Abstract

To enhance the cost-effectiveness of vascular robotic systems in clinical settings, this study constructs an integrated forecasting-optimization framework for long-term resource planning. A weekly demand forecasting model is developed using the SARIMA approach, with model order selection guided by stationarity testing and ACF and PACF analysis. Forecast accuracy is validated to ensure reliable downstream optimization. Based on the predicted 112-week demand, a nonlinear procurement scheduling model is formulated, incorporating Poisson-distributed scrap rates and two types of acquisition strategies: conventional and emergency-use procurement. To solve the mixed-integer nonlinear programming problem under constraints such as maintenance cycles, training limits, and resource coupling, a continuous relaxation method is adopted along with a penalty-based cost function. The problem is then optimized using an Adaptive Sparrow Search Algorithm (ASSA), enhanced with Levy flights and adaptive producer ratios. Extensive sensitivity and interaction analyses are conducted on parameters including scrap rate, training limits, and initial inventory levels. The results not only demonstrate the robustness of the proposed approach but also offer valuable insights into strategic procurement under dynamic clinical demand, providing a novel data-driven paradigm for hospital resource allocation.

Similar content being viewed by others

Introduction

The integration of microelectromechanical systems (MEMS) into medical robotics has revolutionized endovascular diagnosis and treatment. Microvascular and nanorobotic systems, with dimensions below the millimeter scale, have demonstrated promising capabilities for targeted drug delivery, minimally invasive interventions, and real-time monitoring within the human vascular system1,2. These microrobots provide access to anatomically challenging areas where conventional catheters fail, offering enhanced precision, reduced trauma, and faster patient recovery3,4.

Recent clinical studies further highlight the advantages of minimally invasive and robotic-assisted surgeries across various conditions, including pediatric and spinal procedures5,6. In particular, magnetically actuated micro/nanorobots have become a core focus due to their ability to operate without physical tethers, achieving precise steering and propulsion under dynamic blood flow7,8. These systems rely on external magnetic fields to actuate helical or corkscrew-like structures, enabling them to traverse tortuous vascular networks9,10. Researchers have demonstrated advanced designs using spiral geometries11, optimized electromagnetic field control12, and high-fidelity simulations of robotic motion in physiological environments13,14. Several engineering breakthroughs have made these innovations viable in preclinical and early clinical contexts. For instance, real-time imaging technologies such as photoacoustic tracking have enabled accurate navigation of microrobots in vivo15, while robotic-assisted microsurgical techniques are now being evaluated for complex reconstructive procedures16. Novel materials and miniaturization techniques continue to improve localization, durability, and integration into soft biological tissues17,18,19.

Despite these technological advancements, the clinical adoption of vascular robots remains limited due to operational and economic constraints. These systems are often associated with substantial upfront investment, complex maintenance cycles, and low cross-departmental utilization20. As a result, healthcare providers require systematic and data-informed planning to ensure effective deployment and return on investment21.

To address the increasing complexity of medical resource allocation, quantitative optimization methods—particularly those based on mathematical programming and systems engineering—have been widely employed to support procurement planning, clinical scheduling, and logistics coordination, aiming to minimize cost while meeting clinical demand22,23. In recent years, heuristic and metaheuristic algorithms have gained prominence for solving large-scale, nonlinear resource allocation problems that are otherwise intractable using exact methods24. These approaches, including genetic algorithms25 and ant colony optimization26, enable efficient exploration of complex solution spaces under uncertainty and constraints. In the context of vascular robotic systems, which are characterized by nonlinear usage, high cost, and interdepartmental coordination challenges, such methods offer a powerful framework for integrating clinical demand, budget limitations, and operational feasibility into a unified optimization model22,27,28. This facilitates robust planning strategies that improve equipment utilization and cost-effectiveness in real-world deployments.

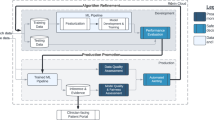

While existing studies have proposed various optimization frameworks for medical resource planning, most focus on static settings or assume simplified usage and replenishment patterns, limiting their applicability to dynamic and nonlinear systems like vascular robotic platforms. Moreover, current models often overlook real-world operational features such as staggered training, preventive maintenance, and high-cost emergency procurement, which are essential in robotic surgery environments. This study contributes to the literature by developing a flexible and practical optimization model that integrates these operational intricacies and by employing a hybrid adaptive sparrow search algorithm (ASSA) to solve the resulting nonlinear problem29. Through comprehensive sensitivity and interaction analysis, our approach not only enhances model robustness but also provides actionable insights for cost-effective resource allocation in high-precision surgical technologies.The complete process is shown in Fig. 1.

Problem and methods

Problem description

To optimize the deployment of vascular robots in clinical settings and maximize cost-effectiveness, this study leverages real surgical records from weeks 1–104 at a tertiary hospital—collected by the Jiangsu Province Society of Industrial and Applied Mathematics—to derive the weekly demand series for vascular robots. The hospital employs the ABLVR model of vascular robot, initially outfitted with 13 containers and 50 skilled manipulators.

Each vascular robot consists of one container and four manipulators; after one week of operation, both components must be taken out of service for a one-week maintenance period. Containers acquired through routine procurement require a one-week maintenance lead time before they can be used, and manipulators similarly undergo a one-week training period conducted by existing skilled manipulators, each of whom can train up to \(\:{\upgamma\:}\) new manipulators per week. If emergency demand arises during weeks 105–112, additional high-cost, ready-to-use containers and manipulators may be procured. Having obtained the historical weekly demand sequence for vascular robots from weeks 1–104 \(\:{\left\{{x}_{t}\right\}\text{}}_{1\le\:t\le\:104}\), we will then forecast the demand for weeks 105–112\(\:{\left\{{x}_{t}\right\}\text{}}_{105\le\:t\le\:112}\) and, on that basis, formulate a procurement strategy for weeks 1–112.

The model’s objective is to minimize the total cost of procurement, training and maintenance, subject to the constraint that weekly inventories and lead-times satisfy surgical demand. Accordingly, we introduce the notation shown in Table 1.

Under this notation, we will next develop an inventory-dynamics, cost-minimization model to provide quantitative decision support for vascular-robot resource replenishment during the hospital’s peak periods.

Establishment of the planning model

The resource-scheduling problem for the vascular robot system can be formulated as deciding, over 112 weeks, the weekly procurement, training, and maintenance plans for containers and manipulators so as to minimize total operating cost while meeting the forecasted robot demand. Each vascular robot consists of 1 container and 4 manipulators20; both must undergo 1 week of downtime maintenance after 1 week of operation before returning to service. Containers procured through routine channels require a 1-week maintenance period before use, and manipulators procured routinely require a 1-week training period, with each skilled manipulator able to train at most new manipulators per week. To address potential peak demand, the hospital may supplement with high-priced, ready-to-use containers and manipulators, which incur no maintenance or training lead time but carry a higher unit cost. Meanwhile, robots in service face the risk of being scrapped due to macrophage engulfment, with the per-unit scrapping probability \(\:{p}_{t\:}\)following a Poisson distribution. The objective is to determine, for weeks 1–112, the quantities of routine and high-priced procurement that minimize “procurement cost + training cost + maintenance cost” while ensuring that, after accounting for scrapping losses and training commitments, available inventory each week is no less than surgical demand30.

