Abstract

In this study, a novel and effective double networks hydrogel (Gl-Cs/CuO-NiO) was fabricated using a method involving natural polymers; gelatin and chitosan along, with copper oxide and nickel oxide (CuO-NiO) nanocomposite in formaldehyde solution. The resulting hydrogel was thoroughly analyzed using SEM, XRD, and FT-IR techniques. The hydrogel was utilized as a catalyst for the reduction of both organic and inorganic pollutants; methyl orange (MO), crystal violet (CV) and potassium hexacyanoferrate (K3[Fe(CN)6]) in the presence of a reducing agent (NaBH4). The Gl-Cs /CuO-NiO hydrogel exhibited performance in reducing the targeted pollutants, which took 120, 28 and 30 s for MO, CV and K3[Fe(CN)6], respectively. Moreover, the catalytic efficiency of the hydrogel was studied for MO by adjusting its concentrations, varying the reducing agent concentration and altering the amount of hydrogel. Lastly, the efficiency of the Gl-Cs/CuO-NiO hydrogel was evaluated for MO removal in real samples and displayed exceptional reduction capabilities.

Similar content being viewed by others

Introduction

Water pollution is a problem that is growing worse with time and is endangering human health as well as the environment. Urbanization and an increase in activity have resulted in a surge in wastewater discharge, which has impacted on the quality of water sources and contaminated aquatic bodies. These industries frequently use substances with qualities that need to be taken into account, such as dyes and inorganic pollutants. Their existence in water sources has the potential to upset the ecosystem equilibrium by polluting food chains and building up living things.

Dyes from the printing, leather, and textile industries that are discarded into surface and groundwater seriously harm both human health and the health of other living organisms. The presence of these pollutants poses a risk of bioaccumulation potentially impacting humans through food chain transfer. This can have effects on health causing various diseases due to their lasting presence in living organisms. In fact, low levels of dye in the water can lead to health issues for humans, even among those that are carcinogenic1,2,3.

Catalysis is an essential technique that produces the required results effectively in water treatment. Therefore, researchers are aiming to develop catalysts that can be created by cleaner and more effective methods, enabling easy separation, recovery and reuse of catalysts. Copper oxide, iron oxide, nickel oxide nanoparticles and so on were studied as nanocatalysts due to their properties, including a high surface to volume ratio and reactivity4,5,6,7,8. CuO-NiO has been used as a promising and prospective material due to its promising and unique characteristics as catalyst9,10,11. However, a significant challenge associated with their lack of liquid–solid separation techniques and recyclability of the nanocatalyst12. To address this issue there is a growing focus on combining nanoparticles with polymer as substrate, like hydrogel, beads, gels and so on.

Polymeric hydrogels are materials with water loving networks that provide support for the nanoparticles. Hydrogels have gained attention as catalysts and adsorbents due to its three dimensional network which efficiently works as support material for incorporating metal nanoparticles in applications13,14,15,16,17,18,19. Moreover, the large surface area within the hydrogel can accommodate nanoparticles creating catalytic sites that enhance reaction rates and efficiency.

As a result of their crucial biocompatibility, biopolymers like gelatin, chitosan, and silk proteins are frequently utilized in hydrogel processes. Hydrogels based on chitosan show potential due to their environmentally friendly nature. It consists of various hydrophilic functional groups; hydroxyl and amino groups that are highly efficient in the catalyst. Additionally, it is friendly, degradable, compatible, with living tissues and possess properties. Gelatin, an animal derived protein contains NH2 and COOH groups has the ability to form hydrogels18,19,20,21. However the hydrogel of the individual polymer lacks chemical stability, which can be enhanced by combining them with a polysaccharide to create a composite hydrogel13,16,18,20,22,23,24,25. Therefore, combining two polymers to form hydrogel material enhances the structure and strength of the gel network, improving the chemical and mechanical characteristics and offering a wide range of applications.

Hence, the main aim of this study is to create a three-dimensional network hydrogel using the easily available gelatin and chitosan in combination of CuO-NiO nanocomposite. This hydrogel has been designed to improve the properties and strength of the material. The prepared hydrogel Gl-Cs/CuO-NiO nanocomposite was studied as a catalyst for the reduction of azo dyes (MO and CV) and inorganic pollutant (K3[Fe(CN)6). To analyze the resulting hydrogel, SEM analysis, FT-IR and XRD techniques were conducted. Additionally, the developed hydrogel exhibits low cost, high efficiency for the removal of dyes, potential recyclability, and easy separation. Lastly, the Gl-Cs/CuO-NiO hydrogel was applied to effectively remove MO from real water samples.

