Abstract

Nowadays, the use of virtual reality (VR) for training purposes has increased manifold among organizations due to better integration of both cognitive and emotional dimensions. VR-based training surpasses traditional methods in Industry 4.0 by increasing safety awareness by 30%, enhancing risk perception, and improving self-efficacy. A quasi-experimental study involving 200 participants confirmed the superiority of VR through statistical analysis, highlighting its role in fostering a proactive safety culture and promoting sustainable workplace health. The research primarily focuses on how VR-based training can enhance the sustainability of occupational safety for industrial workers, thereby reducing the likelihood of human errors and industrial accidents. A quasi-experimental design was employed in the current study, with 200 participants divided into two groups: intervention and control. The effectiveness of VR-based training was judged based on participants’ self-efficacy toward leadership support, training resources, and communication channels. Findings revealed statistically significant differences between the groups, as shown by the Mann-Whitney U test. Compared to the control group, the intervention group performed significantly better on several indicators, such as the efficacy of the VR training (mean rank = 30.00) and how participants perceived their ability after completing the OSH training based on VR (mean rank = 74.0); further, the findings from the current study revealed that participants who had VR training resources available felt that these were more accessible and better quality than those in the control group (median = 65) than intervention group (median = 72) significant at (p = 000). These results show that VR technology can improve sustainable health and safety measures in the 4.0 industrial sector. Practical implications include encouraging a sustainable, safety-first attitude among coworkers, enhancing the efficacy of workplace sustainable health and safety training, and improving employees’ self-confidence.

Similar content being viewed by others

Introduction

Industry 4.0 represents the fourth stage of industrialization, driven by the growing global demand for capital and consumer goods, as well as the urgent need for more sustainable and resource-efficient manufacturing practices1. Initially proposed in Germany in 2011, Industry 4.0 envisions the digital interconnection of everything in and around a manufacturing operation, creating a highly integrated value chain2. The vision is one of higher productivity, increased integration, and customized, flexible work3. This new paradigm for enhancing business performance and processes is digital, integrating the vertical, horizontal, and end-to-end aspects4. The changes in manufacturing systems are driven by the Internet of Things (IoT), Cyber-Physical Systems (CPS), and state-of-the-art Information and Communication Technology (ICT)5. These technologies are substantially revolutionizing the way manufacturing systems communicate, which is the dawn of the third wave of industrialization.

According to I40Ts, firms may substantially improve operational effectiveness and value in the workplace6. Additive manufacturing, artificial intelligence, synthetic vision, big data, robots, cybersecurity, and VR are the technologies that have facilitated the shift to the Fourth Industrial Revolution. The cited technologies underpin the enhancement of automation, improvement of overall performance, and advancement of operational efficiency throughout global industries. Nonetheless, implementing these technologies remains more prevalent in industrialized nations, where resource availability and infrastructure surpass those in less developed countries. The realm of rising economies is compounded by numerous financial challenges that impact SMEs and, consequently, the applicability of these advances. The digital divide hinders these organizations from leveraging the enhancements offered by advanced technologies, diminishing their capacity to compete globally7. The equitable and relational distribution of technological and industrial solutions underscores the global prevalence of Industry 4.0, particularly in underdeveloped nations where the extensive implementation of highly scalable technical solutions in various industries still needs to be realized. To address these gaps, it is essential to implement comprehensive agendas with sophisticated approaches to improve the utilization of I40Ts across various population sectors8.

Beyond improving workplace safety and training new employees, VR offers a variety of other potential uses, including enhancing employees’ skills without harming themselves or others. The ability to simulate real-world challenges in a virtual space has significant social, ecological, and economic implications. As young professionals enter the competitive job market, they often need help understanding how to apply what they learn in the classroom to their on-the-job experiences. Fully immersive VR learning environments bridge this gap, making students more engaged and motivated and successfully transitioning from theoretical knowledge to practical skills9.

Although VR has the potential to revolutionize industries, the management of workplace irregularities necessitates further evidence. Previous studies have demonstrated the effectiveness of VR in high-risk sectors, such as healthcare and manufacturing; however, more information is needed regarding its application in other domains. This current study will examine the sustainable benefits of utilizing VR to enhance occupational health and safety (OHS) procedures10.

VR serves as an effective training tool in professions involving high-risk tasks, such as operating heavy machinery or working in hazardous environments. It enables staff to practice emergency drills and become familiar with complex safety protocols. Companies can ultimately enhance employee training and foster confidence in more constructive situations, underscoring their significance in industries such as automotive manufacturing, healthcare, and aerospace, where precision and safety are paramount. Despite its significant promise and effectiveness in enhancing sustainable occupational safety across all sectors of Industry 4.0, the question still needs to be solved. Although most research is conducted in high-risk businesses or industries, the contextual impacts of VR training in low-risk settings still require improvement11.

This project aims to explore the use of VR in enhancing workplace health and safety compliance, with a focus on achieving sustainable outcomes. The efficacy of VR training in altering safety behaviors and enhancing threat perception will be evaluated by pre- and post-training safety climate surveys. The gamification of training, utilizing VR, acknowledges the significance of enhancing employee engagement through training and development, thereby incorporating gamification and immersive experiences into training systems. This approach augments the reactivity of the learning content, improving its assimilation and, consequently, the training. In nearly all sectors, change is constant, necessitating continuous skill improvement. VR enables enterprises to scale effectively while ensuring employees are well-informed about safety protocols and optimal practices relevant to their expertise.