Cost objective function

To quantify the economic efficiency of any procurement plan, the total cost is decomposed into three weekly cost components:

Routine Procurement Cost\(\:{\:C}_{t}^{\text{reg}}\), meaning the cost of containers and manipulators purchased at the base unit price that require one week of preparation or training;

High-Priced Ready-to-Use Procurement Cost\(\:{\:C}_{t}^{\text{high}}\), meaning the cost of additional equipment procured at a higher unit price and ready for immediate use without preparation;

Operating Cost \(\:{C}_{t}^{\text{opr}}\), including the training cost of routine manipulators and the maintenance cost of equipment undergoing upkeep in the current week.

The corresponding cost-component formulas are:

The above definitions clarify how the three types of cost—routine procurement, emergency procurement, and operating maintenance—are calculated in week\(\:\text{t}\), establishing a unified metric foundation for subsequent strategy comparison. Based on the same inventory set, the maintenance and training recursions, and the demand-satisfaction constraints, the objective function of this paper is as follows:

General recurrence relations and constraint conditions

In order to solve the objective function within the feasible region and thereby derive the hospital’s procurement policy, it is first necessary to establish the dynamic balance of resources as they evolve over time, and on that basis to characterize the static constraints of demand satisfaction and training capacity.

At the beginning of any given week, the available inventory equals last week’s ending usable stock minus surgical consumption and scrappage losses, plus equipment that was under maintenance (or training) last week and is released upon completion this week, together with routine new units ordered the previous week that have now completed their lead-time preparation. The equipment consumed by surgery during the same period (excluding scrapped units), along with all regular and high-priced ready-to-use units procured this week, will enter the maintenance or training queue in the following week. Let:

Here, \(\:{d}_{t}\) is the number of robots scrapped in week \(\:t\) (each such scrapped robot corresponds to the permanent loss of 1 container and 4 manipulators), and let \(\:{\uprho\:}\) be the scrappage probability per robot per surgery, assumed to be 20%. The recurrence relations for containers and manipulators are then given by:

Equation (4) sequentially presents four recurrence relations for the inter-week flow of equipment: the first updates next week’s available containers; the second determines which containers will require maintenance in the following week; the third updates next week’s available manipulators while deducting those consumed by surgery and those allocated to training; and the fourth identifies the manipulators that will need maintenance or training in the next week. Here, \(\:{\text{h}}_{\text{t}}/{\upgamma\:}\) denotes the number of skilled manipulators assigned to training, ensuring that new‐operator training does not exceed the available training capacity.

In any given week, surgical demand must be met by available inventory together with that week’s high-price ready‐to‐use procurements; routine procurement volumes must not exceed the remaining training capacity of skilled manipulators for that week; and all inventory, maintenance, and procurement variables must remain nonnegative. Accordingly, the following feasibility constraints must be satisfied during the model’s computation:

Equations (6) and (7) sequentially requires that the surgical demand in the current week be met by available inventory together with that week’s high-price ready-to-use procurements; that the available manipulators cover both the surgical consumption and the redeployment of skilled manipulators for training; that the routine procurement volume of manipulators not exceed the remaining training capacity of skilled manipulators in that week; and that all inventory, maintenance, and procurement variables be nonnegative. Initial values are set as \(\:{V}_{1}=13,{H}_{1}=50,{M}_{1}^{V}={M}_{1}^{H}={v}_{0}=\) \(\:{h}_{0}=0\). Thus, the recurrence relations and the feasibility constraints, together with the two aforementioned cost objective functions, form the complete optimization model for comparing the economic performance of full-cycle routine procurement and peak-period high-price emergency sourcing strategies. The complete model is presented as follows:

Adaptive sparrow search algorithm (ASSA)

To efficiently solve the planning model in Sect. "Establishment of the planning model" without sacrificing feasibility, this study adopts the adaptive sparrow search algorithm (ASSA) coupled with a penalty-function technique. This meta-heuristic combines global exploration with local exploitation capabilities, making it particularly well suited for high-dimensional, strongly nonconvex problems that involve nonlinear recursive constraints29.

Prior to the algorithm design, it is necessary to establish a unified quantitative representation of the decision variables by encoding the discrete and interdependent actions of “weekly ordering–maintenance–training–emergency procurement” into a high-dimensional vector and defining its feasible domain. Let:

Thus, the dimensionality is \(\:\text{d}=4\text{T}=448\). Each dimension is then continuously relaxed to the interval:

Final weekly integer decisions are obtained via rounding. Compared with the conventional IP/MILP approach, this technique markedly reduces the likelihood that the solver will be rendered completely infeasible in early iterations by the big-M constraints.

Penalty-Function construction

To endow the search process with a navigational capability toward the feasible domain, penalties for constraint violations must be explicitly incorporated into the objective function; at the same time, the penalty term must remain smooth so that the continuous optimization operators (exponential step size, Gaussian perturbation, Lévy flights) can elicit stable directional responses31.

For all inequality constraints \(\:{g}_{j}\left(z\right)\le\:0\) in the planning model of Sect. "Establishment of the planning model", a quadratic penalty term is constructed as follows:

here, \(\:m\) is set to five constraints per week over a horizon of 112 weeks. Let \(\:{\uplambda\:}\gg\:1\), the composite objective of feasibility and cost is:

here, \(\:\text{C}\left(\text{z}\right)\) refers to Eq. (6), and \(\:F\left(\varvec{z}\right)\) denotes the fitness function employed by the algorithm. Through multiple trial runs, \(\:{\uplambda\:}={10}^{5}\) ensures that any constraint-violating solution is numerically inferior to any feasible solution.

Adaptive sparrow search algorithm

The Sparrow Search Algorithm (SSA), proposed by Xue and Shen (2020), is a swarm-intelligence optimization method that simulates sparrow foraging and anti-predation behaviors29. To overcome the original SSA’s shortcomings of premature convergence and susceptibility to local optima on highly nonconvex, dynamic, or high-dimensional problems, this study introduces time-varying weighting coefficients into the producer ratio, adaptive step-size scaling, and danger-perception mechanisms, thereby forming the Adaptive Sparrow Search Algorithm (ASSA). Below, we systematically derive ASSA’s core formulas from a mathematical modeling perspective and explain the mechanisms of each adaptive strategy31,32.

