Abstract

This study have taken Nanning Ronghe East Railway Station City Plaza as the engineering background, the O-cell method for static load testing of foundation piles were adopted to systematically carry out the effect of combination grouted in the strongly weathered mudstone stratum. A comparative experiment was conducted using two sets of six test piles to analyze the bearing capacity and internal force differences between grouted and ungrouted piles. The results show that the load-settlement curves of test piles were slow-variation type, with obvious mutation characteristics, which confirms that the pile-soil interaction exhibits the friction-type pile characteristics in the mudstone layer. In the mudstone layer, a very small relative pile-soil displacement could trigger a significant change in the lateral resistive force of the pile, and the greater the difference in the weathering strength of the mudstone, the more pronounced is the difference in the lateral resistive performance of the foundation pile. Under the same working conditions, significantly enhance the lateral resistance and end resistance of the pile, and then improve the stability of the pile foundation bearing performance. The bearing capacity of post-grouted piles was increased by 1.71, 1.75, and 1.72 times compared with the design values, and the ultimate lateral resistance of strongly weathered mudstone and strongly weathered sandstone was increased by 43.4% and 44.3% compared with the test values of ungrouted piles, respectively. The ultimate end resistance of post grouting for strongly weathered mudstone and strongly weathered sandstone was improved by 39.5% and 46.9% respectively compared with the surveyed values. This method can meet the design requirements under the condition of shortening the pile length, and the results can provide an important reference basis for similar projects in strongly weathered mudstone strata.

Similar content being viewed by others

Introduction

As the prevalence of super high-rise buildings continues to grow, so are the demands on foundation load-bearing capacity1,2. Bored piles represent the predominant foundation type employed in high-rise constructions. To meet the structural load-bearing demands of buildings, there has been a progressive augmentation in the dimensions of pile foundations during the design process. The large-scale pile foundation raises the complexity of the construction process for piles, which also increases economic costs, resource consumption, and carbon emissions. The alleviation of soil stress is a consequence of the construction procedure for bored piles, encompassing the disruption of the soil in the vicinity of the pile and the load-bearing stratum at the pile’s terminus, thereby affecting the exertion of pile lateral resistance3,4,5 and reduces pile end resistance6,7,8, resulting in a significant dispersion of the carrying ability of bored piles. Post-grouting9,10,11,12 is widely acknowledged as an effective method to address the aforementioned challenges and improve the load-bearing capacity of pile foundations.

End-bearing resistance originates from the interaction between the pile tip and the underlying bearing stratum. In contrast, side friction resistance arises from the frictional forces between the pile shaft and the surrounding soil. Post-grouting13,14,15 is a sophisticated technique aimed at bolstering the piles’ load-bearing capabilities, encompassing several techniques such as end post-grouting, side post-grouting, and a combination of both. This method is designed to ameliorate the soil’s stress distribution and address issues like the formation of a mud skin on the pile’s surface and the presence of slag at the pile’s tip. This is achieved by the post-construction injection of a grout into the pile’s end or along its side. Following post-grouting, there is a marked increase in the soil’s strength and rigidity adjacent to the pile, which in turn amplifies the skin friction and end-bearing resistance, consequently elevating the pile’s overall load-bearing capacity.

For the last 60 years, post-grouting has been used in field tests, and research has shown that compared to traditional bored piles after grouting, bored piles’ bearing capacity has greatly increased, which can effectively control pile settlement. Bruce16 succinctly encapsulated the post-grouting process and testing procedures, drawing from field tests conducted on large-diameter piles. Ghazali17 pioneered the use of large-diameter post-grouting piles in soil layers composed of coral calcareous material; they provided static load test results of post-grouting piles, indicating the applicability of post-grouting in coral calcareous strata. Robson and Wahby18 presented the side and tip grouting tests conducted on bored piles in the sandy soil area of Egypt, which showed that the pile side resistance exhibited a 2–3 fold increase in comparison to ungrouted piles. Byrne19 conducted post-grouting experiments in South Africa on sandy soil layers, yielding results that indicated a twofold increase in the side resistance following pile side grouting. Wang20 conducted post-grouting experiments on four bored piles situated within pebble-bearing layers. The outcome was an enhancement in the load-carrying ability of the pile foundation and a reduction in pile settlement. Zhang21,22 conducted grouting tests on 361 bored piles and obtained the relationship between grouting parameters for the pebble layer foundation with cohesive soil as the bearing layer. Wan23,24,25 led a significant number of post-grouting tests on calcareous sand and clay areas. Empirical evidence has established that the incorporation of post-grouting into the construction process can lead to a reduction in both pile diameter and length, resulting in decreased consumption of concrete and steel. This practice aligns with the principles of sustainable development, environmental conservation, and resource conservation.

