Abstract

A novel kind of cascade refrigeration cycle for ultra-low temperature applications has been proposed in the present work to enhance thermal performance with reduced carbon footprints more economically. The conventional cascade refrigeration system (CCRS) has been modified, implementing a single auxiliary cycle (CRSAC) and dual auxiliary cycle (CRDAC) between HT and LT cycle and their performances are compared with CCRS and cascade refrigeration system with mechanical precooling (CRMP). The implementation of auxiliary cycles enables the modified cascade refrigerators to operate with lower compression ratio. The CRDAC cycle consumes 24–40% less energy than CCRS, 51–68% less than CRMP, and 23–38% less than CRSAC. Keeping the condenser temperature fixed at 318 K, varying the evaporative temperature from 193 to 220 K, the COP values of CRDAC, CRSAC, CRMP, and CCRS vary from 1.245 to 2.181, 0.89 to 1.41, 0.44 to 0.64, and 0.68 to 1.1 respectively. The CRDAC cycle provides approximately 40%, 62%, and 32% lower TEWI values and 13%, 25%, and 33% fewer E.I.I. values than CCRS, CRMP, and CRSAC cycles. Under the same operating conditions, the CRDAC cycle runs at 30–41% lower operational cost than CRSAC, 35–68%, and 37–60% lower than CRMP and CCRS, respectively.

Similar content being viewed by others

Introduction

The COVID-19 pandemic has increased the demand for supplying COVID-19 vaccines worldwide within a limited time. The ultra-low temperature storage requirement for procuring COVID-19 vaccines has raised concerns about designing the cascade refrigeration system, which can produce a cooling effect up to 193 K evaporative temperature. The cascaded refrigeration cycles implemented in the refrigerated van used to transport vaccines are designed to produce a cooling effect of up to 220 K and were unsuitable for preserving COVID-19 Vaccines1. This inability of refrigerated vans to transport the vaccines worldwide leads to the loss of wealth, properties, and even human life. Especially in India, during the transportation phase of COVID-19 vaccines, almost 50% of vaccines were ruined, resulting in various losses of properties, wealth, and the lives of patients1. This hazardous situation has raised concerns about developing a cold supply chain to safeguard the transportation, distribution, and storage of COVID-19 vaccines.

To overcome these difficulties, ultra-low temperature cooling is required, which can be achieved by an auto-cascade refrigeration system and a traditional double vapor compression cascade refrigeration system to produce a cooling effect up to 193 K evaporative temperature2. Although the Stirling cycle is also suitable for producing cold effects up to 193 K, its heavy weight, noisy operation, and bulky size restrict it from being implemented in refrigerated vans2. Many researchers have done significant research in ACRS to achieve ultra-low temperatures3. The conventional ACRS retrofitted to operate with a mixture of refrigerants having different boiling points can achieve an evaporative temperature of up to 183 K4. Using multiple refrigerants in a single compressor causes an increase in the pressure, as well as the temperature at the outlet of the compressor. This results in many losses, such as the failure of lubricating oil, which destroys the compressor unit5,6,7. Another drawback of ACRS is its lower cooling capacity and poor refrigeration separation process, leading to lower COP7. With the ability to operate with different kinds of refrigerant mixtures, the conventional cascade refrigeration cycle (CCRS) is always preferred over auto-cascade refrigeration cycles (ACRS), making the CCRS more economical and flexible3,7.

Many researchers investigated the conventional cascade refrigeration system (CCRS) using different combinations of refrigerants to operate with. The greater advantage of using CCRS is its ability to operate multiple combinations of refrigerants in both high and low-temperature cycles. Many researchers used R717, R1290, R290, R600, R600A, RE170, HFE7000, HFE7100, R404A, R410A, and R134A etc, as refrigerants in HT cycle and R23, R41, R170, R744A, R508A, R744, R1150 etc in LT cycle. The refrigerant pair R508A-R404A can provide a larger cooling capacity with high COP8. A comparative study to analyze the performances of CCRS was conducted by Yilmaz et al.9 using different refrigeration combinations. The study results in a higher COP of the system operating with R1270/R170 compared to the CCRS operating with R508B-R404A. The use of a single refrigerant in both cycles of CCRS can lead to high COP as compared to mixed refrigerants but cannot achieve larger temperature lift10. For cooling up to 223 K evaporative temperature, the refrigerant pair R717/R744 is best among all refrigerant pairs to provide high COP and lower carbon emission rate due to the lower GWP values of each refrigerant11. However, the flammability and toxic behavior of R717 raise concerns about finding an alternate refrigerant. Eco-friendly refrigerants like R290 and R1270 can provide better energetic and exergetic efficiency compared to R71712. Replacing R717 with R290 and R1270 results in lower operating costs with higher COP and exergy efficiency13,14. Victor et al.15 compared the performances of various alternatives of R717 in the HT cycle of CCRS and found that the refrigerant HFE7000 is best-suited among other refrigerants because of its lower environmental impact. In the earliest research, many researchers have used R744 as the working fluid in the lower cycle to provide the cold effect. Many researchers conducted thermal and economical performance analysis of R744-based cascade refrigeration with different refrigerants like R717, R717, R1234yf, R290, R1270, and R1234ze, etc. in the upper cycle to enhance the refrigerator’s performances16,17,18.

Li et Al.19 analyzed ted R744R717 cascade refrigerator using data driven strategy to find optimal conditions. All these researchers concentrate on increasing the thermal performance of the cascade refrigeration cycle to produce a cooling effect up to 223 K for generating a cold effect at ultra-low temperature, approx 193 K; R744 is not a recommended refrigerant due to its triple point, which limits the use of R744 as refrigerant for providing cooling up to 216 K. To produce a cold effect at 193 K evaporative temperature, the refrigerants should have a very low normal boiling point and a triple point. The refrigerants such as R41, R170, R1150, R13, R23, and R744A can cool up to 193 K as they possess lower normal boiling points (Table 1)20,21,22. Aktemur et al.23 analyzed the performances of R41 refrigerant paired with RE170, R1234zf, and R600 and found that the refrigerant pair R41/RE170 performs far better than other refrigerant pairs. Further, the refrigerant pair R170/R290 also provides higher COP and better economic conditions than R1150/R29024,25. Yang et al.26 compared the thermodynamic performances of the cascade refrigeration cycle with R717/R170, R717/R41, and R717/R1150 and noted higher COP as well as exergy efficiency for refrigerant pair R717/R170. Implementing the Topsis analysis method to optimize the thermal performances of cascade refrigeration, Prajapati et al.27 minimized the operation cost to USD 65228/year with an enhanced COP of 63.65%.