ASSA iterates a population of \(\:{\varvec{Z}}^{\left(t\right)}=\left[{\varvec{z}}_{1}^{\left(t\right)},\dots\:,{\varvec{z}}_{N}^{\left(t\right)}\right](N=100)\) over \(\:\mathcal{X}\). At generation \(\:\text{t}\), the update is governed by a cosine-based schedule, given by the formula:

Here, \(\:t\) denotes the current iteration number; \(\:N\) denotes the population size; \(\:{P}_{D}\left(t\right)\) denotes the producer ratio at generation \(\:t\), which increases smoothly from 10 to 20% over time according to a cosine schedule; \(\:{N}_{P}\left(t\right)\) indicates the actual number of Producers at generation \(\:t\); \(\left\lceil {\text{*}} \right\rceil\) denotes the ceiling function. The top \(\:{\text{N}}_{\text{P}}\left(\text{t}\right)\) individuals, when sorted by ascending fitness, are designated as Producers, while the remainder are designated as Scroungers; their role-competition process is illustrated in Fig. 2.

Population search via three update mechanisms

-

Adaptive Producer Update Operator.

\(\:{\text{P}}_{\text{D}}\left(\text{t}\right)\) increases smoothly from 10 to 20%, ensuring initial global exploration followed by intensified local exploitation. Exponential step-size decay is then applied to the r-th Producer as follows:

Here, \(\:{\mathbf{z}}_{r}^{\left(t\right)}\) is the position vector of the \(\:r\)-th Producer in the \(\:t\)-th generation; \(\:r\) is the rank of this Producer among all producers; \(\:\gamma\:\) is the step-size decay rate, taken as \(\:\gamma\:=1\) in this study; \(\:{\xi\:}_{r}\) is a random number drawn from the uniform distribution \(\:\mathcal{U}\left(\text{0,1}\right)\), enhancing individual heterogeneity; \(\:\sigma\:N\) denotes a Gaussian perturbation of the same dimension; and \(\:\odot\:\) represents the Hadamard product. The former term ensures fine-grained search in later iterations, while the latter maintains diversity in the early stages.

-

Scrounger Update Operator.

Multi-directional jumping is achieved by differencing with the worst‐performing individual \(\:{\text{z}}_{\text{wor\:}}^{\left(\text{t}\right)}\):

where \(\:{\varvec{z}}_{i}^{\left(t\right)}\) is the position vector of the \(\:i\)-th Scrounger in generation \(\:t\); \(\:{\varvec{z}}_{\text{wor\:}}^{\left(t\right)}\) is the position vector of the worst individual in generation \(\:t\); and \(\:{A}_{i}\) determines the jump direction—toward or away from the worst individual.

-

Adaptive Danger-aware Update Operator.

This operator simulates the population’s “probing–escaping” behavior around disadvantageous regions. To reflect predation threat, \(\:{S}_{D}N\left({S}_{D}=0.1\right)\) sparrows are randomly selected for vigilance updates. If their fitness is inferior to that of the global best individual, denoted by \(\:{F}^{*}\left(t\right)\), they are updated as follows:

Otherwise, they are updated as follows:

Here, \(\:{\upepsilon\:}\) denotes the vigilance perturbation amplitude, which is set to \(\:\epsilon\:=1\);\(\:{\updelta\:}={10}^{-9}\) to prevent a zero denominator. This aggregation–dispersion mechanism both contracts the search radius and enables rapid dispersion when local density becomes excessive.

The above differential–aggregation mechanisms jointly accomplish the synergistic search process of “foraging–evasion–escape,” as illustrated by the foraging and aversion behaviors in Fig. 3(A–C).

-

Lévy Long-Tailed Jump Mechanism.

If the improvement in the global best value over \(\:{\text{K}}_{\text{stag\:}}=300\) consecutive iterations remains below \(\:\epsilon={10}^{-8}\), the algorithm triggers a Lévy long-tailed jump:

Here, \(\:{\upalpha\:}\) denotes the jump scale, and \(\:\text{u}\) and \(\:\text{v}\) are determined by the Mantegna formula. This operation is applied only to the current global best individual and the worst \(\:30\text{\%}\) individuals, leveraging Lévy jumps to geometrically traverse multiple local-optimum basins.

The complete algorithm flowchart is illustrated in Fig. 4.

Vascular robot demand forecasting

Accurate forecasting of vascular robot demand is essential for the rational allocation of hospital resources. To ensure that hospitals can satisfy demand while minimizing operational costs, this study employs time series forecasting methods to predict future demand for vascular robots.

Stationarity test

According to time series theory, stationarity can be classified into four deterministic-component forms: no intercept and no trend (None), intercept only (Intercept), intercept and linear trend (Intercept and Trend), and intercept with quadratic trend (Intercept and Quadratic Trend). We then apply the augmented dickey–fuller (ADF) test to assess the series’ stationarity. The core principle of the ADF test is to determine the presence of a unit root via a regression model, thereby establishing whether the series is stationary. Testing begins with the intercept-and-trend model; if the trend term is not significant, the model is successively simplified to the intercept-only form or to the no-intercept–no-trend form. The specifications of these models are as follows:

where \(\:{Y}_{t}\) is the observed value of the time series. \(\:\varDelta\:{Y}_{t}={Y}_{t}-{Y}_{t-1}\) is the first order difference term. \(\:\gamma\:\) is the unit root coefficient, which is used to determine whether the series is smooth or not. \(\:{\sum\:}_{i=1}^{p}\:{\alpha\:}_{i}\varDelta\:{Y}_{t-i}\) is the lag difference term, which controls the autocorrelation of the series. \(\:\epsilon_{t}\) is the random error term. \(\:{\beta\:}_{0}\) is the intercept term, which indicates the extent to which the mean value of the time series deviates from zero. \(\:{\beta\:}_{1}t\) is the trend term, \(\:{\beta\:}_{2}{t}^{2}\) is the quadratic trend term, which indicates the linear trend of the time series over time.

Subsequently, we calculated the smoothness test results for the different models as shown below (Table 2):

Table 2 shows that for the original series, only under the “Intercept and Quadratic Trend” specification does the ADF statistic reach − 3.743 with a p-value of 0.063; although this fails to achieve significance at the 5% level, it can be considered marginally stationary at the 10% level. Consequently, we proceed to model the original series under this specification. After first differencing, the p‐values for all four specifications fall well below 0.05, confirming that the differenced series is clearly stationary. Given that the “Intercept only” model demonstrates stronger stationarity and greater parsimony, we adopt this specification for further analysis. Subsequent modeling will be performed on both the original and first‐differenced series to compare the effectiveness of the two representations.

