Abstract

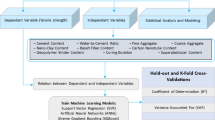

This article provides a concise overview of the modification mechanism of silver nanoparticles-functionalized multiwalled carbon nanotube (Ag-PM-WCNT), ground granulated blast furnace slag (GGBFS), and carbon quantum dots (CQD) on the mechanical and reliability properties of structural geopolymer reinforced-composite beams (GR-CBs). The structural GR-CBs were prepared with a geopolymer binder which included sodium carbonate and hydrated lime, GGBFS, Ag-PM-WCNT, and CQD, as well as the SP. A number of features were tested at 7, 28, 90, 180, 365, 2185, and 4370 days, including, compactness, porosity, shear, bending, and compressive strengths, Young’s modulus, and SEM analysis, as well as fluidity of fresh state of GR-CBs. The outcomes indicate that the incorporation of 0.5–0.7 wt% Ag‒PM‒WCNT and 2.5 wt% CQD leads to a decrease in fluidity and porosity while concurrently increasing the shear, bending, and compressive strengths by more than 104%, 160%, and 180%, respectively. The most remarkable shear, bending, and compressive strengths were observed in GR-CB11, measuring 9.5 MPa, 10.6 MPa, and 75 MPa respectively, after 4370 days. The Young’s modulus of the GR-CB, which includes Ag‒PM‒WCNT, GGBFS, and CQD, demonstrated a significant enhancement, alongside a remarkable level of densification within the microstructure and a variety of constitutive mathematical models. Therefore, developed GR-CB has the potential to facilitate practical implementation in real-world structure projects and infrastructure renewal.

Similar content being viewed by others

Introduction

Since the early twentieth century, macro- and microfibers have been employed to augment cement-based composites at the millimeter and micrometer scales1,2,3,4. Nevertheless, it does not compensate for the deficiencies of geopolymer paste at the nanoscale. In light of advancements in nanotechnology and the densified particle packing theory5, nanofibers with exceptional properties are currently being incorporated into structural materials to increase the continuity of heterogeneous materials at the submicroscopic scale, thereby modifying the intrinsic characteristics of composites from the fundamental level upward6,7,8. Among the various types of nanofillers, carbon nanotubes (CNTs) are particularly promising for nanoscale modification because of their high mechanical strength, excellent toughness, and favorable Young’s modulus9. Numerous studies have demonstrated that CNTs can markedly enhance the mechanical properties of composites10,11,12,13,14,15,16. The beneficial effects of CNTs can be attributed to three principal factors: their ability to fill the pores of the matrix, thereby refining the microstructure; their capacity to bridge stresses; and their influence on the nanostructure of calcium silicate hydrate (C–S–H) gel and the interface transition zone (ITZ)17. As a result, the uneven dispersion of CNTs greatly limits the enhancement effects that they can have on the reinforced geopolymer beam composite. To increase the dispersibility of CNTs in a binder matrix, surface modification and coating are often employed, with the introduction of surfactants and covalent modifications representing a common strategy18,19,20,21. Owing to its high hardness, toughness, and ferromagnetic properties, metallic silver is an ideal choice for coating CNTs22. Silver coating techniques, such as thermal decomposition23, vapor deposition24, surface chemical reduction25, and γ-radiation26, have therefore been studied extensively. In addition, to address the weak interactions between Ag and inorganic surfaces and the aggregation of AgNPs, a new dispersant was synthesized in which the AgNP coating was applied to surfaces such as CNT fibers, steel fibers, and other two-dimensional (2D) inorganic materials (mica nanosheets), resulting in highly conductive films27. In addition to the mechanical strengths, shear, bending, and compressive strengths, the deformation properties of structural geopolymers filled with Ag‒PM‒WCNTs are also critically important. Nevertheless, the effects of Ag‒PM‒WCNT on the Young’s modulus and Poisson’s ratio, which reflect the elastic deformation capacity of geopolymer composites, remain uncertain. In addition, to characterize the whole damage process of the Ag‒PM‒WCNT‒modified geopolymer under uniaxial compression, the characteristic relationship and the macroscopic response of the composites to internal deformation have not been clearly established. Furthermore, the mechanism underlying the effect of Ag‒PM‒WCNT on the composites requires further investigation to determine how to regulate and apply Ag‒PM‒WCNT‒doped structural geopolymer-reinforced composite beams. The thermal cracks caused by the heat of hydration should also not be ignored. The strength properties of geopolymer-bonded composites are closely linked to their internal structural defects, such as microcracks and voids, and the thermal cracks caused by the heat of geopolymer hydration should not be neglected. According to reports, CNTs have an excellent thermal conductivity of 3000 W/(m–K)28, which helps transmit hydration heat, reduce the temperature stress and reduce the thermal cracking of composites29,30. In addition, Ag‒PM‒WCNTs can more easily achieve effective contact in the binder matrix, which is conducive to the formation of a thermal network and the improvement of the thermal conductivity of composites because the silver coating layer on the surface of Ag‒PM‒WCNTs significantly increases their diameter and specific surface area17,22.

In addition to the previously mentioned silver coating of CNTs and its effects on the physical and strength features of geopolymer-bonded composites, graphite mac carbon quantum dots (CQDs) have the potential to enhance the properties of binders. This enhancement has been observed in structural composite materials, particularly those containing reactive powders such as fly ash31,32,33,34,35,36,37, marble powder38, RubberCrete39, polyvinyl alcohol fibers40, and various construction binders41. The addition of graphite mac carbon quantum dots (CQDs) into a reactive powder cement or pure cement system can enhance the setting time and increase the strength gained, potentially outweighing any negative effects. The water absorption, apparent volume, apparent density, CH content, setting time, fluidity, and strength gain appear to be favorable compared to those of pure cement and graphite nanoparticle-blended cement31,32,33,34,35,36,37. Kırgız indicated that the incorporation of graphite mac carbon quantum dots (CQDs) into reactive powder cement and pure cement systems appears to accelerate the setting time and enhance the strength gain, potentially outweighing any potential negative effects. The water absorption, apparent volume, apparent density, carbon content, setting time, fluidity, and strength gain of this system appear to be favorable compared with those of pure cement and graphite nanoparticle-blended cement38. The mechanism between reactive marble powder and CQD was further elucidated by Kırgız for cement-based materials. These findings suggest that the addition of CQD and the superplasticizer to mortar containing 35% MP and 65% pure Portland cement may result in notable increases in the strength, water absorption, and density of the mortar. Compared with the performance of pure Portland cement mortar, the addition of CQD and the superplasticizer led to an increase in the bending strength of more than 28% and compressive strength of more than 22% in marble powder–cement mortar38. Hamza et al. explored the use of graphite nanoparticles (GNPs) for cement mortar containing reactive rubber particles from tire waste. These findings suggest that an optimal rubber content of 15% is effective in ensuring workability while also limiting rheological characteristics. The thermal conductivity, water absorption, and water penetration properties increased with increasing rubber content and GNP concentration. Notably, no adverse effects on the mechanical properties or chloride ion penetration of self-compacting concrete (SCC) were observed when rubber powder and GNPs were incorporated39. Relatedly, Bheel and other authors have demonstrated the efficiency of the use of GNPs in the manufacture of engineered cementitious composites (ECCs) containing reactive fly ash and polyvinyl alcohol (PVA) fibers. Their findings indicated that incorporating GNP as a nanomaterial in an ECC mixture up to a concentration of 0.08% resulted in optimal outcomes, particularly in terms of compressive strength, tensile strength, and modulus of elasticity after 28 days. It appears that the composite strength increased and that the chemical bonding between the GNPs, PVA fibers, and cement matrix was responsible for the excellent mechanical characteristics of the GNP-reinforced ECC mixture40. Furthermore, Ag nanoparticle (NP)-enhanced MWCNTs exhibit a synergistic effect, elevating both electrical and thermal conductivity as well as the toughness of the material42,43,44. Pal and colleagues45 employed molecular-level mixing to fabricate MWNT-reinforced silver matrix composites, investigating the influence of functionalized MWNTs on thermal conductivity. Their results indicated that functionalized MWNTs boosted the thermal conductivity of pure silver from 430 to 530 W/m K, underscoring the promise of these composites. Li and associates46 utilized chemical and ball milling techniques to affix Ag nanoparticles to the surfaces of MWNTs, improving thermal conductivity from 0.65 to 0.75 W/m K. However, they did not assess the thermogravimetric or morphological alterations in the Ag/MWCNT composites, and the ball milling process could introduce impurities, thereby diminishing purity. Wang and associates47 initially created high-loading Sn-MWCNT composites via a chemical replacement method, subsequently substituting tin with silver ions to form Ag-MWCNT composites. The silver nanoparticles were evenly distributed across the nanotube surface, significantly enhancing thermal conductivity. Nonetheless, tin predominantly exists as stable + 4 ions during the replacement reaction, which rapidly escalates silver content and leads to nanoparticle aggregation. Natsuki and colleagues48 devised a one-step green method to bond Ag nanoparticles to MWCNTs, achieving uniform 5 nm Ag nanoparticles on the surface through straightforward separation. This method propels the application of Ag/MWNT composites in electronic pastes. Suh and colleagues49 found that Ag/MWNT thermal interface materials exhibited peak performance with a thermal conductivity of 160 W/m K. The nano-silver on the nanotube surface enhances thermal conductivity by establishing an efficient thermal pathway between silver flakes, thereby improving carrier concentration and mobility. Amoli and colleagues50 investigated the role of silver nanoparticles in functional materials, emphasizing the significance of surface chemistry on their properties. It was discovered that silver nanoparticles with short-chain modifications exhibit conductivity, whereas their long-chain counterparts do not. In the realm of conductive adhesives, the presence of short-chain nanoparticles markedly enhances conductivity. Amoli and colleagues51 explored the impact of various polymers and conductive fillers- including silver nanoparticles, micrometer-sized silver flakes, carbon nanotubes, and graphene- on electrically conductive adhesives (ECAs). They proposed innovative strategies for improving conductivity and outlined potential avenues for future research, highlighting the importance of assessing the economic viability of these materials for practical applications moving forward.

