The novel contribution lies in evaluating the combined effects of chemical (vinegar) and thermal (250 °C) treatments on SS and identifying optimal substitution levels (1–3%) that achieve enhanced sustainability without compromising structural integrity.

Additionally, research is being done on the employment of agricultural solid wastes as admixtures, additives, and aggregates in concrete. Billions of tons of agricultural waste are produced by agriculture in many countries of the world. Many wastes can only be burned to produce energy, and they cannot be used in any other value chain. Agricultural wastes frequently lead to disposal issues15,16. Therefore, studies on the effective utilization of these solid wastes will contribute to addressing the consumption of the materials in a more ecologically responsible manner17,18,19. Researchers have recently demonstrated that ashes from a variety of agricultural leftovers can be used in the concrete industries. Because of the high proportions of CaO, SiO2, Al2O3, and Fe2O3 in its chemical composition, it can partially replace conventional stabilizers like cement and quicklime20,21,22,23,24. Green concrete—a concrete that is more sustainable and friendly to the environment—can be made in the concrete industry by using agricultural residue ash25,26,27,28,29.

Current studies investigated the utilization of SS as a promising material for concrete and cement mortars, building on the research into the utilization of agricultural waste and addressing both environmental concerns and the rising costs of traditional materials. In these materials, cement plays a vital role in ensuring the cohesiveness of the cement paste and its adherence to aggregate particles, both of which affect the concrete’s strength30. However, the cost of building has increased due to the rising cost of cement, necessitating the use of alternative materials. Sesame shell, an agricultural waste product, offers a way to save expenses while addressing environmental issues. If not managed appropriately, sesame shell—which is usually burned, disposed of, or allowed to decompose—can produce a large amount of trash as well as pose health and environmental risks. Sesame straw can be added to concrete and mortar mixtures to reduce waste and provide the construction industry with an eco-friendly, more inexpensive building material31,32.

The utilization of agricultural waste in cementitious materials has gained significant attention as a sustainable alternative to conventional construction resources. While studies have explored various agro-waste materials, the potential of SS remains underexplored. For instance, Sulaiman, et al.33 investigated sesame straw ash (SSA) as a 10–30% cement replacement in concrete, reporting a 15% reduction in compressive strength at 20% substitution. Their methodology involved grinding ash to 45 μm and testing strength at 28 days. Similarly, Elmardi, et al.34 incorporated sesame stalk fibers (SSF) at 0.5–2% by volume, observing improved flexural strength but reduced workability due to fiber clumping. These studies focused solely on ash or fiber forms, neglecting untreated SS and dual replacements. Furthermore, Orame, et al.35 explored the potential of sesame plant mucilage (Sesamum indica) as an additive in concrete. Their analysis revealed that sesame mucilage contains 25.58% SiO2, Al2O3, and Fe2O3 collectively. Over a 28-day curing period, the compressive strengths of concrete mixtures with 1.0%, 1.5%, and 2.0% sesame mucilage content were higher than those of the control mix, achieving values of 33.2 MPa, 31.3 MPa, and 30.8 MPa, respectively. Additionally, increased sesame mucilage content enhanced the flexural and tensile strengths of the mixtures at all curing ages, surpassing those of the control mix. Lastly, Sulaiman, et al.31’s study examined the impact of SSA combined with rice husk ash (RHA) in place of cement on the durability and flexural strength of concrete. In the experiment, cement was substituted out for mixed rice husk and sesame straw ashes in increments of 0, 10, 15, 20, 25, and 30%. The blend of SSA and RHA was shown to be a useful addition to cementitious ingredients for making concrete.

In contrast, Orame, et al.35 explored sesame mucilage (1–2% by weight) as a concrete admixture, achieving 33.2 MPa compressive strength at 28 days through polysaccharide-enhanced hydration. However, their work did not address SS as a direct cement or sand substitute. Walnut shell studies, such as Aadi, et al.36replaced cement with 5–10% untreated walnut powder, resulting in a 25% strength loss due to poor pozzolanicity. Mohammed et al. [31] Mohammed, et al.37 substituted sand with walnut shells (10–30%), finding optimal performance at 20% under high temperatures. These works highlight trade-offs in single-material substitutions but lack insights into combined cement-sand replacements or SS-specific treatments. In another study, the fine aggregate was replaced by walnut shells (WS) in three ratios (10, 20 and 30) % in production cement mortar exposed to room temperature, 400 ⁰C and 600 ⁰C by Mohammed, et al.38. There was a negative impact of usage walnut shells on mortar’s properties and they concluded that the best ratio of WS is 20% with water to cement ratio 0.5 for structural construction exposed to 400 ⁰C. The fine and coarse aggregates were replaced by WS in five ratios (5, 10, 15, 20 and 25) % in producing concrete by Hilal, et al.39. The concrete’s mechanical properties affected negatively by usage WS and they found that the best ratio of WS is 15% for fine and coarse aggregate to get appropriate properties for concrete. Moreover, the WS was utilized as substitution of coarse aggregate in ten ratios (5, 10, 15, 20, 25, 30, 35, 40, 45 and 50) % in casting of self-compacting concrete (SCC) by Hilal, et al.40. The WS led to reduce fresh and hardening properties of SCC and produced lightweight SCC.

