Abstract

In this study, copper and tin doped TiO2 nanocomposite (NCs) (Cu-Sn-TiO2) were sunthesized using a precipitation method and their potential for nanoremediation of pesticide residues in soil was investigated. To characterize the physicochemical properties of the Cu-Sn-TiO2 NCs, X-ray diffraction, scanning electron microscopy, transmission electron microscopy, energy dispersive X-ray spectroscopy and Fourier transform infrared spectroscopy were used. To assess their antibacterial activity against Escherichia coli and Staphylococcus aureus, bacterial growth inhibition and bacterial membrane damage were measured. The photocatalytic experiment was conducted under natural climatic sunlight. The soil samples were hand-spread to a height of 5 mm in a glass tray and sprayed with an aqueous pesticide solution. The catalyst concentration that worked best was 0.01%. Validated UFLC with PDA detection was used to quantify the samples. Kinetic parameters such as rate constant (k) and DT50 were calculated using pesticide residue dissipation data. After 20 h of exposure, the Cu–Sn–TiO2 NCs demonstrated significant antibacterial activity, reducing bacterial viability by more than 70%. Based on the formation of reactive oxygen species and the disruption of the bacterial membrane, the mechanism of the antibacterial and photocatalytic action of the Cu–Sn–TiO2 NCs was discussed. The agricultural and environmental sectors may benefit from the Cu–Sn–TiO2 NCs promising potential for the nanoremediation of pesticide residues in soils.

Similar content being viewed by others

Introduction

Nanotechnology has provided a wide range of applications in the last few decades. Metals and their oxides Nanoparticles have applications in biomedical, chemical, physics, and electronics because their large surface area to volume ratio allows them to perform unique activities in optical, magnetic, and catalyst roles, as well as sensing and biology. Copper-containing nanoparticles have unique properties when compared to their bulk material. Copper Oxide nanoparticles (CuO NCs) are p-type semiconductors with a band gap of 1.7 eVAs a result, CuO NCs are used in batteries, gas sensors, catalysts, superconductors, solar energy conversion, food, pharmaceutical, agriculture, and organic–inorganic nanostructure composites. CuO NCs have also shown promise as antibacterial, antioxidant, and anticancer agents1.

Photocatalysis is a specific type of chemical transformation. It makes use of energy delivered by reactions that are difficult, if not impossible, to carry out in the dark. A wide range of photocatalytic materials have been investigated for effective light absorption, charge separation, and charge transfer2. Photocatalysis holds the promise of resolving issues related to the intermittent nature of sunlight, which is regarded as a renewable and ultimate energy source for powering human activities on the planet3. Heterogeneous semiconductor photocatalysis is an environmentally friendly, versatile and affordable pollutant treatment technology. Many parts of the world, including developing countries, are now commercializing technology4. Photocatalysis research is expanding in order to develop green technologies for pollutant remediation and energy generation. Semiconducting materials are used in the study to convert light energy into chemical energy5. Photocatalytic materials can improve the efficiency and sustainability of processes. They offer novel ways to address issues across a wide range of fields. Photo-excited electrons are produced by heterogeneous photocatalysis, which can be used to degrade a variety of organic pollutants in water and air6. Organic pollutants can be degraded directly or indirectly by these hydroxyl radicals, holes, and conduction-band electrons. The visible-light activation of TiO2 and its application to environmental remediation are the focus of this research. The photocatalytic degradation of cypermethrin using iron–titanium dioxide (Fe–TiO2) was investigated in this study. The degradation was carried out in a flat plate solar reactor at room temperature and natural pH. The best results were obtained by using Evonik TiO2 P-25, Fe:Ti 1/4 07. The researchers used a simple precipitation method to enhance the photocatalytic activity of the catalyst and degrade neonicotinoid insecticides when exposed to visible light. Background organics present in secondary effluent and lake water significantly hampered the removal of 10-min irradiation cycles, which was maintained at more than 75%. The enhanced photocatalyst was used to remove various water contaminants in this study8. The toxicity of water was a major issue facing today’s world. The two major water pollutants are pesticides like chlorpyrifos and malathion. Many methods for removing these pesticides have been developed. Metal nanoparticles are being widely used due to their unique properties9. A photocatalyst with a simple, cheap ball molding ball is produced for TiO2/GO/CuFe2O4. The photocatalytic degradation of 17 chlorinated pesticides (persistent organically pollutants) has been investigated using the prepared photocatalyst. With UV irradiation, the nanocomposite photo catalytically removed from water nearly 96.5% of the typical pesticide DDE10,11. Persistent pollutant-containing industrial effluents contribute significantly to environmental emissions. Classical techniques such as chlorination, coagulation, ion flotation, membrane phase, and sedimentation have been used to decontaminate waste water12. Scientists’ interests over recent years have acquired on nanophotocatalytic treatments based on titanium (TiO2) and zinc oxide (ZnO)13,14. In modern agriculture, pesticides revolutionized and significantly decreased crop losses. The photocatalytic degradation of pronephros and triazophos in Chinese chalk, Brassica chinensis was studied in this research15. The polymetal compound particles were spherical, highly porous and fluffy7,16. Photocatalytic nanomaterials based on biocompatible titanium dioxide (TiO2) can dislocate agricultural development, harvest, and problems following harvest. As antimicrobial, growth controllable and fertilizer-like agents, TiO2-PN was used. It was found that about 5% of current research in actual agricultural environments was carried out17,18,19. Pesticide pollution by pesticide residues has become a growing concern due to the high soil persistence and toxicity of certain pesticides to non-target organisms. This knowledge can be used to incorporate pesticide residue control systems into soil and to cause toxicity assessments20,21,22. Tebuconazole (TB) is the active ingredient in Orios 25 EW, which is used to treat a variety of crops. The United States Environmental Protection Agency has classified tebuconazole as a Group C-Possible Human Carcinogen. Under aerobic conditions, TB has a half-life of 49–610 days in soil and has moderate mobility. Mas et al. created pH-sensitive gated mesoporous silica nanoparticles loaded with tebuconazole, which significantly increased TB cytotoxicity22,23. Trifloxystrobin is a novel strobilurin fungicide that is effective against a wide variety of fungal plant pathogens. According to the current research, it is highly effective in controlling powdery mildew on "eld-grown apple, mango, and nectarine trees." It is an excellent compound for esoteric integration into fungal pathogen control programmes.24,25,26,27. Photocatalysis is the process of using light energy to drive chemical reactions on a photocatalyst, such as titanium dioxide. It involves light absorption, which excites electrons and forms electron–hole pairs29. The excited electrons and holes are separated, allowing them to participate in redox reactions. These reactions can either donate electrons to reduce substances or accept electrons to oxidize them. The resulting chemical transformations may result in the breakdown of pollutants, hydrogen production from water splitting, or other desired processes. Photocatalysis has several applications, including environmental cleanup, water purification, and energy production30.