Pile post-grouting26,27,28,29 has been successfully applied in a variety of formations. However, their application in weathered mudstone formations has been rarely reported. Weathered mudstone is a strongly weathered rock containing sensitive clay minerals whose physical properties are strongly influenced by changes in environmental humidity. In natural conditions, weathered mudstone is often hard-plastic and usually exists in large blocks. However, after encountering water, weathered mudstone tends to depolymerize and at the same time, has a certain degree of expansion and contraction. Given the clear practical benefits of post-grouting for enhancing the load-bearing performance of pile foundations, it is crucial to conduct a more in-depth analysis of the impact of post-grouting on the load-bearing capacity of pile foundations in weathered mudstone strata. Conducting such research holds substantial significance in addressing the issue of pile foundation softening within weathered mudstone formations when encountering water, as well as harnessing its advantages in practical engineering projects. In this test, the O-cell30,31,32 method is utilized to evaluate the load-bearing capacity of a pile foundation within the strongly weathered mudstone strata in Nanning, in conjunction with the Nanning Ronghe East Station test pile project. To delve deeper into the effects of post-grouting on the load-bearing capacity for individual piles, the force and displacement for each pile will be measured. The analysis focused on the load transfer properties of both positive and negative frictional resistance of the pile body, as well as the bearing features of the pile’s end and sides within the mudstone layer. These findings offer significant insights for the design and theoretical assessment of pile foundations in weathered mudstone strata.

Test overview

Site geology and test pile overview

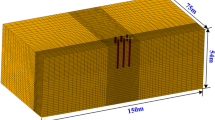

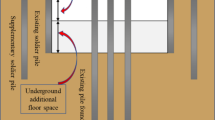

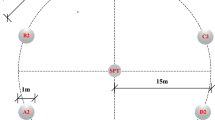

The test site was situated at Nanning East Railway Station in Nanning, Guangxi, China. The foundation design adopts large-diameter bored piles. The arrangement of the test piles is depicted in Fig. 1. As shown in Fig. 2, the soil strata along the pile from top to bottom are fill soil, fine sand, strongly weathered mudstone, and moderately weathered mudstone. The initial design of the pile was more than 60 m long and embedded in the moderately weathered mudstone strata, making it extremely difficult to construct. In order to enhance the carrying capacity of pile foundations, this study adopts post-grouting for pile foundations, optimizes the design of pile depth, and reduces overall project costs.

The soil properties are reported in Table 1, where ρ is the gravity, c is the cohesion, φ is the internal friction angle, qak is foundation bearing characteristic performance value, qsik is pile side resistance characteristic value, qpk is pile tip resistance characteristic value.

To provide an invaluable resource for the design, 6 test piles were selected from the same site for testing in this test. The piles underwent integrated tip and side grouting, with C45-grade concrete used for the test piles. Table 2 presents the details of the test piles.

The piles were subjected to side grouting, complemented by the use of three seamless steel tubes with a 3 mm wall thickness and a 50 mm diameter. These tubes are evenly positioned along the interface between the pile and the soil, outside the reinforcement cage, serving as conduits for both the side and tip grouting, and they are bound and fixed with the reinforcement bars of the reinforcement cage. Elastic grout injection pipes were installed at a depth of 8 m below the pile top and at every 6m interval below that. Two 60 mm diameter seamless steel pipes acoustic transmission pipes also serve as pile tip grouting pipes, and the slurry outlet adopts a one-way shut-off valve. The grout injection valves used in the post-grouting pipes are capable of withstanding static water pressure of 1MPa or more. The slurry’s water-cement ratio was 0.5, and pile tip grouting stops at 4MPa pressure. The water-cement ratio of the grout was 0.5, and grouting at the pile tip ceases when the pressure reaches 4 MPa. Grouting begins 5 h after pile completion, with both the grout volume and applied pressure conforming to the design specifications. The test pile grouting parameters are shown in Table 3.