However, the refrigerants R170 and R41 can be replaced by R744A, a natural refrigerant with low GWP and zero ODP, as R744A has high latent heat and also high volumetric cooling capacity as compared to formers28. In association with ILK, researchers at the Karlsruhe University of Applied Science developed two cryogenic systems to achieve 193 K cooling temperature using R744A as refrigerant29. Kumar et al.30 compared the thermal performances of the cascade refrigeration cycle along with an economic analysis, considering R744A as the main fluid used to operate in the LT cycle and other eco-friendly refrigerants in the HT cycle. The refrigerants used for analysis in the HT cycle were R290, R1270, R600, R600A, RE170, R717, and HFE. The study concludes that the optimum thermal performance of the cascade refrigeration cycle running with the R744A/R600 refrigerant pair outperforms other combinations with very low operational costs.

The above literature highlights the use of eco-friendly refrigerants to produce ultra-low temperature cooling and indicates methods for increasing thermal performance. The use of internal heat exchangers and economizers, as well as replacing throttle valves with ejectors, expanders, etc., results in higher COP and exergy efficiency. Mechanical subcooling and air preheating can also increase energy efficiency31. The mechanical subcooling results in higher COP but lowers the exergetic efficiency. Previous studies show that using an internal heat exchanger and ejector expansion harms the environmental and economic performances of the cascade refrigerator32,33. Zare et al.34 optimized thermal performances of refrigeration cycle implementing ejector with booster mechanism. Further the power requirement can also be reduced by implementing the thermoelectric generator to recover the waste heat35,36.

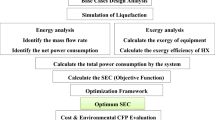

As per the literature, it is clear that finding the best refrigerant pair for a cascade refrigeration system to provide a cold effect up to 193 K is very demanding. Several types of research have been done, and some refrigerants have been provided that are best suitable for low-temperature cooling applications. However, a few researches have been done to improve the design of conventional cascade refrigerators. The condenser of the cascade refrigeration cycle operates normally at a temperature range of 313 K to 323 K and the evaporation is done at 193 K to achieve ultra low temperature cooling. This large temperature difference causes the cycle to operate at higher pressure ratio. The pressure ratio of the compressors of each cycle directly impacts the work input requirement of the cycle and, hence, the COP. The larger the pressure difference, the more work consumption by the compressor, resulting in a lower COP. To overcome these difficulties, two novel designs of cascade refrigeration systems are proposed and analyzed to increase the system’s performance. One kind of cycle comprises a traditional double vapor cascade refrigeration cycle implemented with an auxiliary cycle between low and high-temperature cycles. The second one uses two auxiliary loops in parallel positions, allowing each auxiliary cycle to interact with both LT and HT cycles. The present study will analyze energy, exergy, and environmental analysis, environmental impact index, and total operational cost of the cycles. It will be compared with traditional cycle and mechanical pre-cooled conventional cascade refrigerators to achieve ultra-low evaporation temperature. The thermodynamic properties at each stage are calculated by developing system codes on EES software and further tested using Referprop V.8.0. The main focus of the present work is to achieve higher thermal performances with lower operational costs and reduced carbon footprints to safeguard the environment from ozone depletion and global warming using R744A in the LT cycle and R600 in the HT cycle.

Methodology

Figure 1a shows the schematics of the conventional cascade refrigeration cycle and the corresponding P–h diagram is shown in Fig. 1b. In Fig. 1a,b, the lower cycle i.e. 1-2-3-4-1 runs with R744A as the working fluid to achieve 193 K evaporation temperature. Meanwhile, the upper cycle, '5-6-7-8-5,' runs with R600 as a working fluid. Both cycles are composed of a compressor, condenser, and expansion valve and are cascaded with each other by means of the cascade heat exchanger. The cascade heat exchanger serves as an evaporator and condenser for the upper and lower cycles, respectively, at the same time. The refrigerant flowing through the lower cycle gets condensed in the cascade heat exchanger, causing the evaporation of refrigerant flowing in the upper cycle. The cascade refrigerator is assumed to work between 193 and 323 K temperature limits. The compressors of both cycles run on different pressures. The refrigerant in each cycle is being compressed in each compressor of respective cycles (process 1–2 in the lower cycle and 5–6 in the upper cycle). Processes 2–3 and 6–7 represent the condensation of the lower and upper cycles, respectively. The expansion process is shown through 3–4 and 7–8 for the upper and lower cycles, respectively, whereas the evaporation process for respective cycles is shown through 4–1 and 8–5, respectively.

(a) Conventional Cascade Refrigeration System (CCRS). (b). Cascaded cycle’s P–h diagram16. (c) Cascade Refrigeration Cycle with Mechanical Precooler (CRMP). (d). P–h diagram Cascaded Refrigerator with mechanical precooler.

Figure 1c represents the conventional cascade refrigerator incorporated with a dedicated mechanical precooling cycle viz: 6-7-8-9-6. The refrigerant R744A in a lower cycle of the cascade refrigerator is now being precooled (process 2–3) before reaching the cascade condenser, where it is again condensed by losing heat to the evaporator of the upper cycle (process 13–10). Both the upper and mechanical precooling cycles are running with R600 as working fluid, and the condenser of both cycles is considered an air-cooled condenser. The temperature limits of lower cycles are considered 193 K to 255 K and those for the mechanical precooling cycle and for the upper cycle of the cascade refrigerator are considered 255 K to 323 K and 250 K to 323 K, respectively. As the condensers of these cycles are considered air-cooled condensers, both are working at the same temperature. The lower and upper cycles of the cascade refrigerator with mechanical pre-cooler are represented by 1-2-3-4-5-1 and 10–11-12–13-10, respectively. The corresponding P–h diagram is shown in Fig. 1d.