The current work was carried out in this respect to evaluate the parameters for the photocatalytic activity of Cu-Sn- TiO2 NCs in soil decontamination of Tebuconazole and Trifloxystrobin residues.

Materials and methods

Reagents and chemicals

Tebuconazole (Purity 99.2%) and Trifloxystrobin (99.5%) reference standard were procured from LGC Laboratories GmbH. Tebuconazole 50% SC and Trifloxystrobin 50% SC was purchased from the local market. Rankem, Chennai, India, provided HPLC quality acetonitrile (Purity 99.9%). Potassium dihydrogen orthophosphate (Purity 99.0%) , Di-sodium hydrogen orthophosphate (Purity 99.1%), Potassium chloride (Purity 98.9%), Boric acid (99.1%), Sodium hydroxide (98.87%), Orthophosphoric acid (Purity 85.7%), Ammonium chloride (Purity 99.3%), Magnesium chloride (Purity 99.6%), Calcium chloride (Purity 99.7%), Magnesium sulphate (Purity 99.1%), and Ethylene diamine tetraacetic acid (Purity 98.4%), AR grade, provided by M/s. Merck India Ltd., Mumbai. M/s. Rankem, Chennai, India, Ferric chloride, GR grade.

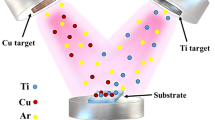

Preparation of copper and tin co-doped TiO2 NCs

For the typical synthesis, 0.02 mol tetrabutyl orthotitanate was placed into 50 mL ethanol (100% purity), resulting in a solution that was rapidly agitated for 20 min at room temperature before adding 3 drops of Conc. HNO3. The reaction mixture was then treated with 0.20 mmol copper nitrate and tin chloride (the Cu to Sn molar ratio was 1:1) and agitated continuously for 60 min until the Cu and Sn dopants were dissolved. Following that, the above solution has been added 2 mL of deionized water. The solution mixture is then kept in the room for 2 h, with the stirring constantly forming a gel that was aged at room temperature for 12 h. After drying at 80 °C for 24 h, the product was annealed at 400 °C for 3 h. The same process was used to prepare an un-doped TiO2 (anatase) sample, but without the addition of Copper Nitrate and Tin Chloride, giving pure TiO2. The concentrations of doping are provided in millimoles of titanium atoms.

Characterization

The structural properties of the samples were obtained by using an X-ray diffractometer (Philips X’Pert; MPD 3040, EA Almelo, The Netherlands) that was equipped with Cu Kα radiations in the 2θ range of 10–70°. The crystal structure and phase purity of the sample were investigated, and the crystallite size was calculated from the XRD patterns using the “Debye Scherrer” equation. The surface morphology of Cu–Sn–TiO2 NCs was investigated using SEM (TESCAN, CZ/MIRA I LMH). The particle size and shape have been studied using TEM (FEI, TECNAI G2 TF20-ST). A JASCO FT/IR-6300 FT-IR spectrometer was used to record the infrared transform (FT-IR) spectra in KBr pellets. Energy dispersive X-ray analysis (EDX) was utilized to determine the elemental composition of Cu–Sn–TiO2 NCs.