Static load test

In this test, the O-Cell method33,34 was utilized in performing the pile load test, which was executed using the sustained low-rate loading approach. The loading procedure was executed in compliance with the “technical specification for static loading test of self-balanced method of building foundation piles35”. As shown in Figs. 3 and 4, the O-cell was embedded within the pile body, and bi-directional loading was conducted through the O-cell. The load from the pile’s upper portion and the frictional resistance work together to counterbalance the frictional resistance of the pile’s lower section as well as the end-bearing resistance at the pile’s tip, thus maintaining a state of equilibrium. Concurrently, the load-bearing ability of the pile’s upper and lower portions were assessed, facilitating an accurate determination of the total pile’s capacity to support weight.

Figure 5 illustrates the position of the soil layer that corresponds to the test pile, as well as the placement of the O-cell and strain gauges during installation. The locations of stress gauges was determined based on the test pile’s geotechnical properties and the load distribution principles along the pile shaft. Considering the aforementioned factors, strain gauges were positioned at the boundary locations among soil layers along the test pile. Additionally, an appropriate number of stress gauges were placed at a certain distance within each soil layer to accurately reflect the axial stress conditions at different depths within each soil layer and near the soil layer interfaces. To ensure the accuracy of the test outcomes, three stress gauge measurement points were evenly distributed throughout each measurement section. Within 1 m above and below the O-cell’s top and bottom plates, additional reinforcement was provided outside the steel cage. The O-cell was fitted with two displacement sensors to measure the movement of its upper and lower plates.

Test results

Results of O-cell test

The test results are presented in Fig. 6 and summarized in Table 4. Figure 6 demonstrates that the load–displacement curves for both sets of test piles exhibit a gradual change type accompanied by distinct features of sudden shifts. This aligns with the deformation properties of friction piles in soft soil layers in mudstone areas, and compared to ungrouted piles, grouted piles have much superior bearing performance. At higher loads, the growth of displacement in the lower section of ungrouted piles is significantly larger than that of post-grouted piles. The load–displacement relationship for the ungrouted pile adheres to a non-linear style, and the distinction between the two pile types becomes increasingly apparent through the pattern of change in their load–displacement curves. Upon reaching the ultimate load, the ultimate displacement value for the ungrouted pile significantly exceeds that of the grouted pile. At an equivalent displacement level, the grouted pile demonstrates a substantially higher load capacity compared to the ungrouted pile. This can be attributed to the pile’s change in load transfer characteristics due to the combined grouting. Although the grouted pile may be shorter than its ungrouted counterpart, the post-grouting process has led to a significant alteration in its load-bearing properties. Consequently, the grouted pile experiences a reduced rate of displacement relative to the ungrouted pile.

Equivalent load–displacement curve of pile top

The O-cell gathers load–displacement data, which can be transformed through mathematical calculations into pile-top load–displacement curves. This process is guided by Eqs. (1), (2), (3) in the Chinese standards “Technical specification for static loading test of self-balanced method of building foundation piles”35. Based on the “Technical Code for Building Pile Foundations36”, the performance of the test piles, as shown in Fig. 7 and Table 4, was compared to the design-bearing performance QD.

where Q is the equivalent pile top load, s is the equal pile top displacement, Qu is the upper section pile ultimate bearing capacity, Qd is the lower section pile ultimate bearing capacity, ∆s is the pile compression volume, Lu is the length of upper section pile, Ep is the modulus of elasticity of pile, Ap is pile cross-sectional area, \(\gamma\) is equivalent conversion coefficient.