As would be understood from the manuscript, entitled “Activation of slag through a combination of NaOH/NaS alkali for transforming it into geopolymer slag binder mortar- Assessment the effects of two different Blaine fines and three different curing conditions,” published by us52, there already has tested geopolymer materials throughout 208 days. Our motivation is to make GR-CB monitored throughout 4370 days, because no study could have been done this previously, even though the geopolymer-based construction materials are new and were made plenty of much by-product, like GGBFS, fly ash, metakaolin, and etc., inserted into it. And no one knows what the by-product will do future. Therefore, the manuscript’s aim is to determine long-term behavior of the GR-CBs in terms of physical, mechanical, durability, and microstructure analyses. To gain further insight into the features of geopolymer reinforced-composite beams (GR-CBs), a series of experiments were conducted. These measurements included porosity, shear, bending, compressive strength, and Young’s modulus. In addition, the authors carried out SEM analysis on several samples. In the spirit of collaboration and advancement, several constitutive models of Ag-PM-WCNT- and CQD-modified GR-CBs were established to facilitate predictions of the strengths of structural geopolymer reinforced-composite beams (GR-CBs) during the curing period. In conclusion, the underlying mechanism by which Ag‒PM‒WCNT and CQD enhance the properties of GR‒CB has been explained.

Materials and methods

In this investigation, the use of a geopolymer binder (Na2CO3 and hydrated lime) was explored, with the aim of providing a more comprehensive analysis of the geopolymer binder. Table 1 lists the results of chemical analysis of standard cement, sodium carbonate (Na2CO3), hydrated lime, ground granulated blast furnace slag (GGBFS), and graphite mac carbon quantum dots (CQDs). The mixing water mentioned in standard EN 1008 was drinkable tap water53, and the superplasticizer used was a polycarboxylic ether (PCE) polymer-based superplasticizer (PCEP-BSP).

Table 2 lists the principal properties of the blending of Na2CO3 + hydrated lime. In addition to the Na2CO3 + hydrated lime based geopolymer binder, the following components were utilized in the mixture: fine aggregate, coarse aggregate, GGBFS, Ag-PM-WCFNT, and CQD in the structural geopolymer reinforced-composite beam (GR-CB) samples.

The particle density of the stack of fine and coarse aggregates used is 1705 kg/m3, according to Table 3, which details the physical and mechanical properties of the fine aggregates and coarse aggregates utilized in the GR-CB.

Preparation of functionalized MWCNTs with silver nanoparticles (Ag)

Multiwalled carbon nanotubes (MWCNTs) with a diameter of 10–20 nm were utilized in this research. Carbon nanotubes (CNTs) are characterized by their remarkable physical strength, lightweight nature, flexibility, and excellent electrical and thermal conductivity54. Owing to the absence of functionalization, CNTs demonstrate low reactivity. To facilitate the dispersion and attachment of silver nanoparticles (AgNPs) onto the surfaces of CNTs, several functional methods, including chemical55, electrochemical56, mechanochemical57, and plasma58 methods, have been introduced in nature. The types of functional methods introduced were not specifically restricted, allowing for the formation of hydrogen bonds with hydroxyl (–OH) or carboxylic acid (–COOH) media. In this study, the following modification technique was employed, utilizing nitric acid (HNO3) and lysine (L ( +)-lysine) to alter the MWCNTs. The process for obtaining nitric acid-modified MWCNTs involved several steps. Initially, 0.15 g of MWCNTs was combined with 70 mL of HNO3 in a flask and stirred at 120 °C for 10 h in an oil bath. Following the reaction, the mixture was centrifuged at 5000 × g for 1 min, and the supernatant was discarded. The resulting precipitate was washed with distilled water and centrifuged twice at 7500 rpm for 2.2 min each time. The modified CNTs were then suspended in 1.1 L of distilled water and allowed to sit for 24 h to neutralize their pH. After another centrifugation at 7500 rpm for 1.5 min, the supernatant was removed, and the remaining residue was dried at 55 ± 5 °C until the nitric acid-modified MWCNTs retained their yield59,60,61,62.

Preparation of GR-CBs and reference composite

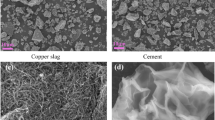

The aim of this GR-CB preparation was to consider the impact of Ag-PM-WCFNTs and CQDs, which incorporate a polycarboxylic ether polymer-based superplasticizer (PCEP-BSP) and ground granulated blast furnace slag (GGBFS). Figure 1 shows the images of materials used for preparation of GR-CBs and reference composite, upper row (left to right): neat cement, CQD, and Na2CO3 powder (sodium carbonate ash), bottom row (left to right): hydrated lime, GGBFS, and Ag-PM-WCNT.

Table 4 presents the mixing proportions of each component. To make geopolymer binder together with CQD favorable, the work used the blending of sodium carbonate (Na2CO3) and hydrated lime and GGBFS as following Table 4. In other words, the researchers did not use aluminosilicate in the geopolymer binder. Instead, it used sodium carbonate (Na2CO3) as alkali activator and hydrated lime as natural binder and GGBFS as source of aluminum and silicon oxides, and CQD as activator for calcium hydroxide in the geopolymer binder. This meant that the researchers did not need the aluminosilicate to conduct the research and write the paper.

In the interest of moving forward with this research, a total of twenty groups of GR-CBs and one group of reference composite beams were designed as per rule EN 206-2013, EFNARC 2002, EN 14889-1:2006, SIST EN 15167-1:2006, and EN 15167-2:2024 standards63,64,65,66,67,68,69, comprising four different contents of GGBFS (35%, 50%, 65%, 80%, and 90%) and three different contents of Ag-PM-WCFNT. The values following the letters GR-CB represent binder contents and geopolymers (10%, 20%, 35%, 50%, and 65%). The reference group was composed of CEM I 52.5 N cement, natural course aggregate, natural fine aggregate, and drinkable water. Importantly, the reference group does not contain geopolymer, Ag-PM-WCFNT, PCE-BSP, or GGBFS. Importantly, the process of vibrating composites, although often overlooked, is a crucial step in the construction process, contributing to the achievement of a high-quality final product. The process of composite pouring and setting requires a certain degree of skill and knowledge, and there are numerous reasons why it is inadvisable to rush the vibration procedure. In this work, the authors employed both inner and outer vibrator techniques to ensure the best possible outcome.

Test methods

In accordance with the standards outlined in SIST EN 12350-8:2019, the flow of the newly mixed concrete was measured via the Abrams cone method68. This provides insight into how the incorporation of Ag-PM-WCNTs, GGBFS, and PCSPF influences the uniformity of the flow and the consistency of the GR-CB. Following this, we proceeded to assess the hardened state of the material. This involves the characterization of several key physical properties, including compactness, porosity, shear strength, bending strength, compressive strength, and Young’s modulus. The compactness of the GR-CB was determined via Eq. (1).

where C is the compactness of the GR-CB in %, and P is the porosity of the GR-BC in %.

The porosity test could have been conducted via a range of laboratory equipment, including a water curing cabinet, a digital weighing scale with a precision of 0.01 g, and a digital furnace capable of drying a significant quantity of the sample simultaneously. Firstly, the composite sample was dried in a furnace at 50 ± 5 °C until it reaches a constant mass. The recorded composite mass (Wd) (g) is then used for subsequent calculations. Next, the sample was carefully placed within a water curing cabinet, where a precise amount of water was applied until it reached a height of 50 mm on the surface. After a thorough 24-h period, a digital weighing scale was used to record the initial wet mass of the composite sample. This wet weighing measurement process was then methodically repeated, ensuring that there was no 1% difference between the last and current measurements, to ensure the most accurate results. The constant current water saturation of the grout can be recorded as the ultimate wet mass (Ww) (g). Finally, the water-absorbed, hardened grout is immersed in volume-level water to measure the displaced water level as the water-saturated volume (Wsw). If this is correct, the apparent porosity (P) can be calculated according to Eq. (2)5,38.

As shown in Table 4, a variety of GR-CBs and reference beam types were assessed via fluidity, compactness, and porosity tests. Figure 2 shows the reference and GR-CB samples prepared, and their curing in water and testing e.g. flow test, shear strength test, bending strength test, compressive strength test, and modulus of elasticity test.