Experimental

Material

All reagents were analytical and spectral purity grade. Metal salts of nickel(II) sulfate, copper(II) sulfate, potassium hexacyanoferrate and organic dyes (methyl orange (MO), crystal violet (CV)) were obtained from Sigma-Aldrich. Biopolymers (Gelatin and chitosan) were obtained also from Sigma-Aldrich.

Synthesis of CuO-NiO nanocomposite

The CuO-NiO nanocomposite was synthesized through coprecipitation method19,20. Initially, CuSO4 and NiSO4(NO3)2 were combined in a ratio of 1:1 with dropwise addition of NaOH to get the pH up to 11. The preparation process was carried out for four hours at 80 °C while stirring until the precipitation completely formed. After filtering, the product was finally collected, repeatedly cleaned with distilled water, and dried on a lab bench top for 24 h at 25 °C. Moreover, the sample was calcined at 500 °C for 4 h.

Synthesis of Gl-Cs/CuO-NiO hydrogel

The Gl-Cs/CuO-NiO nanocomposite hydrogel was prepared by mixing the CuO-NiO nanocomposite with the Gl-Cs. To create the gelatin hydrogel, Gl powder (2.5 g) was combined with 25 mL of deionized water. To make sure the polymer completely dissolved, the solution was agitated for 60 min while being gradually heated till 60 oC. Simultaneously, a 1% acetic acid (0.025 g) chitosan solution was made and agitated at 50 ̊C for one hour. The Cs solution was added to the Gl solution and stirred for two hours. After being sonicated, 60 mg of CuO-NiO nanocomposite was combined with recently made Gl-Cs solution. To fully disperse the CuO-NiO nanocomposite in the viscous Gl-Cs solution, the mixture was agitated for two hours. The Gl-–Cs/CuO-–NiO solutionmixture was cross-linked by 4 mL of formaldehyde. The Gl-Cs/CuO-NiO mixture was left for 24 h at room temperature to form a stable hydrogel. The prepared hydrogel was separated from tubes and washed with large amount of deionized water to remove the unreacted formaldehyde molecules.

Characterization

A field-emission scanning electron microscope ((FE-SEM), JEOL JSM- 7600 F, Japan) fitted with an Oxford energy-dispersive X-ray spectrometer ((EDX), oxford-EDS system) was used to examine the samples for morphological investigation. Thermo Scientific equipment was used to measure the samples’ X-ray diffraction (XRD) patterns in order to determine the crystal structure. From 5° to 50° (2θ), diffraction patterns were analyzed. ATR-FTIR spectrometer (NicoletTM iS50 FTIR Spectrometer-Thermo Fisher Scientific) was used to record the Fourier transform infrared (FT-IR) spectra of the samples in the range of 400–4000 cm−1. The concentration of the dyes solution were measured using a UV-visible spectrophotometer in order to monitor the catalytic experiments.

Catalytic reduction

To study the catalytic reduction, the prepared Gl-Cs/CuO-NiO hydrogel was cut to small pieces using a scalpel. Initially, the catalytic reduction was accomplished in the UV-vis cuvette. First, 2.5 mL of MO (0.05 mM) was checked before any addition of NaBH4 and hydrogel. After that, 0.5 mL of NaBH4 was added to the MO followed by the addition of hydrogel. The orange color of MO progressively faded away during the degrading process. Finally, Gl-Cs/CuO-NiO hydrogel was also evaluated toward CV and (K3Fe[CN]6). The conversion percentage of all compounds was calculated by utilizing Eq. 1:

To quantify the rate of these reactions, the UV-Vis spectral data were treated according to the following Eq. 2:

where C0 and Ct are the absorbance values at 464 nm noted from the UV-visible spectra of MO dye solution before and after addition of the reductant and catalyst, Ct and C0 represent the concentrations, respectively.