Figure 7 indicates that the equivalent load–displacement curves for all test piles display notable points of inflection. The slope of the equivalent conversion Q-s curve for the ungrouted pile changes little, and characterized by linear steep deformation, while the slope of the equivalent conversion Q-s curve of the grouted pile increases significantly with increasing equivalent load. In the early loading stage, the vertical load is mainly borne by the lateral friction force of the pile, and the top load not yet transferred to the pile end. As the load increases, the bearing performance of the two types of test piles differed significantly, and the top displacement of ungrouted piles under the same conditions was significantly larger than that of grouted piles and grew faster. Zhang37 suggested that the pre-damage load value could be used as the bearing’s ultimate performance. Table 5 displays the definitive load-bearing capacity for the test pile. The pile’s load-carrying capacity load post-grouting conforms to the prescribed design specifications. The calculations reveal that the compression of the ungrouted piles TS1, TS2, and TS3 constitutes 30.39%, 26.65%, and 28.02%, respectively, of the overall displacement at the pile top. In contrast, the compression of the grouted piles TS4, TS5, and TS6 represents 38.39%, 36.46%, and 29.89%, respectively, of the total displacement at the pile top. These findings indicate that the carrying ability of grouted piles exceeds that of ungrouted piles, emphasizing the superior effectiveness of post-grouting in enhancing the lateral resistance of the piles. At the maximum load capacity, the carrying ability of test piles TS1 ~ TS6 has improved by 1.23, 1.16, 1.01, 1.71, 1.75, and 1.72 compared to the design bearing performance. The test findings demonstrate that combined grouting greatly enhances overall ultimate bearing performance and that the top pile settlement can be effectively controlled.

The load transfer characteristics of piles

Axial force distribution

According to the obtained measured frequency of the steel stress gauges under various levels of loading, combined with its calibration curve, the strain value of the steel stress gauges can be obtained. In adherence to the principle of synchronized deformation between steel bars and concrete, the axial force38,39 F can be ascertained as follows:

where \(\varepsilon_{1i}\), \(\varepsilon_{2i}\), \(\varepsilon_{3i}\) are the strain values of the three reinforcement bars in section i; Es is the modulus of elasticity of the reinforcement bars (kPa), Ec is the modulus of elasticity of the concrete (kPa), As is the cross-sectional area of the reinforcement bars (m2), and Ac is the cross-sectional area of the concrete (m2).

Figure 8 illustrates that the distribution of axial forces along test piles TS1 through TS6 can be determined using static load testing and computations. The axial force distribution diagram within the pile, obtained using the O-cell method, shows a gradual decrease towards both ends of the pile, with the O-cell serving as the distinguishing point. In comparison, the axial force distribution curve from conventional static load tests shows a trapezoidal pattern along the pile, with force diminishing from the top to the tip. The figure demonstrates that the test pile’s axial force curves follow a uniform trend. When contrasted with the pile section that is farther from the O-cell, the gradient of the axial force curve near the O-cell is significantly less steep, and there is a considerable amount of relative displacement within the soil layer. The axial force and lateral resistance of the pile are first applied at the loading point, with the upper and lower sections bearing more force due to their closeness to the loading point. This force diminishes progressively as one moves toward either end of the pile. In contrast to the ungrouted pile, the grouted pile displays a slightly gentler slope in its curve, indicating that it possesses enhanced side resistance. Additionally, it illustrates how pressure grouting enhances the mechanical and physical properties of the soil surrounding the pile and the boundary where the pile meets the soil, thereby improving the ability of the grouted and reinforced soil layer to bear loads.

The side resistance of piles

In accordance with Gong’s calculation method40, Fig. 9 presents the calculation result of the side resistance distribution in each soil layer of the pile. The lateral friction resistance curves of the pile show significant scatter. Notably, the curves corresponding to the strongly and moderately weathered mudstone layers near the loading point exhibit greater variability. This indicates a more pronounced reduction in the pile’s lateral friction resistance within these soil layers. The lateral friction resistance curves in the upper soil layers cluster closely, showing little force reduction. In soil layers of different strengths, the interaction between pile segments and the rock layer varies significantly. Specifically, in weaker soil layers, the interaction between the upper pile segment and the rock layer is much less than that in the lower pile segment. As the strength of the mudstone increases, this difference diminishes gradually. Moreover, during the initial phase of loading, the upward movement of the pile is approximately 0.2 mm, yet there is a pronounced lateral frictional resistance in both the upper and lower soil layers adjacent to the pile’s end. This suggests that even a slight relative displacement or tendency between the pile and soil is enough to initiate the gradual development of lateral friction resistance in the soil layer at the loading site.

