Abstract

A flexible screen-printed graphite electrode was fabricated as an anode for developing fast-charging lithium-ion batteries with low tortuosity. A homogenous anode ink was prepared by mixing graphite as the active material, carbon black (C45) as the conductive additive, and polyvinylidene fluoride (PVDF) as the binder in N-Methyl-2-pyrrolidone (NMP) solvent. The ink was deposited on a flexible copper foil via a stainless-steel screen consisting of an array of pores, that act as secondary pore networks (SPNs), using the screen-printing process. Lithium-ion battery half-cells were assembled using the printed graphite anode, lithium metal foil as the counter electrode, and 1.2 M lithium hexafluorophosphate (LiPF6) in ethyl carbonate: ethyl methyl carbonate (EC: EMC = 3:7) as the electrolyte. The effect of SPNs on the cell performance was investigated by performing formation, rate and cycling tests on the assembled cells, at different C-rates. It was observed that the cells consisting of SPNs with a pore size of 100 μm and edge-to-edge distance of 100 μm between the pores exhibited significantly higher specific capacities of 168 and 129 mAh/g when compared to reference cells without SPNs, which had capacities of 120 and 85 mAh/g, at high C-rates of 4 C and 6 C, respectively. The cells with SPNs also demonstrated excellent cycling performance with ~ 95% capacity retention after 100 cycles at 2 C.

Similar content being viewed by others

Introduction

With the growth in demand for electric vehicles (EVs), fast charging ability has become a key parameter for today’s lithium-ion battery (LIB) technology1,2. LIBs consist of porous electrodes, a separator, and a liquid electrolyte. Typically, the electrodes (both anode and cathode) have been developed by mixing an active material, conductive additive, polymer binder, and solvent thoroughly until a homogenous slurry is obtained. Then, these slurries are coated onto current collectors (copper for anode, aluminum for cathode) and vacuum dried to evaporate the solvent3,4. Following this, the electrodes are calendered to a desired porosity to enhance particle contact and volumetric energy density of the cell before subjecting them to electrochemical testing5. During charging, lithium ions (Li+) migrate from the cathode to the anode through the separator. Similarly, during discharge, the process is reversed with current being drawn from the terminals of the battery6. Graphite, lithium titanium oxide (LTO), and silicon (Si) are among the widely used anode materials. Similarly, lithium nickel manganese cobalt oxides (NMC), lithium iron phosphate (LFP), and lithium cobalt oxide (LCO) are widely used as cathode materials to achieve LIBs with superior electrochemical performance7.

Even though there have been several research efforts and continuous advancements in the battery field, the accelerated degradation of capacity and power capability of batteries remains a major concern at high current rates, or fast charging C-rates such as 1 C or higher8. C-rate is defined as measure of charging speed which is expressed as multiple of battery’s capacity. A 1 C-rate means that the battery can be charged/discharged in one hour while a higher C-rate indicates faster charge/discharge and lower C-rate indicates slower charge/discharge. Lithium plating, dendrite formation, and mechanical failure remain the major reasons for degradation at high current rates due to current-dependent overpotential9. Lithium plating/dendrite formation is a phenomenon that often occurs on the anode surface of LIBs, leading to the irreversible loss of lithium, resulting in electrolyte decomposition and rapid capacity fading, and in turn mechanical failure of the LIBs9. The root cause for the lithium plating and dendrite formation is attributed to the high tortuosity of the electrodes, resulting in twisted pathways that are narrow and distorted, thus making it difficult for Li + transportation and, in turn, affecting the fast-charging ability of LIBs during charge/discharge cycles. This also results in increased internal ionic resistance of the LIB10. Therefore, reducing the tortuosity of the electrodes can enhance Li+ flow, along with electrolyte mass transfer, resulting in enhanced electrochemical performance of the LIB. In other words, low tortuosity in LIBs facilitates effective ion transportation within electrode structure, which in turn leads to enhanced rate capability, lower ionic resistance, more uniform ion distribution, reduced stress on electrodes, improved columbic efficiency, ensures better utilization of active material, and promotes safer fast charging cycling stability11.

Several researchers have explored various strategies to reduce tortuosity in LIBs, such as optimizing electrode thickness12, controlling particle size and shape13, using nano materials14, and aligning electrodes along the ion flow direction15. However, these methods often require precise control over material uniformity, involve complex fabrication process (such as electrospinning or advanced templating)16 and are material specific limiting their compatibility with all electrode materials. Moreover, reducing electrode thickness can lead to low energy density which is not ideal for batteries performance.

Fabricating structured electrodes is an efficient way to overcome the limitations associated with LIBs in terms of tortuosity. Electrochemical simulations have shown that introducing secondary pore networks (SPNs) in the electrodes enhances the transportation of electrolyte and Li+, which will have a significant effect in improving the electrochemical properties of the LIB17,18,19. The implementation of structured electrodes can effectively mitigate the problem of lithium plating on the surface of the anode electrode20,21,22,23. Despite these advantages, LIBs with structured electrodes are not yet commercially available to the best of our knowledge. This is due to the limitations associated with the large-scale fabrication of structured electrodes. Several advanced manufacturing processes, such as laser patterning, freeze casting, aerosol jet printing, inkjet printing, gravure printing, and screen printing, can be implemented to fabricate structured electrodes24,25,26,27,28,29,30,31,32,33. Processes such as inkjet and aerosol jet printing result in electrodes with very low mass loadings, typically in the range of 0.1–1 mg/cm2, due to the low viscosity of the inks24,25. Similarly, in the freeze-casting process, SPNs can be introduced into the electrode using the cooling stage while drying at -50 °C during the curing process. However, this process takes more than 48 h, and the uniformity of the structured electrode is not reliable26. In other words, the consistency in obtaining the same pore sizes and distance between the pores in SPNs is challenging. In contrast, screen-printing emerges as a promising approach for the precisely fabricating structured electrodes with high mass loadings, which can be implemented in high-volume roll-to-roll (R2R) printing. Screen printing offers design flexibility and a simple, swift, and repeatable method for manufacturing electrode architectures with variable mass loadings34.

In this work, a homogenous anode ink was prepared by mixing graphite, carbon black, and polyvinylidene fluoride (PVDF) in N-Methyl-2-pyrrolidone (NMP) solvent. Screen printing was implemented for depositing the ink on a flexible copper current collector. Novel SPN-based microstructures with different pore diameters and edge-to-edge (ETE) distances were introduced during screen printing into the graphite electrode. Later, half-cell LIBs were assembled using the screen-printed graphite electrodes with and without SPNs. Electrochemical tests were conducted by performing formation, rate, and cycling tests on the assembled coin cells. Battery data were analyzed to study the significance between electrodes with and without SPNs (structured and reference electrodes).

Experimental

Materials and ink Preparation

The anode ink was formulated using graphite as the active material (5 μm particle size), carbon black (C-45, 100–200 nm, MSE Supplies) as the conductive additive, PVDF (5130, Kureha) as the binder, and NMP as the solvent (Sigma Aldrich®). All the materials were used as received without any further modification. Figure S1a (please see the supplementary information) represents the schematic of ink preparation. Initially, the graphite and carbon black were added to the PVDF binder (8% in NMP) in wt% of 90:3:7, respectively. Then, the mixture was dispersed in NMP, and the resulting electrode slurry was transferred to a Thinky AR-100 planetary centrifugal mixer. Following this, the slurry was mixed at 2000 rpm until a homogenous and uniform ink slurry was obtained for screen printing. The prepared ink had 60% solid loading without any residuals, indicating homogeneity and suitability for printing.

Ink characterization

Certain properties of an ink affect the print quality, such as surface tension, and contact angle with respect to the substrate employed. These properties provide a better understanding of the wetting properties of the ink and were measured using an FTA200 goniometer. Figure S1b, c show the surface tension and contact angle of the graphite ink, respectively (please see the supplementary information). Following this, the viscosity of the ink was measured with an Anton Paar ® MCR-302 rheometer using parallel-plate geometry. The ink slurry was placed between parallel plates at room temperature and viscosity was recorded by varying the shear rate from 1 s to 1 up to 500 s–1. Figure S2a shows the shear thinning behavior of the graphite ink with varied shear rates (please see the supplementary information). Figure S2b (please see the supplementary information) represents the anode ink’s thixotropic behavior.