Notably, no studies have systematically evaluated the synergistic effects of chemical treatments (e.g., vinegar) combined with thermal processing on SS or their role in mitigating the performance drawbacks observed in untreated SS-based mortars. Furthermore, the majority of research on agricultural waste replacements focuses on single-material substitution (either cement or sand), leaving a gap in understanding how dual replacements influence mechanical and durability outcomes.

This study addresses these gaps by (1) investigating SS as a partial replacement for both cement and sand in mortars, (2) comparing untreated SS with SS treated via vinegar and heat (250 °C) to enhance pozzolanic activity, and (3) identifying optimal replacement ratios (1–3%) that balance sustainability with performance. The research aims to establish whether SS, through tailored treatments and replacement strategies, can serve as a viable alternative to conventional materials while maintaining compliance with structural and durability standards. By bridging the knowledge gap on SS’s dual role and treatment efficacy, this work advances the development of eco-friendly mortars and contributes to circular economy principles in construction. The methodology of the present study is illustrated in Fig. 1.

Research significance

The construction industry continuously seeks sustainable alternatives to conventional materials to reduce environmental impacts and improve the mechanical properties of concrete. In recent years, the incorporation of agricultural waste materials such as sesame shells has emerged as a promising solution due to their abundance, low cost, and potential pozzolanic activity. However, limited research has been conducted on using sesame shells as both a partial replacement for cement and fine aggregates in mortar, especially with a focus on durability and mechanical performance.

This study addresses this gap by evaluating the feasibility of using sesame shell powder and crushed sesame shell as partial replacements for cement and sand, respectively. The significance lies in providing experimental evidence on the mechanical properties and durability performance of such modified mortars, contributing to the body of knowledge in sustainable construction materials. The findings aim to support the development of eco-friendly mortars while also offering a method for agricultural waste management.

Experimental program

The materials, procedures, and tests used in this investigation are described in this section. Tests for hardened cement mortar properties (compressive strength, ultrasonic pulse velocity, absorption, and porosity) as well as fresh cement mortar properties (flow test) are included here.

Materials

Cement

All cement mortar samples were made using ordinary Portland cement type-I in accordance with Iraqi Standard (IQS) No. 541. Tables 1 and 2, respectively, provide an illustration of the used cement’s chemical and physical characteristics.

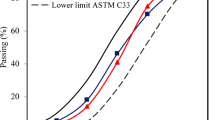

Sand

The specific gravity, fineness modulus, and water absorption of the sand employed in this investigation were 2.68, 3.02, and 1%, respectively. Dry quantities of sand were used for each mixture. The used sand’s sieve analysis is displayed in Fig. 2.

Sesame

The SS were collected by burning sesame waste, which contributes to the cement’s chemical composition. Its specific gravity is 2.69 and its moisture content is 1.95%. The forms used include SS that were washed and treated with vinegar, untreated sesame powder, and sesame powder treated with vinegar. Portable water was used for mixing and curing. Moreover, the chemical composition of the SS was not determined via X-ray fluorescence (XRF) analysis due to resource constraints. Therefore, the pozzolanic nature of the SS used remains unverified through direct oxide quantification. However, previous research has reported that many types of agricultural waste—such as rice husk ash, palm oil fuel ash, and corn cob ash—contain significant amounts of reactive silica (SiO₂), alumina (Al₂O₃), and iron oxide (Fe₂O₃), which are key indicators of pozzolanic behavior15,20,25,42. Treatment processes like acid washing and moderate thermal exposure (e.g., 250 °C) have been found to enhance pozzolanic reactivity by removing lignin, hemicellulose, and other organics, while preserving amorphous silica42,43. These principles guided the treatment strategy in this study using vinegar (acetic acid) and heating, similar to methods used for other biomass materials. Nonetheless, without XRF or XRD characterization, SS in this research should be considered as a potential filler or physical additive with assumed pozzolanic potential based on indirect evidence and prior literature. Future investigations should incorporate detailed chemical and mineralogical analyses to validate the pozzolanicity of SS. Figure 3 presents the sesame shells (SS) in their unprocessed form prior to grinding, whereas Fig. 4 displays the untreated SS powder obtained after the burning process.

Methods

Mix proportions and tests

The SS used in this study were obtained from industrial waste in Mosul city, Iraq. The preparation and testing of cement mortar specimens using various sesame by-products as partial substitutes for sand and cement comprised the four main phases. Three distinct types of sesame by-products were prepared for the mix proportions: SS for sand replacement, and untreated and treated sesame powder for cement replacement. The SS were washed, vinegar-treated, and completely dried in order to prepare them. SS were sun-dried, soaked in vinegar for an hour, and then heat-treated at 250 °C for an hour in an oven before being ground into a powder. This process produced treated sesame powder. A control mix containing no sesame, mixes with sand replaced by SS at 1%, 2%, and 3%, mixes with cement replaced by untreated sesame powder at 1%, 2%, and 3%, and mixes with treated sesame powder at 1%, 2%, and 3% were all produced. Specimens of cement mortar were made in compliance with applicable standards and guidelines and allowed to cure for 7, 28, and 56 days, following standard procedures.