Under lower load conditions, the load is primarily supported by the lateral resistance of the soil layer adjacent to the O-cell. As the load increases, the lateral resistance of the soil layer in the lower part of the O-cell also shows a gradual upward trend. The lateral resistance of the soil layer in the lower half of the O-cell develops gradually as the load increases. When the load approaches the ultimate bearing performance, the increase in side resistance of strongly weathered mudstone and strongly weathered sandstone decreases, indicating that the side resistance of these soil layers has been fully utilized. In contrast, the side resistance of moderately weathered mudstone still has the potential to continue to increase. The pile tip resistance of TS2 starts to develop when the load exceeds 2 × 4560kN, and it increases significantly when loaded to 2 × 12160kN. At a load of 2 × 12920kN, the pile tip resistance reaches 4807 kPa. However, as more load is applied, the resistance at the sides and tip of the pile noticeably decreases, signifying that the pile’s carrying capacity has reached its maximum potential. When TS5 is loaded near the ultimate bearing performance of 2 × 9100kN, the increase in side resistance of strongly weathered mudstone and strongly weathered sandstone decreases, indicating that the side resistance of this soil layer has been more fully utilized. In contrast to ungrouted piles, the final stage of loading for grouted piles exhibits a less pronounced reduction in both side and tip resistance relative to the maximum load. Subsequent to post-grouting, under identical conditions, it can enhance the frictional resistance of the piles, leading to a marked enhancement in the stability of their load-bearing capabilities.

Pile tip resistance-displacement

The pile tip resistance is determined by subtracting the lower section’s lateral friction from the lower O-cell’s downward load. Likewise, the pile tip displacement is calculated by deducting the lower pile body’s compression from the lower O-cell’s downward displacement. Figure 10 presents the pile tip resistance-displacement curves for each test pile.

Figure 10 illustrates that the change in resistance at the pile’s tip relative to tip displacement is roughly consistent across all test piles. Pressure grouting serves as an exceedingly effective method for strengthening the soil and surrounding sediments at the pile’s tip, thereby enhancing the soil layer’s rigidity and load-bearing capacity at the base of the pile. This leads to an enhanced initial rigidity of the soil layer surrounding the pile tip in grouted piles compared to those that are ungrouted. Consequently, the grouted pile exhibits superior tip resistance in comparison with the ungrouted pile. The stability of the tip resistance in grouted piles, due to the pressure grouting, is greater than that found in ungrouted piles. This shows that post-grouting is efficacious in mitigating the influence of external factors, such as construction activities, diminishing pile tip displacement, and enhancing pile end load-bearing performance. The ultimate tip resistance of ungrouted piles TS1-TS3 accounts for 17.9%, 19.7%, and 17.1% of the ultimate bearing performance, respectively, while the ultimate tip resistance of grouted piles TS4-TS6 accounts for 13.2%, 13.1%, and 13.4% of the ultimate bearing performance, respectively. This suggests that the combined grouting process does not change the characteristics of the test pile’s end-bearing friction pile.

Frictional resistance-displacement of the pile-soil interface

In view of the significant influence of combined grouting on the soil body on the pile side, this paper carries out statistical analysis on the measured data of pile side friction resistance and pile-soil relative displacement, and compares the relevant data before and after the combination of grouting, in order to investigate the influence of combined grouting on the force characteristics of the pile side of the drilled pile in the strongly weathered mudstone stratum. Among them, the pile-side mechanical resistance is indirectly obtained by the steel bar stress gauges at different locations of the pile body, and the relative displacement can be obtained by the method of the paper38,39.

In this study, a comparative analysis was conducted on the common soil layers in the upper half of the O-cell for each test pile. Figure 11 displays the findings that suggest a strong correlation between the progression of lateral frictional resistance and the relative movement between the pile and the soil. As the relative displacement increases, the lateral frictional resistance transitions from a linear to a nonlinear pattern. In the case without grouting treatment, the required displacement for each soil layer to fully develop its lateral frictional resistance is 10 mm, and at this displacement, it enters the plastic phase. After grouting treatment, the plain fill and fine sand layer can fully exert lateral resistance with only a displacement of 5 mm, and the lateral resistance can be maintained stably without significant decay as the displacement continues to increase. For the strongly weathered mudstone and sandstone after grouting, the lateral resistance is fully developed at a displacement of 5–10 mm, and the lateral frictional resistance shows a slight trend of decay as the displacement further increases. This observation indicates that the post-grouting can substantially enhance the soil layer’s capacity for lateral frictional resistance and diminish the required of relative displacement between the pile and the soil needed to attain the peak lateral frictional resistance.

