Abstract

Given the global water shortage crisis and the prevalent use of drinking water in concrete production, exploring practical solutions, such as reusing various wastewater, is essential. This study investigates the properties of self-compacting concrete (SCC) incorporating treated industrial wastewater sourced from dye factories. Propylene fibers at lengths of 6 mm and 12 mm were employed at volumes of 0.1% and 0.2%, with a water-to-cement ratio (w/c) of 0.5. Additionally, a 0.1% fiber concentration was tested in SCC with a w/c of 0.36, involving a 20% reduction in coarse aggregate in both scenarios except for control samples. While the use of treated industrial wastewater did not affect workability, propylene fibers reduced workability. When comparing samples using drinking water, the addition of 0.1% enhanced compressive strength by 10%, whereas a 0.2% propylene fiber concentration resulted in a 30% decrease in compressive strength. The inclusion of 1% propylene fibers with a length of 6 mm, combined with treated industrial wastewater, led to a reduction in compressive strength for low-cement mixes with a w/c of 0.5. Conversely, in high-cement mixes with a w/c of 0.36 using treated wastewater and 0.1% propylene fiber, the compressive strength increased compared to the control sample using treated industrial wastewater. Incorporating 2% silica fume as a cement replacement for both mixing designs resulted in a significant improvement in compressive strength at 90 days. Ultrasonic test results exhibited a strong correlation with compressive strength, highlighting the effectiveness of this method in evaluating mechanical properties. The volumetric water absorption increased with fiber incorporation, peaking at 66% higher than the control when using 0.2% fibers. However, the volumetric water absorption of the new sample mixture with 6 mm propylene fibers, 440 kg/m3 cement, treated industrial wastewater, and silica fume is under 5%. These findings underscore the potential of both propylene fibers and silica fume to enhance concrete strength and reduce volumetric water absorption when using treated industrial wastewater, indicating progress in sustainable concrete technologies. SEM images reveal that SCC samples made with treated industrial wastewater exhibit more voids, cracks, and Ettringite, potentially compromising their compressive strength. Nevertheless, the addition of silica fume improves the integration and homogeneity of the cement paste. Significantly, the presence of C–S–H is more prominent in these samples, with a lower Ca/Si ratio correlating with increased compressive strength.

Similar content being viewed by others

Introduction

The global water crisis poses a significant threat, as water is a fundamental necessity for life worldwide. With increasing world water consumption and limited resources1, some researchers predict water shortages will affect approximately 1800 million people globally by the end of 20252. Water scarcity resulting from economic and population growth is recognized as a key threat to human societies and a barrier to sustainable development3. One highly effective approach to water conservation is through its reuse. Recent research indicates that the most economically viable and universally accepted method of water reuse is the substitution of treated wastewater for irrigation and industrial purposes4.

Water for numerous construction activities typically comes from freshwater sources, with approximately one-sixth of the world’s freshwater consumed in the construction industry. Concrete, following water, stands as the most extensively utilized material by humans5. The predominant adverse impacts of this industry include environmental pollutants like air and water pollution, along with the depletion of primary resources6.

With the escalating demand for infrastructure, the utilization of concrete is steadily on the rise7. It’s estimated that nearly 150 L of fresh water are required to produce each cubic meter of concrete6. Research indicates that water that is not suitable for drinking can be effectively employed in concrete production8. Concrete stands out as one of the most widely used building and structural materials, offering advantages such as ready availability, ease of use, flexibility (moldability), and cohesiveness9. Recently, several researchers have explored the use of various domestic and industrial wastewater as alternatives to drinking water in the preparation for normal and SCC.

Concrete is a construction material with low tensile strength and limited strain capacity, making it susceptible to cracking. This vulnerability manifests in the short term due to plastic shrinkage and the containment of imposed strains, and in the long term due to applied loading and durability concerns. To address cracking at the serviceability limit state and to mitigate deflection while enhancing resistance to durability issues, traditional steel-reinforced concrete can be strengthened by incorporating various types of fibers. These fibers assist in resisting different forms of cracking10.

Hassan et al.11 explored the addition of jute fibers (20 mm) to SCC at volumes from 0.1 to 1%. While Jute Fiber Reinforced SCC (JFR-SCC) showed improved mechanical strengths (up to 21% in splitting tensile), higher fiber content reduced passing ability. The fibers also enhanced durability by filling microcracks, making JFR-SCC a viable eco-friendly alternative to conventional SCC.

Fibers in general, and specifically polypropylene fibers, have gained increasing popularity in recent years for enhancing the cracking resistance and toughness of concrete12. Given their properties and cost-effectiveness, the use of polypropylene fibers is recommended for remedying concrete defects13. These fibers exhibit chemical resistance to acids and alkalis and are compatible with any type of Portland cement14. Research indicated that polypropylene fibers can enhance flexural ductility, compressive strength, toughness, tensile crack resistance, peeling resistance, impact resistance, and the long-term durability of concrete15.

Concrete that incorporates discontinuous fibers with random orientations is referred to as fiber-reinforced concrete (FRC). Randomly oriented fibers effectively resist crack propagation and opening within the cement matrix, thereby enhancing post-crack ductility under both static and impact loads16. Consequently, it can be stated that fibers have been widely used to improve the ductility of concrete. Polypropylene fibers have a low Young’s modulus; therefore, they cannot prevent the creation and propagation of cracks under high-stress conditions, but they can bridge larger cracks7,17. Numerous scholars have investigated the use of various types of wastewaters in concrete. For instance, Tay and Yip18 conducted a study on the use of treated wastewater in concrete mixtures. Their laboratory findings indicated that treated wastewater had no adverse impact on compressive strength across various concrete mixtures. Similarly, Al-Jabri et al.19 conducted experiments on the effects of wastewater usage on the characteristics of high-strength concrete, yielding comparable results.

Al-Joulani20 investigated the impact of employing eight types of wastewaters in concrete mixtures. The study revealed the significant potential of quarry wastewater for producing structural concrete, while other types of wastewaters were found suitable for non-structural applications. Experimental results for concrete and mortar samples suggest that the incorporation of stone slurry wastewater in concrete mixes enhances workability, compressive strength, crack tensile strength, and natural absorption. Conversely, the use of oily water and tannery wastewater is associated with reduced compressive strength and tensile strength at all ages, making their application in concrete production, without primary treatment and further investigation, not recommended.

Asadollahfardi and Peighambrzadeh21 reviewed the use of treated domestic wastewater in the preparation and production of concrete samples. The review indicates a reduction in concrete strength, which remains within the allowed range of BS EN 100822. Similarly, studies conducted on slump and surface electrical resistivity indicated that the use of treated domestic wastewater did not affect these characteristics21. Peighambarzadeh et al.17 investigated the effect of using treated wastewater on the fracture toughness of concrete. The results showed that the use of treated domestic wastewater in concrete, instead of drinking water, decreased the fracture toughness by 2–6%. This reduction is not considered significant and is also influenced by the water used for curing.

Yahyaei et al.23 conducted the mechanical and durability characteristics of self-compacting concrete (SCC) using treated domestic wastewater. The results fell within the range of European guidelines for SCC. The compressive strength of various concrete mixes utilizing treated domestic wastewater was 1–8% lower than samples made with drinking water. Asadollahfardi and Mahdavi24 explored the feasibility of reusing treated industrial wastewater from Tehran Refinery and Distribution Company in concrete production. The results revealed that substituting treated industrial wastewater for drinking water led to a 6.9% decrease in the compressive strength of cement-sand mortar at 28 days. Additionally, the compressive strength of the concrete sample produced using treated industrial wastewater decreased by 8.7%.

Several researchers have focused on concrete with fibers. For example, Zhou and Hwa25 examined the behavior of concrete containing fibers for tunnel lining. The results demonstrated a 23% increase in tensile strength when using polypropylene fibers, accompanied by a 10% reduction in water absorption. Mohammad Hosseini et al.26 investigated the impact of polypropylene carpet fibers on the workability and mechanical properties of reinforced concrete. Their findings indicated a reduction in slump for fresh concrete with added fibers. Moreover, using these fibers enhanced tensile strength, flexural strength, ductility of concrete, and improved crack distribution. Shen et al.27 discovered that longer polypropylene fibers in high-performance concrete not only reduced cracking temperature but also decreased cracking stress ratio and concrete creep.