A series of tests were conducted on ten cubic cement mortar specimens, each measuring 70.7 × 70.7 × 70.7 mm, during the first (control) phase of the program. Using a flow table instrument, the workability of each cement mortar was assessed in compliance with ASTM C143744. One specimen was tested for compressive strength after 7 days of curing, three specimens after 28 days, and three specimens after 56 days. The specimens used for compressive strength testing—three samples at 28 days and another three at 56 days—were also subjected to ultrasonic pulse velocity (UPV) testing in accordance with ASTM C59745 in order to determine the longitudinal stress wave pulses’ propagation velocity through the cement mortar specimens. Three specimens underwent an absorption test based on ASTM C 64246 standard. First, they were oven-dried for 24 h at 105 ± 5 °C, and then their dry and wet weights were measured after they were submerged in water for 48 h. Two of the samples that were used in the absorption test were subjected to vacuum saturation in order to ascertain their porosity values after all air has been extracted from the hardened cement mortar specimens and they have been saturated with water. To conduct the porosity test47,4850 × 50 × 50 mm samples are cut from the original specimens, which have dimensions of 70.7 × 70.7 × 70.7 mm. After being oven-dried for 24 h at 105 ± 5 °C, their dry weight (Wd) is determined. Subsequently, the samples are placed within a desiccator that has a tightly sealed lid, and gel is added to maintain a consistent moisture level. Subsequently, the samples undergo a full day of 0.1 kPa suction pressure to eliminate any pore air, and after that, they are immersed in water for a further 24 h. After that, the specimen’s weight is determined both with it saturated with water (Wsat) and submerged in water (Ww). By knowing these weights, it is possible to assess the specimens’ overall porosity. The samples underwent standard water curing throughout this stage.

In the second phase, 1%, 2%, and 3% substitution levels of vinegar-treated and cleaned SS were utilized as a partial replacement of sand. Ten cubic mortar specimens were cured using nylon bags before being subjected to the similar testing series as in the first phase. The reason behind using nylon bags as a curing method is that when the samples were initially cured using standard water curing method it was observed that all the samples began to crack after passing 2 to 3 days. In the third phase, however, cement was partially substituted with untreated sesame powder at the same percentages (1%, 2%, and 3%). In this phase, also ten cubic cement mortar samples were cast and tested under standard water curing. Lastly, at the same substitution levels (1%, 2%, and 3%), sesame powder treated with vinegar and thermally processed for an hour at 250 °C was utilized as a partial substitute for cement in the fourth phase. Following the preceding process, ten cubic mortar specimens were cast, and the samples underwent conventional water curing. The combinations employed in this experimental investigation are all listed in Table 3. The symbols utilized for mixes are consisted from letters and numbers; the first letter (S) refers to SS, the second letter (S or C) refers to sand or cement replacement, the third and fourth letters (V, NV) refer to use vinegar or nonuse vinegar for treatment sesame, the other letter T refers to treatment of sesame to high temperature, and the numbers refer to ratios of sesame as sand or cement substitution. For example, SCVT1 refers to mix contains 1% sesame treated by vinegar and high temperature. Table 4 summarizes the tested parameters and the experiments conducted for each group.

Vinegar (acetic acid) was selected over other acids (e.g., HCl or NaOH) due to its mild reactivity, which effectively removes surface oils and lignin from SS without damaging silica-rich structures critical for pozzolanic activity43. Thermal treatment at 250 °C was chosen to carbonize residual organic matter while preserving the amorphous silica content, as higher temperatures (> 300 °C) risked crystallizing silica, reducing reactivity42. Alternative methods, such as alkaline activation (NaOH) or pyrolysis, were excluded due to complexity and higher environmental impact49. Figure 5 illustrates the specimens containing SS as a sand replacement while undergoing the treatment process. While Fig. 6 shows the specimens during the burning process.

Results and discussion

Compressive strength

In first series compressive strength decreased with increasing the ratio of SS at all ages (see Fig. 7). At the 1% ratio, the compressive strength at the ages of 7 and 28 days was the same, at the 2% the compressive strength values were the same at age of 28 and 56 days. While at 3% ratio, the compressive strength was variable at the ages of 7, 28 and 56 days. This may be due to the fact that the SS treated with vinegar had some pozzolanic properties that increased with age, and this was clear with the increase in its percentage. In any case, there was a slight reduction in strength with the increase of the percentage of SS treated with vinegar. The maximum compressive strength was 33.5 MPa for 1% ratio of SS at age of 56 days.

For the first series, the decrease in compressive strength increased with the increase in the percentage of SS treated with vinegar as seen in Fig. 8. This decrease varied with age, and the largest decrease was approximately at the age of 56 days, at the ratios of 1 and 2%, but at a rate of 3%, the largest decrease in strength was at the age of 7 days, which means that there is a negative effect on compressive strength with age for this series. The maximum reduction was 54% for mix SSV3 at age 7 days and the minimum decrease was 16.4% for mix SSV1 at age 7 days. The 54% compressive strength reduction observed at 3% sand replacement (SSV3) aligns with trends reported by Sulaiman, et al.33who noted a 15% strength loss at 20% sesame straw ash (SSA) cement replacement. The sharper decline here may stem from SS’s lower pozzolanicity compared to SSA, as untreated SS lacks the amorphous silica content critical for secondary hydration21,22. This suggests that untreated SS, unlike ash forms, cannot compensate for reduced cementitious bonding, leading to pronounced strength losses.

