Abstract

To overcome the limitations of conventional water-based dust suppression in arid, high-temperature open-pit coal mine haul roads, this study developed an innovative molasses-based dust suppressant with enhanced water retention and consolidation capabilities. The formulation leverages molasses-a sugar industry byproduct with inherent anti-evaporation properties-as its core component, supplemented with surfactant (sodium dodecyl benzene sulfonate, SDBS), humectant (glycerol), and hygroscopic (calcium chloride, CaCl₂) additives. Employing response surface methodology (RSM), the optimal composition was determined to be: 31.06% molasses, 0.73 g/L SDBS, 1.68% glycerol, and 1.50% CaCl2. Experimental validation confirmed the model’s reliability, showing < 3% deviation between predicted and actual performance metrics. Field evaluation produced significant results: small-scale testing with 2.5-ton and 4.4-ton mine vehicles maintained dust-free conditions for three consecutive days, while medium-scale trials with loaded (550-ton) and unloaded (225-ton) haul trucks achieved effective dust control for over 6 h. The suppressant creates a durable, homogeneous consolidation layer with substantial mechanical strength when applied. The suppression mechanism combines immediate dust wetting with prolonged suppression via dust particle solidification post water evaporates.

Similar content being viewed by others

Introduction

China, the world’s largest energy consumer, derived 53.2% of its 5.96 billion tons of standard coal energy consumption from coal in 2024, highlighting coal’s pivotal role in national energy security1,2. Coal mining methods are broadly categorized into underground and open-pit mining, with the latter being prioritized due to their large-scale operations, high efficiency, lower energy consumption, and enhanced safety3. Open-pit mining involves the removal of overlying soil and rock layers, followed by coal extraction in an open environment. However, the reliance on off-highway mining trucks (some exceeding 600 tons in gross vehicle mass)4and the extensive use of unpaved, mud-bound gravel haul roads5,6results in significant dust pollution. This road dust has become the primary source of emissions in open-pit coal mines7,8,9posing severe environmental and occupational health risks that include accelerated equipment wear and reduced service life10,11,12. Consequently, effective dust prevention and control on haul roads are essential for occupational safety and environmental protection in open-pit mining operations.

The most common method for dust control on haul roads is watering. However, over 80% of China’s open-pit coal mines are located in arid or semi-arid regions of the northwest13,14where low precipitation, high evaporation rates, and scarce water resources prevail. Under these challenging conditions, conventional watering proves largely ineffective. During hot and dry summer periods in particular, sprayed water evaporates rapidly, often drying completely within 3 to 30 min, thereby failing to provide sustained dust suppression. To overcome these limitations, researchers have focused on enhancing the anti-evaporation properties of aqueous solutions by integrating specialized dust suppression materials, improving dust control efficiency15,16. Various materials have been investigated, including traditional hygroscopic salts, eco-friendly natural or synthetic polymers, and microbial-based agents17,18,19,20,21,22all designed to enhance water retention, wetting capability, and solidification properties for effective control of soil, rock, and coal dust in open-pit mining environments.

For instance, Dong et al.23 developed a soy protein isolate-based foam that forms a protective hard shell on coal dust surfaces, while Xu et al.24 created a low-viscosity starch-based suppressant specifically for high-concentration dust in open-pit coal mines. Yu et al.25 synthesized a composite suppressant using humic acid and acrylamide, which demonstrates excellent wind erosion resistance and anti-evaporation properties. Zhou et al.26 utilized sugarcane bagasse cellulose as a matrix, combined with polyvinyl alcohol and polyacrylamide monomers, to prepare an environmentally friendly suppressant with remarkable consolidation strength and permeability. Jin et al.27 developed a cross-linked dust suppressant derived from soy protein isolate that forms a dense, wind-resistant shell on coal piles. Li et al.28 engineered a high-performance crust-forming suppressant from waste paper cellulose, exhibiting superior hardness, weather resistance, and ecological compatibility for coal pile dust in laboratory tests. Xia et al.29 formulated a multifunctional composite suppressant with exceptional wetting, moisturizing, and antifreeze properties, while Chen et al.30 pioneered innovative microbial-based solutions for blast pile dust control.

