Abstract

The surface wear characteristics of the armature passing through the rail are crucial as they relate to the quality of electromagnetic launch and the lifespan of the device. Charging voltage and initial surface roughness are significant factors influencing wear behavior. It is urgent to clarify the evolution of armature wear patterns and fundamentally suppressing material damage. Therefore, in this paper, an electromagnetic railgun experimental platform was established. LSCM measurement, SEM and EDS detection were performed on the surface of the post-launch armature, and the wear mechanism was analyzed in conjunction with the thermal effects and changes in contact resistance. The results show that as the charging voltage increases, the armature transitions from abrasive wear to oxidative wear and fatigue wear. For this work, the optimal charging voltage is 2100 V, with a wear rate of 0.38% and wear roughness of 8.46 μm. As the initial surface roughness decreases, abrasive wear, oxidative wear, and adhesive wear occur sequentially. The optimal initial roughness range is 0.55–1.05 μm, with a wear rate of 0.21–0.25% and wear roughness of 7.91–8.31 μm. During this process, both Joule heat and frictional heat continuously increase, with the former increasing more rapidly. There is an initial relatively large value of contact resistance, which fluctuates smoothly, and experiences a sharp increase when the armature exits the barrel, indicating the armature wear caused by the action of transition arc. Finally, a numerical model for armature wear is proposed, along with optimization directions for armature design.

Similar content being viewed by others

Introduction

Electromagnetic launchers drive the load using a strong magnetic field1, achieving high-speed propulsion without the need for conventional fuels2. This offers advantages of environmental friendliness, high initial velocity, and long range3,4, making it promising for applications in satellite launch5, high-speed trains6, space station cleanup7 and more. An inevitable challenge is that the armature is prone to wear when sliding relative to the fastened rail8and the wear state directly affects the electrical contact quality between the armature and rail. Contact failure may lead to transition erosion, severely impacting the service life of the device9. Additionally, wear also weakens the mechanical performance of the armature itself, compromising launch safety10. Charging voltage and initial surface roughness are significant factors influencing wear behavior11. To fundamentally suppress armature wear failure and extend the service life of the device, this paper investigates the wear characteristics of the armature under different launching conditions and proposes optimization directions for armature design.

The actual contact surface between the armature and rail is composed of multiple tiny conductive spots, with the effective contact area being only about 1% of the nominal contact area12. Friction experiments show that both the contact area and wear diameter increase with the current, which is controlled by the charging voltage of pulse source13,14. Another key factor affecting contact quality is surface roughness15,16. Textured surfaces have gained general interest due to their favorable tribological properties, such as altering the contact area and enhancing lubrication or blocking effects17. Different initial roughness magnitudes of armature surface were set in the simulation. These were found to be closely related to the material melting rate and thickness18; However, no experimental verification was conducted. Since the experiment was conducted in a confined rail, it is difficult to measure the wear process in real-time online. Currently, research on armature wear mechanism mainly relies on post-launch morphology observation and modeling analysis19. The Archard wear model suggests that defects such as gouging holes on the armature surface trigger melting and loss of material20,21,22, and aluminum debris deposition can be clearly observed on the steel rail. Measurements show that the thickness of aluminum deposition layer is approximately 3–10 µm23, and the maximum erosion depth occurs at the top and bottom edges of armature surface24. However, no specific depth of wear was provided, and the photographs of armature were limited to a simple qualitative assessment25,26. The main heat sources during the armature launching process are Joule heating and frictional heating27. The three-dimensional characteristics of Joule heating for armatures with different shapes were analyzed28, as well as the destructive patterns of dry friction heating on the armature-rail contact surface29. Two heat sources were considered to simulate the internal ballistic dynamic process of armature wear30, but specific wear mass was not obtained. At the same time, these models remain at the theoretical level of thermal field analysis and have not been linked to the actual wear characteristics of the armature.

Given the insufficient experimental study under different launch conditions, a series of experiments with varying charging voltages and initial surface roughness were carried out in this work. To address the limitation in current research, where armature wear morphology is only qualitatively described, a curve-based quantitative characterization of the armature surface contour undulation was performed using image processing algorithm and precision instrumentation. This allowed for a precise determination of the wear state. Finally, combining microstructure and thermal effects analysis, the dynamic evolution process of the armature wear pattern was proposed.

This paper is structured as follows: The Methods section introduces the experimental platform and testing techniques, and the operation procedure of electromagnetic launch experiment is described. The Results section quantitatively analyses the wear characteristics of armature surface using mass weighing and LSCM contour measurement. The dynamic wear behavior of armature under different launch conditions is analyzed by SEM micro-scanning with EDS composition detection. In particular, the evolution of armature wear pattern is revealed. The Discussion section establishes a cross-scale correlation between the armature thermal effects, variation in contact resistance and wear pattern through calculations of current, Lorentz force, frictional heat, and Joule heat. A numerical model for armature wear is derived, and a basic scheme for guiding the design of device is proposed. The last part concludes this work.

Experimental apparatus and procedures

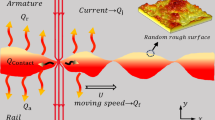

The electromagnetic rail launch system operates under short-duration pulse discharge conditions. To achieve the required current amplitude and energy intensity for firing, the widely used energy drive device is the capacitive energy storage pulse power supply31. To reduce the parasitic mass of the launch components and improve the effective payload ratio, the inner bore of launcher should be designed to be approximately square rather than circular32. Based on this, a set of electromagnetic rail launch experimental platform is built, with its circuit diagram, physical photo and the armature dimension shown in Fig. 1.