Fabrication

Screen printing was used to fabricate the graphite electrodes using an HMI MSP-485 semi-automatic screen-printer. Stainless-steel screens consisting of an array of pores with varying diameters of 1000 μm, 500 μm, and 100 μm and an ETE distance of 2000 μm between the pores were fabricated at Microscreen®35. The screen size was 12 × 12 inches with a mesh count, wire diameter, and mesh angle of 325, 20 μm, and 22.5 degrees, respectively. It was made of MS-22 emulsion (Grafic HSS from Saati Chemicals) which is NMP resistant with a thickness of 15 μm. Figure S3 (please see the supplementary information) illustrates the fabricated screens and screen designs showing their respective SPN pore diameter (in red), and the ETE distance between the SPNs (in pink). The scale for the artwork was set to 200 μm for all the images. The blue color area in the images represents the emulsion (MS-22) which prevents the ink deposition through the screen onto the substrate resulting in the creation of a void in its place on the substrate. Based on the initial battery data (provided in the results section), SPNs with a small pore size of 100 μm exhibited better battery performance. For further investigation of SPNs pore diameter of 100 μm was kept constant and the ETE distance between the pores was gradually reduced from 2000 μm to 400 μm, 300 μm, 200 μm, 150 μm, and 100 μm.

Figure 1a shows the schematic representation of the electrode fabrication using the screen-printing process. To fabricate the anode, the copper substrate with ~ 9 μm thickness was placed on the screen printer platen and was cleaned with isopropyl alcohol (IPA). This helps in removing any dust particles present on the copper substrate. The platen consists of vacuum pores which enable the copper substrate to be held firmly to the platen. Graphite ink was uniformly spread on the screen and a silicone squeegee was used for printing the ink onto copper substrate. After screen-printing the graphite ink onto the copper substrate, the printed electrode was cured in a VWR® oven at 45 °C for 4 h to partially evaporate the NMP solvent. Then, the electrode was transferred to a vacuum oven from Across International® and was cured at 80 °C for 10 h to ensure complete evaporation of NMP. Figures S4 and S5 (please see the supplementary information) show the fabricated screen-printed graphite electrodes along with their optical microscopic images. Uniform printing was observed for all the samples. The electrode representations along with their respective mass loadings are summarized in Table 1. Electrode A (solid block without SPNs) was used as a reference electrode for comparing the electrochemical performance of the fabricated anodes. Electrodes B, C, and D have SPNs with diameters of 1000 μm, 500 μm, and 100 μm, respectively. The ETE distance was 2000 μm (2 mm) for these electrodes. For electrodes E to I, the size of SPNs was kept constant at 100 μm and the ETE distance between the pores was gradually reduced to 400 μm (electrode E), 300 μm (electrode F), 200 μm, (electrode G), 150 μm (electrode H), 100 μm (electrode I).

Figure 1b represents the schematic for lithium-ion flow in conventional electrodes without SPNs. Due to the sluggish kinetics of Li+, it takes more time for the Li+ to reach the current collector. This results in an increased tortuosity of the LIB, which can lead to capacity fading at fast charging rates. Novel SPNs introduced during fabrication help in reducing the electrode’s tortuosity as shown in Fig. 1c. In addition, these SPNs increase the transportation of liquid electrolyte through the electrode, which enhances the Li+ accessibility via a shorter route (Fig. 1d). The enhanced Li+ accessibility, along with superior contact between the active material and the liquid electrolyte, is an essential condition for achieving fast-charging LIBs with higher capacities. The schematics shown in Fig. 1a–d are for illustration purpose only. The introduction of SPNs in the electrode through screen printing process can be applied to electrodes with different thicknesses and the size of SPNs and the ETE distance between the pores can be varied based on screen designs. Figure 1e shows the scanning electron microscopy (SEM) cross-section image of pore in the electrode using a Jeol® JSM-IT200. Figure 1f represents the thickness of the electrode measured around 54.4 ± 4.0 μm. The different pore diameters and ETE distances will result in different mass loading for each sample since the number of pores in a unit area varies with respect to pore diameter and ETE distance. Therefore, the mass loadings of all the electrodes were adjusted in the range of 6–7 mg/cm2 to have a fair comparison between the electrodes with and without SPNs. All the electrodes were calendered between cylindrical rolls and the porosity (ε) was controlled at approximately 35%. Porosity was calculated using Equation S1 as shown in supplementary data. The calendering process helps in improving the particle-particle contact and reduces electrode porosity, increasing the electrode density and thereby enhancing the volumetric energy density of the assembled cell.

(a) Schematic of electrode fabrication using screen-printing; and illustrations of lithium-ion flow in (b) conventional electrode, (c) proposed electrode with SPNs, (d) free flow of lithium ions through the SPNs with low tortuosity, (e) cross-section SEM images showing the pore in the electrode, and (f) thickness measurement (54 ± 4.0 μm) of the electrode. (Note: Schematics in Fig. 1a–d are purely for illustration purpose.)

Mechanical characterization

Mechanical characterization was performed on the fabricated electrodes by subjecting them to cyclical bend tests using a Mark-10 ESM 301 motorized test stand. Electrodes A and I were chosen for the bend test considering no SPNs in electrode A, and the highest pore density in a unit area for electrode I. The Young’s modulus for the graphite and copper film was measured using an Instron 4301 tensile tester and the values are tabulated in Table S1 (please see supplementary information). Initially, simulations were performed using COMSOL Multiphysics software to study the maximum stress distribution on the printed electrodes during the bend test. Figures S6 and S7) (please see the supplementary information) represent the COMSOL simulations of electrodes A & I, respectively for bending radius varying from 10 to 60 mm.

The experimental setup for performing the bend test using a three-point attachment is shown in Fig. S7c (please see the supplementary information). The electrodes were cut into test samples of size 40 mm x 20 mm. Since the electrodes experienced the highest stress at 10 mm, as per the simulations, the same bending radius was chosen for 100 bending cycles at room temperature.

XRD, and SEM analysis

X-ray diffraction (XRD) analysis was performed on graphite anode powder from 10° to 90° with XRD from Rigaku Systems® (Fig. 2a). SEM analysis was performed to study the microstructural surface morphology of the screen-printed graphite electrodes A-I which is represented in Fig. 2b-j.

Cell assembly and test protocol

The electrochemical performance of the flexible screen-printed graphite anode was obtained by punching 1.6 cm2 disks and assembling a CR-2032 half-cell LIB with Li-metal foil acting as the counter electrode. Three half-cells were assembled for each electrode specification to evaluate the electrochemical performance. EC: EMC (3:7) by weight dissolved in 1.2 M lithium hexafluorophosphate (LiPF6) was used as electrolyte and polypropylene/polyethylene/polypropylene (PP/PE/PP) was used as the separator. All the coin cells were assembled inside a glove box under Argon gas. Coin cells assembled using electrodes A-I are represented as cells A-I, respectively.

Electrochemical testing of the cells, such as formation, rate, and cycling tests, was performed in the voltage range of 0.01 V to 1.5 V using a CT 3002AU (5 V 50 mA) battery tester from Landt instruments. A constant current rate of 0.1 C was used for performing the formation tests. The protocol was designed to run three cycles of discharging and charging at 0.1 C on all coin cells at room temperature. The current rate of 0.1 C corresponds to the testing time of ten hours (1/0.1 = 10 h). After the formation test, the cells were subjected to a rate test using constant current-constant voltage (CC-CV) protocol for the charging and discharging process. The cells were charged at a constant current of 0.33 C to 1.5 V, with a voltage hold at 1.5 V until the charging time reached three hours or until the current is less than 0.05 C (C/20). Similarly, the cells were discharged to 0.01 V at current densities of 0.1 C, 0.5 C, 1 C, 2 C, 4 C, and 6 C. Voltage hold was applied during discharging at each C-rate until the current was less than 0.05 C (C/20) or until the time reached ten, two, one, half, one-fourth, and one-sixth hours at respective C-rates. All the cells were recovered back to 0.1 C at the end of the rate test to examine the capacity retention. At each C-rate, the cells underwent three cycles of testing. An example of applied current calculation has been provided in the supplementary information. A cycling test was conducted on the cells using CC-CV mode with a voltage range of 0.01 V to 1.5 V.

A 2 C rate was used for the discharge of the cells and a current density of 0.33 C was used for the charging process. Voltage hold was applied during charging and discharging until the testing time reached 3 h and half-hours, respectively or the current went lower than 0.05 C.