Even though substitution levels of SS were low (1–3%), there was evidence of reduction in compressive strength because SS is non-cementitious and has no binding or load bearing property as cement and sand. Furthermore, the non-spherical and rough surface structure of SS particles could cause poor packing density and low interfacial adhesion, resulting in relatively high porosity and low strength of the corresponding composite. Restricted pozzolanic reaction of the untreated/mildly treated SS makes an additional contribution in this regard (as it does not always get involved in the hydration reactions). These are the causes of the decrease in strength for the low levels of replacement.

The compressive strength decreased when cement was replaced with untreated sesame treated with vinegar for all ages, and the change in compressive strength remained slight with changing the proportions of untreated sesame with vinegar, (see Fig. 9). The lowest compressive strength was at 2%, and this may be due to the fact that the pozzolanic properties of untreated sesame with vinegar are less than cement, and that changing the proportions had a slight effect.

In the second series, the lowest decrease in compressive strength was at the age of 56 days, and the highest decrease was at the age of 7 days for ratios 1 and 2%, and at the age of 28 days for ratio 3%, as shown in Fig. 10. Also, the highest decrease in compressive strength for ratio 2% at 7 days age which reflected that replacing cement with sesame not treated with vinegar reduces its effect on compressive strength with age, and indicates that the pozzolanic activity of sesame not treated with vinegar increases with age in interaction with the hydration results of the basic cement components.

Figure 11 shows the decrease in compressive strength was less in third group for all ages. The strength decreased slightly with increasing the percentage of cement replacement with sesame treated with vinegar and exposed to a temperature of 250 °C. This is due to the fact that treating sesame with heat and vinegar led to improving its pozzolanic properties and reducing its negative effects on compressive strength. The maximum strength was 41.8 MPa for 1% SS at age 56 days.

In the third group, the lowest reduction (22.94%) occurred at 56 days for the 1% mix, while the highest reduction was 42.28% at 28 days for the 3% mix and 41.46% at 7 days for the 1% mix, (see Fig. 12). Treating sesame with vinegar and exposing to heat had a positive effect in increasing the pozzolanic activity of the treated sesame, which appears with increasing age, as is clear from the decrease in strength with increasing age, but the best percentage to obtain the best resistance was 1%. Thermal-vinegar treatment improved SS’s pozzolanic activity, yielding 25.46 MPa at 28 days for SCTV3. This aligns with Zeyad, et al.23who demonstrated that 250 °C treatment preserved reactive silica in agro-wastes, unlike higher temperatures (> 300 °C) that crystallize silica and reduce reactivity.

At the age of 7 days, the first series gave the best compressive strength at ratio 1%, the third series had the highest compressive strength at ratio 2%, and the second series had the best strength at ratio of 3% as seen in Fig. 13.

At the age of 28 days, the second series gave a slight increase in compressive strength more than the rest of the series at ratio of 3% (see Fig. 14). At ratios 1% and 2%, all series had almost the same strength and almost the best strength at 1% ratio.

At the age of 56 days (Fig. 15), the third series gave the highest compressive strength at 1 and 2% ratios and the second series gave the highest strength at ratio of 3%. The ratio of 1% gave the highest strength for all series and the changes were slight between all proportions and the strength for all ratios and series was more than 30 MPa. This means that the pozzolanic activity increases with age for the third and second groups.

Dry density

Figure 16 shows that the density decreased for the first series and the reduction increased with the increase in the ratio of sesame. The lowest density was at the age of 7 days and the highest density was at the age of 28 days. This means that sesame shell is lighter than sand and that there are chemical reactions that occur with age leading to a slight increase in weight with age.

It is noted at the first series that the greatest relative decrease in density compared with reference mix was (−8.75%) at the age of 7 days, where this reduction increased with the increase in the ratios of SS. However, the less relative decrease in density was at the age of 28 days, where it followed the same trend as the age of 7 days, with a different percentage of decrease. Finally, the smallest relative decrease in density (−2.19%) at the age of 56 days, with the same trend as the two previous ages, with a different percentage of reduction, (see Fig. 17). This is evidence that chemical reactions and hydration products increase with age and thus the weight and density increase that leads to reduce the relative decrease.

In the second series (Fig. 18), the density decreased significantly at the age 56 days for all ratios of SH. At age 28 days, the density was greatest for 1% and 2% ratios. However, at age 7 days, the density was in moderate values for 1% and 2% ratios and at ratio of 3% the maximum density (2235,47 kg/m3) was found. This means that with advancing age more water evaporation occurs.

It is noted that the greatest decrease in density is (−6,4%) at the age 7 days for ratios 1% and 2% for the second series (see Fig. 19), and the less decrease in density for the same age is (−2.06%) at a rate of 3%, while the least decrease in density is (−1.0%) at the age of 28 days at a ratio of (1 and 2) %. The reason may be that the pozzolanic activity of SS appears at early ages, which leads to an increase in hydration products with age, and consequently an increase in density and a reduction in its decrease.