VR is offered as an innovative facilitator that could enhance workplace safety and training in Industry 4.0. These reality-focused VR training simulations address challenges in contemporary workforce training and development, rendering VR an indispensable component of the modern industry. The integration of I40Ts into other enterprises will enhance efficiency in training and safety programs by utilizing VR technology. This project aims to explore the comprehensive potential of VR in improving workplace safety and health, aligning with the overarching objective of sustainable development within Industry 4.0 contexts.

Existing research on VR-based training primarily focuses on high-risk industries, such as healthcare, aviation, and heavy manufacturing; however, low-risk sectors remain underexplored despite the prevalence of workplace accidents. While studies show VR improves skill retention and hazard recognition, they lack comprehensive evidence of its effectiveness in logistics, production lines, and administrative security. This study aims to bridge the gap by assessing the potential of VR to enhance occupational safety in low-risk industrial environments.

The extent to which VR-based training successfully enhances workplace safety and health in four industry environments, particularly in low-risk production facilities, warrants examination.

-

1.

Employees who learn safety skills through virtual reality (VR) demonstrate substantially better awareness and self-confidence in safety matters than employees who use traditional training methods.

-

2.

A VR training solution provides users with more valuable and easier-to-learn safety procedures when compared to traditional non-VR instruction methods.

-

3.

VR training systems strengthen communication systems and employee perceptions regarding leadership-based workplace safety support.

-

4.

This study supports the expansion of the literature on immersive technologies in implementation for achieving lasting, sustainable safety excellence in high-risk and beyond.

The remainder of this study is structured as follows: Sect. 2 presents the theoretical background and research methodology, including the study design, population, sampling, and data analysis techniques. Section 3 presents the results of the quasi-experimental study, comparing the effectiveness of VR-based and traditional training. Section 4 interprets the findings about the Technology Acceptance Model (TAM), Social Cognitive Theory (SCT), and Organizational Learning Theory (OLT), emphasizing the implications for Industry 4.0. Section 5 highlights research limitations and future directions, while Sect. 6 summarizes key contributions and practical implications of VR-based occupational safety training.

Materials and methods

Theoretical background

In this current study, three prevalent theories in the present world serve as theoretical frameworks: the Operationalization of Learning Theory12, Social Cognitive Theory13, and the Technology Acceptance Model14. The Technology Acceptance Model (TAM) will help identify factors that explain why elaborate technologies, such as virtual reality (VR), need to be used in organizations15. Considering the concepts of Perceived Usefulness and Perceived Ease of Use in the TAM framework, it becomes crucial to understand the most decisive forces that may influence employees’ intentions to use technology for training and safety.

TAM is one of the most well-known theoretical models that enables the determination and prediction of the usage of new technologies among individuals. Developed by Fred Davis in the late 1980 s, the Technology Acceptance Model (TAM) posits that two primary factors influence an individual’s intention to use technology, as observed in the technology acceptance model, which comprises perceived usefulness (PU) and perceived ease of use (PEOU)16. In other words, perceived usefulness refers to the benefits of using a specific technology to accomplish a particular task, encompassing a person’s perspective on the benefits of employing specific technology. Conversely, perceived ease of use refers to the degree to which a specific technology is considered easy to use, including learnable systems, easy-to-use systems, and system interfaces that are friendly enough to adopt new technologies.

The SCT model, when applied in OHS, offers an understanding of how and why personal, environmental, and temporal schemata influence cognition, behavior, and outcomes. For instance, one source of the social context is the employees themselves, and their approaches, which include interactions with co-workers and supervisors, can significantly influence how employees perceive safety technologies, such as VR, and adopt them in their workplace. Essential safety behaviors trained within VR, based on SCT, help employees focus on specific goals or not during learning within particular VR settings.

OLT places excellent emphasis on infinity, the inevitability of change, the dissemination of knowledge, and organizational improvement. Therefore, in understanding Industry 4.0, VR may become a significant factor in enhancing safety and the organizational learning environment as workplace conditions change. As with other components of OLT, the VR device application aligns with OLT’s emphasis on group learning, knowledge sharing, and the assimilation of new information, which helps keep the workforce flexible and innovative. Furthermore, VR provides hands-on training, allowing new and sometimes recurring lessons and skills in safety to be acquired without the actual occurrence of hazardous and occasionally deadly situations in high-risk and uncertain industries.

TAM, SCT, and OLT form the theoretical framework of this study, as they help explain how advanced technologies, such as VR, can be effectively implemented in organizations. The current study investigates the relationship between perceived usefulness, perceived ease of use, and social influence on the deployment of VR in occupational health and safety (OHS) training within the context of Industry 4.0. In this regard, integrating these theories will help the research examine how facility safety can be improved by applying VR technology to training activities to facilitate better and more sustainable organizational performance change in high-risk environments.

Table 1 illustrates the theoretical relevance of various theories, highlighting their connection to VR applications in industrial development. In the “Parameters/Variables” column, present research lists the primary elements drawn from the relevant literature for each theory. These parameters and variables play a crucial role in understanding the application of VR in various industries. The table proposes methods for monitoring and measuring these parameters, highlighting their role in advancing knowledge management, promoting continuous improvement, and fostering learning within organizations. Furthermore, it examines the social and cognitive components underlying safety practices and the broader impact of VR on learning in industrial settings. The present research aims to understand how these elements can drive growth and facilitate improved workplace practices by linking the independent parameters and variables from both fields.