Figure 2a shows the schematics of the cascade refrigeration cycle incorporated with an auxiliary cycle operating with R600 as a working fluid. In Fig. 2a,b, the cycle ‘1-2-3-4-5-1’ represents the LT cycle to generate cold, and the cycle ‘10–11-12–13-14–10’ represents the HT cycle. Meanwhile, the cycle ‘6-7-8-9-6’ is the auxiliary cycle implemented in between LT and HT cycle. After being compressed through the LT compressor, the refrigerant of the LT cycle gets condensed by transferring heat to the refrigerant flowing through the evaporator of the auxiliary cycle and then again condensed in the cascade heat exchanger incorporated between the LT and HT cycle. Similarly, the refrigerant of the HT cycle is evaporated twice, viz; through the cascade heat exchanger unit incorporated between the LT and HT cycle and then by the cascade heat exchanger unit incorporated between the Auxiliary and HT cycle. The HT cycle runs within 253 K to 323 K temperature limits, and the auxiliary cycle runs within the temperature limit of 223 K to 263 K. The LT cycle runs between 193 to 228 K temperature limits. The pressure-enthalpy diagram of the cycle is shown in Fig. 2b.

The auxiliary cycle reduces the compressor work by reducing the compressor ratio of the compressors running in both HT and LT cycles, increasing the COP with lower electricity consumption compared to the conventional cycle. However, the larger temperature difference between the LT cycle’s condenser and the HT cycle’s evaporator results in maximum exergy destruction, which results in lower exergy efficiency. To overcome this limitation, a new design of cascade refrigeration cycle is being proposed in this study, as shown in Fig. 2c. This cycle consists of two auxiliary cycles between the HT and LT cycles to reduce the pressure ratio of compressors of each cycle to reduce electricity consumption (Fig. 2d). Each auxiliary cycle is incorporated with both LT and HT cycles, which enables each cycle to operate with a smaller temperature gap in each cascade heat exchanger unit, resulting in a lower exergy destruction rate and increased exergy efficiency. The temperature limits for the cycle are 193 K to 228 K. The auxiliary cycle, represented by cycle 6-7-8-9-6, runs within temperature limits of 223 K to 273 K, and the auxiliary cycle, represented by cycle 10-11-12-13-10, operates within 218 K to 268 K. The temperature limits of the HT cycle (14-15-16-17-18-14) are 263 K to 323 K. The corresponding P–h diagram is shown in Fig. 2d.

Mathematical modeling

To investigate the thermal performances viz; energy and exergy analysis, along with environmental analysis, each cycle is assumed to operate with following assumptions:-

-

1.

Mass flow rate in lower cycle of each configuration is taken as 1 kg/s.

-

2.

The throttling process for each cycle is considered as fully adiabatic.

-

3.

Isentropic efficiency of each compressor running in each cycle is considered equal to 0.7

-

4.

Each systems operating at steady state conditions with negligible kinetic and potential energy.

-

5.

Heat drop and pressure loss in each pipe is negligible.

Enery and exergy analysis

Energy analysis provides the amount of heat and work transferred through system boundaries, whereas exergy analysis provides the actual amount of maximum useful work that can be obtained from a thermodynamic system before reaching a dead state. Thus, energy analysis of the cascade refrigeration cycle relates to the quantity of energy, while the exergy analysis measures the system’s quality. In the present work, both energy and exergy analysis has the following balancing equations:-

The balancing equation for mass for each cycle is as follows:-

Similarly, the energy balance for each configuration is given as:

The total work input requirement for each cycle is given as:-

For Conventional Cascade Refrigeration Cycle:-

For Cascade Refrigeration Cycle with Mechanical Precooler:-

For Modified Cascade Refrigeration cycle with Single Auxiliary Cycle:-

For Modified Cascade Refrigeration cycle with Dual Auxiliary Cycle, total work input is calculated as:-

The heat rejected in the condensation process of the HT gas cooler and through evaporation in the LT cycle for each configuration is calculated as follows:

The energy balance at the cascade heat exchanger yields the mass flow rate of each cycle’s refrigerant as:

The COP for each cycle can be written as:

The above expression only relates to the amount of cooling effect produced by individual cycles concerning power input. Thus, it measures the system’s quantitative effort. The exergy analysis of any thermodynamics system measures the system’s quality by estimating the amount of useful work obtained by the system from given input energy. The exergy balance equation for the cascade refrigerator can be expressed as:-

Neglecting the potential energy and kinetic energy and assuming zero the surface tension effects, the total exergy of the system can be written as:

The energy destruction rate for each system component can be found as follows:

Total exergetic efficiency can be expressed as:-

Economical analysis

The economic analysis considers only the system components’ investment and operational costs to determine the refrigeration system’s total cost. Table 2 shows the capital cost associated with each component of all refrigerator configurations.

A simple logarithmic mean temperature difference analysis will be conducted to find the area of each heat exchanger device and expressed as follows:

The values of overall heat transfer coefficient ‘U’ are 30, 40, and 1000 Wm−2K−1 for the evaporator, condenser, and cascade condenser, respectively. The operational cost can be estimated by calculating the power consumption by the cycle and can be given as:

The total cost is calculated as:-

where CRF is the capital recovery factor and is calculated as:

The refrigerants used in the cascade refrigeration cycle also emit carbon to the environment. The cost associated with the carbon emission can be expressed in terms of environmental cost as:-

where \(\dot{m}_{{{\text{co}}2}}\) and \(C_{{{\text{co}}2}}\) represents mass of carbon dioxide gas emitted by the cascade cycle and the cost associated with CO2 emissions in kg and USD, respectively. The cost of CO2 emission is assumed to be approximately 90 USD per ton of CO2 emissions. The total mass of carbon dioxide gas emissions for the present cascade cycle is estimated as follows:

where ‘H,’ the total operation hours per year for each configuration is considered equal to 6570 h in a year, and \({\mu }_{co2}\) is the emission conversion factor considered as 0.968 kg/kWhr.