Results and discussion

The surface tension of the graphite ink was measured to be ~ 6.2 dynes/cm using the pendant drop method (Fig. S1b)36. The surface energy of copper foil (substrate) was also measured with de-ionized (DI) water and hexadecane as 76 dynes/cm based on the Owens-Wendt method. The surface tension value obtained was less than the surface energy of the substrate indicating that the ink was printable onto the substrate. Similarly, a contact angle of 62.4° was measured for the ink with respect to a 9 μm thick copper substrate (MSE Supplies) using the sessile drop method using an FTA200 goniometer37. Contact angles < 90° indicate good wetting characteristics of the ink on the copper substrate.

Since the prepared ink had high solid loading, the initial viscosity of 230 Pa.s was recorded at a shear rate of 1 s− 1 and it reduced to 0.7 Pa.s at 500 s− 1 indicating shear-thinning behavior, which helps in seamless ink transfer onto the substrate through the stainless-steel screen mesh. The viscosity of the ink was reduced from ~ 231 Pa.s to ~ 0.7 Pa.s and recovered to ~ 226 Pa.s, as the shear rate was varied from 1 s− 1 to 500 s−1 and back to 1 s−1, respectively for the anode ink’s thixotropy study. This demonstrates that the ink is stable and suitable for continuous deposition on the copper substrate.

The COMSOL simulation results of mechanical characterization have shown that the VonMises stress (MPa) is maximum on the electrodes when the bending radius is lower (10 mm) and the stress gradually reduces with an increase in bending radius [Figures S6 and S7a (please see the supplementary information)]. At a 60 mm bent radius, a small stress distribution was observed. Bending radii of 10 mm and 20 mm produced higher stress due to their extreme bending angles in comparison with other bent radii. Figure S7b (please see the supplementary information) shows the plot of average stress with respect to different bending radii from 10 to 60 mm, obtained from COMSOL simulations. Electrode-I experienced a stress of approximately 9.7 MPa at a 10 mm bending radius in comparison with electrode-A which experienced 10.9 MPa. The results show that the printed electrode with SPNs (electrode-I) experienced slightly lower stress compared to electrode-A without SPNs.

(a) XRD analysis of graphite anode; SEM surface morphologies of (b) electrode-a, (c) electrode-b, (d) electrode-c, (e) electrode-d, (f) 1electrode-e, (g) electrode-f, (h) electrode-g, (i) electrode-h, (j) electrode-i, (k,l) SEM image of graphite electrode at high magnification along with its EDS analysis. Note: Scale for (b) 20 μm, (c–j) 200 μm, and (k,l) 2 μm.

Following this, the surface morphology of the graphite anode samples was analyzed using SEM for any micro-structured cracks induced due to the applied mechanical stress after 100 bending cycles. Figure S8a–d (please see the supplementary information) shows the SEM images of the test samples before and after the bending test for electrodes A & I. No microcracks were observed on the graphite anode surface for electrodes A and I. This shows that the printed electrodes can withstand high stress without any damage.

For XRD, the intensity peak (002) observed at 26.5° represents the graphitic layers with no contaminations in the graphite anode powder38. A smooth surface morphology was observed for the electrodes using SEM where the voids represent the pore region that facilitates the interaction between the electrode material and electrolyte solution, resulting in high ionic mass transport. Uniform printing was observed for all the electrodes with different pore diameters and ETE distances. The shapes of 1000 μm and 500 μm SPNs, which had an ETE distance of 2 mm between pores, were circular and not significantly affected by ink spreading during the printing process. However, for smaller SPNs (100 μm) with a closer ETE distance (100 –400 μm), the pore shape was not completely circular due to ink spreading. Maintaining pore structures closer to the designed specifications is a significant challenge, especially when pore diameters become smaller (< 200 μm) in screen printing considering the limitations in screen production where the currently available stainless-steel mesh opening is limited to ~ 53 μm with a wire diameter of ~ 20 μm which can create a pore close to ~ 100 μm35. Since the pore diameter of the SPNs is 100 μm, inks with very high viscosities should be used for printing to avoid the spreading of printed patterns especially when the ETE between the pores is small (100–400 μm). Considering the smaller mesh opening and wire diameter, it is challenging to print the smaller patterns accurately. Energy dispersive X-ray spectroscopy (EDS) analysis was performed for element mapping, where uniform distribution of graphite (an allotrope of carbon), and fluoride (binder) were detected (Fig. 2k-l).

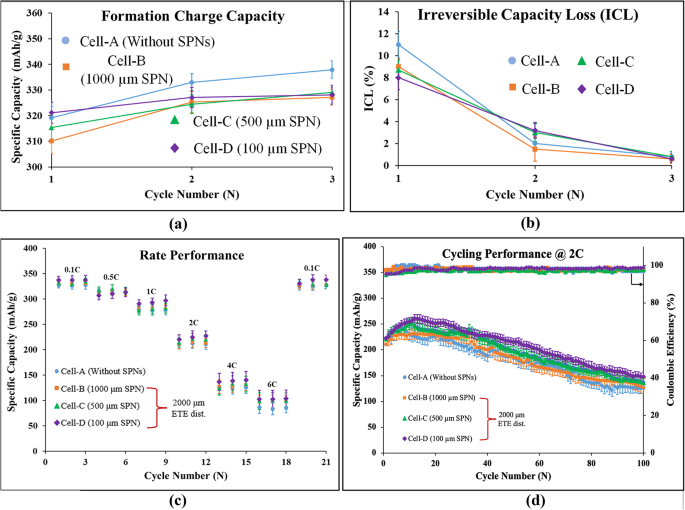

Initially, coin-cells A to D were assembled using electrodes A to D, to study the effect of the pore size on the electrochemical performance. Figure S9a-d (please see the supplementary information) show the voltage profile of the formation test cycles. Cells A, B, C, and D exhibited initial discharge capacities of 351, 339, 345, and 349 mAh/g, respectively. All the tested cells exhibited similar discharge curves with a slope feature above 0.25 V and three voltage plateaus around 0.25 V, 0.15 V, and 0.05 V. These plateaus can be correlated to the lithiation characteristics of graphite. The charge capacities were in the range of 325–330 mAh/g for cells B, C, and D when compared to cell A which exhibited ~ 338 mAh/g capacity at the end of the formation test. Figure 3a, b represents the charge capacities and irreversible capacity loss (ICL) values of cells A, B, C, and D during formation. The ICL was less than 1% for all the cells at the end of formation test. In addition, there was no significant difference in the capacity of the cells at the end of the formation test. This indicates that SPNs have minimal effect at very low C-rates such as 0.1 C. This could be due to reduced volumetric active material density. Introducing SPNs lowers the packing density of active materials. At low C-rates such as 0.1 C, when ionic transport is not limiting, the absolute amount of active material per unit volume governs capacity. An electrode with SPN therefore contains slightly less active material mass in same footprint, leading to lower capacity under low-rate conditions.

After formation, cells were subjected to the rate test by applying the CC-CV protocol. Figure 3c shows the rate test results of specific discharge capacity for cells A-D at varied C-rates. Cell D demonstrated slightly better capacities especially at higher rates such as 2 C, 4 C, and 6 C in comparison to cells A, B, and C. For example, cell D exhibited capacities of 227, 139, and 103 mAh/g when compared to cell A (reference electrode) which exhibited capacities of 210, 120, and 85 mAh/g at 2 C, 4 C, and 6 C, respectively. All the cells demonstrated good capacity retention close to their initial capacities at 0.1 C by the end of the rate test. The drop in the capacity at higher C-rates can be correlated to overpotential because of the limited Li+ diffusion in electrodes39.

A cycling test was performed on the coin cells for 100 cycles at 2 C to determine the long-term stability. Figure 3d shows the cycling performance of specific discharge capacity for cells A to D. An increase in the capacities of the coin cells was observed at the beginning of the cycling test. This increase can be correlated to the improved electrode wetting, gradual activation of electrode material, or increased reversibility of interfacial process. In addition, during early cycles a thick SEI layer is generated and as the cell undergoes more cycles, the SEI layer starts getting thinner and more uniform. This could lead to recovery of some Li+ which lowers the impedance momentarily and could contribute to capacity increase40,41. This SEI layer is crucial for the long-term stability and performance of the battery. During the formation of uniform SEI layer, an initial rise in capacity might occur as it provides additional pathways for Li+ transport and improves electrode-electrolyte interface kinetics. In addition, during initial cycles at a higher C-rate, the electrolyte may redistribute inside the cell, leading to improved wetting of the electrode surface and enhanced ion transport. This electrolyte redistribution can contribute to the initial rise in capacity as the cell reaches optimal electrochemical conditions. Capacities of approximately 125, 127, 135, and 148 mAh/g were recorded for cells A, B, C, and D at the end of the cycle test (i.e., 100th cycle), respectively. A similar trend, as the rate test, was observed during the cycling performance, where cell D demonstrated the highest capacity retention of ~ 68% when compared to a capacity retention of ~ 59% for cell A at the end of the 100th cycle. In addition, larger SPNs result in the reduction of the energy density of the batteries in comparison to smaller SPNs due to reduced active material in unit area, electrode integrity, and diffusion limitations (larger pores might have slower Li+ diffusion than smaller pores due to more vacant region without any electrode material)42.