Result and discussion

Preparation of hydrogel

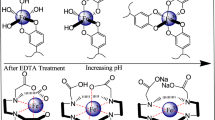

The Gl and Cs are biopolymers composed of a polypeptide of higher molecular weight. Due to its low mechanical strength, Gl was previously strengthened by adding chitosan and formation of nanocomposite for further benefits. The use of nanocomposites in combination with Gl-Cs often leads to improved characteristics compared to the bulk material. This improvement can be attributed to the high surface-to-volume ratio of the nanocomposite. Thus, these materials were prepared and used for the reductive degradation of two toxic carcinogenic dyes and an inorganic pollutant. As illustrated in Fig. 1, the preparation of the Gl-Cs/CuO-NiO hydrogel, as discussed earlier, is depicted. Due to the presence of a large number of functional groups, such as amine and carboxylic acid groups in the Gl structure as well as amine and hydroxyl groups in the Cs structure, it readily reacts with formaldehyde to form a Gl-Cs/CuO-NiO hydrogel consisting of strong covalent bonds (Fig. 2).

Characterization

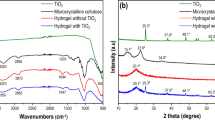

FT-IR

FT-IR is a crucial approach to study the molecular structure of organic molecules and their nanocomposites with inorganic materials. Various types of interactions, among the elements in these nanocomposites can result the shifts in the peaks positions and their breadth, within the spectrum. To examine how the synthesized CuO-NiO nanocomposite interacts with GL-Cs, all samples were analysis by FT-IR. Figure 3. displays the FT-IR spectra of CuO-NiO, Gl, Gl-Cs and Gl-Cs/CuO-NiO hydrogel across the 400 to 4000 cm−1 range. In the FT-IR, spectrum of Gl and Gl-Cs hydrogel, peaks at 3283 and 3289 cm−1 were identified as stretching related to the N-H and O-H groups on gelatins and chitosan surfaces. The peak at 1650 cm−1 was attributed to C = O stretching. Additionally, peaks at 1300–1460 cm−1 correspond to C-H bending and C-N stretching vibrations from amino group. Peaks between 400 and 600 cm−1 (M-O stretching) confirm the presence of copper oxide and nickel oxide in the nanocomposite.

Field-emission scanning electron microscope (FE-SEM)

The surface morphology of the prepared materials; CuO-NiO nanocomposite, Gl hydrogel, Gl-Cs hydrogel and Gl-Cs/CuO-NiO hydrogel was analyzed using SEM. Figure 3, represents the prepared materials with the high and low magnification pictures on the left and right, respectively. The images of Fig. 4(a-a`) indicated the particles of CuO-NiO which looks spherical and random in size. As depicted in Fig. 5, GL-Cs/CuO-NiO hydrogel contained carbon (C), nitrogen (N), oxygen (O), copper (Cu), and nickel (Ni) elements according to EDS analysis. It is worth noting that the detected fluorine signal is attributed to external sources such as carbon tape or instrumental artifacts, as no fluorine-containing compounds were used during the preparation of the hydrogel. The EDS results confirmed that CuO-NiO nanocomposites were successfully integrated into the biopolymer matrix. The image of pure gelatin was found rough and uneven, as shown in Fig. 4(b-b`)13,15. Figure 4(c-c`) attributed that chitosan could ameliorate the smoothness of the surface of gelatin film. On the other hand, CuO-NiO nanocomposite was dispersed well in the Gl-Cs hydrogel, as shown in Fig. 4(d-d`).

X-ray diffraction XRD

The crystal structures and phase purities of Gl-Cs/CuO-NiO hydrogel, CuO-NiO nancomposite and Gl hydrogel were examined by X-ray diffraction. The pattern of the CuO-NiO nancomposite showed diffraction peaks suggesting the presence of both CuO-NiO phases. As shown in Fig. 6, the diffraction peaks (111) and (200) at 2θ = 36.7° and 43.2° confirming the NiO in the cubic phase, whereas the diffraction peaks (110), (111), (111) and (202) at 2θ = 32.2°, 36.6°, 38.6° and 48.8°, indicating the monoclinic structure of CuO25,27,28,29. The XRD of pure Gl hydrogel showed only a broad peak at 2θ = 20°- 30°, which may be the result of the amorphous nature of the gelatin. On the other hand, the XRD curve of Gl-Cs/CuO-NiO hydrogel showed only broad peak in the XRD pattern at 2θ = 20°- 30°, which may be the result of the amorphous nature in the matrix30. Also, no peaks of CuO-NiO presence in the XRD pattern for Gl-Cs/CuO-NiO hydrogel due to the small amount of CuO-NiO in the matrix.