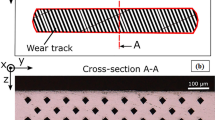

The experimental platform in Fig. 1 consists mainly of a charging unit, a launcher, and detection equipments. In the charging unit, a charger with a capacity of 10 kVA is connected to a boost transformer, which is rectified by a silicon stack, D1, to charge the pulse power module. The maximum charging voltage is up to 100 kV, with a charging current of 100 mA. The power supply module uses two sets of 4 mF/5 kV capacitors to generate a pulsed high current, which is discharged to the launcher through a large-capacity semiconductor switch component, T. Switch T is connected in a internal type33 to reduce the risk of thyristor breakdown, and is equipped with the necessary dynamic pulse absorption circuit and pulse triggering circuit. A wave-modulating inductor, L, is used to adjust the pulse width and peak value of the output from capacitors, in order to broaden the waveform and mitigate high current surges. After discharging, energy is dissipated through the freewheeling diode D2. The launcher is designed with a rectangular aperture of 15 mm×20 mm. The rails are made of two parallel pieces of 1200 mm×23 mm×2 mm 45 medium carbon structural steel, and the inner bore is kept stable by polytetrafluoroethylene (PTFE) insulating support and pre-tightened bolts. The armature is made of 6063-T6 aluminum alloy, weighing approximately 15.667 g. It adopts a typical C-type solid structure, with specific dimensions as shown in Fig. 1(c).

Before the formal experiment, a no-load test was conducted to check whether the circuit connection was functioning properly and ensure that the capacitor could be effectively charged. The charging voltage was measured by a voltage divider (with a division ratio of 1000:1) and its accompanying digital meter. After experiment, a KathMatic Laser Spectrum Confocal Microscope (LSCM) was used for three-dimensional contour measurement to obtain data such as armature wear height and roughness. The micro-morphology of armature surface was examined using a Carl Zeiss GeminiSEM 300 schottky field emission Scanning Electron Microscope (SEM), and its micro-area composition was analyzed using the matching Energy Dispersive Spectrometer (EDS).

Result

Surface wear characteristics of the armature

To investigate the effects of charging voltage and initial roughness on armature wear performance, two sets of experiments were carried out by controlling a single variable:

-

a)

Using unpolished armatures, the charging voltages were set to 1900 V, 2000 V, 2100 V, 2200 V, 2300 V, and 2400 V respectively.

-

b)

For the second set, the charging voltage was set to 2000 V, and before launching, the armature surfaces were pre-polished using sandpapers with grits of 120 cw, 180 cw, 240 cw, 600 cw, 800 cw, 1000 cw, 1500 cw, and 2000 cw. The initial surface roughness of textured surface, measured by LSCM, was 2.65 μm, 2.15 μm, 1.65 μm, 1.05 μm, 0.55 μm, 0.25 μm, 0.15 μm, and 0.05 μm, corresponding to the respective sandpaper grits. That is, the smaller the sandpaper grit, the rougher the polished armature surface.

It is worth mentioning that Chen L. et al. from Huazhong University of Science and Technology measured the thickness of aluminum debris left on the rails, finding that the average wear ranged from 3 to 10 µm23. Lu J. Y. et al. from the Naval University of Engineering conducted extreme condition current-carrying friction tests, with the measured depth of the ablation pits on the sample surface reaching up to 20 µm34. Zhang H. H. et al. from Yanshan University measured the maximum surface deformation of the armature to be 3.8 μm, and pointed out that “the wear generated on the rail surface by a single launch can be neglected, but this does not mean that the wear on the armature surface can be ignored. Rails are components used for multiple launches, and even small amounts of wear from each launch will affect the next one”35. Therefore, in this work, it is valid to polish the initial surface roughness of the armature to µm level and obtain the wear amount of µm magnitude.

Macroscopic morphology and wear rate

To preliminarily assess the wear degree of armature surface and guide subsequent SEM scanning positioning, macroscopic images of the armatures were captured after launching. The typical surface wear morphology of the armatures under different charging voltage experiments is shown in Fig. 2, where the red marks represent conductive adhesive applied during SEM testing and can be ignored.

As can be seen from Fig. 2, with the increase of voltage, the concave grinding pits and strip-shaped furrows on the armature surface after launching gradually transform into tiny pittings and dense scratches. The bare aluminum alloy substrate appears white, while the black area is metal oxide, which begins at the edge of the tail and spreads toward the head of the armature. At 2100 V and 2200 V, the black area is most widely distributed. However, after exceeding 2300 V, there is a decreasing trend, accompanied by a tumorous tissue morphology.

Figure 3 provides the surface wear morphology of the armatures under different initial roughness experiments. It should be noted that before launching, the armature was pre-polished without strictly maintaining a consistent scratch direction, but rather allowing the scratches to be randomly and uniformly distributed. This was done to simulate the random distribution of micro-protruding conductive spots, aiming at obtaining the optimal initial roughness for the contact state, which would guide the design of the armature and improve launching efficiency. At the same time, considering the reproducibility of the study, instead of using sandpaper grit numbers directly, the initial surface roughness was measured to server as the evaluation criterion36,37,38,39.

In Fig. 3, for initial roughness values above 1.05 μm, as the initial roughness decreases, the grinding pits and scratches on the post-launch armature surface gradually become shallower, with the polishing textures are still visible in local areas. Below 0.55 μm, the black oxide spreads further forward and converges with each other to form gullies. The edges of these gullies melt upwards, resulting in complex tumorous and flowing tissue morphologies.

In order to quantitatively evaluate the wear of the armature, the mass before and after launching was measured using a precision electronic balance. To reduce the errors introduced by the manufacturing process, the wear rate was calculated as the ratio of mass loss after launching to the mass before launching. The results at different charging voltages are shown in Fig. 4(a).

As seen in Fig. 4(a), as the charging voltage increases initially, the wear rate first decreases and then increases. Combined with Fig. 2, below 2100 V, as the voltage increases, the number of pits decreases, changing from large and centrally distributed grinding pits to more smaller and shallower pittings. The wear process transitions from localized severe damage to more uniform and slight damage, resulting in a decrease in wear rate. However, after exceeding 2100 V, the oxidation layer on the surface of the armature peels off, exposing a large area of aluminum alloy substrate, which leads to an increase in wear rate.

Similarly, the wear results at different initial roughness were calculated as shown in Fig. 4(b).

As depicted in Fig. 4(b), with the decrease in initial roughness, the wear rate first decreases and then slightly increases. Combined with Fig. 3, as the initial surface becomes smoother, the number of grinding pits decreases and their distribution becomes more dispersed. When the initial roughness is below 0.25 μm, oxidative wear intensifies. However, unlike the material peeling observed in elevated voltage conditions, the armature forms a complex erosive morphology due to the deformation and accumulation of metal and its oxides. As a result, while the white aluminum alloy region decreases, the increase in wear rate is not significant.