Monteiro et al.28 studied the effect of polypropylene fibers on self-compacting concrete, using fiber contents of 0.33%, 0.66%, and 1.10%. The results showed a decrease in slump flow of 18%, 19%, and 34%, respectively, with the 1.10% fiber sample falling below EFNARC guidelines29 and showing inappropriate viscosity and deformability, making it unsuitable as self-compacting concrete.

Akbulut et al.30 studied the impact of silica fumes and polypropylene fibers on structural lightweight concrete. Silica fumes improved microstructure and reduced water absorption, while polypropylene fibers created voids, reducing density and compressive strength. Adding fibers decreased compressive strength by up to 28% but increased tensile strength. The hybrid use of micro and macro fibers improved workability, mechanical properties, and durability due to strong adhesion between fibers and the cement matrix. Gencel et al.31 studied the effect of polypropylene fibers on SCC with different cement contents (350 and 450 kg/m3). The addition of fibers reduced slump flow and increased J-Ring height, especially with lower cement content. Fibers also increased V-funnel time, compressive strength, splitting tensile strength, flexural strength, and elasticity modulus, while decreasing pulse velocity.

Bhagwat et al.32 found increasing polypropylene fiber content in SCC reduced workability. However, at an optimal fiber volume of 0.15%, workability increased. Higher fiber content did not significantly affect strength and elasticity, but water absorption decreased, and penetration depth. Moreover, the increased fibers enhanced resistance to chlorides and acids. The optimal 0.15% fiber content also improved corrosion resistance, and delayed crack initiation due to stress corrosion cracking.

The main objective of this study was to investigate the concurrent roles of treated industrial wastewater and propylene fiber, along with two water-to-cement (w/c) ratios, on the workability, mechanical properties, and durability of self-compacting concrete (SCC). The use of industrial or domestic wastewater in concrete has been extensively studied in recent years. Notable contributions to this field have been made by Al-Joulani in 201525, Asadollahfardi and Mahdavi in 201929, Asadollahfardi et al. in 202433, Kenshlo et al. in 202434, and Jahandideh et al. in 202435. Additional research were also advanced by Yip and Tay in 198718, as well as by Al-Jabri et al. in 201119.

Similarly, significant attention were garnered by the incorporation of various fibers in concrete. Key studies in this realm have been conducted by Hosseinzadeh et al. in 202341, Zhou and Hwa in 200925, Mohammad Hosseini et al. in26, Shen et al. in 201927, Bhagwet et al. in 202332, and Taghizadeh et al. 202236. The combination of treated industrial wastewater and propylene fiber to determine workability, mechanical properties, and durability in SCC is new.

The changes in properties of SCC using treated industrial wastewater arise from some key aspects. The quality of the wastewater impacts hydration and bonding within the cement matrix, potentially introducing impurities that affect workability and mechanical characteristics. The addition of propylene fibers performs to increase tensile strength but can decline workability depending on fiber concentration and length. The experimental design’s decreasing in coarse aggregate affects density and porosity, leading to variations in compressive strength and water absorption. Additionally, combining silica fumes improve microstructural integrity by improving the formation of calcium silicate hydrate (C–S–H), which is fundamental for strength development whereas addressing water absorption issues. These parameters together emphasize the complexity of optimizing SCC formulations for sustainable construction considering the global water crisis.

Significance of the study

Water consumption in concrete production is notably high, not only due to the mixing process but also because fresh water is required for washing aggregates, cleaning concrete trucks, and the daily maintenance of concrete production facilities. Additionally, a significant amount of drinking water is utilized for concrete curing. Consequently, the concrete industry plays a considerable role in impacting environmental conditions through its water consumption.

In recent years, concerns regarding water shortages, environmental pollution, and the high costs associated with producing drinking water have driven scientists to investigate new methods for conserving water and protecting the environment. One of the most effective strategies for conserving water is its reuse. Recent studies indicate that substituting treated wastewater for irrigation and industrial applications is an economically viable and widely accepted approach, although this may lead to a reduction in the mechanical properties of concrete.

To address this concern, silica fumes and polypropylene fibers are incorporated to enhance the mechanical properties and performance of concrete. Fibers, particularly polypropylene fibers, have gained popularity in recent years for their ability to improve cracking resistance and toughness in concrete. Due to the favorable properties and cost-effectiveness of polypropylene fibers, their use is recommended for this study investigates the effects of different material combinations on the properties of Self-Compacting Concrete (SCC) by employing two distinct water-to-cement ratios. Using treated industrial wastewater, silica fume, and polypropylene fibers uniquely influences the concrete’s workability and strength. Treated industrial wastewater often contains elevated levels of dissolved salts and compounds, which can affect the cement hydration process. As a result, a higher water-to-cement ratio may be required to maintain workability. Our findings were also compared with those from existing studies.

Conversely, silica fume enhances the concrete’s strength and durability as a cement replacement but necessitates a carefully controlled water-to-cement ratio to achieve the desired workability. Polypropylene fibers, which are utilized to mitigate cracking and improve mechanical properties, similarly require a balanced mix to perform optimally.

By testing two different water-to-cement ratios—one with an increased water content to enhance workability and another with reduced water to maximize strength—this study provides a comprehensive assessment of how these materials behave under various conditions. This ultimately aids in identifying the optimal mix that enhances the workability, strength, and durability of SCC.

Additionally, this research aims to understand how the experimental results can be applied to concrete construction in the vicinity of the Persian Gulf and the Oman Sea, where the code of practice37 mandates a minimum cement content of 375 kg/m3 and a maximum of less than 450 kg/m3. Given the region’s hot climate and the associated limitations on cement use to reduce heat generated during hydration, these findings are particularly relevant.

Considering literary reviews and emphasizing the environmental advantages associated with the use of treated industrial wastewater in Self-Compacting Concrete (SCC), as well as the crack prevention properties of polypropylene fiber, a unique exploration combining these elements in SCC has not yet been conducted rarely. While each of these components has been studied individually, their concurrent use, including the combination of polypropylene fibers, treated industrial wastewater, and silica fume as a cement replacement, has not been extensively explored. The novelty of this study lies in investigating the combined impact of these materials in a single process, a comprehensive approach that has not been thoroughly examined in previous studies. Therefore, this study endeavors to investigate the influence of polypropylene fibers with different lengths and proportions, in conjunction with the application of treated industrial wastewater (derived from a paint factory), on the workability, mechanical strength, durability, and fracture toughness of Self-Compacting Concrete (SCC).

Materials and methods

Materials

Table 1 provides an overview of the physical and chemical properties of cement, silica fume, and limestone powder utilized in the study. The Portland Type 2 cement, adhering to the ASTM C150 standard38, was sourced from the Qazvin cement factory. The limestone powder employed in the research was obtained from Saveh Mines. Silica fume, serving as an additive substitute for cement, was sourced from Beton Plast Company in Tehran and met the specifications outlined in the ASTM C1240 standard39. According to ASTM C1240-1539, the permitted maximum Loss on Ignition (LOI) is 6%. With an LOI of 5.8% (Table 1), the silica fume used in this study complies with the standard. Notably, a high LOI can indicate a higher level of combustible materials, which may absorb water during mixing, potentially leading to a stiffer and less workable mix and reduced concrete strength, as reported by Hamada et al.40.

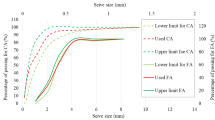

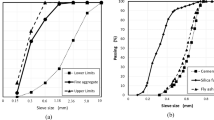

The study employed crushed aggregate from Hashtgerd Mine in Karaj, specifically including, limestone. The coarse aggregate, prepared as pea-type with a maximum nominal size of 9.5 mm, exhibited a specific weight of 2620 kg/m3. Additionally, twice-washed fine aggregate (sand) with a fineness modulus of 3.6 and a specific weight of 2180 kg/m3 was utilized. Figure 1 presents the sieve analysis of both fine and coarse aggregates.

Drinking water sourced from Karaj City served as the base for the control samples of SCC. This water is deemed suitable for concrete production (Table 2). Treated industrial wastewater samples were collected from the Bhrngan dyeing factory, located within an industrial compound in Esfahan City. Grab and composite sampling methods were used, and the samples were placed in an ice-filled container for preservation. The specimens were then transported to the central laboratory of Kharazmi University in Tehran, where their physical and chemical properties were analyzed according to the methods outlined by Rice et al.41. The treated industrial wastewater was found to adhere to the standards specified in BS EN 100822. The existing wastewater treatment processes in the factory include oil removal, sedimentation, flocculation, and activated sludge treatment.