Despite these significant advancements, few studies have systematically evaluated the performance of these suppressants under actual open-pit mining conditions. Zhao et al.31 achieved 3–4 days of effective dust suppression using a polyacrylamide-based moisturizing suppressant, while Zhao et al.32 developed an antifreeze suppressant maintaining effectiveness for 4-day − 140 times longer than watering. However, the application of molasses-based suppressants, renowned for their anti-evaporation characteristics, dust aggregation capability, and wind erosion resistance33remains unexplored in heavy-duty haul road environments. Laboratory studies by Zhou et al.34 demonstrated a molasses-based foam suppressant achieving a 98% dust fixation rate at high wind speeds, and Wang et al.35 explored its synergistic combination with microbial agents for enhanced soil dust treatment.

This study directly addresses this critical research gap in field application by optimizing a novel molasses-based dust suppressant using response surface methodology (RSM) and conducting rigorous field tests to evaluate its water retention capacity, anti-evaporation performance, and dust consolidation properties. The results provide valuable practical insights for effective dust control in open-pit coal mines, while contributing to the green and sustainable development of the mining industry, in alignment with ecological protection goals.

Materials and methods

Dust sampling and processing

Road dust samples were collected from the + 1025 horizontal end-slope road in the Haerwusu open-pit coal mine (39°43’∼39°45’ E, 111°13’∼111°15’ N), located 13 km from Xuejiawan Town, Zhungeer Banner, Ordos City, Inner Mongolia, China (Fig. 1).

Sampling locations of Haerwusu open-pit coal mine. (https://map.baidu.com/@11673463.457750902,4158860.1016630097,5.5z).

The Haerwusu mine, one of China’s largest open-pit coal mines with an annual production capacity of 35 million tons36spans 57.7 square kilometers, with current operations focused on a 2 km working line in the initial mining area. The geological profile consists of a 40-meter-thick loess layer, a 100-meter-thick middle rock layer, and a 21-meter-thick coal seam. Located in northern China’s semi-arid region, the mine experiences a continental semi-dry climate characterized by cold winters and hot summers. Annual temperatures range from 5.3 to 7.6 °C, with extremes reaching 38.3 °C and − 30.9 °C. The average wind speed ranges between 1.9 and 3.4 m/s, and the freezing period extends from October to April. With annual rainfall averaging 400 mm (primarily concentrated from July to September) and evaporation reaching approximately 2,000 mm37these conditions cause rapid moisture evaporation - particularly during hot, dry summers when water evaporates within 3–30 min - severely limiting the effectiveness of water-based dust suppression while exacerbating water resource challenges.

Dust samples were sealed in airtight bags (Fig. 2a), transported to the laboratory, and sieved through an 80-mesh standard sieve after removing gravel and larger particles. Following sieving, samples were dried at 40 °C for 6 h in a forced-air drying oven38 and subsequently cooled to room temperature in a desiccator, yielding the experimental road dust sample as shown in Fig. 2b.

Response surface methodology (RSM)

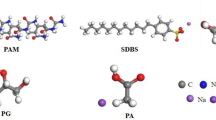

Four key components were selected for the road dust suppressant formulation: molasses as the primary constituent, sodium dodecyl benzene sulfonate (SDBS) as the surfactant, glycerol as the water-retaining agent, and calcium chloride (CaCl₂) as the moisture-absorbing agent. All chemicals were of analytical grade.

A response surface experiment was designed using the Box-Behnken Design model in Design Expert 13.0 software. The experimental design incorporated four factors - molasses concentration (A), SDBS concentration (B), glycerol concentration (C), and CaCl₂ concentration (D) - with three response values: evaporation rate (Y₁), failure resistance force (Y₂), and penetration depth (Y₃) (Table 1). Based on this design, 29 independent experiments were conducted, with all experimental groups performed in triplicate to ensure statistical reliability, and the final results calculated as mean values.