As shown in Tables 6 and 7, the test results of ungrouted piles demonstrate that the ultimate side resistance of plain fill and fine sand matches the survey values. The ultimate side resistance of strongly weathered mudstone, strongly weathered sandstone, and moderately weathered sandy mudstone has increased by 17.8%, 30.5%, and 22%, respectively, compared with the surveyed values. The test pile results of grouted piles show that the ultimate side resistance of plain fill, fine sand, strongly weathered mudstone, and strongly weathered sandstone increased by 84.2%, 104%, 69.1%, and 88.4%, respectively, compared with the surveyed values. Among these, the ultimate side resistance of strongly weathered mudstone and strongly weathered sandstone increased by 43.4% and 44.3%, respectively, compared with the test values of ungrouted piles. Compared with the 55.52% increase in lateral resistance in extra-thick fine sand layer26, the 21.5% increase in lateral resistance in coral reef tuff layer38, and the 77% increase in lateral resistance in loess area41, post-grouting in strongly weathered mudstone strata also achieves better results. According to the calculations, the ultimate tip resistance of post-grouting for strongly weathered mudstone and strongly weathered sandstone are 2093.2 kPa and 2131.4 kPa, respectively, which are 39.5% and 46.9% higher than the surveyed values. Tables 5 and 6 show that the strength of each soil layer was significantly improved after post-grouting reinforcement, which is of great significance to the healthy and sustainable development of the pile foundation projects.

Conclusions

In this study, a field test involving large-diameter, extra-long drilled piles was conducted within the highly weathered mudstone strata of the Nanning region. The objective was to investigate the impact of combined grouting on pile-bearing performance, resulting in the following conclusions:

-

(1)

The O-cell method test of six piles in mudstone area was conducted. The results show that the front section of the load–displacement curve of each test pile changes slowly and smoothly. With the increase of load, the curve shows mutation characteristics, which indicates that the pile is characterized by friction pile. This reflects that in a strongly weathered mudstone stratum, the bearing behavior of the pile is mainly dominated by the pile side friction resistance, and the interaction between the pile body and the surrounding rock and soil mass has obvious stages.

-

(2)

The lower the mudstone strength, the more significant the difference between the upper section pile body and rock layer action force and the lower section pile action situation is, and this difference gradually decreases with the increase of mudstone strength. The weathering strength of mudstone has a significant effect on the bearing performance of foundation piles, and the larger the difference in weathering strength is, the larger the difference in bearing performance of foundation piles is, indicating that the non-homogeneity of mudstone stratum has an important effect on the bearing performance of piles.

-

(3)

Combined grouting effectively improves the boundary conditions between the pile body and soil body, and increases the strength and stiffness of the soil body around the pile. The bearing capacity of post grouted piles was increased by 171%, 175% and 172% respectively compared with the design value, and the bearing capacity performance was more stable; in the hard layer such as mudstone, post grouting treatment, the pile side resistance and pile end resistance were increased by more than 40%, which proved the significant effect of the combined post grouting technology in enhancing the bearing capacity of the piles.

-

(4)

By combining grouting technology, the pile length was reduced from more than 50 m to more than 30 m under the premise of meeting the design requirements, avoiding the pile embedded in the harder medium-weathering mudstone stratum. This approach not only reduces the economic cost and protects the environment, but also shows great advantages in energy saving and emission reduction as well as sustainable development of high-rise buildings, which is an important reference value and promotion significance for similar projects.

Data availability

The datasets used and/or analyzed during this study are available from the corresponding author upon request.

References

Chen Y et al. Experimental and analytical study on the bearing capacity of caisson foundation subjected to V-H combined load. Marine Georesources & Geotechnology. 1–13 (2025).

Sun G et al. Bearing capacity of large-diameter pile foundation under combined VHM loadings in soft clay. Ships and Offshore Structures.1–15 (2024).