Total equivalent warming impact (TEWI) Analysis

The environmental analysis brings estimation of Total Equivalent Warming Impact (TEWI) and an Environmental Impact Index (EII) analysis for any cascaded refrigerator. The TEWI analysis estimates the greenhouse gas emission rate for any thermodynamic system and their global warming impact. The value of total equivalent warming impact cab me mathematically expressed in terms of direct and indirect CO2 emissions as follows:

In the above equation, M represents the refrigerant charge for cycle, L is leakage rate, and N represents life cycle of the cascade refrigerator in years (Table 3). The recycling factor α is assumed equal to 0.7 for each cycle.

Environmental impact index analysis

TEWI analysis involve estimation of green house gas emitted by electric sources used to run the cascade refrigerator, emission of green house gases during life span of refrigerator and refrigerant leakage. Whereas, the environmental impact index analysis estimates the life cycle assessment of the cascade refrigerator estimating the green house gas emission due to extraction and disposal of raw material used and can be expressed as follows:-

where, EM represents the emission cost for electricity generation which varies for different methods of electricity generation (Table 3), and AEC represents the annual electricity consumption of the cascaded refrigerator.

When refrigerator is operating at reversible conditions, the above equation can be written as:-

Similarly for actual operating conditions:-

From Table 4, EMavg is taken as 0.508 KgCO2/KWh, and EMmin is taken as 0.032 KgCO2/KWh, considering the generation of electric energy using solar PV modules.

Now, The “environmental impact index” (EII) can be expressed as31:

Result analysis

In the present work, different configurations of cascade refrigeration cycles viz; Conventional Cascade Refrigeration Cycle (CCRS), Cascade Refrigeration Cycle with Mechanical Precooling (CRMP), Cascaded Refrigeration cycle with Single Auxiliary Cycle (CRSAC), and Cascaded Refrigeration cycle with Dual Auxiliary Cycle (CRDAC) have been considered to analyse their thermal performances along with economical and environmental impact index analysis. In each configuration, R744A is used as refrigerant in lower cycle R600 in upper cycle. The evaporative temperature in each cycle is varied from 193 to 220 K with varying condenser temperature from 308 to 323 K keeping cascade heat exchanger temperature difference equal to 5 K for each configuration. Other parameters used to simulate each cycle are listed in Table 5.

Energy and exergy analysis

Figure 3 shows the percentage of exergy destruction per kilo joule work input provided for each configuration. The cascade refrigeration cycle with a single auxiliary cycle has the maximum percentage of exergy destruction for each temperature profile compared to others due to the larger pressure difference in the cascade heat exchanger of the LT and HT cycle. An increase in condenser temperature for each configuration, except CRSAC, increases the exergy destruction rate. Meanwhile, evaporative temperature has a reverse effect on the exergy destruction rate. The conventional cascade refrigeration cycle has a maximum exergy destruction rate of 60% when operating at 323 K condenser temperature to generate cold at 193 K evaporative temperature. This exergy destruction rate can be reduced to 55% when the system operates within temperature limits of 220 K evaporative and 308 K condenser temperatures. Similarly, the cascade refrigerator with a mechanical precooling cycle (CRMP) has the lowest exergy destruction rate. The exergy destruction rate for CRMP varies from its minimum value of 32% to a maximum of 37%, which is far lower than that of the other configurations. The minimum percentage exergy destruction rate per kilo joule work input for a modified cascade refrigeration system with single and dual auxiliary cycles viz; CRSAC and CRDAC, are observed as 77%, 50%, respectively, and the maximum is observed as 96% and 56% respectively. The CRDAC cycle has a 5–12% lower percentage exergy destruction rate than CCRS and 35–41% lower than CRSAC. This makes the cycle more adorable than both CCRS and CRSAC. CRMP has a lower percentage exergy destruction rate than CRDAC, which is 32–36% lower than CRDAC (Fig. 4).

Figure 5 shows the variation in the pressure ratio for each cascade refrigerator. The CRDAC cycle has the lowest pressure ratio compared to the other configurations due to its lower discharge pressure. An increase in the condenser temperature results in a higher discharge temperature for the compressor, resulting in a higher pressure ratio in the HT cycle and, hence, a larger pressure ratio in each cascade unit. The increase in evaporative temperature, keeping condenser temperature constant, reduces the pressure ratio for a lower cycle and, in turn, reduces the cascade pressure ratio. The dual auxiliary cycles of CRDAC enable the cycle to run within a temperature limit of 268 K to 318 K for the HT cycle and 193 K to 228 K for LT Cycle, while, for CCRS, these temperature limits vary from 263 K to 318 K for HT cycle and 193 K to 268 K for LT cycle with 5 K cascade heat exchanger temperature difference. These larger temperature gaps in CCRS cause the compressor to run with a higher pressure ratio; hence, high work input is required to run the system.

The variation in the exergy destruction and total work input requirement for CCRS, CRMP, CRSAC, and CRDAC configurations with evaporative temperature is shown in Fig. 6. The high operating pressure ratio of the CRMP cycle (as shown in Fig. 5) causes the cycle to operate at a very high work input requirement compared to others. The CRMP cycle requires 685 KJ of energy to produce cold at 193 K evaporative temperature when the HT cycle condenser temperature is 323 K. At TC = 318 K, the cycle consumes 635 KJ of energy, 7% less than the former. The lowest energy consumption, i.e., 383 KJ, for CRMP, was observed when the cycle was used to run within temperature limits of 220 K evaporative temperature and 308 K evaporative temperature. Meanwhile, the CRDAC cycle has the lowest energy consumption rate compared to each cycle. To generate a cooling effect at 193 K temperature with 323 K condenser temperature, CRDAC consumes only 264 KJ energy while CCRS, CRMP, and CRSAC consume 421 KJ, 685 KJ, and 380 KJ energy, respectively. Keeping the Condenser temperature fixed at 318 K and increasing the evaporative temperature from 193 K to 220 K, the energy consumption for CCRS, CRMP, CRSAC, and CRDAC was reduced by 34%, 28%, 34%, and 40%, respectively. For the same temperature conditions, the CRDAC cycle consumes 24–40% less energy than CCRS, 51–68% less than CRMP, and 23–38% less than CRSAC. Similarly, for the same operating conditions, the CRDAC cycle has a 29–50% less exergy destruction rate than CCRS, 28–51%, and 60–76% less exergy destruction compared to CRMP and CRSAC cycles.