Model construction

After determining the series’ stationarity characteristics and identifying the basic model form, the next step is to select the optimal combination of lag orders and seasonal terms. To this end, we first perform a preliminary screening of potential AR and MA orders as well as seasonal orders by examining the cutoff and tailing patterns of the autocorrelation function (ACF) and the partial autocorrelation function (PACF). We then apply stepwise fitting to eliminate lag terms that are statistically insignificant or contribute minimally to the model fit, followed by a white noise test on the residual series. Through this process, we obtain a parsimonious forecasting model with sufficient explanatory power.

Parameter selection

We plotted the autocorrelation function (ACF) and partial autocorrelation function (PACF) for both the original series and its first-differenced series and, based on these plots, determined the orders of the autoregressive (AR) and moving average (MA) terms. The results are presented in Figs. 5 and 6.

From Fig. 5, the autocorrelation function (ACF) of the original series exhibits a gradual decay (tailing off), whereas the partial autocorrelation function (PACF) shows significant spikes at lags 1 and 2 before rapidly diminishing and then a single peak at lag 5 prior to cutting off. This pattern aligns with the identification rule for autoregressive (AR) models: a tailing ACF combined with a cut-off PACF indicates the AR order. Accordingly, we select AR(1) and AR(2) to characterize the dominant short‐term dependencies and include AR(5) to capture an additional impulse effect at lag 5.

For the first-differenced series (Fig. 6), the ACF displays a strong negative spike at lag 1 followed by periodic oscillations with positive peaks recurring every 4 lags, suggesting the presence of a nonseasonal moving average (MA) component and a seasonal component of period 4; hence, MA(1) and SMA(4) are specified. The PACF of the differenced series remains significant through lags 1–5 before tailing off, indicating that short‐term momentum persists in an AR form; thus, AR(1)–AR(5) are retained.

In summary, the model for the original series is specified with AR(1), AR(2), and AR(5), while the model for the differenced series incorporates AR(1)–AR(5) alongside MA(1) and SMA(4) to fully describe the data’s short-term dependencies and seasonal characteristics.

Model fitting

After determining the lag orders, we applied stepwise regression to both the original series and its first-differenced series for parameter selection, and completed the final model estimation using ordinary least squares (OLS). The regression coefficients, significance levels, and goodness-of-fit statistics for each model are presented in Tables 3 and 4.

Based on the regression results in Tables 3 and 4, the stepwise selection for the original series retains only the intercept, the quadratic trend term, AR(1), and AR(5). In Model (3), all four coefficients are significant at the 1% level, indicating that the model adequately captures the dynamic characteristics of the original series. For the first-differenced series, non-significant lag terms were sequentially removed, and the final Model (3) retains the intercept, AR(1), AR(4), AR(5), MA(1), and seasonal MA(4). Except for the intercept, all coefficients are significant at the 5% level or higher, and the adjusted R² is 0.814, demonstrating a good fit to the short-term dependencies and seasonal effects of the differenced series.

Model diagnostics

To verify whether the residuals of the two models satisfy the i.i.d. assumption, we conduct Ljung–Box white-noise tests on each model’s residuals. The results are shown in Table 5.

Based on the results in Table 5, although Model (6) has a slightly lower adjusted R² than some other candidates, all of its parameters remain significant at the 5% level, and the Ljung–Box test fails to reject the null hypothesis of white-noise residuals at all tested lags. This satisfies the basic validity requirements. Balancing parameter significance and diagnostic checks, Model (6) offers greater robustness and interpretability than models with higher fit but residual autocorrelation. We therefore select Model (6) as our final forecasting model. Its specification is as follows:

Here, \(\:\varDelta\:{y}_{t}={y}_{t}-{y}_{t-1}\) denotes the first difference of the original series; \(\:{\epsilon\:}_{t}\) the pure random residual; \(\:{\epsilon\:}_{t-1}\) the non-seasonal MA term; \(\:{\epsilon\:}_{t-4}\) the seasonal MA term; and \(\:\varDelta\:{y}_{t-1},\varDelta\:{y}_{t-4},\varDelta\:{y}_{t-5}\) the AR lag terms.

Forecast results

After constructing and specifying the final model expression, we extrapolated the demand for vascular robots over the next 8 periods based on this model. Since the model was built on the first-differenced series, the forecasted values were converted back to the original level series by cumulatively adding the last observed value. To evaluate the stability and confidence of the forecasts, 95% confidence intervals were calculated and adopted as forecast error bounds to characterize potential fluctuations at different forecast horizons. The forecast results and corresponding confidence intervals are presented below.

As shown in Fig. 7, the demand for vascular robots exhibits a gradual upward trend over the next 8 periods, with volatility increasing notably after Period 5. Forecasts from Period 1 to Period 4 remain relatively stable with minimal fluctuations and narrow confidence intervals, indicating low uncertainty in the short-term predictions; however, from Period 5 onward, both the point forecasts and the confidence intervals expand, reflecting increased uncertainty in the medium- to long-term forecasts. This outcome is consistent with the characteristic accumulation of errors inherent in differenced models.

Results and sensitivity analysis

As shown in Table 6, we systematically configured the parameters for the planning problem. The parameter values were primarily drawn from existing empirical studies in the field of medical device resource scheduling and adjusted to reflect the actual operating conditions of a tertiary hospital in Jiangsu Province, thereby enhancing practical applicability. Because the model incorporates inventory rollovers and demand uncertainty, a Poisson distribution was employed to simulate intraoperative robot scrapping, and a ready-to-use procurement channel—priced above conventional purchase rates—was introduced to establish a more comprehensive hybrid procurement mechanism.

Model results

To validate the effectiveness of the proposed ASSA model solver, we conducted a benchmark experiment under the predetermined algorithmic parameter settings (Table 7). Given the high dimensionality of the model and the significant impact of initial solution quality on search efficiency, an empirically constructed set of prior solutions was first introduced as the initial input for the ASSA algorithm to enhance the feasibility ratio and convergence speed during the early iterations. The algorithm was then executed 20 times under fixed parameter settings to mitigate the influence of stochastic perturbations on result stability, with the performance of each run recorded.

For interpretability, the individual yielding the optimal objective function value among the 20 runs was selected as the representative solution, and its complete weekly ordering schedule was output; concurrently, the convergence trajectories of the five best runs were plotted to illustrate the algorithm’s progression along different search paths. Furthermore, to provide a robust evaluation, the average of the best fitness values across all 20 runs was reported as the benchmark performance metric for the planning model. The results are shown in Fig. 8.

Benchmark Model Solution Results. (A) Convergence trajectories of the five best runs out of 20 independent experiments, with an average best fitness value of 20520.52, a 95% confidence interval of [20213.43, 20827.62], and zero penalty for all decision variables. (B) Solution of the individual achieving the optimal objective function value among the 20 runs.