Transmission Electron microscopy (TEM)

The TEM images show Gl-Cs/CuO-NiO hydrogel containing CuO-NiO nanoparticles displays a semi-transparent fibrous polymeric network typical of hydrogel matrices (Fig. 7). The structure contains dark well-defined nanoparticles which show spherical shapes while some exhibit faceted shapes indicating partial crystallinity. The nanoparticles show localized aggregation which indicates strong bonding between the CuO-NiO nanocomposite and the Gl-Cs network. The internal fibrous structure of the hydrogel becomes visible at 8000× magnification which shows its porous nature and large surface area. The uniform distribution of CuO-NiO nanoparticles throughout the hydrogel matrix demonstrates successful nanomaterial embedding which will boost the hydrogel’s functional capabilities especially for catalytic and adsorption uses

Catalytic reduction study

Reduction study of dye

According to the literature, approximately 10–15% of dye chemicals are lost into the aquatic environment which endangering human health and marine life. These dyes, containing benzene rings, are resistant to sunlight, acids, and bases, causing an ecological imbalance as they accumulate in water. Thus, water dyes must be taken into consideration and eliminated to solve this problem31,32.

Among the dyes, methyl orange (MO) was chosen due to its being a widely used dye. It is an anionic azo dye found in industries such as paper, cosmetics, plastics, textiles, pharmaceuticals, printing and in laboratories. Exposure to MO has been linked to health concerns, like vomiting, diarrhea, breathing difficulties and nausea. The degradation of MO dye is a significant focus of study since it raises serious environmental and health issues18,21,33.

The UV-Vis spectrum of MO treated with Gl-Cs/CuO-NiO hydrogel and its visual representation, over time are shown in Fig. 8. The color decreased significantly within 5 min aligning with the changes observed in the UV-Vis spectra. MO is a type of anionic dye containing an azo group that gives it its color. The chromophore group displayed its highest visible absorption wavelength at 464 nm with π to π* transitions related to rings causing absorbance at 270 nm. In Fig. 8.

(a) the absorbance for these bands at 464 and 270 nm gradually weakened over time suggesting that the conjugated structure of MO was either disrupted or adsorbed by Gl-Cs/CuO-NiO hydrogel. Simultaneously, a new absorption peak at 248 nm appeared in line with the solution UV-Vis spectra of sulfonic acid and grew stronger over time indicating that sulfonic acid was one of the products and that reduction played a significant role in the decolorization mechanism Fig. 1122. Over 93% of MO was reduced in around 180 s, by the rapidly disappearing intensity band at 468 nm. The pseudo first-order reaction’s rate constant was calculated to be 1.16 × 10−2 s−1.

The process of the reduction, with Gl-Cs/CuO-NiO hydrogel can be influenced by the concentration of the pollutant and reducing agent. Thus the effect of MO concentrations was studied in the presence of 0.1 g of Gl- Gl-Cs and Gl-Cs/CuO-NiO hydrogel and (0.1 M) NaBH4. The data shown in Fig. 8(a), the catalyst reduction was very slow with Gl-Cs hydrogel, and it reduced only 25% of MO in 12 min. While it reduced in only 3 min with Gl-Cs/CuO-NiO hydrogel. Therefore, Gl-Cs/CuO-NiO hydrogel in the presence of (0.1 M) NaBH4 with (0.07, 0.05 and 0.01 mM) MO were used to study the effect of different concentrations. The results showed that the reduction rate increased as the concentration of MO decreased. The rate constants for MO were found to be 1.16 × 10−2 s−1, and 1.53 × 10−2 s−1 and 8.23 × 10−3 s−1 for 0.01 mM, 0.05 mM and 0.07 mM. The reduction percentage for all examined concentrations ranged between 93 and 96% as shown in Fig. 8.

(a) UV-Vis spectra for the reduction of (0.05 mM) MO using 0.1 g of Gl-Cs hydrogel in the presence of NaBH4, (b-c) UV-Vis spectra for the reduction of (0.07 mM, 0.05 mM and 0.01 mM) MO using 0.1 g of Gl-Cs/CuO-NiO hydrogel in the presence of NaBH4, (e) kinetics of MO using 0.1 g of Gl-Cs/CuO-NiO hydrogel in the presence of NaBH4.