One of the primary challenges encountered in conducting this study was the preparation of industrial wastewater. Due to the presence of toxic and chemical substances in industrial wastewater, permission for its use was often denied by many factories, even after treatment. With a letter from Kharazmi University emphasizing that the wastewater was intended solely for research and application in concrete, we were granted access to the treated wastewater for testing.

The superplasticizer employed was the NSG-SH7 type, based on polycarboxylate and manufactured by NSG company, boasting a specific weight of 1213 kg/m3. Polypropylene fibers, with lengths of both six and twelve millimeters, were utilized, and these fibers were supplied by Beton Clinic Company of Iran. Table 3 indicates detailed specifications of the polypropylene fibers.

While we acknowledge that the treated industrial wastewater from the dye factory has low quality, particularly in terms of chloride content, it adheres to the guidelines outlined in BS EN 100822 (Table 2), which states that it is suitable for concrete without reinforcement or embedded metal. The physical and chemical properties of the treated industrial wastewater align with the standards. Additionally, the treated wastewater from the dye factory requires further advanced treatment and remains a topic of ongoing research.

Table 3 indicates the propylene fiber. Polypropylene fibers enhance the toughness of high-strength concrete (HSC) and reduce its susceptibility to spalling at elevated temperatures. Fiber-reinforced concrete (PFRC) becomes particularly significant after exposure to high temperatures, especially in applications related to engineering or in the repair of concrete structures that have been damaged by fire42. The use of polypropylene fibers significantly increases the energy absorption capacity of concrete mixtures while meaningfully reducing plastic shrinkage cracks43 . A decrease in the length of polypropylene fibers has been found to improve the workability of concrete, and excessive fiber length may result in increased balling and uneven distribution within the concrete. For enhancing the mechanical properties and durability of self-compacting concrete (SCC) specimens, 0.1% polypropylene fibers with a length of 6 and 12 mm have been selected mostly.

Industrial wastewater, particularly from dyeing factories, presents a significant challenge that is common across all textile manufacturing operations. Removing dyes from this wastewater is a critical issue in industrial wastewater treatment. Several scholars have explored the use of textile wastewater in concrete; notable studies include those by Zhan et al.44, Raza et al.45, and Raza et al.46. It is essential to clarify that our work extends beyond a mere case study.

Figure 2 indicates the components used in the study, including polypropylene fibers, silica fume, limestone powder, and treated wastewater.

Mix design

Table 4 presents the specifications of the SCC mixing plan for the prepared concrete samples, which were adjusted according to the manual provided by the International Center of Aggregates Research (ICAR) at the University of Texas47. Assessing the workability, mechanical strength, and durability properties of the SCC samples, three batches of mixes were formulated. The first category involved a water-to-cement ratio of 0.5, using a selected 400 kg/m3 of cement. In the second group, a water-to-cement ratio of 0.36 was employed, and the chosen cement quantity was 440 kg/m3. The SCC designs for one cubic meter of concrete encompassed variables such as tap water, treated industrial wastewater, silica fume at 8% by weight of cement, and polypropylene fibers with varying lengths.

This study investigates the effects of different material combinations on the properties of Self-Compacting Concrete (SCC) by employing two distinct water-to-cement ratios. Using treated industrial wastewater, silica fume, and polypropylene fibers uniquely influences the concrete’s workability and strength. Treated industrial wastewater often contains elevated levels of dissolved salts and compounds, which can affect the cement hydration process. As a result, a higher water-to-cement ratio may be required to maintain workability. Our findings were also compared with those from existing studies.

Conversely, silica fume enhances the concrete’s strength and durability as a cement replacement but necessitates a carefully controlled water-to-cement ratio to achieve the desired workability. Polypropylene fibers, which are utilized to mitigate cracking and improve mechanical properties, similarly require a balanced mix to perform optimally.

By testing two different water-to-cement ratios—one with an increased water content to enhance workability and another with reduced water to maximize strength. This study provides a comprehensive assessment of how these materials behave under various conditions. It ultimately aids in identifying the optimal mix that enhances the workability, strength, and durability of SCC.

Additionally, this research aims to understand how the experimental results can be applied to concrete construction in the vicinity of the Persian Gulf and the Oman Sea, where the code of practice37 mandates a minimum cement content of 375 kg/m3 and a maximum of less than 450 kg/m3. Given the region’s hot climate and the associated limitations on cement use to reduce heat generated during hydration, these findings are particularly relevant.

In the 0.5-C400 specimen, a water-to-cement (w/c) ratio of 0.5, 400 kg/m3 of cement, and drinking water were used. The 0.5-C400-PP0.1%-6 specimen includes 1% of 6 mm polypropylene fibers, along with the same w/c ratio of 0.5 and 400 kg/m3 of cement, using drinking water. In the 0.5-C400-PP0.2%-6mm mixing plan, the same nominal control compositions were used, with the exception that 2% of 6 mm polypropylene fibers were added. In the 0.5-C400-PP0.1%-12mm mixing scheme, 1% of 12 mm polypropylene fibers were used, along with a w/c ratio of 0.5 and 400 kg/m3 of cement, using drinking water. In the 0.5-C400-IWW specimen, industrial treated wastewater was used instead of drinking water, maintaining a w/c ratio of 0.5 and 400 kg/m3 of cement. In the 0.5-C400-PP0.1%-6mm-IWW mixing scheme, 6 mm polypropylene fibers were added, along with the use of industrial wastewater and 400 kg/m3 of cement.

The 0.36-C440 specimen used drinking water, with a water-to-cement (w/c) ratio of 0.36 and 440 kg/m3 of cement. The 0.36-C440-PP0.1%-6mm specimen included drinking water, a w/c ratio of 0.36, 440 kg/m3 of cement, and 0.1% polypropylene fiber with a length of 6 mm. The 0.36-C440-PP0.1%-12mm specimen included drinking water, a w/c ratio of 0.36, 440 kg/m3 of cement, and 0.1% polypropylene fiber with a length of 12 mm. The 0.36-C440-IWW specimen used treated industrial wastewater, with 440 kg/m3 of cement and a w/c ratio of 0.36. The 0.36-C440-PP0.1%-6mm-IWW specimen included treated industrial wastewater, a w/c ratio of 0.36, 440 kg/m3 of cement, and 0.1% polypropylene fiber with a length of 6 mm. Lastly, the 0.36-C440-PP0.1%-6mm-IWW-SF specimen included treated industrial wastewater, 440 kg/m3 of cement, a w/c ratio of 0.36, 0.1% polypropylene fiber with a length of 6 mm, and silica fume.

The process of concrete production

SEM and EDX experiments of a fiber-reinforced concrete mix are like conventional concrete; nevertheless, incorporating fibers impacts the mix’s workability, resulting in decreased fluidity. As the volume and length of the fibers increase, workability tends to diminish even more. Tackling this challenge when establishing the mix proportions, various modifications to the design may be necessary. Potential adjustments could include reducing the volume of coarse aggregates, increasing the cement content, augmenting the sand proportion, utilizing a superplasticizer, or lowering the maximum size of the aggregates. In the present study, in line with the guidelines set forth by the National Building Regulations of Iran48, the amount of coarse aggregate has been decreased by 20% in all SCC samples except control samples (0.5-C400,0.36–440,0.5-C400-IWW, and 0.36-C440-IWW), and used superplasticizer.

The measured fine and coarse aggregates are combined with cement in the mixer container, and the mixer runs for 3–5 min. Water and superplasticizer are then added, and the mixture is blended for an additional 2–3 min. Finally, propylene fiber is gradually added to the mixer, and mixing continues for 2–5 min.

Curing

The specimens were demolded between 24 and 48 h after casting, depending on the laboratory temperature conditions, and then transferred to a curing chamber. The chamber was filled with a saturated solution of drinking water and limestone powder (Fig. 3) to ensure proper curing and care. According to the Iranian National Standard No. 1704049 and the ASTM C511:2019 standard50, the water in the curing chamber was saturated with calcium hydroxide (high-calcium hydrated lime) to prevent leaching of calcium hydroxide from the concrete samples. This ensured that there was an excess of undissolved calcium hydroxide in the curing water. The specimens were retrieved from the curing chamber after 7, 28, and 90 days, following the standard testing schedule, to undergo the desired tests.