Compared to others, the high discharge pressure and higher work input requirement of the CRMP cycle result in very low COP (Fig. 7). At TC = 308 K, varying the evaporative temperature from 193 K to 220 K, the COP values for the CRMP cycle vary from 0.51 to 0.76, which are 33–65% lower than that of the conventional cycle. At the same temperature conditions, the CRSAC cycle provides 17–20% higher COP than the conventional cycle. The CRDAC has the highest COP compared to others for each working condition. For TE = 193 K, the COP values for the CRDAC, CRSAC, CRMP, and CCRS cycle at a condenser temperature of 308 K are 1.24, 0.95, 0.51, and 0.76, respectively. Keeping the condenser temperature fixed at 318 K, varying the evaporative temperature from 193 K to 220 K, the COP values of CRDAC, CRSAC, CRMP, and CCRS vary from 1.245 to 2.181, 0.89 to 1.41, 0.44 to 0.64, and 0.68 to 1.1 respectively (Fig. 7). Keeping the evaporative temperature fixed at 193 K, for the condenser temperature of 318 K, the exergetic efficiency of CRMP, CCRS, CRSAC, and CRDAC cycle is observed as 0.63, 0.405, 0.145, and 0.44, respectively. The CRSAC cycle has the lowest value of exergetic efficiency due to the high pressure difference in the cascade heat exchanger incorporated between HT and LT cycles (Fig. 8). This larger pressure difference is being reduced using another auxiliary cycle in the CRDAC cycle. Although the CRMP cycle has higher exergetic efficiency, its lowest COP and higher electric work consumption make it a less suitable cycle than others. For the same operating conditions, the CRDAC cycle provides approximately 146–270% higher COP than CRMP. At TC = 323 K and TE = 220 K, the maximum COP and exergy efficiency for the CRDAC cycle is 2.188 and 0.51, while for the CRMP cycle, these values are 0.5923 and 0.6724, respectively. This high COP value of the CRDAC cycle, approx 73% higher than CRMP, overcomes the lesser exergetic value for the CRDAC cycle compared to the CRMP cycle.

Economical analysis

The variation in yearly electricity consumption and annual operating cost with respect to evaporative temperature for each cascade configuration is shown in Fig. 9. The CRMP cycle has the highest annual electricity consumption and operational cost compared to others at each temperature limit. At TC = 318 K, for varying the evaporative temperature from 193 K to 220 K, the annual electricity consumption values vary from 484 kW-h to 288 kW-h for the CRDAC cycle, 1159 kW-h to 831 kW-h for the CRMP cycle, 672 kW-h to 444 kW-h for CRSAC cycle and 724 kW-h to 475 kW-h for CCRS cycles respectively. The annual operational cost and electricity consumption for each cycle decrease with a rise in evaporative temperature and vice versa for the condenser temperature. Each cycle runs at minimum operational cost when refrigerators operate at 308 K condenser and 220 K evaporative temperatures. At TC = 308 K, varying the evaporative temperature from 193 K to 220 K, the CRDAC cycle consumes 24–30% less electricity than CRSAC, 25–29%, and 51–59%, less than CCRS and CRMP cycle respectively. CRSAC and CCRS cycles consume 36–41% and 35–39% less energy than the CRMP cycle at the same temperature conditions. Similarly, at TC = 308 K and TE = 193 K, the annual operational costs for CRDAC, CRSAC, CRMP, and CCRS are observed as $53,134, $69,475, $109,395, and $70,615, respectively. A rise in condenser temperature, keeping the evaporative temperature fixed at 193 K, increases the discharge pressure of HT cycle compressors, leading to more electric power consumption through the compressor. Increasing the TC from 308 K to 318 K with fixed evaporative temperature, i.e., 193 K, the operational cost for CRSAC, CRMP, and CCRS increases by 6%, 16%, and 12%, respectively, while the operational cost of CRDAC cycle increases by 0.5% only. The dual auxiliary cycle of CRDAC reduces the pressure ratio compared to CRMP and CCRS cycles, enabling the CRDAC cycle to operate more economically at a larger pressure difference (Tables 6 and 7).

Tewi analysis

Figure 10 depicts the amount of carbon emission and its associated environmental cost for each cycle. Increasing the evaporative temperature reduces carbon emission and its associated environmental cost. At TC = 323 K, the maximum carbon emission for CRDAC, CRSAC, CRMP, and CCRS obtained at 193 K evaporative temperature is 466 kg, 668 kg, 1210 kg, and 744 kg, respectively. This value for each mentioned cycle further reduces to 277 kg, 445 kg, 876 kg, and 496 kg, respectively, when these cycles operate at 220 K evaporative temperature, keeping a fixed condenser temperature. Reducing the condenser temperature also reduces the carbon emission rate and each cycle’s environmental cost. The minimum carbon emission and environmental cost values for each cycle are observed at TC = 308 K and TE = 220 K. At these temperature conditions, the CRDAC, CRSAC, CRMP, and CCRS cycle records 280 kg, 399 kg, 670 kg, and 398 kg carbon emission rates, respectively. At fixed evaporative temperature, with a 5 K increase in condenser temperature, the carbon emission rate for CCRS, CRMP, CRSAC, and CRDAC increases by 6–7.65%, 7.73–9.05%, 3.08–3.98%, and 0.27–0.46%, respectively. The CRDAC cycle has the lowest carbon emission rate as well as the lowest environmental cost than others at every operating condition.