Evaporation rate test

For evaporation rate testing, a 10 mL dust suppressant solution was uniformly sprayed onto 20 g of experimental road dust in a 90 mm diameter Petri dish and dried at 70 °C in a blast drying oven. Sample mass was measured at predetermined intervals, and the evaporation rate Y₁ (g/h) was calculated using Eq. 1:

where m0 represents the initial mass of the petri dish with dust after spraying (g), m denotes the mass after evaporation (g), and t is the evaporation time (h).

Failure resistance force test

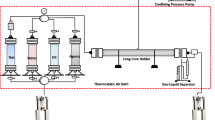

The consolidated dust block formed after complete water evaporation was tested using an HP-1 K digital force gauge (Fig. 3a). The maximum destructive force recorded during testing was designated as the failure resistance force Y₂.

Penetration depth test

Penetration depth (Y₃) was measured using a forward penetration experiment. A bottomless glass tube (30 cm length, 1 cm inner diameter) was wrapped with filter paper at the bottom, filled with 15 cm of compacted dust, and vertically fixed on an iron frame. Subsequently, 2 mL of dust suppressant solution was added dropwise into the tube, with penetration depth Y₃ recorded at 10-minute intervals over a total duration of 1 h, as illustrated in Fig. 3b.

Field test of road dust suppressant

Field testing was conducted on the + 1025 horizontal end-slope road at the Haerwusu open-pit coal mine in Ordos City, Inner Mongolia, China (Fig. 1). The region experiences annual sunshine duration of over 3000 h and receives only about 400 mm precipitation annually, while evaporation reaches over 2000 mm - approximately five times the precipitation amount. The mine’s unpaved roads, constructed from stripped rocks and loess, currently rely on water spraying for dust control, which proves ineffective due to rapid evaporation during summer months, leaving the dust suppression efficiency of Haerwusu’s road dust unresolved.

Small-scale field test

A 10 m × 6 m experimental area was sprayed with suppressant at 1.5 L/m² using an electric sprayer, with a control section sprayed with water for comparison (Fig. 4). Small mine vehicles (2.5-ton command vehicle and 4.4-ton engineering vehicle) were driven through the area while dust conditions were documented photographically over 3 days. Testing occurred under ambient conditions of 40.2 °C air temperature, 23.8% relative humidity, and 49 °C road surface temperature.

Medium-scale field test

To evaluate dust suppression under normal working conditions, a 200 m × 20 m area was sprayed with suppressant at 1.5 L/m² using a 20-ton mining sprinkler truck (Fig. 5). Mining trucks operated under standard working conditions while dust generation, road consolidation, and wear were observed and photographically documented over time.

Results and discussion

Design and analysis of response surface experiment

The results of the 29 response surface experiments are presented in Table 2.

Regression analysis of the experimental data yielded quadratic polynomial equations for evaporation rate (Y₁), failure resistance force (Y₂), and penetration depth (Y₃):

The analysis of variance (ANOVA) results is shown in Table 3.

A significance threshold of α = 0.05 was selected for evaluating the model. The F-values, representing the influence of each parameter on the response variables, indicate that higher values correspond to greater impact. The P-values demonstrate the significance levels, where values between 0.01 and 0.05 indicate significance, 0.001–0.01 indicate high significance, and < 0.001 denote extreme significance. As shown in Table 3, the F-values (29.54, 26.38, and 11.18) and P-values (< 0.0001) confirm highly significant regression fits. The correlation coefficients (R²) of 0.9673, 0.9635, and 0.9179 suggest that 96.73%, 96.35%, and 91.79% of variations in evaporation rate, failure resistance force, and penetration depth, respectively, can be explained by the four independent variables. Signal-to-noise ratios > 4 and misfit term P-values > 0.05 further validate the models’ robustness and predictive capability for determining optimal experimental conditions.