Weighing could only provide the overall mass loss data. To obtain more accurate 3D wear data, LSCM measurement was further conducted.

Wear contour and surface roughness

LSCM utilizes optical slicing technique to scan the wear surface layer by layer, achieving 3D reconstruction of the armature contour. Still taking the armature emitted at 1900 V as an example, Fig. 5 provides the height map obtained from scanning, the 3D contour map plotted from point cloud data, and its projection.

As shown in Fig. 5, darker areas in the height map represent surface protrusions, while lighter areas indicate concavities. The 3D contour of the armature was reconstructed based on point cloud data, which visually displays the wear depth and projects the topographic edges of the wear area. It can be observed that there are grinding pits and furrows at the head of armature. The maximum diameter of the grinding pit is 5030.10 μm, with a volume of 209595.92 μm³. Several furrows are arranged undulatingly, extending towards the tail to a range of 9157.23–22965.71 μm, with most of their widths being around 1100 μm. The armature tail exhibits an expanding flowing morphology, eroding forward from the rear end to about 5000 μm, with an average fluctuation height of about 280 μm. To compare the damage between the front and rear ends of the armature, two equal-area regions, A1 and A2, were selected, and four intersecting lines, x1 to x4, were drawn for contour measurement. The selected positions of these lines and the extreme values of measured roughness are shown in Fig. 6.

In Fig. 6, Ra, Rp, and Rv denote the arithmetic mean deviation of the line contour height, the maximum peak height, and the maximum valley depth, respectively. Sa, Sz, and Sdr denote the arithmetic mean deviation of the surface height (also referred to as roughness later on), the maximum height, and the interfacial extended area ratio. The variation in peak height along the four intersecting lines is shown in Fig. 7.

Figures 6 and 7 show that all the four intersecting lines exhibit significant fluctuations in the anterior section, while the posterior section tends to flatten out. Due to the presence of grinding pits and furrows, there are obvious concavities at the armature head. The highest peak of region A1 exceeds the original datum by 322.77 μm, with the maximum valley depth being 203.55 μm. The rear end of the armature mainly exhibits flowing tissues and folds formed by the accumulation of oxides after the aluminum is melted by heat. The posterior section of the contour line shows small but dense undulations, with the maximum peak height and valley depth being only 181.83 μm and 86.92 μm, respectively. The surface roughness of region A2 is significantly reduced, but due to its wider distribution of folds, the interfacial extended area actually becomes larger. The wear mechanism of the front and rear ends of the armature will be explained in detail in the discussion section.

To compare the variation in the degree of armature wear at different charging voltages, the surface roughness Sa, maximum peak height Sp, maximum valley depth Sv, and maximum height Sz were statistically analyzed. It is worth noting that LSCM measurement requires setting a reference datum plane, but the armature surface is not perfectly smooth. To maximize the measurement accuracy, before each measurement, the standard roughness sample equipped with the instrument is used to calibrate the datum reference plane. Also, areas at the front end of the armature that are either unworn or lightly worn are selected and marked as reference points for the coordinate system, further calibrating the reference plane. Parameters such as laser power, scanning rate, and step size are kept consistent for measurement of each armature, and after removing extreme outliers to ensure three valid measurements, take the average of these three as the results. Furthermore, the focus is on the overall surface roughness (i.e., Sa) of the armature. The relative height variation of the surface profile during the wear process (i.e., Sz) is investigated rather than relying solely on absolute height values. Therefore, even with some measurement errors and reference plane deviations, the trend and pattern of relative height differences are not affected.

In addition, to save space and avoid unnecessary repetition, only the typical armature images are shown in Figs. 2 and 3. In fact, five launching experiments were conducted for each launching condition, and the surface roughness data were statistically analyzed using LSCM. The Sa and Sz, which minimize the random errors, were selected as the determination criteria, as shown in Table 1.

As demonstrated in Table 1, out of the five results obtained for each condition, the maximum and minimum outliers were removed, and the average of the remaining three measurements was taken as the result to be discussed. The same approach was applied to the other indicators.

The variation of armature wear at different charging voltages is shown in Fig. 8(a).

Figure 8(a) illustrates that with the increase in charging voltage, the absolute values of Sp and Sv tend to decrease. Sa initially decreases, then slightly rebounds and then decreases again, while Sz continues to decrease. At 1900 V, the armature surface exhibits significant pits and protrusions, with maximum values of Sp and Sv, as well as high surface roughness, Sa, and peak-to-valley difference, Sz. As the voltage increases, the wear is alleviated, and the values of each wear parameter decrease. The wear rate in Fig. 4 also decreases, implying that the actual contact area between the armature and rail may increase at this point. When the voltage reaches 2100 V, although the depth of localized grinding pits decreases, causing Sp, Sv, and Sz to reduce, a flowing molten morphology appears on the surface due to increased heat generation and oxidation, leading to an increase in overall roughness, Sa. As the voltage continues to rise, more uniform erosive expansion and the large-scale peeling of surface metal eliminate the sharp micro-protrusions and fill in the deep pits, making the armature surface flatter. Consequently, both Sa and Sz gradually decrease, but the wear rate in Fig. 4 increases, indicating material loss.

The variation in the degree of armature wear at different initial roughness is shown in Fig. 8(b).

In Fig. 8(b), as the initial surface roughness decreases, the absolute values of Sp and Sv first decrease and then increase. Unlike in Fig. 8(a), where there is a slight difference between the two, the trends of Sz and Sa are essentially the same here, both first decreasing and then increasing. When the initial roughness is 2.65 μm, the surface of post-launched armature is uneven, with large peak height, valley depth, and roughness. As the initial roughness decreases, the surface shows a trend toward greater smoothness, with both the peak-to-valley difference, Sz, and overall roughness, Sa, decreasing. However, when the initial roughness drops below 1.05 μm, severe high-temperature oxidation and molten ablation occur between the armature and rail, resulting in a significant accumulation of oxide layers, accompanied by the formation of ablation pits, cracks, and even grooves, which leads to a substantial increase in both Sz and Sa.