Electrochemical performance of cells A, B, C, and D representing (a) formation capacity at 0.1 C for three cycles, (b) irreversible capacity loss (ICL) during formation as a function of cycle number, (c) rate performance showing specific discharge capacities at different C-rates, (d) cycling performance showing specific discharge capacities at 2 C-rate for 100 cycles.

Based on the formation, rate, and cycling tests of cells A to D, SPNs with pore diameters of 100 μm were considered for further optimization of structured electrodes to enhance the fast-charging capabilities of the LIBs. The ETE distance between the pores was gradually reduced from 2000 μm to 400 μm, 300 μm, 200 μm, 150 μm, and 100 μm (electrodes E-I). The pore size and ETE were limited to 100 μm due to the screen manufacturing limitations and reducing them further will result in the complete erosion of screen emulsion. Coin cells were assembled for electrodes E-I with varying ETE distances between the pores and electrochemical performance was investigated by conducting formation, rate, and cycling tests. No changes were made to the testing protocols.

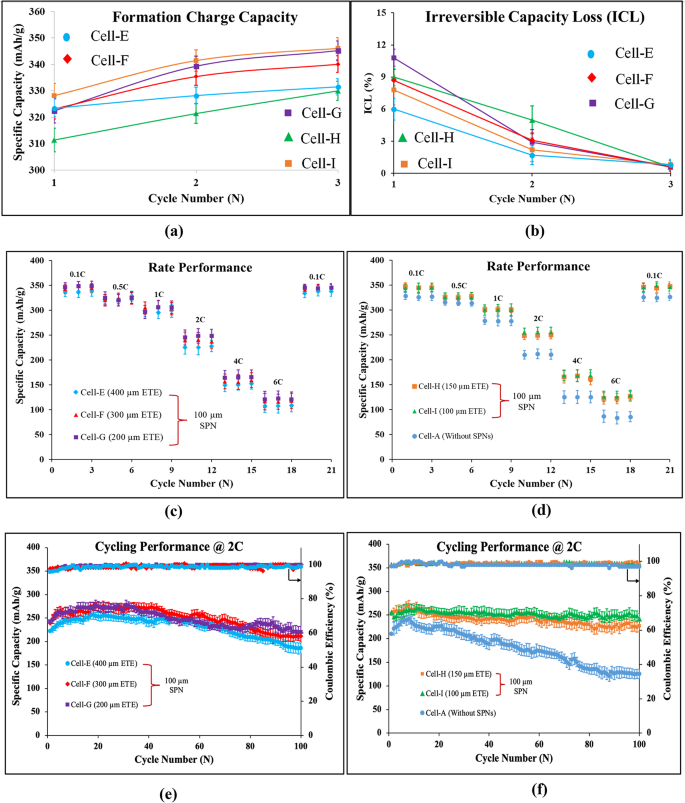

Figure S10a-e (please see the supplementary information) displays the voltage profiles of the formation test cycles for the assembled coin cells E to I. Similar discharge slopes were observed around 0.25 V, 0.15 V, and 0.05 V indicating the lithiation properties of graphite. At the end of the formation, discharge and charge capacities were approximately in the range of 335–345 mAh/g indicating very little capacity loss of less than 1% by the end of the third cycle. Figure 4a-b shows the formation capacity and ICL of cells E to I.

Later the cells were subjected to a rate test using the CC-CV protocol. Figure 4c, d shows the rate performance of specific discharge capacity for cells E to I, at various current rates. The cells displayed similar capacities at 0.1 C, 0.5 C, and 1 C indicating minimal effect of SPNs at low C-rates. An increment in the capacities was observed at higher C-rates as the ETE distance between the pores was gradually reduced. Capacities of 225, 237, 245, 249, and 255 mAh/g were observed at 2 C for cells E to I, respectively. At 4 C, the cells E to I, exhibited capacities of 149, 158, 164, 164, and 168 mAh/g, respectively. Similarly, when the current rate was increased to 6 C, capacities of 108, 116, 120, 122, and 129 mAh/g were measured for cells E to I, respectively. All the electrodes achieved capacities close to their initial capacities towards the end of the rate test. The results show that cell I exhibited remarkable rate capacities at high C-rates among all the tested cells (Fig. 4d). Cell I achieved capacity improvements of 21%, 40%, and 52% at higher C-rates such as 2 C, 4 C, and 6 C, respectively, when compared to cell A (without SPNs). At 6 C, cell I displayed an increase in capacity of approximately 1.5 times greater when compared to electrode-A. Figure S11 (please see the supplementary information) displays the voltage profile of the rate test for cells A and I from 0.01 to 1.5 V. A larger potential gap was observed for cell-A with an increase in C-rates when compared to cell I. These rate test results indicate the superior performance of electrodes with smaller SPNs and closer ETE distance between the pores when compared to conventional bar-coated electrodes.

Similar to the rate performance, cell I displayed superior stability when compared to other cells at the end of the cycling test. Figure 4e, f represents the cycling performance of specific discharge capacity for cells E to I. Capacity retentions of approximately 83%, 88%, 91%, 91%, and 95% were measured for cells E to I, respectively, at the end of the cycling test. This retention corresponds to the final capacity of the battery when compared to its initial capacity at the beginning of the cycling test. An overall improvement of 48%, 69%, 76%, 82%, and 94% was observed in terms of specific capacity for cells E to I when compared to cell A at the end of the cycling test, and the capacity fading in cell A can be correlated with the sluggish kinetics of Li+ transportation. For further evaluation, cells A and I were tested at C-rates of 4 C and 6 C to get a more comprehensive evaluation of cycling performance. Figure S12 (please see the supplementary information) displays the cycling performance of cells A and I at 2 C, 4 C, and 6 C. At 4 C, cell A and cell I recorded capacity retention of approximately 30% and 91% respectively. Similarly, when the C-rate was increased to 6 C-rate, capacity retention of 70% was recorded for cell-I (with SPNs) while cell-A (without SPNs) has dropped down to zero capacity after 76 cycles. Similarly, the remarkable stability for printed electrodes can be attributed to the electrode design with SPNs which resulted in enhanced transport of electrolyte through the electrode along with an increase in Li+ diffusion during cycling especially at fast charging current rates. Introducing larger SPNs (1000 μm, 500 μm) results in the decline of the energy density of the battery. This poor performance of large SPNs arises from combination of reduced electrode surface area and longer diffusion distance between pores. This means that the Li+ must travel farther to reach all storage sites inside the electrodes with larger SPNs. In addition to smaller SPNs, the ETE distance between the pores plays a significant role in fast charging capability. Closer ETE distance between the pores results in increased SPNs in a unit area. Thus, smaller SPNs with closer ETE distance between pores result in further enhancement of three-dimensional Li+ transfer efficiency through the electrode in addition to the increased energy density of fast-charging LIBs. In other words, the smaller SPNs with closer ETE distance between the pores help in attaining stable, fast charging, high capacity and energy density LIBs by providing shorter diffusion paths, uniform ion distribution, and faster kinetics at high rates41,42.