Interaction analysis

Evaporation rate (Y₁)

The first-order coefficients of the regression equation reveal the following factor influence hierarchy: A (molasses) > C (glycerol) > B (SDBS) > D (CaCl₂). Molasses (A), containing non-volatile polysaccharides and pectin39significantly reduces aqueous solution vapor pressure, thereby decreasing evaporation rates. Glycerol (C), with its abundant hydroxyl groups (-OH), exhibits strong hydrophilicity, forming stable hydrogen bonds with water molecules to enhance moisture retention40. SDBS (B) extends evaporation time by improving solution wettability and penetration depth, though its effect is relatively modest. CaCl₂ (D) demonstrates hygroscopic properties that enhance water retention under high humidity; however, at 70 °C, this effect becomes negligible, resulting in minimal evaporation suppression. Figure 6 presents response surface diagrams illustrating the interaction effects on evaporation rate.

The response curves for AB (molasses-SDBS), AC (molasses-glycerol), and AD (molasses-CaCl₂) exhibit significant curvature, indicating strong interactions between molasses and the other three factors. In Fig. 6a, SDBS shows minimal effect on evaporation rate, while increasing molasses concentration substantially reduces evaporation. Figure 6b highlights the synergistic interaction between molasses and glycerol, where higher concentrations of both components yield optimal evaporation rates (~ 2 g/h). Figure 6c demonstrates molasses’ dominant effect compared to CaCl₂. Conversely, interactions between SDBS, glycerol, and CaCl₂ (Fig. 6d-f) display weaker curvature, indicating limited impact on evaporation rate, with the SDBS-CaCl₂ interaction being least significant.

Failure resistance force (Y₂)

The factor influence hierarchy on failure resistance force follows: A (molasses) > C (glycerol) > D (CaCl₂) > B (SDBS). Molasses solidifies dust particles, forming a cohesive structure with enhanced mechanical strength. Glycerol retains water, thereby reducing mechanical strength, while CaCl₂ improves adhesion through Ca²⁺ interactions with polysaccharides and pectin. SDBS contributes to strength improvement via permeation but exhibits relatively weaker impact. Figure 7 presents response surface diagrams of the interaction effects on failure resistance force.

The AB, AC, and AD response surfaces in Fig. 7 show pronounced curvature, indicating strong interactions. Figure 7a demonstrates rapid increase in failure resistance force with molasses concentration, stabilizing above 30%, while SDBS shows negligible effect. Figure 7b reveals that higher glycerol concentrations reduce failure resistance, though this effect is counterbalanced by increasing molasses concentration. Figure 7c confirms molasses’ dominant role, with CaCl₂ exhibiting minimal impact. The SDBS-glycerol-CaCl₂ interactions (Fig. 7d-f) display weaker curvature, indicating limited influence on failure resistance.

Penetration depth (Y₃)

The factors affecting penetration depth follow this hierarchy: A (molasses) > C (glycerol) > D (CaCl₂) > B (SDBS). Molasses enhances hydrophilicity through bioactive compounds like oligosaccharides and phospholipids, promoting solution penetration. Glycerol forms stable hydrogen bonds with water, prolonging moisturizing time and increasing penetration depth. CaCl₂ forms gels with pectin that hinder penetration, while SDBS within its critical micelle concentration (CMC) range shows minimal variation. Figure 8 presents response surface diagrams of the interaction effects on penetration depth.

The response surfaces in Fig. 8 exhibit significant curvature, indicating strong interactions. Figure 8a shows penetration depth increasing with molasses concentration, peaking at ~ 30%, while SDBS has minor effect. Figure 8b demonstrates glycerol concentration’ direct proportionality to penetration depth, with optimal results at higher concentrations of both molasses and glycerol. CaCl₂ shows negligible impact on penetration depth (Fig. 8c-f).