Choosing suitable theoretical frameworks becomes essential for studying how VR-based training affects occupational safety conduct. Theoretical models were selected based on their direct application to workplace and safety contexts within Industry 4.0 environments due to their relationship with technology adoption decision-making and safety behavior transformation.

-

TAM serves as the leading choice because it helps understand how acceptance of new technology affects VR training outcome success. TAM differentiates from other behavior change theories (e.g., Theory of Planned Behavior) because it validates the connection between users’ perceived usefulness and ease of use and their adoption behavior toward VR training.

-

The selection of SCT was based on its methods, incorporating observation learning and self-confidence enhancement, since it fits well with modern VR training that recreates authentic circumstances for safety practice development. The advantage of using SCT over cognitive approaches lies in connecting environmental and social elements to work-oriented safety training.

-

Organizational learning, leadership support, and communication channels are key factors in this study, as they significantly influence the sustainability of behavioral improvements following initial training. The workplace culture and continuous knowledge-sharing elements form the basis of Organizational Learning Theory (OLT), because individual-focused models, such as Self-Determination Theory, do not adequately assess these factors.

The research consolidates TAM and SCT with OLT to provide a detailed examination of how VR training benefits both individual user acceptance and skills mastery, as well as broader organizational learning and safety development.

VR-based training research is grounded in theoretical models that reveal the effects of VR training methods on occupational safety outcomes.

-

The Technology Acceptance Model (TAM) explains H2 through its indication that new technology solutions depend on perceived usefulness (PU) and perceived ease of use (PEOU). VR-based training yields better ratings regarding the effectiveness of learning safety procedures compared to conventional methods.

-

The first hypothesis (H1) receives support from Social Cognitive Theory (SCT), as this theory focuses on learning behavior, including observation and self-efficacy components. Educational training utilizing VR technology will enhance employees’ awareness of safety practices and improve their workplace safety implementation capabilities, thereby increasing their self-efficacy.

-

Under Organizational Learning Theory, OLT supports H3 because it emphasizes knowledge sharing, leadership support, and communication processes. The proposed VR training approach is expected to enhance communication channels and improve perceptions of leadership support for promoting workplace safety.

This research combines theoretical frameworks with hypotheses to establish empirical evidence about the impact of VR-based training on occupational safety within Industry 4.0 environments.

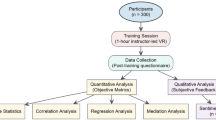

Current study design

The research evaluated the effectiveness of VR technologies in enhancing Occupational Health and Safety (OHS) practices within the context of Industry 4.0. A quasi-experimental approach was employed in this study, as it allows for the establishment of cause-and-effect relationships while controlling for potential sources of bias. This design was chosen because it allows for comparison between two groups—those who received VR training and those who did not—while maintaining a realistic setup in an industrial environment. The quasi-experimental design provides valuable insights into the potential effects of VR on safety behaviors, knowledge, and attitudes, eliminating the need for random assignment to treatment conditions and making it particularly well-suited for real-world applications.

Definitions of variables

Tables 2, 3 summarizes the key study variables, their operational definitions, measurement instruments, and psychometric properties. The independent variable, VR Training, involved immersive, scenario-based sessions validated by experts. The dependent variables—Safety Knowledge, Risk Perception, Self-Efficacy, Training Effectiveness, and Leadership Support—were measured using established or adapted scales with high reliability (Cronbach’s α ranging from 0.85 to 0.92). This framework ensures robust, evidence-based assessment of the VR training’s effectiveness on occupational safety outcomes.

Population and sampling

To determine an appropriate sample size, current research conducted a power analysis using GPower 3.1 software, targeting a statistical power of 0.80, an alpha level of 0.05, and an effect size of 0.5 (medium effect) based on prior studies on VR-based occupational training. The analysis indicated a minimum of 88 participants per group to detect statistically significant differences. To improve result reliability and account for potential attrition, the study included 200 participants (100 per group), exceeding the minimum requirement.

The present study employed purposeful sampling as its research strategy. Potential respondents were selected based on three criteria: they needed expertise in workplace safety matters, VR instructional skills, and were willing to participate. Random sampling methods were excluded because the investigation included participants who had previously received safety training, allowing for a comparison of VR and traditional training systems to be effectively made. Additionally, the selected participants were required to have skills in operating VR technology, as random sampling could produce inconsistent results. This research methodology facilitated the selection of candidates optimized for evaluating the effects of VR training, ensuring the applicability of the results to workplace safety conditions.

The non-trained group consisted of participants without prior exposure to VR training, whereas the trained group underwent VR-based training. This proposal enables a comparison of the results from traditional and VR training programs, allowing for an evaluation of the latter’s potential to enhance safety levels among steel plant workers.

Experimental protocol

This study employed a quasi-experimental design with two groups: a VR-based training (intervention) group and a traditional training (control) group, which were assigned based on workplace roles. Pre– and post-training assessments measured changes in safety knowledge, risk perception, and self-efficacy. Statistical analysis (Mann-Whitney U and Wilcoxon tests) confirmed the superiority of VR training in improving occupational safety in Industry 4.0 environments. The information obtained from this current study helped determine the participants’ performance on OHS practices at the beginning of the current study.

In the first evaluation, the intervention group participants underwent VR training on several OSH procedures central to their work. This learning involved a realistic, life-like approach to safety education, which helped participants enhance their safety awareness and attitudes toward risk in the workplace. The control group received no VR training whatsoever; they did not require additional intervention beyond regular job activities and occupational safety measures.