For each cascade configuration, the TEWI analysis results obtained for condenser temperatures of 313 K and 318 K with varying evaporative temperatures are shown in Fig. 11. Total TEWI values for any cycle consist of direct and indirect TEWI values, of which the indirect TEWI value contributes a major part of total TEWI values, approximately 96%. The direct TEWI values are associated with the refrigerant’s GWP value and life span. In the present work, each cycle configuration uses R744A in the lower cycle and R600 in the upper cycle, including mechanical precooler and auxiliary cycles, leading to a small difference in direct TEWI values for each cycle. The indirect values of TEWI are associated with compressors’ power consumption (equation 36). The higher the discharge pressure and working pressure ratio, the higher the power consumption. The CRDAC cycle consumes less power than other cycles, followed by CRSAC, CCRS, and CRMP. The lower power consumption of the CRDAC cycle contributes to lower indirect values of TEWI. At TC = 313 K, varying TE from 193 K to 220 K, CRDAC cycle provides 29–39% less TEWI values than CCRS, 55–62% less than CRMP, and 26–32.5% less than CRSAC cycle. The CRSAC cycle provides 39–44% less TEWI values than the CRMP cycle and 3–4% less than CCRS at the same operating conditions. The highest TEWI values at each operating condition are observed for the CRMP cycle, followed by the CCRS, CRSAC, and CRDAC cycle.

Environmental impact index analysis

The TEWI analysis only considers the impact of the GWP value of refrigerant, the cycle’s life span, and the electric power consumption of the cycle. The carbon emitted by the refrigerant during the whole life cycle is being considered in the TEWI analysis. The carbon emission during the production of refrigerant from its raw materials, the global warming impact due to the greenhouse gas emission during the process of production to disposal of the refrigerant, and also, the electricity generation emission rate during the process of electric power generation is not being considered in TEWI analysis. This limits the TEWI analysis’s accuracy in measuring global warming’s impact on the cascade cycle during its life span. All these factors are considered when estimating each cascade refrigerator’s Environmental Impact Index (E.I.I.). The CRDAC cycle consumes less energy and thus contributes to lesser electricity generation emission values, resulting in lower global warming impact. Varying evaporative temperatures 193 K to 220 K, the CRDAC cycle produces 7.6–12.3% less environmental impact than CCRS and 4.6–33.4% less than CRSAC at TC = 318 K (Fig. 12). At TC = 318 K and TE = 193 K, the CRDAC cycles produce 33% less global warming impact than CRSAC. Increasing the evaporative temperature significantly reduces the pressure ratio in the cascade heat exchanger of CRSAC, which decreases electric power consumption and, hence, impacts global warming. At TC = 318 K, the CRSAC cycle provides higher E.I.I. values up to 214 K evaporative temperature, and a further increase in the evaporative temperature reduces the E.I.I. values of CRSAC compared to CRDAC, approx 16% (Fig. 12). For ultralow temperature cooling applications CRDAC cycle is more preferable than others due to lower TEWI and E.I.I. value.

Conclusion

In the present work, different configurations of cascade refrigeration cycles viz; Conventional Cascade Refrigeration Cycle (CCRS), Cascade Refrigeration Cycle with Mechanical Precooling (CRMP), Cascaded Refrigeration cycle with Single Auxiliary Cycle (CRSAC), and Cascaded Refrigeration cycle with Dual Auxiliary Cycle (CRDAC) have been considered to analyze their thermal performance along with economical and environmental impact index analysis. The dual auxiliary cycles incorporated between the HT and LT cycles of the CRDAC cycle reduce the pressure ratio very significantly. This leads the compressor to work at lesser energy consumption with higher COP values. Keeping the condenser temperature fixed at 318 K, varying the evaporative temperature from 193 K to 220 K, the COP values of CRDAC, CRSAC, CRMP, and CCRS vary from 1.245 to 2.181, 0.89 to 1.41, 0.44 to 0.64, and 0.68 to 1.1 respectively. For the same temperature conditions, the CRDAC cycle consumes 24–40% less energy than CCRS, 51–68% less than CRMP, and 23–38% less than CRSAC. The CRDAC cycle has the lowest operational cost among others. The operational cost for the CRDAC cycle varies from 52765 USD to 53134 USD when generating cold at 193 K evaporative temperature with varying TC from 308 K to 323 K. Under the same operating conditions, this cost for CRSAC, CRMP, and CCRS varies from 69475 USD to 756494 USD, 109395 to 136974 USD, and 70615 USD to 84262 USD, respectively. The CRDAC cycle accounts for the lowest TEWI and E.I.I. values at every temperature condition compared to others. The CRDAC cycle provides 29–39% less TEWI values than CCRS, 55–62% less than CRMP, and 26–32.5% less than the CRSAC cycle. The CRSAC cycle provides 39–44% less TEWI values than the CRMP cycle and 3–4% less than CCRS at the same operating conditions. At 318 K condenser temperature, for producing a cold effect at 193 K, the CRDAC cycles produce 33% less global warming impact than CRSAC, 7.6–12.3% less environmental impact than CCRS, and 25.6–26.4% less than CRMP. All these conclusions make the CRDAC cycle more efficient and economical compared to other configurations and lead to the futuristic model for ultra-low temperature cooling technologies.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- COP:

-

Coefficient of performance

- CHX:

-

Cascade heat exchanger

- CCRS:

-

Conventional cascade refrigeration system

- CRMP:

-

Cascade refrigeration system with mechanical precooling

- CRSAC:

-

Cascade refrigeration system with single auxiliary cycle

- CRDAC:

-

Cascade refrigeration system with dual auxiliary cycle

- Z:

-

Cost (US Dollars)

- Q:

-

Heat interactions (KJ)

- W:

-

Work interactions (KJ)

- TC :

-

Condenser temperature (K)

- TE :

-

Evaporative temperature (K)

- αelect :

-

Electricity cost per unit (in USD)

- ŋ:

-

Efficiency

- i:

-

Interest rate

- P:

-

Pressure (MPa)

- α:

-

Recycling factor

- A:

-

Area of heat exchanger

- N:

-

Number of operational days

- ED :

-

Exergy destruction

- HT:

-

High-temperature

- LT:

-

Low temperature

- CFC:

-

Chlorofluorocarbon

- HCFC:

-

Hydro chlorofluorocarbon

- GWP:

-

Global warming potentials

- ODP:

-

Ozone depletion potentials

- Comp:

-

Compressor

- Cond:

-

Condenser

- Exp:

-

Expansion

- Evap:

-

Evaporation

- E.I.I.:

-

Environmental impact index

- USD:

-

U.S. Dollar

- s:

-

Entropy (KJ/Kg-K)

- n:

-

Life cycle (Years)

- h:

-

Specific enthalpy (KJ/Kg)

- \({\mu }_{co2}\) :

-

Emission conversion factor

References

Cattin, M., Jonnalagedda, S., Makohliso, S. & Schönenberger, K. The status of refrigeration solutions for last mile vaccine delivery in low-income settings. Vaccine X 11, 100184. https://doi.org/10.1016/j.jvacx.2022.100184 (2022).