Optimization conditions and verification analysis

Considering dust suppression effectiveness, material economy, and field application feasibility, software analysis determined the optimal formulation as: 31.06% molasses, 0.73 g/L SDBS, 1.68% glycerol, and 1.5% CaCl₂. This ratio predicts an evaporation rate of 2.97 g/h, failure resistance force of 138.4 N, and penetration depth of 8.22 cm.

Model validation included analysis of residual normal probability distribution, residual-predicted value distribution, and predicted-actual value distribution (Fig. 9).

The normal probability plots (Fig. 9a) show residuals uniformly distributed near the straight line with few outliers, indicating excellent model fit. The irregular, random residual distribution versus predicted values (Fig. 9b) confirms residual independence from predicted variables, validating model adaptability. The close alignment of predicted and actual values (Fig. 9c), with most points near the straight line, demonstrates reliable predictive capability.

Three validation experiments under optimized conditions (Table 4) showed < 3% relative errors between predicted and experimental values, confirming model reliability. The optimized dust suppressant formulation is both reasonable and reliable. Laboratory tests exhibited: pH 6.58 (weakly acidic), viscosity 5.5 mPa·s (sprayable), density 1.06 g/cm³ (water-like), and surface tension 28.63 mN/m (significantly lower than water’s 71.31 mN/m), indicating excellent wetting and permeability for practical application.

Field test results analysis

Small-scale field test results

During small-scale testing, industrial water completely evaporated within 3 ~ 30 min, losing dust suppression capability, while the dust suppressant adhered to and solidified with the road surface after 2 h. Figure 10 shows dust conditions before and after vehicle test.

The suppressant-treated area maintained excellent dust suppression over three days, with significant reduction compared to untreated areas, demonstrating effective penetration and consolidation layer formation with mechanical strength resistant to vehicle damage. Minor dust at vehicle rears was observed resulted from test length limitations creating low-pressure vortices carrying untreated area dust. To address this, medium-scale field experiment was conducted to evaluate the suppressant’s performance under normal operating conditions with heavy-duty mining trucks.

Medium-scale field test results

Figure 11. Fugitive dust from fully loaded and empty mining trucks in the test area over time.

Industrial water failed to suppress dust after 30 min (Fig. 11a), while the suppressant demonstrated significant effectiveness on both heavy-duty and non-heavy-duty roads. For loaded mining trucks, effectiveness lasted 5 h, with slight dust at 5.5 h and significant increase by 6 h (≈ 6 h total effectiveness). Empty mining trucks maintained suppression over 6 h.

Road surface sampling analysis

Dust samples were collected from the road surface using the ring knife sampling method, as shown in Fig. 12.

The water-treated road surface could not be fully sampled, while suppressant-treated areas showed complete 7 mm consolidation depth, indicating strong dust-small stone binding. Vehicle pressure caused particle interlocking and molasses solidification into a dense, mechanically strong layer. Water-treated areas exhibited weak bonding and low consolidation strength unable to withstand truck traffic.

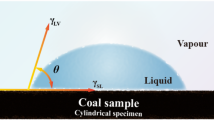

Dust suppression mechanism

The suppressant demonstrated superior efficiency versus water, with excellent field performance. Figure 13 illustrates the mechanism of the dust suppressant’s action.

When dust suppressants are sprayed, surfactant-reduced surface tension enables rapid spreading and deep penetration via molecular forces, capillary action, and gravity. Upon pore saturation, infiltration stabilizes. Compared to water, suppressants reduce evaporation and extend duration through glycerol/CaCl₂-enhanced water retention. Additionally, the suppressant’s viscosity enables bonding layer formation that fills particle gaps, reducing evaporation pathways and lowering the evaporation rate.