In the third series (Fig. 20), the density also decreased with the increase in the ratios of SS and age progress. This indicates that the sesame treated with vinegar and heat is lighter in weight than the cement, and the decrease in density increases with age due to the evaporation of water. The minimum density is 2111.62 kg/m3 for ratio of 3% at age 56 days. Also, the weight of the materials resulting from the reaction of the treated sesame with the hydration products is less in weight than the materials entering into its reaction.

It is noted in the third series (Fig. 21) that the greatest decrease in density is (−5.28%) for ratio of 3% at the age of 7 days and the least at the age of 28 days for all ratios with different decrease values, as these decrease rates ranged between 0.8% and 5.2%. This trend confirms that hydration products increase with age, peaking at 28 days.

Porosity

It is noted in the first series (Fig. 22) that the porosity increased from 14.1 to 15.2% by 1% and decreased to 14.3% by 3%. This indicates that increasing the ratio of SS can fill the continuous gaps and reduces porosity.

It is noted in the second series that the porosity decreased compared to the reference mixture and the reduction increased with the increase in the ratio of SS and was 8.84% for ratio 3%, (see Fig. 23). This means that the untreated sesame replaced as cement is considered capable of filling the continuous gaps and this may be due to the agglomeration of SS particles as a result of its un-treatment. Porosity results (8.84% for SCNV3) are compared to Thiedeitz, et al.15highlighting SS’s superior pore-filling capability relative to rice husk ash.

It is noted in the third series (Fig. 24) that the porosity decreased compared with the reference mixture and the porosity increased with the increase in the ratio of treated and heat-exposed SS and the porosity was 11.08% for ratio 3%. This indicates that treated SS increases continuous voids as its proportion increases, but it remains less than the reference mixture that used only cement. The results show that SS as a cement replacement is more effective than cement in filling the continuous voids.

Ultrasonic pulse velocity (UPV)

It is noted in the first series that the ultrasonic speed decreased slightly by using SS and was approximately 3.5 at the age of 28 days and was 4.405, 4.346 and 4.312 km/sec at age 56 days for 1, 2, and 3% respectively, where at ratio of 3% the UPV has the same at ages (28 and 56) days, that indicates the quality of the mixtures via using SS is very good quality at late age (56 days) as the reference mixture (see Fig. 25).

It is noted in the second series that the UPV decreased slightly by using SS compared to the reference mixture and has the same value at ages (28 and 56) days; it ranges between (4.315 and 4.434) km/sec for all proportions (see Fig. 26). This finding shows that the quality of the mixtures with the use of untreated SS as cement replacement leads to very good quality for all ratios and two ages (28 and 56) days. These results reflect the low porosity of this series compared with reference mix.

It is noted in the third series that the UPV decreased slightly through utilize SS when comparing to reference mix and has almost the same value at ages (28 and 56) days; it ranges between (4.264–4.396) km/sec for all ratios as shown in Fig. 27. The results of this series are similar to findings of second series and have the same indicator of very good quality for all ratios of treated SS as cement replacement in mortar. Also, these findings illuminate some low porosity of this series.

Compressive strength and ultrasonic velocity relationships

Figure 28 shows the relationship between compressive strength and UPV for first series. It found a polynomial formula with coefficient of determination R2 0.969 for age 28 days and a linear expression with R2 0.991 for age 56 days. Linear formulas with R2 0.934 and 0.892 were found for the relationship between compressive strength and UPV at ages 28 and 56 days respectively of second series (see Fig. 29). Figure 30 shows linear expression related compressive strength with UPV with R2 0.902 and 0.959 at ages 28 and 56 days respectively of third series. It is possible to use the obtained formulas to find compressive strength from the values of UPV.

Water absorption

It is noted in the first series that water absorption increased with the use of SS and decreased with the increase in the percentage of SS. It ranges between (7.409–6.068) % which is 23.53–1.17% more the water absorption of reference mix (see Fig. 31). This is evidence that the use of untreated sesame as sand replacement reduces water absorption by increasing its percentage due to the clumping of SS, which reduces water absorption.

It is noted in the second series that water absorption decreased significantly compared to the reference mixture through the use of untreated SS as cement substitution, and the decrease in water absorption increased with increasing the percentage of SS. It ranges between (4.031–1.702) % which 32.79–71.62% less than the reference mix as shown in Fig. 32. This indicates that SS can reduce water absorption and stands as an obstacle to water penetration due to its oily nature. Reduced water absorption (1.7% for SCNV3) is benchmarked against Agwa, et al.25who observed similar trends in cotton stalk ash-modified concrete.

It is noted in the third series that water absorption is significantly lower than the reference mixture, and the decrease increased with the increase in the treated SS exposed to heat. It varied from 2.662 to 2.003% which is 55.614–66.611% less than the reference mix as shown in Fig. 33. The findings show that the used treatment can increase the prevention of sesame husks from absorbing water and made them a moisture barrier.

Workability

It is observed that flow-ability decreased slightly by use of SS as sand in the first series as seen in Fig. 34. While there was a significant reduction in flow table values at mix has 1% SS in second and third series and there was an improvement in workability by using 3% untreated and treated SS as cement as shown in Figs. 35 and 36.