The shear strength, as determined by this study, was evaluated according to EN 12390-669 at 7, 28, 90, 180, 365, 2185, and 4370 days in cubic test samples measuring 150 × 300 mm. The arithmetic mean of three samples was used to obtain the average value of the shear strength. The bending strength was determined in accordance with the methods of EN 12390-570 and at 7, 28, 90, 180, 365, 2185, and 4370 days for samples with dimensions of 100 × 150 × 500 mm, which were obtained from the arithmetic average of three samples. The determination of the compressive strength was carried out according to EN 12390-371 in cubic samples with 150 mm edges, and the arithmetic average of the test results of five samples for each considered age (7, 28, 90, 180, 365, 2185, and 4370 days) was obtained. The Young’s modulus (Ecm) was measured in accordance with the specifications of LNEC E-39772. The test was carried out at 7, 28, 90, 180, 365, 2185, and 4370 days on prismatic samples with dimensions of 100 × 100 × 500 mm, and the results are presented as the average values of the three samples for each type of GR-CB and reference beam. As shown in Table 4, these tests were applied for every type of GR-CB and reference beam. The following figures present a visual representation illustrating the flow, change in strength, and change in Young’s modulus for both the GR-CB beam and reference beam.

Results and discussion

Flow with Abrams

The relative flow and types of fresh geopolymer containing fine aggregates, coarse aggregates, Ag-PM-WCNTs, GGBFS, CQD, and PCEP-BSP, as well as the reference composite, are shown in Fig. 3. Notably, the formwork, which is constructed from wood, steel, or an artificially derived composite material such as plywood, must be physically robust to withstand the horizontal hydraulic pressure exerted on it. The geopolymer composite itself must also be physically robust. The more flowable the material is, the more horizontal water pressure is generated on the formwork in the reconstruction of roads and bridges (as illustrated in Fig. 3). It has been observed that Ag-PM-WCNTs and GGBFS tend to reduce the flowability of freshly prepared geopolymer composites and reference composites (Fig. 3). This characteristic of the reactive powder of GGBFS does not necessarily require the use of a robust mold. Importantly, this does not result in an escalation in the expense of the composite concept. On certain occasions, the aforementioned decrease in flowability can be advantageous for specific applications, such as forming materials without the necessity for vibration and at elevated pouring ratios. Conversely, it is crucial to consider the maximum size of coarse aggregate, as this directly impacts the formation of strong bonds between the geopolymer composite and the formwork. Smaller particle sizes, in this regard, are advantageous because of their increased interface area, which enhances the interfacial energy.

In addition, the maximum size of coarse aggregate should be considered, as benefits may lead to segregation between the aggregate and binder paste composite73. Flow testing began 3.5 min after the water contacted the binder. The testing environment was maintained at 23 °C and 53% humidity to minimize effects on measurements due to laboratory conditions. Adding reactive powder and Ag-PM-WCNT fibers can increase water capture within the composite mixture, reducing the formwork pressure. This is especially clear with reactive powder-GGBFS. The low water uptake capacity of the GGBFS does not significantly affect the flow of the composite material, as shown in Fig. 3. The reference composite has the highest flow, as expected. Consequently, the reference concrete is considered the most flowable material, as it does not comprise any reactive powder, Ag-PM-WCNT, or PCEP-BSP. The GGBFS with Ag-PM-WCNT reduces the lateral formwork pressure of the geopolymer composite, as observed in the GR-CBs. The composite type of GR-CB8, which contained 35 wt% geopolymer, 65 wt% GGBFS, 0.5 wt% Ag-PM-WCFNT, 2.5 wt% CQD, and 1.67 wt% PCEP-BSP, showed the greatest reduction in flow. The 65 wt% GGBFS, 0.5 wt% Ag-PM-WCNT, and 2.5 wt% CQD reduced the flow by 70% for the types of GR-CB8 (Fig. 1). This could be indicative of the flow level of the GR-CBs possibly being influenced by the water demands of the GGBFS, which might alter the water-to-cement ratio (w/c) in this blend, potentially reaching a level that might hinder optimal flow. The high demand of the reactive powder for water could explain the lower flow rate than that of the reference composite. GGBFS, Ag-PM-WCNT, CQD, and PCEP-BSP were blended into GR-CB, resulting in an average flow rate 30.8% lower than that of the reference composite. GGBFS and Ag-PM-WCNT and CQD reduce thixotropy, which is enhanced by PCEP-BSP. Similar results were reported in the literature. For example, Berra et al.74 noted a comparable outcome regarding the detrimental impact of incorporating nanoparticles on the workability of Ordinary Portland Cement (OPC) pastes. The slump measurements for all four mixtures, both with and without graphene, exceeded 200 mm, surpassing the recommended slump values for OPC concrete75. The elevated slump values observed in alkali-activated concrete can be attributed to the spherical nature of fly ash particles. Conversely, it was noted that the alkali-activated concrete mixtures, regardless of the presence of graphene, exhibited a certain stiffness due to the viscous sodium silicate solution. This stiffness rendered the alkali-activated concrete mixes somewhat challenging to place and compact. Similar findings concerning the fresh state characteristics of fly ash-based geopolymer concrete were documented by Olivia and Nikraz76. The expectation was that the inclusion of graphite-based carbon would lead to a reduction in the workability of alkali-activated concrete, primarily due to the water loss associated with the high surface area of graphite. In Hadi et al.’s investigation, the water content and the quantity of admixture in the mix design were elevated compared to the conventional mix designs of alkali-activated concrete referenced in earlier studies77,78. It was indicated that a ratio of additional water to aluminosilicate materials up to 0.38 yielded satisfactory compressive strengths for alkali-activated concrete79. Exceeding this threshold could potentially have a negative impact on the compressive strength of alkali-activated concrete80. In Chindaprasirt et al.’s study, the minor reduction in flow values resulting from the addition of graphene did not significantly influence the fresh state of the alkali-activated concrete. The mixture proportions for the alkali-activated concrete, both with and without graphene, were deemed appropriate for casting the necessary specimens for testing. There was no notable difference in the handling of alkali-activated concrete, irrespective of the presence of graphite-based carbon. However, GGBFS and Ag-PM-WCNT have been shown to reduce the thixotropy of the geopolymer binder, facilitating the use of pure geopolymer, reactive powder, and PCEP-BSP to provide a lower lateral hydraulic formwork pressure for GR-CB-based infrastructure renewal. GGBFS and Ag-PM-WCNT and CQD do not increase infrastructure renewal costs; they reduce the lateral hydraulic formwork pressure without chemical additives or vibration work loading. The PCEP-BSP is also classified as an admixture for reducing lateral hydraulic formwork pressure for infrastructure renewal.

Compactness

Figure 4 shows the relative compactness, curing days in water, and types of hardened GR-CBs, as well as the reference composite, (a) the relative compactness of GR-CB at 7d, 28d, and 90d, and (b) the relative compactness of GR-CB at 180d, 365d, 2185d, and 4370d. One of the following methods can be used to reduce the carbon footprint of concrete buildings, according to the results of earlier research and the guidelines provided in the literature81: (A) Components that optimize material strength to increase the composite strength per unit of binder mass while decreasing the volume of the composite relative to members with the same structural strength. (B) The composite formulation is adjusted to lower the binder content per cubic meter of composite while preserving strength and consistency. This is accomplished by increasing the packing density through design parameters and by replacing the binder with GGBFS. The design characteristics of approach (B) include the use of superplasticizers to meet the strength and workability requirements, a decrease in the W/C ratio, and an increase in the packing density through a combination of these three factors. The suggested methodology (A) states that geopolymer has a strength class of 105 MPa75 and is the optimal choice because it enables a reduction in the quantity of cementitious material and the overall volume of concrete utilized for the specified elements82. With respect to method (B), geopolymers are usually combined with other powder additions, although they can also be used. The use of geopolymers with low environmental impact and high performance, such as blast furnaces and composite cements, is advised. The strength classes of these geopolymers (Na2CO3 + hydrated lime) with GGBFS and fly ash are 74.4 and 76.5 MPa, respectively83,84. Reactive powder can be partially substituted in the creation of geopolymer composites to reduce the amount of geopolymer.

Since the aforementioned constituents, Na2CO3, hydrated lime, and GGBFS, represent the main building blocks of these geopolymer composites, the amount of binder can be decreased. Owing to the higher hydrated lime percentage (above 95%) of this geopolymer binder, which permits the use of larger quantities of added material via geopolymer binder replacement, the additions are used in the case of geopolymer composites to partially replace the geopolymer binder within the composite matrix. On the other hand, some of the previously mentioned additives, such as pozzolans, which are frequently used to replace geopolymer binders, have a slow hardening process. Nevertheless, it speeds up its hydration process when mixed with lime that is high in calcium oxide, which lessens the restrictions on its application (Fig. 4a,b).

Porosity

The relative porosities, curing days in water e.g. 7d, 28d, 90d, 180d, 365d, 2185d, and 4370d, and types of hardened geopolymer composite (GR-CB) containing fine aggregates, coarse aggregates, Ag-PM-WCNT, GGBFS, CQD, and PCEP-BSP, as well as the reference composite, are shown in Fig. 5a,b. All mixtures exhibit remarkably comparable porosity values, approximately 1.1%, alongside a reduction in porosity when contrasted with their 7-day measurements. Adding supplementary cementitious materials (SCMs) to geopolymer composite through fine-ground additions is a very advantageous procedure that improves the overall performance of GR-CBs, including porosity, fluidity, and compactness, in addition to preserving or improving their mechanical qualities. Essentially, the extra binder element e.g. the CQD fulfills two different functions at the same time. (1) They aid in the hydration of the binder, which makes it possible for calcium hydroxide (C–H) products to develop and for new calcium-silicon-hydrate (C–S–H) gels and calcium carbon hydroxide (C–C–H) to form, which reduce the porosity of the GR-CB.