However, repeated compaction by heavy trucks reduces the porosity of open-pit mine roads, increasing their density and consequently slowing suppressant penetration. Field experiments conducted under summer conditions, where road temperatures reach up to 70 °C, demonstrate rapid water evaporation from the suppressant, leading to increased concentration and viscosity. This increased viscosity reduces permeability, causing the suppressant to accumulate on the surface and lose its dust-wetting capability, thereby significantly compromising its anti-evaporation performance. Prior to complete evaporation, the suppressant functions primarily through wetting and water retention mechanisms. During the evaporation process, the concentration of low molecular weight carbohydrates, polysaccharides, and proteins in the molasses increases progressively, strengthening particle bonding through enhanced adhesion and cohesion forces. As moisture content decreases and the dust solidifies, the suppressant forms a high-strength consolidation layer with the road dust that effectively resists external disturbances. Following complete evaporation, the suppressant maintains its dust control capability by continuing to prevent secondary dust emission through consolidation.

Conclusions

This study successfully developed an optimized molasses-based dust suppressant exhibiting superior water retention and consolidation properties for effective dust control on haul roads in open-pit coal mines under arid and high-temperature conditions. The formulation was systematically optimized using response surface methodology (RSM), with comprehensive performance evaluation through field tests. The principal findings are summarized as follows:

-

a)

The Box-Behnken Design method in RSM enabled establishment of quadratic regression equations for three key response variables: evaporation rate, failure resistance force, and penetration depth. Variance analysis confirmed the model’s statistical significance, demonstrating its robust predictive capability for relationship between response variables and dust suppressant component concentrations.

-

b)

Response surface optimization yielded an ideal formulation comprising 31.06% molasses, 0.73 g/L SDBS, 1.68% glycerol, and 1.50% CaCl₂. This optimized composition achieved exceptional performance metrics: evaporation rate of 2.97 g/h, failure resistance force of 138.40 N, and penetration depth of 8.22 cm. Validation experiments confirmed high reliability, with < 3% deviation between predicted and observed values, underscoring the formulation’s practical applicability.

-

c)

Field testing demonstrated the suppressant’s ability to form dense, mechanically robust consolidation layer on road surfaces. Small-scale tests (2.5-ton and 4.4-ton mine vehicles) showed complete dust suppression for 72 h, while medium-scale trials achieved 6-hour effectiveness for 550-ton loaded trucks and > 6-hour performance for 225-ton unloaded trucks, forming 7 mm consolidation layer under operational compaction. The dual-phase suppression mechanism involves initial wetting followed by post-evaporation solidification and consolidation.

While these results are promising, several practical challenges require further investigation, including performance under variable weather conditions and long-term durability. Future research directions should prioritize: (a) mechanistic studies of suppression phenomena at molecular levels, (b) extended field validation under diverse operational conditions, (c) formulation optimization balancing durability and cost-effectiveness, and (d) comprehensive environmental impact assessment across seasonal variations, and (e) performance development integrated with road maintenance practices for sustainable mining applications.

Data availability

Data availabilityThe corresponding author provides data supporting the findings of this study upon reasonable request.

References

National Bureau of Statistics. Statistical bulletin of the People ‘s Republic of China on national economic and social development. (2024). https://www.stats.gov.cn/sj/zxfb/202502/t20250228_1958817.html (2024).

Li, L. et al. Multidimensional Spatial monitoring of open pit mine dust dispersion by unmanned aerial vehicle. Sci. Rep. 13, 6815 (2023).

Zhao, J. C., Gao, L. & Ren, S. H. Prediction of open-pit mine truck travel time based on LSTM-TabTransformer. Sci. Rep. 15, 7427 (2025).

Cai, Q. X. & Chen, Y. L. Review of 70 years’ achievements and high-quality development architecture system of surface coal mining in China. J. China Coal Soc. 49, 235–260 (2024).

Lu, X. et al. Experimental study of the freeze-thaw damage of alpine surface coal mine roads based on geopolymer materials. Water 15, 3093 (2023).

Thompson, R., Peroni, R. & Visser, A. Mining Haul Roads: Theory and Practice7–17 (CRC, 2019). https://doi.org/10.1201/9780429491474

Feng, S. M. & Zhang, J. Quantitative inversion of integrated hyperspectral and optical remote sensing images to monitor dust distribution in open pit mines. All Earth. 37, 1–13 (2025).