Figure 3 shows the casting, curing, and workability experiments of SCC specimens.

Method of testing

Workability tests for the SCC, including slump flow, T50, Visual Stability Index (VSI), J-Ring, and L-Box, were conducted following ASTM C1611 (2014)51, ASTM C162152, and EFNARC guidelines29. These standardized procedures ensure a thorough assessment of SCC’s workability. Figure 3 displays photographs from the workability experiments conducted on the SCC specimens.

Compressive strength tests were conducted using 100 × 100 mm cubic casts at 28 and 90 days, following the BS 1881-116 standard53. Additionally, the tensile strength of the concrete was determined through the splitting tensile strength method or Brazilian test on cylindrical specimens at 28 days, following the guidelines of ASTM C496 / C496M54.

The flexural strength of SCC samples was assessed using a universal testing machine with a three-point or four-point bend fixture at 28 days. The test measured the resistance of concrete against vertical forces. The procedure adhered to the ASTM C293 / C293M-16 standard55.

The Ultrasonic Pulse Velocity (UPV) test, a non-destructive method for assessing the homogeneity and strength of concrete, was conducted on the SCC samples at 28 days. The test followed the standards outlined in ASTM C59756.

The Volumetric Water Absorption test was executed on 100 × 100 mm cubic samples for each mix design according to the BS standard57. Water absorption was calculated using the following equation.

\({M}_{1,t}\): Weight of concrete after placing in water for t

At: percentage of water absorption.

\({M}_{0}\): Weight of dry concrete after placing it in the oven.

The Capillary Water Absorption test was conducted on 100 × 100 mm cubic samples for each mixture design in accordance with the ASTM C1585-20 standard57. After 28 days of curing, the cubic samples were exposed to a ventilated greenhouse at a 110-degree temperature of Celsius. After 24 h, the dry weight was measured. Subsequently, the lower part of the sample was immersed in water by 1 to 2 mm. The humidity of the surrounding environment was monitored, and the absorption rate of capillary water was determined at intervals of 30 min, 1 h, 2 h, and 24 h.

The test to assess the fracture toughness of concrete components was conducted using a parameter known as total fracture toughness. This parameter quantifies the resistance against crack growth and expansion. The test followed the guidelines outlined in58. The performance of this test was that concrete beams measuring 10 × 40 cm were fabricated in the Concrete Technology Laboratory at Kharazmi University of Karaj and cured for 28 days. Subsequently, the machine was utilized to induce cracks in the beams. The fracture toughness of the samples was determined by recording the maximum force applied to the beams using the universal testing machine in the Mechanical Laboratory at Kharazmi University.

Fracture toughness value was computed for experimenting with concrete specimens from the Eq. (1)58:

Pf = the fracture load. S = the distance between the bottom supports. w and t = the width and thickness of the SENB sample. KI* = a dimensionless form of KI, which is subjected to the length of the crack ratio a/w and span -to -width ratio S/w in the SENB sample. To compute KI*, we used Eq. (2) for SENB samples with a ratio of S/w = 4 using a numerical technique58:

By substituting the length of crack ratio into Eq. (2), the parameter \({K}_{I}^{*}\left(\alpha \right)\) was calculated for each sample.

SEM and EDX experiments

The Scanning Electron Microscope (SEM) is the most prevalent type of electron microscope, employed to examine the microstructure of materials by scanning the surface with an electron beam. It operates similarly to optical microscopes but boasts significantly higher resolution and a more extensive depth of field. A notable feature of the scanning electron microscope is its ability to provide three-dimensional images due to its substantial depth of field.

The SEM imaging was carried out following the guidelines of ASTM C1723–1059. Eight 10 × 10 cm cubic specimens, aged 28 days, were subjected to core extraction to facilitate further testing. The extracted cores, measuring 1 × 1 × 2 cm, were meticulously handled to minimize exposure to mechanical stress, light, and environmental factors that could potentially compromise their integrity. To ensure reliable results, the cores were carefully packaged and transported to the Rastak Laboratory in Tehran, where they underwent scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX) analyses. These advanced characterization techniques enabled a detailed examination of the microstructural and chemical properties of the specimens. The extracted cores were then subjected to Energy Dispersive X-ray Analysis to analyze and identify the chemical elements in the samples.

This study involved the development of 13 distinct self-compacting concrete (SCC) designs, as outlined in Table 2. The designs incorporated drinking water or treated industrial wastewater with polypropylene fibers of two lengths (6 mm and 12 mm) and two different percentages (0.1% and 2%). Furthermore, the cement content was varied, with two different amounts utilized: 400 kg/m3 and 440 kg/m3.

Each design underwent triplicate sampling, facilitating a comprehensive evaluation that encompassed five different concrete workability tests, five different mechanical strength tests, two different durability tests, and two advanced analytical tests: Energy-dispersive X-ray spectroscopy (EDX) and Electron Spectroscopy for Chemical Analysis (ESM). The compressive strength of the samples was evaluated at three intervals: 7 days, 28 days, and 90 days.

A total of 572 concrete samples were tested, with the average and standard deviation calculated for each design based on the three sampling repetitions. The primary parameters influencing performance included cement content, polypropylene fiber percentage, fiber length (6 mm and 12 mm), and the type of water used (drinking or treated industrial wastewater). The effects of these parameters on workability, mechanical strength, and durability are thoroughly discussed in the article, with a detailed analysis presented in the discussion section.

Results and discussion

To attain the optimum fiber content, various percentages, namely 0.1%, 0.2%, 0.3%, 0.4%, and 0.5%, were tested. Through trial and error, it was determined that fiber amounts equivalent to 0.1% and 0.2% of the concrete volume were found to be suitable for self-compacting concrete. However, in this research, the optimal amount of fiber for conducting experiments was chosen equal to 0.1% of concrete volume.

Workability

Figure 4 illustrates the results of slump flow and T50. As the volume of fibers increases, there is a notable decrease in workability. Specifically, in designs with 0.2% fibers, the slump flow decreased by 6.4% compared to those with 0.1% fibers. Interestingly, at the same volume, the length of the fibers does not exert a noticeable impact on workability or slump flow. The sample with 0.2% fiber volume exhibited the lowest slump flow and the highest T50. Additionally, samples containing silica fumes and fibers required a higher dosage of superplasticizers to achieve the target slump, leading to an increase in T50 time. Notably, when industrial treated wastewater was substituted for tap water in the self-compacting concrete (SCC) mixing design, there was no significant change in the amount of slump or T50 compared to the control samples. While fibers and treated industrial wastewater have been used simultaneously in SCC with a lower amount of cement (400kg/m3 of cement) and a w/c of 0.5, slump flow and T50 reach almost similar results. However, in the SCC sample with higher cement content (440kg/m3 of cement), treated industrial wastewater, and fiber, the slump flow decreased by 9.5%, and the T50 time increased by 10.5% compared to the sample without fiber.

Saeedi et al.60discovered in their research that the addition of fibers to SCC results in a reduction of paste characteristics. Moreover, at higher fiber volumes, the concrete loses its self-compacting properties. Consequently, they recommend establishing limits for using fibers, considering the length and the quantity added to the mixing design.

It is indicated by Ghobadi et al.61 that adding two different types of fibers resulted in a reduction of slump flow and an increase in the duration of the T50 test. A similar trend is exhibited by our results when propylene fiber is used. However, there is a difference in our study compared to theirs. Experiments incorporating fibers, treated industrial wastewater, and silica fume concurrently were conducted, aspects that were not addressed by Ghobadi et al.61.