Antibacterial activity

The disc diffusion assay method was used to determine the antibacterial activity of synthesized Cu-Sn-TiO2 nanocomposite. Luria Bertani media was prepared and poured into sterilized Petri plates before being inoculated with Staphylococcus aureus, Bacillus subtilis and Escherichia coli. The samples were then added to sterile discs in various concentrations, and the plates were incubated at 37 °C for 24 h. The zone of inhibition was then determined.

Standard stock solution preparations

The stock solutions of reference analytical standards were formed by weighing roughly 10 mg of known purity tebuconazole and trifloxystrobin into each of the different 10 mLvolumetric flasks using an analytical balance. The contents of each flask were dissolved in acetonitrile and adjusted to the appropriate level.

Formulation solution preparations

In each of the 20 mL volumetric flasks, the needed amount of herbicide formulation (Tebuconazole 50% SC and Trifloxystrobin 50% EC) was weighed. The contents have been dissolved in Milli Q water and adjusted to meet the specifications.

Formulation | Application dosage |

|---|---|

Tebuconazole 24% SC | T0-Control T1-1 µg/g |

Trifloxystrobin 24% EC |

UFLC separation parameters

The Shimadzu UFLC system with labsolutions software was employed, and it was outfitted with a reversed-phase column eclipse Zorbex C18 (250 mm × 4.6 mm i.d × 5 µm particle size). The oven temperature was maintained at 40 °C, and the sample volume injected was 20 l. Acetonitrile and 0.1 percent orthophosphoric acid [90:10 (v/v)] were the A and B mobile phases, respectively. The flow rate was held constant at 1.0 mL/min, and the wavelength was detected at 225 nm. Tebuconazole (about 4.1 min) and trifloxystrobin (approximately 5.5 min) retention times.

Method validation

Specificity

UFLC was used to assess specificity by injecting aliquots of mobile phase solvents, controls, standard solution, and test solution.

Preparation of calibration solutions

Calibration solutions of different known concentrations of tebuconazole and trifloxystrobin were produced by diluting aliquots of the stock solution into each individual volumetric flask in acetonitrile for linearity determination.

Assay recovery and LOQ

Three different amounts of each herbicide at 0.05 and 0.5 mg/kg were fortified in four distinct soils for recovery trials. At each concentration level, three duplicate determinations were conducted, as well as two controls. A recovery study will be used to determine the quantification limit.

Statistical analysis

Using an excel data sheet of Microsoft 2010, the following statistical parameters linked to the study, calibration curve, and deterioration graphs were calculated.

Study | Statistical parameters |

|---|---|

Specificity | No interference of main peak, peak purity was passed |

Linearity | Regression equation (Y = mX + c, m-slope and C-intercept) and correlation coefficient (R) |

Precision | Mean, standard deviations (SD), percentage of relative standard deviation (%RSD) and Horwitz Limit = 2−(1−0.5 × log C) × 0.67 |

Recovery | Mean, standard deviations (SD), percentage of relative standard deviation (%RSD) and Horwitz Limit = 2−(1−0.5 × log C) × 0.68 |

Photocatalysis studies | DT50 |

Preparation of experimental soil

To analyse the photocatalytic decontamination of herbicide under natural climatic circumstances, test soils (Sandy clay and Clay) were gathered from three distinct areas (Paravada, Gajuwaka) in Visakhapatnam district, Andhrapradesh. A 2 mm sieve is used to filter the soil. The sieved soil is maintained at − 18 °C in a deep freezer until the experiment begins.

Test procedures for soil physico-chemical characteristics

Soil texture

20.0 g of air-dried soil was put to a tall 1-liter beaker, and 50 mL of 30% w/v hydrogen peroxide (H2O2) was added and thoroughly mixed. After allowing the reaction to continue for 5 minutes, it was immersed in a hot water bath for roughly 30 minutes. A watch glass was placed over the beaker. To avoid frothing, the stirring was kept going. 20 mL H2O2 was added, and the mixture was put in the water bath for 20 minutes. The ingredients were diluted with water to around 150 mL and brought to a boil on a hot plate. The purpose of using H2O2 is to oxidise the organic materials in the soil.

Acid treatment

The contents of the beaker were chilled before adding 25 mL of 2N HCl. The reaction was allowed to occur for an hour after the material was diluted to around 250 mL. 10 mL NH4Cl, NH4OH, and 1N NaOH were added.

Estimation of clay and silt

The suspension was placed to a 1000 mL spoutless cylinder and filled to 1000 mL. A rubber stopper was used to seal the cylinder. Repeated inversions of the cylinder shook the suspension. The cylinder was left untouched when the stopper was removed. After 4 minutes, 20 mL of the suspension was pipetted out and the contents were poured into a weighted porcelain basin. The liquid was evaporated, and the residue was dried at 105 °C before being cooled and weighed. The proportion of clay and silt was determined and given as a result.

Estimation of clay

After allowing the suspension to sit undisturbed for 6 hours, 20 mL of the suspension was pipetted out, the liquid evaporated, the residue was dried at 105 °C, the basin was cooled, and the weight was taken. The proportion of clay was determined and provided as a result.