Additionally, the effectiveness of the reduction process was influenced by the NaBH4 concentration. The experiment involved using the same amount of Gl-Cs/CuO-NiO hydrogel to test different NaBH4 concentrations (0.05, 0.1 and 0.2 M) utilizing (0.01mM) MO. The rate constant of catalytic reduction of MO in the presence of (0.05, 0.1 and 0.2) M NaBH4, were determined to be 1.14 × 10−2, 1.16 × 10−2 s−1 and 5.19 × 10−2 s−1. As the results indicated (Fig. 9), higher NaBH4 concentration caused a quicker decrease rate in a shorter time than lower concentrations19,20.

To enhance the activity, Gl-Cs/CuO-NiO hydrogel was tested for reducing CV in the presence of NaBH4. The progress of the reaction was followed using a UV-Vis spectrophotometer. The CV displayed an absorption peak at 570 nm. However, the large absorption peak of CV was reduced gradually after the introduction of 0.1 g of Gl-Cs/CuO-NiO hydrogel into the mixture of CV and NaBH4. During the reduction, the color of the CV solution disappeared steadily. As depicted in Figs. 10, 96% of CV peak at 570 nm was eradicated within 28 s. The rate constant was determined to be 3.36 × 10−1 s−1.

The cationic nature of the CV dye facilitated their strong attraction toward the Gl-Cs/CuO-NiO hydrogel resulting in the transfer of electrons to the dye molecules. NaBH4 is also used to provide hydrogen, which then interacts with dyes once it transfers electrons to Gl-Cs/CuO-NiO. The reaction outcome led to the formation of colorless product of the reduced versions of CV23,24. Afterwards, the colorless crystal violet desorbed naturally from the Gl-Cs/CuO-NiO surface (Fig. 11).

Reduction study of K3[Fe(CN)6]

Furthermore, Gl-Cs/CuO-NiO hydrogel was utilized to reduce a common inorganic pollutant, K3[Fe(CN)6], in the presence of NaBH4. As can be observed, in Fig. 12, the absorption peak at 415 nm for K3[Fe(CN)6] gradually disappeared within 30 s due to the conversion of the [Fe(CN)6]−3 to [Fe(CN)6]−4. Based on the results depicted, 96% of the K3[Fe(CN)6] content was removed, with a rate constant value of 3.4 × 10−2 s−1.

An electron-transfer reaction is one probable mechanism for the reaction of K3[Fe(CN)6] in the presence of both catalyst and NaBH4, as indicated in the Eq. (3). Therefore, K3[Fe(CN)6] catalytic reaction mechanism consists of two main stages. The catalyst initially polarize when exposed to the reducing agent NaBH4. The catalyst surface then transfers electrons to the [Fe(CN)6]−3 pollutant, where they are reduced to [Fe(CN)6]−4.

The data obtained from this study using Gl-Cs/CuO-NiO hydrogel was compared with literature, as displayed in Table 124,33,34,35,36,37,38,39,40.

Catalytic stability

Catalytic stability is just as important as catalyst activity when assessing the catalyst’s effectiveness and its uses. The stability of Gl-Cs/CuO-NiO hydrogel was investigated toward the catalytic reduction of MO. Based on the data obtained, Gl-Cs/CuO-NiO hydrogel was able to reuse up to three times under the identical conditions as the experimental section for the catalytic reduction of MO. Following each usage, the Gl-Cs/CuO-NiO hydrogel was cleaned three times with distilled water before being evaluated for the next cycle. The first use of MO required 3 min for catalytic reduction, whereas the second and third uses required 4 min and 6 min, respectively, as shown in Fig. 13. This implies that the catalyst is still reducing MO actively and effectively. Consequently, it was possible to activate the Gl-Cs/CuO-NiO hydrogel for up to three cycles.