Finally, after cycling tests, EIS measurements were performed on the coin cells to investigate the resistance offered by the electrode and SEI layer. Figure S13a-d (please see the supplementary information) represents the EIS plots for a frequency range of 0.01 Hz to 100 kHz. Generally, the Nyquist plot consists of two semi-circles in the high and medium frequency regions and a diagonal line at low frequencies (Warburg impedance). The first semi-circle represents the Li+ transfer that occurs in the SEI film formed on the graphite surface. The second semi-circle is related to charge transfer resistance caused due to Li+ intercalation process in the battery. This resistance usually occurs in the mid-frequency range followed by Warburg impedance in the low-frequency region43. In LIBs, the increase in resistance after cycling for graphite anode can be correlated to a poor electrical network between the active material and the conductive additive, in addition to internal stress that originates from continuous Li+ diffusion in and out of the graphite anode, especially at high charging rates. From the EIS plots, it was observed that the cells made of electrodes A to D displayed impedance of approximately 80 Ω − 120 Ω before cycling (Fig. S13a) (please see the supplementary information) which was reduced to 20 Ω − 40 Ω for the cells after cycling (Fig. S13c) (please see the supplementary information). Cells E-I displayed similar trend with EIS resistance in the range of 50–100 Ω for all the cells before cycling (Fig. S13b) (please see the supplementary information). Cells H and I which exhibited superior cycling stability had Rct (resistance due to charge transfer) of approximately 3.845 Ω and 3.798 Ω, respectively (Fig. S13d) (please see the supplementary information) after cycling. Similarly, for cells E to G the measured Rct impedance values were 6.613 Ω, 5.073 Ω, and 4.329 Ω, respectively (Fig. S13d) (please see the supplementary information). The internal resistance, SEI resistivity and charge transfer resistances of the tested cells after cycling are summarized in Table S2 (please see the supplementary information). The reason for increase in resistance of cells before cycling is due to electrode activation, wetting, and SEI formation. Before cycling, the graphite surface might be partially wetted by the electrolyte and the ionic pathways are still finding their way to into the pores across the electrode. This could lead to high series and charge transfer resistance. After cycling, electrolyte fully penetrates the pore network, and very thin SEI is formed resulting in lower impedance compared to nascent film that forms during initial cycles before cycling. These EIS results revealed that the cells assembled from electrodes with 100 μm SPN and closer ETE distance between pores had very little internal impedance of Li+ transport indicating a low hindrance effect even after cycling for 100 cycles. Figure S13e represents the equivalent circuit model for fitting the impedance spectra (please see the supplementary information) based on work published by S. Ahmadi et al.44. In the Nyquist plot, a very small resistance is observed at the beginning of the real part which represents the internal resistance of battery’s bulk materials (electrolyte, separator, and copper current collector for anode). It is referred to as electrolyte resistance and does not affect the state-of-charge. This is represented as Rb in the equivalent circuit45,46,47. We observe two semi-circles in high and mid-frequency range. In the equivalent circuit, RSEI represents the contact resistance which can be correlated with resistance between copper current collector and graphite particles46,47,48,49. This resistance is generally referred to as SEI resistance which occurs in high-frequency regions of Nyquist plot and occurs due to impedance of SEI layer formation due to electrolyte decomposition50. Rct represents the distance under the second semi-circle which is defined as charge transfer resistance for electrons. This occurs during transfer process from one phase to another in addition to surface coating, active material particle size, and temperature. This resistance is linked to the electrochemical reaction kinetics50. Higher transfer resistance indicates higher capacity fade50. The low frequency region of Nyquist plot is generally correlated with diffusion of Li+ inside active materials can be represented by Warburg components in the equivalent circuit49.

Li+ diffusion coefficient was calculated based on Eq. (1) based on44, where ‘D’ represents the diffusion coefficient, ‘R’ represents universal gas constant, ‘T’ is absolute temperature, ‘A’ is working area of electrode, ‘n’ represents the electronic transport ratio during redox process (n = 1), ‘F’ represents Faraday constant, ‘c’ represents molar density of Li+ in electrolyte (c = 1.2 mol L− 1), and ‘σ’ is slope on diffusion state of EIS measurement and is calculated based on Warburg coefficient’s phase element. Table S3 and S4 represents the Li+ diffusion coefficient values calculated for different electrodes and comparison of Li+ diffusion coefficient to other published results recently.

The results from EIS data indicated low resistance to Li+ transport and charge transfer for printed structured electrodes with smaller SPN and closer ETE distance when compared to reference electrode. These results can also be correlated to superior cycling stability for cells E to I with structured electrodes. These results demonstrate the significance of implementing micro-structured SPNs that enhance the charge transfer kinetics inside the battery for achieving fast-charging LIBs with high capacity and cycling stability51.

Lithium plating characterization

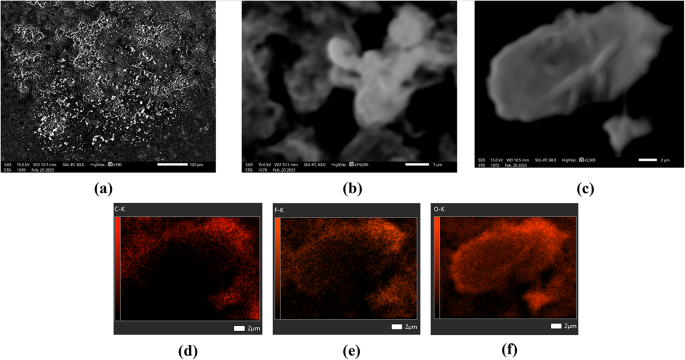

After cycling, lithium plating characterization was performed on the electrodes with and without SPNs. Lithium plating usually occurs on an anode surface due to the accumulation of lithium ions at the electrode surface. It is a major concern in LIBs and results in rapid capacity loss of the battery along with safety concerns such as short-circuiting in the cell52,53. Considering the electrochemical performance during rate and cycling tests, electrode I (with SPNs) was chosen along with electrode A (without SPNs) for lithium plating analysis on the anode surface to validate the importance of introducing SPNs into the electrode. The cells from electrodes A and I were disassembled inside a glovebox under argon gas. The cells were rinsed with EMC and were dried overnight before transferring them to SEM for surface morphology analysis.

The SEM surface morphology of electrode A displayed agglomerates of small white particles on the anode surface along with graphite particles as shown in Fig. 5a. Figure 5b, c represents the SEM images at higher magnification (x14,000 and x5,500 respectively) clearly showing the white particles present on the anode surface with irregular shapes and sizes. The EDS analysis of cycled electrode A indicated that the white particles consist only of oxygen with the absence of carbon (C), fluorine (F), and phosphorus (P) elements (Fig. 5d, f). The lack of elements C, F, and P eliminates the possibility of these white particles as oxidized lithium salt from liquid electrolyte or during the formation of the SEI layer54. Since the Li element cannot be detected, considering its low energy radiation properties and atomic mass, it is highly feasible that the detected oxygen element occurred due to plated lithium particles which were oxidized while transferring the electrode from the glovebox to SEM.

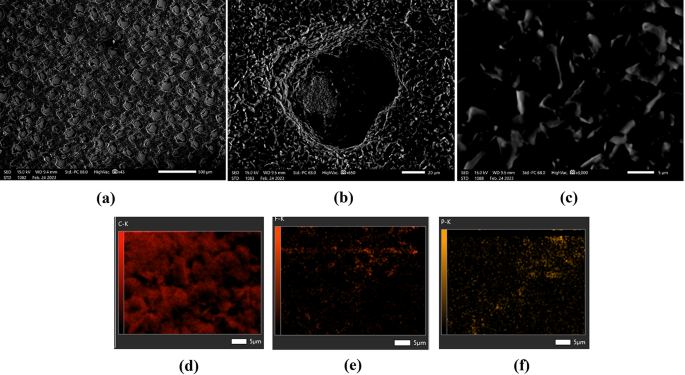

On the other hand, electrode I was able to successfully suppress the lithium plating on the anode surface. Figure 6a shows the SEM surface morphology of the cycled electrode I. Figure 6b, c represent the surface morphology at higher magnification and Fig. 6d–f shows the EDS analysis. Unlike electrode A, electrode I did not have any white particles on the anode surface, and elements such as C, F, and P were detected throughout the electrode surface indicating the capability of the printed electrode I to suppress lithium plating even after 100 cycles at 2 C. There was a homogeneous carbon distribution which can be attributed to the graphite anode material (Fig. 6d–f). Uniform distribution for the ‘F’ element was also observed which was correlated to uniform electrolyte decomposition. This uniform elemental distribution represents anode surface film with less aging-instigated growth effect6. The implementation of SPNs demonstrated the suppression of lithium plating at higher current densities, which could also have been the reason for the superior rate and cycling performance of electrode I when compared to electrode A at higher current densities. In addition, the surface morphology of both electrodes did not display any signs of mechanical damage after cycling at a high rate. This also validates that screen-printing can be performed to fabricate the electrodes without affecting the mechanical stability of the electrodes.