J- ring and L box test

The findings depicted in Fig. 5 reveal that in both SCC designs (w/c = 0.36 and w/c = 0.5), the substitution of treated industrial wastewater leads to a reduction in the difference in the height of the ring compared to designs prepared with tap water, and they are in the acceptable range of EFNARC 200529. Consequently, the passing ability is enhanced. However, using PP fibers with a length of 6 mm, w/c = 0.5, and tap water, the J-ring reached above 10 cm except for the two mentioned samples. The remaining J-ring of the samples are between 6 and 8 cm, which is defined by EFNARC for different applications in civil engineering. Moreover, no significant alteration in the L-box ratio was observed. Additionally, adding fibers amplifies the J-Ring height difference and diminishes the L-Box ratio. In the 0.5-C400-PP0.1%-6 mm-IWW sample, which simultaneously contains fibers and treated wastewater, the J-Ring height difference decreased by 25% at a w/c of 0.5, and the value of the L-Box ratio also reduced by 10.5%. In contrast, this drop in the samples with a w/c of 0.36 was 37.5% and 6.7%, respectively.

In a study conducted by Kagar et al.62, it was determined that adding polypropylene fibers into the concrete mixture resulted in a decrease in both the self-compaction and filling criteria of the concrete. The test results exceeded permissible limits, leading to issues such as lumping or blockage and an overall increase in implementation problems. Motaghed et al.63 observed that an increase in the dosage of polypropylene fibers and steel hooks is associated with a decrease in the L-box value and a reduction in the workability of concrete. The similarity between our work and other studies is the reduction of workability when using fiber. The difference between the present work and previous research is that we concurrently used treated industrial wastewater, propylene fiber, and silica fume, which were not studied by other researchers.

Visual stability index (VSI)

Figures 6 and 7 indicate the VSI results of different types of SCC samples. According to Fig. 6, the addition of fiber causes an increase in separation and shedding, and as a result, it has a higher VSI. Increasing the volume of fibers in SCC caused VSI to increase from 1 to 2, which indicates that this sample is separated and watered. Also, replacing treated industrial wastewater instead of tap water in SCC samples has no significant effect on the VSI. The usage of Silica fume has also made the sample more stable. As indicated in Figs. 6 and 7, all SCC mixture designs except 0.5-C400-PP0.2%-6 mm SCC sample with VSI = 2 have good stability and are acceptable according to ASTM C1611 standard51.

Upon examining the VSI values in Figs. 6 and 7, it is evident that only the 0.5-C400-pp0.2%-6 mm specimen achieves a VSI of 2. Consequently, we have chosen not to incorporate 0.2% polypropylene fibers into most of the concrete specimens for the experiments, as this was found to negatively impact workability.

First, using treated industrial wastewater instead of traditional drinking water does not impair the fluidity and workability of Self-Compacting Concrete (SCC). Second, as shown in Table 4, there is minimal variation in the amount of superplasticizer across different samples with water-to-cement ratios of either 0.36 or 0.5. Additionally, according to the standards for reinforced concrete structures in Iran48, when incorporating fibers, it is recommended to either reduce the coarse aggregate content by 20% or increase the amounts of fine aggregates or superplasticizers to ensure fluidity and workability.

In this study, all samples, excluding the control samples (0.5-C400, 0.36-C440, 0.5-C400-IWW, and 0.36-C440-IWW), exhibited a 20% reduction in coarse aggregate content compared to the control samples. This reduction can sometimes prevent enhanced compressive strength when fibers are incorporated.

Mechanical properties

Compressive strength

Figure 8 illustrates the compressive strength results of different SCC mixture designs. Compressive strength tests were conducted for all SCC designs on 7, 28, and 90 days. The findings indicate that in SCC samples with lower cement content (400 kg/m3 and w/c = 0.5), the 28-day compressive strength of the 0.5-C400-PP 0.1%-6 mm sample increased by 10% compared to the control sample. Moreover, altering the fiber length did not result in any significant change in compressive strength, and increasing the amount of fiber higher than 0.1% by volume of cement slightly decreased compressive strength.

Adding treated industrial wastewater led to an 8% reduction in the 28-day compressive strength compared to the control SCC sample. Notably, the variations in results between samples with more cement (440 kg/m3) and those with less cement (400 kg/m3) are discernible. In samples with higher cement content at 90 days, the addition of fibers resulted in a decrease in slight compressive strength. It may cause fibers to absorb some water during mixing, leading to less cement hydration related to the control design. In lower cement content when using PP fiber and treated industrial wastewater, the reduction in 90-day compressive strength was slight compared to the SCC control sample with treated industrial wastewater. In the design with lower cement content (400 kg/m3 and w/c = 0.5) containing PP fiber, treated industrial wastewater, and silica fume, the 90-day compressive strength improved compared to the SCC control sample.

In the design with lower cement content (400 kg/m3), the 90-day compressive strength with 0.1% fiber with a length of 6 mm reached better compressive strength compared with fiber with a length of 12 mm. In SCC samples with more cement (440kg/m3 of cement and w/c = 0.36) using PP fiber with lengths of 6 and 12 mm, 90 days, the compressive strengths slightly decreased compared to the SCC control sample. The length of PP fibers did not affect compressive strength. Using treated industrial wastewater instead of tap water in the SCC sample with more cement (440kg/m3 of cement and w/c = 0.36) reduced compressive strength. However, adding PP fiber in the SCC sample with treated industrial wastewater slightly increased compressive strength compared to using treated industrial wastewater only. Finally, adding PP fiber and silica fume powder in a sample containing treated industrial wastewater increased compressive strength.

Asadollahfardi et al.4 conducted a study exploring the utilization of treated domestic wastewater, in the production and curing of conventional concrete. The research findings indicated that when complying with Iran’s concrete regulations, incorporating treated domestic wastewater in concrete manufacturing and curing did not result in a significant reduction in compressive strength of the samples. Furthermore, curing the concrete samples with treated domestic wastewater offers the potential for substantial water conservation without compromising the quality of the concrete. This suggests a viable and sustainable approach to optimizing limited water resources in concrete production.

Asadollahfardi and Mahdavi24 conducted a study on the impact of treated industrial wastewater on conventional concrete. They found that substituting it for drinking water resulted in a reduction of approximately 10% in the compressive strength of the concrete. Yahyaei et al.23 used treated domestic wastewater instead of drinking water to produce SCC samples. Their results indicated using treated wastewater to decrease compressive strength. Our results are in line with the above-mentioned studies.

Industrial-treated wastewater typically contains elevated sulfates, chlorides, nitrates, and phosphates. According to Table 2, the sulfate and chloride concentrations were measured at 1099.104 mg/L and 2131.726 mg/L, respectively, indicating significant levels. These anions can disrupt the hydration process of cement paste, inhibiting the formation of calcium-based hydrates and ultimately leading to diminished compressive strength. Furthermore, the total dissolved solids in the treated industrial wastewater were relatively high, recorded at 7448 mg/L, which may contribute to compressive strength reduction. Also, the total dissolved solids contain organic materials that can alter the hydration kinetics, further compromising compressive strength.

In a study, Kakooei et al.14 observed that, according to the results of compressive strength tests, the strength of concrete showed a direct correlation with the increase in volume ratios of polypropylene fibers. The highest compressive strength was achieved using 1.5 kg/m3 and 2 kg/m3. Hosseinzadeh et al.64 also showed an increase of PP fiber in conventional concrete up to a certain level increase in compressive strength. Our work is in line with the research mentioned. The distinctive feature of the present work lies in the simultaneous utilization of treated industrial wastewater with polypropylene fibers of two different lengths, along with the inclusion of silica fume.

Flexural strength

The flexural strength test was conducted at the 28-day mark, and the average results are presented in Fig. 9a. The findings indicate that in the design with lower cement content (400 kg/m3), the flexural strength decreased with the addition of fibers compared to the control sample. This reduction was less pronounced in the design with higher cement content (440 kg/m3). As the volume percentage of fibers increased, the decrease in strength became more significant. Consequently, the design containing 0.2% fibers exhibited the lowest flexural strength.

In designs with lower cement content (400 kg/m3), the introduction of treated industrial wastewater led to a 3.5% decrease in flexural strength compared to the control sample. In the fiber design incorporating treated industrial wastewater, the addition of 0.1% fibers resulted in an 8% increase in bending strength compared to the treated wastewater control sample. Furthermore, the inclusion of silica fume powder led to a 7% increase in flexural strength compared to the sample without silica fume powder. Additionally, samples in which both fibers and treated wastewater were used experienced a 3.5% drop in flexural strength at a w/c ratio of 0.5.