Estimation of coarse and fine sand

The sediment was moved to a tall beaker constructed with distilled water to a height of 10 cm above the base after the bulk of the supernatant liquid was emptied away from the cylinder. It was well mixed and set aside for 4 minutes. The turbid suspension was then emptied out. The beaker was refilled with water to the mark, and the process was repeated until the liquid was clear. The residue (coarse and fine sand) was transferred to a porcelain basin that had already been weighed and dried at 105 °C before being cooled and weighed. Total sand was used to compute the percentage (coarse and fine).

Estimation of coarse sand

The coarse and fine sand fractions were sieved after being transported from the porcelain basin to a 0.2 mm sieve. The sieve waste was transferred to a porcelain basin that had already been weighed, dried at 105 °C, weighed, and the percentage of coarse sand measured. By subtracting the quantity of coarse sand from the total sand, the percentage of fine sand was computed.

pH

30 g soil was weighed into a 100 mL beaker, and 75 mL of distilled water was added. The soil water suspension was well agitated with a glass rod, and the pH was measured using a pH meter.

Electrical conductivity

30 g of soil was weighed into a 100 mL beaker, and 75 mL of distilled water was added. The soil water suspension was well mixed and left to stand for 30 minutes. Electrical conductivity was measured while the electrode was submerged in the soil suspension.

Organic carbon

A 500 mL conical flask was filled with 1.0 g of soil sample (sieved with a 0.2 mm screen) and 10 mL of 1N K2Cr2O7, which was swirled. The flask was protected by an asbestos carpet. 20 mL of concentrated H2SO4 was progressively introduced through the flask’s wall, stirred, and left to stand for 30 minutes. This was mixed with 200 mL of distilled water (to prevent additional oxidation), 10 mL of orthophosphoric acid (to stabilize the oxidation potential of FeSO4 during titration), and 1 mL of diphenylamine indicator. Titrated against 0.5 N ferrous ammonium sulphate solutions until the blue hue became green. Simultaneously, a blank (without dirt) was evaluated.

Estimation of cation exchange capacity

Procedure

In a 250 mL beaker, ten grammes of air-dried soil were mixed with 50 mL of neutral ammonium acetate solution, swirled thoroughly, and left overnight covered with a watch glass. Transferred the soil to filter paper (Whatman No. 3), leached it eight times with 30 mL volumes of ammonium acetate solution, and collected the filtrate in a beaker. (I transferred the filtrate to a 250 mL volumetric flask, adjusted the volume to the mark, and saved it for estimating individual exchangeable cations.) A pinch of solid ammonium chloride was added to the filter paper, which was then leached with 250 mL of distilled water. Using 60 percent alcohol, I transferred the soil in the beaker entirely to the filter paper and cleaned it with alcohol until the filtrate was chloride-free. The process involved carefully removing filter paper and soil from a distillation flask, adding distilled water until it was half full. Next, 25 mL of 0.1 N H2SO4 was added to a 500 mL ice tumbler, along with methyl red indicator. The ice tumbler was placed below the delivery end of the flask, ensuring it touched the surface of the 0.1 N H2SO4. 10 mL of 40% NaOH was added to the flask, and the flask was stopped and tested for ammonia. The end point was the appearance of light or straw yellow from red color.

Photocatalytic studies

The photocatalytic investigations were carried out at Krishna University, Machilipatnam (Longitude-81.13 and Latitude-16.17) in natural climatic circumstances under sun light. To obtain a homogenous 0.01 percent (w/w) of Cu–Sn–TiO2 NCs in soil, soil samples were extensively mixed with an aqueous solution of Cu–Sn–TiO2 NCs. The loaded Cu–Sn–TiO2 NCs soil is spread by hand to a height of 5 mm in a glass tray and sprayed with an aqueous herbicide formulation solution dissolved in 50 mL distilled water for 1Kg soil using a 1L High-density polyethylene bottle sprayer and kept in an oven at 110 °C for 2 hours to allow water molecules to evaporate. The glass trays were exposed to sunlight from 8 a.m. to 5 p.m. in March. Three duplicates were kept for each soil type and each soil sample that was exposed to sunlight. Cu-Sn- TiO2 NCs charged soil is sprayed with distilled water and used as an untreated control to determine herbicide presence in treated soil and herbicide absence in untreated soil. During the period of the soil samples’ exposure to sunlight, the daytime temperature varied from 30 to 42 °C. The intensity of the sunlight temperature is measured using a LUX metre during the exposure duration.

Sampling of soil

Soil samples were taken from the glass tray at different places on different times after exposure to sunlight (0, 5, 10, 24, 48, 72, and 90 hours for photocatalytic experiments). The soil sample is properly mixed, then a sub-sample of 50 g is extracted to extract the herbicide.

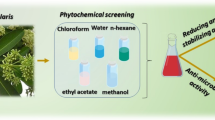

Extraction procedure of soils

An amount of 10 g homogenized soil sample was taken into a 250 mL conical flask. To the samples, 5 mL of distilled water was added followed by 45 mL ethyl acetate: cyclohexane (90:10) and kept in cooling incubator shaker for 15 minutes. The extracts were filtered through Whatman No.1 filter paper.