Figure 8 illustrates the solution performance and optimization characteristics of the benchmark model under the ASSA algorithm. In panel (A), the convergence curves of the top five experiments demonstrate that the model attains stable convergence within approximately 300 iterations, indicating both rapid convergence and robust stability. The average best fitness value across 20 experiments is 20520.52, with a 95% confidence interval of [20213.43, 20827.62], and all decision penalty values are zero, confirming that the algorithm maintains strong robustness under varying initial populations and that all solutions lie within the feasible region, where fitness values correspond directly to objective function values. Panel (B) presents the solution of the individual with the optimal objective function value, using a lollipop chart to depict weekly ordering quantities for conventional and high-price procurement of containers (v and v_high) and manipulators (h and h_high), alongside a line chart showing weekly scrap quantities. It is evident that high-price emergency procurement is primarily concentrated during periods of abrupt scrap increases or demand peaks, reflecting the model’s capacity to effectively respond to demand shocks under resource constraints through a hybrid procurement strategy. The optimization results exhibit clear sparsity and periodicity.

Sensitivity analysis of single parameters

Parameter sensitivity analysis is critical for assessing the model’s stability and adaptability under varying conditions. We conducted a one-factor sensitivity analysis focusing on two key parameters: the scrap rate \(\:\left(\rho\:\right)\) and the number of new manipulators trainable per skilled manipulator per week \(\:\left(\gamma\:\right)\). During the analysis, these parameters were set to \(\:\rho\:\in\:\left\{\text{0.10,0.15,0.20,0.25,0.30}\right\}\) and \(\:\gamma\:\in\:\{5,10,15,20,25\}\), respectively, while all other model parameters remained constant. For each parameter configuration, the ASSA algorithm was executed independently 20 times to evaluate the impact of parameter variations on the model’s optimization outcomes. We then present the convergence trajectories of the best runs from the 20 experiments under each parameter setting, as well as the average best fitness value plots for the different parameter configurations (as shown in Fig. 9).

Effects of Single Parameter Adjustments on the Model Optimization Process. (A) Convergence trajectories of the best runs out of 20 experiments under parameter \(\:{\uprho\:}\), with all decision penalty values equal to zero. (B) Average best fitness values under parameter \(\:{\uprho\:}\). (C) Convergence trajectories of the best runs out of 20 experiments under parameter \(\:{\upgamma\:}\), with all decision penalty values equal to zero. (D) Average best fitness values under parameter \(\:{\upgamma\:}\).

Figure 9 illustrates the impact of single-parameter adjustments on the model optimization process. Penalty values were zero in all experiments, indicating that decisions were made within the feasible region and that fitness values correspond directly to objective function values. Panels (A) and (B) show that as the scrap rate parameter \(\:\rho\:\) increases, the model’s convergence slows and the average best fitness value gradually rises, indicating that cost increases with \(\:\rho\:\). In contrast, panels (C) and (D) reveal that lower values of the \(\:\gamma\:\) parameter lead to slower convergence but only minor changes in optimal fitness values, demonstrating that \(\:\gamma\:\) has a limited impact on the optimization process. Therefore, the scrap rate parameter \(\:\rho\:\) exerts a significant influence on model optimization and cost, whereas the effect of \(\:\gamma\:\) is comparatively weak.

To quantify the influence of parameter variations on decision variables, we introduce the Sensitivity Index. The Sensitivity Index evaluates the degree to which each parameter affects decision variables (e.g., procurement quantities, inventory levels). The specific calculation formula is as follows:

where \(\:SI\left(p\right)\) denotes the Sensitivity Index of a given parameter, \(\:\stackrel{-}{X\left(p\right)}\) is the mean value of the decision variables (e.g., container or manipulator order quantities) over 20 runs under the specified parameter, and \(\:X\left({p}_{\text{ref\:}}\right)\) is the mean value of the decision variables over 20 runs under the baseline parameter value. This index reflects the relative impact of variations in parameter \(\:\text{p}\) on the decision variables. Finally, based on the calculated Sensitivity Indices, we employ a radar chart (as shown in Fig. 10) to display the Sensitivity Indices for different parameter settings, thereby visually conveying the relative influence of each parameter on the optimization outcomes.

Figure 10 presents the Sensitivity Indices of the decision variables under two parameter settings: the scrap rate parameter \(\:\rho\:\) and the manipulator training capacity parameter \(\:\gamma\:\). As shown in Fig. 10(A), the Sensitivity Index of decision variable \(\:{\text{h}}_{\text{high\:}}\) remains consistently above the baseline value of 1 across the range of parameter \(\:\rho\:\), indicating a high degree of sensitivity to changes in the scrap rate. By contrast, decision variable \(\:{v}_{\text{high\:}}\) only surpasses the threshold of 1 at elevated scrap rate levels, signifying a marked sensitivity only under higher values of parameter \(\:\rho\:\). Other decision variables, including \(\:v\) and \(\:\text{h}\), exhibit indices below 1, implying limited responsiveness to variations in the scrap rate. In Fig. 10(B), irrespective of the value of parameter \(\:\gamma\:\), all decision variables maintain Sensitivity Indices below 1, reflecting a generally minor impact of the manipulator training capacity. Nonetheless, decision variable \(\:{v}_{\text{high\:}}\) demonstrates a relatively higher Sensitivity Index when parameter \(\:\gamma\:\) is low, although it remains below the baseline of 1, with a discernible trend. Overall, the scrap rate parameter \(\:\rho\:\) substantially influences high-value ready-to-use container \(\:{v}_{\text{high\:}}\) and manipulator \(\:{\text{h}}_{\text{high\:}}\), whereas the manipulator training capacity parameter \(\:{\upgamma\:}\) exerts only a modest effect on the decision variables.

Interaction sensitivity analysis

Interaction Sensitivity Analysis aims to gain deeper insights into how the interplay among multiple parameters affects model outputs. In this study, we focus on two parameter combinations: the pair of parameter \(\:\rho\:\) and γ, and parameters \(\:{V}_{0}\) (initial container inventory) and \(\:{H}_{0}\) (initial manipulator inventory). Specifically, we selected 5 distinct values for each parameter and conducted independent experiments for every parameter pair combination. By calculating the Sensitivity Index for each interaction scenario, we quantified the effects of these interactions on decision variables (e.g., procurement quantities, inventory levels), thereby elucidating how parameter interactions influence the model’s optimization process.

Interaction sensitivity analysis of parameter \(\:\rho\:\) and γ

We first conduct the interaction sensitivity analysis of parameter \(\:\rho\:\) and γ. Based on the parameter values identified in the single-parameter sensitivity study, we selected five distinct scrap-rate values for \(\:\rho\:\) and five distinct γ values, yielding 25 experimental configurations. For each configuration, the ASSA algorithm was independently executed 20 times to assess the impact of these parameter variations on the model’s optimization performance. The results are presented via convergence curves of the best individuals for each experiment and plots of the average best fitness values under the different parameter settings (as shown in Fig. 11).