Dynamic wear behaviour analysis

In an effort to investigate the microstructure and tissue composition of the armature wear surface, and clarify the formation process and phenomenon essence of its damage, based on contour detection, the typical wear region with the highest surface roughness was selected. The sampling size was set to 2 mm × 2 mm. SEM micromorphology observation and EDS compositional analysis were carried out on the armature surfaces under different launching conditions to explore their dynamic wear behavior.

Wear behaviour at different charging voltages

The SEM micromorphology of the armature surface at different charging voltages is shown in Fig. 9.

According to Fig. 9, as the charging voltage increases, the grinding debris become finer, the small holes and micro cracks deteriorate into deeper cracks, and flake peeling traces eventually appear. At 1900 V, irregularly shaped large grinding debris were formed, with a relatively sparse distribution. This is because, under the action of high-speed current carrying friction, the harder steel rail scrapes off abrasive debris from the surface of softer aluminum alloy armature, which macroscopically manifests as isolated and dispersed grinding pits as shown in Fig. 2. As the voltage increases, the armature moves faster, reducing the duration of shear force. At the same time, the normal component of the Lorentz force increases. The debris become finer and sharper under the crushing action, which aids in cutting the armature surface, leading to the formation of elongated scratches in Fig. 2 and a reduction in surface roughness. As the voltage continues to rise, the circuit current increases, and the accumulated Joule heat promotes oxidation, softening the metal, which leads to the formation of granular melting holes on the armature surface. A few fatigue cracks appeared at the bottom or edges of the holes where the stresses were concentrated, and the deterioration continued to deepen, increasing surface roughness. This indicates that after exceeding 2100 V and 2200 V, the wear pattern begins to transition from abrasive wear40 to oxidative wear and fatigue wear41. Cracks continue to expand along the direction of armature movement and connect with each other, ultimately causing the metal material to peel off or accumulate. At 2300 V, patchy traces of flaked layers as well as corrugated sediments could be seen on the armature surface. These sedimentary layers effectively filled the indentations in the aluminum substrate, with the melt erosion expanding more uniformly, making the armature surface flatter, and reducing roughness. By 2400 V, the peeling layer changes from gray-black to silver-gray, meaning that the surface metal and brittle oxide layer fall off in large patches, exposing the underlying aluminum substrate.

Additionally, the elemental information of the wear interface was detected by EDS. The distribution of elements in the wear area at 1900 V, for example, is shown in Fig. 10.

As depicted in Fig. 10(a) and (b), the main elements detected in the wear area are C, O, Al, Fe, Cu, and Si. Among them, Al element accounts for more than 58.34%, corresponding to the original 6063-T6 aluminum alloy armature substrate, whose main components also include Fe, Si, Cu, and others. In Fig. 10(a), the dispersed purple, orange, and magenta colors represent Fe, O, and C elements, respectively, indicating that steel rail debris from the scraping process covers the green Al element layer. The variation in the elemental content of the wear area at different charging voltages was counted, and the corresponding energy spectrum and variation curves are shown in Fig. 11.

From the data presented in Fig. 11, as the voltage increases, the content variation of Al, Si, and Cu elements is generally consistent, initially decreasing and then increasing, which reflects the change of the proportion of aluminum alloy material in the wear area. In contrast, the variation in O element shows the opposite trend. Below 2100 V, as the voltage increases, on one hand, the abrasive wear is alleviated, and the large pits on the armature surface decrease, which also leads to a decrease in Sz in Fig. 8(a). On the other hand, oxidative wear intensifies, and the coverage area of the oxide layer becomes more extensive. As a result, the proportion of Al decreases while O increases. Above 2100 V, the intense oxidation reaction and uneven distribution of heat allow cracks to expand or even penetrate at areas of local stress concentration. The oxide layer, being more brittle and fragile compared with aluminum, are easily fractured and peel off in lamellar form under the cutting and ploughing action of sharp abrasive debris, thereby exposing the flatter aluminum alloy substrate again. This causes the content of Al to rise, and Sz in Fig. 8(a) also decreases. The trend of Fe element is not exactly the same as that of Al. Combined with the variation in C, it indicates that there is a bidirectional transfer of metal material during the armature-rail wear process42. The filling of steel rail debris also helps reduce the surface roughness of the armature at 2000 V in Fig. 8(a) to a certain extent.

Wear behaviour at different initial roughness

The SEM micromorphology of the armature surface at different initial roughness is shown in Fig. 12.

Based on Fig. 12, as the initial roughness decreases, the abrasive debris becomes smaller, and the armature surface temporarily becomes relatively flat, which in turn presents a more severe material loss or accumulation. Comparing with Fig. 9, it can be found that the abrasive debris produced by polishing with sandpaper and then launching were more rounded and blunt in their edges, resulting in reduced cutting ability. This slightly improves the armature wear rate (compared to Figs. 4(a) and (b)) and surface roughness (compared to Figs. 8(a) and (b)). With an initial roughness of 2.65 μm, the loose micro-protrusion during the launch process grinds the aluminum alloy at a certain angle of attack, leaving dents or flanges on the armature surface. As the initial roughness decreases, the surface becomes smoother and the abrasive wear is reduced to the extent that polishing marks could still be seen in localized areas when the roughness reaches 1.65 μm. However, when the roughness drops below 1.05 μm, the polished surface is too smooth and instead reduces the conductive spots on the armature-rail contact surface, which diminishes the effective transmission path of current and enhances the contact resistance. The accumulation of heat causes the armature to continuously warm up and soften, and the aluminum substrate undergoes plastic deformation under the cutting action of abrasive debris. Yet it does not peel off completely, instead it extrudes and accumulates on the surface, forming ploughing creases and flowing tissues. Meanwhile, local high temperatures and compressive stresses may cause the molten metal liquid film to undergo instantaneous cold welding, accelerating the formation of dark oxide layer. The brittle oxide layer is prone to fracture, shedding into abrasive debris, which then adhere to the armature surface. This leads to further melting and stacking, leaving behind corrosion pits and protrusions. Additionally, the adherent oxide transforms the original steel-aluminum contact into a more mutually compatible homogeneous material contact, which, on one hand, enhances the strength of joint and facilitates adhesive wear43, and on the other hand, reduces the conductive area. As a consequence, more energy is converted into heat as the current passes through the armature, further aggravating the wear and degradation. At a roughness of 0.05 μm, a dazzling white light area was observed, indicating that the sample’s conductivity was so poor that a charging effect occurred under the SEM lens44.