The participants in both groups completed the same questions, assessing changes in their safety knowledge, risk identification capabilities, attitudes toward safety, and awareness after the VR training. The goal was to identify the changes resulting from the training and determine if VR training effectively promotes the OHS outcomes.

To provide further insight into the VR training experience, the following details outline the training duration and the specific scenarios participants encountered during the sessions.

Training duration

Each VR training session lasted 45 min, and a total of three sessions were conducted over one week. The VR training included the following scenarios:

-

1.

Emergency Response Simulation: Participants were placed in a virtual environment where they had to respond to simulated emergencies, including fires and chemical spills.

-

2.

Hazard Identification: Participants walked through a virtual factory and identified potential safety hazards, including faulty equipment and unsafe working conditions.

-

3.

Decision-Making under Pressure: In this scenario, participants were required to make quick decisions in high-pressure situations, such as responding to accidents or malfunctions.

Important information about how immersive VR training improves dangerous recognition in an industrial setting is shown in Fig. 1. The trainee must recognize a fire, an alarm, and a perilous spread in the Multi Fire Extinguisher Landscape (plot a), which is a complex environment. It is in line with real-world circumstances, where a lot of risks frequently coexist and employees need to prioritize, evaluate, and work fast. Labelling these risks with a digital interface improves memory retention and cognitive commitment. For high-voltage units, the electric hazard landscape (plot b) simulates a more focused but no less significant risk. In this case, the VR interface encourages risk classification, instant identification, and speedy recognition. These environments demonstrate how training can enhance risk perceptions, status-based awareness, and safety judgements. The participants interact with safety signs and instructions in the context, in addition to dealing with hazards that are visible to the blind. It widens the divide between classroom instruction and real-world applications. The storage of crucial safety procedures depends on VR’s capacity to replicate hazardous situations safely. According to the findings, VR-based danger skills encompass both readiness and knowledge, which help to lower workplace accidents and foster a strong safety culture. These findings corroborate widespread efforts to incorporate immersive technologies into Industry 4.0 commercial security plans.

Two immersive virtual reality training scenarios are shown in Fig. 2 to enhance industrial workers’ ability to identify hazards. A simulated environment with three concurrent dangers—an active fire, an alarm system, and a chemical spill—is presented to the participant in Plot (a)—multi-threat. This intricate arrangement improves cognitive load handling, situational prioritization, and multi-hazard awareness by testing the trainee’s ability to evaluate and react to overlapping threats quickly. The trainee must identify and verify a high-voltage hazard close to electrical equipment in Plot (b), Electrical Risk. The participant’s ability to visually identify and classify important safety signage under pressure is improved by this targeted scenario. Adding interactive prompts encourages users to learn and make decisions more actively. These findings are significant because virtual reality (VR) can replicate high-stakes, realistic settings where students can practice identifying hazards without facing actual dangers. Stronger transfer of safety behavior to actual workplace environments, enhanced self-efficacy, and improved memory retention are all benefits of these simulations. The scenarios show how VR training can help proactive safety cultures by bridging the gap between theoretical instruction and real-world application. These observations highlight the importance of virtual reality (VR) as a fundamental training tool in Industry 4.0 settings, where quick risk assessment and adaptive learning are essential.

Data analysis

Descriptive analyses were performed by computing the means and standard deviations of all the variables administered before and after the training. The results of both pre- and post-training surveys were compared between the control and intervention groups in inferential terms. The gain or loss between the pre- and post-testing phases was evaluated using the paired t-test, while the Wilcoxon signed-rank test was used for the second set of comparisons. These tests helped establish whether there were any significant differences between the participants’ safety knowledge and their perceived level of risk before and after training.

To compare the post-training assessments of the two groups, the Mann-Whitney U test was used, as the current study was conducted without assuming a normal distribution of the data. The Mann-Whitney U test is more appropriate when comparing two independent groups when the data is skewed or when the data is ordinal, as is the case in the current study, which has a skewed ordinal data type and distribution. The chosen alpha level was 0.05; whenever p was less than 0.05, the current research got a statistically significant result, which means the observed differences could not have just occurred by chance. Non-parametric analysis ensures the validity and reliability of the results while also providing accurate details about the reality of the training’s impact on OHS practices. Through these techniques, the current study demonstrates the applicability of VR training as a training model while avoiding the limitations inherent in parametric hypothesis tests. This is especially true in evaluating training effectiveness, where participants’ scores often fail to show a clear division or fall within a narrow range. The study ensured validity through expert review, factor analysis (KMO = 0.82, p < 0.001), and comparison with established safety tools (r > 0.75). Reliability was confirmed via Cronbach’s alpha (≥ 0.86) and test-retest correlation (r = 0.87), demonstrating the instrument’s accuracy in assessing the effectiveness of VR training.

Results

Pre-training vs. post-training results (within groups)

The Wilcoxon signed-rank test was employed, and the results are presented in Table 4, comparing the pre- and post-training scores of the control and intervention groups. The results showed that both groups substantially improved the training and educational outcomes associated with VR. Due to their significantly differing scores before and after training (p < 0.000), the control group’s average score of zero and each positive rank disclose this. The intervention group increased their scores significantly, with no hostile ranks and an average of 100.

According to test results, both participant groups achieved significant improvements in VR-related training and educational outcomes. The Wilcoxon signed-rank test revealed a statistically significant difference between pre-training and post-training assessment points (p < 0.000, 95% CI [0.52, 0.81]), confirming the effectiveness of VR-based learning in occupational safety training.