Chen, Y.-J., Lin, W.-Y., Topacio, A. & Phoon, K.-K. Evaluation of interpretation criteria for drilled shafts with tip post-grouting. Soils and Foundations. 5, 1354-1369 (2021).

Gong, Z., Dai, G., Xu, W., Chen, X. & Liu, H. Field and 3D numerical investigation on bearing characteristics of the long-core SDCM piles under vertical load in sandy soil. Acta Geotechnica. 20, 1341-1362 (2025).

Zhang, Z. M., Yu, J., Zhang, G. X. & Zhou, X. M. Test study on the characteristics of mudcakes and in situ soils around bored piles. Can. Geotech. J. 46, 241–255 (2009).

Dapp SD, Mullins G. Pressure Grouting Drilled Shaft Tips: Full-Scale Research Investigation for Silty and Shelly Sands. American Society of Civil Engineers, 335-350. (2002)

Mullins, G., Dapp, S. D. & Lai, P. Pressure-Grouting Drilled Shaft Tips in Sand (ASCE, 2000).

Zhang, J., Zhao, C. & Wu, Y. Experimental Study on Post-Grouting Pile Vertical Bearing Performance Considering Different Grouting Methods and Parameters in Cohesive Soil. Appl Sci-Basel. 13, 12175(2023).

Mullins, G., Winters, D. & Dapp, S. Predicting end bearing capacity of post-grouted drilled shaft in cohesionless soils. J. Geotech. Geoenviron. Eng. 132, 478–487 (2006).

Youn, H. & Tonon, F. Numerical analysis on post-grouted drilled shafts: A case study at the Brazo River Bridge, TX. Comput. Geotech. 37, 456–465 (2010).

Thiyyakkandi, S., McVay, M., Bloomquist, D. & Lai, P. Measured and predicted response of a new jetted and grouted precast pile with membranes in cohesionless soils. J. Geotech. Geoenviron. Eng. 139, 1334–1345 (2013).

Thiyyakkandi, S., McVay, M., Bloomquist, D. & Lai, P. Experimental study, numerical modeling of and axial prediction approach to base grouted drilled shafts in cohesionless soils. Acta Geotech. 9, 439–454 (2014).

Karimi, A. H., Eslami, A., Zarrabi, M. & Khazaei, J. Study of pile behavior by improvement of confining soils using frustum confining vessel. Sci. Iran. 24, 1874–1882 (2017).

Khazaei, J. & Eslami, A. Postgrouted helical piles behavior through physical modeling by FCV. Mar. Georesour. Geotechnol. 35, 528–537 (2017).

Useche-Infante, D. J., Aiassa-Martinez, G. M., Arrua, P. A. & Eberhardt, M. Performance evaluation of post-grouted drilled shafts: a review. Innov. Infrastruct. Sol. 7, 230 (2022).

Bruce, D. A. Enhancing the performance of large diameter piles by grouting. Int. J. Rock Mech. Min. Sci. Geomech. Abst. 23, 240 (1986).

Ghazali, F. M., Sotiropoulos, E. & Mansour, O. A. Large-diameter bored and grouted piles in marine sediments of the Red. Can. Geotech. J. 25, 826–831 (1988).

Robson J, Wahby A. Base and shaft grouted bored pile foundations for the first residential complex. Proceedings International Conference on Piling and Deep Foundations, Rotterdam. (1994).

Byrne G, Strydom J, Du P. The performance of piled foundations supporting a large hotel on estuarine deposits in Durban. 7th International Conference and Exhibition on Piling and Deep Foundations, Vienna. (1999).

Wang, X., Zhao, S. & Ding, X. Study on behavior of bored piles with grouted-base on gravel stratum. Chin. J. Rock Mech. Eng. 22, 2903–2907 (2003).

Zhang, Z. M., Wang, H. Q. & Zou, J. In-situ test and analysis of pile end post grouting in gravel strata with cohesive soils. Chin. J. Geotech. Eng. 32(02), 308–314 (2010).

Zhang, Q. Q. & Zhang, Z. M. Complete load transfer behavior of base-grouted bored piles. J. Cent. South Univ. 19(007), 2037–2046 (2012).