Catalytic efficiency of Gl-Cs/CuO-NiO hydrogel in real samples

Under ideal circumstances, two real samples; tap water obtained from (Dammam Laboratory, and sea water from Jazan city in Saudi Arabia) were used to evaluate the efficacy of the Gl-Cs/CuO-NiO hydrogel. Each sample (1 mL) was diluted individually in 100 mL with deionized water to create the real samples aliquots. Subsequently, 2.0 mL of the real sample solution was transferred to UV cuvettes, and 0.5 mL of MO (0.05 mM) and 0.5 mL of NaBH4 (0.1 M) were added. Lastly, each of the individual 0.1 g of Gl-Cs/CuO-NiO hydrogel was added to the mixture. The hydrogel’s catalytic reduction was observed using a UV-vis spectrophotometer. All data obtained was summarized in Table 2. According to the result, Gl-Cs/CuO-NiO hydrogel was reliable and reasonable for the reduction of real samples either tap water or sea water.

Conclusion

In this work, the successful fabrication and comprehensive characterization of a novel double network’s hydrogel (Gl-Cs/CuO-NiO) made from gelatin, chitosan and a composite of copper oxide and nickel oxide. By examining its structure and chemical composition using SEM, TEM, XRD and FT-IR techniques the unique properties of the hydrogel were confirmed. The Gl-Cs/CuO-NiO hydrogel demonstrated performance in reducing various organic and inorganic pollutants such as methyl orange (MO) crystal violet (CV) and potassium hexacyanoferrate (K3[Fe(CN)6]) in the presence of NaBH4 as the reducing agent. Notably, this hydrogel showed reduction in short reaction times indicating its potential for effective pollutant removal. The study also explored the hydrogels efficiency in MO removal by testing concentrations of MO, varying reducing agent concentrations and adjusting the amount of hydrogel used, all showcasing its outstanding reduction capabilities. In conclusion, these results based on hydrogels and their potential role in cleanup and wastewater treatment processes is a contribution and new addition to advance catalysis.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Mekki, A. et al. Fe and Ni Nanoparticles-loaded zeolites as effective catalysts for catalytic reduction of organic pollutants. Microporous Mesoporous Mater. 310, 110597 (2021).

Vikrant, K. et al. Recent advancements in bioremediation of dye: Current status and challenges. Bioresour Technol. 253, 355–367 (2018).

Haji, A. & Naebe, M. Cleaner dyeing of textiles using plasma treatment and natural dyes: A review. J. Clean. Prod. 265, 121866 (2020).

Lv, H. & Sun, H. Electrospun foamlike nio/cuo nanocomposites with superior catalytic activity toward the reduction of 4-Nitrophenol. ACS Omega. 5, 11324–11332 (2020).

Gajurel, S., Dam, B., Bhushan, M., Singh, L. R. & Pal, A. K. CuO–NiO bimetallic nanoparticles supported on graphitic carbon nitride with enhanced catalytic performance for the synthesis of 1, 2, 3-triazoles, Bis‐1, 2, 3‐triazoles, and tetrazoles in parts per million level. Appl. Organomet. Chem. 36, e6524 (2022).

Arulkumar, E., Thanikaikarasan, S. & Siddhardhan, E. V. Synthesis and characterization of CuO@NiO/g-C3N4 nanocomposite for photocatalytic and electrochemical application. Results Chem. 7, 101439. (2024).

Gnanasekaran, L. et al. Synthesis and characterization of metal oxides (CeO2, CuO, NiO, Mn3O4, SnO2 and ZnO) nanoparticles as photo catalysts for degradation of textile dyes. J. Photochem. Photobiol B. 173, 43–49 (2017).

Sree, G. S., Botsa, S. M., Reddy, B. J. M. & Ranjitha, K. V. B. Enhanced UV–Visible triggered photocatalytic degradation of brilliant green by reduced graphene oxide based NiO and CuO ternary nanocomposite and their antimicrobial activity. Arab. J. Chem. 13, 5137–5150 (2020).

Dharmalingam, K. et al. Direct Z-Scheme heterojunction impregnated MoS2–NiO–CuO nanohybrid for efficient photocatalyst and dye-sensitized solar cell. Sci. Rep. 14, 14518 (2024).

Al-Yunus, A., Al-Arjan, W., Traboulsi, H. & Hessien, M. The effect of composition on the properties and application of CuO-NiO nanocomposites synthesized using a saponin-green/microwave-assisted hydrothermal method. Int. J. Mol. Sci. 25, 4119 (2024).