The variation in the elemental content of the wear area at different initial roughness was also detected, and the results are shown in Fig. 13.

From the data presented in Fig. 13, as the initial roughness decreases, the contents of Al, Si, and Cu elements first decrease, then marginally increase, and subsequently decrease again. The high content of O indicates the presence of an oxide layer, and Fe and C elements fluctuate slightly. When the roughness exceeds 1.65 μm, as the surface flatness of the armature improves, the abrasive wear decreases, resulting in a smaller proportion of exposed aluminum substrate. The fluctuation of Fe and C elements suggests the residual presence of rail debris on the armature surface. As the initial roughness decreases, the increase in contact resistance leads to heat accumulation, and the wear pattern between the armature and rail transitions from abrasive wear to oxidative wear. This generally tends to equilibrate at 1.65–1.05 μm, with slight improvement in roughness (as shown in Fig. 8(b)). Subsequently, the heat-affected zone continues to expand, and the oxide layer does not peel off as violently as raising the charging voltage, but accumulates on the armature surface, causing flowing tissues and tumorous defects under repeated ploughing and cutting behavious45. Thus, the contents of Fe, C, and O from the oxide layer continue to increase, while the proportion of aluminum substrate elements decreases. Besides, a small amount of S was detected at 0.25–0.05 μm, possibly due to the reaction between the metal and sulfides in the air under high-speed and high-temperature friction46which further exacerbates the armature ablation.

Discussion

Driven by high-power pulsed current, a large amount of Joule heat is generated on the armature surface, while the frictional heat arises from high-speed sliding under the Lorentz force. The accumulation of heat leads to armature softening or localized loss, which deteriorates the contact state and further exacerbates the heat production47. It is the combined effect of these two heat sources that causes the complex thermal effects on the armature surface, significantly influencing the wear process. To clarify the relationship between the heat production on the armature and the wear mechanism, the variation in current, I, and Lorentz force, FL, during the launch process was first recorded, using the 1900 V case as an example, as shown in Fig. 14.

From Fig. 14, it is evident that the pulse current rises rapidly within 0-0.9 ms, reaching a peak of 37 kA before slowly decreasing to zero. The surface current density can reach 37 kA/(15 mm × 20 mm) = 1.23 × 108 A/m2, which complies with the equivalent criterion of “current density reaching 108 A/m2” proposed by Prof. Lu J. Y.’s team at the Naval University of Engineering49. This also indirectly demonstrates the effectiveness of this work. The Lorentz force also exhibits a pulsed pattern of rising and then falling; but its variation lags behind the current because it originates from the magnetic field induced by the change in electric current. The current primarily affects the variation of Joule heat, while the cosine component of Lorentz force, FLn, and the initial preload force, F0, together comprise the normal contact pressure, Fn, of the armature, which is directly related to the frictional heat. The time-dependent variation in the peak values of the heat flux densities for Jole heat, QJ, and frictional heat, QF, are presented in Fig. 15.

Figure 15 clearly indicates that the Joule heat flux density also rises in a pulsed pattern and then falls, and the frictional heat flux density continues to rise. Throughout the entire launch process, the velocity of armature is relatively low in the itial stage, but the current and Lorentz force quickly reach their pulse peak. Due to the skin effect, the current is mainly distributed at the front end of armature and always tends to take the “shortest path”, concentrating locally, especially at rough peaks. This inevitably leads to concentration of the Lorentz force and contact pressure. Under the action of inhomogeneous Joule heat and contact pressure, pitting-type ablation forms at the front end of the armature. After 3.05 ms, as the velocity of armature motion increases, the frictional heat rises to exceed the Joule heat, which forms a flaky high-temperature region at the tail and dominates the expansive erosion phenomenon. This explains the formation of different morphologies and three-dimensional contours at the front and rear ends of the armature in Figs. 6 and 7. The research of He L. et al. pointed out that Joule heat concentrated at the band of armature head, and the frictional heat accumulating at the rear end was harmful to the armature27. The conclusion aligns with our work and reinforces the validity of the results.

In turn, the variation in the peak values of two heat flux densities for different charging voltages and initial roughness was calculated, as shown in Fig. 16.

According to Figs. 16(a) and (d), with the increase in charging voltage and the reduction in initial surface roughness, the peak values of both Joule heat and frictional heat flux density continue to rise. The initial peak value of Joule heat is lower, but its rising rate is faster, surpassing the frictional heat at a voltage of 2100 V and an initial roughness of 0.55 μm. This is consistent with the conclusion drawn by Guo Z. X. et al. that “frictional heat mainly acts during low-speed motion of the armature”48. In addition, at 2400 V, the Joule heat flux density is 13.63 × 108 W/m², compared to 12.33 × 108 W/m² at an initial roughness of 0.05 µm, indicating that the increase in Joule heat caused by the rise in charging voltage is more significant than the reduction in initial roughness. In other words, at low voltages, abrasive wear mainly occurs to form pits, and cracks are produced where the stresses are concentrated at the concave edges, as depicted in Fig. 16(b). As the charging voltage raises, the current increases, and it will concentrate detour through the crack, leading to excessive current density at the crack edges. The electromagnetic force at edges drives the crack to propagate and coalesce. However, the locally concentrated Joule heat softens the material, causing the cracks to deepen or even fuse. The combined effect of electromagnetic force and Joule heat produces the “magnetic saw effect”, which ultimately leads to partial detachment of the armature. In contrast, as the initial roughness is reduced to below 0.25µm, the excessively smooth surface causes a sharp increase in contact resistance and Joule heat. However, it does not result in material detachment, but rather catalyzes the oxidation reaction of the metal. A large amount of oxide and metal debris adheres to the armature surface, accompanied by irregular erosion pits, forming a complex molten morphology. This significantly reduces the conductivity of armature to the point where a “charged effect” occurs, producing an overexposed and abnormally bright light, as presented in Fig. 16(c).