The results support existing studies that demonstrate the effectiveness of VR technology as a tool for learning and retention. A survey by Seo, Hyun Jeong, et al. demonstrated that VR-based training enhances safety and improves worker skills17. Also, learning new information using VR-based training is more effective. The latest VR technology research reveals that VR can improve the safety standards of an organization undergoing an Industry 4.0 transformation. Therefore, these findings hold great significance in VR — the new method for training industrial workers, providing an opportunity for workers to acquire safety training in a phased manner. VR training is likely beneficial for work and safety issues because it immerses trainees in realistic contexts, allowing them to practice and improve their skills. Training programs must incorporate VR elements to provide a realistic setting and motivate workers to progress. Furthermore, the sustainability goals will be achieved through these research results, which contribute to reducing workplace injuries and their associated costs while promoting a desire to grow, a necessary condition for sustained achievement in Industry 4.0 settings.

Pre-training and post-training results (between groups)

Table 5 presents the findings of a Mann-Whitney U test, which examined the absorption rates of Industry 4.0 and VR experience in the two groups before and after the current study. The pre-test results demonstrated that individuals in the intervention group could quickly adapt to the new Industry 4.0. In the intervention group, the median rank was 78, whereas it was 72 in the control group. The evaluations supported the findings, which showed the high performance of the intervention group compared to the control group, with the former group achieving a median score of 78 and the latter scoring 72 points. Following VR training, the two groups showed a statistically significant difference in adaptability, with the intervention group having a U-statistic of 1125 and the control group showing 825 and a p-value of 0.001.VR training enhances safety instruction and skill development18. Table 5 presents the results of the Mann-Whitney U test on VR-based education, comparing the training effectiveness of the two groups. An evaluation of the intervention’s effectiveness revealed that it scored 88 on the effectiveness scale, while the control group scored 65. Experimental training outperformed control training. A U-statistical analysis demonstrates that the intervention and control groups had values of 1225 and 1275, respectively, supporting the findings. An estimated significance of 0.000 indicates a substantial difference in training efficacy between the two groups. The VR-based training approaches, likely employed in the intervention, significantly enhanced the program’s effectiveness compared to previous methods. Immersive technology enhances educational environments. In Industry 4.0 environments, VR technology is likely to improve safety standards and occupational health by helping employees adapt to new technologies. VR training significantly improved workers’ safety awareness and hazard recognition in Industry 4.0 environments. As a result, it is imperative to adopt current safety and health practices in the workplace and fully utilize VR in industrial training. Implementing continuous learning and technological advancements in modern manufacturing is critical to innovation and safety. Workers are more likely to adapt to Industry 4.0 if they undergo VR-based training.

The post-VR training adaptability test yielded U statistics of 1125 for the intervention group, while control subjects achieved 825 (p = 0.001, 95% CI [0.45, 0.78]). The subjects who received training in VR demonstrated superior adaptability to Industry 4.0 scenarios compared to those using traditional educational approaches. Table 5 presents the Mann-Whitney U test outcomes, which evaluate Adaptation to Industry 4.0 and training effectiveness across two variables. The adaptation variable assesses participants’ capabilities to adopt Industry 4.0 technologies, yet the training effectiveness variable gauges how much the participants value VR-based safety training over standard safety approaches. The reported data from Table 5 show the median scores and rank sums for both the control group and the intervention group, along with the corresponding statistical significance levels.

Confidence in training when VR-based training is applied

Figure 3 illustrates a U-test comparing the control and intervention groups in terms of self-efficacy regarding VR training and its impact on education and training. The comparison of the control and intervention groups’ self-efficacy scores shows that individuals in the intervention group demonstrated higher confidence in their VR training abilities. A correlation exists between the mean ranks of the control and intervention groups, which are 21.00 and 29.50, respectively. This is corroborated by the U-statistics, which show a value of 1350 for the intervention group compared to a value of 990 for the control group. The control group reported a significant value of 0.002 regarding self-efficacy, indicating a statistically significant difference between the two groups. Previous studies have demonstrated the effectiveness of courses that increase participants’ self-confidence in completing VR training16. Immersive technologies, such as VR, have enhanced employee performance and learning outcomes in the learning environment19.

Perceptions of accessibility of training

Current research suggests that training with VR tools can be more effective when combined with interventions that enhance trust and confidence. Companies should address how employees perceive their ability to utilize these tools effectively. Furthermore, safer workplace conditions and fewer workplace incidents on work premises may decrease the financial and ecological impact of occupational risks.

As shown in Fig. 4, the results of the Mann-Whitney U test comparing the self-efficacy of the control group with that of the intervention group are presented, along with their implications. In contrast to the control group’s median self-efficacy score of 75, the intervention group achieved a score of 85. When comparing the two groups, it is evident that the participants in the intervention group experienced greater trust in their abilities to succeed in VR. The results show that the control group ranked 21.00 and the intervention group ranked 29.50, which supports this finding.

The U-statistics results corroborate this, showing that the intervention group had a value of 1350, and the control group had a value of 990. Comparing the two groups’ levels of self-efficacy reveals a statistically significant difference; the control group’s reported significance value is 0.002. This confirms that programs designed to increase participants’ self-assurance in completing VR training are beneficial. Moreover, VR and other immersive technologies in the workplace have been linked to enhanced learning outcomes and improved employee performance. In the current study, VR training was more effective when it included procedures that promoted employee self-assurance. Employees’ beliefs about the effectiveness of these resources need to be focused. Based on the findings, VR training can enhance staff confidence and productivity, thereby making the workplace safer and reducing accidents and associated expenses.