Santos, A. F., Gaspar, P. D. & de Souza, H. J. L. Refrigeration of COVID-19 vaccines: Ideal storage characteristics, energy efficiency and environmental impacts of various vaccine options. Energies 14(7), 1849. https://doi.org/10.3390/en14071849 (2021).

Kumar, S. & Chahal, V. A review of various kinds of cascade refrigeration cycle and application of ejector mechanism. In Advances in materials and mechanical engineering, (Pandey, C., Goyat, V., Goel, S. eds.) Lecture Notes in Mechanical Engineering. (Springer, Singapore, 2021). https://doi.org/10.1007/978-981-16-0673-1_20

Oh, J., Binns, M., Park, S. & Kim, J. Improving the energy efficiency of industrial refrigeration systems. Energy 112, 826–835. https://doi.org/10.1016/j.energy.2016.06.119 (2016).

Liu, J., Liu, Y., Yan, G. & Yu, J. Thermodynamic analysis on a modified auto-cascade refrigeration cycle with a self-recuperator. Int. J. Refrig 137, 117–128. https://doi.org/10.1016/j.ijrefrig.2022.02.012 (2022).

Liu, Y. & Yu, J. Performance analysis of an advanced ejector-expansion auto-cascade refrigeration cycle. Energy 165, 859–867. https://doi.org/10.1016/j.energy.2018.10.016 (2018).

Liu, J., Liu, Y., Yu, J. & Yan, G. Thermodynamic analysis of a novel ejector-enhanced auto-cascade refrigeration cycle. Appl. Therm. Eng. 200, 117636. https://doi.org/10.1016/j.applthermaleng.2021.117636 (2021).

Wang, H., Song, Y. & Cao, F. Experimental investigation on the pull-down performance of a – 80 °C ultra-low temperature freezer. Int. J. Refrig 119, 1–10. https://doi.org/10.1016/j.ijrefrig.2020.04.030 (2020).

Yılmaz, B., Mançuhan, E. & Yılmaz, D. Theoretical analysis of a cascade refrigeration system with natural and synthetic working fluid pairs for ultra low temperature applications. Isı Bilimi Ve Tekniği Dergisi 40(1), 141–153 (2020).

Sun, Z. et al. Performance comparison of the single-refrigerant cascade refrigerating system. Energy Rep. 8, 8259–8270. https://doi.org/10.1016/j.egyr.2022.06.055 (2022).

Getu, H. M. & Bansal, P. K. Thermodynamic analysis of an R744–R717 cascade refrigeration system. Int. J. Refrig. 31(1), 45–54. https://doi.org/10.1016/j.ijrefrig.2007.06.014 (2008).

Chen, Q., Zhou, L., Yan, G. & Jianlin, Y. Theoretical investigation on the performance of a modified refrigeration cycle with R170/R290 for freezers application. Int. J. Refrig. 104, 282–290. https://doi.org/10.1016/j.ijrefrig.2019.05.037 (2019).

Sánchez, D., Cabello, R., Llopis, R., Catalán-Gil, J. & Nebot-Andrés, L. Energy assessment and environmental impact analyses of an R134a/R744 cascade refrigeration plant upgraded with the low- GWP refrigerants R152a, R1234ze(E), propane (R290) and propylene (R1270). Int. J. Refrig. 104, 321–334. https://doi.org/10.1016/j.ijrefrig.2019.05.028 (2019).

Patel, V., Panchal, D., Prajapati, A., Mudgal, A. & Davies, P. An efficient optimization and comparative analyses of cascade refrigeration system using NH3/CO2 and C3H8/CO2 refrigerant pairs. Int. J. Refrig 102, 62–76. https://doi.org/10.1016/j.ijrefrig.2019.03.001 (2019).

Adebayo, V., Abid, M., Adedeji, M., Dagbasi, M. & Bamisile, O. Comparative thermodynamic performance analyses of a cascade refrigeration system with new refrigerants paired with CO2. Appl. Therm. Eng. 184, 116286. https://doi.org/10.1016/j.applthermaleng.2020.116286 (2021).

Llopis, R., Sánchez, D., Sanz-Kock, C., Cabello, R. & Torrella, E. Energy and environmental comparison of two-stage solutions for commercial refrigeration at low temperature: Fluids and systems. Appl. Energy 138, 133–142. https://doi.org/10.1016/j.apenergy.2014.10.069 (2014).

Zhu, Y., Peng, Z., Wang, G. & Zhang, X. Thermodynamic analysis of a novel multi-target-temperature cascade cycle for refrigeration. Energy Convers. Manage. 243, 114380. https://doi.org/10.1016/j.enconman.2021.114380 (2021).

Soni, S., Mishra, P., Maheshwari, G. & Verma, D. S. Theoretical energy analysis of Cascade refrigeration system using low Global warming potential refrigerants. Mater. Today Proc. 63, 164–169. https://doi.org/10.1016/j.matpr.2022.02.436 (2022).

Li, Y., Pan, X., Liao, X. & Xing, Z. A data-driven energy management strategy based on performance prediction for cascade refrigeration systems. Int. J. Refrig 136, 114–123. https://doi.org/10.1016/j.ijrefrig.2022.01.012 (2022).

Mota-Babiloni, A. et al. Ultralow-temperature refrigeration systems: Configurations and refrigerants to reduce the environmental impact. Int. J. Refrig. 111, 147–158. https://doi.org/10.1016/j.ijrefrig.2019.11.016 (2020).