Kamran, M., Jiskani, I. M., Wang, Z. M. & Zhou, W. Decision intelligence-driven predictive modelling of air quality index in surface mining. Eng. Appl. Artif. Intel. 133, 108399 (2024).

Zhou, W. D. et al. Study on the characteristics of dust diffusion during a truck travelling in an open-pit coal mine affected by the vertical wind shear. J. Hazard. Mater. 483, 136611 (2025).

Liu, B., Liu, X. H., Wan, H. W., Ma, Y. & Lu, L. H. Long-term quantitative analysis of the temperature vegetation dryness index to assess mining impacts on surface soil moisture: a case study of an open-pit mine in arid and semiarid China. Appl. Sci. 15, 1850 (2025).

Deng, Y. Y. et al. Microscopic characteristics and sources of atmospheric dustfall in open-pit mining coal resource-based City in the arid desert area of Northwest China. Sci. Rep. 14, 6272 (2024).

Penchala, A. et al. Assessment of vertical transport of PM in a surface iron ore mine due to in-pit mining operations. Measurement 240, 115580 (2025).

Wu, T., Yang, Z., Wang, A. A. & Zhang, K. A study on movement characteristics and distribution law of dust particles in open-pit coal mine. Sci. Rep. 11, 14703 (2021).

Wang, Z. M., Zhou, W., Jiskani, I. M., Yan, J. L. & Luo, H. T. Optimizing open-pit coal mining operations: leveraging meteorological conditions for dust removal and diffusion. Int. J. Coal Sci. Technol. 11, 2095–8293 (2024).

Kung, H. C., Lin, W. C., Huang, B. W., Mutuku, J. K. & Chang-Chien, G. P. Techniques for suppressing mineral dust aerosol from Raw material stockpiles and open pit mines: a review. Aerosol Air Qual. Res. 24, 230166 (2024).

Zhang, J. S. et al. Study on the synergistic effect of surfactant composite on foam wetting and stabilization in the process of foam dust reduction. J. Environ. Chem. Eng. 13, 115674 (2025).

Niu, W. J. et al. Development and characterization of a high efficiency bio-based rhamnolipid compound dust suppressant for coal dust pollution control. Environ. Pollut. 330, 121792 (2023).

Taehee, L., Christopher, P. C., Bumjoon, K. & Minkyu, K. Environmentally friendly Methylcellulose blend binder for hydrophobic dust control. ACS Appl. Polym. Mater. 4, 1512–1522 (2022).

Zhang, S. H. et al. Preparation, characterization, and synergistic soil moisture retention effects of a by-product-based dust suppressant for fugitive dust suppression. Atmos. Pollut Res. 15, 102004 (2024).

Jin, H., Zhang, Y. S., Wu, G. A., Yang, J. J. & Li, N. Optimization via response surface methodology of the synthesis of a dust suppressant and its performance characterization for use in open cut coal mines. J. Environ. Sci. 121, 211–223 (2022).

Zhu, Y. Y. et al. Fabrication and characterization of a multi-functional and environmentally-friendly starch/organo-bentonite composite liquid dust suppressant. Powder Technol. 391, 532–543 (2021).

Parvej, S., Naik, D. L., Sajid, H. U., Kiran, R. & Huang, Y. Thanki, N. Fugitive dust suppression in unpaved roads: state of the Art research review. Sustain 13, 2399 (2021).

Dong, H., Yu, H. M., Xu, R. X., Cheng, Y. & Zhao, D. L. Research on application effect and mechanism of degradable multifunctional dust suppression foam in coal mine. J. Environ. Chem. Eng. 12, 112694 (2024).

Xu, R. X., Yu, H. M., Dong, H., Ye, Y. X. & Xie, S. Preparation and properties of modified starch-based low viscosity and high consolidation foam dust suppressant. J. Hazard. Mater. Lett. 452, 131238 (2023).

Yu, X. X. et al. Preparation and evaluation of humic acid-based composite dust suppressant for coal storage and transportation. Environ. Sci. Pollut R. 29, 17072–17086 (2022).