To investigate more about lithium plating, open circuit voltage (OCV) and differential/derivative open circuit voltage (dOCV) analysis were performed on cells A and I as reported by Konz et al.55. Using the OCV analysis, undesired lithium plating that occurs during fast charging conditions can be detected as shown in Fig. S14a (please see the supplementary information). Figure S14b (please see the supplementary information) shows the sample OCV (yellow) and dOCV (green) curves representing the lithium plating onset of chemical intercalation of lithium during the rest period. The initial lithium plateau corresponds to the mixed potential between lithiated graphite (LixC6) and plated lithium. As more intercalation of lithium plating occurs, the Li/LixC6 potential converts to pure LixC6 after consuming some amount of surface lithium. These decay features are more notable as a function of derivative voltage, (dOCV) which was initially presented by Schindler et al.56. This OCV analysis helps to determine the state-of-charge (SOC) of the LIB at which the plating onset becomes significant. This is a key parameter in determining the fast-charging capability of the LIB along with good cycling life. To the best of the authors’ knowledge, this OCV analysis has never been used to study the effect of SPNs in printed electrodes57,58.

Lithium plating onset test was performed on coin-cells A and I. Figure S15 (please see the supplementary information) shows the test protocol of plating onset at 2 C between SOC of 10% and 95%, in increments of 5% (shown up to 50% SOC in the figure for better legibility). All the coin cells were charged to 1.5 V at a C-rate of C/3. Then the cells were discharged at 2 C without voltage hold and rested for 30 min and the data during the rest period (highlighted in red, Fig. S15) was used for plotting the OCV and dOCV curves. The same protocol was used to perform the lithium plating onset test at fast-charging C-rates of 4 C and 6 C.

Figure S16 (a-b) and (c-d) (please see the supplementary information) shows the OCV and dOCV plots of cell A at 2 C-rate from 10 to 95% SOC, respectively. At 2 C-rate, no significant plating was observed from 10 to 50% SOC (Fig. S16(a)). A similar trend was observed until 95% SOC. A significant plateau was observed close to 95% SOC which was highlighted using a green marker in Fig. S16(b-d), indicating the lithium-plating intercalation onset in both the OCV and dOCV curves. Similarly, OCV and dOCV curves for cell I are shown in Fig. S17 (a-b) and (c-d), respectively (please see the supplementary information). There were no significant voltage plateaus indicating lithium intercalation on the anode surface of printed electrode-I (with SPNs) at 2 C-rate. This reveals that the printed electrode with SPNs was able to successfully suppress lithium plating at 2 C rate when compared to electrodes without SPNs. This can also be correlated to the better cycling stability of cell I in comparison to cell A.

Figure S18 (a-b) and (c-d) represent the OCV and dOCV curves for electrode-A at 4 C-rate (please see the supplementary information). There was no significant lithium intercalation observed at lower SOCs until 50% SOC (Fig. S18(a, c)). The first sign of lithium intercalation plateau was observed close to 60% SOC as shown in Fig. S18(b). The plateau became more significant as the SOC increased from 60 to 95%. Figure S18(d) represents the dOCV analysis from 55 to 95% SOC where the lithium plating peaks were obvious and more prominent starting from 60 to 95% SOC. Figure S19a–d (please see the supplementary information) represent the OCV and dOCV curves for cell I at 4 C-rate. The first sign of lithium intercalation at 4 C occurred between 80 and 85% SOC (close to 85%) and was prominent until 95% SOC which was also observed during the dOCV analysis where lithium plating peaks were significant between 85 and 95% SOC. From the OCV curves, it is clear that as the C-rate increased from 2 C to 4 C, electrode-A degradation is much faster due to the chemical interaction of lithium than electrode I, which did not show any significant voltage plateaus until 80% SOC.

A similar trend was also observed at 6 C for the lithium plating onset test between 10 and 95% SOC (Fig. S20 and S21) (please see the supplementary information). Cell A had significant lithium intercalation and plating peaks in both OCV and dOCV curves starting around 50% SOC (Fig. S20a, c), when compared to cell I, which was able to suppress the lithium plating up to 75% SOC (Fig. S21b, d). This could be due to shallow destructive conditions in electrode A at lower SOCs which eliminate the feasibility of prior nucleated lithium that could advance early plating in the succeeding cycles32. These lithium plating onset tests demonstrated the SPN’s impact in suppressing the formation of lithium plating on anode surface even at very high C-rates such as 4 C and 6 C, resulting in prolonged cycling life with the ability to achieve higher capacities. Table S4 (please see the supplementary information) shows the summary of lithium plating onset for cells A and I at fast-charging C-rates such as 2 C, 4 C, and 6 C. From the table, it is evident that significant lithium plating is more prominent at higher SOCs greater than 50% for electrode A. Whereas, the screen-printed SPNs were able to suppress the formation of plating for a longer duration even at high current rates.

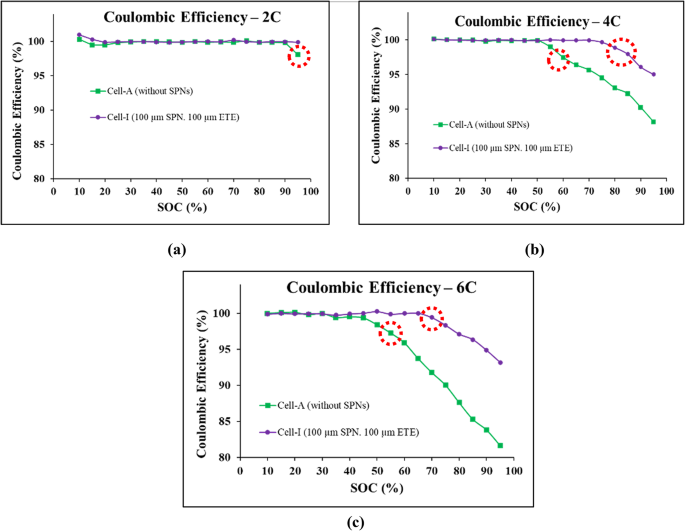

Coulombic efficiencies (CE) were also analyzed for cells A and I by using the ratios between discharge and charge capacities during lithium plating onset testing, following the methodology outlined by Konz et al.55. Figure 7 represents the summarized CEs for the electrodes at 2 C, 4 C, and 6 C. The initial drops in CE in Fig. 7a–c are highlighted in red which corresponds to the SOC where the lithium plating onset was first detected. At 2 C, cell A experienced a drop from 99.8 to 98.1% in CE around 95% SOC while cell I maintained CE greater than 99.8% consistently throughout the test (Fig. 7a). At 4 C, cell A experienced initial plating onset around 60% SOC corresponding to a drop in CE from 99 to 97.5% (Fig. 7b). The CE drop was more evident with an increase in SOC (CE of ~ 88% at 95% SOC). The initial drop in CE for cell I at 4 C was observed from 98.9 to 96.9% around 85% SOC. It recorded a CE of approximately 95% at the end of the onset test. Similarly, at 6 C, cell A exhibited a CE of 81.6% at the end of the test with an initial drop in the CE value from 99.3 to 98.3% around 50% SOC. Whereas, cell I exhibited a CE of 93.1% at 95% SOC with an initial drop in CE from 99.4 to 98.3% which was observed at 75% SOC (Fig. 7c). The results indicate lower CE for cell A in comparison to cell I and this can be correlated to early detection of lithium plating onset on the anode surface which results in the reduction of CE as the SOC gradually increases. The printed electrodes with SPNs were able to suppress lithium plating for a longer duration, especially at 4 C and 6 C resulting in less reduction in CE when compared to electrodes without SPNS.

These lithium plating results portray the significance of introducing SPNs into the electrode to effectively counter the lithium plating on the anode surface in addition to achieving high capacity, fast-charging, and stable LIBs, especially for EV applications. Although SPNs help with Li+ and mass liquid electrolyte transportation, the pore size of SPNs and the ETE distance between the pores play a significant role in determining the battery’s performance and stability. From this work, it is evident that larger SPNs did not have a significant effect on improving the battery’s performance considering the size of Li+ being much smaller than the diameter of SPNs. In addition, introducing larger SPNs into the electrode will also lead to a significant reduction in the energy density of the battery. Thus, by reducing the pore diameter of SPNs, we can increase the number of pores in a unit area which helps in assisting the mass transfer of liquid electrolyte. Similarly, reducing the ETE distance between the pores will enhance Li+ diffusion. Even though the current work illustrates the significance of introducing SPNs into the electrode through rate, cycling, and lithium plating tests at the coin-cell level, further printing and electrochemical tests are required for these electrodes by assembling pouch cells using a Systec® roll-to-roll (R2R) cylindrical screen printer to demonstrate high-volume manufacturability. Figure S23 (please see the supplementary information) shows the schematic representations of transitioning from sheet-to-sheet (S2S) printing to R2R printing for fabricating electrodes for LIBs. Implementing R2R printing will further help in optimizing the printing conditions depending on the size and ETE distance of the SPNs since printing smaller SPNs with closer ETE distances could be challenging. NMC will be used as the cathode material for testing R2R screen-printed flexible electrodes to achieve high-capacity and fast-charging LIBs. Converting the fabrication technique from S2S to R2R will enhance the ease of implementation of SPNs in the electrodes on a commercial and industrial basis with little material wastage.