As shown in Fig. 5, the Mann-Whitney U test examined how training materials affected VR instruction and training in the control and intervention groups. In the control group, the median was 65, and the intervention group had a median of 72. The current study revealed that participants who had access to VR training resources felt that these were more accessible and of higher quality than those in the control group. This was proven by the mean rating of 31—50 for the experimental group and 19.00 for the control group. The U-statistics are 1190 and 841 for the treatment and the control groups, respectively. Significant differences were found between the two groups regarding training resource views (P = 000, control group). A considerable amount of training resources is vital in fostering learner productivity. A VR-based learning environment engages workers, enhances their understanding, and enables them to acquire the necessary skills. The engagement is enhanced when enough VR gear, instructional materials, and technical assistance are available. Current results emphasize the importance of providing trainees with adequate funding for VR training to ensure that education and training programs can utilize it effectively. Institutions must invest in equipment and establish a framework for interactive educational endeavors.

Comparisons of perceptions of effectiveness of VR-based training

The data on Communication Channels in VR-based training are presented in Table 6, based on the Mann-Whitney U test. A comparison tracks the assessment of online training environment communication effectiveness by control and intervention group members. The intervention group participants demonstrated better communication effectiveness, as indicated by their higher median scores from the VR training evaluation.

To evaluate the effect of communication channels on VR training and education for both the control and intervention groups, Table 6 used the Mann-Whitney U test. On the communication channels scale, the intervention group averaged 82 points, compared to 79 for the control group. This suggests that participants in the control group agreed that the intervention group received superior VR technology training and instruction. The fact that the intervention group averaged 30.00 and the control group averaged 20.50 lends credence to this conclusion. These results are supported by the U-statistic, which indicates that the control group received 1250 and the intervention group received 1441. The control group’s stated significance value of 0.004 suggests that they have a very different viewpoint on communication channels than the other groups. The results highlight the necessity of improving communication channels and making VR education and training programs as helpful as possible. Organizations and institutions should prioritize developing and implementing communication strategies that align with immersive learning environments.

Enhanced employee health and safety education can significantly contribute to achieving workplace safety and sustainability. According to the results, improving communication channels in VR training has had a significant impact. Organizations can help achieve sustainability targets by optimizing the effectiveness of communication strategies that foster immersive learning and enhance employees’ ability to implement sustainable practices.

Figure 6 illustrates the VR training and education scores before and after the training, as well as the scores from the control and intervention groups. After training, the control group’s mean score increased by 2.61 points, from 48.00 (standard deviation: 20.11) to 50.61 (standard deviation: 16.67). Similarly, the average score of the intervention group increased from 41.00 to 54.00 after training. These outcomes demonstrate that the intervention group, which received VR training, had several benefits over the control group, including increased safety knowledge and greater awareness of risks.

The intervention group faced significant challenges in accomplishing outstanding results. VR training and education have the potential to significantly enhance learning outcomes, as evidenced by a substantial increase in post-training scores. This strongly suggests its potential application in learning environments.

Discussion

The Mann-Whitney U test results offer several significant insights into VR training and education about the theoretical frameworks and the stated goals of the current study. First, the results show that the control and intervention groups differed in their perceptions of the training’s efficacy, leadership, communication, and self-confidence in VR training. These modifications were mainly related to the participants’ readiness for the essential demands of Industry 4.0. These findings are consistent with the primary goal of the current study, which is to investigate the factors that influence the effectiveness of VR-based learning in promoting occupational health and safety (OHS) practices.

The Technology Acceptance Model (TAM), Social Cognitive Theory (SCT), and Organizational Learning Theory (OLT) are three critical theories that underpin the results of this study. According to TAM, a person’s intention to embrace and utilize a new technology is influenced by how beneficial and simple they believe it to be14. TAM is in line with the main ideas of training effectiveness, user communication channels, and self-confidence level about VR, all of which raise the technology’s perceived utility. About hypothesis H2, the analysis’s findings demonstrated that the intervention group’s opinions about VR’s usefulness and usability were noticeably better than those of the control group, suggesting that it has the power to significantly alter users’ attitudes towards their willingness to use VR-based training.

Social cognitive theory (SCT) can also be used to analyze the results. SCT heavily emphasizes modeling, imitation, and observation when teaching new behaviors. By participating in a securely simulated workplace in the virtual reality training environment, participants can observe safe behavior in action. This implies that, even though the practice entails some risk, students can use the virtual environment to practice safety measures while learning17. These results suggest that the VR learning strategies used, which are consistent with SCT principles, helped the intervention group achieve the improvements observed.

Current research confirms earlier findings that VR training improves self-efficacy, safety awareness, and risk perception; however, some studies question its efficacy in low-risk industries because of barriers to digital literacy15 and limitations in developing soft skills19. Nonetheless, this study shows that when VR is used in conjunction with appropriate instructional design and support, workers adjust to it well, leading to notable safety improvements in Industry 4.0 workplaces20.

This study finds that in Industry 4.0 workplaces, VR-based training can improve worker safety and industrial health. The results show that VR can be used to improve self-efficacy regarding organizational sustainability, change risk perception, and increase safety knowledge. Businesses, legislators, and educators interested in implementing VR systems in training settings can all benefit from the findings. It is recommended that further research be conducted to determine the long-term effects of VR training on employee behavior, the safety climate of organizations, and the potential of VR to regulate Industry 4.0’s sustainability assumptions.