Zhou, G. et al. Wetting-consolidation type dust suppressant based on sugarcane Bagasse as an environmental material: preparation, characterization and dust suppression mechanism. J. Environ. Manage. 330, 117097 (2023).

Jin, H. et al. Preparation and performance characterization of a new dust suppressant with a cross-linked network structure for use in open-pit coal mines. Environ. Sci. Pollut R. 29, 7001–7013 (2022).

Li, S. L. et al. Synthesis and performance characteristics of a new ecofriendly crust-dust suppressant extracted from waste paper for surface mines. J. Clean. Prod. 258, 120620 (2020).

Xia, S. Y., Song, Z. L., Zhao, X. L., Ma, Z. M. & Li, J. Y. Study on Preparation and properties of antifreeze compound road dust suppressant. Sci. Rep. 14, 16642 (2024).

Chen, J. et al. Preparation and performance evaluation of an efficient microbial dust suppressant for dust control in disturbed areas of blast piles in open-pit coal mines. J. Environ. Manage. 373, 123684 (2025).

Zhao, X. L. et al. Ma Z. M. Research and industrial testing of truck road moisturizing dust suppressant for North Open-pit coal mine. J. Environ. Eng. Technol. 14, 446–454 (2024).

Zhao, X. L. et al. Research on Chlorine salt antifreeze road dust suppressants for open-pit coal mines. Atmos. Pollut Res. 15, 102161 (2024).

Liu, J. G. et al. Suppression characteristics and mechanism of molasses solution on coal dust: A low cost and environment friendly suppression method in coal mines. Int. J. Environ. Res. Public. Health. 19, 16472 (2022).

Zhou, G. et al. Environmental application of molasses-based foam dust suppressant: preparation, performance evaluation and mechanism analysis. Constr. Build. Mater. 458, 139541 (2025).

Wang, J. Q. et al. Effects of molasses-based microbial dust suppressant on soil dust and microbial community. Powder Technol. 441, 119831 (2024).

Wang, G. L., Zhou, W., Wang, Z. M., Lu, X. & Zhang, Y. R. Characterization and concentration prediction of dust pollution in open-pit coal mines. Atmosphere 15, 1408 (2024).

Wang, H., Wang, Z. M. & Wang, R. X. Characteristics of dust pollution and its influencing factors during cold period of open-pit coal mines in Northern China. Front. Earth Sci. 13, 1458847 (2025).

Zhang, W. Q. et al. Performance study on synergistic wetting of ionic liquid [C12MIm]Br and surfactant on high-rank coal dust. J. Mol. Liq. 413, 125801 (2025).

Hama, S. M., Manshad, A. K. & Ali, J. A. Review of the application of natural surfactants in enhanced oil recovery: state-of-the-art and perspectives. Energ. Fuel. 37, 10061–10086 (2023).

Wang, G. et al. Effect of glycerol microemulsion on coal seam wetting and moisturizing performance. J. Mol. Liq. 367, 120405 (2022).

Funding

This work was financially supported by the National Key Research and Development Program of China (Grant No. 2023YFF1306001).

Author information

Authors and Affiliations

Contributions

Y.Z: Data curation, validation, methodology. J.L.Y.: Investigation, writing-original draft, validation, supervision. W.Z.: Administration, methodology analysis, investigation, formal analysis, W.Q.Z.: Administration, methodology analysis, formal analysis, writing-original draft, writing-review, and editing. X.L.: Methodology analysis, investigation, formal analysis. P.Y.L.: Writing-original draft, writing-review, and editing writing-review. F.H.Y.: Investigation, writing-original draft. Z.F.W.: Investigation. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, Y., Yan, J., Zhou, W. et al. Optimization and field application of an eco-friendly molasses-based dust suppressant for open-pit coal mine haul roads. Sci Rep 15, 26039 (2025). https://doi.org/10.1038/s41598-025-11965-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-11965-0