Conclusions

The use of SS as a cement replacement improved durability characteristics such as water absorption and porosity, with minimal to moderate reductions in compressive strength. Treated SS showed improved pozzolanic reactivity, further enhancing the performance of cement mortar. These outcomes highlight the viability of using agricultural waste—specifically sesame husks—to reduce reliance on cement and natural sand, lowering CO₂ emissions and conserving natural resources. This study thus supports the development of more sustainable building materials and aligns with circular economy goals in the construction sector. There are the following concluded points:

-

1.

There is a reduction in compressive strength by using SS as a sand substitute (first series) for all ages, and this reduction is augmented when the ratio of SS increases. However, it can get 24 MPa and 28.64 MPa at age (28 and 56) days respectively for mortar containing 3%. Using treated and untreated SS as cement replacement (second and third series) led to less reduction in compressive strength for all ages. The 27.92 MPa and 37.89 MPa at ages (28 and 56) days respectively were found when using 3% untreated SS as cement substitute, and 3% treated SS as cement replacement led to 25.46 MPa and 34.95 MPa at ages (28 and 56) days respectively. However, the increased ratio of SS in the second and third series caused more reduction in compressive strength.

-

2.

The density decreased through the use of SS as sand and cement replacement; more reduction happened by using SS as sand followed by the use of treated SS as cement, then the use of untreated SS as cement for all ages (7, 28, and 56) days. This reduction is slightly increased when the ratio of SS is augmented. The 2084 kg/m3, 2119 kg/m3, and 2112 kg/m3 at age 56 days were found for first, second, and third series respectively.

-

3.

The porosity increased by using SS as sand replacement (first series) and this increase decreased via increasing the ratio. While the porosity was reduced by using untreated and treated SS as cement substitute (second and third series); the minimum porosity was 8.84% for the mix containing 3% untreated SS as cement.

-

4.

The UPV decreased slightly in the first, second, and third series at ages (28 and 56) days. The second and third series shows approximate values of UPV at ages (28 and 56) days. The results indicate the very good quality of mortar contained untreated and treated SS as sand or cement, and these findings reflect the obtained results of lower porosity.

-

5.

The water absorption increased through the use of SS in the first series, and the increase was reduced via the increased ratio of SS. The water absorption decreased significantly in the second and third series and the minimum value was 1.7% for mix has 3% untreated SS as cement. The behavior of water absorption is the same as that of porosity.

-

6.

Workability showed a minimal reduction in the first series, indicating that substituting SS for sand had a lesser impact on flowability compared to SS used as a cement replacement. The mix that contained 3% untreated and treated SS as cement has better workability than mixes contained 1% in the second and third series.

-

7.

It found good relationships between compressive strength and UPV for all series and two age (28 and 56 days) with R2 more than 0.9.

-

8.

The treatment of SS with vinegar and heating has less influence on the properties of the mortar.

-

9.

It is recommended to use 3% untreated SS as cement in the production of sustainable mortar with good strength and durability.

This study demonstrated the potential of using sesame husk as a partial replacement for both cement and sand in mortar mixes. The findings revealed that incorporating sesame husk up to 10% replacement of cement and 25% replacement of sand can enhance certain mechanical and durability properties while contributing to sustainable construction practices through waste utilization.

However, the study had some limitations. Firstly, only short-term mechanical and durability performance was assessed. Long-term behavior, such as shrinkage, creep, and resistance to aggressive environmental conditions, was not investigated. Secondly, the chemical interaction between sesame husk components and cement hydration products was not explored in detail. Moreover, the influence of different processing methods (e.g., thermal or chemical treatment of the husk) on its performance was not considered.

To improve the efficiency of sesame husks in future studies, it is recommended to:

-

Explore chemical or thermal pre-treatment methods to reduce organic content and improve bonding with the cement matrix.

-

Investigate hybrid combinations of sesame husk with supplementary cementitious materials (e.g., fly ash, GGBFS) for synergistic effects.

-

Assess long-term durability and microstructural properties under various environmental exposures.

-

Evaluate the economic and environmental impact through life cycle analysis to establish practical applicability in large-scale construction.

The findings from this research can directly benefit sustainable building practices, especially in regions with abundant sesame production. By offering an eco-friendly solution for agricultural waste management, the study contributes to reducing cement consumption and sand mining, both of which have significant environmental footprints.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Hakeem, I. Y. et al. Effects of nano sized Sesame stalk and rice straw ashes on high-strength concrete properties. J. Clean. Prod. 370, 133542 (2022).

Bignozzi, M. C. Sustainable cements for green buildings construction. Procedia Eng. 21, 915–921 (2011).

Ali, M. K., Kareem, Q., Ahmad, S., Shawkat, I. A. & Kassim, M. in E3S Web of Conferences. 02017 (EDP Sciences).

Allah, S. J. S., Kassim, M. M. & Salman, G. A. The Durability of Concrete Mortars with Different Mineral Additives Exposed to Sulfate Attack. Salud, Ciencia y Tecnología-Serie de Conferencias 3, 851–851 (2024).

Arel, H. Ş. & Aydin, E. Use of industrial and agricultural wastes in construction concrete. ACI Mater. J. 115, 55–64 (2018).

Qader, D. N., Merie, H. D. & Abdulhaleem, K. N. Impact of incorporating plastic fibers, walnut shells, and tire rubber fibers on the mechanical properties of concrete. Electron. J. Struct. Eng. 25, 19–24 (2025).