In addition, to more closely relate metal wear to the behavior of the launch system, the contact resistance between the armature and rail was obtained based on the relationship between voltage and current. The variations in contact resistance for different charging voltages and initial roughness are shown in Fig. 17.

As shown in Fig. 17, the variation trends of the contact resistance under different conditions are generally consistent during the launching process, mainly divided into three stages. In Stage I, there is a relatively large initial value due to the preload force. In Stage II, the contact resistance approaches zero during steady launching. In Stage III, as the armature exits the barrel, there is a sudden change in the contact resistance. Meanwhile, according to the current shown in Fig. 17 and Marshall’s law49“a transition occurs when the contact pressure between the armature and rail is less than 1 g/A”. The intense light observed at the muzzle during the experiment also indicates the occurrence of transition and arc phenomena. At this moment, the contact between the armature and rail shifts from solid-solid contact to arc plasma contact, causing the contact resistance to suddenly increase, even approaching infinity. From Fig. 17(a), the increase is not significant at 1900 V and 2000 V, but after exceeding 2100 V, the resistance increases sharply, and the arc becomes more intense observed in the experiment. From Fig. 17(b), when the initial roughness is 2.65 μm and 2.15 μm, a noticeable sudden increase has already occurred. But this is alleviated when the roughness is between 1.65 μm and 0.55 μm, and after dropping below 0.25 μm, a sharp transition and intense arcing appear again.

Summarizing the analysis of wear morphology, thermal effects and contact resistance, the dynamic wear process of the armature under elevated charging voltage is depicted in Fig. 18.

As can be seen from Fig. 18, at low voltage, the armature initially experiences abrasive wear, forming grinding pits and furrows on the surface that extend in the direction of motion. As the voltage rises, the grinding debris become finer under the action of normal squeezing force, and the abrasive wear is reduced. The accumulation of heat simultaneously catalyzes oxidative wear, forming a black brittle oxide layer on the armature surface. After exceeding 2100 V, Joule heating rises sharply, and the high-speed moving armature continuously contacts the new room-temperature rails ahead, causing heat to be rapidly dissipated with a higher cooling gradient. Under the effect of alternating forces generated by the strong alternating temperature field, cracks are formed and propagate on the armature, eventually causing the surface metal, particularly the brittle oxides, to peel off in flakes. The wear then transitions to fatigue wear. During this process, with the increase in voltage and the appearance of wear gaps, the contact pressure fails to meet the requirements of Marshall’s law. This leads to the occurrence of transition and muzzle arcs between the armature and rail, intensifying the formation of oxidation black spots shown in Fig. 2.

The dynamic wear process of the armature with reduced initial roughness is summarized in Fig. 19.

As shown in Fig. 19, the armature initially undergoes abrasive wear. As the initial roughness decreases, the abrasive debris become more rounded and blunt, reducing the cutting action and thereby alleviating abrasive wear. However, the appearance of surface gaps still leads to the occurrence of transitions, which aggravates the ablation shown in Fig. 3. At the same time, due to the reduction in conductive spots, the contact resistance increases. The aluminum alloy surface reacts with the gas medium under the action of high temperature, forming an oxide film that adheres to the surface. The oxide film is squeezed and transferred, and the newly exposed surface is re-oxidized and accumulated, eventually forming a complex molten morphology. The combined effect of oxidative and adhesive wear does not result in a significant material loss, but the conductivity of the armature deteriorates.

The above research indicates that the relationship between charging voltage, initial roughness, and the degree of material wear is complex. In order to comprehensively assess the impact of these two factors on the armature wear performance, relationships between the wear rate, wr, the post-launch armature surface roughness, Sa, and the two factors were established respectively:

where, U denotes the charging voltage and Sa0 the initial roughness. Based on the above analyses, we believe that the following methods can improve the wear performance of the armature:

-

1)

Apply an appropriate charging voltage. It is unwise to blindly increase the charging voltage in pursuit of acceleration. For the rail with a length of 1.2 m in our experimental platform, the optimal charging voltage is 2100 V.

-

2)

Set an appropriate surface roughness level. For this platform, the optimal initial roughness range is 0.55–1.05 μm, which can be achieved by polishing with 600 cw-800 cw sandpaper. The conductivity of armatures with rough materials requires particular attention.

-

3)

For C-type solid armatures, the head should be designed for improved heat resistance, while the tail should be reinforced for wear resistance. Suitable plating or coating is expected.

Conclusion

The main objective of this work is to obtain the evolution laws of armature wear under different charging voltages and initial surface roughness through quantitative detection, in order to intrinsically inhibit the occurrence of material failure and guide the optimization design of the device. Launching experiments were conducted with charging voltages ranging from 1900 V to 2400 V and initial roughness values between 0.05 μm and 2.65 μm. After the launch, wear weighing, LSCM contour measurement, SEM morphology scanning, EDS composition detection, thermal effects and contact resistance analysis were performed. With the provided work, the following statements hold:

-

1)

Macroscopically, as the charging voltage rises, the wear rate of the armature first decreases and then increases, while the wear roughness initially decreases, slightly increases, and then decreases again. The optimal charging voltage is 2100 V, with a wear rate of 0.38% and a wear roughness of 8.46 μm. As the initial roughness decreases, the wear rate first decreases and then slightly increases, while the wear roughness generally increases. The optimal initial roughness range is 0.55–1.05 μm, with a wear rate of 0.21–0.25% and a wear roughness of 7.91–8.31 μm.

-

2)

Combining microscopic morphology and composition analysis, as the charging voltage rises, the wear pattern of the armature shifts from abrasive wear to oxidative wear and fatigue wear. At 2400 V, large areas of material detachment appeared. As the initial roughness decreases, the wear pattern transitions from abrasive wear to oxidative wear and adhesive wear. At 0.05 μm, the conductivity of the post-launch armature is severely damaged.