Besides, Bonneau and other authors85 provide a detailed explanation of the underlying chemical processes. (2) It minimizes the spaces between coarser particles, such as aggregates and cement, by acting as a latent hydraulic admixture5. When added to binder powder, the main chemical activator of pozzolans is hydrated lime (CH), which is released during clinker hydration. Pozzolans can be made finer to induce physical activation86. Regarding the second function indicated above, the small particles increase the packing density of the geopolymer binder and lessen the wall effect of the transition zones, which enhances the composite’s strength performance. Niu et al.86 reported that porosity and compressive strength are positively correlated.

Shear strength

For infrastructure and structural regeneration, Fig. 6 shows a comparison of the effects of the GGBFS and the Ag-PM-WCNT and the CQD on the shear strength of GR-BC, types of GR-BC and reference composite, and curing days in water, (a) the relative shear strength of GR-BC at 7, 28, 90, and (b) the relative shear strength of GR-BC at 180d, 365d, 2185d, and 4370d.

Comparison of the effects of the GGBFS and the Ag-PM-WCNT and the CQD on the shear strength of GR-BC, types of GR-BC and reference composite, and curing days in water, (a) the relative shear strength of GR-BC at 7, 28, 90, and (b) the relative shear strength of GR-BC at 180d, 365d, 2185d, and 4370d.

The increase in compactness could have resulted in an increase in the shear strength. For instance, although the PCEP-BSP/geopolymer ratio of the GR-CB11 mixture is 0.013, it exhibits the greatest shear strength of 9.5 (MPa) at 4370 days, when compared to that of the reference concrete, with an average increase of approximately 16.5%. However, the shear strengths of GR-CB5 (8.5 MPa), GR-CB10 (9 MPa), and GR-CB20 (9 MPa), whose the PCEP-BSP/geopolymer ratio is between 0.022 and 0.025, could be greater, when compared with that of reference which has a higher quantity of binder. The enhancement in shear strength through the incorporation of CQD can be ascribed to the densification of the internal framework of alkali-activated concrete. The nanoscale dimensions and elevated aspect ratio of CQD facilitated the filling of voids. Consequently, the internal structure became increasingly compact with the inclusion of graphene87. The peak shear strength was achieved with Mix G-0.5, which contained 0.5% graphene relative to the weight of aluminosilicate materials. It is noteworthy that the shear strength is directly correlated with the compressive strength of concrete88. The physical and chemical reinforcement provided by graphene, which bolstered the compressive strength of concrete, likely played a significant role in enhancing the high splitting tensile strength of alkali-activated concrete. Notably, a distinct influence emerged in the GR-CB and reference composites, revealing that the shear strength of these concretes increased with increasing proportions of ground granulated blast furnace slag (GGBFS) and Ag-PM-WCNT (Fig. 6a,b). Additionally, the enhanced compactness and the effects of vibration likely played a pivotal role in augmenting the shear strength. For example, the reactive GGBFS/geopolymer binder and Ag-PM-WCFNT/geopolymer binder of the GR-CB11 composite mixture stand at 0.53% and 0.7%, respectively, yet they have the highest shear strength compared with that of the reference composite, with an average increase of approximately 16.5% at 4370 days. In contrast, the shear strengths of GR-CB5, GR-CB10, GR-CB15, and GR-CB20 with a reactive powder/geopolymer binder ratio of 9 were evaluated against composites with a lower amount of geopolymer binder. Despite the elevated reactive powder content, both GR-CB5, GR-CB10, GR-CB15, and GR-CB20 demonstrated superior shear strengths compared with those of the reference composite at 4370 days. Figure 7 shows the relationships for predicting the relative splitting tensile strength of GR-CBs from the curing period in water, mathematical models, types of GR-CBs, and the R2 values of mathematical models.

In Fig. 7, a selection of nonlinear regression equations has been employed to illustrate the correlation between the relative shear strength and the curing duration in water for GR-CBs, which encompass GGBFS, Ag-PM-WCNT, and PCEP-BSP. The degree of correlation, represented by R2, is also depicted in Fig. 7, indicating a commendable compatibility between the two specified properties. With an R2 value of 1, it becomes feasible to estimate the shear strength of GR-CBs on the basis of the curing period in water, utilizing the mathematical equations presented in Fig. 7, provided that at least one hardened GR-CB sample is prepared. However, in 2021, Sarvandani and other authors revealed the remarkable bridging effect of carbon nanotubes (CNTs) on the shear strength of glass-reinforced concrete (GR-CB). Their findings indicated a significant increase in the splitting tensile strength, achieving an impressive increase of up to 37%89. A parallel outcome was observed in the study by Al-Rub, where CNTs contributed to a remarkable 60% improvement in the splitting tensile strength90.

Bending strength

Figure 8 shows a comparison of the effects of the GGBFS and the Ag-PM-WCNT and the CQD on the bending strength of GR-BC for infrastructure and structure renewal, types of GR-BC and reference composite, and curing days in water, (a) the relative shear strength of GR-BC at 7, 28, 90, and (b) the relative shear strength of GR-BC at 180d, 365d, 2185d, and 4370d. Conversely, the most significant increase in bending strength was noted for the GR-CB11 blend, which comprised 65 wt% geopolymer binder, 35 wt% GGBFS, and 0.7 wt% Ag-PM-WCNT, 2.5 wt% CQD, and 0.88 wt% PCEP-BSP, when evaluated at 7, 28, 90, 180, 365, 2185 and 4370 days (Fig. 8). The increase in the bending strength of the GR-CB showed that both the increase in the Ag-PM-WCNT content and the inclusion of GGBFS and the CQD led to an average bending strength that was greater than that of the reference composite.

Comparison of the effects of the GGBFS and the Ag-PM-WCNT and the CQD on the bending strength of GR-BC for infrastructure and structure renewal, types of GR-BC and reference composite, and curing days in water, (a) the relative shear strength of GR-BC at 7, 28, 90, and (b) the relative shear strength of GR-BC at 180d, 365d, 2185d, and 4370d.

The decrease in porosity could have resulted in an increase in the bending strength. For instance, although the PCEP-BSP/geopolymer ratio of the GR-CB11 mixture is 0.013, it exhibits the greatest bending strength of 10.59 (MPa) at 4370 days, when compared to that of the reference concrete beam, with an average increase of approximately 17.7%. However, the bending strengths of GR-CB5 (8.95 MPa), GR-CB10 (9.4 MPa), and GR-CB20 (9.5 MPa), whose the PCEP-BSP/geopolymer ratio is between 0.022 and 0.025, could be greater, when compared with that of reference which has a higher quantity of binder. Comparable outcomes, namely the limited impact of graphene nanoplatelets, were reported by Sajjad et al.91. They observed that the flexural strength of mortar beams created with a 1:1 mixture of FA and GGBS remained around 7 MPa, regardless of the dosage of GNPs. This outcome was attributed to the unpredictable alignment of GNPs within the mixture, which may or may not have effectively bridged or reinforced the cracks that developed during testing. In contrast, Liang and Zhang incorporated reduced graphene oxide as an additive in metakaolin geopolymer, achieving a remarkable flexural strength enhancement of approximately 40% at 3 days. The authors attributed this improvement to the distinct chemistry of reduced graphene oxide, which is less susceptible to agglomeration in a highly alkaline environment92. On the one hand, concrete is commonly viewed as a fundamentally nonresilient building material, resulting in variations in the bending strength of mortar during its early stages. This occurrence prevents a thorough analysis of how cement hydration affects the increase in bending strength, as comprehending the link between the microstructure of cement and the strength enhancement is necessary. Importantly, increasing the loss on ignition (LOI) and alkali levels in cement paste may lead to a decrease in strength improvement. This is because the strength improvement is adversely impacted by the existence of LOI and alkali, which are both byproducts of cement hydration. The influence of admixtures with elevated levels of calcium oxide on strength development is affected by variations in silicon oxide (SiO2), sodium oxide (Na2O), and alkali, along with an increase in the LOI. This result shows that a mixture with more than 6% calcium oxide does not positively influence the strength development of concrete93,94,95,96. On the other hand, changing the chemical makeup of geopolymer paste clarifies how admixture-reactive powder and Ag-PM-WCNTs with highly hydrated calcium oxide (lime) work. The incorporation of a high-silicon oxide (SiO2)-based additive promotes ongoing strength development in the composite beyond 7, 28, 90, 180, 365, 2185 and 4370 days, as it triggers the hydration of calcium-rich materials in the binder matrix. As a result, an admixture based on high-silicon oxide (SiO2) serves as a catalyst for enhancing the strength of the composite. The higher the blending ratio of this admixture in the composite is, the greater the increase in the strength gain ratio. Cui and colleagues27 reported that adding MWCNTs without nickel plating at the same concentration led to a 6.5% and 7.2% increase in the bending strength. This outcome differs from the 23.9% decline noted in the use of M5, reinforcing the claim that nickel plating is a successful method. Moreover, the increase in bending strength due to the inclusion of Ni-CNTs is more significant than that from the use of MWCNTs at similar concentrations reported by Reales et al.97 and Sedaghatdoost et al.98. Figure 9 shows a relationship for predicting the relative bending strength of GR-CBs from the curing period in water, mathematical models, types of GR-CBs, and the R2 values of mathematical models.