Avudaiappan, S., Gómez, R., Betancourt, F., Canales Cardenas, C. & Chávez-Delgado, M. Experimental investigations on sustainable mortar containing mining tailing as partial replacement of fine aggregate. Int. J. Min. Reclam. Environ. 39, 235–247 (2025).

Gil-Carrera, L., Browne, J. D., Kilgallon, I. & Murphy, J. D. Feasibility study of an off-grid biomethane mobile solution for agri-waste. Appl. Energy. 239, 471–481 (2019).

Wang, Z., Bui, Q., Zhang, B. & Pham, T. L. H. Biomass energy production and its impacts on the ecological footprint: an investigation of the G7 countries. Sci. Total Environ. 743, 140741 (2020).

Bilgili, F., Koçak, E., Bulut, Ü. & Kuşkaya, S. Can biomass energy be an efficient policy tool for sustainable development? Renew. Sustain. Energy Rev. 71, 830–845 (2017).

Al-Luhybi, A. S. & Qader, D. N. Mechanical properties of concrete with recycled plastic waste. Civil Environ. Eng. 17, 629–643 (2021).

Heniegal, A. M., Ramadan, M. A., Naguib, A. & Agwa, I. S. Study on properties of clay brick incorporating sludge of water treatment plant and agriculture waste. Case Stud. Constr. Mater. 13, e00397 (2020).

Alaei Moghadam, J. & Mousavi Haji, S. R. A research on newly discovered architectural remains of Fardaghan in Farahan (A Sassanian fire temple or an Islamic Castle). Int. J. Humanit. 24, 81–102 (2017).

Saad, M., Agwa, I. S., Abdelsalam Abdelsalam, B. & Amin, M. Improving the brittle behavior of high strength concrete using banana and palm leaf sheath fibers. Mech. Adv. Mater. Struct. 29, 564–573 (2022).

Thiedeitz, M., Ostermaier, B. & Kränkel, T. Rice husk Ash as an additive in mortar–Contribution to microstructural, strength and durability performance. Resour. Conserv. Recycl. 184, 106389 (2022).

Prusty, J. K., Patro, S. K. & Basarkar, S. Concrete using agro-waste as fine aggregate for sustainable built environment–A review. Int. J. Sustainable Built Environ. 5, 312–333 (2016).

Schmidt, W. et al. Sustainable circular value chains: from rural waste to feasible urban construction materials solutions. Developments Built Environ. 6, 100047 (2021).

Schmidt, W., Olonade, K. A., Radebe, N. W., Ssekamatte, V. & Zando, F. Green urban development creates rural employment perspectives. Rural 21, 36–38 (2020).

Schmidt, W. et al. in Proceedings of the 3rd RILEM Spring Convention and Conference (RSCC2020) Volume 1: Strategies for a Resilient Built Environment 3. 119–132 (Springer).

Chandra Paul, S., Mbewe, P. B., Kong, S. Y. & Šavija, B. Agricultural solid waste as source of supplementary cementitious materials in developing countries. Materials 12, 1112 (2019).

Zeyad, A. M., Johari, M. M., Tayeh, B. A. & Yusuf, M. O. Efficiency of treated and untreated palm oil fuel Ash as a supplementary binder on engineering and fluid transport properties of high-strength concrete. Constr. Build. Mater. 125, 1066–1079 (2016).

Zeyad, A. M., Johari, M. A. M., Tayeh, B. A. & Yusuf, M. O. Pozzolanic reactivity of ultrafine palm oil fuel Ash waste on strength and durability performances of high strength concrete. J. Clean. Prod. 144, 511–522 (2017).

Zeyad, A., Johari, M., Tayeh, B. & Saba, A. Ultrafine palm oil fuel ash: from an agro-industry by-product into a highly efficient mineral admixture for high strength green concrete. J. Eng. Appl. Sci. 12, 35 (2017).

Onyelowe, K. C. et al. Evaluating the impact of waste marble on the compressive strength of traditional concrete using machine learning. Sci. Rep. 15, 13417 (2025).

Agwa, I. S., Omar, O. M., Tayeh, B. A. & Abdelsalam, B. A. Effects of using rice straw and cotton stalk ashes on the properties of lightweight self-compacting concrete. Constr. Build. Mater. 235, 117541 (2020).

Johari, M. M., Zeyad, A., Bunnori, N. M. & Ariffin, K. Engineering and transport properties of high-strength green concrete containing high volume of ultrafine palm oil fuel Ash. Constr. Build. Mater. 30, 281–288 (2012).

Mo, K. H., Alengaram, U. J., Jumaat, M. Z., Yap, S. P. & Lee, S. C. Green concrete partially comprised of farming waste residues: a review. J. Clean. Prod. 117, 122–138 (2016).

Jayanthi, V. et al. Innovative use of micronized biomass silica-GGBS as agro-industrial by-products for the production of a sustainable high-strength geopolymer concrete. Case Stud. Constr. Mater. 18, e01782 (2023).

Al-Luhybi, A. S., Al-Jubory, N. H. & Ahmed, A. S. Influence of superplasticizer dosage on workability and mechanical properties of concrete made with recycled aggregate. Journal Eng. & Technological Sciences 54, 873–890 (2022).