Clean up procedure

The filtrate was passed through glass column packed with silica gel and eluted the residue with Acetonitrile and extract was collected into a round bottom flask and concentrated near to dryness with vacuum rotary evaporator and then re-dissolved the residue with 10 mL of acetonitrile. The sample was filtered through a 0.45 µm nylon filter and analyzed by HPLC.

Results and discussion

X-ray diffraction studies

X-Ray Diffraction (XRD) patterns were mainly used to identify the crystallographic phase present in the catalyst, degree of crystallinity, and unit cell parameter and crystallite size of the catalysts. The inset in Fig. 1 is the enlarged XRD peaks of crystal plane (101) for all of the samples. Compared with the un-doped TiO2, peak shift of the peak position is observed. The intensity of anatase TiO2 peaks increased due to doping, and peaks corresponding to CuNO3 and SnCl4 were not detected. This may be due to the well dispersion of Cu2+ and Sn4+ content in TiO2 particles. The well-defined diffraction peaks with 2θ are at about 25°, 38°, 48°, 54°, 62°, 68°, 70°, 74°, and 82° which are assigned to the (101), (004), (200), (105), (204) (116), (220), (215) and (224) crystal planes, respectively. This XRD characteristic pattern is consistent with the standard JCPDS values of anatase TiO2 (JCPDS Card No. 21-1272)1,2,3,4,5,6,7,8,9,10,11,12,13,14 and did not appear in rutile and brookite form.

With the increase in Sn4+, crystallites are progressively decreasing in all three phases. In the structural characteristics field, almost similar ionic radius of Ti4+ (0.605 Å)15 and Sn4+ (0.690 Å)7, in comparison to the Sn2+ which is much larger, would make it possible to easily replace Ti4+ with Sn4+, 1.22 Å. Thus Sn2+ can take place in [TiO4] and [TiO6] interstitial sites, which resulted in a reduction in energy distortion from the lattice strain, whereas Sn4+ can replace Ti4+ in [TiO4] and TiO6] which leads to a greater energy distortion.

Fourier transform infrared spectroscopy study

Figure 2 illustrates the FTIR spectrum of the sample in the frequency range of 500–4000 cm−1. Moreover, the peak at ~ 3500 cm−1 O–H expansion extends the vibrations of the formation of a different –OH group. Due to the Ti–O stretching and Ti–O–Ti bridging modes, the wide intense range between 450 and 700 cm−1 is achieved. The wide absorption peaks of about 3500 cm−1 and the band 1635 cm−1 are equivalent to water on the surface and the hydroxyls28. Because the Ti–O bond is shorter than the Sn–O vibration bond, the TiO2 doping of Sn4+ can change the lower number of Ti–O vibrating grids. The intensity of TiO2 co-doped copper and tin has decreased compared to TiO2 undoped. Cu and Sn doping does not have additional peaks supporting the efficient spread of copper and tin, and indicates lack of copper and tin clusters, in good harmony with the results of the XRD analysis.

Field emission-scanning electron microscopic study

Surface morphology of the samples was studied by using scanning electron microscopy. Figure 3 shows the micrographs of the samples calcined at 400 °C where a mixture of nanoparticles could be clearly seen. The SEM images represent the agglomeration of particles and also with narrow particle size distribution.

The energy dispersive X-ray (EDX)

Figure 4 shows, respectively, the Energy Dispersive Radiation (EDX) spectrum from Cu and Sn TiO2. Copper and tin can be clearly seen in the peaks for titanium, oxygen and the respective doped metals. The Cu2+-Sn4+/TiO2 exhibit four elemental peaks: three for the Ti element located at 4.5, one for the oxygen element located at 0.43, one for the Sn element located at 3.4 keV and another for the Cu element located at 8.1 keV.

Transmission electron microscopy (TEM)

TEM image of Cu–Sn–TiO2 NCs is shown in Fig. 5. The figure shows that the Cu–Sn–TiO2 NCs are uniform and spherical. Using Image-J software, the average particle size was calculated to be around 30 nm.

Antibacterial activity

Cu–Sn–TiO2 NCs antibacterial activity against Gram positive Staphylococcus aureus, Basillus subtilis and Gram-negative Escherichia coli bacteria at different concentrations revealed a strong dose dependent antibacterial activity against the test microorganisms. Bacterial growth was observed to decrease as the concentration of nanoparticles was increased in both cases. Silver nanoparticles’ zone of inhibition against Gram positive bacteria Staphylococcus aureus, Bacillus subtilis, and Gram-negative bacteria Escherichia coli is depicted in and (Table 1 and Fig. 6). Cu–Sn–TiO2 NCs demonstrated effective antibacterial activity against Gram positive and Gram-negative bacteria, respectively. After incubation, inspect to clear zones around disks or wells that inhibit bacterial growth. Measure the diameter of these zones with a ruler or calipers, with larger zones indicating more activity. Repeat the test for accuracy, including control samples.