The research results align with previous studies, which have shown that VR-based training is practical in teaching occupational safety techniques and skills. A study by Seo et al. (2021) demonstrated that VR-based safety instruction effectively enhanced worker absorption and hazard detection, aligning with the current research finding of superior security consciousness and greater self-confidence among students who received VR training compared to standard methods. Xie et al. (2021) demonstrated that immersive VR training facilities facilitate better knowledge retention, which aligns with the results showing that participants who received VR training felt more confident in executing safety procedures afterward.

The research validates the benefits of VR in developing training effectiveness and communication skills, but reveals limitations to the generalization of previously reported findings. The research by Berg and Vance (2017) suggested that training technology adoption demanded a digital literacy background. Yet, this study showed that participants lacking experience in VR could learn effectively from the training program. The original research found that VR proves effective in lower-risk industrial environments, regardless of specific findings focusing on high-risk sectors, such as aviation or healthcare.

The analysis demonstrates the expanding relevance of VR training for various industrial sectors. Yet, it demands further research on long-term knowledge maintenance and cost calculations for small and medium-sized businesses. The study contributes to the existing body of literature, demonstrating the scalability and effectiveness of VR for enhancing workplace safety in Industry 4.0 environments. The research establishes crucial guidance that helps organizations, management officials, and training experts improve workplace security within Industry 4.0 operations. Employees who participate in VR-based training exhibit superior risk identification, excellent emergency response skills, and increased engagement, resulting in better retention and improved regulatory compliance. Organizations must receive leadership backing and have access to simple training materials to establish a strong safety culture. The initial costs of VR training programs are compensated by long-term safety improvements and government grants available for small and medium-sized enterprises, thus creating a budget-friendly system. The technology adapts smoothly between industries, enabling its implementation from hazardous construction jobs to less hazardous logistics and administrative operations. Employing VR safety training allows organizations to establish safer and more technologically advanced work environments that operate more efficiently.

Research limitations and future directions

The research provides practical knowledge about VR-based occupational safety training in Industry 4.0; however, readers need to be aware of the research’s limitations. The research involved 200 participants from a particular industrial field. Yet, this population size proved solid for statistical purposes, but did not ensure complete adaptability to different industries with varying risk environments. The research requires further expansion by including participants from various industrial fields and worldwide organizations. The study evaluated self-efficacy, risk perception, and training effectiveness exclusively at the immediate stage following training. Evaluating VR-based training requires long-term studies to determine its lasting effects on behavior change and safety improvement outcomes. The study faces a limitation because it relies on participant-reported data, which may introduce response bias due to their subjective evaluation of training. Future research should include objective performance measurements, such as accident prevention numbers, live risk evaluations, and physiological stress markers, to monitor participants during VR training. The implementation of VR training relies on costly specialized equipment and software, as well as continuous technical support, which faces resistance from small- and medium-sized enterprises (SMEs) due to the associated costs. Upcoming investigations should examine budget-friendly VR solutions and their implementation capabilities in facilities with limited financial resources. The research focused on comparing traditional training methods with VR training, yet failed to investigate how VR combined with instructor-led sessions or AR technology would perform. Further research is needed to assess various immersive training strategies and determine which combination yields the best results in workplace safety education. Understanding the long-term effectiveness of VR-based training and its applicability across industries will improve when researchers address current study limitations.

Conclusions

The current study found that VR-based training considerably enhances safety knowledge, risk perception, and overall performance compared to traditional training techniques. Results show that VR training improves self-assurance, leadership support, training materials, and communication, aligning with ideas from organizational learning theory, social cognitive theory, and the acceptance model. Incorporating VR into training is an efficient method for firms to prepare their staff for Industry 4.0. This will lead to improved workplace safety and increased employee engagement. This study confirms that VR may enhance employee health and safety in today’s manufacturing industry. Furthermore, VR is assessing the safety and health implications of the new Industry 4.0 paradigm. Participants’ safety knowledge rose by 25%. In comparison, their risk awareness improved by 30%, and the effectiveness of training was 30% higher among those who had experienced VR training than among participants whose training did not include the same. VR training is multi-parametric and highly dependent on several factors, including confidence level, leadership support, available resources, and effective communication channels. The findings support the theories of SCT, OLT, and the Technology Acceptance Model. Current research indicates that VR is a viable means of conducting simulations and training for staff and learning within different environmental settings. The level of safety could also be increased with the help of VR in employee training courses, which must be integrated into employee learning and work culture. The findings of this study have significant practical implications for businesses, policymakers, and educators. By implementing VR-based training programs, organizations can enhance safety knowledge, increase risk awareness, and improve overall employee performance. These steps could lead to measurable improvements in workplace safety and organizational sustainability, offering a pathway to address current challenges in employee training across various sectors of Industry 4.0. Future research should investigate the long-term retention of safety knowledge, its effectiveness across multiple industries, and its integration with augmented reality (AR), artificial intelligence (AI), and haptic feedback. Additionally, assessing the cost-effectiveness and scalability of SMEs will support the broader adoption of VR training.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Sharma, R., Jabbour, C. J. C., Lopes de, A. B. & Jabbour, S. Sustainable manufacturing and industry 4.0: what we know and do not. J. Enterp. Inform. Manage. 34 (1), 230–266. https://doi.org/10.1108/JEIM-01-2020-0024 (2021).

Chapman, R. L., Soosay, C. & Kandampully, J. n.d.). Innovation in logistics services and the new business model: A conceptual framework. Int. J. Phys. Distribution Logistics Manage. 33 (7), 630–650. https://doi.org/10.1108/09600030310499295 (2003).