Ahmed et al.65 concluded that polypropylene fibers positively impact the increase in flexural strength. The enhanced flexural strength is attributed to the delayed propagation of cracks under bending loads, a result of the preferred orientation of polypropylene fibers. This orientation helps create an energy absorption mechanism. The significant size and variable length of polypropylene fibers contribute to a bridging effect within the strands, thereby preventing the formation of additional cracks.

Kazemi and Hashemi66 discovered that the addition of fibers enhances flexural strength. They recognized that the degradation of concrete is largely influenced by the emergence and expansion of microcracks and cracks. The observed increase in flexural strength can be attributed to the fibers acting to bridge these cracks, thereby impeding their convergence. This bridging effect ultimately leads to an increase in bending strength.

The difference between our results and those of other researchers is that we decreased 20% coarse aggregate to the fibrous concrete compared to the control sample. This adjustment was made to meet the required workability as per Iranian regulations.

Tensile strength

Figure 9b illustrates the average tensile strength at 28 days. The results show that, in designs with lower cement content (400 kg/m3), the tensile strength of fiber samples made with tap water increased compared to the control sample. Specifically, fibers with a length of 6 mm exhibited a 9% increase in tensile strength, while those with a length of 12 mm saw a 13% increase. Additionally, increasing the fiber length at the same volume percentage resulted in a 4% improvement in tensile strength. However, exceeding the optimal volume percentage (0.1%) caused a decrease in tensile strength. Notably, fiber samples made with treated industrial wastewater have reduced tensile strength compared to those made with tap water.

Additionally, in designs with higher cement content (440 kg/m3) across all configurations, the introduction of fibers resulted in an observed increase in tensile strength. Specifically, the sample with a fiber length of 12 mm exhibited a 6% improvement in strength compared to the sample with a fiber length of 6 mm. This suggests that fiber length positively influences the tensile strength of the sample. Furthermore, a 10% increase in tensile strength was noted in fiber samples containing treated industrial wastewater compared to the control sample. However, in fiber SCC samples with treated wastewater, tensile strength decreased by 12% at a water-to-cement ratio (w/c) of 0.5 and lower cement content. This indicates that while fibers generally enhance tensile strength, the impact of using treated industrial wastewater was notably more significant. Conversely, with higher cement content and a w/c ratio of 0.36, the reduction in tensile strength was minimal.

Zhou and Hua25 conducted a study on the performance of fiber-reinforced concrete used for tunnel linings. The research findings revealed a significant 23% increase in tensile strength when polypropylene fibers were incorporated into the concrete.

In a study examining the effect of various percentages of polypropylene fibers on the tensile strength of self-compacting concrete (SCC), Kazemi and Hashemi66 found that the presence of fibers consistently improved tensile strength at all ages. This enhancement was observed across different fiber levels (1.5, 1, and 2 kg per cubic meter). Essentially, increasing the volume of polypropylene fibers in the concrete was associated with a significant improvement in tensile strength, highlighting the beneficial impact of fibers on this property. The unique aspect of our current research, in contrast to previous studies, is the simultaneous use of treated industrial wastewater, polypropylene fibers of two different lengths, and silica fume in SCC, presenting a novel approach.

Fracture toughness test results

Table 5 shows the average results of fracture toughness at the age of 28 days, obtained by cutting the beam and applying the maximum force using the universal testing machine. The findings show that the addition of fiber reduces the fracture toughness by 30% and 22%, respectively, in samples with a w/c of 0.5 and 0.36. Increasing the volume of fibers from 0.1% by volume to 0.2% will increase the fracture toughness and this parameter value increased by 15% compared to the sample containing 0.1% fibers. Also, the results of fracture toughness in the sample containing 12 mm fibers, compared to 6 mm fibers (0.1% by volume) in groups 1 and 2, were increased by 10 and 13%, respectively. The increase in treated industrial wastewater led to a decrease of 29% and 21% in the fracture toughness results, respectively, in samples with a w/c of 0.5 and 0.36. In the samples containing wastewater and fibers, the fracture toughness decreased by 38% and 26% respectively for the samples of group 1 and 2.

Mahdipour observed that as the quantity of fibers increases, there is a corresponding increase in deformations before the final rupture. In simpler terms, this implies an augmentation in toughness. Additionally, elevating the slenderness factor (the ratio of length to diameter) of the fibers tends to enhance toughness up to a certain threshold, which is contingent upon the inherent resistance of the fibers67.

Peighambarzadeh et al.17 investigated the impact of utilizing treated domestic wastewater on the fracture toughness of concrete and found that substituting treated domestic wastewater for drinking water in concrete mixing and processing resulted in a decrease in fracture toughness ranging from 2 to 6%, which was deemed insignificant. Taghizadeh et al. 36 explored the effects of utilizing wash water and steel fibers, concluding that replacing wash water with tap water increased fracture toughness by approximately 16%. Moreover, introducing steel fibers into concrete samples using tap water led to a fracture toughness enhancement of about 24% compared to the control sample. Simultaneously applying wash water and steel fibers to concrete samples resulted in a remarkable 49% increase in fracture toughness. In the present study, the simultaneous effects of incorporating fibers and treated wastewater were examined. It was observed that their concurrent addition, with a water-to-cement ratio (w/c) of 0.5 and a higher cement content, resulted in a 39% decrease in toughness. Furthermore, when the w/c ratio was 0.36 and the cement content was higher, the fracture toughness decreased by 27%. Zhang and Li68 stated that when the fiber volume is 0.06%, the effect of fiber on the fracture toughness is not very clear, while with the increase of the fiber content to 0.08%, the fracture toughness is associated with a large increase, and after the volume percentage of 0.08% increased, the rate of increase in fracture toughness decreases Zhang et al.69 stated that when the silica fume content increases from 0 to 3%, the fracture parameters gradually increase, and the fracture relationship curves become more voluminous with the increase of silica fume content. However, the failure parameters start to decrease, and the curves become thinner and thinner after the silica content exceeds 3%. These laws of change of fracture parameters and fracture relationship curves show that silica fume helps to improve the fracture property of concrete composite only when the amount of silica fume does not exceed 3%. The use of 3% silica fume improves the fracture toughness by 19%. Fracture toughness decreases with the increase of silica fume percentage, but its value is still higher than the sample without silica fume.

Volumetric water absorption

Figure 10 illustrates the results of volumetric water absorption. The test was conducted at four different intervals: 0.5 h, 1 h, 2 h, and 24 h, with three samples taken from each design.

The addition of 0.1% propylene fibers with a length of 6 mm in SCC samples increased the volumetric water absorption over 24 h in samples with a w/c ratio of 0.5. The increase in water absorption over 24 h in SCC samples with a w/c ratio of 0.36 is less than 2%. Adding a higher percentage of fibers (0.2%) in SCC with a w/c ratio of 0.5 increases the water absorption more than using 0.1% fibers. The use of longer fibers (12 mm) decreases water absorption compared to using 6 mm fibers with a w/c ratio of 0.5. This increase in water absorption is probably due to the increased porosity of concrete containing fibers. Additionally, the use of treated industrial wastewater did not had a significant effect on the volumetric water absorption of the samples with a w/c ratio of 0.5. The simultaneous use of treated industrial wastewater and fibers also increased water absorption for w/c ratios of 0.36 and 0.5. Using silica fume and 6 mm fibers in both w/c ratios of 0.36 and 0.5 decreased volumetric water absorption when using tap water or treated industrial wastewater69. According to the national regulations of the Persian Gulf and the Sea of Oman, the maximum allowable water absorption of concrete within the first 0.5 h for average environmental conditions is 4%, and all designs fell within the permitted range37.

Al-Jabri et al.19 concluded that replacing treated wastewater in concrete mix designs, with replacement ratios ranging from 25 to 100% of the total water used in the mix, does not significantly affect the volumetric water absorption of high-strength concrete. Additionally, Shen et al.27 conducted a study on the behavior of concrete containing fibers as a lining for tunnels. The results of this research indicated a 10% decrease in water absorption. Asadollahfardi and Mahdavi24 demonstrated that the utilization of treated industrial wastewater did not significantly impact water absorption compared to drinking water. However, in the investigations conducted in our research, the concurrent use of treated industrial wastewater and polypropylene fibers increased the water absorption rate of SCC samples with a water-to-cement (w/c) ratio of 0.5 and a lower cement content. This phenomenon may be attributed to the increased porosity of the concrete samples. The increase in water absorption in SCC samples with a w/c ratio of 0.36 and 0.5 with a higher cement content is much less pronounced.