In Fig. 9, several nonlinear regression equations are utilized to illustrate the connection between the relative bending strength and the curing duration in water of the GR-CBs, which include GGBFS, Ag-PM-WCNT, CQD, and PCEP-BSP. The extent of the relationship of R2 is illustrated in Fig. 9 and indicates a strong compatibility between the two defined properties. Since the correlation coefficient R2 is 1, the bending strength of GR-CBs can be predicted from the water curing duration by employing the mathematical formulas in Fig. 9 and preparing at least one hardened specimen of GR-CB.

Compressive strength

Figure 10 shows a comparison of the effects of the GGBFS, the Ag-PM-WCNT, the CQD, and PCEP-BSP on the compressive strength of GR-BC for infrastructure and structure renewal, types of GR-BC and reference composite, and curing days in water, (a) the relative shear strength of GR-BC at 7, 28, 90, and (b) the relative shear strength of GR-BC at 180d, 365d, 2185d, and 4370d.

Comparison of the effects of the GGBFS and the Ag-PM-WCNT and the CQD on the compressive strength of GR-BC for infrastructure and structure renewal, types of GR-BC and reference composite, and curing days in water, (a) the relative shear strength of GR-BC at 7, 28, 90, and (b) the relative shear strength of GR-BC at 180d, 365d, 2185d, and 4370d.

The most significant increase in compressive strength was recorded for the GR-CB11, which comprised 65 wt% geopolymer binder, 35 wt.% GGBFS, 0.7 wt.% Ag-PM-WCNT, 2.5 wt% CQD, and 0.88 wt% PCEP-BSP evaluated at 7, 28, 90, 180, 365, 2185, and 4370 days (refer to Fig. 10). The decrease in porosity could have resulted in an increase in the compressive strength. For instance, although the PCEP-BSP/geopolymer ratio of the GR-CB11 mixture is 0.013, it exhibits the greatest compressive strength of 75 (MPa) at 4370 days, when compared to that of the reference concrete beam, with an average increase of approximately 19%. However, the compressive strengths of GR-CB5 (62.6 MPa), GR-CB10 (66.2 MPa), and GR-CB20 (66.2 MPa), whose the PCEP-BSP/geopolymer ratio is between 0.022 and 0.025, could be greater, when compared with that of reference which has a higher quantity of binder. A comparable enhancement in compressive strength has been documented in scholarly works by Sajjad et al. (19% increase with a graphene dosage of 0.1%)92, as well as by Liang and Zhang (24% after 3 days) concerning a metakaolin-based geopolymer that incorporates reduced graphene oxide at a dosage of 0.06%99. The observed increase in compressive strength during testing can be attributed primarily to the interaction between free calcium oxide (CaO) and GGBFS, which is known as the pozzolanic effect of the reactive powder and was previously detailed in the author’s published works33,38,100,101,102,103,104. Moreover, the increase in the compressive strength of GR-CB suggests that a higher Ag-PM-WCNT content and the incorporation of GGBFS contribute to an average compressive strength that is 33% greater than that of the reference composite. Therefore, the GR-CB11 mixture is deemed optimal in terms of GGBFS and Ag-PM-WCFNT and PCEP-BSP contents. Additionally, the compressive strength of this mixture surpasses the target strength class with the minimum addition of GGBFS (see Fig. 10). The mechanisms by which GGBFS and Ag-PM-WCNT influence compressive strength are crucial for strength enhancement. The reactive powder of GGBFS provides an artificial pozzolanic effect, whereas Ag-PM-WCNT significantly improves the properties of geopolymer-based composite beams. This synergistic effect results in a compressive strength increase exceeding 33%, making it suitable for infrastructure and structural renewal via a technological composite105. Figure 11 shows a relationship for predicting the relative compressive strength of GR-CBs from the curing period in water, mathematical models, types of GR-CCs, and the R2 values of mathematical models.

In Fig. 11, several nonlinear regression equations are utilized to illustrate the correlation between the relative compressive strength and the water curing duration of the GR-CBs, which include GGBFS, Ag-PM-WCNT, and PCEP-BSP. The degree of correlation, represented by R2, is also indicated in Fig. 11, demonstrating a strong compatibility between the two specified properties. Given that the R2 value is equal to 1, it is possible to estimate the compressive strength of GR-CBs on the basis of the water curing period by employing the mathematical equations presented in Fig. 11, provided that at least one hardened specimen of GR-CB is prepared.

Young’s modulus

Figure 12 shows a comparison of the effects of the GGBFS, the Ag-PM-WCNT, and the PCEP-BSP on the modulus of Young of the GR-CB, which was conducted at 7, 28, 180, 365, 2185, and 4370 days for infrastructure and structure renewal. As the proportions of GGBFS and Ag-PM-WCNT increased, the modulus of elasticity of the GR-CB also increased, whereas the issues related to the interfacial transition zone (ITZ) became more pronounced, leading to a continuous decline in the mechanical properties and durability of the concrete. The addition of GGBFS and Ag-PM-WCNT to the geopolymer binder resulted in an increase in the modulus of elasticity. Specifically, the incorporation of 50% GGBFS led to a modest increase in the modulus of elasticity compared with that of the reference composite, demonstrating that even a small quantity of GGBFS can significantly influence this property.

Furthermore, a notable increase in the elastic modulus was observed when the dosage of Ag-PM-WCNT reached 0.7%, following a pattern akin to that of the flexural strength. This increase in modulus can be attributed to the increased stiffness and flexibility provided by the Ag‒PMWCFNTs, which collectively contributed to the greater overall stiffness of the GR‒CB matrix at 7, 28, and 56 days. The Young’s modulus of the GR-CB11mixture reached its peak value at these intervals owing to its composition of 65% geopolymer binder, 35% GGBFS, 0.88% PCEP-BSP, 0.7% Ag-PM-WCFNT, and 2.5% CQD. The term “strain capacity” is commonly employed to characterize the deformation capacity of cementitious materials. The elongation capacities of the Ag‒PM‒WCFNT-reinforced GR‒CB with GGBFS clearly surpass those of the reference composite. The highest strain capacity is recorded for the GR-CB11, which is approximately 37% greater than that of the reference composite. The GR-CB11 mixture exhibited a strain capacity comparable to that of the reference composite. These results indicate that the incorporation of Ag-PM-WCNTs, GGBFS, CQD, and PCEP-BSP can substantially enhance the toughness of the materials. This enhancement is attributed to the high flexibility of the Ag-PM-WCNTs and the polycarboxylate superplasticizer polymer film (PCEP‒BSP), as well as the strong interactions between the hydrated products and the GGBFS. The increased toughness observed in the samples containing Ag-PM-WCNTs, GGBFS, and CQD suggests a significant improvement in their performance characteristics. Furthermore, the enhancement observed in the modulus of elasticity can be attributed to the dense internal structure of concrete infused with graphene. The unique characteristics of graphene, such as its high aspect ratio and nanoscale dimensions, significantly improved the overall properties of the alkali-activated concrete matrix, resulting in a notably high modulus of elasticity. Furthermore, the incorporation of graphite nano-platelets provided a bridging effect at the micro level within the alkali-activated concrete. Saafi et al.106 noted that the enhancement of the microstructure in geopolymeric nanocomposites, achieved through the addition of nano-tubes, was reliant on the functional properties of these nano-tubes, which likely contributed to the improved Young’s modulus and other mechanical properties of the composites.

SEM analysis

Figure 13 shows the SEM analysis was used to monitor the mineral phase in the GR-CB at 4370 days, (a) SEM image of GR-CB11, (b) SEM image of GR-CB1, (c) EDX of GR-CB11, (ç) EDX of GR-CB1, (d) SEM image of GR-CB11 in detail, (e) XRD analysis of GR-CB11, and (g) XRD analysis of GR-CB1. The scanning electron microscopy (SEM) images presented in Fig. 11 illustrate the presence of ettringite (Aft phase), which increases with increasing proportions of GGBFS, hydrated lime, and sodium carbonate (Na2CO3).