Sulaiman, T. A. et al. Assessment of the characteristics and durability of Sesame husk Ash concrete. J. Environ. Spectr. 4, 14–21 (2024).

Sulaiman, T., Ejeh, S., Lawan, A. & Kaura, J. Experimental investigation of Sesame straw Ash blended with rice husk Ash on flexural strength and durability of concrete. Nigerian J. Sci. Res. 21, 65–71 (2022).

Sulaiman, T. A., Ejeh, S. P., Lawan, A. & Kaura, J. M. Effects of Sesame straw Ash as a substitute for cement on strength characteristics of concrete. FUOYE J. Eng. Technol. 7, 274–279 (2022).

Sulaiman, T., Mohammed, A., Aliyu, I., Ja’e, I. & Wada, S. Assessment of Sesame Straw Ash as Partial Replacement of Cement in Mortar. Proceedings of the Materials Science and Technology Society of Nigeria (MSN), OAU, Ile-Ife, Nigeria 1, 40–45 (2020).

Elmardi, M., Kbbashe, A., Alkhair, O. & Abdelmagid, T. The effect of adding Sesame stalks fibers to concrete mixture. Int. Res. J. Modernization Eng. Technol. Sci. 3, 1402–1409 (2021).

Orame, A. P., Abdulazeez, A. S., Kolawole, M. A. & Student, M. T. An explorative study on the suitability of Sesame plant mucilage (Sesamum Indicum) as admixture in concrete. Int. J. Eng. Appl. Sci. Technol. 4, 574–581 (2020).

Aadi, A. S., Mohammed, A. A., Ali, T. K. M. & Hilal, N. N. Ultra-Fine treated and untreated walnut shell Ash incorporated cement mortar: properties and environmental impact assessments. Ann. Chim. Sci. Matériaux. 46, 313–321 (2022).

Mohammed, A. N., Johari, M. A. M., Zeyad, A. M., Tayeh, B. A. & Yusuf, M. O. Improving the engineering and fluid transport properties of ultra-high strength concrete utilizing ultrafine palm oil fuel Ash. J. Adv. Concr. Technol. 12, 127–137 (2014).

Mohammed, A. S., Hilal, N. N., Ali, T. K. M. & Sor, N. H. in Journal of physics: conference series. 012034 (IOP Publishing).

Hilal, N., Ali, M., Tayeh, B. A. & T. K. & Properties of environmental concrete that contains crushed walnut shell as partial replacement for aggregates. Arab. J. Geosci. 13, 1–9 (2020).

Hilal, N. N., Sahab, M. F. & Ali, T. K. M. Fresh and hardened properties of lightweight self-compacting concrete containing walnut shells as coarse aggregate. J. King Saud University-Engineering Sci. 33, 364–372 (2021).

IQS(No.5). (1984).

Adesanya, D. & Raheem, A. A study of the workability and compressive strength characteristics of corn cob Ash blended cement concrete. Constr. Build. Mater. 23, 311–317 (2009).

Xu, F. et al. Transforming biomass conversion with ionic liquids: process intensification and the development of a high-gravity, one-pot process for the production of cellulosic ethanol. Energy Environ. Sci. 9, 1042–1049 (2016).

ASTM-C1437. in Standard Test Method for Flow of Hydraulic Cement Mortar. (2007).

ASTM-C597. in Standard Test Method for Pulse Velocity Through Concrete. (2016).

ASTM-C642. in. Standard Test Method for Density, Absorption, and Voids in Hardened Concretes (West Conshohocken, 2013).

Al-Luhybi, A. S., Aziz, I. A. & Mohammad, K. I. in Structures. 1932–1938 (Elsevier).

Al-Omari, A. & Khattab, S. I. Al-Hadba minaret, a contribution in characterizing of its brick. Key Eng. Mater. 857, 48–55 (2020).

Bridgwater, A. V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenerg. 38, 68–94 (2012).

Acknowledgements

The authors gratefully appreciate the support provided by the Dirección de Investigación de la Universidad Católica de la Santísima Concepción, Concepción, Chile. Also, this study is supported via funding from Departamento de Ciencias de la Construcción, Facultad de Ciencias de la Construcción y Ordenamiento Territoria, Universidad Tecnológica Metropolitana, Santiago, Chile.

Author information

Authors and Affiliations

Contributions

A.S.A. and D.N.Q. conceived the research idea and designed the experimental program. A.S.A., T.K.M.A., and D.N.Q. conducted the experimental work and data collection. M.A. and N.M. contributed to the statistical analysis and interpretation of the results. P.F.P. and S.A. provided critical insights into the methodology and supervised the technical aspects of the research. All authors contributed to the literature review, manuscript drafting, and final revision. D.N.Q. and S.A. coordinated the project and correspondence. All authors reviewed and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Al-Luhybi, A.S., Ali, T.K.M., Qader, D.N. et al. Evaluating the mechanical performance and durability of cement mortars incorporating sesame shells as partial cement and sand replacement. Sci Rep 15, 21875 (2025). https://doi.org/10.1038/s41598-025-07753-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-07753-5

Keywords

This article is cited by

-

From coal waste to construction resource: evaluating the physical and thermomechanical performance of masonry mortar incorporating fly ash

Journal of Building Pathology and Rehabilitation (2026)