Capillary water absorption

Figures 11 and 12 presents capillary water absorption of SCC at 28-day. The results show that the addition of 0.1% fibers with a length of 6 mm will increase the amount of capillary water absorption by 138% and 85%, respectively, in samples with a water-to-cement ratio of 0.5 and 0.36. Also, adding more fibers (0.2%) will increase water absorption up to 209%. Samples containing fibers with a length of 12 mm also recorded an increase of 69 and 6% in the water-cement ratio of 0.5 and 0.36. This increase in water absorption is probably due to the increased porosity of concrete containing fibers. The use of wastewater also increased the water absorption of samples with a water-to-cement ratio of 0.5 by 19%, while it had no special effect on samples with a lower water-to-cement ratio. The samples that simultaneously contain wastewater and fibers also experienced an increase of 95 and 84% in capillary water absorption. Also, in the main mixtures that simultaneously contain fibers, wastewater and silica fumes, the results of an increase of 117% in the ratio of water to cement 0.5 and it shows a 44% increase in the water-cement ratio of 0.36. As is known, the samples with higher cement showed a lower water absorption rate than the samples with less cement. This can be attributed to the increase in cohesion of the concrete paste and the reduction of pores. According to durability guidelines, the maximum water penetration for concrete exposed to conditions typical of the Persian Gulf and Oman Sea is 50 mm on average, and all samples fell within this permissible range37.

Piasta et al. discovered that capillary water absorption is contingent upon two parameters: paste volume and water-to-cement ratio. As the water-to-cement ratio rises, both the volume of the capillary space and the diameter of the capillary tubes increase accordingly. Moreover, as water absorption increases, the slope of the graph lines also rises, and this escalation in slope is contingent upon two factors: capillary potential and the depth of the sample submerged in water. As the ratio decreases, the water movement-to-cement ratio declines due to the reduction in the diameter of continuous capillary spaces and the augmentation of water movement resistance.

Ultrasonic pulse velocity (UPV)

The ultrasonic pulse velocity (UPV) test is used to assess the quality of concrete. A higher UPV indicates better concrete quality, greater homogeneity (fewer cracks and voids), uniformity, and the absence of defects. Figure 13 illustrates the UPV of SCC samples at 28 days of age. Karaiskos et al.70 reported in 2015 that if the UPV exceeds 4.5 km/s, the concrete quality is considered excellent. If the UPV ranges between 3.5 and 4.5 km/s, the concrete quality is deemed good. A UPV between 3.0 and 3.5 km/s indicates average quality, while a UPV below 3.0 km/s suggests questionable quality.

As depicted in Fig. 13, the quality of the control samples is excellent for a w/c ratio of 0.36 and falls within the good range for a w/c ratio of 0.5. The addition of 0.1% fibers with a length of 6 mm caused a slight decrease in UPV, but the quality of the samples remains within the good range. No significant change in UPV was observed with the addition of 0.1% fiber with a length of 12 mm. On average, the use of treated industrial wastewater reduced the UPV by 15% for a w/c ratio of 0.5 and by 12% for a w/c ratio of 0.36. At 28 days, the quality of these SCC samples falls within the average category, but by 90 days, they fall within the good category.

Furthermore, the simultaneous addition of fibers and treated industrial wastewater for a w/c ratio of 0.5 resulted in a 32% decrease in UPV at 28 days, placing the sample in the average category. However, at 90 days, this decrease was reduced to 7%, moving the sample to the good category. Similarly, for a w/c ratio of 0.36, the simultaneous addition of fibers and wastewater led to a 20% decrease in UPV at 28 days, while at 90 days, the UPV increased by 2%, with both samples classified within the good category. In principle, samples containing treated industrial wastewater, fibers, and silica fume simultaneously experienced an average UPV drop of 17% at 28 days, while at 90 days, there was no significant change compared to the control sample.

Asadollahfardi et al.71 investigated the impact of treated domestic wastewater on the ultrasonic pulse velocity (UPV) of concrete. They noted that the addition of domestic wastewater treated to the concrete samples did not significantly alter the UPV compared to the control sample, and these samples were categorized as good quality. Savio et al.72, in their study on the effect of polypropylene fibers on UPV, observed an increase in UPV with the addition of fibers. However, they used varying volume percentages and lengths of fibers. Their results indicated that the highest UPV was achieved with a fiber volume of 1.2% at a length of 60 mm. Subsequently, the sample containing a 0.8% volume of fibers with a length of 50 mm exhibited the highest UPV. Using fibers, treated industrial wastewater, and silica fume in SCC (self-compacting concrete) samples increases UPV (ultrasonic pulse velocity).

Due to the increasing use of concrete in the construction industry, it is necessary to estimate the structural parameters of concrete in various ways. This research attempts to establish a relationship between the compressive strength of concrete and UPV, a non-destructive test that can be used to estimate compressive strength.

Figure 14 shows the relationship between compressive strength and ultrasonic pulse velocity at the age of 90 days. According to the figure, there is a direct and relatively strong relationship, with an R2 coefficient of 0.7, between 90-day compressive strength and UPV. In other words, samples with higher ultrasonic pulse velocity have higher 90-day compressive strength.

SEM analysis results

To conduct the SEM analysis, eight SCC samples from each design were tested. In nearly all SEM images, calcium hydroxide (CH) gels appeared in light gray, voids appeared in black, calcium silicate hydrate (C-S–H) gels appeared in dark gray, and ettringite appeared as transparent needles.

Figure 15 displays the Scanning Electron Microscopy (SEM) images of various Self-Compacting Concrete (SCC) types: 0.5-C400, 0.36-C440, 0.5-C400-IWW, and 0.36-C440-IWW. The 0.5-C400 sample, which contains less cement and has a higher water-to-cement ratio compared to the 0.36-C440 sample, exhibits more voids. The cement paste in the 0.5-C400 sample is less homogeneous and cohesive. In the mix with less cement and a water-to-cement ratio of 0.5, there are more voids, which can reduce compressive strength. Conversely, in the mix with more cement (0.36-C440 sample), the cement hydration is more complete, and most of the space is filled with hydrated cement products, including calcium silicate hydrate (CSH). This results in higher compressive strength for the 0.36-C440 sample.

In the design containing treated industrial wastewater with less cement (400 kg/m3 of cement and w/c = 0.5), the number of holes and cracks increased, and the amount of ettringite has risen compared to the control sample. These factors contribute to a reduction in strength. In the design with more cement (440 kg/m3 of cement and w/c = 0.36), there are fewer voids and anhydrate clinkers (Fig. 16). Additionally, hydrated monosulfate masses were observed, indicating that concrete with treated industrial wastewater is at risk of sulfate attack. Anhydrate cement particles can absorb and form lumps, trapping large amounts of mixing water, which leads to heterogeneity on the cement surface.

The SEM images of the fiber SCC design incorporating treated industrial wastewater and silica fume powder reveal that the addition of silica fume results in a more cohesive and uniform cement paste. Furthermore, these images (Fig. 16) show a more pronounced presence of C–S–H, which contributes to increased compressive strength. The incorporation of silica fume enhances the continuity of the concrete, preventing the formation of defects. Literature reviews indicate that cement paste with silica fume additives exhibits notably fewer pores and narrower crack widths73. Yuan et al.74 found that in samples without fibers, good bond quality between the aggregate and the cement matrix is achieved when the water-to-cement ratio is 0.3 or 0.35. This results in a dense matrix, although clear cracks are still observed. In contrast, in samples containing polypropylene fibers, the bond quality between the polypropylene fibers and the cement matrix is poor due to the hydrophobic nature of polypropylene. However, the small ridges on the polypropylene fibers create an uneven surface, which enhances physical interaction and improves the interface strength between the polypropylene and the matrix.

The results of EDS-EDAX analysis

The supplementary file includes Figs. S1 to S5, which display the XRD and EDX results. Table 5 presents the 28-day compressive strength and Ca/Si ratios of selected SCC samples.

As indicated in Table 6, a decrease in the Ca/Si ratio leads to an increase in compressive strength. Additionally, increasing the cement content in the SCC sample results in higher compressive strength. However, using treated industrial wastewater instead of tap water decreases compressive strength (Table 5). These results are consistent with the findings of Asadollahfardi and Mahdavi24.