Zaheer, F. et al. Synergistic removal of toxic anionic reactive red dye Me4BL (RRME4BL) from aqueous media using chemically synthesised Nano-Adsorbents (ZnO, CuO, NiO and CoO); Equilibrium, Kinetics and Thermodynamic Studies. Chem. Ecol. 40, 596–626 (2024).

Maslamani, N. et al. Carboxymethyl cellulose nanocomposite beads as Super-Efficient catalyst for the reduction of organic and inorganic pollutants. Int. J. Biol. Macromol. 167 https://doi.org/10.1016/j.ijbiomac.2020.11.074 (2021).

Zhu, J. et al. Preparation of PdNPs doped Chitosan-Based composite hydrogels as highly efficient catalysts for reduction of 4-Nitrophenol. Colloids Surf. Physicochem Eng. Asp. 611, 125889 (2021).

Ren, J., Wang, X., Zhao, L., Li, M. & Yang, W. Double network gelatin/chitosan hydrogel effective removal of dyes from aqueous solutions. J. Polym. Environ. 30, 2007–2021 (2022).

Mohamed, N. A., Abd El-Ghany, N. A. & Synthesis Characterization, and antimicrobial activity of Chitosan Hydrazide derivative. Int. J. Polym. Mater. Polym. Biomaterials. 66, 410–415 (2017).

Marwani, H. M., Ahmad, S. & Rahman, M. M. Catalytic reduction of environmental pollutants with biopolymer hydrogel cross-linked gelatin conjugated tin-doped gadolinium oxide nanocomposites. Gels 8, 86. (2022).

Abd El-Aal, M., Said, A. E. A. A., Goda, M. N., Zeid, E. F. A. & Ibrahim, S. M. Fe3O4@CMC-Cu magnetic nanocomposite as an efficient catalyst for reduction of toxic pollutants in water. J. Mol. Liq. 385, 122317 (2023).

Chen, X., Jiang, R., Zhou, Z. & Wang, X. Synthesis and catalytic properties of ZSM-5 crystals with different morphologies in gelatin hydrogels. J. Dispers Sci. Technol. 42, 561–568 (2021).

Thakur, S., Govender, P. P., Mamo, M. A., Tamulevicius, S. & Thakur, V. K. Recent progress in gelatin hydrogel nanocomposites for water purification and beyond. Vacuum 146, 396–408 (2017).

Sahu, P. K., Sahu, P. K., Gupta, S. K., Agarwal, D. D. & Chitosan An efficient, reusable, and biodegradable catalyst for green synthesis of heterocycles. Ind. Eng. Chem. Res. 53, 2085–2091 (2014).

Kamal, T. et al. Silver nanoparticles embedded in gelatin biopolymer hydrogel as catalyst for reductive degradation of pollutants. J. Polym. Environ. 28, 399–410 (2020).

Sethi, S. & Thakur, S. Synthesis and characterization of nanocomposite chitosan-gelatin hydrogel loaded with ZnO and its application in photocatalytic dye degradation. Mater. Today Proc. 78, 815–824 (2023).

Ali, A. et al. Chitosan-Based hydrogel system for efficient removal of Cu [II] and sustainable utilization of spent adsorbent as a catalyst for environmental applications. Int. J. Biol. Macromol. 247, 125805 (2023).

Maslamani, N. et al. Chitosan@carboxymethylcellulose/CuO-Co2O3 nanoadsorbent as a super catalyst for the removal of water pollutants. Gels 8, 91 (2022).

Bakhsh, E. M. et al. Carboxymethyl cellulose/copper oxide–titanium oxide based nanocatalyst beads for the reduction of organic and inorganic pollutants. Polym. (Basel). 15, 1502 (2023).

Bakhsh, E. M. et al. Carboxymethyl cellulose/copper oxide–Titanium oxide based nanocatalyst beads for the reduction of organic and inorganic pollutants. Polym. (Basel). 15 https://doi.org/10.3390/polym15061502 (2023).

Maslamani, N. et al. Carboxymethyl cellulose nanocomposite beads as Super-Efficient catalyst for the reduction of organic and inorganic pollutants. Int. J. Biol. Macromol. 167, 101–116. https://doi.org/10.1016/j.ijbiomac.2020.11.074 (2021).