Effects of the Interaction between Parameter \(\:\rho\:\) and \(\:\gamma\:\) on the Model Optimization Process. (A) Iteration trajectories of the best runs among 20 independent experiments under each parameter combination, with all decision penalty values equal to 0. (B) Average best fitness values under each parameter combination.

Figure 11 illustrates the effects of the interaction between parameter \(\:\rho\:\) and γ on the model optimization process. In Fig. 11(A), the iteration trajectories of the best runs among the 20 experiments show that, for a given \(\:\rho\:\) value, the curves corresponding to different γ values almost coincide, indicating that \(\:\rho\:\) exerts a dominant influence on convergence, whereas γ has a negligible effect on the iteration process. Figure 11(B) presents the average best fitness values for the various parameter combinations, revealing that the average best fitness increases with \(\:\rho\:\), while variations in γ produce virtually no change in fitness, further confirming the low sensitivity of the optimization outcomes to γ and the primary role of \(\:\rho\:\) in determining model performance.

Moreover, based on the calculated Sensitivity Indices, we use a heatmap (as shown in Fig. 12) to display the indices under different parameter settings, thereby providing an intuitive visualization of the relative impacts of parameter combinations on the optimization results. The Sensitivity Index is computed as follows:

here, \(\:{p}_{1}\) and \(\:{p}_{2}\) respectively denote the two parameters being jointly varied in the interaction analysis.

Sensitivity indices of decision variables to the interaction between parameters \(\:{p}_{t}\) and \(\:{\upgamma\:}\), where (A) corresponds to decision variable \(\:{v}_{t}\), (B) to decision variable \(\:{h}_{t}\), (C) to decision variable \(\:{v}_{t}^{\text{high\:}}\), and (D) to decision variable \(\:{h}_{t}^{\text{high}}\).

Figure 12 presents the interactive effects of parameters \(\:\rho\:\) and \(\:\gamma\:\) on the sensitivity indices of the decision variables. It can be observed that variations in parameters \(\:\rho\:\) and \(\:\gamma\:\) produce notable interactive effects, particularly on the procurement quantities of containers and robotic arms. For the container procurement quantity \(\:{v}_{t}\), when \(\:\rho\:\) is relatively low (e.g., \(\:\rho\:=5\text{\%}\)), the sensitivity index remains high; as \(\:\gamma\:\) varies, the index changes progressively, demonstrating a pronounced interaction effect at low scrap rates. At higher values of \(\:\rho\:\) (such as \(\:\rho\:=20\text{\%}\) and \(\:\rho\:=25\text{\%}\)), the sensitivity index tends to stabilize, indicating that the influence of the scrap rate on this decision variable gradually diminishes.

For the robotic arm procurement quantity \(\:{\text{h}}_{\text{t}}\), the interactive effects are also pronounced. In particular, under conditions of \(\:\rho\:=5\text{\%}\) and \(\:\gamma\:=5\), the sensitivity index remains elevated, indicating that at lower scrap rates the robotic arm procurement quantity is highly responsive to variations in \(\:\gamma\:\). As \(\:\rho\:\) increases, especially at values \(\:\rho\:=20\text{\%}\) and \(\:\rho\:=25\text{\%}\), the sensitivity index declines markedly, demonstrating that the impact of parameter \(\:\gamma\:\) on the robotic arm procurement quantity becomes significantly attenuated.

For the decision variables corresponding to the high-priced ready-to-use container \(\:{v}_{t}^{\text{high\:}}\) and high-priced ready-to-use robotic arm \(\:{h}_{t}^{\text{high}}\), the interaction effects are markedly more complex. At low values of \(\:\rho\:\) (e.g., \(\:\rho\:=5\text{\%}\)), the sensitivity indices remain elevated, indicating that under lower scrap rates the procurement quantities of high-priced ready-to-use equipment respond strongly to variations in both parameters. As the values of \(\:\rho\:\) and \(\:\gamma\:\) increase, the sensitivity indices gradually decline, particularly attenuating the influence of parameter changes on the procurement decisions for both containers and robotic arms.

Overall, the analysis of the interaction effects on the sensitivity indices shows that the scrap rate \(\:{\uprho\:}\) at low values exerts a substantial influence on the decision variables, particularly on the procurement quantities of containers and robotic arms, whereas the impact of parameter \(\:{\upgamma\:}\) remains comparatively minor, especially with respect to the procurement decisions for containers and robotic arms.

Interaction sensitivity analysis of parameters \(\:{\text{V}}_{0}\) and \(\:{\text{H}}_{0}\)

The interaction sensitivity analysis of parameter \(\:{V}_{0}\) (initial container inventory) and parameter \(\:{H}_{0}\) (initial robotic arm inventory) provides insight into how initial inventory settings affect resource scheduling optimization. Accordingly, we configured combinations of \(\:{V}_{0}\in\:\left\{\text{7,10,13,16,19}\right\}\) and \(\:{H}_{0}\in\:\left\{\text{30,40,50,60,70}\right\}\) and executed the model to assess the interaction effects of these two parameters. For each parameter setting, the model was independently run 20 times, and by examining the optimal solution in each run, we analyzed the influence of parameter variations on the optimization process (as shown in Fig. 13) and on the decision variables (as shown in Fig. 14).

Certain parameter combinations—such as extremely low initial inventories—can lead to resource shortages and correspondingly high penalty values. Although the model generally converges, some experimental results produced solutions that did not satisfy all constraints and thus lay outside the strictly feasible region. To avoid misleading comparisons of convergence behavior, we do not present the iteration curves for each parameter combination. Instead, we focus on reporting the average penalty values and average optimal costs across the 20 runs under each parameter setting, thereby evaluating the overall impact of initial inventory configurations on scheduling optimization quality.

Figure 13 illustrates the impact of different combinations of initial container inventory \(\:{V}_{0}\) and initial robotic arm inventory \(\:{H}_{0}\) on the model optimization process. In Fig. 12(A), the average penalty values are significantly elevated at \(\:{H}_{0}=30\) and \(\:{H}_{0}=40\), particularly at \(\:{H}_{0}=30\), where extreme penalties occur across all levels of \(\:{V}_{0}\), indicating that resource allocation under these settings cannot satisfy basic scheduling constraints. As \(\:{H}_{0}\) increases to 50 and above, the penalty values rapidly decline to zero or near zero, demonstrating that the model outputs become essentially feasible within this range. Figure 12(B) shows that, within the feasible region where penalties approach zero, the initial inventory combinations still influence optimization costs, with the lowest average cost achieved under the medium-level combination of \(\:{V}_{0}=16\) and \(\:{H}_{0}=50\). Overall, there is a pronounced interaction effect between initial inventory configurations, and adjusting a single parameter alone is insufficient to attain the optimal solution. Properly matching the initial quantities of containers and robotic arms is therefore critical for ensuring both scheduling feasibility and optimization performance.