Physico chemical characteristics of soil

Soil physicochemical results were presented in Table 2.

Specificity

The specificity was evaluated by analysing the acetonitrile, mobile phase, and reference standard and test item solution. There was no interference at retention time of active ingredient peaks. The standard peak-purity assessment with DAD. Representative peak purity, LOQ level 2D and 3D chromatograms were presented in Figs. 7, 8 and 9.

Figure 7 clearly shows that there are no other peaks merging with the main peak, indicating that the peak purity is 1.0 according to this analysis. The 3D chromatogram (Fig. 8) clearly shows that no other peaks were detected in addition to the main peaks.

Linearity

The techniques were found to be linear with a satisfactory correlation coefficient when evaluated in the range 10.0–02 mg/L for tebuconazole and trifloxystrobin. The Limit of Quantification (LOQ) is set at 0.05 mg/L based on a peak-to-noise ratio of 10:1. Table 3 shows statistical linearity characteristics such as the Correlation Coefficient (R2) and the linear regression equation (Y = MX + C) that were calculated by graphing different concentrations of calibration solutions vs observed calibration solutions. Calibration curves are depicted in Fig. 10.

Recovery and precision

When a 10 × LOQ recovery sample was put into the HPLC five times, precision techniques with an acceptable range of 10% RSD were observed. Table 4 displays statistical data such as standard deviation (SD) and percentage of relative standard deviation (percent RSD). In two separate soils, the approach exhibited an acceptable range of herbicide recovery (80–110 percent). The quantification limit (LOQ) is set at 0.01 mg/L, based on a peak-to-noise height ratio of 10:1. The formula for calculating residue and the statistical parameters are presented below the equation.

where,

A—Peak area of active content in sample (µv*sec).

B—Volume of the sample (mL).

C—Concentration of the standard solution (mg/L).

D—Peak area of active content in standarde solution (µv*sec)

E—Weight of the sample (g).

F—Dilution Factor

where,

C—Concentration.

Photocatalytic decontamination of pesticide in soil

On 0-h examination of tebuconazole fortified soil, the residual of tebuconazole was 0.991 µg/g for loamy sand and 0.993 µg/g for sandy loam soil with 0.01 percent load of catalyst, respectively. Tebuconazole residues evaporated to 0.805 µg/g and 0.857 µg/g after 5 h in loamy sand and sandy loam soil with a 0.01 percent load of catalyst, respectively. Tebuconazole residues evaporated to 0.623 µg/g and 0.598 µg/g after 10 h with a 0.05 percent load of catalyst, respectively. With a 0.01 percent load of catalyst, the tebuconazole residues evaporated to 0.405 µg/g and 0.389 µg/g after 24 h. With a 0.01 percent load of catalyst, the tebuconazole residues evaporated to 0.159 µg/g and 0.218 µg/g after 48 h. Tebuconazole residues decreased to 0.10 µg/g and 0.07 µg/g after 72 h with a 0.01 percent dose of catalyst, respectively, and were completely degraded (BDL = Below detectable level) after 90 h.

On 0-h examination of trifloxystrobin fortified soil, the residual of trifloxystrobin was 0.995 µg/g for loamy sand and 0.986 µg/g for sandy loam soil with 0.01 percent load of catalyst, respectively. Trifloxystrobin residues evaporated to 0.795 µg/g and 0.841 µg/g after 5 h in loamy sand and sandy loam soil with a 0.01 percent load of catalyst, respectively. After 10 h, the trifloxystrobin residues evaporated to 0.606 µg/g and 0.564 µg/g with a 0.01 percent catalyst load, respectively. With a 0.01 percent load of catalyst, the trifloxystrobin residues evaporated to 0.485 µg/g and 0.369 µg/g after 24 h. With a 0.01 percent load of catalyst, the trifloxystrobin residues evaporated to 0.157 µg/g and 0.117 µg/g after 48 h. The trifloxystrobin residues evaporated to 0.09 µg/g and 0.08 µg/g after 72 h with a 0.01 percent load of catalyst, respectively, and were completely degraded (BDL = Below detectable level) after 90 h.

Table 5 and Fig. 11A and B provide summary findings for photocatalytic investigations, and Fig. 12A, B, C and D shows a chromatogram (A, B, C and D). The data demonstrate that the decontamination of herbicide follows pseudo-first-order kinetics in Cu–Sn–TiO2 loaded soil when calculated residues values with time by using below the first-order kinetic formula. The absence of herbicide residues in control was observed because no herbicide was applied and no degradation of pesticides in control was observed due to the inactivation of the Cu–Sn–TiO2 in the absence of light.

The first-order kinetics form is:

where,

C0—Herbicide concentration at times zero.

Ct—herbicide concentration at times t,

K—The rate constant.

DT50—half-life. Kinetic parameters such as rate constant (k), DT50 for photocatalytic decontamination were presented in Tables 6 and 7.