Conclusion

In this work, a flexible graphite anode was fabricated by introducing novel SPNs using the screen-printing process to enhance the LIB’s performance. The cells assembled with micro-structured SPNs of smaller pore size and closer ETE distance demonstrated better rate and cycling performance in addition to displaying the ability to suppress lithium plating at fast charging current rates in comparison to the reference electrode. Rate test of the structured electrode consisting of 100 μm SPN with 100 μm and, 150 μm ETE distance had ~ 50% capacity improvement when compared to the reference electrode at a fast-charging C-rate of 6 C. Superior cycling performance with capacity retention greater than 91% was also observed for cells with structured electrodes when compared to reference electrode which measured retention of 60% by the end of the 100th cycle. Lithium plating tests proved the significance of introducing SPNs to suppress plating and improve the stability of the batteries. Further investigation involves the fabrication of electrodes using a Systec® roll-to-roll cylindrical screen printer for multilayer pouch cell testing.

Data availability

All data generated or analyzed during this study is provided within the manuscript or supplementary information files.

References

Li, S. et al. Fast charging anode materials for lithium-ion batteries: current status and perspectives. Adv. Funct. Mater. 32, 2200796. https://doi.org/10.1002/adfm.202200796 (2022).

Huang, Q. et al. Aligned carbon-based electrodes for fast-charging batteries: A review. Small 17, 2007676. https://doi.org/10.1002/smll.202007676 (2021).

Hawley, W. B. & Li, J. Beneficial rheological properties of lithium-ion battery cathode slurries from elevated mixing and coating temperatures. J. Energy Storage. 26, 100994. https://doi.org/10.1016/j.est.2019.100994 (2019).

Stein, A., Mistry, A. & Mukherjee, P. P. Mechanistic Understanding of the role of evaporation in electrode processing. Food Sci. 164, A1616. https://doi.org/10.1149/2.1271707jes (2017).

Parikh, D., Christensen, T. & Li, J. Correlating the influence of porosity, tortuosity, and mass loading on the energy density of LiNi0.6Mn0.2Co0.2O2 cathodes under extreme fast charging (XFC) conditions. J. Power Sources. 474, 228601. https://doi.org/10.1016/j.jpowsour.2020.228601 (2020).

Kriegler, J. et al. Enhanced performance and lifetime of lithium-ion batteries by laser structuring of graphite anodes. Appl. Energy 303, 117693. https://doi.org/10.1016/j.apenergy.2021.117693 (2021).

Nitta, N., Wu, F., Lee, J. T. & Yushin, G. Li-ion battery materials: present and future. Mater. Today. 18, 252–264. https://doi.org/10.1016/j.mattod.2014.10.040 (2015).

Tomaszewska, A. et al. Lithium-ion battery fast charging: A review. eTransportation 1, 100011. https://doi.org/10.1016/j.etran.2019.100011 (2019).

Liu, Q. et al. Understanding undesirable anode lithium plating issues in lithium-ion batteries. RSC Adv. 6, 88683–88700. https://doi.org/10.1039/C6RA19482F (2016).

Orikasa, Y. et al. Ionic conduction in lithium ion battery composite electrode governs cross-sectional reaction distribution. Sci. Rep. 6, 26382. https://doi.org/10.1038/srep26382 (2016).

Xie, W. et al. Challenges and opportunities toward fast-charging of lithium-ion batteries. J. Energy Storage. 32, 101837. https://doi.org/10.1016/j.est.2020.101837 (2020).

Suthar, B., Northrop, P. W. C., Rife, D. & Subramanian, V. R. Effect of porosity, thickness and tortuosity on capacity fade of anode. J. Electrochem. Soc. 162, A1708. https://doi.org/10.1149/2.0061509jes (2015).

Blaubaum, L. et al. Impact of particel size distribution on performance of lithium-ion batteries. ChemElectroChem 7, 4755–4766. https://doi.org/10.1002/celc.202001249 (2020).

Landi, B. J., Ganter, M. J., Cress, C. D., Dileo, R. A. & Raffaelle, R. P. Carbon nanotubes for lithium ion batteries. Energy Environ. Sci. 2, 638–654. https://doi.org/10.1039/B904116H (2009).

Billaud, J., Bouville, F., Magrini, T., Villevieille, C. & Studart, A. R. Magnetically aligned graphite electrodes for high-rate performance li-ion batteries. Nat. Energy. 1, 1–6. https://doi.org/10.1038/nenergy.2016.97 (2016).

Demirtas, M. S. & Saha, M. C. Engineering highly aligned continuous nanofibers via electrospinning: A comprehensive study on collector design, electrode geometry, and collector speed. Express Polym. Lett. 18, 851–867. https://doi.org/10.3144/expresspolymlett.2024.63 (2024).

Ahmadi, S., Maddipatla, D., Wu, Q. & Atashbar, M. Z. Investigating the impact of thickness and porosity on energy density of screen printed graphite/nmc libs with 3D structures under fast charging condition. IEEE Sens. 1–4. https://doi.org/10.1109/SENSORS52175.2022.9966999 (2022).

Ahmadi, S. et al. Investigating the impact of thickness, calendering and channel structures of printed electrodes on the energy density of LIBs-3D simulation and validation. IEEE International Flexible Electronics Technology Conference (IFETC) 1–3. https://doi.org/10.1109/IFETC49530.2021.9580515 (2021).

Park, J. et al. Challenges, laser processing and electrochemical characteristics on application of ultra-thick electrode for high-energy lithium-ion battery. J. Power Sources. 482, 228948. https://doi.org/10.1016/j.jpowsour.2020.228948 (2021).

Mijailovic, A. S. et al. A master curve describing reaction inhomogeneity and plating onset during fast-charging of graphite electrodes. J. Electrochem. Soc. 170 (7), 070508. https://doi.org/10.1149/1945-7111/acd963 (2023).

Usseglio-Viretta, F. L. E. et al. Enabling fast charging of Lithium-Ion batteries through Secondary-/Dual-Pore network: part I - Analytical diffusion model. Electrochim. Acta. https://doi.org/10.1016/j.electacta.2020.136034 (2020).

Wang, Y. et al. Designing low tortuosity electrodes through pattern optimization for fast-charging. Small Methods. https://doi.org/10.1002/smtd.202201344 (2023).

Sterzl, Y. & Pfleging, W. Optimizing structural patterns for 3D electrodes in lithium-ion batteries for enhanced fast-charging capability and reduced lithium plating. Batteries 10(5), 160. https://doi.org/10.3390/batteries10050160 (2024).

Emani, H. R. K. M. et al. Development of a screen-printed flexible porous graphite electrode for Li-ion battery. IEEE FLEPS. https://doi.org/10.1109/FLEPS51544.2021.9469794 (2021).

Deiner, L. J., Jenkins, T., Powell, A., Howell, T. & Rottmayer, M. High capacity rate capable aerosol jet printed Li-ion battery cathode. Adv. Energy Mater. 21, 1801281. https://doi.org/10.1002/adem.201801281 (2019).

Lawes, S. et al. Inkjet-printed silicon as high performance anodes for Li-ion batteries. Nano Energy. 36, 313–321. https://doi.org/10.1016/j.nanoen.2017.04.041 (2017).

Shen, H. et al. Oriented porous LLZO 3D structures obtained by freeze casting for battery applications. J. Mater. Chem. A. 7(36), 20861–20870. https://doi.org/10.1039/C9TA06520B (2019).

Maddipatla, D. et al. A flexible copper based electrochemical sensor using Laser-Assisted patterning process. IEEE Sens. https://doi.org/10.1109/ICSENS.2018.8589754 (2018).