Scanning electron microscopy (SEM) is a technique that involves analyzing and scanning the surface of materials via a focused electron beam to capture images that reveal intricate details. When electrons interact with the atoms of a sample, they generate various signals related to surface topography and composition, which can identify component failures, detect particles, and examine the interactions between different substances and substrates. Several studies have explored the SEM and energy dispersive X-ray spectroscopy (EDX) analysis of geopolymer concrete (GPC). Compared with that of untreated concrete, the microstructure of concrete treated with geopolymers appears to be more refined and denser. The GR-CB11 sample exhibited randomly oriented portlandite (CH) crystals alongside needle-shaped minority crystals dispersed throughout the matrix. EDX analysis revealed the presence of calcium hydroxide because nonreactive lime particles and the GGBFS were found at levels comparable to those of the reference composite. The primary component of geopolymer cement is lime, which accounts for these observed properties. The EDX elemental analysis of geopolymer-modified GR-CBs revealed significant peaks for calcium, silicon, magnesium, and potassium, largely due to the high concentrations of these elements in the geopolymer cement, with potassium primarily sourced from the alkaline activator. However, after a curing period of 4370 days, the GGBFS particles in the GR-CB11 sample were enveloped by amorphous layered CH hydration products, characterized by C–S–H. The matrix phase primarily consisted of short radicular extensions of C–S–H surrounding the geopolymer binder grains and needle-like minority crystals, as shown in Fig. 13 for the GR-CB1 and GR-CB11 samples. The microstructures of the hydrated GR-CB1 and GR-CB11 samples at 4370 days were characterized by an amorphous gel occupying the voids between hydrated particles. In the GR-CB containing GGBFS and Ag-PM-WCFNT, stratified accumulations of CH crystals, approximately 12 μm in width, were interspersed throughout the matrix. Notably, compaction around the normal geopolymer binder grains was observed because of the partial hydration of GGBFS, Ag-PM-WCFNT, and PCEP-BSP, which facilitated the formation of additional C–S–H. By 2185 days, the GGBFS grains were well integrated within the matrix and embedded in stratified CH. The GR-CB plots for GR-CB1 and GR-CB11 indicated that the grains of the GGBFS exhibited amorphous reaction prisms. In the CH phase, the calcium concentration within the matrix of the GR-CB11 composite beam surpassed that of the reference composite. After 4370 days, the microstructure of the GR-CB continued to densify more than that of the reference composite. It is evident that the needle-shaped minority crystals and calcium hydroxide mass are enveloped by a polymer film, a phenomenon attributed to the interactions of the GGBFS along with a chemical reaction involving metallic cations105. A comparable observation has been documented in the existing literature. For example, the high calcium 100% GGBS system yields a calcium–alumina–silicate–hydrate gel (C–A–S–H) characterized by a low Al/Si ratio of 0.3–0.4 and a Ca/Si ratio ranging from 1 to 1.5, as noted by various researchers107,108 in the context of alkali-activated slag systems. The resultant products bear resemblance to the C–S–H gel found in Portland cement systems, where elevated Ca/Si ratios are typically observed, falling between 1.2 and 2.3109. These products are likely to include diverse forms of calcium silicate hydrates and calcium aluminium hydrates. Notably, the composition of the gel is significantly richer in sodium compared to the calculated bulk composition of its ingredients, and even the unreacted GGBS particles exhibit a considerable sodium content.

Cost analysis of study and its effect on built environment

The worldwide concrete market is anticipated to expand at a Compound Annual Growth Rate (CAGR) of approximately 5.2% from 2025 to 2032, as reported by the European Ready Mixed Concrete Organization (ERMCO), ultimately achieving an estimated worth of USD 308.21 billion by 2032. This expansion is fueled by elements such as growing urbanization, advancements in infrastructure, and an increase in disposable incomes. Many researchers concur that concrete made from geopolymer is significantly more affordable than conventional concrete, as it can partially utilize GGBFS instead of a geopolymer binder. Furthermore, the manuscript encourages readers to reflect on the cost comparison between traditional concrete and green geopolymer composites, which include materials like Ag-PM-WCNT, GGBFS, CQD, and superplasticizer, for a volume of one cubic meter, as outlined in the subsequent Table 5.

Concurrently, the manuscript is poised to facilitate a remarkable reduction in CO₂ emissions, energy usage, and raw material consumption in the creation of green geopolymer-based mixture, like GR-BC 11, about 35%, because it uses the GGBFS by 35%. Moreover, the production of traditional concrete and geopolymer-based composite is projected to witness a substantial decline in the cost, CO₂ emissions, energy demands, and raw material utilization, achieving an extraordinary reduction of over 234% (Table 5). Additionally, green geopolymer composite that incorporate Ag-PM-WCNT, GGBFS, CQD, and superplasticizer may be employed for a variety of applications, including: (1) the building of sophisticated structures, highways, and pavements, (2) bolstering the resilience of both new and existing structure and infrastructure, (3) promoting a smart built environment, (4) enhancing the strength and durability of construction materials for structural, highway, pavement, and infrastructure applications, and (5) enabling the recovery of carbon minerals during the manufacturing of ordinary Portland cement (OPC).

Conclusion

This research investigated the impact of GGBFS, Ag-PM-WCNT, CQD, and PCEP-BSP on the structural characteristics of geopolymer-reinforced composite beams. The results led to several conclusions as following.

-

1.

As the proportions of GGBFS increased from 35 to 90%, there was a significant reduction in fluidity and porosity, accompanied by an increase in compactness.

-

2.

The bending strength, shear strength, and compressive strength were modestly enhanced with the incorporation of GGBFS, Ag-PM-WCNT, CQD, and PCEP-BSP compared with those of the reference composite. The greatest increase was observed in GR-CB11 for shear strength of 9.5 MPa, bending strength of 10.5, and compressive strength of 75 MPa at 4370 days.

-

3.

The Young’s modulus also tended to increase with increasing amounts of GGBFS and Ag-PM-WCNT. Notably, GR-CB11 demonstrated the most remarkable results, indicating superior performance.

-

4.

Moreover, the physical and mechanical properties can be further optimized through the development of the mathematical models presented in the manuscript. The outcomes of this study hold promise for advancing the practical application of GR-CBs in construction and infrastructure projects, as well as their rehabilitation projects.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on request.

References

Schleiting, M. et al. Functional microfiber reinforced ultrahigh performance concrete (FMF-UHPC). Cem. Concr. Res. 130, 105993 (2020).

Zhang, P. et al. Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2. Nanotechnol. Rev. 10(1), 504–517 (2021).

Iorio, M., Marra, F., Santarelli, M. L. & González-Benito, J. Reinforcement-matrix interactions and their consequences on the mechanical behavior of basalt fibers-cement composites. Constr. Build. Mater. 309, 125103 (2021).

Akbar, A., Kodur, V. K. R. & Liew, K. M. Microstructural changes and mechanical performance of cement composites reinforced with recycled carbon fibers. Cem. Concr. Compos. 121, 104069 (2021).

Kırgız, M. S., Smart Nanoconcretes and Cement-Based Materials. In Nano size particle packing for nanoconcretes and cement based materials: mathematical models, theory, and technology, (eds. Liev, M. S., Nguyen-Tri, P., Nguyen, T. A., Kakooei, S.). (Elsevier, 2019). ISBN: 978-0-12-817854-6. https://doi.org/10.1016/B978-0-12-817854-6.00003-9

Zhang, P., Sha, D., Li, Q., Zhao, S. & Ling, Y. Effect of nano silica particles on impact resistance and durability of concrete containing coal fly ash. Nanomaterials 11(5), 1296 (2021).

Han, B. et al. Microstructure related mechanical behaviors of short-cut superfine stainless wire reinforced reactive powder concrete. Mater. Des. 96, 16–26 (2016).

Liu, T., Zhang, P., Cui, G. & Yue, X. Fracture performance prediction of polyvinyl alcohol fiber-reinforced cementitious composites containing nano-SiO2 using least-squares support vector machine optimized with quantum-behaved particle swarm optimization algorithm Theor. Appl. Fract. Mech. 115, 103074 (2021).

Ouyang, M., Huang, J. L. & Lieber, C. M. Fundamental electronic properties and applications of single-walled carbon nanotubes. Acc. Chem. Res. 35(12), 1018–1025 (2002).

Chan, L. Y. & Andrawes, B. Characterization of the uncertainties in the constitutive behavior of carbon nanotube/cement composites. Sci. Technol. Adv. Mater. 10(4), 045007 (2009).

Wang, J., Dong, S., Zhou, C., Ashour, A. & Han, B. Investigating pore structure of nanoengineered concrete with low-field nuclear magnetic resonance. J. Mater. Sci. 56(1), 243–259 (2021).

Abu Al-Rub, R. K., Tyson, B. M., Yazdanbakhsh, A. & Grasley, Z. Mechanical properties of nanocomposite cement incorporating surface-treated and untreated carbon nanotubes and carbon nanofibers. J. Nanomech. Micromech. 2(1), 1–6 (2012).

Sobolkina, A. et al. Dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix. Cem. Concr. Compos. 34(10), 1104–1113 (2012).

Jung, M., Lee, Y. S., Hong, S. G. & Moon, J. Carbon nanotubes (CNTs) in ultrahigh performance concrete (UHPC): Dispersion, mechanical properties, and electromagnetic interference (EMI) shielding effectiveness (SE). Cem. Concr. Res. 131, 106017 (2020).

Mansouri, S. M., Mahdikhani, M., Aghabarati, H. & Haghparast, F. M. Effect of functionalized multiwalled carbon nanotubes on mechanical properties and durability of cement mortars. J. Build. Eng. 41, 102407 (2021).

Li, G. Y., Wang, P. M. & Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multiwalled carbon nanotubes. Carbon 43(6), 1239–1245 (2005).

Xiang, B. et al. MWCNTs dispersion adopting GA and its application towards copper tailings-based cementitious materials. Sci. Rep. 13, 16081. https://doi.org/10.1038/s41598-023-43133-7 (2023).

Glory, J., Mierczynska, A., Pinault, M., Mayne-L’Hermite, M. & Reynaud, C. Dispersion study of long and aligned multiwalled carbon nanotubes in water. J. Nanosci. Nanotechnol. 7(10), 3458–3462 (2007).

Zou, B. et al. Effect of ultrasonication energy on engineering properties of carbon nanotube reinforced cement pastes. Carbon 85, 212–220 (2015).

Parveen, S., Rana, S., Fangueiro, R. & Paiva, M. C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 73, 215–227 (2015).