Conclusions

The study found that Cu–Sn–TiO2 NCs have strong dose-dependent antibacterial activity against Gram-positive, Staphylococcus saureus, and Escherichia coli bacteria at various concentrations. As the concentration of NCs increases, the zone of inhibition reduces bacterial growth. The study suggests that these nanocomposites can be used to prevent bacterial growth. The Cu-Sn-TiO2 NCs were found to be an excellent decontaminating catalyst for pesticides in various soil samples. In the absence of a catalyst, the compound persists for several days. The mobile phase, Acetonitrile, and 0.1% OPA, have demonstrated good resolution of two peaks, and the time required to analyse two different types of soils for chromatographic determination is extremely short. Photocatalytic studies of pesticides in various soils, such as loamy sand and sandy loam, show that activity is greatly increased with Cu–Sn–TiO2 NCs when the time frame is set for a certain number of hours, whereas activity was not found without the addition of Cu–Sn–TiO2 NCs, even though experiments were carried out. When exposed to sunlight and a nano catalyst, pesticides (Tebuconazole and Trifloxystrobin) at BDL level break down into CO₂ and H₂O, indicating complete mineralization. Accordingly, it is concluded that these pesticides were decontaminated in soils. In future studies, the photocatalytic study with various nanomaterials will be compared.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Yang, X. & Wang, D. Photocatalysis: From fundamental principles to materials and applications. ACS Appl. Energy Mater. 1, 6657–6693. https://doi.org/10.1021/acsaem.8b01345 (2018).

Zhu, S. & Wang, D. Photocatalysis: Basic principles, diverse forms of implementations and emerging scientific opportunities. Adv. Energy Mater. 7, 1–24. https://doi.org/10.1002/aenm.201700841 (2017).

Ibhadon, A. O. & Fitzpatrick, P. Heterogeneous photocatalysis: Recent advances and applications. Catalysts 3, 189–218. https://doi.org/10.3390/catal3010189 (2013).

Saravanan, A. et al. Photocatalysis for removal of environmental pollutants and fuel production: a review. Environ. Chem. Lett. 19, 441–463. https://doi.org/10.1007/s10311-020-01077-8 (2021).

Pattanaik, P. & Sahoo, M. K. TiO2 photocatalysis: progress from fundamentals to modification technology. Desalin. Water Treat. 52, 6567–6590. https://doi.org/10.1080/19443994.2013.822187 (2014).

Solano Pizarro, R. A. & Herrera Barros, A. P. Cypermethrin elimination using Fe-TiO2 nanocomposite supported on coconut palm spathe in a solar flat plate photoreactor. Adv. Compos. Lett. 28, 1–14. https://doi.org/10.1177/2633366X20906164 (2020).

Lee, Y. J. et al. Photocatalytic degradation of neonicotinoid insecticides using sulfate-doped Ag3PO4 with enhanced visible light activity. Chem. Eng. J. 402, 126183. https://doi.org/10.1016/j.cej.2020.126183 (2020).

Singhal, A. & Lind, M. L. Removal of pesticide toxicity by cysteine-capped Ag nanocomposite and study of their adsorption kinetics. Int. J. Nanomed. 13, 25–29. https://doi.org/10.2147/IJN.S124700 (2018).

Ismael, A. M. et al. Novel TiO2/GO/CuFe2O4nanocomposite: a magnetic, reusable and visible-light-driven photocatalyst for efficient photocatalytic removal of chlorinated pesticides from wastewater. RSC Adv. 10, 34806–34814. https://doi.org/10.1039/d0ra02874f (2020).

Zandsalimi, Y. et al. Photocatalytic removal of 2,4-Dichlorophenoxyacetic acid from aqueous solution using tungsten oxide doped zinc oxide nanocomposite immobilized on glass beads. Environ. Technol. (United Kingdom) 43, 1–36. https://doi.org/10.1080/09593330.2020.1797901 (2020).

Padmanaban, V. C. et al. Advanced approach for degradation of recalcitrant by nanophotocatalysis using nanocomposites and their future perspectives. Int. J. Environ. Sci. Technol. 13, 1591–1606. https://doi.org/10.1007/s13762-016-1000-9 (2016).

Khan, S. H., Suriyaprabha, R., Pathak, B. & Fulekar, M. H. Photocatalytic degradation of organophosphate pesticides (Chlorpyrifos) using synthesized zinc oxide nanoparticle by membrane filtration reactor under UV irradiation. Front. Nanosci. Nanotechnol 1, 23–27. https://doi.org/10.15761/FNN.1000105 (2015).

Liu, X. et al. Photocatalytic degradation of profenofos and triazophos residues in the chinese cabbage, Brassica chinensis, using ce-doped TiO2. Catalysts 9, 1–12. https://doi.org/10.3390/catal9030294 (2019).

Parveen, S. et al. Synthesis, characterization and photocatalytic performance of iron molybdate (Fe2(MoO4)3) for the degradation of endosulfan pesticide. Mater. Res. Express https://doi.org/10.1088/2053-1591/ab73fa (2020).