Tan, H., Bai, M., Xu, L., Li, X. & Liu, Z. Experimental study on the pull-down performance of a − 80 °C cascade refrigeration freezer. Asia-Pac J. Chem. Eng. 18(3), e2888. https://doi.org/10.1002/apj.2888 (2023).

Kasi, P. & Cheralathan, M. Performance analysis of cascade refrigeration system with alternative refrigerants to reduce carbon emission. J. Therm. Anal. Calorim. 148, 4389–4399. https://doi.org/10.1007/s10973-023-11989-6 (2023).

Aktemur, C., Ozturk, I. T. & Cimsit, C. Comparative energy and exergy analysis of a subcritical cascade refrigeration system using low global warming potential refrigerants. Appl. Ther. Eng. 184, 116254. https://doi.org/10.1016/j.applthermaleng.2020.116254 (2021).

Mouneer, T. A., Elshaer, A. M. & Aly, M. H. Novel cascade refrigeration cycle for cold supply chain of COVID-19 vaccines at ultra-low temperature − 80 °C using ethane (R170) based hydrocarbon pair. World J. Eng. Technol. 9(2), 309–336. https://doi.org/10.4236/wjet.2021.92022 (2021).

Udroiu, C. M., Mota-Babiloni, A. & Navarro-Esbrí, J. Advanced two-stage cascade configurations for energy-efficient – 80 °C refrigeration. Energ. Conver. Manage. 267, 115907. https://doi.org/10.1016/j.enconman.2022.115907 (2022).

Chen, M. et al. Performance comparison of ultra-low temperature cascade refrigeration cycles using R717/R170, R717/R41 and R717/R1150 to replace R404A/R23. Ther. Sci. Eng. Progr. 44, 102048. https://doi.org/10.1016/j.tsep.2023.102048 (2023).

Prajapati, P., Patel, V., Raja, B. D. & Jouhara, H. Energy-exergy-economic-environmental (4E) analysis and multi-objective optimization of a cascade refrigeration system. Ther. Sci. Eng. Progr. 54, 102793. https://doi.org/10.1016/j.tsep.2024.102793 (2024).

Ji, S., Liu, Z., Pan, H. & Li, X. Energy, exergy, environmental and exergoeconomic (4E) analysis of an ultra-low temperature cascade refrigeration system with environmental-friendly refrigerants. Appl. Therm. Eng. 248, 123210. https://doi.org/10.1016/j.applthermaleng.2024.123210 (2024).

Kauffeld, M., Maurath, T., Germanus, J. & Askar, E. N2O/CO2-mixtures as refrigerants for temperatures below − 50 °C. Intl. J. Refrig. 117, 316–327. https://doi.org/10.1016/j.ijrefrig.2020.04.026 (2020).

Kumar, S., Gahlot, P. & Kumar, S. Energy, exergy and economical analysis of N2O based Cascade refrigeration system for ultralow temperature cooling applications using different eco-friendly refrigerants in high temperature cycle. Results Eng. 22, 102259. https://doi.org/10.1016/j.rineng.2024.102259 (2024).

Li, R., Ye, F., Zhang, J., Wang, M. & Li, K. Theoretical analysis of three CO2/C3H8 (R744–R290) cascade refrigeration systems with precooling processes in low-temperature circuits. Appl. Therm. Eng. 234, 121238. https://doi.org/10.1016/j.applthermaleng.2023.121238 (2023).

Kumar, S., Gahlot, P. & Kumar, S. Exergetic sustainability and environmental impact index analysis to reduce carbon footprints of ultra-low temperature cascade refrigeration. J. Therm. Anal. Calorim. https://doi.org/10.1007/s10973-025-14021-1 (2025).

Takleh, H. R. & Zare, V. Employing thermoelectric generator and booster compressor for performance improvement of a geothermal driven combined power and ejector-refrigeration cycle. Energy Convers. Manage. 186, 120–130. https://doi.org/10.1016/j.enconman.2019.02.047 (2019).

Rostamnejad, H. & Zare, V. Performance improvement of ejector expansion refrigeration cycles employing a booster compressor using different refrigerants: Thermodynamic analysis and optimization. Int. J. Refrig. 101, 56–70. https://doi.org/10.1016/j.ijrefrig.2019.02.031 (2019).

Takleh, H. R. & Zare, V. Proposal and thermoeconomic evaluation with reliability considerations of geothermal driven trigeneration systems with independent operations for summer and winter. Int. J. Refrig. 127, 34–46. https://doi.org/10.1016/j.ijrefrig.2020.12.033 (2021).

Takleh, H. R., Zare, V., Mohammadkhani, F. & Sadeghiazad, M. Proposal and thermoeconomic assessment of an efficient booster-assisted CCHP system based on solar-geothermal energy. Energy 246, 123360. https://doi.org/10.1016/j.energy.2022.123360 (2022).

Acknowledgements

The authors gratefully acknowledge Parveen Kumar, Faculty of Mechanical Engineering, University of Ljubljana, Askerceva 6, 1000 Ljubljana, Slovenia, for their significant contributions during the manuscript revision phase. Their efforts included performing formal analysis, validation of calculations, and visualization, particularly in redrawing key figures and graphs based on reviewer feedback. They also provided valuable input during the writing, review, & editing stages.

Author information

Authors and Affiliations

Contributions

Problem Statement, Innovation, Implementation, Methodology and Material preparation, data collection and analysis, and writing phases were performed by Sachin Kumar¹. Data manipulation phase was done by Pardeep Gahlot². Dr Suresh Kumar³ has contributed for the Innovation, Implementation, Methodology phase of the paper. Aman Kumar4 contributed significantly during the manuscript revision phase through investigation, incorporating new references and data, revising significant portions of the text including the abstract and conclusion, and ensuring consistency.

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kumar, S., Gahlot, P., Kumar, S. et al. A novel ultra-low temperature cascade refrigeration with dual auxiliary loop to enhance thermal performance. Sci Rep 15, 23214 (2025). https://doi.org/10.1038/s41598-025-08462-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-08462-9