Goren, A. et al. High performance screen-printed electrodes prepared by a green solvent approach for lithium-ion batteries. J. Power Sources. 334, 65–77. https://doi.org/10.1016/j.jpowsour.2016.10.019 (2016).

Pfleging, W. Recent progress in laser texturing of battery materials: a review of tuning electrochemical performances, related material development, and prospects for large-scale manufacturing. Int. J. Extreme Manuf. 3, 012002. https://doi.org/10.1088/2631-7990/abca84 (2020).

Zhu, P., Ebert, B., Smyrek, P. & Pfleging, W. The impact of structural pattern types on the electrochemical performance of ultra-thick NMC 622 electrodes for lithium-ion batteries. Batteries 10(2), 58. https://doi.org/10.3390/batteries10020058 (2024).

Yuan, Y. et al. Design and fabrication of high-performance multilayer silicon-carbon composite anodes for lithium-ion batteries via femtosecond laser. J. Energy Storage. 110, 115362. https://doi.org/10.1016/j.est.2025.115362 (2025).

Carey, T. et al. Cyclic production of biocompatible few-layer graphene ink with in-line shear-mixing for inkjet-printed electrodes and Li-ion energy storage. npj 2D Mater. Appl. 6(1), 1–11. https://doi.org/10.1038/s41699-021-00279-0 (2022).

Zhang, Y. et al. Ink formulation, scalable applications and challenging perspectives of screen 5 printing for emerging printed microelectronics. J. Energy Chem. 63, 498–513. https://doi.org/10.1016/j.jechem.2021.08.011 (2011).

Micro Screen. mesh specification. https://www.microscreen.com/frames-and-mesh (accessed June 2025).

Stauffer, C. E. The measurement of surface tension by the pendant drop technique. J. Phys. Chem. 69 (6), 1933–1938. https://doi.org/10.1021/j100890a024 (1965).

Kozbial, A. et al. Study on the surface energy of graphene by contact angle measurements. Langmuir 30(28), 8598–8606. https://doi.org/10.1021/la5018328 (2014).

Laziz, N. A. et al. Li-and Na-ion storage performance of natural graphite via simple flotation process. J. Electrochem. Sci. Technol. 9, 320–329. https://doi.org/10.5229/JECST.2018.9.4.320 (2018).

Heubner, C., Schneider, M. & Michaelis, A. Diffusion-limited C-rate: A fundamental principle quantifying the intrinsic limits of lithium-ion batteries. Adv. Energy Mater. 10, 1902523. https://doi.org/10.1002/aenm.201902523 (2019).

Rangom, Y., Gaddam, R. R., Duignan, T. T. & Zhao, X. S. Improvement of hard carbon electrode performance by manipulating SEI formation at high charge rates. ACS Appl. Mater. Interfaces. 11, 34796–34804. https://doi.org/10.1021/acsami.9b07449 (2019).

An, S. J. et al. The state of Understanding of the lithium ion-battery graphite solid electrolyte interface (SEI) and its relation to formation cycling. Carbon 52–76. https://doi.org/10.1016/j.carbon.2016.04.008 (2016).

Mai, W., Usseglio-Viretta, F. L. E., Colclasure, A. M. & Smith, K. Enabling fast charging of Lithium-Ion batteries through Secondary-/Dual-Pore network: part II - Numerical model. Electrochim. Acta. https://doi.org/10.1016/j.electacta.2020.136013 (2020).

Chang, C. et al. An improvement of equivalent circuit model for state of health Estimation of lithium-ion batteries based on mid-frequency and low-frequency electrochemical impedance spectroscopy. Measurement 202, 111795. https://doi.org/10.1016/j.measurement.2022.111795 (2022).

Ahmadi, S., Maddipatla, D., Bazuin, B. J. & Atashbar, M. Z. A comprehensive experimental study on microstructure-graded graphite anode for enhancing fast-charging capability of lithium-ion batteries. Adv. Energy Sustain. Res. 5, 2300213. https://doi.org/10.1002/aesr.202300213 (2024).

Jalkanen, K. et al. Cycle aging of commercial nmc/graphite pouch cells at different temperatures. Appl. Energy. 154, 160–172. https://doi.org/10.1016/j.apenergy.2015.04.110 (2015).

Ansah, S. et al. A modeling approach to study the performance of Ni-rich layered oxide cathode for lithium-ion battery. Comput. Mater. Sci. 196, 110559. https://doi.org/10.1016/j.commatsci.2021.110559 (2021).

Foss, C. E. L. Doctoral Theses (NTNU, 2014).

Heubner, C. et al. Understanding thickness and porosity effect on the electrochemical performance of LiNi0.6Mn0.2Co0.2O2-based cathodes for high energy li-ion batteries. J. Power Sources. 419, 119–126. https://doi.org/10.1016/j.jpowsour.2019.02.060 (2019).

Zheng, H., Tan, L., Liu, G., Song, X. & Battaglia, V. S. Calendering effects on the physical and electrochemical properties of Li[Ni1/3Mn1/3Co1/3]O2 cathode. J. Power Sources. 208, 52–57. https://doi.org/10.1016/j.jpowsour.2012.02.001 (2012).

Ramaraju, B., Li, C. H., Prakash, S. & Chen, C. C. Metal-organic framework derived Hollow polyhedron metal oxide posited graphene oxide for energy storage applications. Chem. Commun. 52, 946–949. https://doi.org/10.1039/C5CC07621H (2015).

Hille, L. et al. Laser structuring of graphite anodes and NMC cathodes – Proportionate influence on electrode charaacteristics and cell performane. Electrochim. Acta. 392, 139002. https://doi.org/10.1016/j.electacta.2021.139002 (2021).

Arora, P., Doyle, M. & White, R. E. Mathematical modeling of the lithium deposition overcharge reaction in lihium-ion batteries using carbon-based negative electrodes. J. Electrochem. Soc. 146, 3543. https://doi.org/10.1149/1.1392512 (1999).

Lin, X., Khosravinia, K., Hu, X., Li, J. & Lu, W. Lithium plating mechanism, detection, and mitigation in lithium-ion batteries. Prog. Energy Combust. Sci. 87, 100953. https://doi.org/10.1016/j.pecs.2021.100953 (2021).

Yang, J. et al. Gradient porosity electrodes for fast charging lithium-ion batteries. J. Mater. Chem. A. 10, 12114–12124. https://doi.org/10.1039/D2TA01707E (2022).

Konz, Z. M., McShane, E. J. & McCloskey, B. D. Detecting the onset of lithium plating and monitoring fast charging performance with voltage relaxation. ACS Energy Lett. 5, 1750–1757. https://doi.org/10.1021/acsenergylett.0c00831 (2020).

Schindler, S., Bauer, M., Petzl, M. & Danzer, M. A. Voltage relaxation and impedance spectroscopy as in-operando methods for the detection of lithium plating on graphitic anodes in commercial lithium-ion cells. J. Power Sources. 304, 170–180. https://doi.org/10.1016/j.jpowsour.2015.11.044 (2016).

Weng, S. et al. Kinetic limits of graphite anode for fast-charging lithium-ion batteries. Nano-Micro Lett. 15, 215. https://doi.org/10.1007/s40820-023-01183-6 (2023).

Wen, K., Xia, M., Deng, P., Lv, W. & He, W. A sandwich-structured double-battery device for direct evaluation of lithium diffusion coefficients and phase transition in electrodes of lithium ion batteries. Chem. Eng. Sci. 200, 80–86. https://doi.org/10.1016/j.ces.2019.01.062 (2019).

Funding

This material is based upon work supported by the U.S. Department of Energy’s Office on Energy Efficiency and Renewable Energy (EERE) under the Advanced Manufacturing Office, award number DE- EE0009111.

Author information

Authors and Affiliations

Contributions

M.Z., Q.W., and D.M. designed and supervised the research. H.R. K. M. E., T.H., and V. P. performed the experiments. H. R. K. M. E. and T. H. analyzed the data. H. R. K. M. E. and D. M. wrote the paper. D. M., G. W., B. N., W. L., Q. W., and M.Z., contributed to valuable feedback of the manuscript. All the authors read and revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Emani, H.R.K.M., Maddipatla, D., Hanson, T. et al. Investigating the effect of screen-printed structured graphite electrodes with low tortuosity for high-capacity and fast-charging lithium-ion batteries. Sci Rep 15, 28700 (2025). https://doi.org/10.1038/s41598-025-12909-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-12909-4