Figure 13 illustrates the distributions of sensitivity indices for the four decision variables under various combinations of initial container inventory \(\:{V}_{0}\) and initial robotic arm inventory \(\:{H}_{0}\), reflecting the extent to which their interaction influences model outputs. Overall, the sensitivity index of decision variable \(\:{\text{h}}_{\text{t}}\) is markedly higher than those of the other variables across multiple combinations, peaking notably when a medium level of \(\:{V}_{0}\) (e.g., \(\:{V}_{0}=\text{10,16}\)) is paired with a relatively high \(\:{H}_{0}\) (e.g., 60 or 70), which indicates that fluctuations in robotic arm inventory exert a more pronounced effect on resource scheduling under these specific conditions.

In contrast, the sensitivity of decision variable \(\:{v}_{t}\) remains generally low, exhibiting only a slight increase under extreme configurations (e.g., low \(\:{V}_{0}=10\) and high \(\:{H}_{0}=60\)). For the immediate-use procurement variables \(\:{v}_{t}^{\text{high\:}}\) and \(\:{h}_{t}^{\text{high\:}}\), their sensitivity responses diverge: variable \(\:{v}_{t}^{\text{high\:}}\) attains a higher sensitivity index under low‐inventory combinations (e.g., \(\:{V}_{0}=7,{H}_{0}=30\) ), indicating that when initial resources are scarce, this variable plays a more significant supplementary role in resource adjustment; by contrast, the sensitivity of variable \(\:{h}_{t}^{\text{high\:}}\) is more dispersed, lacking a clear unidirectional trend, although localized fluctuations are observed under certain medium‐to‐high inventory levels.

Overall, the interaction between initial container and robotic arm inventories exerts heterogeneous effects on different categories of scheduling decision variables, rendering the isolated adjustment of a single parameter insufficient to capture the full impact on system outputs and underscoring the need for integrated interaction analyses to identify the response mechanisms of key variables across varying configurations.

Sensitivity analysis of population size for the ASSA algorithm

To evaluate the optimization performance of the ASSA algorithm under various population size settings, we conducted a sensitivity analysis on its population scale. Specifically, population sizes of 20, 50, 100, 150, and 200 were tested, and the algorithm was independently executed multiple times under identical initial conditions to compare the effects of different scales on the model’s convergence process and optimal fitness values. By presenting the iteration curves and optimal fitness plots for each configuration (as shown in Fig. 15), we assess the influence of population size variation on the algorithm’s stability and search capability.

As shown in Fig. 15, population size settings exert a significant impact on the optimization performance of the ASSA algorithm. With population sizes of 20 and 50, the model generally fails to converge within the predefined number of iterations, producing elevated optimal fitness values and wide error margins, which indicate unstable outcomes and poor convergence. In contrast, when the population size reaches 100 or more, convergence markedly improves, optimal fitness values stabilize, and error ranges narrow substantially. Considering both optimization performance and computational efficiency, a population size of 100 was selected as the baseline for subsequent experiments and parameter sensitivity analysis.

Conclusion

This study develops a resource optimization model aimed at minimizing the procurement, training, and maintenance costs of vascular robots, comprehensively accounting for practical constraints such as random equipment scrapping, maintenance and training cycles, and demand fluctuations. An adaptive sparrow search algorithm (ASSA) is proposed and implemented to effectively solve the resulting high-dimensional, complex optimization problem. The results indicate that the equipment scrapping rate has a pronounced impact on resource allocation, with procurement decisions for high-priced, ready-to-use devices exhibiting heightened sensitivity under low scrapping-rate conditions. Moreover, a judicious combination of initial resource allocations proves critical for ensuring both feasibility and cost-effectiveness; in particular, when demand peaks occur, the model can flexibly adjust the mix between standard and high-priced procurement strategies to achieve effective cost control. In addition, this work delves into historical demand data to extract seasonal and cyclical patterns, and by establishing a robust SARIMA forecasting model, it provides healthcare institutions with a precise and reliable tool for short-term and medium- to long-term demand forecasting.

The study further reveals interaction effects between decision variables and key parameters, highlighting the model’s nonlinear sensitivity to parameter changes in practical applications, and thus offers theoretical support and practical guidance for future resource allocation decisions of hospital medical devices. Future research may explore more refined dynamic optimization strategies, further integrating equipment lifecycle management with supply chain management to enhance the comprehensiveness and effectiveness of resource allocation decisions in healthcare settings.

Data availability

The following supporting information can be downloaded at: https://github.com/maomao2221/Medical-Supply-Engineering.

References

Wang, B., Gao, Y., Zhang, L. & Liu, Y. tPA-anchored nanorobots for in vivo arterial recanalization at submillimeter-scale segments. Sci. Adv. 10, eadk8970. https://doi.org/10.1126/sciadv.adk8970 (2024).

Kong, X. et al. Advances of medical nanorobots for future cancer treatments. J. Hematol. Oncol. 16, 74. https://doi.org/10.1186/s13045-023-01463-z (2023).

Sun, T. et al. Application of micro/nanorobot in medicine. Front. Bioeng. Biotechnol. 12, 1347312. https://doi.org/10.3389/fbioe.2024.1347312 (2024).

Nguyen, T. Q. et al. Retrospective cohort study of minimally invasive surgical approaches for pediatric intussusception. Sci. Rep. 14, 29763. https://doi.org/10.1038/s41598-024-81654-x (2024).

Panero, I. et al. Cost difference between open surgery and minimally invasive surgery for the treatment of traumatic thoracolumbar fractures. World Neurosurg. 194, 123602. https://doi.org/10.1016/j.wneu.2024.123602 (2025).

Harky, A., M, S. & Hussain, A. Robotic cardiac surgery: the future gold standard or an unnecessary extravagance? Braz J. Cardiovasc. Surg. 34 (XII–XIII). https://doi.org/10.21470/1678-9741-2019-0194 (2019).

Fu, S. et al. A magnetically controlled guidewire robot system with steering and propulsion capabilities for vascular interventional surgery. Adv. Intell. Syst. 5, 2300267. https://doi.org/10.1002/aisy.202300267 (2023).

Hu, N. et al. Comprehensive modeling of corkscrew motion in micro-/nano-robots with general helical structures. Nat. Commun. 15, 7399. https://doi.org/10.1038/s41467-024-51518-z (2024).

Alapan, Y. et al. Multifunctional surface microrollers for targeted cargo delivery in physiological blood flow. Sci. Robot. 5, eaba5726. https://doi.org/10.1126/scirobotics.aba5726 (2020).