Adding fiber to the SCC sample enhances compressive strength, with 12 mm fibers providing a slight improvement over 6 mm fibers. The combination of 6 mm fibers, treated industrial wastewater, and silica fume also improves compressive strength, as silica fume generates more C–S–H. Additionally, replacing treated industrial wastewater with tap water in the 0.5-C400-IWW and 0.36-C440-IWW samples (Figures S1 and S2) resulted in a decrease in silicon content, which may contribute to a reduction in compressive strength.

There is also an increase in the weight percentage of sulfur and iron. The ratio of calcium to silica in the treated industrial wastewater design is higher than in the control SCC design, which could be another reason for the decrease in compressive strength and C–S–H in SCC. Adding silica fume to SCC, as seen in the 0.36-440-PP0.1%-6mm-IWW-SF sample, results in a significantly lower Ca/Si ratio compared to the SCC design without silica fume (Table 5 and Figure S1). This leads to an increase in compressive strength in the SCC design with silica fumes, despite using treated industrial wastewater instead of tap water.

Discussion

The 90-day compressive strength of the control sample with water-to-cement ratio of 0.36, and cement content of 440 kg/m3, had slightly higher compressive strength compared to sample with a water-to-cement ratio of 0.36, and 0.1% propylene fiber, due to a higher concentration of coarse aggregate on control sample (20% more than the other concrete specimens). Other samples with drinking water or treated industrial wastewater reduced fluidity when fibers were included. According to the Iranian Reinforced Concrete Code, achieving the necessary fluidity and workability in samples with fiber content typically requires up to 20% reduction in coarse aggregate. To maintain workability, either sand content was increased, or superplasticizer ratios were adjusted accordingly. Since all samples, except four control samples (0.5-C400, 0.36-C440,0.5-C400-IWW and 0.36-C440-IWW) with higher and lower cement content, had a 20% reduction in coarse aggregate, this may have resulted in a slightly lower compressive strength in the fiber-reinforced concrete compared to the control samples. Notably, increasing the fiber content from 0.1 to 0.2% in lower cement content samples led to a decrease in compressive strength, a finding that corroborates previous research.

Conversely, samples containing treated industrial wastewater without fibers demonstrated a decrease in 90-day compressive strength compared to the control, regardless of their cement content or water-to-cement ratio, a conclusion also supported by Asadollahfardi and Mahdavi24 and Nasseralshariati et al.75 However, the addition of 0.1% fiber with a length of 6 mm to the self-compacting concrete (SCC) sample using treated industrial wastewater resulted in an increase in 90-day compressive strength compared to the same sample without fibers. This suggests that incorporating low percentages of fibers into concrete with treated industrial wastewater can effectively enhance compressive strength, highlighting a novel finding in this research area. Furthermore, a concrete sample with treated wastewater and a water-to-cement ratio of 0.36, combined with fiber and silica fume admixtures aimed at improving mechanical properties, exhibited increased compressive strength at 90 days. This significant result suggests that utilizing silica fume alongside fibers in concrete with treated industrial wastewater can further enhance compressive strength, which is new result.

When considering fracture toughness, increasing the polypropylene fiber content from 0.1 to 0.2% in self-compacting concrete (SCC) with 400 kg/m3 of cement and a water-to-cement ratio of 0.5 results in enhanced toughness. However, comparing these results to the control sample is challenging, as the control concrete contains 20% more coarse aggregate than the other SCC samples, complicating direct comparisons. In the concrete mixtures, raising the fiber percentage from 0.1 to 0.2% by using drinking water and maintaining a water-to-cement ratio of 0.5 improves fracture toughness. Additionally, increasing the length of the polypropylene fibers from 6 to 12 mm further enhances fracture toughness.

Conversely, when treated industrial wastewater is used instead of drinking water in the same concrete mixture (400 kg/m3 of cement and a water-to-cement ratio of 0.5), there is a decrease in fracture toughness. These findings are consistent with the results reported by Peighamzadeh et al.17, Taghizadeh et al.36, and Keneshlo et al.34. Simultaneously using 0.1% polypropylene fiber and treated industrial wastewater resulted in a slight reduction in fracture toughness. This finding is noteworthy, as the combination of treated industrial wastewater and polypropylene fiber was not previously studied in SCC. However, adding silica fumes to a sample containing both polypropylene fiber and industrial wastewater—rather than drinking water—leads to an increase in fracture toughness, which represents a novel contribution to the field.

In SCC with a higher cement content of 440 kg/m3, the use of drinking water and a water-to-cement ratio of 0.36 demonstrates that increasing the fiber length from 6 to 12 mm also improves fracture toughness. In this same concrete mix, substituting treated industrial wastewater for drinking water without including fiber results in a reduction in fracture toughness, like the results observed in the SCC with a water-to-cement ratio of 0.5 and a cement content of 400 kg/m3. When treated industrial wastewater is combined with polypropylene fiber (0.1% and 6 mm in length), a slight reduction in fracture toughness occurs, which is anticipated. Finally, in concrete that incorporates treated industrial wastewater, polypropylene fiber, and silica fume, the fracture toughness improves; however, this result is novel.

In the investigation of tensile strength for self-compacting concrete (SCC) samples containing 400 kg/m3 of cement with a water-to-cement (w/c) ratio of 0.5 using drinking water, the addition of 0.1% polypropylene fiber with a length of 6 mm resulted in increasing tensile strength. This finding aligns with research conducted by Zhou and Hua25, and Kazemi and Hashemi66. However, increasing the polypropylene fiber concentration from 0.1% to 0.2%, while maintaining the same specifications, led to a reduction in tensile strength. On the other hand, when the fiber length was increased from 6 to 12 mm while still containing 0.1% polypropylene fiber, tensile strength improved.

If the sample designs are prepared using treated industrial wastewater instead of drinking water—while excluding the use of polypropylene fiber—the increase in tensile strength is only slight. This observation is consistent with the findings of Raza et al.46, who utilized textile wastewater in their concrete formulations. Notably, using treated industrial wastewater combined with 1% polypropylene fiber of 6 mm length results in a decrease in tensile strength. This finding is novel and has no prior comparisons in existing literature.

Furthermore, if we incorporate 2% silica fume into the same concrete formulation while still using treated industrial wastewater and 6 mm-long polypropylene fibers, we observe an increase in tensile strength. Additionally, for concrete with a cement content of 440 kg/m3 and a water-to-cement ratio of 0.36, an increase in tensile strength is also noted. These results are significant and represent new findings that have not been previously explored for this type of sample. Since flexural strength and volumetric water absorption have been sufficiently discussed previously, they will not be addressed in the discussion section.

Our study emphasizes the potential benefits and downsides of incorporating treated industrial wastewater and propylene fibers, along with the role of silica fume in self-compacting concrete (SCC). In contrast, the study by Deng et al.76 focuses on the mechanical properties of geopolymer composites reinforced with polyvinyl alcohol (PVA) fibers, providing a different perspective in materials engineering. Both studies serve as essential references for advancing the understanding and application of sustainable concrete technologies.

Our research investigates the role of treated industrial wastewater in combination with fiber reinforcement in SCC, while Deng77 examine the effects of recycled aggregates and recycled rubber aggregates on the durability of geopolymers against sulfate exposure.

Both Deng et al.’s study78 and our work contribute valuable knowledge to the field of sustainable construction materials but approach the topic from different angles. Our research on treated industrial wastewater and propylene fibers offers insights into enhancing concrete performance, while the Deng study on glass aggregates focuses on addressing specific durability issues related to alkali-silica reaction (ASR) and the role of lithium nitrate (LiNO3) in mitigating these issues. Together, they reinforce the importance of exploring sustainable materials and understanding their interactions and performance in construction applications.

We investigated the use of treated industrial wastewater and propylene fibers in SCC, while Deng et al.79examined the recycling of waste oyster shells (WOS) as fine aggregate in geopolymer mortar. Both studies assess the incorporation of fibers—propylene fibers in our research and PVA fibers in theirs. Each study evaluates the impact of these fibers on various mechanical and physical properties of the concrete or mortar. Our work specifically focuses on SCC using treated industrial wastewater and synthetic propylene fibers, whereas the Deng et al. study concentrates on geopolymer mortar with recycled crushed waste oyster shells and PVA fibers.