Rahdar, A. et al. CuO-NiO nano composites: Synthesis, characterization, and cytotoxicity evaluation. Nanomed. Res. J. 2, 78–86 (2017).

Arulkumar, E., Shree, S. S., Thanikaikarasan, S. Structure, morphology, composition, optical properties of CuO/NiO nanocomposite for electrochemical energy storage devices. Results Chem. 6, 101087 (2023).

Liu, C. et al. Schiff base crosslinked graphene/oxidized nanofibrillated cellulose/chitosan foam: An efficient strategy for selective removal of anionic dyes. Int. J. Biol. Macromol. 252, 126448 (2023).

Banat, I. M., Nigam, P., Singh, D. & Marchant, R. Microbial decolorization of Textile-Dye-Containing effluents: A review. Bioresour Technol. 58, 217–227. https://doi.org/10.1016/S0960-8524(96)00113-7 (1996).

Yadav, S. et al. Adsorption of cationic dyes, drugs and metal from aqueous solutions using a polymer composite of magnetic/β-cyclodextrin/activated charcoal/Na alginate: Isotherm, kinetics and regeneration studies. J. Hazard. Mater. 409, 124840 (2021).

Jara, Y. S., Mekiso, T. T. & Washe, A. P. Highly efficient catalytic degradation of organic dyes using Iron nanoparticles synthesized with Vernonia amygdalina leaf extract. Sci. Rep. 14, 6997 (2024).

Truong, T. B. T. et al. Green synthesised nanocopper/chitosan aerogel biocomposite as a recyclable and nonprecious catalyst for Methyl orange reduction. Colloids Surf. Physicochem Eng. Asp. 680, 132622 (2024).

Sudapalli, A. M., Shimpi, N. G. & Ag@ RGO coral reef morphology exhibits excellent optical properties and photocatalytic activity against Methyl orange under sunlight. Diam. Relat. Mater. 139, 110356 (2023).

Saleem, A. et al. Antimicrobial attributes and enhanced catalytic potential of PVA stabilized Ag-NiO2 nanocomposite for wastewater treatment. Arabian J. Chemistry. 17(2), 105545. (2023).

Murugan, E., Santhosh Kumar, S., Reshna, K. M. & Govindaraju, S. Highly sensitive, stable g-CN decorated with AgNPs for SERS sensing of toluidine blue and catalytic reduction of crystal Violet. J. Mater. Sci. 54, 5294–5310 (2019).

Baran, N. Y., Çalışkan, M., Özpala, A. & Baran, T. Fabrication of Nano-Sized Pd catalyst supported on sodium carboxymethyl cellulose/gum arabic/sodium alginate functionalized microspheres for catalytic reduction of nitro compounds, organic dyes, K3[Fe(CN)6], and Chromium (VI) Pollutants. Int J. Biol. Macromol. 262, 130134. (2024).

Akhtar, K., Bakhsh, E. M., Khan, S. B., Khan, M. & Asiri, A. M. SnLa2O5 wrapped carboxymethyl cellulose mixed calcium alginate nanocomposite beads for efficient reduction of pollutants. Int. J. Biol. Macromol. 233, 123564 (2023).

Bakhsh, E. M. et al. Fe2O3-NiO embedded calcium alginate-carboxymethyl cellulose composite as an efficient nanocatalyst for 4-nitrophenol reduction. Inorg. Chem. Commun. 156, 111157 (2023).

Acknowledgements

This scientific paper is derived from a research grant funded by the Research, Development, and Innovation Authority (RDIA) - Kingdom of Saudi Arabia - with grant number (12894-JAZZAN-2023-JZU-R-2-1-SE).

Author information

Authors and Affiliations

Contributions

Conceptualization, N.M.; methodology, N.M., S.B.K.; validation, N.M, R.A. and M.A.; formal analysis, R.A., Y.A. R.H. and M.A.; investigation, N.M.; resources, S.B.K, Y. O. A.; data curation, N. M.; writing—original draft preparation, N.M; writing—review and editing, E.M.B, M.A.; visualization, N.M, K.A.; All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Maslamani, N., Bakhsh, E.M., Almutairi, R. et al. Metal nanocomposite supported on gelatin chitosan hydrogel as a catalyst for the removal of toxins. Sci Rep 15, 24084 (2025). https://doi.org/10.1038/s41598-025-08503-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-08503-3