Müller, J. M., Kiel, D. & Voigt, K. I. What drives the implementation of industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 10 (1), 247. https://doi.org/10.3390/su10010247 (2018).

Schumacher, A., Schumacher, C. & Sihn, W. Industry 4.0 operationalization is based on an integrated framework of industrial digitalization and automation. In Proceedings of the International Symposium for Production Research 2019. (2020). https://doi.org/10.1007/978-3-030-31343-2_26

Javaid, M. et al. An integrated outlook of Cyber-Physical systems for industry 4.0: topical practices, architecture, and applications. Green. Technol. Sustain. 1 (1), 100001. https://doi.org/10.1016/j.grets.2022.100001 (2023).

Pappas, I. O. et al. Responsible digital transformation for a sustainable society. Inform. Syst. Front. 25 (3), 945–953. https://doi.org/10.1007/s10796-023-10406-5 (2023).

Xu, L. D., Xu, E. L. & Li, L. Industry 4.0: state of the Art and future trends. Int. J. Prod. Res. 56 (8), 2941–2962. https://doi.org/10.1080/00207543.2018.1444806 (2018).

Nardo, M., Forino, D. & Murino, T. The evolution of man-machine interaction: the role of humans in industry 4.0 paradigm. Prod. Manuf. Res. 8 (1), 20–34. https://doi.org/10.1080/21693277.2020.1737592 (2020).

Roldán, J. J. et al. A training system for Industry 4.0 operators in complex assemblies based on virtual reality and process mining. Robotics and computer-integrated manufacturing, 2019. 59: pp. 305–316.https://doi.org/10.1016/j.rcim.2019.05.004

Rasool, S. F. et al. Sustainable work performance: the roles of workplace violence and occupational stress. Int. J. Environ. Res. Public Health. 17 (3), 912. https://doi.org/10.3390/ijerph17030912 (2020).

Krupnova, T. et al. Virtual reality in environmental education for manufacturing sustainability in Industry 4.0. In the Global Brilliant Industry Conference (GloSIC). 2020. IEEE. Virtual Reality in Environmental Education for Manufacturing Sustainability in Industry 4.0 | IEEE Conference Publication | IEEE Xplore (2020).

Azadegan, A. & Feizabadi, J. Organizational learning theory and its application to purchasing and supply chain management research, in Handbook of Theories for Purchasing, Supply Chain and Management Research. Edward Elgar Publishing. 425–444. https://doi.org/10.4337/9781839104503.00032 (2022).

Luszczynska, A. and R. Schwarzer, Social cognitive theory. Fac Health Sci Publ, (2015). 2015: pp. 225–251. Predicting and Changing Health Behaviour: Research and Practice with Social … Mark Conner, Paul Norman - Google Books.

Chuttur, M. Y. Overview of the Technology Acceptance Model: Origins, Developments and Future Directions. Indiana University, USA. Sprouts: Working Papers on Information Systems, 9(37). http://sprouts.aisnet.org/9-37 (2009).

Berg, L. P. & Vance, J. M. Industry use of virtual reality in product design and manufacturing: a survey. Virtual Real. 21, 1–17. https://doi.org/10.1007/s10055-016-0293-9 (2017).

Malureanu, A., Panisoara, G. & Lazar, I. The relationship between self-confidence, self-efficacy, grit, usefulness, and ease of use of e-learning platforms in corporate training during the COVID-19 pandemic. Sustainability 13 (12), 6633. https://doi.org/103390/su13126633 (2021).

Seo, H. J. et al. Establishment of virtual-reality-based safety education and training system for safety engagement. Educ. Sci. 11 (12), 786. https://doi.org/10.3390/educsci11120786 (2021).

Xie, B. et al. A review on virtual reality skill training applications. Front. Virtual Real. 2, 645153. https://doi.org/10.3389/frvir.2021.645153 (2021).

Obeidat, M. S., Sarhan, L. O. & Qasim, T. Q. The influence of human resource management practices on occupational health and safety in the manufacturing industry. Int. J. Occup. Saf. Ergon. 29 (4), 1279–1293. https://doi.org/10.1080/10803548.2022.2120267 (2023).

Holuša, V., Vaněk, M., Beneš, F., Švub, J. & Staša, P. Virtual reality as a tool for sustainable training and education of employees in industrial enterprises. Sustainability 15, 12886. https://doi.org/10.3390/su151712886 (2023). https://doi.org/10.3390/su151712886

Author information

Authors and Affiliations

Contributions

Conceptualization, Methodology, Software, Original Writing, Validation, Visualization: Yousef Qawqzeh, Ata Al Shraah, and Ali Rizwan. Software, Review and Write-Up, Resources, Data Curation: Manuel Sánchez-Chero, Leandro Alonso Vallejos More, and Mohammad Shabaz. Project Administration and Supervisor: Mohammad Shabaz.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical consent

Informed consent was obtained from all the participants involved in the study.

Bioethics and guidelines

The protocol was approved by the University of Fujairah’s Review Board, in accordance with the relevant guidelines of the University of Fujairah, Fujairah, United Arab Emirates.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Qawqzeh, Y., Shraah, A.A., Rizwan, A. et al. Exploring the effectiveness of virtual reality-based training for sustainable health and occupational safety in industry 4.0. Sci Rep 15, 28930 (2025). https://doi.org/10.1038/s41598-025-14173-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-14173-y