Rodríguez-González, V., Terashima, C. & Fujishima, A. Applications of photocatalytic titanium dioxide-based nanomaterials in sustainable agriculture. J. Photochem. Photobiol. C Photochem. Rev. 40, 49–67. https://doi.org/10.1016/j.jphotochemrev.2019.06.001 (2019).

Varma, K. S. et al. Photocatalytic degradation of pharmaceutical and pesticide compounds (PPCs) using doped TiO2 nanomaterials: A review. Water-Energy Nexus 3, 46–61. https://doi.org/10.1016/j.wen.2020.03.008 (2020).

Wang, Y. et al. The application of nano-TiO2 photo semiconductors in agriculture. Nanoscale Res. Lett. https://doi.org/10.1186/s11671-016-1721-1 (2016).

Silva, V. et al. Pesticide residues in European agricultural soils-a hidden reality unfolded. Sci. Total Environ. 653, 1532–1545. https://doi.org/10.1016/j.scitotenv.2018.10.441 (2019).

Chen, X., Zhou, Q., Liu, F., Peng, Q. & Teng, P. Removal of nine pesticide residues from water and soil by biosorption coupled with degradation on biosorbent immobilized laccase. Chemosphere 233, 49–56. https://doi.org/10.1016/j.chemosphere.2019.05.144 (2019).

Dicks, L. W. R. & Goh, S. K. Treatment of pesticide-contaminated soils with thermal desorption technologies. Air Waste 43, 1610–1619. https://doi.org/10.1080/1073161X.1993.10467230 (1993).

Abdennouri, M. et al. Photocatalytic degradation of pesticides by titanium dioxide and titanium pillared purified clays. Arab. J. Chem. 9, S313–S318. https://doi.org/10.1016/j.arabjc.2011.04.005 (2016).

Zhang, C., Li, T., Xiao, L., Zhou, S. & Liu, X. Characterization of tebuconazole resistance in Botrytis cinerea from tomato plants in China. Phytopathol. Res. https://doi.org/10.1186/s42483-020-00064-9 (2020).

Želonková, K. et al. Fungicide tebuconazole influences the structure of human serum albumin molecule. Molecules 24(17), 1–15 (2019).

Maroneze, M. M., Zepka, L. Q., Vieira, J. G., Queiroz, M. I. & Jacob-Lopes, E. A tecnologia de remoção de fósforo: Gerenciamento do elemento em resíduos industriais. Rev. Ambient. e Agua 9, 445–458. https://doi.org/10.4136/1980-993X (2014).

Reuveni, M. Efficacy of trifloxystrobin (Flint), a new strobilurin fungicide, in controlling powdery mildews on apple, mango and nectarine, and rust on prune trees. Crop Prot. 19, 335–341. https://doi.org/10.1016/S0261-2194(00)00026-0 (2000).

Chen, J., Loo, B. & Ray, C. Determination of trifloxystrobin and its metabolites in Hawaii soils by ASE-LC-MS/MS. J. Agric. Food Chem. 56, 1829–1837. https://doi.org/10.1021/jf071527z (2008).

Reuveni, M. Activity of trifloxystrobin against powdery and downy mildew diseases of grapevines. Can. J. Plant Pathol. 23, 52–59. https://doi.org/10.1080/07060660109506909 (2001).

Ismail, M. A., Taha, K. K., Modwi, A. & Khezami, L. ZnO nanoparticles: Surface and X-ray profile analysis. J. Ovonic Res. 14, 381–393 (2018).

Singh, V., Singh, J. & Mishra, V. Development of a cost-effective, recyclable and viable metal ion doped adsorbent for simultaneous adsorption and reduction of toxic Cr (VI) ions. J. Environ. Chem. Eng. 9, 105124. https://doi.org/10.1016/j.jece.2021.105124 (2021).

Abuzeyad, O. H., El-Khawaga, A. M., Tantawy, H., Gobara, M. & Elsayed, M. A. Photocatalytic degradation of methylene blue dye by promising zinc copper ferrite nanoparticles for wastewater treatment. J. Inorg. Organomet. Polym. Mater 34, 2705–2715. https://doi.org/10.1007/s10904-024-03006-6 (2024).

Acknowledgements

This research work was funded by Institutional Fund Projects under grant no. (IFPIP:921-903-1443). The authors gratefully acknowledge technical and financial support provided by the Ministry of Education and King Abdulaziz University, DSR, Jeddah, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

P.M.Z.: Conceptualization, data curation, visualization, formal analysis and investigation, methodology, resources, and sofware.T.N.R.:Writing—original draft, writing—review and editing. F.A.: Conceptualization, data curation, visualization, methodology, resources, and sofware. N.A.: Visualization formal analysis, methodology, review and editing. A.A.M.: Supervision, project administration, writing—review and editing, resources, and sofware.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hasan, P.M.Z., Rao, T.N., Ahmed, F. et al. The antibacterial and photocatalytic properties of copper and tin doped titanium dioxide nanoparticles for the nano remediation of pesticide residues in soil. Sci Rep 15, 33060 (2025). https://doi.org/10.1038/s41598-025-13304-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-13304-9