Li, P. et al. Development and verification of a micro magnetically guided helical robot with active locomotion and steering capabilities for guidewires. Sens. Actuators Phys. 369, 115123. https://doi.org/10.1016/j.sna.2024.115123 (2024).

Chuang, C. M., Cheng, Y. H. & Wu, Y. R. Electro-optical numerical modeling for the design of UVA nitride-based vertical-cavity surface-emitting laser diodes. IEEE J. Sel. Top. Quantum Electron. 28, 1700606. https://doi.org/10.1109/JSTQE.2021.3114411 (2022).

Meng, X. et al. Programmable Spatial magnetization stereolithographic printing of biomimetic soft machines with thin-walled structures. Nat. Commun. 15, 10442. https://doi.org/10.1038/s41467-024-54773-2 (2024).

Fischer, F. et al. Magneto-oscillatory localization for small-scale robots. Npj Robot. 2, 1. https://doi.org/10.1038/s44182-024-00008-x (2024).

Xu, H. et al. 3D nanofabricated soft microrobots with super-compliant Picoforce springs as onboard sensors and actuators. Nat. Nanotechnol. 19, 494–503. https://doi.org/10.1038/s41565-023-01567-0 (2024).

Cheng, G., Zhou, D., Monkowius, U. & Yersin, H. Fabrication of a solution-processed white light emitting diode containing a single dimeric copper(I) emitter featuring combined TADF and phosphorescence. Micromachines 12, 1500. https://doi.org/10.3390/mi12121500 (2021).

Huang, J. J. et al. Robotic-assisted nipple-sparing mastectomy followed by immediate microsurgical free flap reconstruction: feasibility and aesthetic results – case series. Int. J. Surg. 95, 106143. https://doi.org/10.1016/j.ijsu.2021.106143 (2021).

Wrede, P. et al. Real-time 3D optoacoustic tracking of cell-sized magnetic microrobots Circulating in the mouse brain vasculature. Sci. Adv. 8, eabm9132. https://doi.org/10.1126/sciadv.abm9132 (2022).

Kaya, M. et al. Visualization of micro-agents and surroundings by real-time multicolor fluorescence microscopy. Sci. Rep. 12, 13375. https://doi.org/10.1038/s41598-022-17297-7 (2022).

Wang, B., Kostarelos, K., Nelson, B. J. & Zhang, L. Trends in micro-/nanorobotics: materials development, actuation, localization, and system integration for biomedical applications. Adv. Mater. 33, 2002047. https://doi.org/10.1002/adma.202002047 (2021).

Lengyel, B. C., Chinnadurai, P., Corr, S. J., Lumsden, A. B. & Bavare, C. S. Robot-assisted vascular surgery: literature review, clinical applications, and future perspectives. J. Robot Surg. 18, 328. https://doi.org/10.1007/s11701-024-02087-2 (2024).

Abbas, A., Bakhos, C., Petrov, R. & Kaiser, L. Financial impact of adapting robotics to a thoracic practice in an academic institution. J. Thorac. Dis. 12, 89–96. https://doi.org/10.21037/jtd.2019.12.140 (2020).

Rajak, A. K. Multi-supplier, multi-objective supply chain cost-optimization model. Res. Math. 10, 1. https://doi.org/10.1080/27684830.2023.2245189 (2023).

Kim, C. K., Lee, C., Kim, D., Cha, H. & Cheong, T. Enhancing supply chain efficiency: A two-stage model for evaluating multiple sourcing and extra procurement strategy optimization. Sustainability 15, 16122. https://doi.org/10.3390/su152216122 (2023).

Cheimanoff, N., Féniès, P., Kitri, M. N. & Tchernev, N. Exact and metaheuristic approaches to solve the integrated production scheduling, berth allocation and storage yard allocation problem. Comput. Oper. Res. 153, 106174. https://doi.org/10.1016/j.cor.2023.106174 (2023).

Diaz-Garcia, J. A., Ruiz, M. D. & Martin-Bautista, M. J. A new framework for irrelevant content filtering in social media according to credibility and expertise. Expert Syst. Appl. 208, 118063. https://doi.org/10.1016/j.eswa.2022.118063 (2022).

Ding, K. & Fan, L. Q. Architecture, operation, and implementation for blockchain-driven turnkey project under I4.0 workshop based on RAMI 4.0. Comput. Ind. Eng. 173, 108737. https://doi.org/10.1016/j.cie.2022.108737 (2022).

Fowler, J. W. & Mönch, L. A survey of scheduling with parallel batch (p-batch) processing. Eur. J. Oper. Res. 298, 1–24. https://doi.org/10.1016/j.ejor.2021.06.012 (2022).

Fariman, S. K. et al. A robust optimization model for multi-objective blood supply chain network considering scenario analysis under uncertainty: a multi-objective approach. Sci. Rep. 14, 9452. https://doi.org/10.1038/s41598-024-57521-0 (2024).

Xue, J. K. & Shen, B. A novel swarm intelligence optimization approach: sparrow search algorithm. Syst. Sci. Control Eng. 8, 22–34. https://doi.org/10.1080/21642583.2019.1708830 (2020).

Zhang, C. et al. A literature review of perishable medical resource management. Front. Eng. Manag. 10, 710–726. https://doi.org/10.1007/s42524-023-0278-9 (2023).

He, Y. & Wang, M. An improved chaos sparrow search algorithm for UAV path planning. Sci. Rep. 14, 366. https://doi.org/10.1038/s41598-023-50484-8 (2024).

Wang, Z. et al. An improved sparrow search algorithm with multi-strategy integration. Sci. Rep. 15, 3314. https://doi.org/10.1038/s41598-025-86298-z (2025).

Funding

“This research is funded by the Special Funds for the Basic Operating Expenses of the Central Universities of China University of Labor Relations, Project Title: Statistical Modeling and Analysis of Regional Economy and Employment Structure, grant number: 202503010103.”

Author information

Authors and Affiliations

Contributions

Conceptualization, Y.L., S.Z., X.L., S.J. and W.Z.; methodology, Y.L. and X.L.; software, Y.L. and X.L.; validation, S.Z.; formal analysis, Y.L.; investigation, Y.L. and S.Z.; resources, Y.L. and S.Z.; data curation, Y.L. and X.L.; writing—original draft preparation, Y.L., S.J., X.Y. and W.Z.; writing—review and editing, Y.L., S.Z.; visualization, Y.L.; supervision, X.L.; project administration, X.L.; funding acquisition, Z.W All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Y., Song, Z., Xia, L. et al. Application of the adaptive sparrow search algorithm in medical supply engineering. Sci Rep 15, 35775 (2025). https://doi.org/10.1038/s41598-025-11793-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-11793-2