Gao, Y. et al. Influence of ultrasonication on the dispersion and enhancing effect of graphene oxide-carbon nanotube hybrid nano reinforcement in cementitious composite. Compos. B Eng. 164, 45–53 (2019).

Chiu, C.-W. et al. Controlling the structures, flexibility, conductivity stability of three-dimensional conductive networks of silver nanoparticles/carbon-based nanomaterials with nanodispersion and their application in wearable electronic sensors. Nanomaterials 10(5), 1009. https://doi.org/10.3390/nano10051009 (2020).

Jia, X., Ma, Y., Liu, Y., Wang, Y. & Zhang, Q. Silver nanoparticles decorated by amino groups on the periphery of litchi-like P(MMA-AA-DVB)@Fe3O4 microspheres for the catalytic reduction of methyl orange. Catal. Lett. 149, 2873–2886 (2019).

Hoyos-Palacio, L. M. et al. Compounds of carbon nanotubes decorated with silver nanoparticles via in situ by chemical vapor deposition (CVD). J. Mater. Res. Technol. 8, 5893–5898 (2019).

Chiu, C. W., Lee, Y. C., Ou, G. B. & Cheng, C. C. Controllable 3D hot-junctions of silver nanoparticles stabilized by amphiphilic tri-block copolymer/graphene oxide hybrid surfactants for use as surface-enhanced Raman scattering substrates. Ind. Eng. Chem. Res. 56, 2935–2942 (2017).

Sharma, A. K., Kaith, B. S., Shanker, U. & Gupta, B. γ-radiation induced synthesis of antibacterial silver nanocomposite scaffolds derived from natural gum Boswellia serrata. J. Drug Deliv. Sci. Technol. 56, 101550 (2020).

Coppola, B., Di Maio, L., Incarnato, L. & Tulliani, J. M. Preparation and characterization of polypropylene/carbon nanotubes (PP/CNTs) nanocomposites as potential strain gauges for structural health monitoring. Nanomaterials 10, 814 (2020).

Cui, X. et al. Mechanical properties and reinforcing mechanisms of cementitious composites with different types of multiwalled carbon nanotubes. Compos. A Appl. Sci. Manuf. 103, 131–147 (2017).

Hassanzadeh-Aghdam, M. K., Ansari, R., Mahmoodi, M. J., Darvizeh, A. & Hajati-Modaraei, A. A comprehensive study on thermal conductivities of wavy carbon nanotube-reinforced cementitious nanocomposites. Cem. Concr. Compos. 90, 108–118 (2018).

Bourchy, A. et al. Optimization of concrete mix design to account for strength and hydration heat in massive concrete structures. Cem. Concr. Compos. 103, 233–241 (2019).

Kırgız, M. S. Advances in physical properties of C class fly ash–cement systems blended nanographite (Part 1). ZKG Int. 12, 42–48 (2015).

Kırgız, M. S. Advances in physical properties of C class fly ash–cement systems blended nanographite (Part 2). ZKG Int. 1–2, 60–67 (2015).

Kırgız, M. S. Advance treatment by nanographite for pulverized fly ash cement (the class F) systems. Compos. Part B 82(12), 59–71. https://doi.org/10.1016/j.compositesb.2015.08.003 (2015).

Kırgız, M. S. Supernatant nanographite solution for advance treatment of C Class fly ash–cement systems (Part 2). ZKG Int. 5, 42–47 (2015).

Kırgız, M. S. Supernatant nanographite solution for advance treatment of C class fly ash–cement systems (Part 1). ZKG Int. 4, 56–65 (2015).

Kırgız, M. S. Pulverized fuel ash cement activated by nanographite. ACI Mater. 115(6), 803–812. https://doi.org/10.14359/51689101 (2018).

Kırgız, M. S. Green cement composite concept reinforced by graphite nanoengineered particle suspension for infrastructure renewal material. Compos. Part B 154(12), 423–429. https://doi.org/10.1016/j.compositesb.2018.09.012 (2018).

Kırgız, M. S. Advancements in mechanical and physical properties for marble powder–cement composites strengthened by nanostructured graphite particles. Mech. Mater. 92(1), 223–234. https://doi.org/10.1016/j.mechmat.2015.09.013 (2015).

Hamza, B., Belkacem, M., Kenai, S. & Kırgız, M. S. RubberCrete: A rubber based concrete system with superplasticizer and graphite nano particle- rheology, strength, shrinkage, and durability feature. ZKG Int. 5, 35–44 (2023).

Bheel, N., Ali, M. O., Kırgız, M. S., Shafiq, N. & Gobinath, R. Effect of graphene oxide particle as nanomaterial in the production of engineered cementitious composites including superplasticizer, fly ash, and polyvinyl alcohol fiber. J. Mater. Today Proc. https://doi.org/10.1016/j.matpr.2023.03.010 (2023).

Katman, H. B. Y. et al. Transforming conventional construction binders and grouts into high-performance nanocarbon-binders and grouts for today’s construction. Buildings 12(7), 1041. https://doi.org/10.3390/buildings12071041 (2022).

Dinh, N. X., Van Quy, N., Huy, T. Q. & Le, A.-T. Decoration of silver nanoparticles on multiwalled carbon nanotubes: Antibacterial mechanism and ultrastructural analysis. J. Nanomater. 2015, 814379 (2015).

Bi, C. & Zhao, D. Enhancement in mechanical properties and conductivity of modified epoxy resin composites. High Perform. Polym. 30, 1169–1182 (2018).

Yadav, A., Upadhyaya, A., Gope, J., Gupta, S. K. & Negi, C. M. S. Silver-decorated multiwall carbon nanotubes: Synthesis characterization and application in polymer composite-based devices. J. Mater. Sci. Mater. Electron. 31, 1451–1460 (2020).

Pal, H. & Sharma, V. Thermal conductivity of carbon nanotube–silver composite. Trans. Nonferrous Met. Soc. China 25, 154–161 (2015).

Li, Y. et al. Ag-NPs/MWCNT composite-modified silver-epoxy paste with improved thermal conductivity. RSC Adv. 9, 20663–20669 (2019).

Wang, Y. et al. Ag-MWCNT composites for improving the electrical and thermal properties of electronic paste. Polymers 16, 1173 (2024).

Natsuki, J. & Natsuki, T. Silver nanoparticle/carbon nanotube hybrid nanocomposites: One-step green synthesis, properties, and applications. Nanomaterials 13, 1173 (2023).

Suh, D., Moon, C. M., Kim, D. & Baik, S. Ultrahigh thermal conductivity of interface materials by silver-functionalized carbon nanotube phonon conduits. Adv. Mater. 28, 7220–7227 (2016).

Amoli, B. M., Gumfekar, S., Hu, A., Zhou, Y. N. & Zhao, B. Thiocarboxylate functionalization of silver nanoparticles: Effect of chain length on the electrical conductivity of nanoparticles and their polymer composites. J. Mater. Chem. 22, 20048–20056 (2012).

Amoli, B. M., Hu, A., Zhou, N. Y. & Zhao, B. Recent progresses on hybrid micro–nano filler systems for electrically conductive adhesives (ECAs) applications. J. Mater. Sci. Mater. Electron. 26, 4730–4745 (2015).

Biricik, H. et al. Activation of slag through a combination of NaOH/NaS alkali for transforming it into geopolymer slag binder mortar—Assessment the effects of two different Blaine fines and three different curing conditions. J. Mater. Res. Technol. 14, 1569–1584. https://doi.org/10.1016/j.jmrt.2021.07.014 (2021).

BSI. BS EN 1008:2002. Mixing water for concrete. (British Standards Institute (BSI), 2002).

Konnola, R. & Joseph, K. Effect of sidewall functionalisation of multiwalled carbon nanotubes on the thermomechanical properties of epoxy composites. RSC Adv. 6, 23887–23899 (2016).

Maity, K. P., Patra, A. & Prasad, V. Influence of the chemical functionalization of carbon nanotubes on low temperature ac conductivity with polyaniline composites. J. Phys. D. Appl. Phys. 53, 125303 (2020).

Quintero-Jaime, A. F., Cazorla-Amorós, D. & Morallón, E. Electrochemical functionalization of single wall carbon nanotubes with phosphorus and nitrogen species. Electrochim. Acta 340, 135935 (2020).

Nakonechna, O. I., Belyavina, N. N., Dashevskyi, M. M., Ivanenko, K. O. & Revo, S. L. Novel Ti2CuCx and Ti3Cu2Cx carbides obtained by sintering of products of mechanochemical synthesis of Ti, Cu and Carbon nanotubes. Phys. Chem. Solid State 19, 179–185 (2019).

Garzia Trulli, M. et al. Toward highly stable aqueous dispersions of multiwalled carbon nanotubes: The effect of oxygen plasma functionalization. J. Colloid Interface Sci. 491, 255–264 (2017).

Singh, B., Lohan, S., Sandhu, P. S., Jain, A. & Mehta, S. K. Functionalized carbon nanotubes and their promising applications in therapeutics and diagnostics. Nanobiomater. Med. Imaging Appl. Nanobiomater. 455–478 (2016).

Ajori, S., Ansari, R. & Darvizeh, M. Vibration characteristics of single- and double-walled carbon nanotubes functionalized with amide and amine groups. Phys. B Condens. Matter 462, 8–14 (2015).