Wan, Z. H., Dai, G. L. & Gong, W. M. Field study on post-grouting effects of cast-in-place bored piles in extra-thick fine sand layers. Acta Geotech. 14(5), 1357–1377 (2019).

Wan, Z. H. et al. Study on the response of postside-grouted piles subjected to lateral loading in calcareous sand. Acta Geotech. 17(7), 1–17 (2021).

Wan, Z. H. et al. Axial bearing mechanism of post-grouted piles in calcareous sand. Appl. Sci. 12(5), 2731–2731 (2022).

Wan, Z. H., Dai, G. L. & Gong, W. M. Field and theoretical analysis of response of axially loaded grouted drilled shafts in extra-thick fine sand. Can. Geotech. J. 57(3), 391–407 (2020).

Zhao, C. F., Wu, Y., Zhao, C. & Wang, Y. Load-displacement relationship of single piles in clay considering different tip grouting volumes and grouting returned heights. Int. J. Geomech. 20(2), 04019158–04019158 (2020).

Wang, S. Y., Chan, D. H., Lam, K. C. & Au, S. K. A. Numerical and experimental studies of pressure-controlled cavity expansion in completely decomposed granite soils of Hong Kong. Comput. Geotech. 37, 977–990 (2010).

Wang, T. et al. Investigation of the seismic behavior of grouted sandy gravel foundations using shaking table tests. Front. Struct. Civil Eng. 16(9), 1196–1211 (2022).

Osterberg, J. New device for load testing driven piles and dilld shaft separates friction and end bearing. Piling Deep Found. 1, 421–427 (1989).

Xing, H., Wu, J. & Luo, Y. Field tests of large-diameter rock-socketed bored piles based on the self-balanced method and their resulting load bearing characteristics. Eur. J. Environ. Civ. Eng. 23(12), 1535–1549 (2019).

Ou, X. et al. Research on analytical conversion method of self-balanced test pile results. Eur. J. Environ. Civ. Eng. 26, 7209–7225 (2021).

Wang, W. et al. Effect of base grouting on the bearing capacity of bored piles. Sustainability 15(5), 4148–4148 (2023).

Tao, H. et al. Field study on the side resistance-softening and resistance-reinforcing effects of large-diameter combined grouting drilled shafts. Sustainability 14(11), 6835–6835 (2022).

Technical specification for static loading test of self-balanced method of building foundation piles. China Architecture & Building Press, Beijing, JGJ/T 403. (2017).

Technical Code for Building Pile Foundations. China Architecture & Building Press, Beijing, JGJ 94. (2008).

Zhang, Q. Q., Li, S. C. & Li, L. P. Field study on the behavior of destructive and non-destructive piles under compression. Mar. Georesour. Geotechnol. 32, 18–37 (2014).

Wan, Z., Dai, G. & Gong, W. Full-scale load testing of two large-diameter drilled shafts in coral-reef limestone formations. Bull. Eng. Geol. Environ. 77(3), 1127–1143 (2018).

Hou, Z. et al. Experimental study of the bearing characteristics of a novel energy-saving and environmentally friendly pile: drilling with prestressed concrete pipe cased piles. International Journal of Geomechanics. 24, 4 (2024).

Gong, W. et al. Full-scale field test study of bearing characteristics of post-grouting pile for offshore wind turbines. Ocean Eng. 268, 113451 (2023).

Zhou, Z. et al. Experimental study of the influence of different hole-forming methods on the bearing characteristics of post-grouting pile in Loess areas. Transp. Geotech. 27, 100423 (2020).

Acknowledgements

The authors convey their gratitude to the reviewers for the insightful comments and helpful suggestions that have contributed to the improvement of this manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 52468045), Nanning City Innovation and Entrepreneurship Leading Talents Yongjiang Plan Project (2023016).

Author information

Authors and Affiliations

Contributions

Xiaoduo Ou: Writing. Runhui Sang: Writing-review. Jie Jiang: Supervision. Yipeng Feng: Conceptualization, review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ou, X., Sang, R., Jiang, J. et al. Field study of bearing performance of combined grouted piles in strongly weathered mudstone strata with bored piles. Sci Rep 15, 26292 (2025). https://doi.org/10.1038/s41598-025-12155-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-12155-8