-

3)

Driven by the pulse current and Lorentz force, the main heat sources during electromagnetic launch process are Joule heat and frictional heat. Over time, Joule heat first increases and then decreases, while frictional heat continuously increases, surpassing the former at around 3.05 ms. Whereas both Joule heat and frictional heat keep increasing as the charging voltage rises or the initial surface roughness decreases, Joule heat starts at a lower value but increases at a faster rate. There is an initial relatively large value of contact resistance, which fluctuates smoothly, and experiences a sharp increase when the armature exits the barrel, indicating the armature wear caused by the action of transition arc.

-

4)

Admittedly, due to the limitations of the current experimental conditions, we were unable to simulate a real-sized electromagnetic launch system with actual current levels. Instead, we focused on exploring the fundamental mechanisms based on equivalent current density. In future work, we will consider expanding collaborations to conduct experiments on real prototypes or obtain data from engineering sites. This work provides a theoretical foundation for the performance enhancement and optimization design of electromagnetic launch devices. In actual launches, a voltage hard limit should be set to avoid material ablation and degradation caused by blindly increasing the voltage. For C-type solid armatures, appropriate surface roughness can be achieved through polishing or material selection. The head can be sprayed with a thermal barrier coating to improve heat resistance, and the tail can be coated with a cladded wear-resistant layer to enhance wear resistance, thus enhancing the equipment performance and durability.

Data availability

The data supporting the findings of this study are interpreted, verified, and presented in main text, and are available from the corresponding authors upon request.

References

Magdy, M. M., El-Hussieny, H., El-Bab, F., Abdo, A. M. R., Ahmed, S. M. & M. M. M. & Modeling and optimization of a modified iron-yoked electromagnetic propulsion system using the gravitational search algorithm. Sci. Rep. 14, 24970 (2024).

Einat, M. & Orbach, Y. A multi-stage 130 m/s reluctance linear electromagnetic launcher. Sci. Rep.13218. (2023).

Guo, Z. X., Yuan, Z. K., Jin, Y. X., Chen, J. H. & Li, T. Y. A multi-physics field modeling approach for the electromagnetic railgun launch of intelligent projectiles. IEEE Access12, 134091–134100 (2024).

Li, S. Z., Li, J., Xia, S. G., Zhang, Q. X. & Liu, P. Z. Phase division and critical point definition of electromagnetic railgun sliding contact state. IEEE Trans. Plasma Sci.47(5), 2399–2403 (2019).

Abdo, M. M. M., El-Hussieny, H., Miyashita, T. & Ahmed, S. M. Design of a new electromagnetic launcher based on the magnetic reluctance control for the propulsion of Aircraft-Mounted microsatellites. Applied System Innovation6(5), 81 (2023).

Choi, S., Cho, M. & Lim, J. Electromagnetic drag forces between HTS magnet and tube infrastructure for hyperloop. Sci. Rep.13, 12626 (2023).

Owlia, E., Mirjalili, S. A. & Shahnazari, M. Design and modeling of an electromagnetic launcher for weft insertion system. Text. Res. J. 89 (5), 834–844 (2019).

Guo, A. X., Du, X. Y., Wang, X. Z. & Liu, S. W. Calculation of armature melting wear rate based on contact surface heat distribution. IEEE Trans. Plasma Sci.52(7), 2981–2990 (2024).

Tang, B., Xu, Y. T., Lin, Q. H. & Li, B. M. Synergy of melt-wave and electromagnetic force on the transition mechanism in electromagnetic launch. IEEE Trans. Plasma Sci.45(7), 1361–1367 (2017).

Li, B., Lu, J. Y., Tan, S., Zhang, Y. S. & Cai, X. Y. Study on dynamic wear process of high-speed sliding electric contact armature surface. J. Electr. Eng. Technol.38(1), 131–139 (2023).

Yang, F., Zhai, X. F., Liu, H. & Peng, Z. R. Research on the contact characteristics of the armature-rail considering the wear amount of the C-shaped solid armature. IEEE Trans. Plasma Sci.51(9), 2726–2735 (2023).

Yang, C. Z., Peng, P. H., Pan, L. K., Chen, L. M. & He, F. Numerical simulation of impact response for pantograph slide plate. Sci. Rep.14, 29299 (2024).

Ren, S. D., Feng, G. & Liu, S. W. Study on wear of electromagnetic railgun. IEEE Access10, 100955–100963 (2022).

Tang, L. L. et al. Experimental study on the erosion characteristics of armature current in small caliber electromagnetic railgun. High. Volt Eng. 42 (9), 2857–2863 (2016).

Mengottia, E. et al. Fretting corrosion: analysis of the failure mechanism for low voltage drives applications. Microelectron. Reliab. 54 (9–10), 2109–2114 (2014).

Vishwanatha, J. S. et al. Image-processing-based model for surface roughness evaluation in titanium based alloys using dual tree complex wavelet transform and radial basis function neural networks. Sci. Rep.14, 28261 (2024).

Feng, K., Ni, J., Wang, Z. X. & Meng, Z. Tribological properties of high-speed steel surface with texture and vertical fibers. Sci. Rep. 13, 13180 (2023).

Li, B., Lu, J. Y., Tan, S., Jiang, Y. Z. & Zhang, Y. S. Effect of sliding electrical contact interface roughness on armature melting characteristics. J. Electr. Eng. Technol.33(7), 1607–1615 (2018).

Lin, Q. H. Multifield and multiscale modeling of armature wear in electromagnetic railgun. IEEE Trans. Plasma Sci.50(6), 1971–1976 (2022).

Yao, J. M., Xia, S. G., Chen, L. X. & He, J. J. Analysis of the melt erosion patterns at rail-armature contact of rail launcher in current range of 10–20 kA/mm. IEEE Trans. Plasma Sci.47(3), 1674–1680 (2019).

Zhang, H. H., Li, S., Gao, X., Lu, T. G. & Liu, F. Distribution characteristics of electromagnetic field and temperature field of different caliber electromagnetic railguns. IEEE Trans. Plasma Sci.48(12), 4342–4349 (2020).