Afrin, R. & Shah, N. A. Room temperature gas sensors based on carboxyl and thiol functionalized carbon nanotubes buckypapers. Diam. Relat. Mater. 60, 42–49 (2015).

Balasubramanian, K. & Burghard, M. Chemically functionalized carbon nanotubes. Small 1, 180–192 (2005).

CEN. EN 206-2013: Concrete—Specification, performance, production and conformity. (British Standard Institute, 2013).

EFNARC. Specification and Guidelines for Self-Compacting Concrete. European Federation for Specialist Construction Chemicals and Concrete Systems (EFNARC) (2002).

CEN. EN 14889-1:2006: Fibers for concrete—Part 1: Steel fibers—Definitions, specifications and conformity. (British Standard Institute, 2006).

SIST. SIST EN 15167-1:2006. Ground granulated blast furnace slag for use in concrete, mortar and grout—Part 1: Definitions, specifications and conformity criteria (Slovenski Standards Institute, 2006).

CEN. EN 15167-2:2024. Ground granulated blast furnace slag for use in concrete, mortar and grout—Part 2: Assessment and verification of constancy of performance (British Standard Institute, 2024).

SIST. SIST EN 12350-8:2019. Testing fresh concrete—Part 8: Self-compacting concrete—Slump-flow test (Slovenski Standards Institute, 2019).

CEN. EN12390-6: Testing hardened concrete—Part 6: Tensile splitting strength of test specimens (British Standard Institute, 2000).

CEN. EN 12390-5. Testing hardened concrete Part 5: Flexural strength of test specimens (British Standard Institute, 2009).

CEN. EN 12390-3. Testing hardened concrete Part 3: Compressive strength of test specimens (British Standard Institute, 2009).

Laboratório Nacional de Engenharia Civil (LNEC). LNEC E-397, Hardened concrete—Determination of the modulos of elasticity of concrete in compression, 1993, Portuguese Institution of Science and Technology (Instituição Portuguesa de Ciência e Tecnologia).

Kırgız, M. S. Fresh and hardened properties of green binder concrete containing marble powder and brick powder. Eur. J. Environ. Civil Eng. 20:64–101 (2016). Issue Sup1: Supplement: Green Binder Materials for Civil Engineering and Architecture Applications.

Berra, M., Carassiti, F., Mangialardi, T., Paolini, A. E. & Sebastiani, M. Effects of nanosilica addition on workability and compressive strength of Portland cement pastes. Constr. Build. Mater. 35, 666–675 (2012).

Hadi, M. N. S., Zhang, H. & Parkinson, S. Optimum mix design of geopolymer pastes and concretes cured in ambient condition based on compressive strength, setting time and workability. J. Build. Eng. 23, 301–313 (2019).

Olivia, M. & Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater. Des. 36, 191–198 (2012).

Hadi, M. N. S., Farhan, N. A. & Sheikh, M. N. Design of geopolymer concrete with GGBFS at ambient curing condition using Taguchi method. Constr. Build. Mater. 140, 424–431 (2017).

Farhan, N. A., Sheikh, M. N. & Hadi, M. N. S. Investigation of engineering properties of normal and high strength fly ash based geopolymer and alkali-activated slag concrete compared to ordinary Portland cement concrete. Constr. Build. Mater. 196, 26–42 (2019).

Wang, S.-D., Scrivener, K. L. & Pratt, P. L. Factors affecting the strength of alkali-activated slag. Cem. Concr. Res. 24(6), 1033–1043 (1994).

Chindaprasirt, P., Chareerat, T. & Sirivivatnanon, V. Workability and strength of coarse high calcium fly ash geopolymer. Cem. Concr. Compos. 29(3), 224–229 (2007).

Proske, T., Hainer, S., Rezvani, M. & Graubner, C.-A. Eco-friendly concretes with reduced water and cement content—mix design principles and application in practice Constr. Build. Mater. 67, 413–421. https://doi.org/10.1016/j.conbuildmat.2013.12.066 (2014).

Naik, T. & Moriconi, G. Environmental-friendly durable concrete made with recycled materials for sustainable concrete construction CANMET/ACI. In: International Symposium on Sustainable Development Cement Concrete 2 (2005).

Alrefaei, Y., Wang, Y. & Dai, J. The effectiveness of different superplasticizers in ambient cured one-part alkali activated pastes. Cem. Concr. Compos. 97, 166–174 (2019).

Bouaissi, A. et al. Mechanical properties and microstructure analysis of FA-GGBS-HMNS-based geopolymer concrete. Constr. Build. Mater. 210, 198–209 (2019).

Bonneau, O., Poulin, C., Dugat, M. & Tcin, P. C. A. Reactive powder concretes: From theory to practice. Concr. Int. 18(4), 47–49 (1996).

Niu, Q., Feng, N., Yang, J. & Zheng, X. Effect of superfine slag powder on cement properties. Cem. Concr. Res. 32(4), 615–621. https://doi.org/10.1016/S0008-8846(01)00730-X (2002).

Abbasi, S. M., Ahmadi, H., Khalaj, G. & Ghasemi, B. Microstructure and mechanical properties of a metakaolinite-based geopolymer nanocomposite reinforced with carbon nanotubes. Ceram. Int. 42(14), 15171–15176 (2016).

Gunasekera, C., Setunge, S. & Law, D. W. Correlations between mechanical properties of low-calcium fly ash geopolymer concretes. J. Mater. Civ. Eng. 29(9), 04017111. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001916 (2017).

Sarvandani, M. M., Mahdikhani, M., Aghabarati, H. & Fatmehsari, M. H. Effect of functionalized multiwalled carbon nanotubes on mechanical properties and durability of cement mortars. J. Build. Eng. 41, 102407 (2021).

Al-Rub, R. K. A., Ashour, A. I. & Tyson, B. M. On the aspect ratio effect of multiwalled carbon nanotube reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 35, 647–655 (2012).

Sajjad, U., Sheikh, M. N. & Hadi, M. N. Experimental study of the effect of graphene on properties of ambient-cured slag and fly ash-based geopolymer paste and mortar. Constr. Build. Mater. 313, 125403 (2021).

Sajjad, U., Sheikh, M. N. & Hadi, M. N. Incorporation of graphene in slag-fly ash-based alkali-activated concrete. Constr. Build. Mater. 322, 126417 (2022).

Kırgız, M. S. Chemical properties of blended cement pastes. J. Constr. Eng. Manag. 37(12), 1036–1042. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000378 (2011).

Kırgız, M. S. Effects of blended–cement paste chemical composition changes on some strength gains of blended–mortars. Mater. Sci. J. Sci. World 204, 11. https://doi.org/10.1155/2013/625350 (2014).

Kırgız, M. S. Strength gain mechanisms of blended-cements containing marble powder and brick powder. KSCE J. Civil Eng. 9(1), 165–172. https://doi.org/10.1007/s12205-014-0557-4 (2015).

Kırgız, M. S. Strength gain mechanism for green mortar substituted marble powder and brick powder for Portland cement. Eur. J. Environ. Civil Eng. Issue Sup 1 Suppl. Green Binder Mater. Civil Eng. Archit. Appl. 20, 38–63. https://doi.org/10.1080/19648189.2016.1246691 (2016).

Reales, O. A. M., Duda, P. & Filho, R. D. T. Effect of a carbon nanotube/surfactant aqueous dispersion on the rheological and mechanical properties of portland cement pastes. J. Mater. Civ. Eng. 30(10), 04018259 (2018).

Sedaghatdoost, A. & Behfarnia, K. Mechanical properties of Portland cement mortar containing multiwalled carbon nanotubes at elevated temperatures. Constr. Build. Mater. 176, 482–489 (2018).

Liang, W. & Zhang, G. Effect of reduced graphene oxide on the early-age mechanical properties of geopolymer cement. Mater. Lett. 276, 128223 (2020).

Meng, T., Yu, Y. & Wang, Z. Effect of nano-CaCO3 slurry on the mechanical properties and microstructure of concrete with and without fly ash. Compos. B Eng. 117, 124–129 (2017).

Corinaldesi, V. & Nardinocchi, A. Reuse of recycled glass in mortar manufacturing. Eur. J. Environ. Civil Eng. 20, 140–151 (2016). Issue Sup1: Supplement: Green Binder Materials for Civil Engineering and Architectural Applications.

Meng, W. & Khayat, K. H. Mechanical properties of ultrahigh-performance concrete enhanced with graphite nanoplatelets and carbon nanofibers. Compos. B Eng. 107, 113–122 (2016).

Colangelo, F., Cioffi, R. Mechanical properties and durability of mortar containing fine fraction of demolition wastes produced by selective demolition in south Italy, special issue on composite lattices and multiscale innovative materials and structures edited by Luciano Feo, Fernando Fraternali, David Hui, Robert E. Skelton. Compos B Eng. 115, 43–50.

Wosu, S. N., Hui, D. & Daniel, L. Hygrothermal effects on the dynamic compressive properties of graphite/epoxy composite material. Compos. B Eng. 43, 841–855 (2012).

Mehta, P. & Monteiro, P. Concrete: Microstructure, Properties, and Materials 3rd edn. (McGraw-Hill Education, 2008).

Saafi, M. et al. Multifunctional properties of carbon nanotube/fly ash geopolymeric nanocomposites. Constr. Build. Mater. 49, 46–55 (2013).