Merrill, R. & Stefani, F. A turbulent melt-lubrication model of surface wear in railgun armatures. IEEE Trans. Magn. 41 (1), 414–419 (2005).

Chen, L. X. et al. Experimental study of armature melt wear in solid armature railgun. IEEE Trans. Plasma Sci. 43 (5), 1142–1146 (2015).

Stefani, F. & Merrill, R. Experiments to measure melt-wave erosion in railgun armatures. IEEE Trans. Magn. 39 (1), 188–192 (2003).

Li, C. X. et al. Influence of caliber height on armature current melt erosion in rail gun. IEEE Trans. Plasma Sci. 48 (8), 2932–2938 (2020).

Singer, I. L., Veracka, M. J., Boyer, C. N. & Neri, J. M. Wear behavior of lubricant-conditioned copper rails and armatures in a railgun. IEEE Trans. Plasma Sci.39(1), 138–143 (2011).

Li, H., Lei, B., Lv, Q. A. & Li, Z. Y. Analysis on thermal character of interface between rail and armature for electromagnetic railgun. IEEE Trans. Plasma Sci.41(5), 1426–1430 (2013).

Shvetsov, G. A. & Stankevich, S. V. Three-dimensional numerical simulation of the joule heating of various shapes of armatures in railguns. IEEE Trans. Plasma Sci.39(1), 456–460 (2011).

Fedorchenko, A. I. Influence of dry frictional heating on acceleration disruption in a railgun with a metal armature. Eng. Fail. Anal. 109, 104384 (2020).

Wu, J. G., Wan, G., Cheng, N. K., Li, L. & Li, B. M. Research on armature’s wearing and dynamic interior ballistic of a railgun. IEEE Trans. Plasma Sci. 45 (7), 1202–1207 (2017).

Lu, F. L., Yan, Z. M., Deng, H. M. & Wang, Y. Asynchronous discharge of an eight-module superconducting pulsed power supply for driving an electromagnetic railgun. IEEE Trans. Appl. Supercond.29(2), 1–5 (2019).

Bayati, M. S. & Keshtkar, A. Study of the current distribution, magnetic field, and inductance gradient of rectangular and circular railguns. IEEE Trans. Plasma Sci. 41 (5), 1376–1381 (2013).

Ma, W. M. & Lu, J. Y. Research status and challenges of electromagnetic emission technology. Trans. China Electrotech. Soc.38(15), 3943–3959 (2023).

Lu, J. Y., Jia, S. K., Li, B. & Tan, S. Electromagnetic emission track surface protection based on sales disk current carrying friction platform. J. Nav Univ. Eng. 36 (2), 1–5 (2024).

Zhang, H. H., Feng, Y. & Gao, X. Analysis of pivot rail contact state considering interference fit and wear. Ord Mater. Sci. Eng.42(1), 79–83 (2019).

Tian, Z. Q. et al. Study on polishing mechanisms of BEOL metal interconnects based on chemical and mechanical synergy. Microsyst. Nanoeng.11, 109 (2025).

Liu, N. et al. Damage-free highly efficient plasma-assisted Polishing of a 20-mm square large mosaic single crystal diamond substrate. Sci. Rep. 10, 19432 (2020).

Dong, C. L. et al. Coupling mechanism between wear and oxidation processes of 304 stainless steel in hydrogen peroxide environments. Sci. Rep.7, 2327 (2017).

Han, C. F. et al. The influence of sandpaper mesh size on the contact resistance of carbon fiber composite materials. Cotton Text. Technol 1–8 (2025).

Kumar, T. S., Raghu, R., Priyadharshini, G. S., Robert, Č & Kanak, K. A study on microstructural, mechanical properties, and optimization of wear behaviour of friction stir processed AZ31/TiC composites using response surface methodology. Sci. Rep.14, 18729 (2024).

Xie, L. & Wang, Y. M. High temperature wear and corrosion behavior of detonation sprayed Fe-based amorphous coatings. Sci. Rep.14, 29410 (2024).

Li, C. X. et al. Influence of armature/rail structure coordination on the evolution of rail deposition layer. IEEE Trans. Plasma Sci.52(8), 3294–3302 (2024).

Vignesh, M. et al. Influence of Cu and Co addition on metallurgical and wear characteristics of alcrfeni high entropy alloy. Sci. Rep.14, 27398 (2024).

Fan, W. J. et al. Charged effect problem of non-conducting samples in X-ray photoelectron spectroscopy tests and its improvement methods. Anal. Test. Technol. Instrum. 30 (6), 385–391 (2024).

Xing, Z. X., Wang, J., Li, H. J., Han, Z. Y. & Li, Q. M. Influence of aluminum deposition layers on sliding electrical contact at the pivot-rail interface under repetitive emission. Trans China Electrotech Soc40(10), 3044–3055 (2025).

Chen, F. J. et al. Sulfidation corrosion mechanism of FV(520)B stainless steel under high temperature and high pressure conditions. J. Mater. Heat. Treat. 36 (6), 211–215 (2015).

Zhang, Y. S. et al. Heat generation and thermal management of a rapid-fire electromagnetic rail launcher. IEEE Trans. Plasma Sci. 47 (5), 2143–2150 (2019).

Du, W. T., Cheng, L., Long, X. L., Lu, J. Y. & Li, S. C. Research on equivalent test method for magnetic field environment of electromagnetic orbital emission. J. Ord. Equip. Eng.43(5), 138–145 (2022).

Marshall, R. A. & Wang, Y. Railguns: their science andtechnology. Beijing: China Machine Press 3–4 (2004).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (NSFC) under Project Numbers 92266112.

Author information

Authors and Affiliations

Contributions

L. Y. L. conducted experiments and wrote the main manuscript text, H. S. L. guided the conduct of the experiment and the framework of the thesis, P. F. L. assisted in the experiment, H. X. C. and A. M. A. A. helped enhance the figures, and L. Z. and Q. Q. L. participated in the discussion of the concepts. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, L., Liu, H., Lu, P. et al. Wear characteristics of armature surface and its thermal effects under different electromagnetic launch conditions. Sci Rep 15, 26755 (2025). https://doi.org/10.1038/s41598-025-12396-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-12396-7